Page 1

Instruction manual

Bedienungsanleitung

Calibration software WIKA-Cal

Kalibriersoftware WIKA-Cal

EN

DE

Calibration software WIKA-Cal

Page 2

Instruction manual WIKA-Cal Page 3 - 64

EN

Bedienungsanleitung WIKA-Cal Seite 65 - 127

DE

Further languages can be found at www.wika.com.

©

04/2014 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

2 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 3

Contents

Contents

1. General information 5

1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Licence agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 System requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. First steps and installation 8

3. Overview 11

3.1 Main window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Menu bar and tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.1 File: Import, backup database, restore database, exit . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.2 Tools: Unit converter, Mass calculator and Manual control of controller . . . . . . . . . . . . . 12

3.2.3 Setup: Language, dongle upgrade, database connection, object manager . . . . . . . . . . . 13

4. Cal-Template calibration certificate 15

4.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Entry of calibration data . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.1 General data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2.2 Calibration item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.3 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.4 Place of calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.5 Measurement conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.2.6 Measurement results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.7 Evaluation (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.8 Measurement uncertainty (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.9 Statement of compliance (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.10 Additional information (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

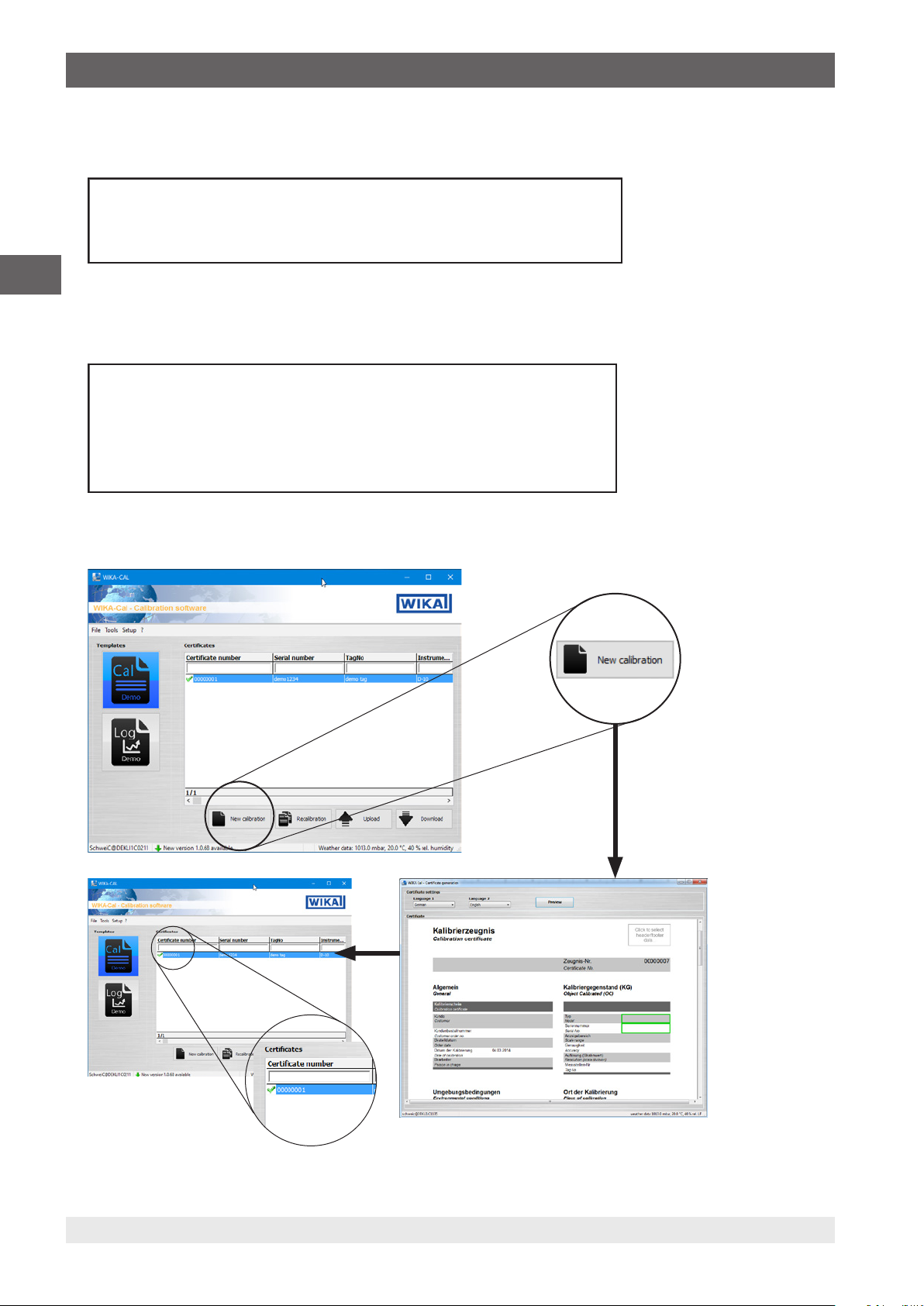

4.3 New calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

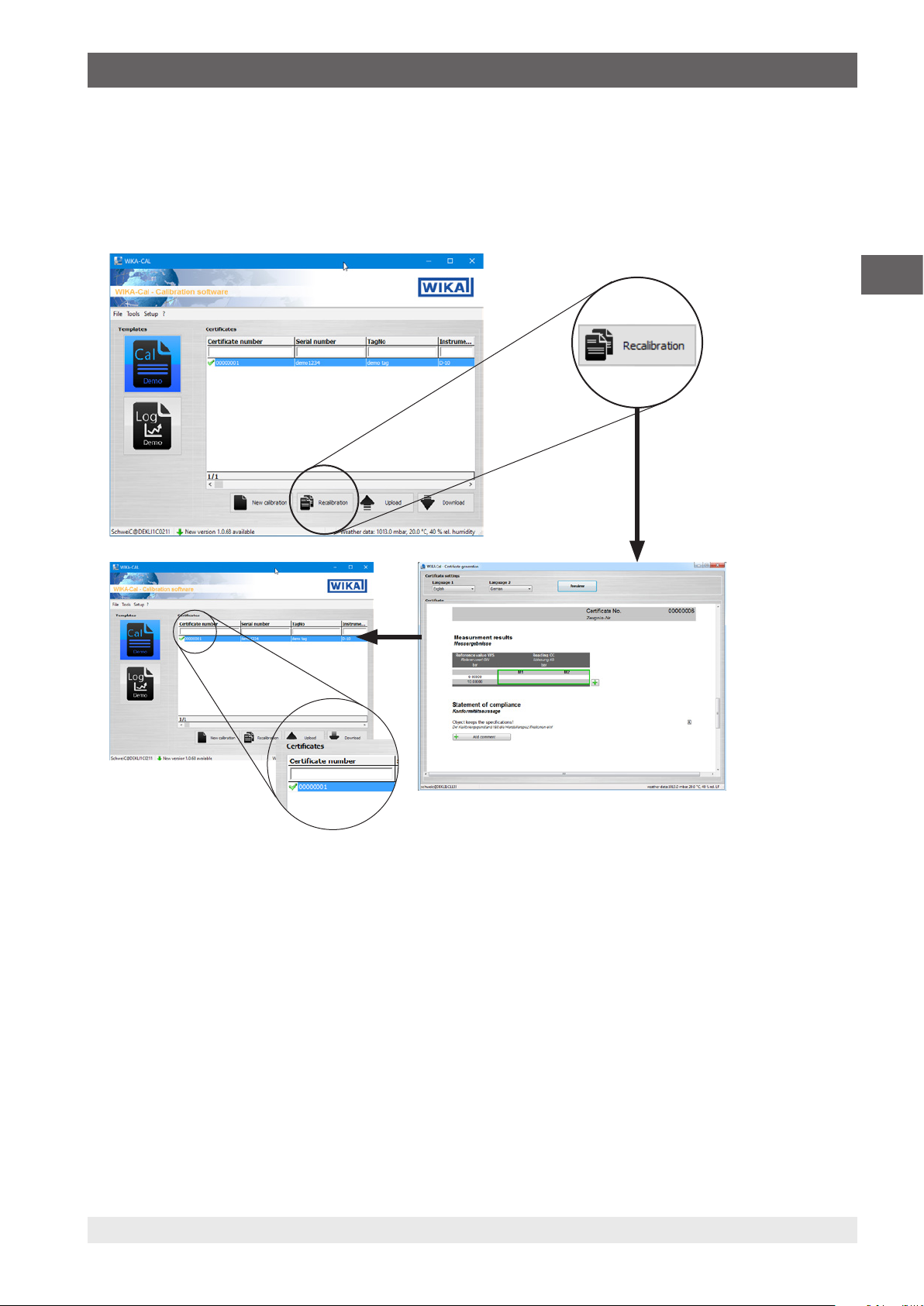

4.4 Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

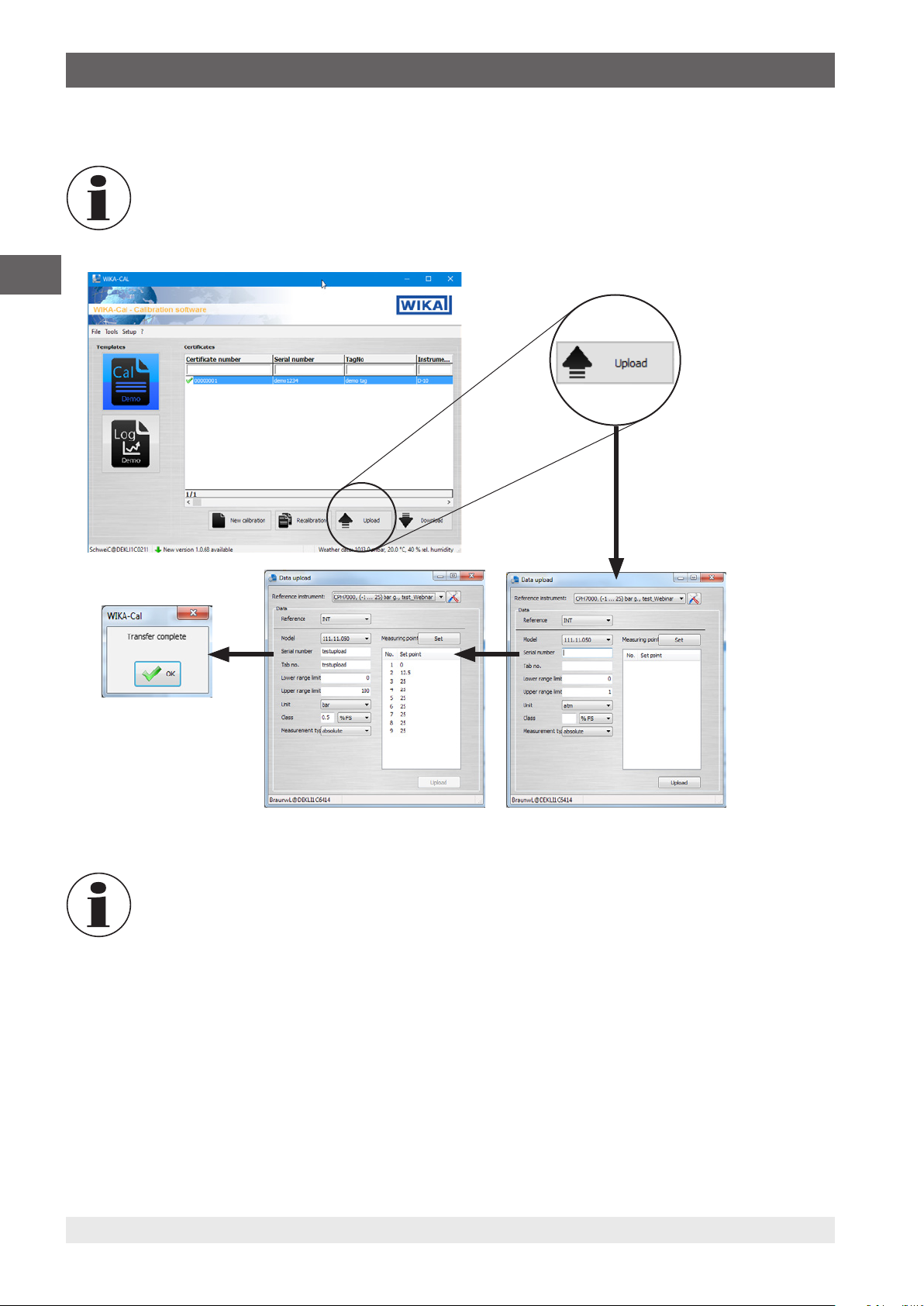

4.5 Upload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

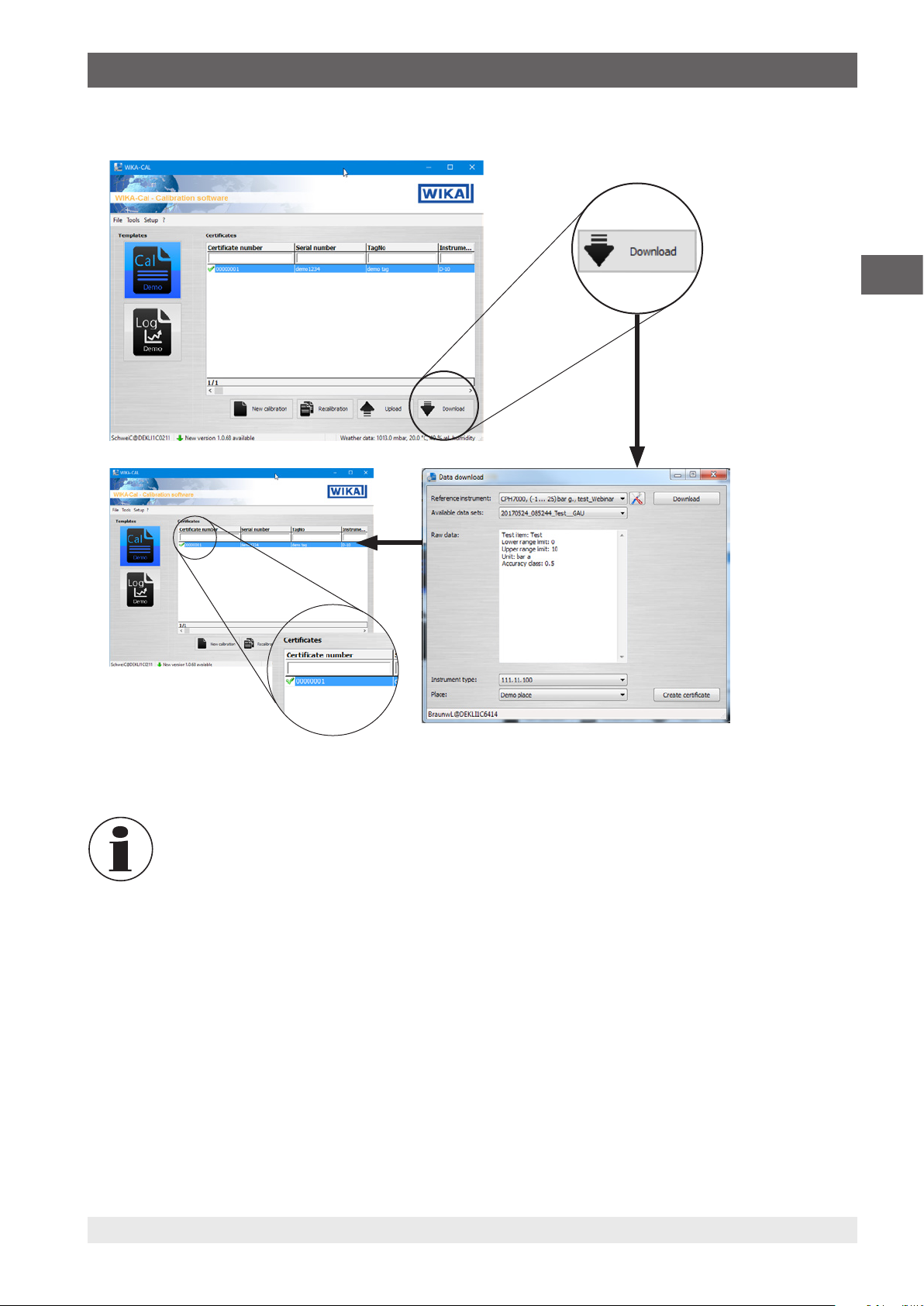

4.6 Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.7 Calibrate and finish certificate. . . . . . . . . . . . . . . . . . . . . . . . . 22

4.8 Multicalibration (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5. Log-Template logger protocol 24

5.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 Entry of the logger data . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2.1 General data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.2.2 Measurement conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

