Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Calibration system for SF6 gas density measuring

instruments model BCS10

Kalibriersystem für SF6-Gasdichtemessgeräte

Typ BCS10

Système d'étalonnage pour instruments de

mesure de la densité de gaz SF

type BCS10

6

Sistema de calibración para instrumentos de

medición de densidad del gas SF

modelo BCS10

6

GB

D

F

E

Calibration system for SF6 gas density measuring instruments

model BCS10

Page 2

GB

Operating instructions model BCS10 Page 3 - 27

D

Betriebsanleitung Typ BCS10 Seite

F

Mode d‘emploi type BCS10 Page

E

Manual de instrucciones modelo BCS10 Página

© 2012 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

28 - 54

55 - 80

81 - 106

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions calibration system, model BCS10

14051046.01 10/2012 GB/D/F/E

Page 3

Contents

Contents

1. General information 4

2. Safety 5

3. Specications 9

4. Design and function 11

5. Transport, packaging and storage 13

6. Commissioning, operation 14

7. Maintenance and cleaning 25

8. Faults 25

9. Dismounting, return and disposal 26

GB

10. Accessories 27

Appendix 1: EC Declaration of conformity model BCS10 28

Declarations of conformity can be found online at www.wika.com.

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

3

Page 4

1. General information

1. General information

■

The pressure transmitter described in the calibration instructions has been designed

and manufactured using state-of-the-art technology. All components are subject

GB

to stringent quality and environmental criteria during production. Our management

systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument. Working safely requires that all safety instructions and work instructions are

observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions, assignment of insuciently qualied skilled personnel or unauthorised modications to the instrument.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Factory calibrations / DKD/DAkkS calibrations are carried out in accordance with

international standards.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- relevant data sheet: SP 60.08

- application consultant:

Tel.: (+49) 9372/132-8971

Fax: (+49) 9372/132-8008971

E-mail: sf6-sales@wika.de

4

WIKA operating instructions calibration system, model BCS10

14051046.01 10/2012 GB/D/F/E

Page 5

1. General information / 2. Safety

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light

injuries or damage to the equipment or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient

and trouble-free operation.

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate calibration system has been selected in terms of measuring range,

design and specic measuring conditions.

Non-observance can result in serious injury and/or damage to the equipment.

GB

Further important safety instructions can be found in the individual

chapters of these operating instructions.

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

5

Page 6

2. Safety

2.1 Intended use

The calibration system model BCS10 serves for the inspection of SF6 gas density

measuring instruments.

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

GB

The technical specications contained in these operating instructions must be

observed. Improper handling or operation of the instrument outside of its technical specications requires the instrument to be taken out of service immediately and

inspected by an authorised WIKA service engineer.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

Handle electronic precision measuring instruments with the required care (protect from

humidity, impacts, strong magnetic elds, static electricity and extreme temperatures,

do not insert any objects into the instrument or its openings). Plugs and sockets must be

protected from contamination.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to equipment.

■

The activities described in these operating instructions may only be

carried out by skilled personnel who have the qualications described

below.

■

Keep unqualied personnel away from hazardous areas.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge of country-specic regulations, current standards and directives, are capable of

carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

6

WIKA operating instructions calibration system, model BCS10

14051046.01 10/2012 GB/D/F/E

Page 7

2. Safety

2.3 Additional safety instructions for SF6 gas in switchgear

The plant operator must ensure that the handling of SF6 gas is only carried out by a

qualied company or by qualied persons which have been specially trained in accordance with IEC 61634, section 4.3.1 or IEC 60480, section 10.3.1.

Valid standards and guidelines for SF

Installation, assembly, commissioning:

■

IEC 61634 (Handling of the SF6 gas)

■

IEC 60376 (new SF6 gas, technical SF6 gas)

■

IEC 60480 (used SF6 gas)

■

CIGRE report 276, 2005 (Practial SF6 gas handling instructions)

Leaks during operation:

■

IEC 60376 (new SF6 gas, technical SF6 gas)

■

IEC 60480 (used SF6 gas)

■

CIGRE 2002 („SF6 gas in the electrical industry“)

Repair work and maintenance:

■

IEC 61634 (Use and handling of SF6 gas in high-voltage switchgear and controlgear)

■

CIGRE 1991 (handling of the SF6 gas)

■

CIGRE report 276, 2005 (Practical SF6 gas handling instructions)

■

CIGRE report 163, 2000 (Guide for SF6 gas mixtures)

gas

6

GB

is a colourless and odourless, chemically neutral, inert and not

SF

6

inammable gas which is approx. ve times heavier than air, not toxic and

not harmful to the ozone layer.

Detailed information is given in IEC 60376 and IEC 61634.

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

7

Page 8

2. Safety

2.4 Personal protective equipment

The personal protective equipment is designed to protect the skilled personnel from

hazards that could impair their safety or health during work. When carrying out the

various tasks on and with the instrument, the skilled personnel must wear personal

protective equipment.

GB

Follow the instructions, displayed in the work area, regarding personal protective equipment!

The required personal protective equipment must be provided by the operating company.

Wear safety goggles!

Protect eyes from ying particles and liquid splashes.

Wear protective gloves!

Protect hands from friction, abrasion, cuts or deep injuries and also from

contact with hot surfaces.

2.5 Special hazards

WARNING!

Residual media in the pressure measuring instrument can result in a risk

to persons, the environment and equipment.

Take sucient precautionary measures.

WARNING!

The wetted parts have been designed exclusively for SF

SF

/N2 mixtures.

6

The pressure inside the test pump can be extremely high. Ensure therefore that all connections of the calibration system are connected correctly.

8

WIKA operating instructions calibration system, model BCS10

gas and

6

14051046.01 10/2012 GB/D/F/E

Page 9

2. Safety / 3. Specications

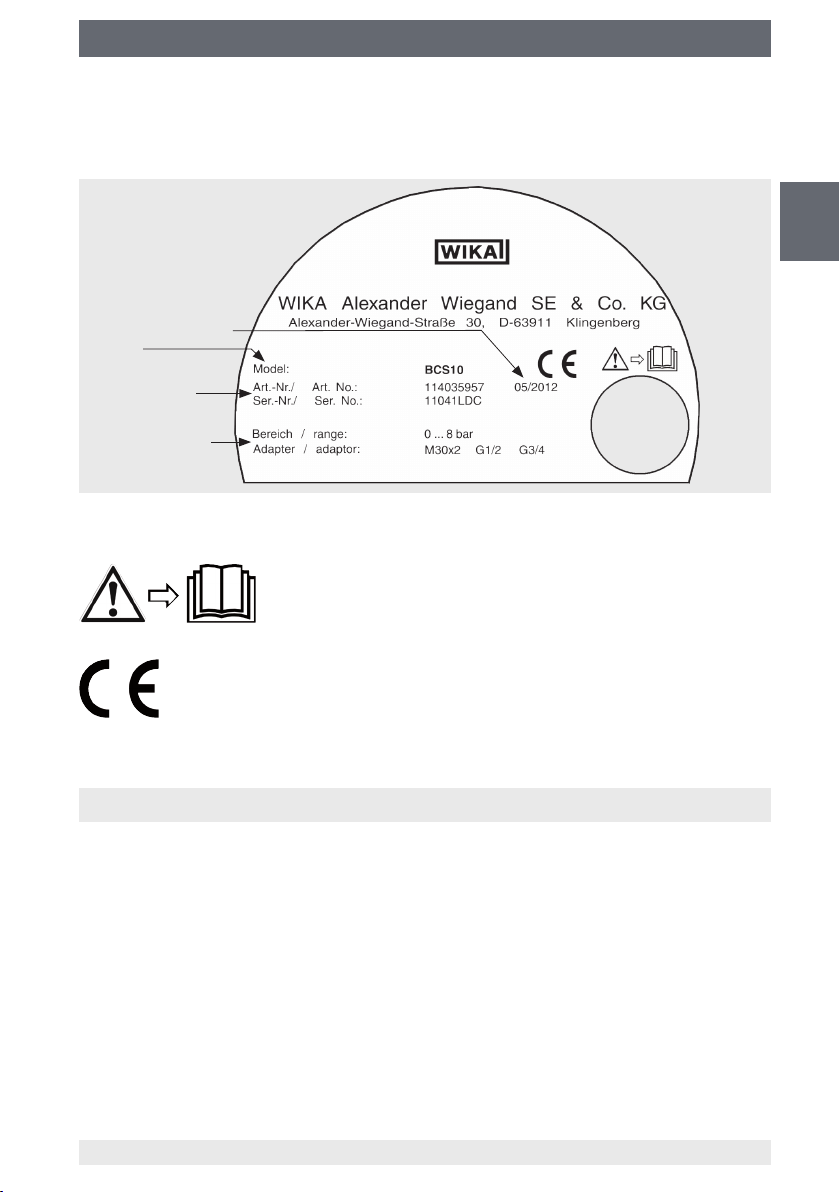

2.6 Labelling, safety marking

Product label

Date of manufacture

Model

Article number

Serial number

Measuring range

Adapter

Explanation of symbols

Before mounting and commissioning the instrument, ensure

you read the operating instructions!