5.2.3 Measurement results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

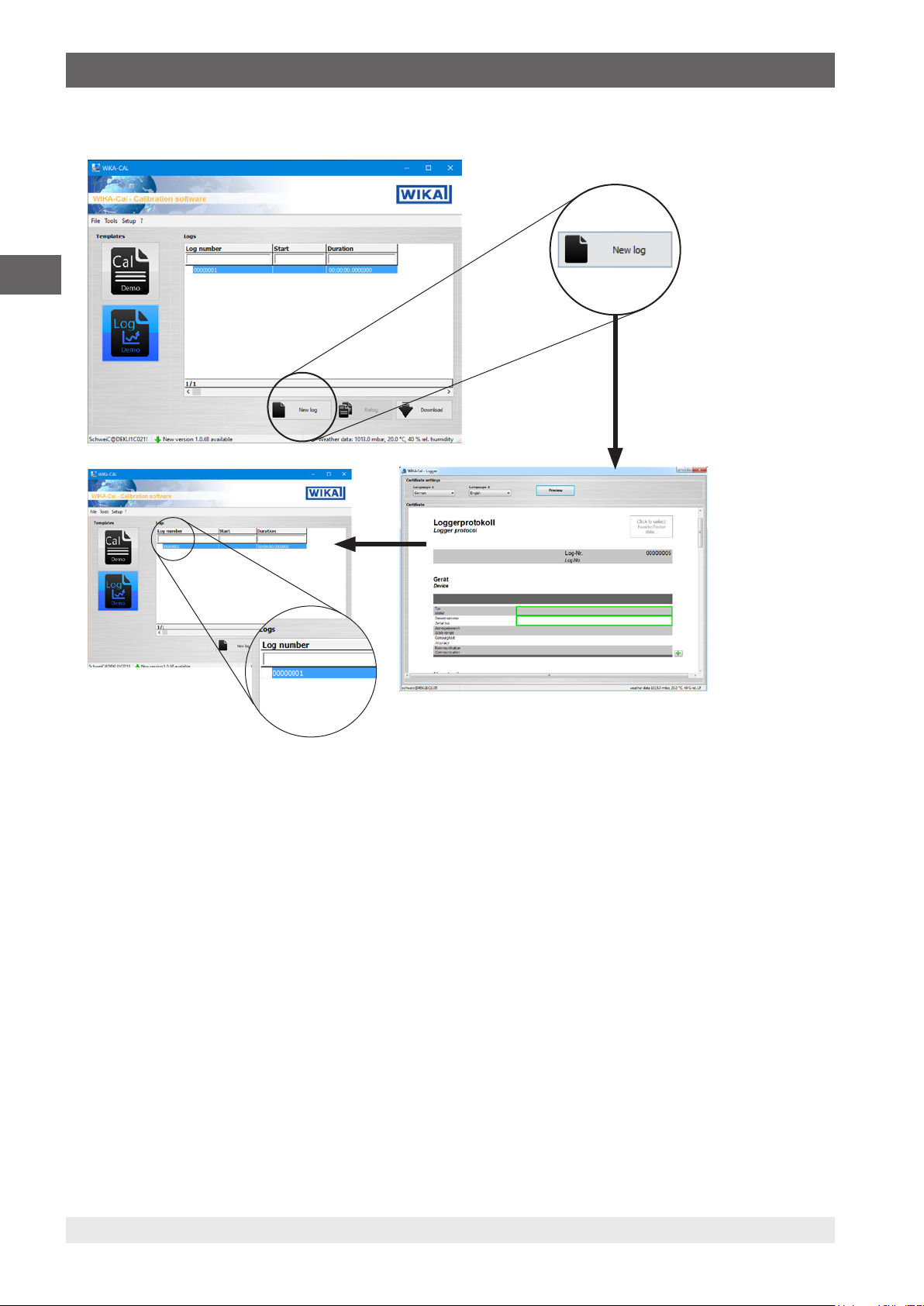

5.3 New log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

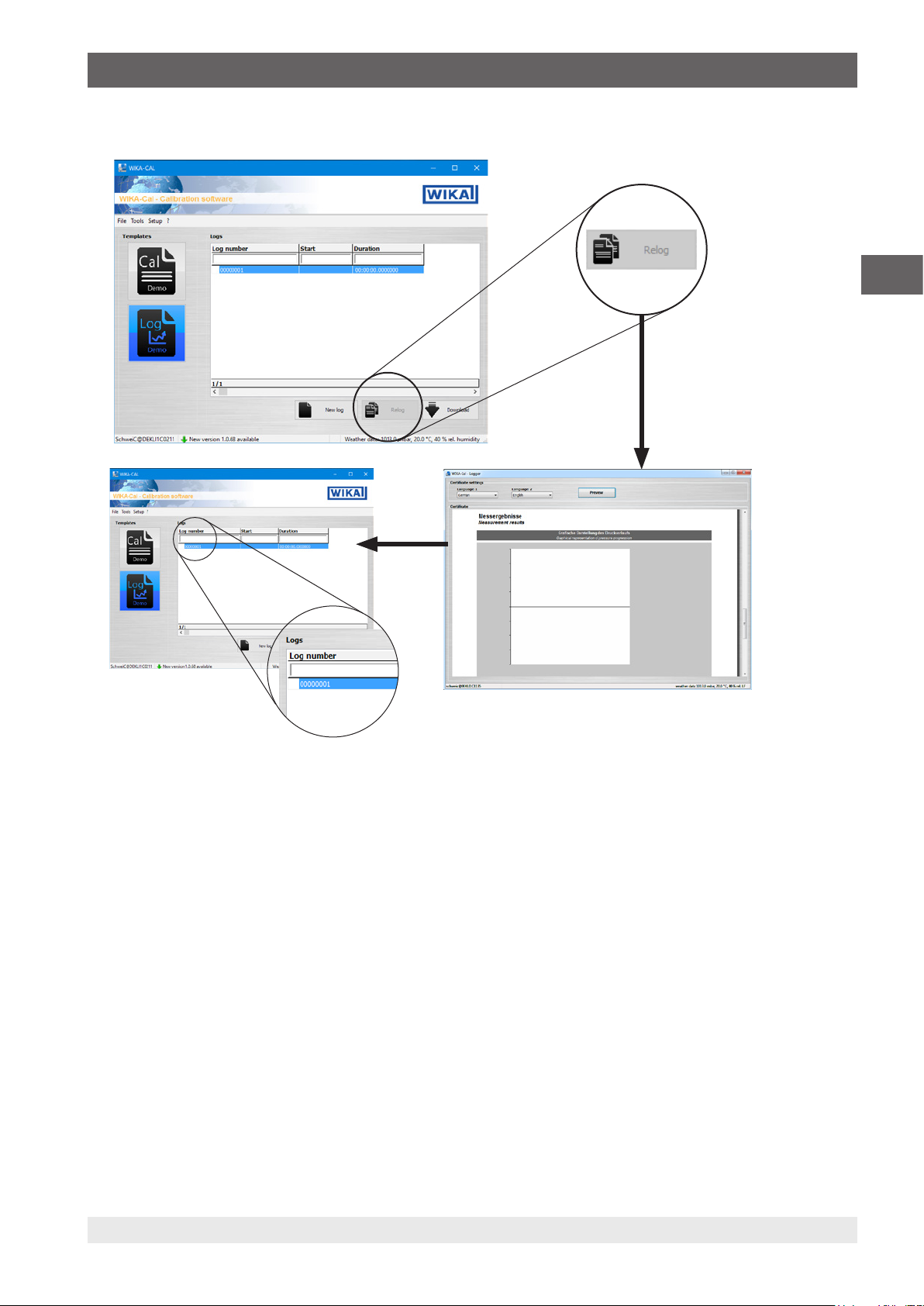

5.4 Relog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

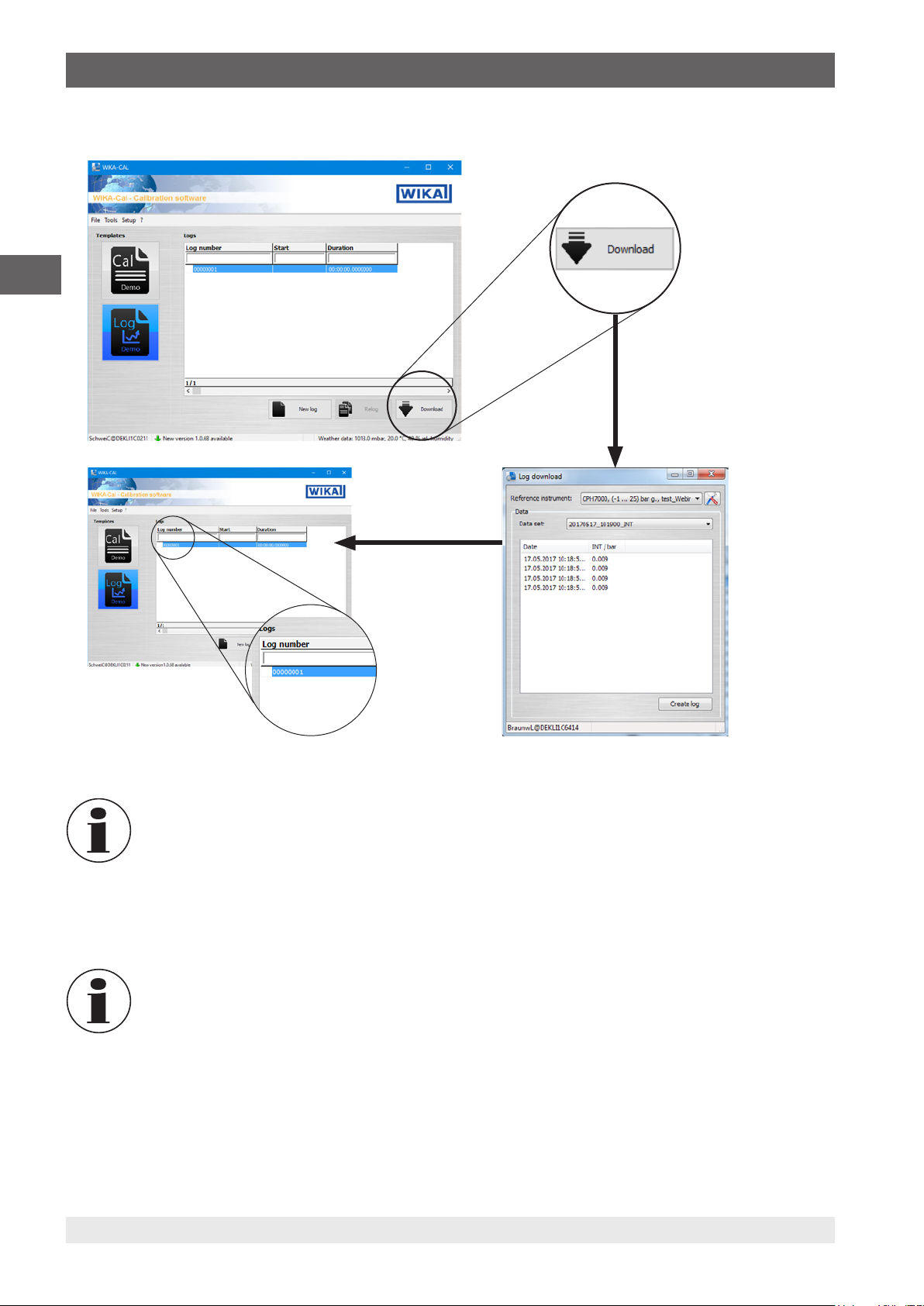

5.5 Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.6 Log and finish protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

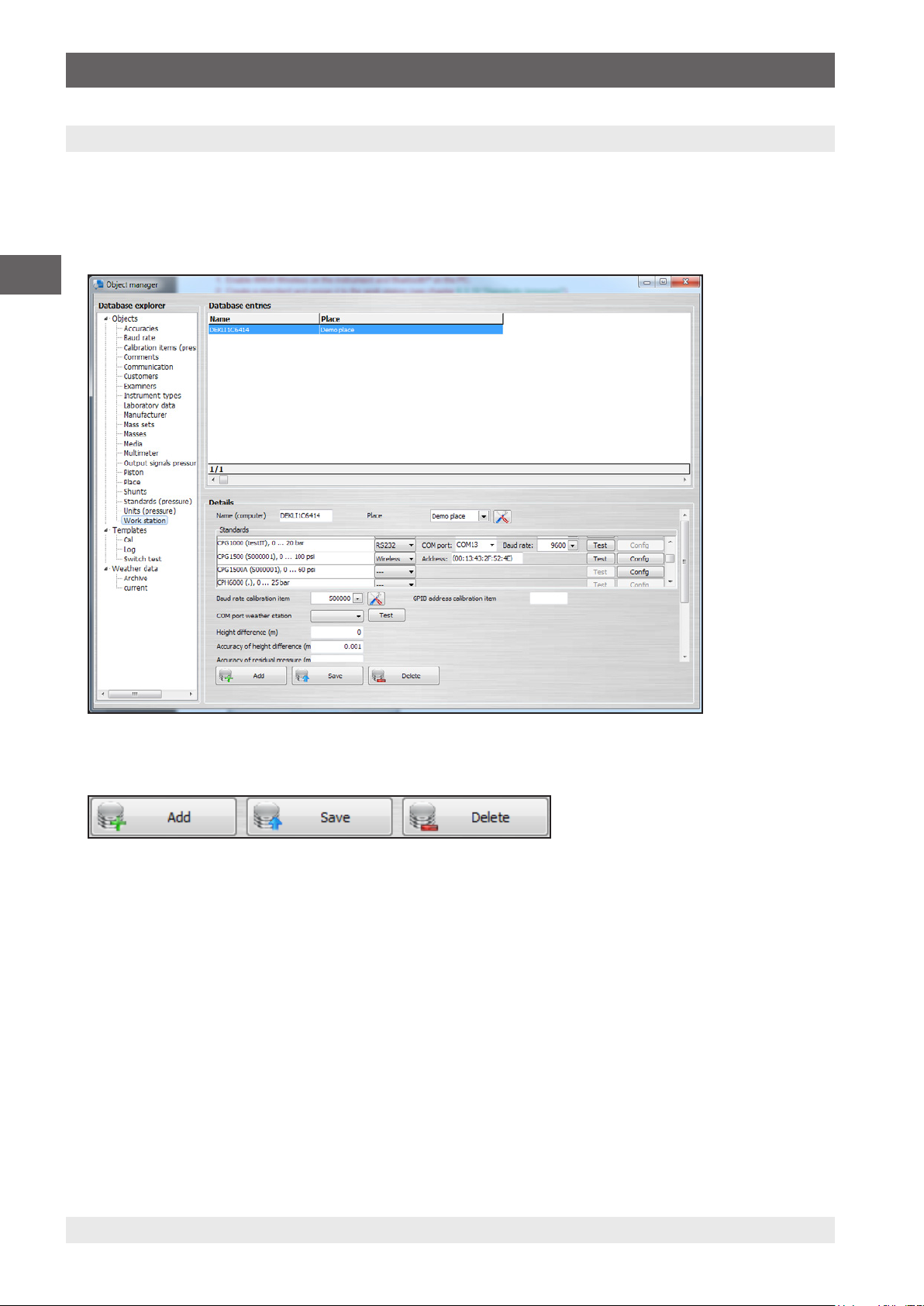

6. Object manager 30

6.1 Add, save and delete. . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3 Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.1 Work station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.3.2 Output signals pressure transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3.3 Baud rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3.4 Comments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.5 Units (pressure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.3.6 Accuracies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3.7 Instrument types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3.8 Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.9 Calibration items (pressure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

14097663.03 05/2017 EN/DE

EN

3WIKA instruction manual WIKA-Cal

Page 4

Contents

6.3.10 Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3.11 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3.12 Customers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.3.13 Laboratory data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.3.14 Masses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.3.15 Mass sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.3.16 Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

EN

7. Setting up calibration instruments 48

8. Using a Microsoft® Excel® certificate template 56

6.3.17 Multimeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.3.18 Multiplexer (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3.19 Standards (pressure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

6.3.20 Place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.3.21 Examiner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.3.22 Shunts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.4 Templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.4.1 Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.4.2 Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.5 Weather data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.1 Loading necessary drivers . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2 Setting up the CPH6x00 models . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3 Setting up the CPCx000 models . . . . . . . . . . . . . . . . . . . . . . . . 49

7.4 Setting up the CPBx000 models . . . . . . . . . . . . . . . . . . . . . . . . 50

7.5 Setting up the CPU6000 series . . . . . . . . . . . . . . . . . . . . . . . . 51

7.5.1 Setting up the CPU6000-W weather station . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.5.2 Setting up the CPU6000-S pressure balance sensor box . . . . . . . . . . . . . . . . . . . . . 52

7.5.3 Setting up the CPU6000-M digital multimeter . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.6 Setting up wireless instruments . . . . . . . . . . . . . . . . . . . . . . . . 54

7.7 Setting up of multimeter and multiplexer . . . . . . . . . . . . . . . . . . . . . 55

8.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.2 Creating a Microsoft Excel certificate template . . . . . . . . . . . . . . . . . . . 56

8.3 Embedding an Excel template . . . . . . . . . . . . . . . . . . . . . . . . 62

8.4 Export in an Excel template . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.5 Automated exporting in an Excel template . . . . . . . . . . . . . . . . . . . . 63

4 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 5

1. General information

1. General information

1.1 Description

The WIKA-Cal calibration software is used for generating calibration certificates or logger protocols for pressure measuring

instruments and is available as a demo version for a cost-free download on the website. Calibration certificates can be created

with the Cal-Template and logger protocols can be created with the Log-Template. In order to switch from the demo version

to a full version of the respective template, a USB stick with the template must be purchased. The pre-installed demo version

automatically changes to the selected full version when the USB stick is inserted and remains available so long as the USB

stick is connected to the computer.

1.2 Licence agreement

Object of the agreement

The subject of the contract is the USB stick for unlocking the respective templates within the WIKA-Cal calibration software.

Grant of licence

You, as the licensee, are entitled to use the USB stick in your company at any place, also at several work stations. However,

one USB stick may only unlock the relevant templates for one work station.

You, as licensee, may not:

modify, translate, reconvert, decompile, disassemble or decode the program in whole or in part as well as develop other

software derived from the program.

EN

Ownership of rights

With the purchase, you only acquire ownership of the USB stick, on which the activation is coded. You will not hold the rights to

the program itself. Any and all rights for publication, reproduction, editing and usage of the program shall remain with WIKA.

Warranty and limitation of liability

■

WIKA guarantees that the USB sticks, on which the release of the templates is coded, are faultless with regard to the

selected material under normal operating conditions. Should the USB sticks present any defect, the USB sticks may be

returned to WIKA within 30 days from the date of first purchase. The USB sticks will be replaced promptly and free of

charge.

■

WIKA guarantees that the program is generally usable in the sense of the program description. As it is not possible

according to the state of the art to develop computer programs that work error-free in all applications and combinations,

WIKA shall not assume any liability with regard to freedom from defects and uninterrupted operation of the program. In

particular, WIKA does not guarantee that the program meets the user's requirements or works together with other programs

selected by the user. The purchaser (licensee) is responsible for the correct selection and the consequences of the program

use as well as for the intended or obtained results.

■

WIKA is not responsible for correct entry of values and handling of the program. WIKA does not assume any liability for any

damage due to incorrect entries, configuration, transfer or consequences thereof. WIKA recommends to check the correct

function of each sensor based on the plausibility of some manual measurements over the entire measuring range after

configuration.

■

WIKA is liable without limitation

- in the event of intent or gross negligence

- for a damage to life, limb or health

- in accordance with the provisions of product liability legislation

- to the extent of a guarantee provided by the seller.

14097663.03 05/2017 EN/DE

5WIKA instruction manual WIKA-Cal

Page 6

1. General information

■

For a slightly negligent breach of duty which is essential for the attainment of the licence agreement (cardinal duty), WIKA's

liability is limited to the level of damage which is foreseeable and typical for the type of business in question.

■

Any further liability of WIKA does not exist.

■

The preceding limitation of liability also applies to the personal liability of WIKA's employees, agents and managing bodies.

Duration of the contract

EN

This contract is in force until the licensee terminates it by destroying the program and all copies. Furthermore, it terminates

when the contract terms are violated. The licensee undertakes to destroy the program and all copies on termination of the

contract.

Improvements and refinements

WIKA is entitled to make improvements and refinements of the program in its sole discretion.

Breach of contract

WIKA points out that the licensee shall be liable for any and all damages from copyright infringements, which are caused to

WIKA due to a breach of the contract terms by the licensee.

This licence agreement shall be governed by the laws of the Federal Republic of Germany to the exclusion of the UN

Convention for the International Sale of Goods of 11 April 1980 (UN CISG). The place of performance is Klingenberg am Main,

Germany. The exclusive place of jurisdiction is Aschaffenburg, in the case that each party is a merchant or corporate body

under public law or has no general jurisdiction in Germany.

1.3 System requirement

Specifications

Minimum system requirements Intel® Pentium® 4 or AMD Athlon® 64

Microsoft® Windows® XP with Service Pack 3, Windows® 7 with Service Pack 1,

Windows® 8 and Windows® 10

1 GB RAM and 1 GB free hard disc space (no installation possible on portable flash

storage media)

1024 x 768 pixel screen resolution (1280 x 800 pixel recommended) with 16-bit colour

depth and 256 MB VRAM

Without the activation USB stick, the software only works in demo mode.

For fully automatic calibrations, at least one RS-232-COM port per instrument is required

for communication.

If an SQL server is to be installed locally, .NET Framework 3.5 is required and, for Win7

and newer, also 4.x.

Language versions German, English, French, Italian, Polish, Romanian, Dutch and Portuguese

Possible communication interfaces USB, RS-232, GPIB IEC-625-Bus, Ethernet and Bluetooth® 2.1

Microsoft® and Windows® are registered trademarks of Microsoft Corporation in the United States and other countries.

®

Bluetooth

is a registered trademark of Bluetooth SIG, Inc..

6 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 7

1. General information

Specifications

Features Creating and archiving test reports with the templates Cal, Cal Light, Cal Demo, Log and

Log Demo

Tools for mass calculator with the CPU6000 and unit converter

Object manager allows for an intelligent use of laboratory and equipment data and

facilitates the standardised testing process

Archiving of customer-specific test reports in the SQL database

Automatic reading and controlling of measuring instruments by means of communication

types

Communication types CPH6000, CPH6200, CPH62I0, CPH6300, CPH6400, CPH65I0, CPH6600, CPH7000,

CPH7600, CPG500, CPG1000, CPG1500, CPT6100, CPT6180, CPG2500, CPC2000,

CPC3000, CPC4000, CPC6000, CPC6050, CPC8000-I (II), CPC8000-H, CPG8000-I

(II), CPT2500, CPD8000, pressure sensor via digital multimeter Agilent 34401A, Agilent

34410A or Keithley 196A, CPU6000-W, CPU6000-S, CPU6000-M

Microsoft® and Windows® are registered trademarks of Microsoft Corporation in the United States and other countries.

®

Bluetooth

is a registered trademark of Bluetooth SIG, Inc..

EN

■

Further information:

WIKA Alexander Wiegand SE & Co. KG

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: CT 95.10

- Application consultant:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.com

Abbreviations, definitions

“XXX” Name of the menu item

[XXX] Press [XXX] button in the program

CI Calibration item

■

Bullet

▶

Instruction

1. ... X. Following the instruction step by step

Result of an instruction

⇒

14097663.03 05/2017 EN/DE

7WIKA instruction manual WIKA-Cal

Page 8

2. First steps and installation

2. First steps and installation

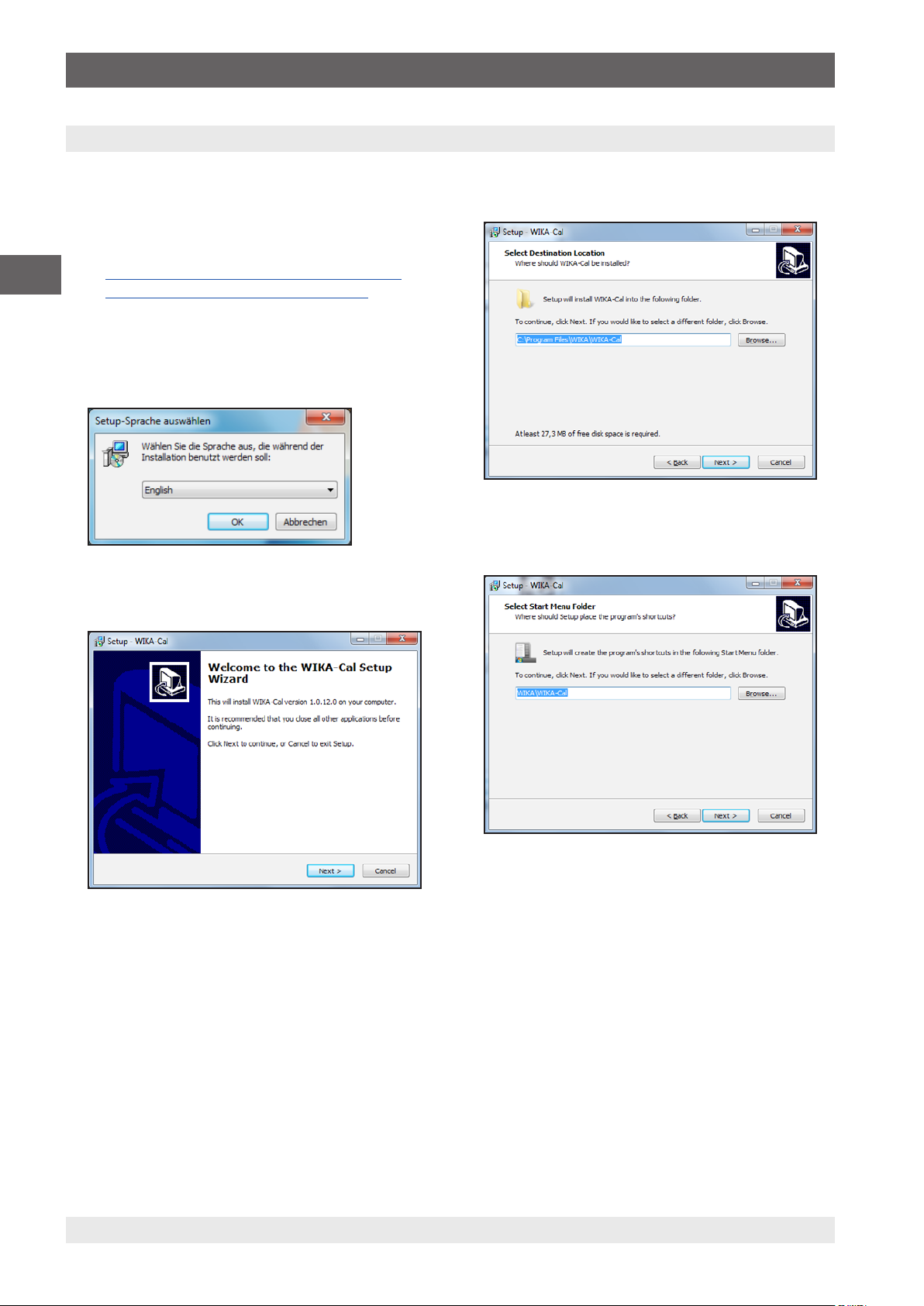

To install the WIKA-Cal calibration software, carry out the

following steps:

1. Download of the WIKA-Cal demo version directly from our

local website.

EN

http://en-co.wika.de/download_software_digital_

⇒

pressure_gauges_calibration_en_co.WIKA

or WIKA website/Download/Software/Calibration.

2. Unpack WIKA-Cal-Setup-vX_X_X_X.zip file.

3. Start WIKA-Cal-Setup-vX_X_X_X.exe file.

4. Follow the instructions of the installation wizard.

5. Select a language for the installer and confirm with [OK].

6. In the welcome dialogue, select [Next >].

7. Select the target folder for the installation of WIKA-Cal

and confirm with [Next >].

8. Select a windows start menu entry and confirm with

[Next >].

8 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 9

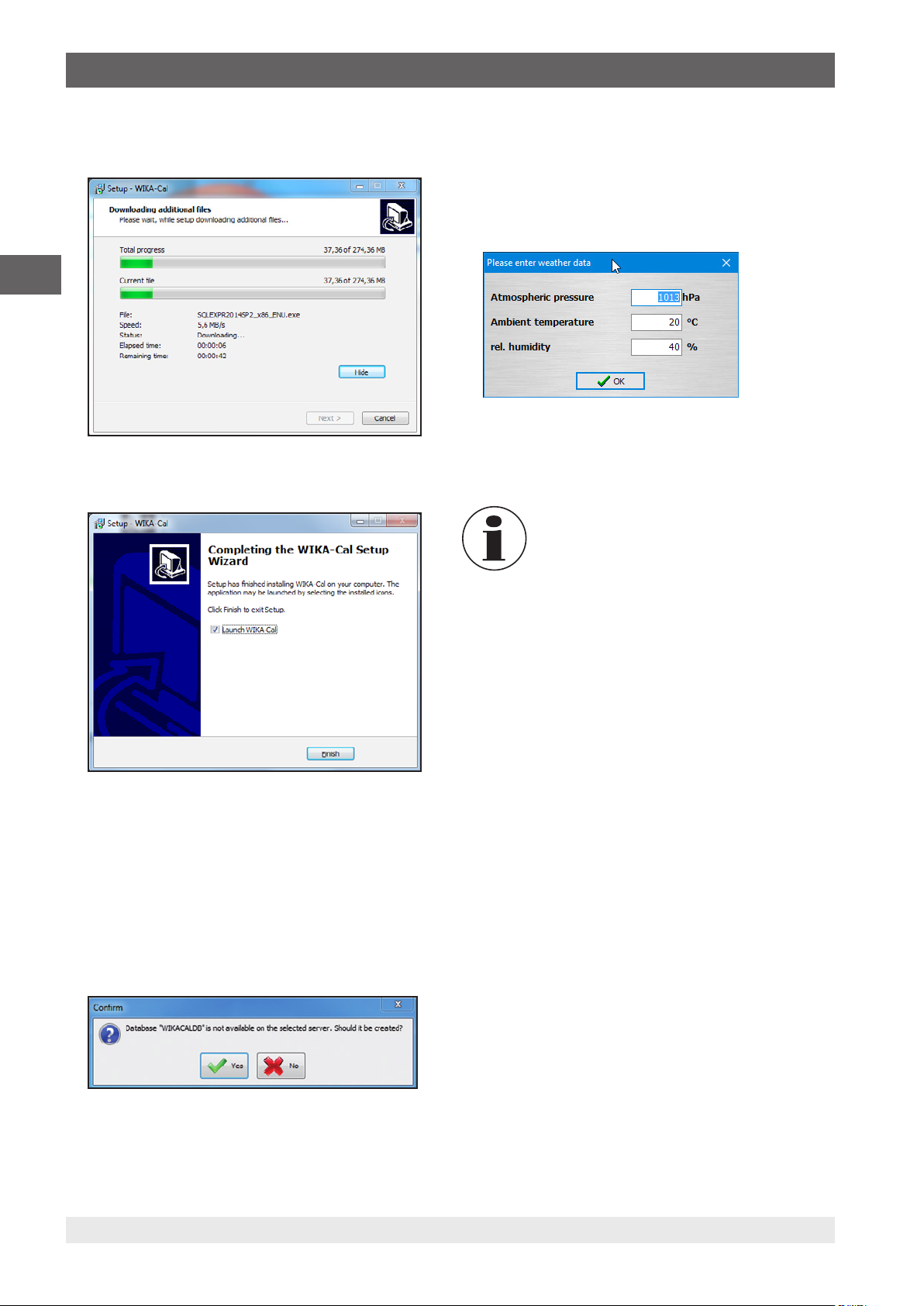

2. First steps and installation

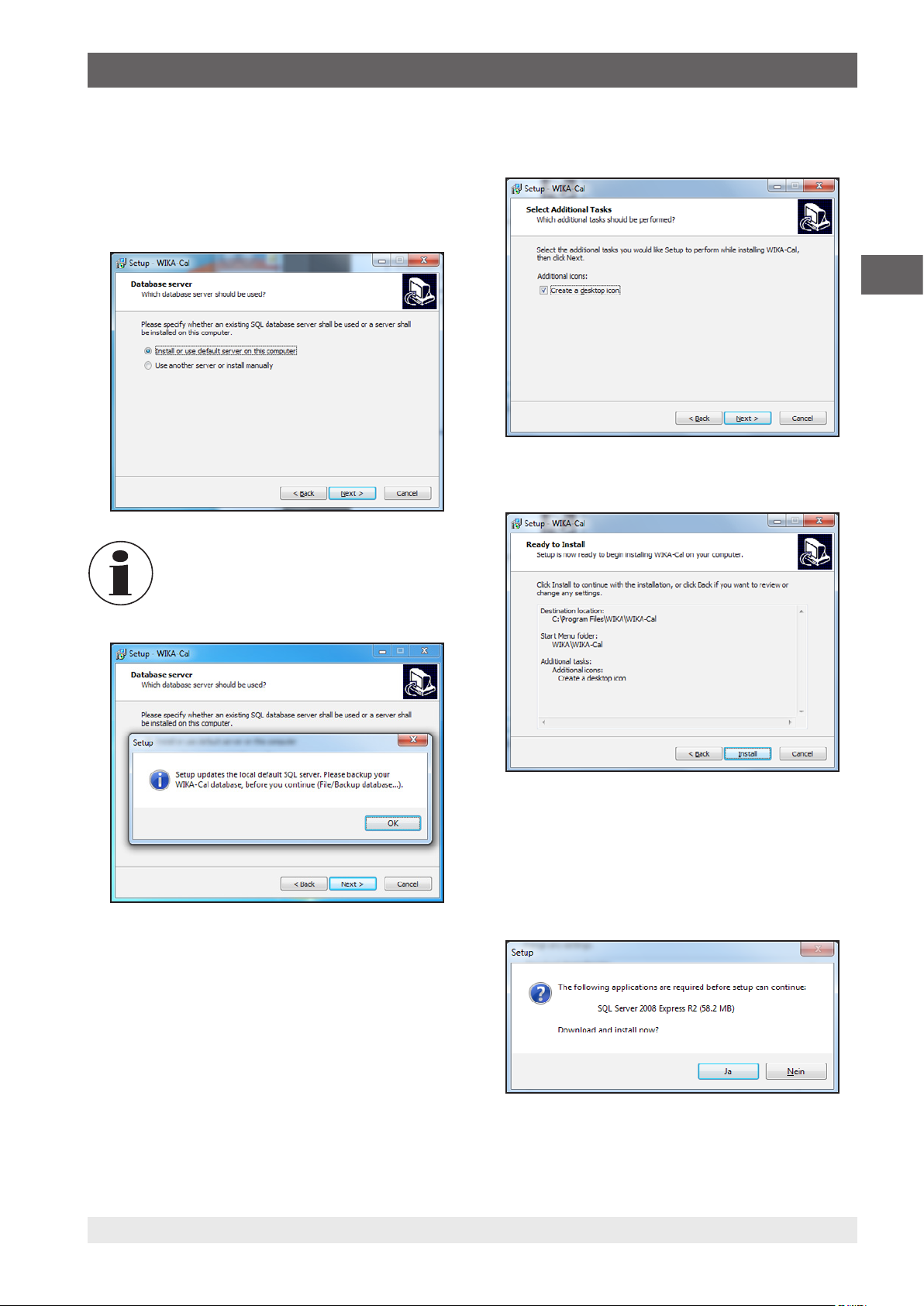

9. Select “Install or use default server on this

computer“ if the SQL server for WIKA-Cal is to be

installed locally on the computer or is already installed.

Select “Use another server or install manually”, if an

SQL server will be used on a different PC.

Then confirm with [Next >].

If you are using an older SQL version (esp. for

Windows® 10), this pop-up will appear.

10. Select whether a desktop symbol is to be created and

confirm with [Next >].

EN

11. Start the installation with [Install].

14097663.03 05/2017 EN/DE

12. In the following dialogue, the required SQL server

installation is downloaded from the internet. The

download and installation is initiated by pressing [Yes].

If there is no access to the internet, an installer version

can be requested via the WIKA contact address, which

includes a version of the SQL server installer.

9WIKA instruction manual WIKA-Cal

Page 10

2. First steps and installation / 3. Overview

13. Wait for download and installation to complete. This may

take a few minutes.

EN

14. The software is installed now and can be started.

16. If the database has been created correctly, the software

starts with a “Weather data” dialogue. Here the data can

be entered manually or received automatically by the

CPU6000-W. After confirming with [OK], the weather

data is stored in the database (see chapter 6.5 “Weather

data”).

17. The installation is complete now and the software is ready

for use.

For the installation of the software, no USB

stick is needed. By inserting the USB stick,

the coded version stored on the stick is

automatically accessed from within the demo

version.

15. When WIKA-Cal is started for the first time, there is

a check as to whether a WIKA-Cal database can be

found on the SQL server. If this is not the case, the

database can be created by selecting [Yes]. Without the

WIKACALDB database, the WIKA-Cal software will not

work.

The dialogue serves to protect the server. If an incorrect

SQL server was selected accidentally, selecting [No]

here will prevent installation on a remote server.