GB

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European directives.

3. Specications

Measuring range

■

Measuring range: 0 ... 20 bar relative

■

Overpressure limit: 42 bar

■

Burst pressure: 140 bar

Accuracy data

■

Accuracy: 0.05 % FS

■

Compensated temperature range: 0 ... 50 °C

■

Temperature error: 0.005 % of the span/K (outside of the compen-

sated temperature range)

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

9

Page 10

3. Specications

Digital indicator

■

Type of indication: 7-segment LCD

■

Digits: 5 ½-digit

■

Resolution: 0.001

■

GB

Character size: 16.53 mm (0.65")

■

Bargraph display: 20 segment bargraph, 0 ... 100 %

■

Possible pressure units: bar, psi, kg/cm2, kPa, MPa and 15 other units

Operating conditions

■

Ingress protection: IP 65

■

Ambient temperature: -10 ... +55 °C

■

Medium temperature: 0 ... +55 °C

■

Storage temperature: -20 ... +70 °C

■

Relative humidity: < 95 % r.H. (non-condensing)

Communication

■

Interface: USB, RS-232

Functions

■

Overpressure protection: Adjustable overpressure valve

■

Pressure ne-adjustment: By means of the ne-adjustment valve

■

Measuring rate: 30/min. to 10/sec. selectable

■

Memory: MIN/MAX values

■

Data logger: Cyclic data logger: automatic recording of up to 8.500

Integrated data logger

values

10

Cycle time: selectable from 1 ... 3.600 sec. in the following

steps

1 s, 2 s, 5 s, 10 s, 30 s, 1 min, 2 min, 5 min, 10 min,

30 min and 1 h

CPGLog data-logger evaluation software is needed to

use the data logger function.

The order number of the CPGlog software is given in the

data sheet SP 60.08.

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

Page 11

3. Specications / 4. Design and function

Voltage supply

■

Power supply: 3 x 1.5 V AA alkaline batteries

■

Battery life: approx. 1.500 ... 2.000 h

■

Battery status indication: Icon in display for low battery level

Process connection

■

Test item adapter with quick-acting coupling for G ½

■

Test item adapter with quick-acting coupling for G ¾

■

Test item adapter with quick-acting coupling for M30 x 2

CE conformity

■

EMC directive: 2004/108/EC, EN 61 326-1 emission (group 1, class B)

and interference immunity (appendix A)

Plastic case

■

Dimensions in mm: 395 x 295 x 106

■

Weight: approx. 4 kg (with contents)

For further specications see WIKA data sheet SP 60.08 and the order documentation.

4. Design and function

4.1 Short description

The modular calibration system model BCS10 serves for pressure generation and

inspection of mechanical and electronic SF

means of comparative measurements at 20 °C.

The test pump can generate a pressure of 0 ... 35 bar. Individual measuring points can

be approached with highest accuracy by means of the ne-adjustment valve.

The results of the measurements can be displayed in one of the 21

customer units using the built-in digital pressure gauge.

gas density measuring instruments by

6

measuring units or in

GB

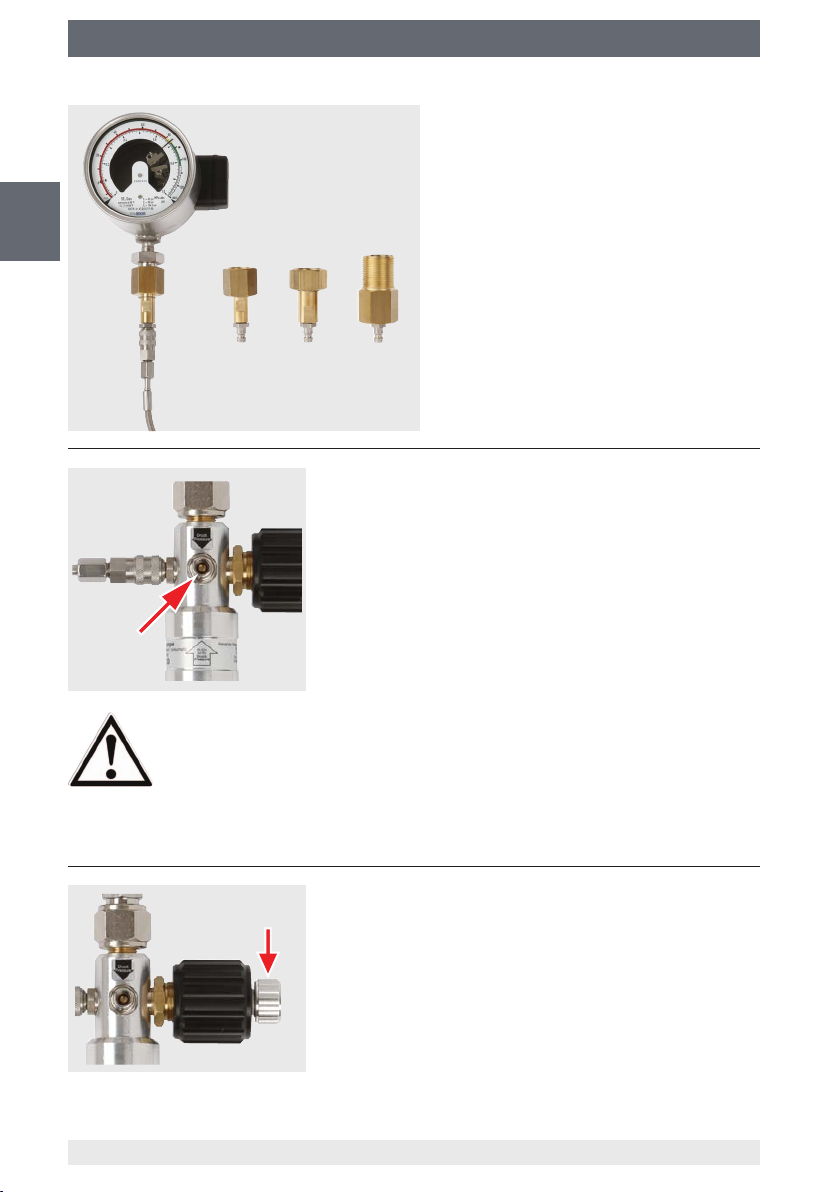

4.2 Scope of delivery

■

Precision digital pressure gauge model CPG1000 with attached pneumatic test

pump model CPP30

■

Test item adapter with quick-acting coupling for G ½

■

Test item adapter with quick-acting coupling for G ¾

■

Test item adapter with quick-acting coupling for M30 x 2

■

Adjustable overpressure valve

■

Metal flexible hose for connecting the test item, length 2 m

■

Plastic case, incl. foam insert nad operating instructions

Cross-check scope of delivery with delivery note.