10 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 11

3. Overview

3. Overview

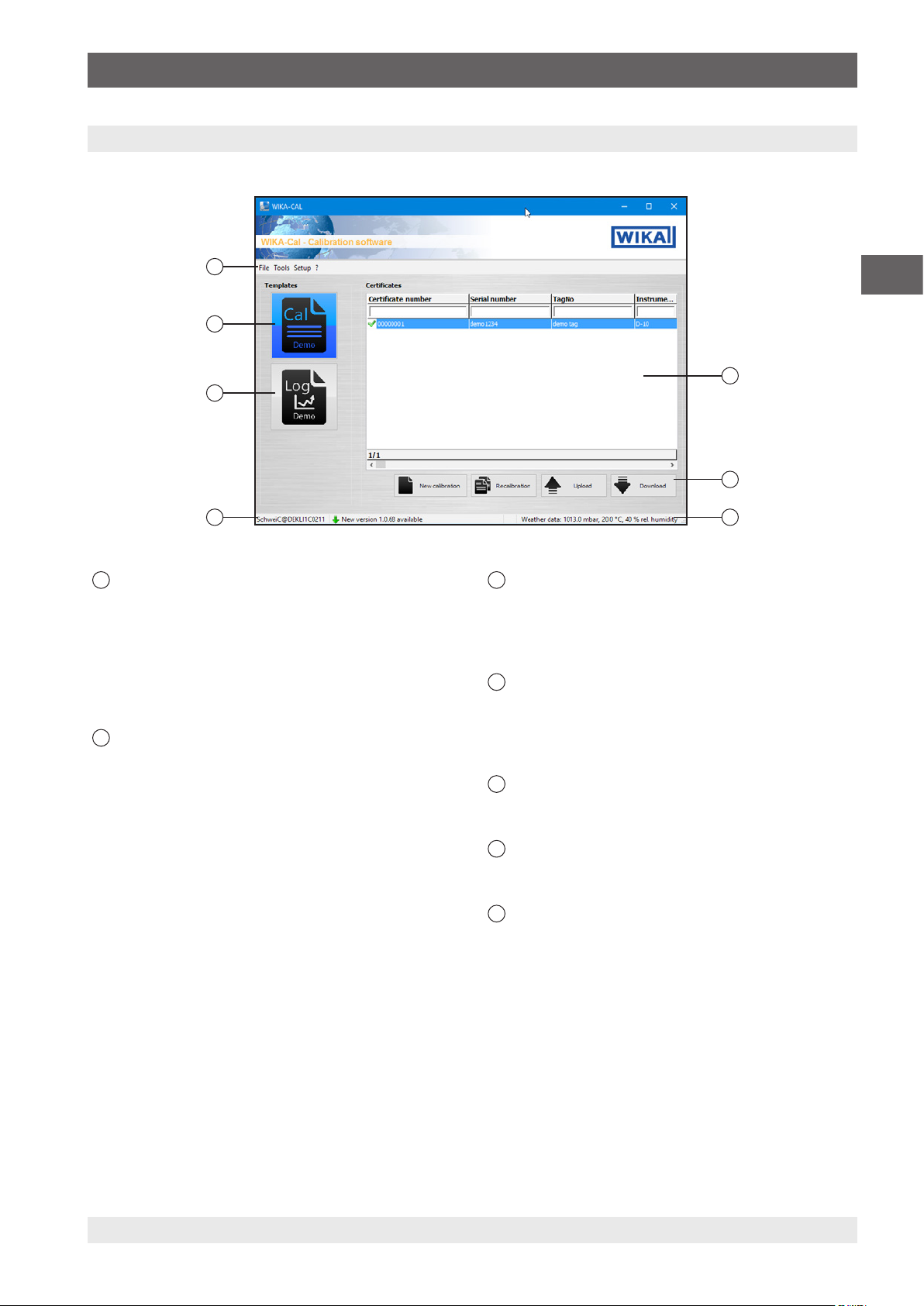

3.1 Main window

7

6

5

1

Certificates

Database of all the documents for the selected

template. It can be filtered against a term via the filter

bar.

Example: “Serial number = 12345”, displays all

documents for the serial number 12345.

“Serial number = *12345*”, displays all documents

which contain 12345 in their serial number.

2

Function buttons

■

New calibration, New log

Creates a document from the selected template (see

chapter 4.3 “New calibration” or chapter 5.3 “New

log”).

■

Recalibration, Relog

Creates a prefilled document from the selected

template. Only finished documents (green

check mark) can be selected (see chapter

4.4 “Recalibration” or chapter 5.4 “Repeat logging”).

■

Upload (only available for Cal-Template)

Loads a calibration process onto a mobile

instrument (see chapter 4.5 “Upload”).

1

2

34

3

Weather data

Indication of the current ambient conditions

- Clicking on the bar will open the “Weather data”

window in the “Object manager” (see chapter

6.5 “Weather data”).

4

Work station

Indication of the current computer name

- Clicking on the bar will open the “Work station”

window in the “Object manager” (see chapter

6.3.1 “Work station”).

5

Templates

Log-Template selection (see chapter 5 “Log-Template

logger protocol”).

6

Templates

Cal-Template selection (see chapter 4 “Cal-Template

calibration certificate”).

7

Menu bar

Loading and saving the database, tools such as

calculator or unit converter, etc. (see chapter 3.2 “Menu

bar and tools”).

EN

mass

■

Download

A document based on the selected template will

be loaded from a mobile instrument (see chapter

4.6 “Download”).

14097663.03 05/2017 EN/DE

11WIKA instruction manual WIKA-Cal

Page 12

3. Overview

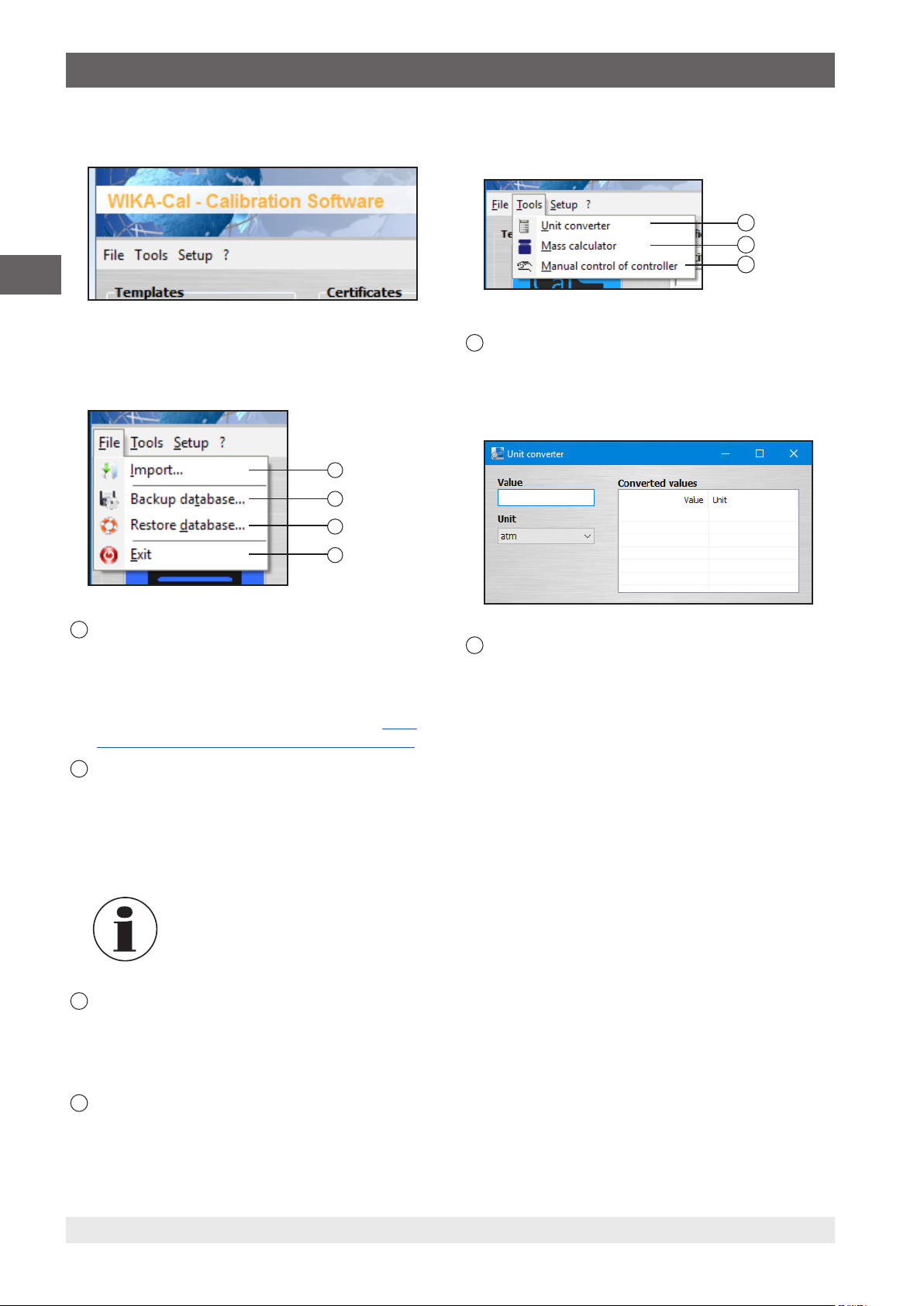

3.2 Menu bar and tools

EN

3.2.1 File: Import, backup database, restore database,

exit

1

2

3

4

3.2.2 Tools: Unit converter, Mass calculator and Manual

control of controller

5

6

7

5

Unit converter

If a number is entered under “Value”, this will be

converted with the specified unit into all available units

and displayed under “Converted values” (see chapter

6.3.5 “Units (pressure)”).

1

Import

Importing pressure balance data. Via the import of an

XML file, a pressure balance can be inserted into the

database as a standard (see chapter ). The XML files

are stored online under a file name, e.g. for file name

“50556CPB5000”, the XML file is stored under http://

apps.wika.com/apps/CPB-CAL/50556CPB5000.xml

2

Backup database...

Using this function, the complete database (see

chapter 6 “Object manager”) can be saved in a .bak

file. Here a path must be selected for which write

permissions for the database exist. The installed SQL

database must be able to access the selected path.

The write permissions of the SQL

database are different from the logged-in

Windows user. Experience has shown

that a newly created folder, e.g. “C:\

Temp\”, is a good option to save .bak files.

3

Restore database...

A .bak file saved using “Backup database....” can

be reloaded via “Restore database...”. Here, the old

database will be deleted and the selected database in

the .bak file will be restored.

4

Exit

Exits the program.

6

Mass calculator

The tool is used to convert masses into pressure, and

vice versa, for pressure balances. First, an instrument

(pressure balance) and the associated piston must

be chosen. The mass set is chosen accordingly. The

pressure balance data must have been previously

entered in the object manager or imported via an XML

file (see chapter 6.3.19 “Standards (pressure)” or

3.2.1 “File: Import, backup database, restore database,

).

exit”

By pressing [Enter] after entering a pressure value in

the left column, the cells above will be prefilled with

regularly distributed values. For example, entering an

end value in the lower left → cell will cause regularly

distributed values to be entered in the cells above, up

to the start of the measuring range.

It is also possible to calculate fine increment masses

in order to calculate the masses for a pressure value,

or vice versa. It is also possible to enter the mass

numbers.

For the correction of the measured values, the

measured ambient conditions and the piston

temperature are used. The piston position is used to

display the floating position. In addition, for absolute

pressure instruments, the vacuum residual pressure

must also be specified. Through CPU6000 series

instruments, this can be read automatically.

12 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 13

3. Overview

7

Manual control of controller

Once connection to the selected controller has been

established, you can manually set the desired nominal

value in increments.

1. Use the [▲] and [▼] buttons to change the pressure

range.

2. Click [OK] to confirm the change in pressure.

The new pressure range is set

⇒

The bar graph represents the pressure range

graphically.

Click [Disconnect] to disconnect the controller.

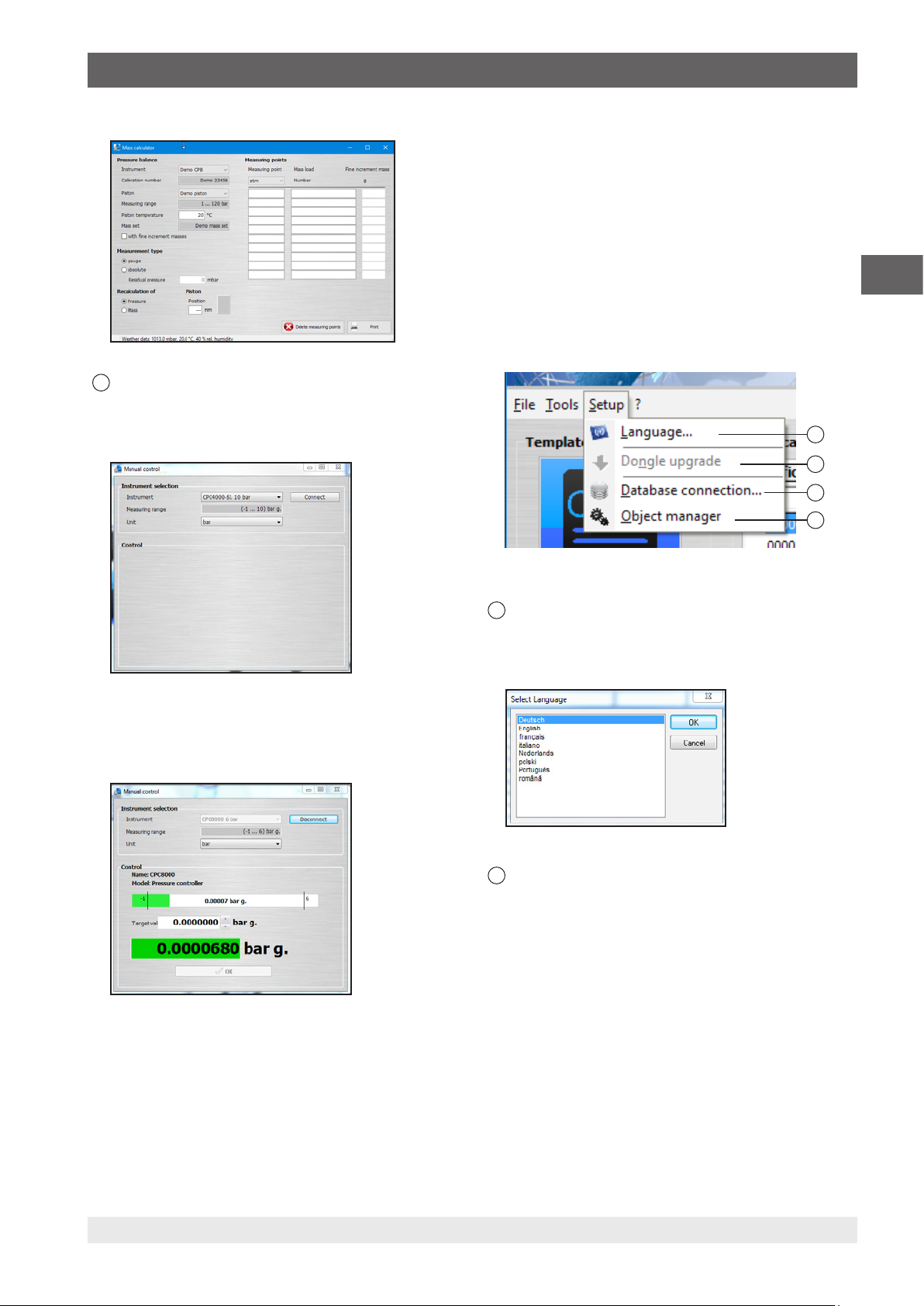

3.2.3 Setup: Language, dongle upgrade, database

connection, object manager

10

11

EN

8

9

Select the controller under “Instrument” and the desired

pressure range under “Unit”.

Use [Connect] to access the controller.

8

Language

Selection of the different languages. The software is

continually being updated and additional languages are

being added.

9

Dongle upgrade

When a USB stick is connected, via the “Dongle

upgrade”, the serial number of the USB stick can be

determined. This serial number can be passed to your

WIKA contact in order to expand the USB stick by new

functionality. Find out about additional functionality for

your USB stick from your WIKA contact.

14097663.03 05/2017 EN/DE

13WIKA instruction manual WIKA-Cal

Page 14

3. Overview

10

EN

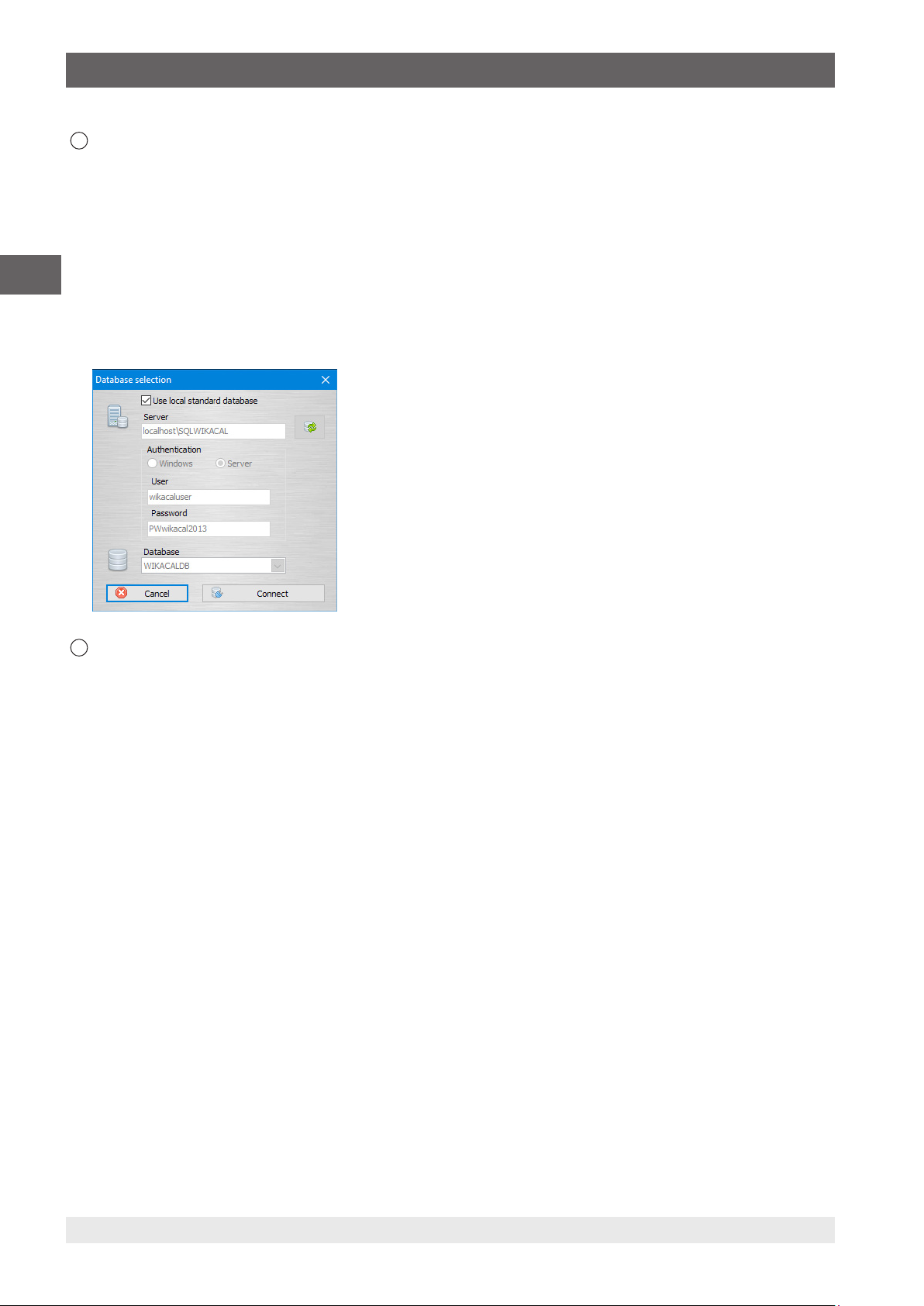

Database connection

In the database selection dialogue, by deactivating the

“Use local standard database”, another server can

be selected.

The server, on another computer in the network,

can be connected via “Networkcomputername\

SQLWIKACAL”. The values under “Authentication”

and “Database” should remain there. The adjustment

of these values requires advanced knowledge of SQL.

After pressing [Connect], one is connected to the

database and should be able to call this via the object

manager.

11

Object manager

See chapter 6 “Object manager”.

14 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 15

4. Cal-Template calibration certificate

Calibration certificate

Kalibrierzeugnis

Certificate No. 00000122

Zeugnis-Nr.

Page 2 / 2

Seite

Demo laboratory

Demo street 123

12345 Demo city

Demo country

Tel.: 01234/56789

Fax: 01234/56789

E-Mail: demo@demo.com

www.demo.com

Measurement results

Messergebnisse

Statement of compliance

Konformitätsaussage

Reference value WS Reading DUT

Referenzwert GN Ablesung KG

bar bar

↑ ↓

0.00000 0.0000 0.0010

10.00000 10.0010 10.0020

Object keeps the specifications!

Der Kalibriergegenstand hält die Herstellerspezifikationen ein!

Calibration certificate

Kalibrierzeugnis

Certificate No. 00000122

Zeugnis-Nr.

Page 1 / 2

Seite

Demo laboratory

Demo street 123

12345 Demo city

Demo country

Tel.: 01234/56789

Fax: 01234/56789

E-Mail: demo@demo.com

www.demo.com

General

Allgemein

Device under test (DUT)

Kalibriergegenstand (KG)

Environmental conditions

Umgebungsbedingungen

Place of calibration

Ort der Kalibrierung

Measurement conditions

Messbedingungen

Calibration certificate

Kalibrierschein

Customer Demo customer

Kunde

Demo street

DE-12345 Demo city

Customer order No.

Kundenbestellnummer

Order date

Bestelldatum

Date of calibration 01/02/2017

Datum der Kalibrierung

Operator Demo User

Bearbeiter

Electrical gauge

Elektrisches Druckmessgerät

Model D-10

Typ

Serial number demo1234

Seriennummer

Scale range (0 ... 10) bar g

Anzeigebereich

Accuracy 0.05 % FS

Genauigkeit

Resolution (scale division) 0.0001 bar

Auflösung (Skalenwert)

Measuring point No. demo tag

Messstellen-Nr

Temperature (20,0 ± 0,1) °C

Temperatur

Atmospheric pressure (1013,0 ± 0,1) hPa

Atmosphärischer Luftdruck

Rel. humidity (40 ± 1) %

Rel. Luftfeuchte

Demo place

g = (9.80946 ± 0.01) m/s²

Musterort

Working standard (WS) Pressure controller

Gebrauchsnormal (GN) Druckcontroller

Model Demo CPC

Typ

Calibration mark Demo 12345

Kalibrierzeichen

Scale range (0 ... 10) bar g

Anzeigebereich

Accuracy 0.02 % FS

Genauigkeit

Calibration certificate

Kalibrierzeugnis

Certificate No. 00000122

Zeugnis-Nr.

General

Allgemein

Device under test (DUT)

Kalibriergegenstand (KG)

Calibration certificate

Kalibrierschein

Customer Demo customer

Kunde

Demo street

DE-12345 Demo city

Customer order No.

Kundenbestellnummer

Order date

Bestelldatum

Date of calibration 01/02/2017

Datum der Kalibrierung

Operator Demo User

Bearbeiter

Electrical gauge

Elektrisches Druckmessgerät

Model D-10

Typ

Serial number demo1234

Seriennummer

Scale range (0 ... 10) bar g

Anzeigebereich

Accuracy 0.05 % FS

Genauigkeit

Resolution (scale division) 0.0001 bar

Auflösung (Skalenwert)

Measuring point No. demo tag

Messstellen-Nr

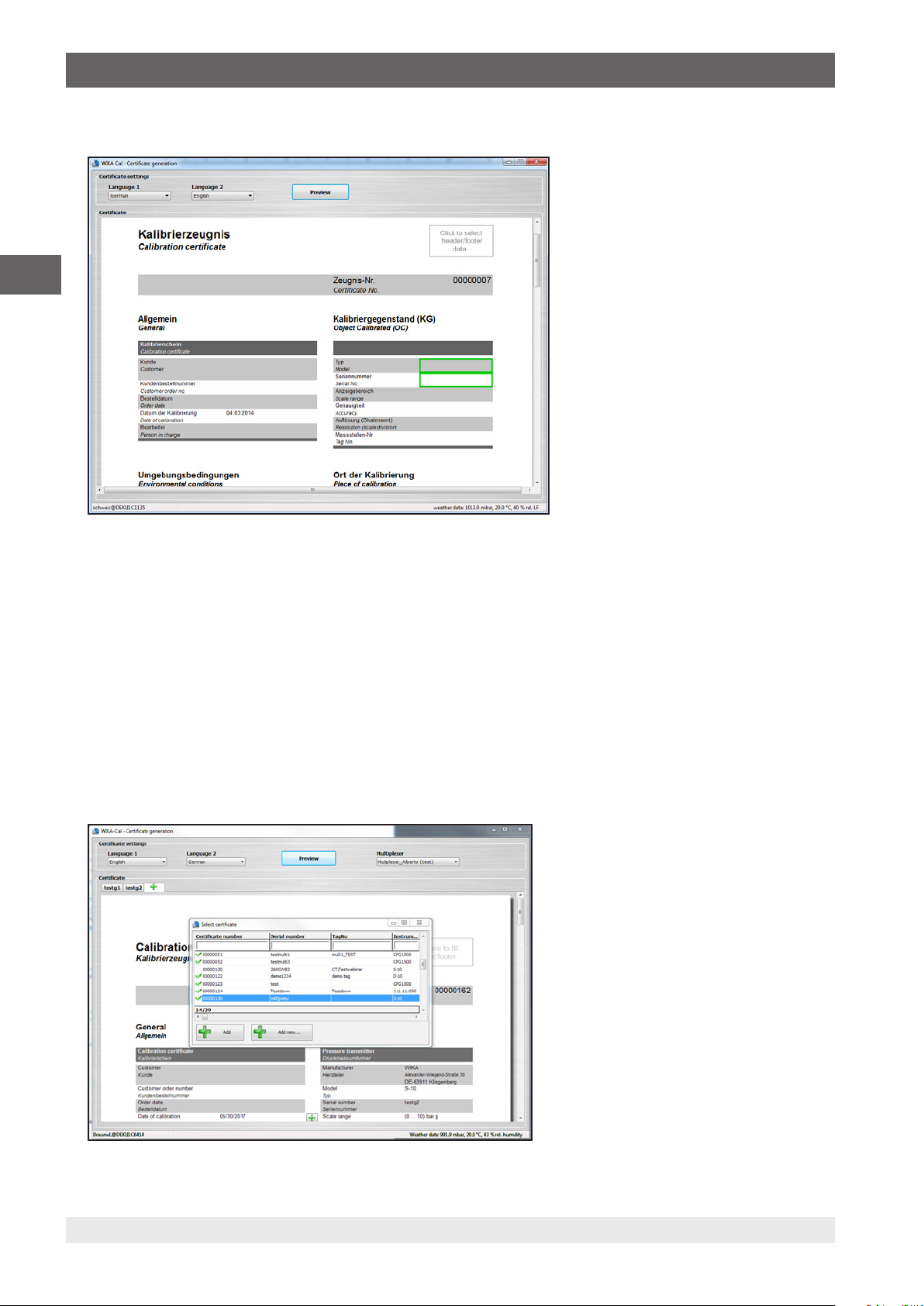

4. Cal-Template calibration certificate

4.1 General information

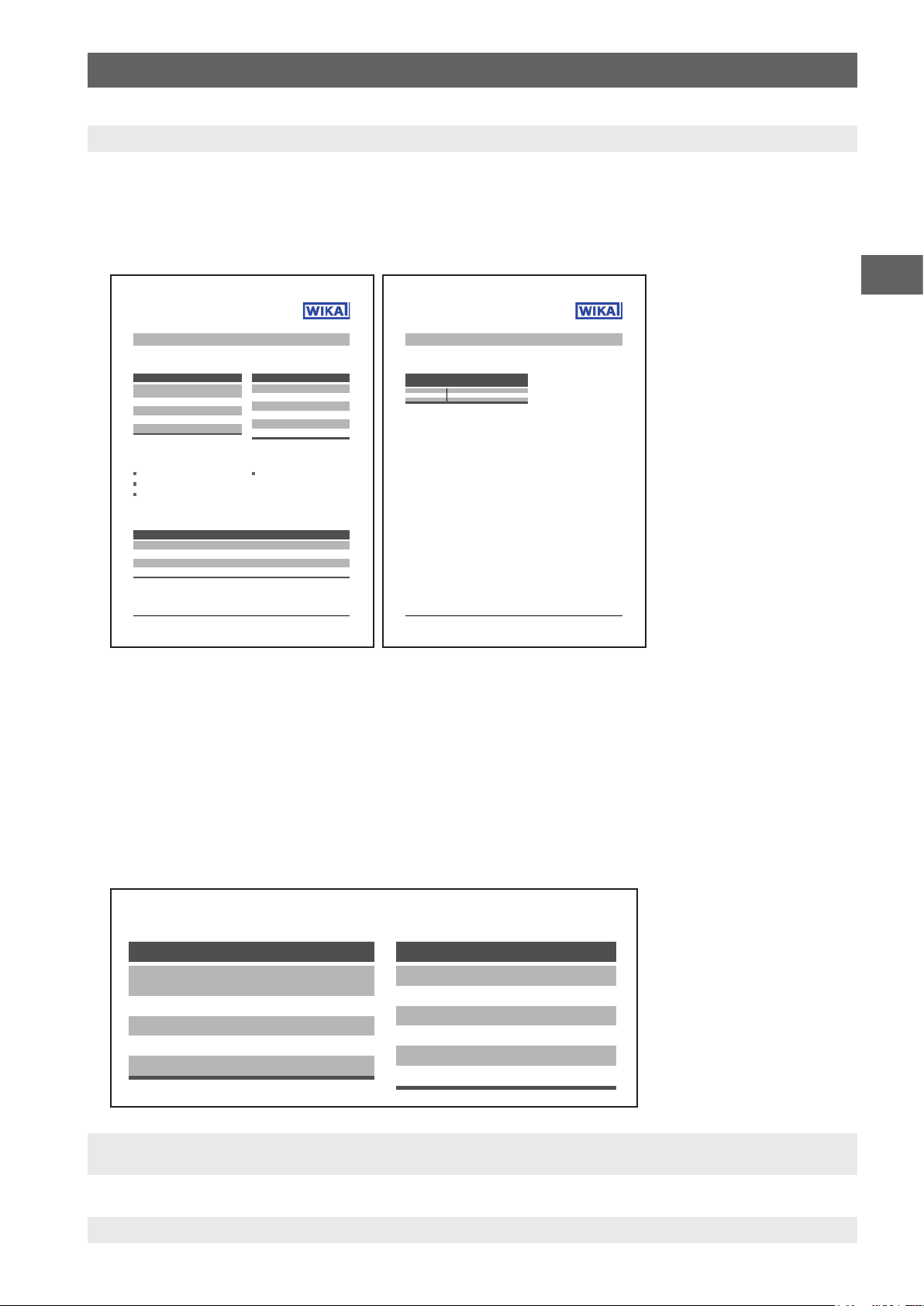

With the Cal-Template, calibration certificates for mechanical and electronic pressure measuring instruments can be

generated. The calibration certificates have a format derived from the WIKA DKD/DAkkS calibration certificate and contain the

same functions and calculations. The template has many additional features. For example, the company logo, the address, the

contact or individual labelling can be customised by the user.

EN

4.2 Entry of calibration data

4.2.1 General data

Specification of company-specific data, such as customer address, order number or order date. The label texts can be

amended in the database.

4.2.2 Calibration item

Information on the measuring instrument which is to be calibrated. The table dynamically adapts to the selected instrument

type. Thus, for example, with pressure transmitters, an additional line is displayed for the output signal (e.g. 4 ... 20 mA).

Fig. left: General data

Fig. right: Calibration item

14097663.03 05/2017 EN/DE

15WIKA instruction manual WIKA-Cal

Page 16

4. Cal-Template calibration certificate

Calibration certificate

Kalibrierzeugnis

Certificate No. 00000122

Zeugnis-Nr.

General

Allgemein

Device under test (DUT)

Kalibriergegenstand (KG)

Environmental conditions

Umgebungsbedingungen

Place of calibration

Ort der Kalibrierung

Calibration certificate

Kalibrierschein

Customer Demo customer

Kunde

Demo street

DE-12345 Demo city

Customer order No.

Kundenbestellnummer

Order date

Bestelldatum

Date of calibration 01/02/2017

Datum der Kalibrierung

Operator Demo User

Bearbeiter

Electrical gauge

Elektrisches Druckmessgerät

Model D-10

Typ

Serial number demo1234

Seriennummer

Scale range (0 ... 10) bar g

Anzeigebereich

Accuracy 0.05 % FS

Genauigkeit

Resolution (scale division) 0.0001 bar

Auflösung (Skalenwert)

Measuring point No. demo tag

Messstellen-Nr

Temperature (20,0 ± 0,1) °C

Temperatur

Atmospheric pressure (1013,0 ± 0,1) hPa

Atmosphärischer Luftdruck

Rel. humidity (40 ± 1) %

Rel. Luftfeuchte

Demo place

g = (9.80946 ± 0.01) m/s²

Musterort

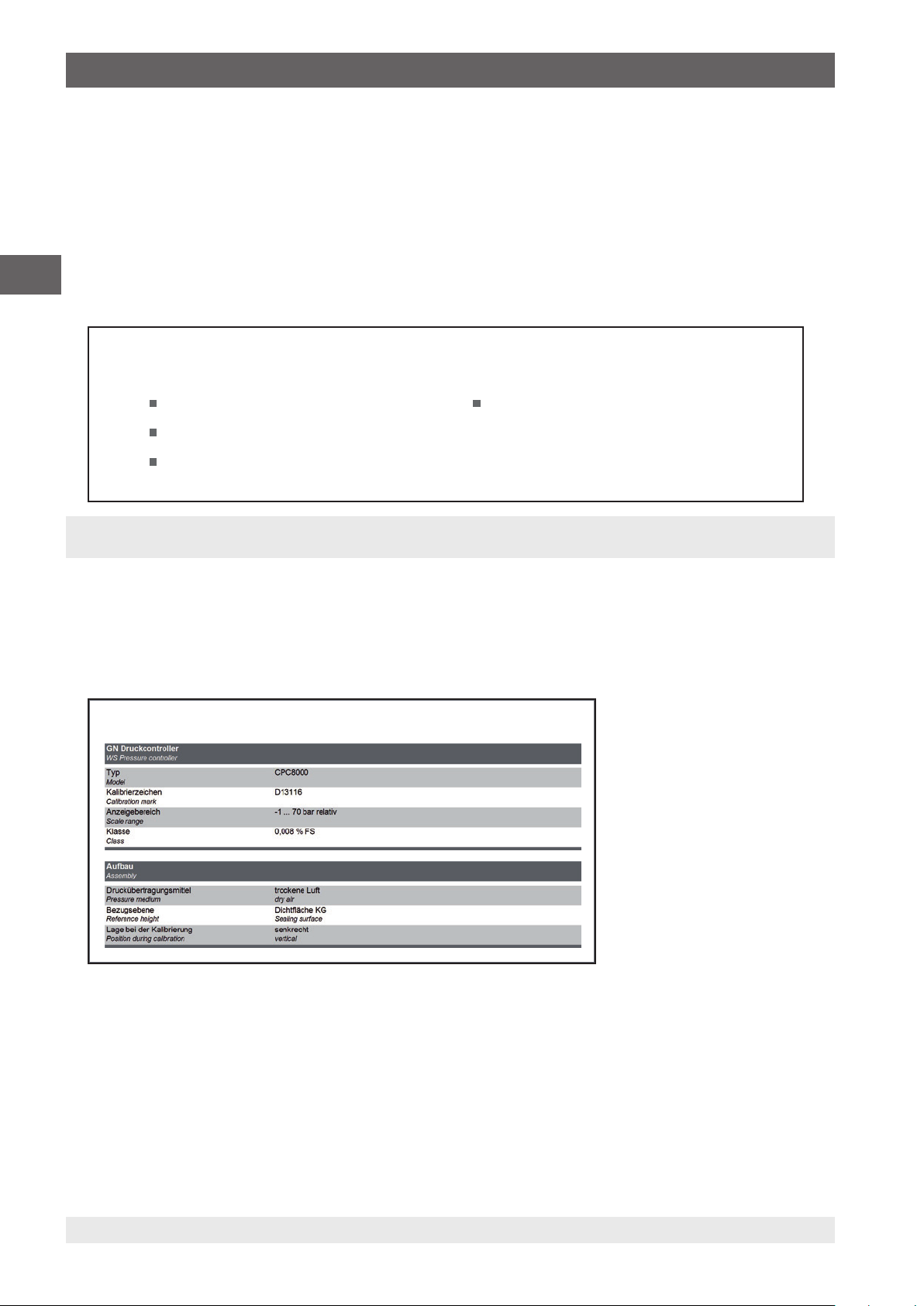

4.2.3 Ambient conditions

Indication of the ambient conditions. The values are entered every 3 minutes via a manual dialogue or read automatically by a

model CPU6000-W weather station.