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

11

Page 12

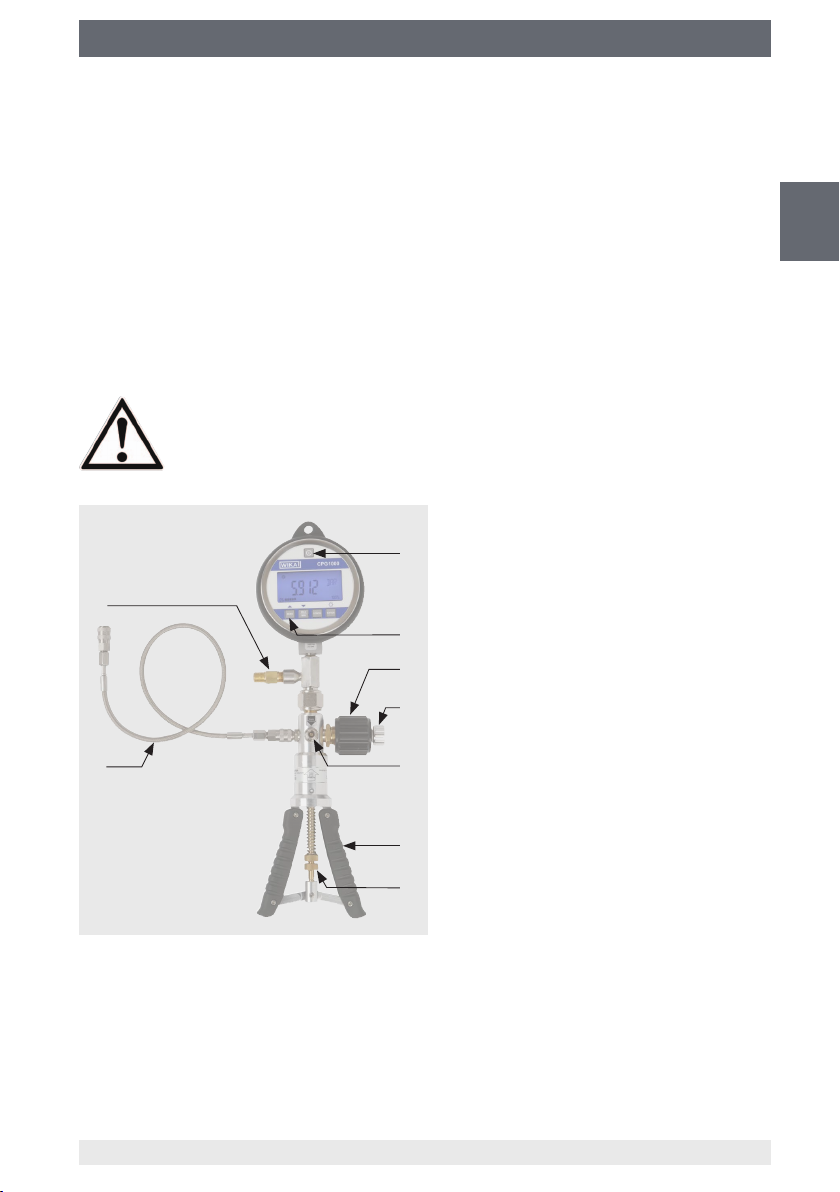

4. Design and function

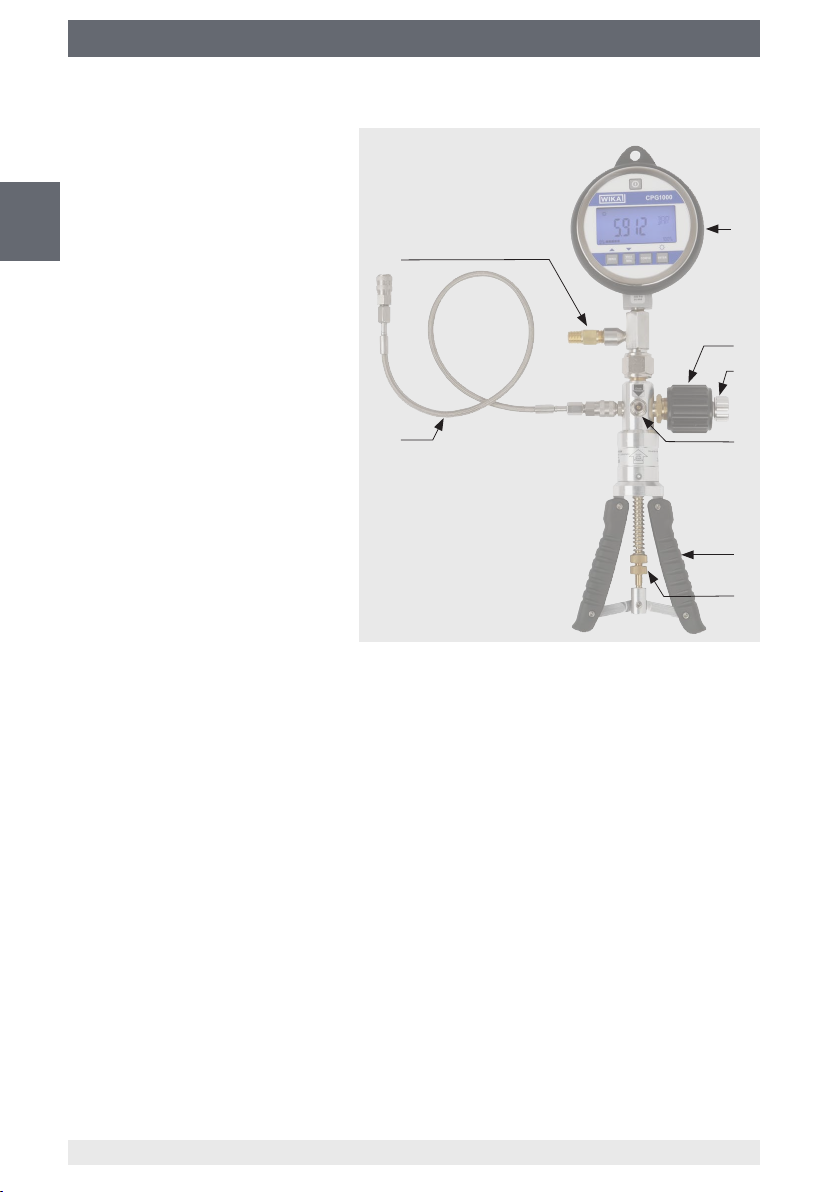

4.3 Design of the calibration system

1) Digital pressure gauge

2) Fine-adjustment valve

GB

3) Pressure relief valve

4) Switching between pressure or

vacuum generation

1

8

5) Pump handles

6) Adjustable knurled nut for

setting the pump performance

2

3

(overpressure protection)

7) Metal protection hose for

7

4

connecting the test item, with

quick-acting coupling on both

sides, length 2 m

8) Adjustable overpressure valve

5

6

4.4 Battery life time

The battery life time amounts to approx. 1.500 hours of operation (without backlighting).

In the upper left corner of the digital indicator you will nd a symbol of the battery capacity. This symbol appears when the battery voltage is too low.

For instructions on batteries see chapter 3 "Specications".

For battery replacement see chapter 6.8 "Battery replacement".

4.5 Serial interface

The digital pressure gauge has as standard a serial interface. The serial data transmission can be used for conguration, calibration and transmission of measured values of

the measuring instrument.

12

WIKA operating instructions calibration system, model BCS10

14051046.01 10/2012 GB/D/F/E

Page 13

5. Transport, packaging and storage

5. Transport, packaging and storage

5.1 Transport

Check the calibration system for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change

in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

see chapter 3 "Specications"

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Potentially explosive environments, ammable atmospheres

Store the calibration system in its original packaging in a location that fulls the conditions listed above. If the original packaging is not available, pack and store the instrument as described below:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with the shock-absorbent material, in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag containing a

desiccant inside the packaging.

GB

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

13

Page 14

6. Commissioning, operation

6. Commissioning, operation

Commissioning may only be carried out by trained and qualied personnel. The calibration system was comprehensively checked ex works for tightness.

GB

WARNING!

Only connect or disconnect test and calibration installations once the

system has been depressurised!

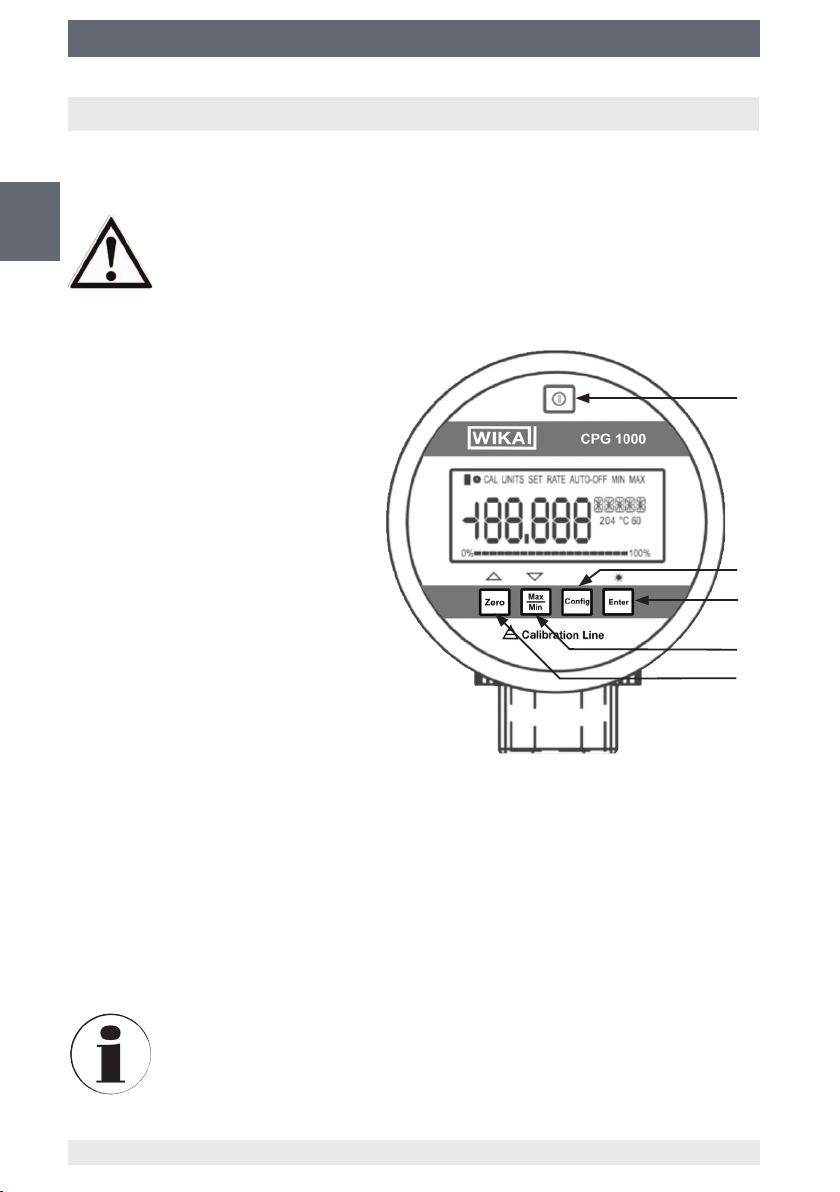

6.1 Switching on and o

To switch on the calibration system,

press the Power key (1). Press the

Power key again to switch o the

calibration system.

After switching on the version of the

rmware is indicated on the display for

approx. 1 second.

6.2 Zero point adjustment

To set the displayed value as zero

point, simply press the ZERO key (3).

The display changes immediately to the

0 value.

6.3 MIN/MAX value

The digital pressure gauge saves the

minimum and maximum pressure.

If the MAX/MIN key (4) is pressed once,

the maximum pressure from the memory is displayed. If the MAX/MIN key is pressed

again, the minimum pressure is displayed from the memory.

1

2

5

4

3

After 2 seconds, the display switches back to the operating mode. To clear the MAX/MIN

memory, press the MAX/MIN key (4) for at least 2 seconds until the message "CLr" is

displayed.

The bargraph display at the bottom of the display indicates the applied pressure relative

to the total measuring range.

Due to a possible Tare setting, the displayed pressure value can dier

from the applied pressure.

14

WIKA operating instructions calibration system, model BCS10

14051046.01 10/2012 GB/D/F/E

Page 15

6. Commissioning, operation

6.4 Backlighting

The backlighting makes it easier to read the values of the digital indicator. Press the

ENTER key (5) to turn the backlighting on and o.

6.5 Conguration

The calibration system model BCS10 functions in two dierent modes, the operating

mode and the conguration mode.

In the operating mode, the digital pressure gauge measures the pressure and shows it

on the digital indicator.

The conguration mode is used for the setting of the system.

The following setting can be modied:

■

Units

■

Automatic disconnection

■

Damping

■

Sampling rate

■

Tare function

■

Function locking

For the detailed description of the individual points see chapter 6.6 "Functions".

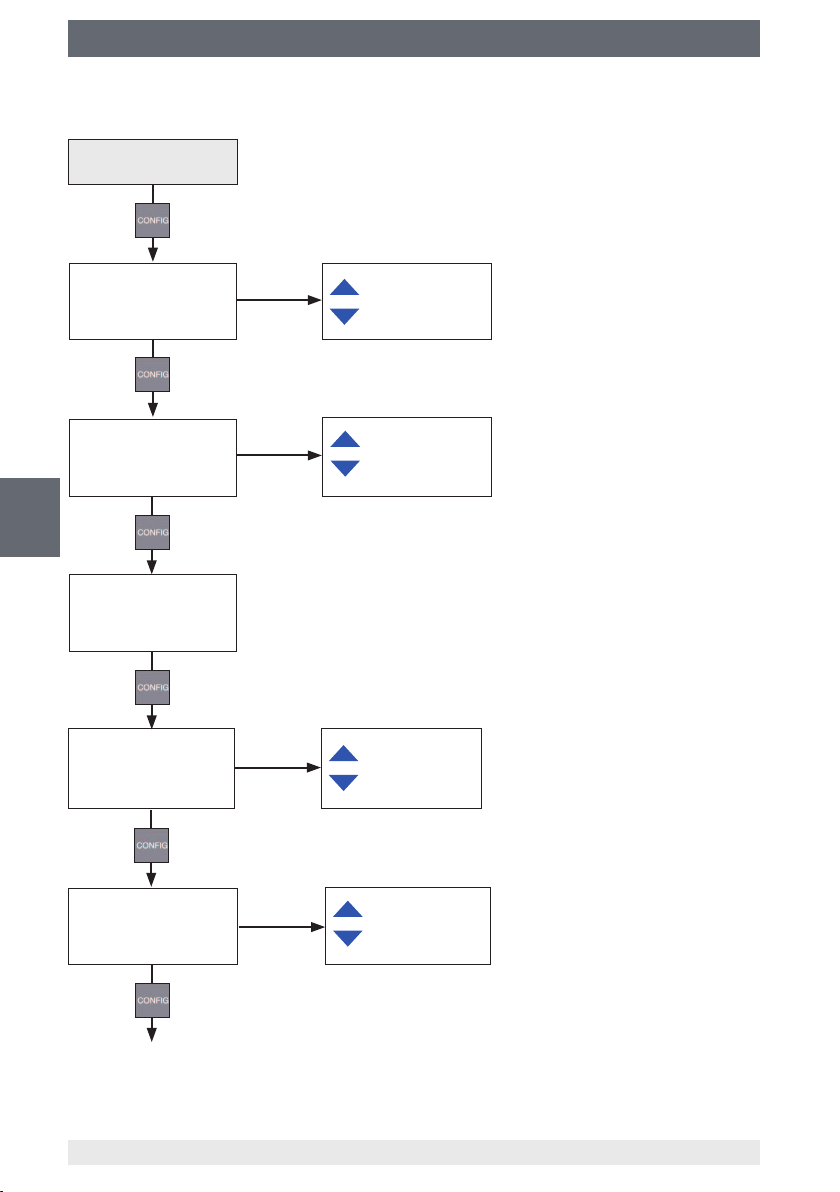

Conguration menu

To call up the conguration menu of the digital pressure gauge, press the CONFIG key

(2).

GB

The individual menu items are set via the ZERO key (3) and the MAX/MIN key (4). Hold

down the key to scroll faster.

To save all changes and exit the conguration menu, press the ENTER key (5).

You can exit the conguration menu at any time by pressing the ENTER

key. That will save all changes and the calibration system will return to the

operating mode.