The manual input or automatic reading of a CPU is made from a work station that is assigned to a place. All other work stations

which are allocated to that place benefit directly from the registered values.

4.2.4 Place of calibration

EN

Description of the place in which the calibration was carried out.

Will be selected automatically from the work station (computer name) which is assigned to that place in the database.

Fig. left: Ambient conditions

Fig. right: Place of calibration

4.2.5 Measurement conditions

Information about the reference used, the multimeter or the general assembly. The information is made dynamically based on

the specified test item.

Several different references can be specified. With the definition of the measuring points, these are assigned before the

calibration.

Messbedingungen

Measurement conditions

16 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 17

4. Cal-Template calibration certificate

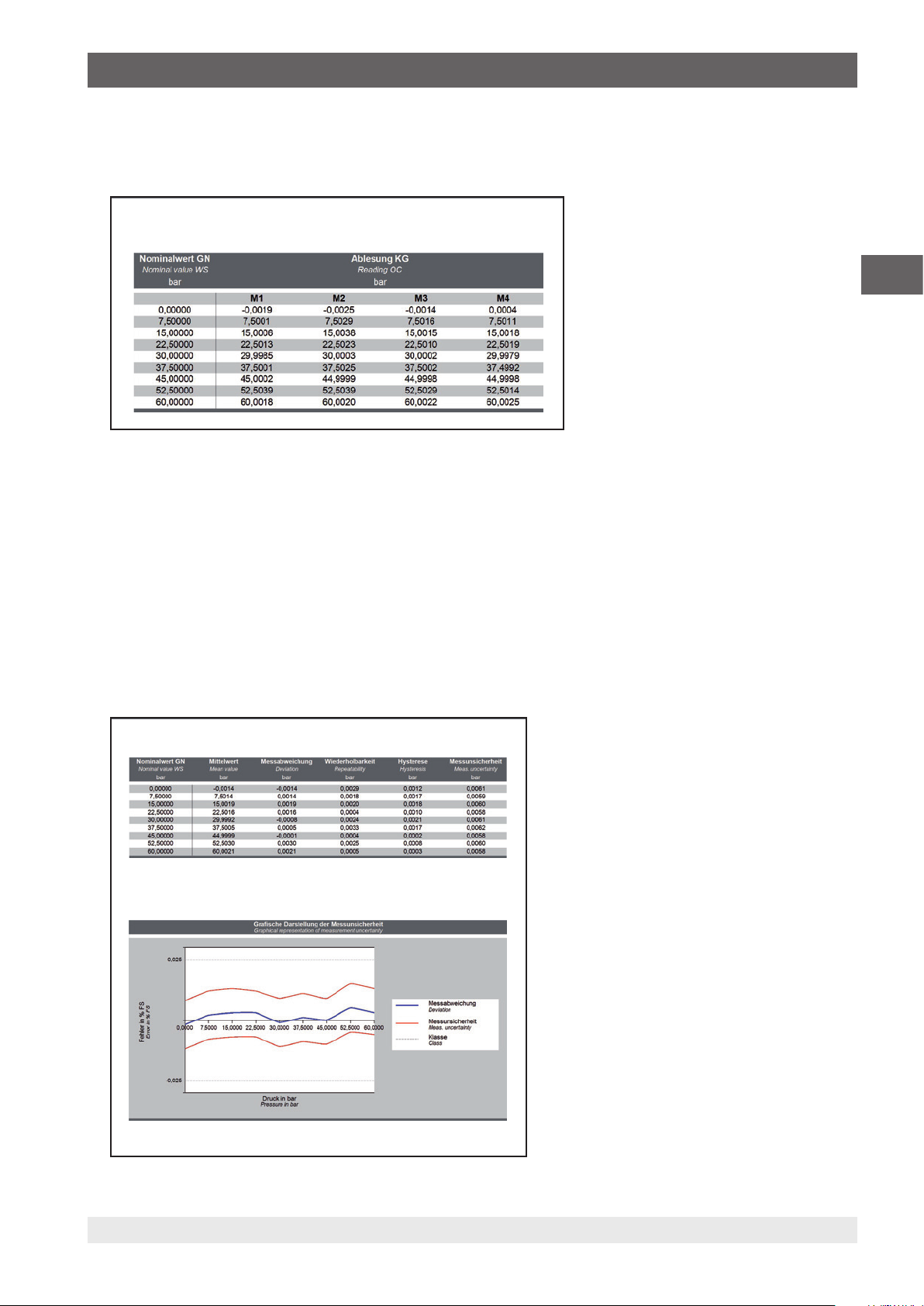

4.2.6 Measurement results

Results of the calibration. The table automatically adapts to the selected models. Thus, for example, for pressure transmitters,

two tables (one for the electrical signal and one for the pressure values) are defined.

Messergebnisse

Measurement results

4.2.7 Evaluation (optional)

Evaluation of the measuring deviation. Can be set via the database in percentage or pressure unit (see chapter 6.4.1 “Cal”).

EN

4.2.8 Measurement uncertainty (optional)

Evaluation of the measurement uncertainty can be enabled via the database (see chapter 6.4.1 “Cal”). First, the mean values

are calculated by means of a zero setting in accordance with DKD-R 6-1. The corresponding measuring deviation results from

“mean value - measuring deviation”. Repeatability, hysteresis and measurement uncertainty are also calculated in accordance

with DKD-R 6-1. During their calculation, all entries from the creation process are used.

In addition, the note from DKD-R 6-1 is listed below the table. The graphical representation is optional, too, and can be

enabled via the database (see chapter 6.4.1 “Cal”).

The final assessment of the instrument´s accuracy is the biggest calculated “measuring deviation + measurement uncertainty”.

Messunsicherheit

Uncertainty of measurement

Angegeben ist die erweiterte Messunsicherheit, die sich aus der Standardmessunsicherheit durch Multiplikation mit

dem Erweiterungsfaktor k = 2 ergibt. Sie wurde gemäß DAkkS–DKD–3 ermittelt. Der Wert der Messgröße liegt mit einer

Wahrscheinlichkeit von 95 % im zugeordneten Werteintervall.

The uncertainty stated is the expanded uncertainty obtained by multiplying the standard uncertainty by the coverage factor k = 2. It has

been determined in accordance with DAkks–DKD–3. The value of the measurand lies within the assigned range of values with a

probability of 95%.

Die Genauigkeit des Gerätes beträgt 0,0090 bar

The accuracy of the device is 0,0090 bar

14097663.03 05/2017 EN/DE

17WIKA instruction manual WIKA-Cal

Page 18

4. Cal-Template calibration certificate

Konformitätsaussage

Statement of compliance

Der Kalibriergegenstand hält die Herstellerspezikationen ein!

Object keeps the specications!

4.2.9 Statement of compliance (optional)

Written confirmation of compliance or non-compliance with the manufacturer's specifications based on the evaluation.

Konformitätsaussage

Statement of compliance

Der Kalibriergegenstand hält die Herstellerspezikationen ein!

Object keeps the specications!

EN

4.2.10 Additional information (optional)

Additional remarks/comments

Weitere Hinweise

Additional information

Die Deutsche Akkreditierungsstelle GmbH ist Unterzeichner der multilateralen Übereinkommen der European

cooperation for Accreditation (EA) und der International Laboratory Accreditation Cooperation (ILAC) zur gegenseitigen

Anerkennung der Kalibrierscheine. Die weiteren Unterzeichner innerhalb und außerhalb Europas sind den Internetseiten

von EA (www.european–accreditation.org) und ILAC (www.ilac.org) zu entnehmen.

The DAkkS is signatory to the multilateral agreements of the European co–operation for Accreditation (EA) and of the International

Laboratory Accreditation Cooperation (ILAC) for the mutual recognition of calibration certicates. The other signatories in and outside

Europe can be seen on the Websites of EA (www.european–accreditation.org) and ILAC (www.ilac.org).

4.3 New calibration

18 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 19

4. Cal-Template calibration certificate

The [New calibration] button starts a new calibration certificate in the document view and adds it to the database. When

a certificate has been completed, a green check mark will be displayed next to the certificate data set. A double click on a

finished certificate always opens the PDF file, while, for others, the document view will always be opened with the latest status.

4.4 Recalibration

EN

The [Recalibration] button starts a new calibration certificate in the document view and adds it to the database. The button is

only available if a completed certificate has been marked in advance. All data in the marked certificate will be transferred to the

new calibration certificate and the calibration can begin immediately.

14097663.03 05/2017 EN/DE

19WIKA instruction manual WIKA-Cal

Page 20

4. Cal-Template calibration certificate

4.5 Upload

This button / function is only available for Cal-Template.

EN

The [Upload] button allows you to configure a calibration process and load it onto a created reference instrument.

This option is only available for hand-held products supporting download to WIKA-Cal.

Pressing the [Upload] button opens the “Data upload” dialogue. Then select the reference instrument created in the object

manager. The associated communication is stored in the respective work station object.

All the information needed on the test item has to be entered before the upload. Click “Set” and define the measuring points.

To apply the selection, click [Upload]. This will load the calibration process onto the mobile instrument. The transmission

process is represented by a green bar at the bottom of the dialog box. Once transmission is complete, the “Transfer

complete” window appears and needs to be confirmed with [OK].

The calibration process can now be started and performed on the mobile instrument.

20 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 21

4. Cal-Template calibration certificate

4.6 Download

EN

With the [Download] button, data can be downloaded from a defined reference instrument.

This option is only available for hand-held products supporting download to WIKA-Cal.

Clicking the [Download] button opens the “Data download” dialogue. Then select the reference instrument created in the

object manager. The associated communication is stored in the respective work station object. Confirm the selection with

[Download] and the data will be displayed under “Available data sets” on the hand-held instrument. By selecting a data set,

the raw data is displayed and the instrument type/place can be assigned. If [Create certificate] is pressed, a new calibration

certificate will be created in the database. This is, for the time being, still editable, so not provided with a green check mark.

14097663.03 05/2017 EN/DE

21WIKA instruction manual WIKA-Cal

Page 22

4. Cal-Template calibration certificate

4.7 Calibrate and finish certificate

EN

The green border indicates the order of entry. Other possible entries can also be selected. So, for example, by clicking on the

logo in the upper right, a different laboratory can be selected, for which a different logo is assigned from the database.

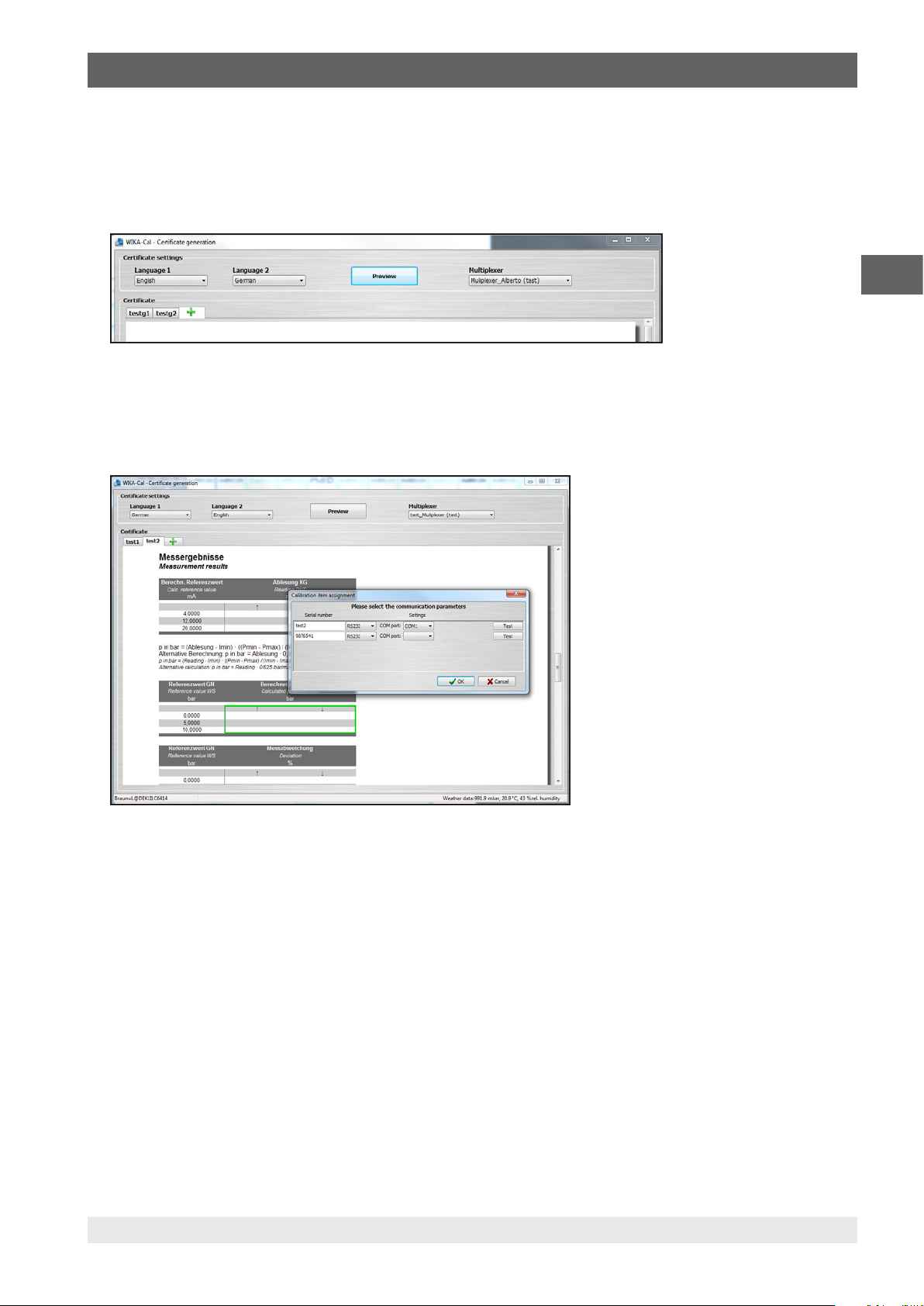

4.8 Multicalibration (optional)

To use the “Multicalibration” option, proceed as follows:

1. Multimeter and multiplexer need to be configured, see chapter 7.7 “Setting up of multimeter and multiplexer”.

2. Create a standard and assign it to the work station (see chapter 6.3.19 “Standards (pressure)”).

3. Start a new calibration process by clicking the [New calibration] button.

The document view opens

⇒

Enter the data of the first calibration item, then select the reference. Clicking “+” allows you to add the next calibration item.

You may either select an existing one from the list or add a new one by entering the serial number. In this case, instrument

type, measuring range and accuracy will automatically be applied from the first calibration item.

22 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 23

4. Cal-Template calibration certificate

After adding all calibration items (max. 7 items), the measurement series and measuring points need to be adjusted and/or

confirmed. To do so, click the measurement table highlighted with a green frame.

Make sure that different multimeters are set for the different calibration items in the certificate view. If this is not the case,

click on the multiplexer in the upper right corner of the certificate view. The multimeters are now properly reassigned to the

calibration items.

Clicking again in the green border allows you to redefine and/or confirm the communication parameters in a separate window.

The measurement window then opens and calibration starts. You can use the various tabs to switch between the calibration

items during the calibration process. If a calibration item is out of class during the measurement, this will be indicated by an

exclamation mark symbol in the corresponding tab.

EN

14097663.03 05/2017 EN/DE

23WIKA instruction manual WIKA-Cal

Page 24

5. Log-Template logger protocol

Loggerprotokoll

Logger protocol

Log-Nr. 00000049

Log No.

Gerät

Instrument

Elektrisches Druckmessgerät

Electrical gauge

Typ CPG1500

Model

Seriennummer S000001

Serial number

Temperatur loggen ☒

Log temperature

Anzeigebereich (0 ... 100) bar g

Scale range

Genauigkeit 0,1 % FS

Accuracy

Kommunikation Wireless (00:13:43:19:D0:88)

Communication

5. Log-Template logger protocol

5.1 General information

The Log-Template can generate logger protocols, which can be used for recording data.

As with the Cal-Template, the user is guided through the document view and arrives at the end with a completed protocol from

the logged data as a PDF/A document.

The data in the PDF/A document is also available as .csv file for processing in another program, such as Microsoft

EN

Loggerprotokoll

Logger protocol

Log-Nr. 00000049

Log No.

Gerät

Instrument

Elektrisches Druckmessgerät

Electrical gauge

Typ CPG1500

Model

Seriennummer S000001

Serial number

Temperatur loggen ☒

Log temperature

Anzeigebereich (0 ... 100) bar g

Scale range

Genauigkeit 0,1 % FS

Accuracy

Kommunikation Wireless (00:13:43:19:D0:88)

Communication

Messbedingungen

Measurement conditions

Einstellungen

Setup

Modus Automatisch

Mode Automatic

Intervall (ms) 20

Interval (ms)

Dauer (hh:mm:ss) 00:00:12

Duration (hh:mm:ss)

Startzeit (hh:mm:ss) 16:43:09

Start time (hh:mm:ss)

®

Excel®.