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

15

Page 16

6. Commissioning, operation

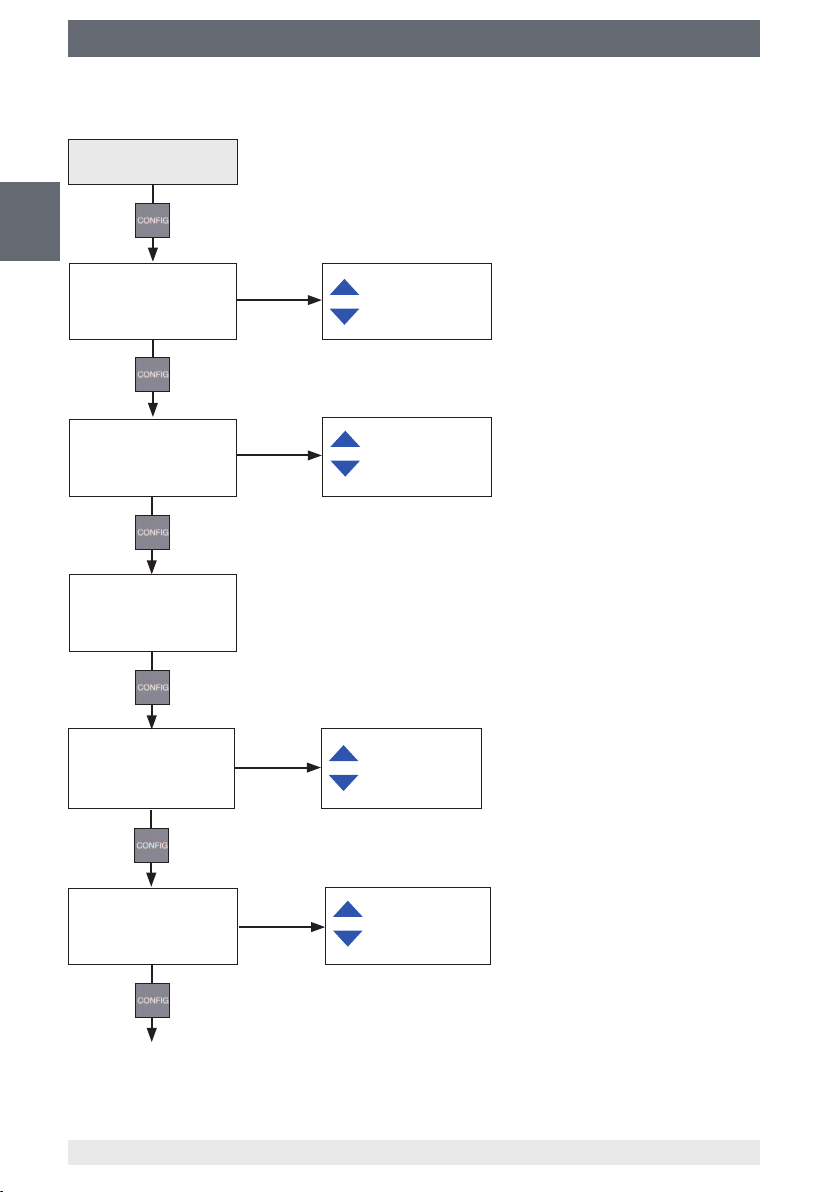

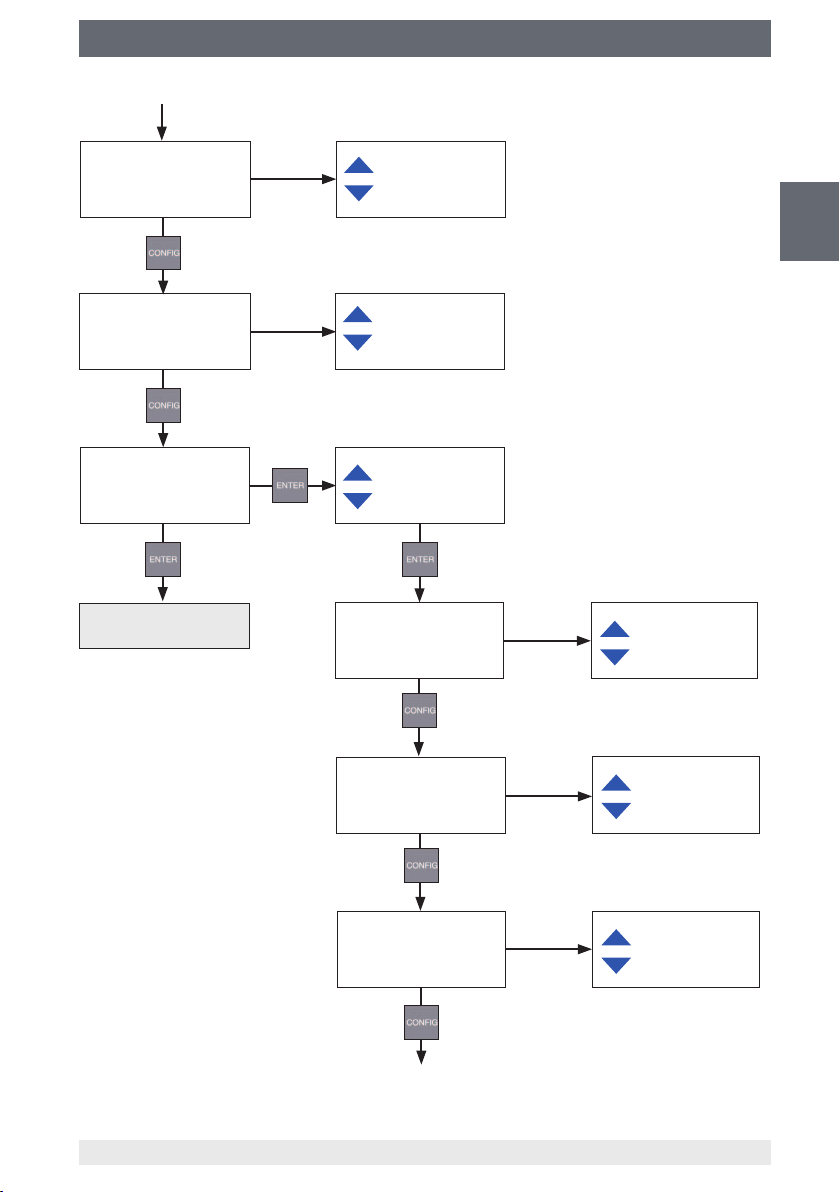

Menu navigation

Operating mode

GB

Unit selection

UNITS SET

Automatic

disconnection

SET AUTO-

Battery status

Temperature display

OFF

BAR

PSI

MPA ...

OFF

1 ... 30 min

°C

°F

Damping

SET DAMP

next page

16

ON

OFF

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

Page 17

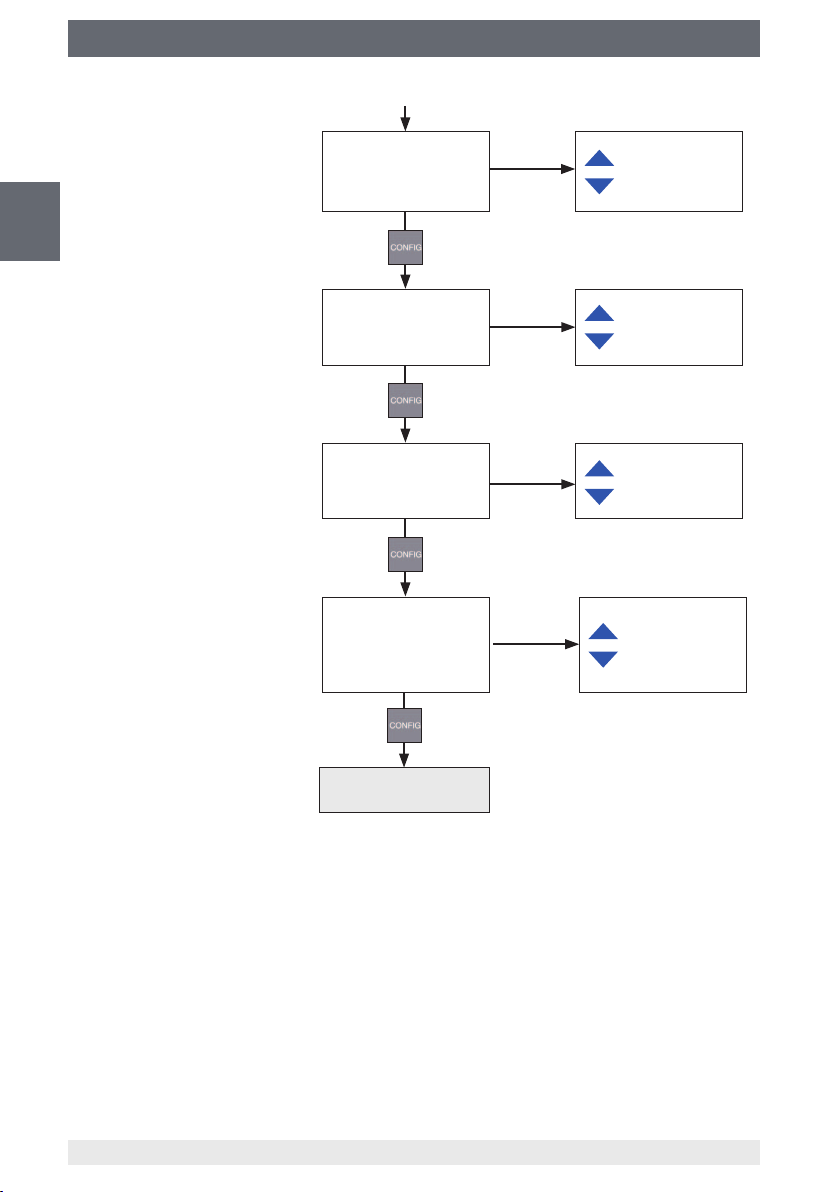

6. Commissioning, operation

Sampling rate

SET RATE

Tare function

SET TARE

Function locking

LOCK

FUnC

Operating mode

0.5/SEC

1/SEC

3/SEC

10/SEC

Values are

dependent on

the selected unit

Password

request:

enter 101

Zero point adjustment

(ZERO key)

lock/unlock

GB

The password 101 is factory-set and

cannot be changed.

UnLOC

LOC

Unit selection

lock/unlock

Automatic

disconnection

lock/unlock

next page

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

UnLOC

LOC

UnLOC

LOC

17

Page 18

6. Commissioning, operation

GB

Damping

lock/unlock

Sampling rate

lock/unlock

Tare function

lock/unlock

User-dened unit

(enter scaling)

SET FACTR

UnLOC

LOC

UnLOC

LOC

UnLOC

LOC

Setting see

chapter 6.7

18

Operating mode

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

Page 19

6. Commissioning, operation

6.6 Description of the menu items

Pressure units

The calibration system is factory set (see delivery note).

For the list of the available units see chapter 3 "Specications".

For conguration details of the user-dened units see chapter 6.7 "Conguration of the

function locking".

Automatic disconnection

The automatic disconnection can be adjusted in minute steps in the range from

1 ... 30 minutes. For continuous operation of the instrument, deactivate this menu item

with "OFF".

Battery voltage display

The current battery status is displayed as a voltage value and progress bar indication.

Temperature display

This menu item displays the temperature measured by the internal sensor. The value

can be displayed in °F or °C.

Damping

With enabled damping the measured values are smoothed by the pulsating pressure

sources.

GB

Sampling rate

Species the interval in which the pressure is measured and the display updated.

0.5 measurements per second correspond to 30 measurements per minute.

TARE (tare function)

In this menu item, a constant oset value can be set, which will be subtracted from the

measured pressure.

The TARE value depends on the selected values and can be set on the maximum scale

range.

The progress bar indication always indicates the actual pressure depending on the

entire measuring range, irrespective of the Tare setting. This is done for safety to

indicate that even if "0" is displayed that pressure is being applied to the calibration

system.

Example:

If, for example, TARE is set to 30 bar and the measured pressure is 37 bar, the measured

value displayed will be 7 bar. The pressure of 27 bar would then be displayed as -3 bar.

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

19

Page 20

6. Commissioning, operation

Function locking

The calibration system model BCS10 is delivered from the factory with unlocked access

to all settings and they can be changed.

The access to the adjustable parameters can be limited or completely prohibited to

prevent unauthorized changes of the conguration.

GB

This is achieved by the function locking.

In addition, user dened units can be scaled here.

For conguration of the function locking see chapter 6.7 "Conguration of the function

locking".

6.7 Conguration of the function locking

Scroll to the menu item "FUnC

appears the message "0PWRD". Enter the password "101". The password is factory set

and cannot be changed.

The functions that can be locked or unlocked:

- zero point adjustment (ZERO button)

- setting the units

- auto Power-O Settings

- setting of the damping

- setting of the sampling rate

- tare setting

The command LOC locks the respective function and UnLOC unlocks it again.

Locked functions are not displayed in the conguration menu any more and therefore

cannot be changed.

Setting of a user-dened unit or a user-dened measuring range:

In the menu item SET FACTOR, a multiplier between 0.001 and 100 can be set for

a user-dened measuring range. The dened factor is multiplied by the measured

pressure value in psi. The result is displayed.

Example: 40 psi correspond to 1.000 g of a product in a tank. The weight of the product

should appear on the display.

If 25 is dened as the multiplicator, the pressure of 40 psi corresponds to the value

1.000 (40 x 25). „CUST“ is displayed on the instrument as a technical unit.

LOCK

" and press the ENTER key. On the digital indicator

20

WIKA operating instructions calibration system, model BCS10

14051046.01 10/2012 GB/D/F/E

Page 21

6. Commissioning, operation

6.8 Battery replacement

1. Turn the orice plate of the digital pressure gauge approx. 90° to the right and

remove it.

2. Remove the front panel of the digital pressure gauge. This will give you access to

the battery compartment.

3. Replace the batteries. Use 1.5 V AA alkaline batteries only.

4. Close the instrument again. Ensure that the front is properly aligned.

6.9 Measurement setup and adjustment

WARNING!

Only connect or disconnect test and calibration installations once the

system has been depressurised!

1) Turn the instrument on and o

2) Perform a zero-point adjustment

1

3) Fine-adjustment valve

8

4) Pressure relief valve

2

5) Switching valve pressure/vacuum

3

4

generation

6) Pump handles

7) Adjustable knurled nut for

9

5

setting the pump performance

(overpressure protection)

GB

6

7

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

8) Adjustable overpressure valve

9) Metal exible hose for connecting

the test item, with quick-acting

coupling on both sides, length 2 m

21

Page 22

6. Commissioning, operation

GB

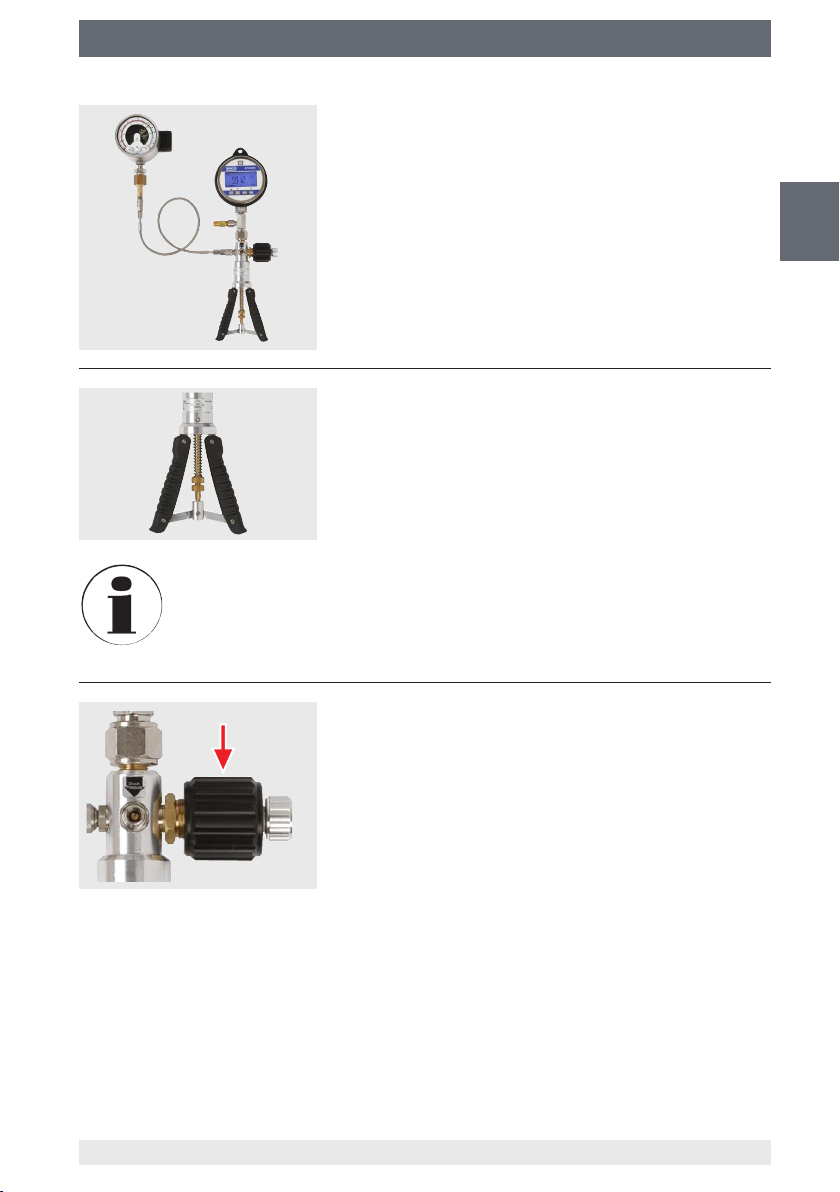

Select an appropriate adapter and

screw it together with the test item.

Connect the test item via the quickacting coupling to the metal exible

hose.

Connect the other side of the metal exible hose via

the quick-acting coupling to the calibration system.

Check that the switching for pressure or vacuum

generation (arrow) is set to pressure.

The calibration system is suitable for pressure

generation only.

22

WARNING!

The construction of the calibration system is not designed for vacuum

generation. Always set the switching valve to pressure generation.

Never adjust the switching valve when the system is under pressure,

switch only when the release valve is open.

Close the pressure relief valve.

Turn the pressure relief valve clockwise until the valve

is closed. No hard stop can be felt.

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

Page 23

6. Commissioning, operation

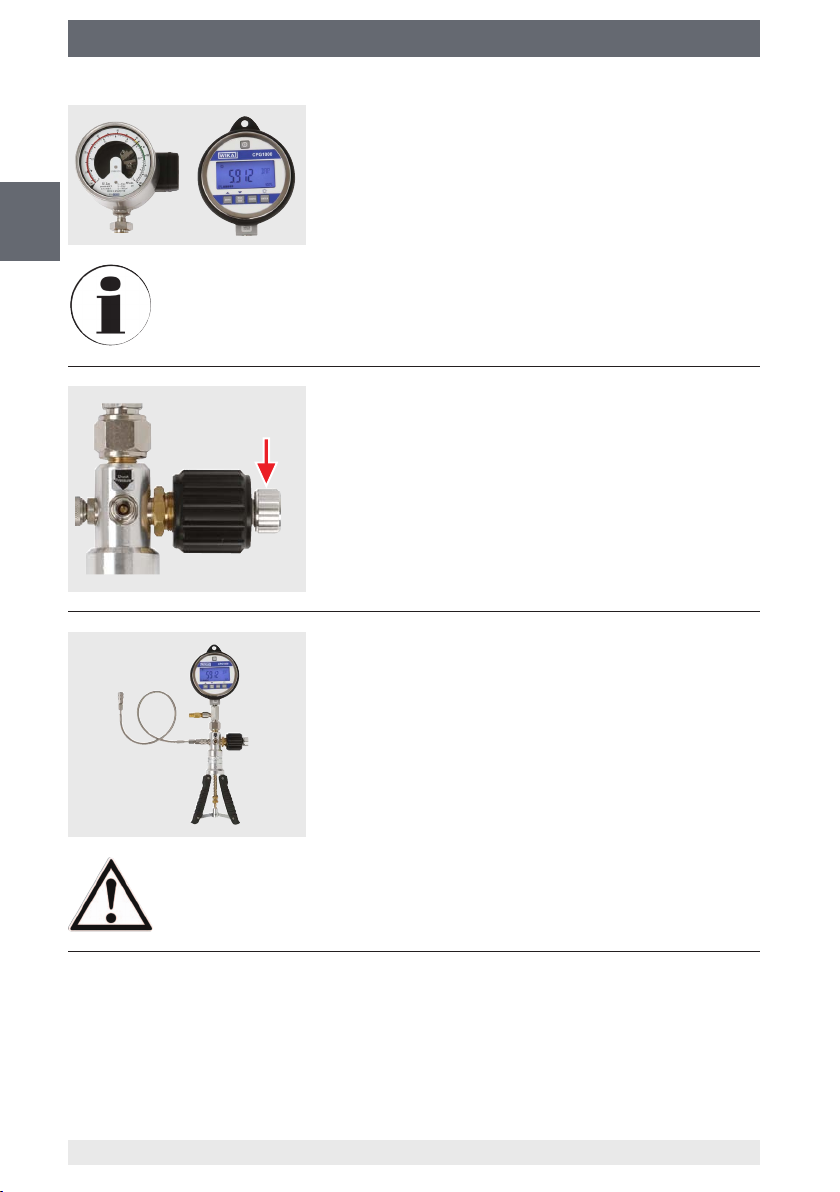

Switch on the calibration system.