5.2 Entry of the logger data

5.2.1 General data

Information on the measuring instruments with which the logging will be made. It can read up to three instruments

simultaneously. The table dynamically adapts to the selected instrument types. Thus, for example, with pressure transmitters,

an additional line is displayed for the output signal (e.g. 4 ... 20 mA).

24 WIKA instruction manual WIKA-Cal

Seite 1 / 2

Page

14097663.03 05/2017 EN/DE

Page 25

5. Log-Template logger protocol

Loggerprotokoll

Logger protocol

Log-Nr. 00000049

Log No.

Gerät

Instrument

Messbedingungen

Measurement conditions

Elektrisches Druckmessgerät

Electrical gauge

Typ CPG1500

Model

Seriennummer S000001

Serial number

Temperatur loggen ☒

Log temperature

Anzeigebereich (0 ... 100) bar g

Scale range

Genauigkeit 0,1 % FS

Accuracy

Kommunikation Wireless (00:13:43:19:D0:88)

Communication

Einstellungen

Setup

Modus Automatisch

Mode Automatic

Intervall (ms) 20

Interval (ms)

Dauer (hh:mm:ss) 00:00:12

Duration (hh:mm:ss)

Startzeit (hh:mm:ss) 16:43:09

Start time (hh:mm:ss)

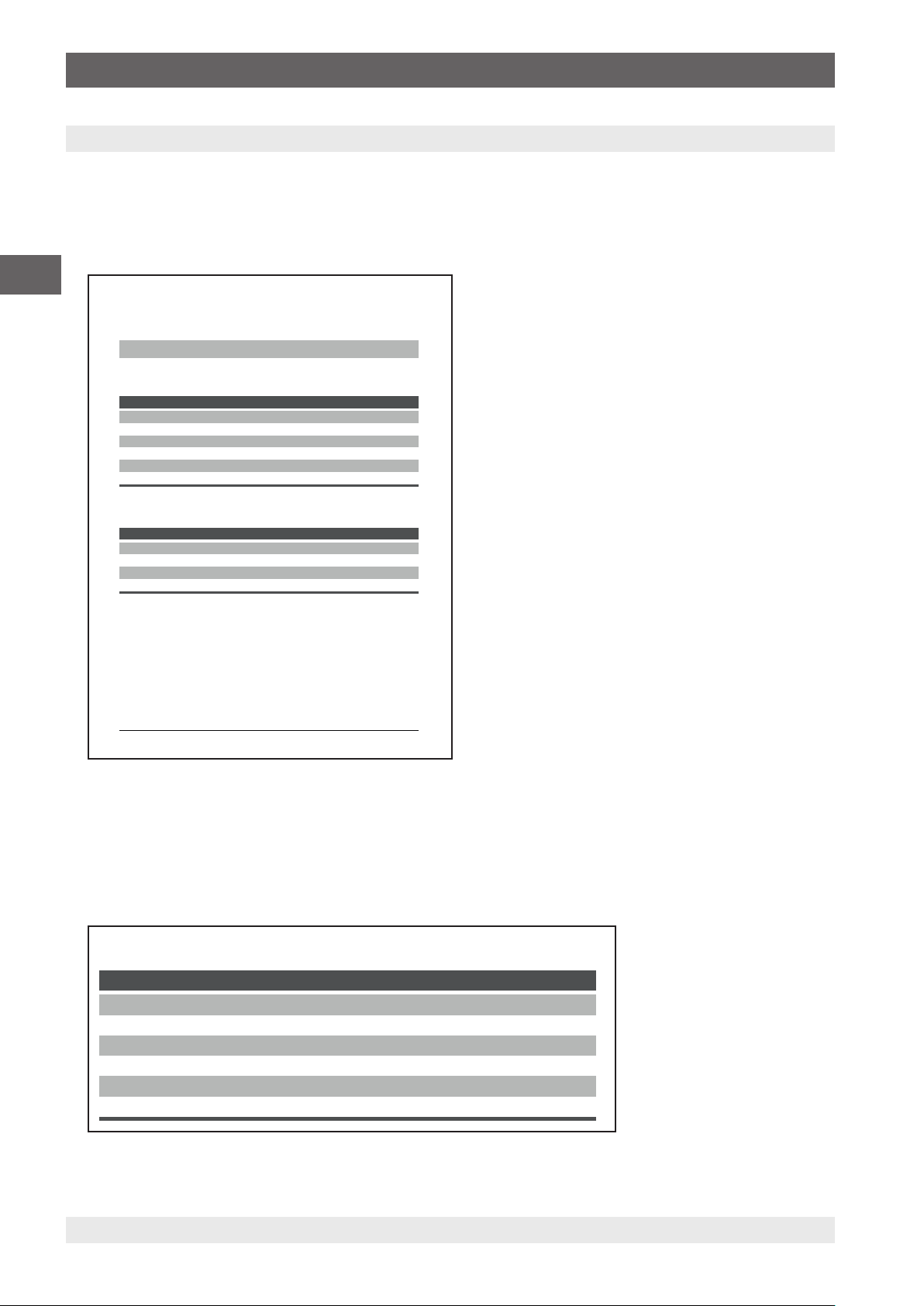

5.2.2 Measurement conditions

Information on the time-related conditions for the logger sequence.

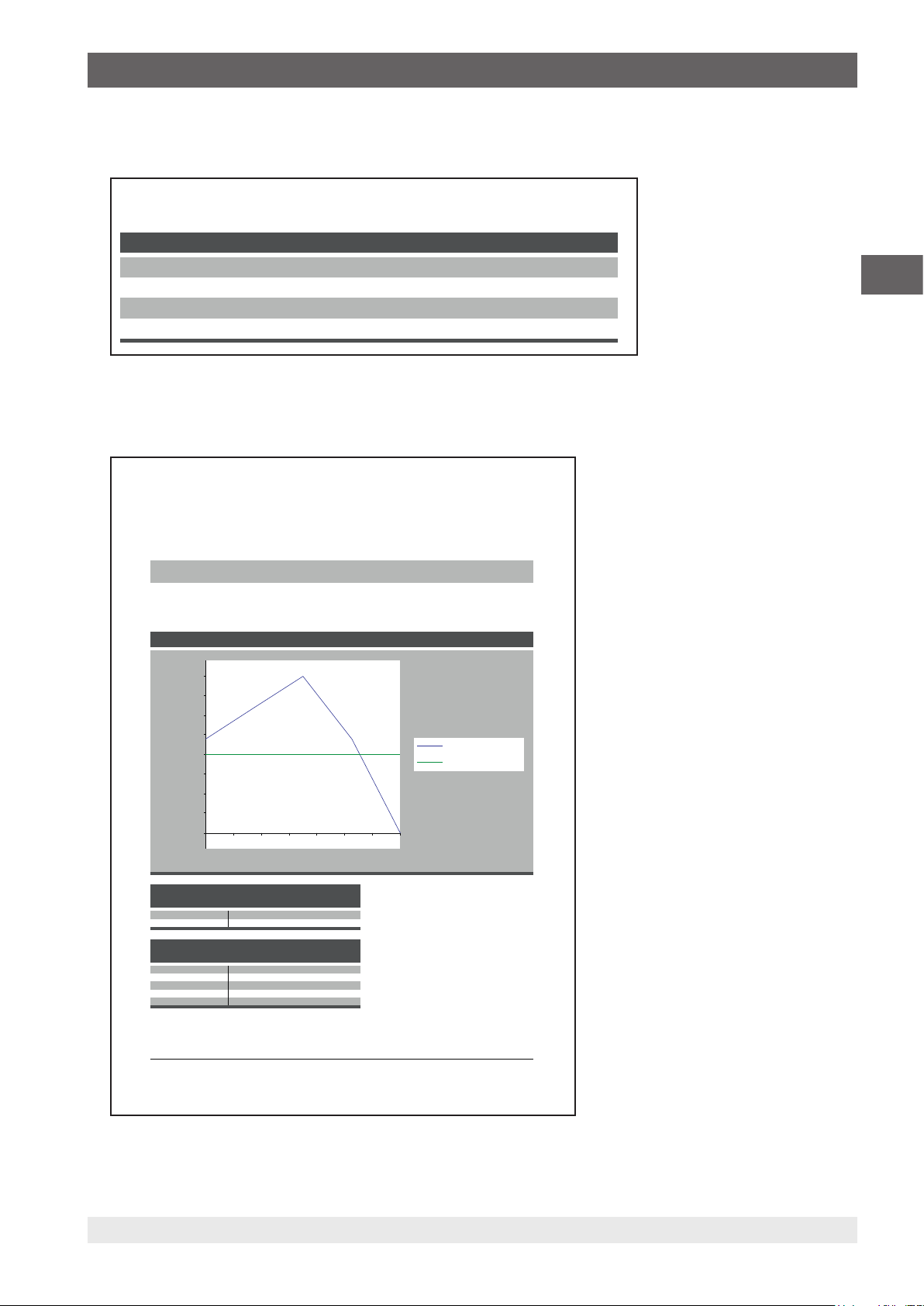

5.2.3 Measurement results

Graph and table of the measured values which were recorded over the time under the specified measuring conditions.

Loggerprotokoll

Logger protocol

EN

Messergebnisse

Measurement results

100

88

75

63

50

Value in %

Wert in %

38

25

13

0

16:43:09.880 16:43:09.903 16:43:09.926 16:43:09.949

Wert in Grafik Gemessener Wert Gemessener Wert

Value in graph Measured value Measured value

% bar °C

0 -0,0136 19,5

100 -0,0131 23,9

Zeitstempel Gemessener Wert Gemessener Wert

Timestamp Measured value Measured value

14.12.2016 16:43:09.880 -0,0133 21,7

14.12.2016 16:43:09.900 -0,0132 21,7

14.12.2016 16:43:09.920 -0,0131 21,7

14.12.2016 16:43:09.940 -0,0133 21,7

14.12.2016 16:43:09.960 -0,0136 21,7

bar °C

Log-Nr. 00000049

Log No.

Grafische Darstellung des Verlaufs

Graphical representation of progression

Druck

Pressure

Temperatur

Temperature

Zeit

Time

Seite 2 / 2

Page

14097663.03 05/2017 EN/DE

25WIKA instruction manual WIKA-Cal

Page 26

5. Log-Template logger protocol

5.3 New log

EN

With the [New log] button, a new logger protocol is started in the document view and created in the database. When a

protocol has been completed, a green check mark will be displayed next to the data set. A double click on a finished logger

protocol opens the PDF file, while, for others, the document view will be opened with the latest status.

26 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 27

5. Log-Template logger protocol

5.4 Relog

EN

The [Relog] button starts a new logger protocol in the document view and creates it in the database. The button is only

available if a completed protocol has been marked in advance. All data in the marked protocol will be transferred to the new

logger protocol and the logging can begin immediately.

14097663.03 05/2017 EN/DE

27WIKA instruction manual WIKA-Cal

Page 28

5. Log-Template logger protocol

5.5 Download

EN

With the [Download] button, data can be downloaded from a defined reference instrument.

This option is only available for hand-held products supporting download to WIKA-Cal.

Pressing the [Download] button opens the “Log download” dialogue. Then select the reference instrument created in the

object manager. The associated communication is stored in the respective work station object. Select the data set first, then

press [Download].

With the portable process calibrator model CPH7000, it is not necessary to press “Download” again after

selecting the data set, as the raw data will be displayed directly.

On the hand-held instrument, the data is displayed under “Data set”. Pressing [Create log] will create a new logger protocol

in the database. This is, for the time being, still editable, so not provided with a green check mark.

14097663.03 05/2017 EN/DE

28 WIKA instruction manual WIKA-Cal

Page 29

5. Log-Template logger protocol

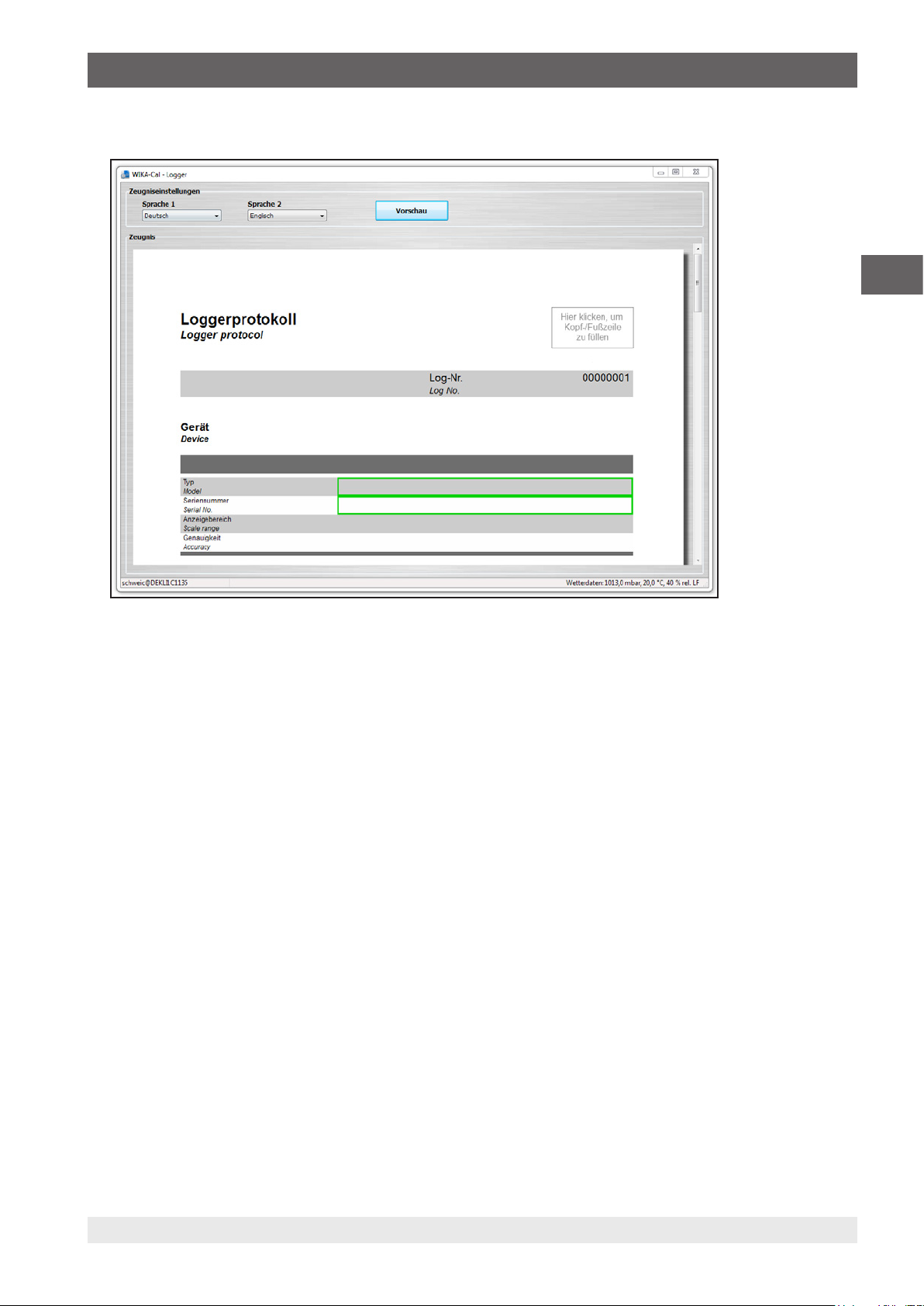

5.6 Log and finish protocol

EN

The green border indicates the order of entry. Other possible entries can also be selected. So, for example, by clicking on the

logo in the upper right, a different laboratory can be selected, for which a different logo is assigned from the database.

14097663.03 05/2017 EN/DE

29WIKA instruction manual WIKA-Cal

Page 30

6. Object manager

6. Object manager

The object manager is accessed via “Menu bar / Setup / Object manager”. It opens the database explorer. Here, all

important settings for the current calibration are entered and stored. The respective settings are explained in detail in the

following chapters.

The settings are either created, added or deleted (see chapter 6.1 “Add, save and delete”).

EN

6.1 Add, save and delete

Add

This button adds the displayed data set as a new data set. Usually, changes are made to an existing data set and stored under

a new data set using the [Add] button. In some tables, names can not be assigned twice. This prevents there being duplicate

data records.

Save

The displayed data set can be amended and, after pressing [Save], this change is written into the displayed data record and

saved.

Delete

Deletes the selected data set from the database. This can only be deleted when all references have already been deleted from

other tables. For example, a pressure balance can only be removed from the database if the associated piston and mass sets

have been removed or the reference has been changed.

14097663.03 05/2017 EN/DE

30 WIKA instruction manual WIKA-Cal

Page 31

6. Object manager

6.2 Structure

Database explorer (Object manager)

Objects

Calibration items (pressure)

Place

Customers

Laboratory data

Examiners

Shunts

Templates

Cal

Log

Weather data

Place

Instrument type

Accuracy

Communication

Units (pressure)

Output signal pressure transmitters

Remark

Media

Work station

Standards (pressure)

Instrument type

Piston

Units (pressure)

Output signal pressure transmitters

Baud rates

Media

Multimeter

Instrument type

Baud rates

Instrument type

Accuracy

Communication type

Standards

Measurement series

Measuring points

EN

Accuracy

Communication type

Mass set

Masses

Accuracy

Communication type

14097663.03 05/2017 EN/DE

31WIKA instruction manual WIKA-Cal

Page 32

6. Object manager

6.3 Objects

6.3.1 Work station

EN

The work station is the computer on which the work is carried out and is assigned to a specific place. Thus, for example,

several work stations can be assigned to a single place.

A work station can be connected to a CPU6000-W and thus supplies all the weather data for the place. All further work stations

belonging to this place automatically have the correct weather data.

The standards are also allocated to the work stations. Thus the program will be able to pre-select the standard assigned to a

test item.

The standards are displayed in the work station and the settings for communication can be carried out.

Please note when communicating via various interfaces:

■

Communication via RS-232 interface (also USB)

Make sure to select the right COM port and the corresponding baud rate. This must match the settings in the respective

instrument.