The measurement setup shall be now as in the gure.

Actuate the pump handles several times until the

desired pressure is slightly exceeded.

To achieve the maximum pumping capacity, the spring above the knurled

nut must be relaxed.

For test items with low measuring ranges, the stroke path can be reduced

by turning the knurled nut. This will reduce the pressure increase per

stroke and minimize the risk of the overpressure.

GB

Set the desirede pressure via the ne-adjustment

valve (arrow).

Normally, the test is carried out when the pressure falls

because the gas density measuring instruments are

generally specied and adjusted in such a way.

To reduce the pressure, turn the ne-adjustment valve

counterclockwise.

Further reduction of the pressure is possible by means

of the pressure relief valve.

To increase the pressure, turn the ne-adjustment

valve clockwise.

Use the digital pressure gauge to read the set pressure.

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

23

Page 24

6. Commissioning, operation

GB

To improve the readability of the display, the backlighting can be activated

by means of the ENTER key.

Compare and record the displayed value of the test

item with the displayed value of the digital pressure

gauge.

Open the pressure relief valve after calibration to

depressurize the system.

The test item can be separated from the calibration

system.

24

The calibration system can be dismount now in the

reverse order.

WARNING!

Only disconnect once the system has been depressurised!

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

Page 25

7. Maintenance and cleaning / 8. Faults

7. Maintenance and cleaning

7.1 Maintenance

Repairs must only be carried out by the manufacturer.

7.2 Cleaning

CAUTION!

■

Clean the instrument with a moist cloth.

■

Electrical connections must not come into contact with moisture.

■

Residual media on the calibration system can result in a risk to

persons, environment and equipment. Take sucient precautionary

measures.

For information on returning the instrument see chapter 9.2 "Return".

7.3 Recalibration

DKD/DAkkS certicate - Ocial certicates:

We recommend that the calibration system is regularly recalibrated by the manufacturer,

with time intervals of approx. 12 months. Every factory recalibration includes, additionally, an extensive free-of-charge check of all system parameters with respect to their

compliance with the specication. The basic settings will be corrected if necessary.

8. Faults

8.1 Digital pressure gauge fault

Display indication Causes Measures

OL

-OL

No display or undenable

characters

Low battery voltage

functioning is only guaranteed for a

short period of time

Reading above or below the

measuring range

Battery at

Power supply unit is set incorrectly

or the polarity is revered

System error

Instrument faulty

Replace alkaline batteries

Adjust the line pressure to the

admissible range

Replace alkaline batteries

Set the power supply unit

correctly and ensure correct

polarity

Switch o the instrument, wait

for a short period of time and

switch on again

GB

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

Send to the manufacturer for

repair.

25

Page 26

8. Faults / 9. Dismounting, return and disposal

CAUTION!

If faults cannot be eliminated by means of the measures listed above,

shut down the calibration system immediately, and ensure that pressure

and/or signal are no longer present, and secure the instrument from being

put back into operation inadvertently.

GB

8.2 Test pump fault

Problem Causes Measures

The test pump is leaking Pressure relief valve is open

In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in chapter 9.2

"Return".

Close the pressure relief valve

The pump handles are sti

to operate

The pressure and vacuum switching is not switched correctly

(The switching is in the middle

position)

The pump has not been used for a

long time

Turn the shift lever to pressure

generation.

Actuate the pump until it

functions smoothly

CAUTION!

If faults cannot be eliminated by means of the measures listed above,

shut down the calibration system immediately, and ensure that pressure

and/or signal are no longer present, and secure the instrument from being

put back into operation inadvertently.

In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in chapter 9.2

"Return".

9. Dismounting, return and disposal

WARNING!

Residual media on submersible calibration system can result in a risk to

persons, the environment and equipment.

Take sucient precautionary measures.

9.1 Dismounting

Only dismount measurement setups once the system has been depressurized!

26

WIKA operating instructions calibration system, model BCS10

14051046.01 10/2012 GB/D/F/E

Page 27

9. Dismounting, return and disposal / 10. Accessories

9.2 Return

WARNING!

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances (acids, bases, solutions, etc.).

When returning the instrument, use the original packaging or a suitable transport

package.

To avoid damage:

1. Wrap the calibration system in an antistatic plastic lm.

2. Place the calibration system, along with shock-absorbent material, in the packaging.

Place shock-absorbent material evenly on all sides of the transport packaging.

3. If possible, place a bag containing a desiccant inside the packaging.

4. Label the shipment as carriage of a highly sensitive measuring instrument.

Information on returns can be found under the heading "Service" on our

local website.

9.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specic waste disposal regulations.

GB

This marking on the instruments indicates that they must not be disposed

of in domestic waste. The disposal is carried out by return to the manufacturer or by the corresponding municipal authorities (see EU directive

2002/96/EC).

10. Accessories

For use of the calibration system model BCS10 with the CPGlog data-logger evaluation

software see instruction manual "Data-logger software" at www.wika.de.

The order number of the CPGlog data-logger is given in the data sheet SP 60.08.

14051046.01 10/2012 GB/D/F/E

WIKA operating instructions calibration system, model BCS10

27

Page 28

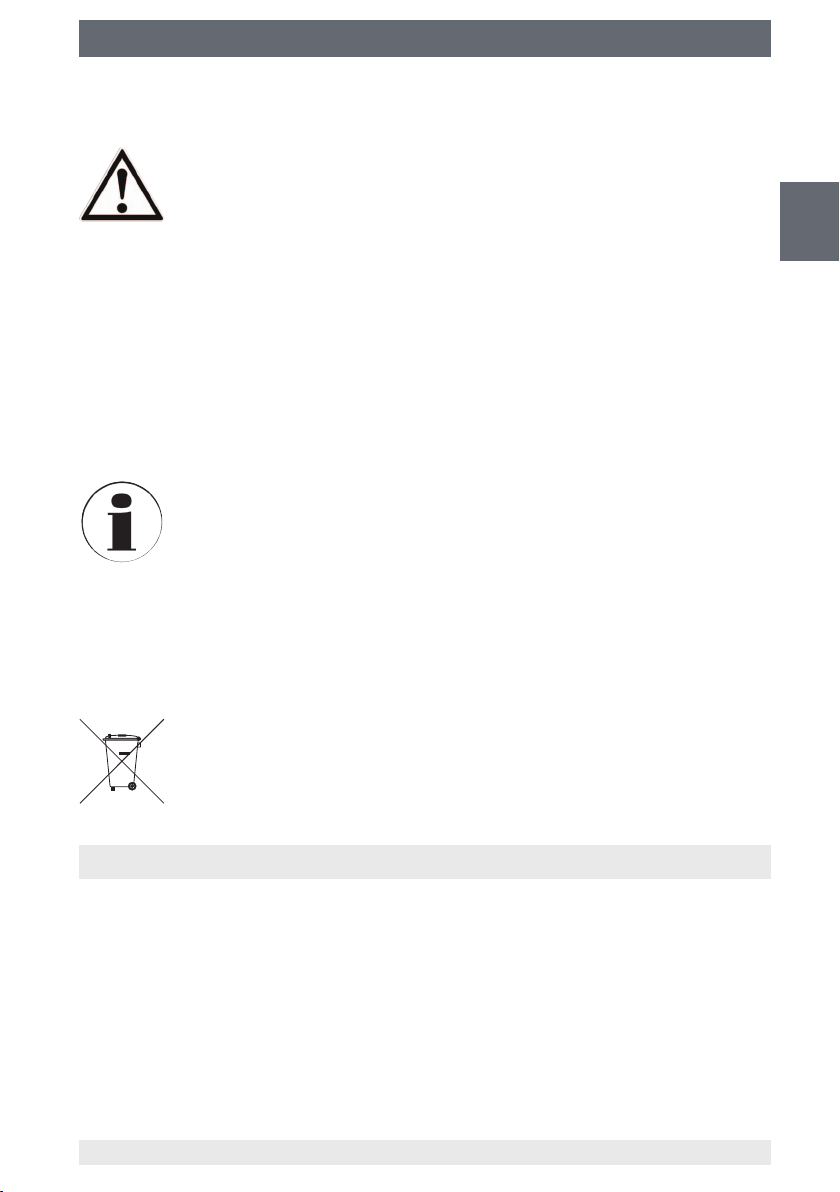

Appendix 1: Declaration of conformity for model BCS10

GB

28

WIKA operating instructions calibration system, model BCS10

14051046.01 10/2012 GB/D/F/E

Page 29

Inhalt

Inhalt

1. Allgemeines 30

2. Sicherheit 31

3. Technische Daten 35

4. Aufbau und Funktion 37

5. Transport, Verpackung und Lagerung 39

6. Inbetriebnahme, Betrieb 40

7. Wartung und Reinigung 51

8. Störungen 51

9. Demontage, Rücksendung und Entsorgung 52

D

10. Zubehör 53

Anlage 1: EG-Konformitätserklärung Typ BCS10 54

Konformitätserklärungen nden Sie online unter www.wika.de.