■

Communication via IEEE-488-GPIB bus

When the IEEE-488 GPIB bus is used, the address set on the instrument must be entered.

■

Communication via Ethernet

Select TCP/IP and enter the address set on the instrument and the port into WIKA-Cal.

Pressing the [Test] button will send a pressure query to the instrument. If the settings are correct, the subsequent dialogue

should display the current pressure value.

The communication must correspond to the selected communication type for the respective instrument type. For more

information on this, see chapter 6.3.7 “Instrument types”.

The COM port for the calibration items will be identified automatically. The baud rate used for measurements is set under

“Baud rate calibration item”.

If a mass ↔ pressure calculation is carried out for pressure balances with WIKA-Cal, the values will be corrected. The

specification of the height difference to the test item corrects the calculated pressure value by the entered height difference.

The accuracy of the measured height difference is entered into the measurement uncertainty calculation.

The residual pressure is also required for correction of values on pressure balances, but only for absolute pressure gauges.

The accuracy with which this is measured is added to the measurement uncertainty.

32 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 33

6. Object manager

6.3.2 Output signals pressure transmitter

Definition of all selectable output signals as soon as a pressure transmitter is selected for the calibration. The multimeter is

configured depending on whether it is a voltage or a current signal. A shunt might be required.

EN

6.3.3 Baud rate

Definition of all selectable baud rates.

Baud rates can be selected in the work station object (see chapter 6.3.1 “Work station”).

14097663.03 05/2017 EN/DE

33WIKA instruction manual WIKA-Cal

Page 34

6. Object manager

6.3.4 Comments

EN

Under “Comments”, there are various languages available for generating the certificates. The languages available for

selection are German, English, Spanish, French, Italian, Japanese, Polish, Russian, Greek, Romanian, Swedish and Dutch

6.3.5 Units (pressure)

All units shown with the respective conversion factors relate to “1 bar”.

Example:

1 atm x Conversion factor to 1 bar (1.01325) = 1.01325 bar

34 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 35

6. Object manager

6.3.6 Accuracies

This is where the accuracy options need to be specified in advance. Each instrument type can have the defined accuracies

assigned to it.

EN

6.3.7 Instrument types

When a new, unknown instrument type should be calibrated, it can be generated beforehand. For this instrument, information

such as name, measurand, manufacturer, type of instrument and possible accuracies are defined and stored with [Add].

Instrument type

■

An electrical pressure measuring instrument is selected if the instrument is provided with a digital interface.

■

A pressure transmitter is used for electrical instruments that need to be read using a multimeter.

Instrument types can be created for standards, calibration items, multimeters and even shunts. There can, for example, be two

standards on the instrument type “CPC8000”. The different CPC8000 standards can thus have only predefined accuracies.

This has the advantage that when you create the calibration certificate, only the predefined accuracies for that model can be

selected. If only one accuracy has been defined, this will be used automatically.

14097663.03 05/2017 EN/DE

35WIKA instruction manual WIKA-Cal

Page 36

6. Object manager

6.3.8 Manufacturer

EN

Here, the manufacturer with their address is added or edited. The information is simply stored in the database, and is not

displayed in the document view.

Representation of manufacturer details can be set in the “Object manager” under “Templates / Cal”. See chapter

6.4.1 “Cal”. This setting is possible as of version v1.0.65.

6.3.9 Calibration items (pressure)

Calibration items are automatically created when a certificate is created. If a calibration item arrives for recalibration, it is

automatically detected after entering the serial number and the certificate is filled out in advance. The content corresponds to

that of the last certificate.

36 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 37

6. Object manager

6.3.10 Piston

EN

Pistons can be assigned to a standard, which correspond to a model with the type of instrument “Dead weight tester”. If the

piston of the pressure balance is assigned, it can be selected for the calibration, or is automatically pre-selected.

Mass (kg) Weight of the piston

Density (kg/m³) Density of the piston

Effective area (m²) Effective area of the piston

TC alpha + beta (1/K) The temperature coefficient consists of the sum of the alpha and beta of the piston

Distortion coeff. (1/bar) Distortion coefficient of the piston

Circumference (m) Calculated circumference of the piston

MRS Start of measuring range

MRE End value of measuring range

14097663.03 05/2017 EN/DE

37WIKA instruction manual WIKA-Cal

Page 38

6. Object manager

Unit Pressure unit of the measuring range

Resolution Resolution of the calculated value, e.g. 0.0001

Class Selection of the class/accuracy

Class abs Selection of the class for the absolute pressure range

Medium Selection of the pressure transmission medium

Vacuum piston The piston can also act as a vacuum piston via an equaliser bar. This lowers the pressure, with

EN

Surface tension is already

considered in mass

Coeff. V (Budenberg) Volume coefficient, specific for Budenberg pressure balances

Coeff. C (Budenberg) Additional design value correction value, specific for Budenberg pressure balances

Floating position If a CPU6000-S is present at the work station, you can use the [Read position] button to read

6.3.11 Communication

the calculation of the pressure value, when placing the masses.

The additional weight, acting as a result of the surface tension of the medium, which acts on the

piston can also be provided directly in the piston weight. The weight via the surface tension is

ignored when setting the option, and must be included in the piston weight.

the current floating position of the masses by means of the distance sensor and save the value.

To select a communication type under instrument types, it must first be created under “Communication”. For this, the name

for the communication type to be selected is simply entered and the predefined communication class selected. For some

instruments, the channel information is also important here. If the mouse cursor is held over the channel for a while, it launches

a tooltip with the available channels and their meaning, individually for each instrument.

38 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 39

6. Object manager

6.3.12 Customers

EN

In the general section of a certificate, a customer can be specified. Usually the full address is also given here.

6.3.13 Laboratory data

In a calibration certificate, the company logo is inserted in the top right and the company contact information in the footer.

When selecting the laboratory (e.g. click on company logo), you can select the desired one via the already created

laboratories.

If a new certificate is created, initially the standard selected laboratory is selected in the document view of the calibration

certificate.

14097663.03 05/2017 EN/DE

39WIKA instruction manual WIKA-Cal

Page 40

6. Object manager

6.3.14 Masses

EN

Masses are generally stated as “Overhang”, “Mass” and “Topmass”. These masses are assigned to a mass set and this, in

turn, to one or more pistons.

Overhang e.g. overhangs (bell jars) or plates, “mass” weights can be placed only on these.

Mass e.g. mass loads with a bore (recess); these masses can only be placed if an “Overhang” has been placed

first.

Topmass e.g. mass loads without a bore (recess); these masses can always be placed. Either directly on a piston, on

an “Overhang” or on a “Mass”.

6.3.15 Mass sets

A mass set consists of several masses. The mass set can be assigned to several pistons. One piston can only have one mass

set assigned to it.

40 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 41

6. Object manager

6.3.16 Media

The pressure transmission medium in the pressure balance is specified in the “Media” field. It can be created in advance or

selected from the list.

The selection list and required additional information is maintained in the medium object.

EN

The pressure transmission medium can be entered in German, English, Spanish, French, Italian, Japanese, Polish, Russian,

Greek, Romanian, Swedish and Dutch.

6.3.17 Multimeter

For the multimeter to be tested, different accuracies and resolutions can be set for the voltage and current ranges.

The electrical module of a CPH6000 or CPH7000 will also be defined as a multimeter in the database.

If a multimeter is not assigned to any work station, this multimeter can be used at any work station. This is recommended if the

multimeter is to be used in different work stations.

If you tick the “Use of shunts” option, a voltage measurement with a shunt will be performed instead of a current

measurement.

14097663.03 05/2017 EN/DE

41WIKA instruction manual WIKA-Cal

Page 42

6. Object manager

6.3.18 Multiplexer (optional)

Multicalibration is available as an optional (with costs) feature (since January 2017). This feature gives the user the option to

calibrate several instruments of the same model in parallel. Currently, the multicalibration option is not available for mechanical

pressure gauges.

EN

Instrument type, measuring range and accuracy must be the same for the calibration items involved. For pressure transmitters

it is possible to use either several multimeters (such as WIKA CPU6000-M, for example) or a multiplexer to which all

multimeters are connected. Agilent 34970A and Netscanner 9816 are supported as multiplexers.

A multiplexer is indispensable for assigning the calibration item to its corresponding multimeter.

6.3.19 Standards (pressure)

All reference instruments used in the software are listed under “Standards (pressure)”.

42 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 43

6. Object manager

Depending on the instrument type, there are different entries to choose from.

If a standard is not assigned to a work station, this standard can be used at any work station. This is recommended if the

standard is to be used in different work stations. Each standard has its own settings which depend on the selected instrument

type.

EN

Range stability (%FS) This is the pressure range within which the reference pressure value needs to be stable while

approaching the nominal value (e.g. with pressure controllers). The value needs to be stable for

the time specified under “Stability time (s)” until the calibration item's value is read and the

next pressure value can be approached.

Stability time (s) This is the time during which a reference maintains the pressure value until the calibration item's

value is read and the next pressure value is approached.

Piston stability (mm) This is the range within which the floating position needs to be stable for the time specified

under “Stability time (s)” until the calibration item's value is read and the next pressure value can

be approached.

6.3.20 Place

Once a place has been defined, a work station can be assigned to that place. All work stations assigned to a place benefit

from the ambient conditions and the variables for the accuracy. In addition, the local gravity is recorded with accuracy.

If a laboratory has different premises, these premises should be defined as different “Places”. In these places, different

ambient conditions or the local gravity for the individual work stations can be added.

14097663.03 05/2017 EN/DE

43WIKA instruction manual WIKA-Cal

Page 44

6. Object manager

The place information can be entered in German, English, Spanish, French, Italian, Japanese, Polish, Russian, Greek,

Romanian, Swedish and Dutch.

6.3.21 Examiner

EN

The laboratory staff must be created as examiner in the database. The software recognises the respective examiner from the

computer login and displays it in the document view. The selection of the examiner is not needed as long as the user has an

own Windows login (user account).

If “Admin rights for database access” is enabled, only users with these permissions will have access to the object manager

and all other users will be locked out. If no user has enabled “Admin rights for database access”, all users will have access

to the object manager.

The status specifies where the users are selectable in the document view. Some roles like “Head” and “Assistant head”, for

example, can only be selected from particular places in the document view. “Employee”, “Assistant head” and “Head” can

always be selected as users.

From version 1.0.65 on, it is possible to assign a password to a tester to provide administrators with access to the object

manager independently of the logging on to Windows.

Once assigned for the first time, passwords can be reset by means of the [Reset password] button then displayed.

44 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 45

6. Object manager

6.3.22 Shunts

EN

Shunts (measuring resistors) are not assigned to any instruments or work stations and are thus available for each work station.

In the document view, they are only available for selection if a multimeter has been selected (see chapter ) and if the “Use of

shunts” option has been enabled.

Shunts continue to have, as multimeters and standards used, an additional influence on the measurement uncertainty.

6.4 Templates

6.4.1 Cal

Under “Templates-Cal”, the properties of the calibration template can be set.

These include:

■

Number of measurement series

■

Number of measuring points

14097663.03 05/2017 EN/DE

45WIKA instruction manual WIKA-Cal

Page 46

6. Object manager

■

Standards applied (The different standards can be defined for specific instrument types.)

■

Display of measurement uncertainty

■

Preloads

- Quantity

- Exposure time

- Pause time

■

Time durations during calibration

EN

- Interval between the measurement series

- Duration of final value loads for tube pressure gauges or other instruments

- Steady time

■

Deviation evaluation in percentage or absolute values

■

Display of the manufacturer

■

Display of the statement of conformity

For the calibration certificate template, the “Automatic preset of the certificate number” can be deactivated (default

setting: Automatic incrementing is activated). After deactivating this setting, the number of the calibration certificate is no

longer incremented automatically and can be set in a dialogue before starting calibration.

It is also possible to enter a preceding abbreviation for all calibration certificates.

6.4.2 Log

For the logger protocol template, the “Automatic preset of the certificate number” can be deactivated (default setting:

Automatic incrementing is activated). After deactivating this setting, the number of the logger protocol is no longer incremented

automatically and can be set in a dialogue before starting logging.

It is also possible to enter a preceding abbreviation for all logger protocols.

Under “Default view” you can select “Diagram and/or table”.

The “Display x-axis” defines the x-axis as a “continuous time” or “absolute time stamp”.

46 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 47

6. Object manager

6.5 Weather data

EN

Under “Weather data”, the place-dependent weather data is stored. These are either entered manually by a user via the

designated work station or automatically read from a work station via a CPU6000-W.

Every 10 seconds, WIKA-Cal loads a new value from the CPU6000-W and displays it under “current”.

The current value is stored under “Archive” every 2 minutes.

The weather data includes information on the calibration place, current prevailing atmospheric pressure, ambient temperature

and relative humidity in %.

14097663.03 05/2017 EN/DE

47WIKA instruction manual WIKA-Cal

Page 48

7. Setting up calibration instruments

7. Setting up calibration instruments

7.1 Loading necessary drivers

Before setting up the desired calibration instrument, the necessary drivers need to be installed.

1. Connect the calibration instrument to the PC/laptop using the USB cable supplied.

2. Download the driver directly from the local website and install.

EN

CPH6000

http://en-co.wika.de/cph6000_en_co.WIKA

→ Software → Interface driver

CPH6200

http://en-co.wika.de/cph6200_en_co.WIKA

Depending on the USB cable adapter, different drivers must be used

→ Software → Interface driver (if the USB-RS-232 adapter board is integrated into the cable)

→ Software → Windows driver for USB6200-V2 (if the USB-RS-232 adapter board is integrated into the USB connector)

CPH6300

http://en-co.wika.de/cph6300_en_co.WIKA

→ Software → Interface driver

CPH6400

http://en-co.wika.de/cph6400_en_co.WIKA

→ Software → Interface driver

CPC3000, CPC4000, CPC6000, CPC6050, CPC8000, CPC8000-H

http://en-co.wika.de/upload/SO_USB_Driver_en_um_34833.zip

→ Software → Interface driver

CPC2000

http://www.ftdichip.com/Drivers/VCP.htm

→ Windows VCP driver, 32 bit or 64 bit

CPU6000-W, CPU6000-S or CPU6000-M

http://en-co.wika.de/cpu6000_w_cpu6000_s_cpu6000_m_en_co.WIKA

→ Software → Interface driver

The driver has been correctly installed if a COM port appears under “Connections” in Windows Device

Manager when you switch the calibration instrument on or off.

Any settings required for communication are made in the “Object manager” under “Objects / Work station”.

Setup of the individual calibration instruments is described in the following chapters.

48 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 49

7. Setting up calibration instruments

7.2 Setting up the CPH6x00 models

1. Configure the CPH6x00 individually so that the output is configured accordingly to USB or RS-232.

If the CPH6x00 has a multimeter function for reading current or voltage, it must be defined as a multimeter under

“Objects / Multimeter” (see chapter 6.3.17 “Multimeter”).

2. Create a standard and assign it to the work station (see chapter 6.3.19 “Standards (pressure)”).

3. In the “Object manager” under “Objects / Work station”, select, under “COM port”, the new COM port of the created

CPH6x00 (also multimeter if available).

4. Set baud rate 9600.

5. Use the [Test] button to test communication.

Communication works properly if the pressure value displayed on the instrument appears after pressing the test button.

⇒

6. Save the data set with [Save].

The settings are applied.

⇒

EN

Use the [Config] button to open a dialogue for configuring the instrument.

For each CPH6x00 there is an individual dialogue which enables various settings on the instrument.

7.3 Setting up the CPCx000 models

Configure the CPCx000 individually so that the instruction set from Mensor is configured. If one is dealing with a

CPC8000-1 (first generation), then the SCPI instruction set must be selected.

1. Create a CPCx000 standard in the “Object manager” under “Objects / Standards (pressure)” and assign it to the work

station (see chapter 6.3.19 “Standards (pressure)”).

2. In the “Object manager” under “Objects / work station”, select, under “COM port”, the new COM port of the created

CPCx000.

3. Adjust the baud rate to the instrument settings (e.g. 9600 or 57600).

4. Use the [Test] button to test communication.

Communication works properly if the pressure value displayed on the instrument appears after pressing the test button.

⇒

14097663.03 05/2017 EN/DE

49WIKA instruction manual WIKA-Cal

Page 50

7. Setting up calibration instruments

5. Save the data set with [Save].

The settings are applied.

⇒

EN

7.4 Setting up the CPBx000 models

1. For each model CPBx000 dead-weight tester, there is an associated XML file which contains all data such as coefficients

and weights. You can download your XML file via a download link.

Example:

http://apps.wika.com/apps/CPB-CAL/51080CPB5000.xml

The name of the XML file is always matched to the particular dead-weight tester. The structure is basically as follows:

“Serial number” + “Model” + “.xml”

“51080” + “CPB5000” + “.xml” = 51080CPB5000.xml

2. After downloading, the file can be imported via “File / Import…”.

3. In WIKA-Cal, you can check the imported data sets in the “Object manager” under “Standards (pressure)”, “Pistons”,

“Mass sets” and “Masses”. Should a file be corrupted or incomplete, please contact your responsible contact at WIKA.

50 WIKA instruction manual WIKA-Cal

14097663.03 05/2017 EN/DE

Page 51

7. Setting up calibration instruments

7.5 Setting up the CPU6000 series

7.5.1 Setting up the CPU6000-W weather station

1. In the “Object manager” under “Objects / Work station”, select the new COM port under “COM port weather station”.

2. Save the data set with [Save].

The settings are applied.

⇒

EN

Every 10 seconds, the software requests a new value from the CPU6000-W, displays it under “Weather data / current” and

saves the current value every 2 minutes in the “Archive” under “Object manager / Weather data / Archive”. In addition, the

ambient conditions are also updated in the document view and in the bottom right in the status bar.

14097663.03 05/2017 EN/DE

51WIKA instruction manual WIKA-Cal

Page 52

7. Setting up calibration instruments

7.5.2 Setting up the CPU6000-S pressure balance sensor box

1. Create the pressure balance and assign it to the work station (see chapter 6.3.19 “Standards (pressure)”).