14051046.01 10/2012 GB/D/F/E

29WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

Page 30

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Kalibriersystem wird nach dem aktuellen

Stand der Technik konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und

Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO 14001

zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshin-

D

weise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten

Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Werkskalibrierungen / DKD/DAkkS-Kalibrierungen erfolgen nach internationalen

Normen.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt: SP 60.08

- Anwendungsberater:

Tel.: (+49) 9372/132-8971

Fax: (+49) 9372/132-8008971

E-Mail: sf6-sales@wika.de

30 WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

14051046.01 10/2012 GB/D/F/E

Page 31

1. Allgemeines / 2. Sicherheit

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod

oder zu schweren Verletzungen führen kann, wenn sie nicht gemieden

wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden

führen kann, wenn sie nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

ezienten und störungsfreien Betrieb hervor.

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das richtige

Kalibriersystem hinsichtlich Messbereich, Ausführung und spezischen

Messbedingungen ausgewählt wurde.

Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

D

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen

Kapiteln dieser Betriebsanleitung.

14051046.01 10/2012 GB/D/F/E

31WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

Page 32

2. Sicherheit

2.1 Bestimmungsgemäße Verwendung

Das Kalibriersystem Typ BCS10 dient der Überprüfung von SF6 gasdichtemessgeräten.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der technischen Spezikationen macht die sofortige Stilllegung und Überprüfung durch einen

autorisierten WIKA-Servicemitarbeiter erforderlich.

D

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

Elektronische Präzisionsmessgeräte mit erforderlicher Sorgfalt behandeln (vor Nässe,

Stößen, starken Magnetfeldern, statischer Elektrizität und extremen Temperaturen

schützen, keine Gegenstände in das Gerät bzw. Önungen einführen). Stecker und

Buchsen vor Verschmutzung schützen.

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch

Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten

Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Fachpersonal nachfolgend beschriebener Qualikation durchführen

lassen.

■

Unqualiziertes Personal von den Gefahrenbereichen fernhalten.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der

Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezischen Vorschriften, geltenden Normen und Richtlinien in der Lage, die beschriebenen

Arbeiten auszuführen und mögliche Gefahren selbstständig zu erkennen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

aggressive Medien.

32 WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

14051046.01 10/2012 GB/D/F/E

Page 33

2. Sicherheit

2.3 Zusätzliche Sicherheitshinweise für SF6 gas in Schaltanlagen

Der Betreiber muss sicherstellen, dass die Handhabung von SF6 gas durch ein hierzu

qualiziertes Unternehmen oder von gemäß IEC 61634 Abschnitt 4.3.1 bzw. IEC 60480

Abschnitt 10.3.1 geschulten Mitarbeitern durchgeführt wird.

Geltende Normen und Richtlinien für SF

gas

6

Installation, Errichtung, Inbetriebnahme:

■

IEC 61634 (Handhabung von SF6 gas)

■

IEC 60376 (neues SF6 gas, technisches SF6 gas)

■

IEC 60480 (gebrauchtes SF6 gas)

■

CIGRE report 276, 2005 (Practial SF6 gas handling instructions)

Leckagen während des Betriebs:

■

IEC 60376 (neues SF6 gas, technisches SF6 gas)

■

IEC 60480 (gebrauchtes SF6 gas)

■

CIGRE 2002 („SF6 gas in the electrical industry“)

Reparaturarbeiten und Wartung:

■

IEC 61634 (Use and handling of SF6 gas in high-voltage switchgear and controlgear)

■

CIGRE 1991 (Handhabung von SF6 gas)

■

CIGRE report 276, 2005 (Practical SF6 gas handling instructions)

■

CIGRE report 163, 2000 (Guide for SF6 gas mixtures)

gas ist farb- und geruchlos, chemisch neutral, inert, nicht entamm-

SF

6

bar und etwa fünfmal schwerer als Luft, nicht toxisch und nicht ozonschädigend.

Detaillierte Angaben benden sich in der IEC 60376 und IEC 61634.

D

14051046.01 10/2012 GB/D/F/E

33WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

Page 34

2. Sicherheit

2.4 Persönliche Schutzausrüstung

Die persönliche Schutzausrüstung dient dazu, das Fachpersonal gegen Gefahren

zu schützen, die dessen Sicherheit oder Gesundheit bei der Arbeit beeinträchtigen

könnten. Beim Ausführen der verschiedenen Arbeiten an und mit dem Gerät muss das

Fachpersonal persönliche Schutzausrüstung tragen.

Im Arbeitsbereich angebrachte Hinweise zur persönlichen Schutzausrüstung

befolgen!

Die erforderliche persönliche Schutzausrüstung muss vom Betreiber zur Verfügung

D

gestellt werden.

Schutzbrille tragen!

Schutz der Augen vor umheriegenden Teilen und Flüssigkeitsspritzern.

Schutzhandschuhe tragen!

Schutz der Hände vor Reibung, Abschürfung, Einstichen oder tieferen

Verletzungen sowie vor Berührung mit heißen Oberächen.

2.5 Besondere Gefahren

WARNUNG!

Messstoreste im ausgebauten Druckmessgerät können zur Gefährdung

von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

WARNUNG!

Die medienberührten Teile wurden ausschließlich für SF

SF

/N2-Gemische konzipiert.

6

Der Druck im Inneren der Prüfpumpe kann extrem hoch sein. Daher

ist sicherzustellen, dass alle Anschlüsse des Kalibriersystems korrekt

verbunden sind.

34 WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

gas und

6

14051046.01 10/2012 GB/D/F/E

Page 35

2. Sicherheit / 3. Technische Daten

2.6 Beschilderung, Sicherheitskennzeichnungen

Typenschild

Herstelldatum

Typ

Artikelnummer

Seriennummer

Messbereich

Adapter

Symbolerklärung

Vor Montage und Inbetriebnahme des Gerätes unbedingt die

Betriebsanleitung lesen!

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den zutreenden

europäischen Richtlinien.

3. Technische Daten

Messbereich

■

Messbereich: 0 ... 20 bar relativ

■

Überlast-Druckgrenze: 42 bar

■

Berstdruck: 140 bar

D

Genauigkeitsangaben

■

Genauigkeit: 0,05 % FS

■

Kompensierter Temperaturbereich: 0 ... 50 °C

■

Temperaturfehler: 0,005 % der Spanne/K (außerhalb des kompen-

sierten Temperaturbereiches)

14051046.01 10/2012 GB/D/F/E

35WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

Page 36

3. Technische Daten

Digitalanzeige

■

Anzeigetyp: 7-Segment-LCD

■

Stellen: 5 ½-stellig

■

Auösung: 0,001

■

Ziernhöhe: 16,53 mm (0,65")

■

Bargraphanzeige: 20-Segment-Bargraph 0 ... 100 %

■

Mögliche Druckeinheiten: bar, psi, kg/cm2, kPa, MPa und 15 weitere Einheiten

D

Einsatzbedingungen

■

Schutzart: IP 65

■

Umgebungstemperatur: -10 ... +55 °C

■

Messstotemperatur: 0 ... +55 °C

■

Lagertemperatur: -20 ... +70 °C

■

Relative Luftfreuchte: < 95 % r. F. (nicht betauend)

Kommunikation

■

Schnittstelle: USB, RS-232

Funktionen

■

Überdruckschutz: Einstellbares Überdruckventil

■

Druckfeineinstellung: Mittels Feinregulierventil

■

Messrate: 30/min. bis 10/sek. auswählbar

■

Speicher: MIN-/MAX-Werte

Integrierter Datenlogger

■

Datenlogger: Zyklischer Datenlogger: automatische Aufzeichnung von

bis zu 8.500 Werten

Zykluszeit wählbar von 1 ... 3.600 s in folgenden

Schritten:

1 s, 2 s, 5 s, 10 s, 30 s, 1 min, 2 min, 5 min, 10 min,

30 min und 1 h

Datenlogger-Auswertesoftware CPGLog wird zur

Verwendung der Datenloggerfunktion benötigt.

Bestellnummer der Software CPGlog ist dem Datenblatt

SP 60.08 zu entnehmen.

36 WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

14051046.01 10/2012 GB/D/F/E

Page 37

3. Technische Daten / 4. Aufbau und Funktion

Spannungsversorgung

■

Hilfsenergie: 3 x 1,5 V AA-Alkalibatterien

■

Batterielebensdauer: ca. 1.500 ... 2.000 h

■

Batteriestandsanzeige: Symbolanzeige im Display bei niedrigem Batteriestand

Prozessanschluss

■

Prüflingsadapter mit Schnellkupplung für G ½

■

Prüflingsadapter mit Schnellkupplung für G ¾

■

Prüflingsadapter mit Schnellkupplung für M30 x 2

CE-Konformität

■

EMV-Richtlinie: 2004/108/EG, EN 61 326-1 Emission (Gruppe 1,

Klasse B) und Störfestigkeit (Anhang A)

Kunststokoer

■

Abmessungen in mm: 395 x 295 x 106

■

Gewicht: ca. 4 kg (mit Inhalt)

Weitere technische Daten siehe WIKA-Datenblatt SP 60.08 und Bestellunterlagen.

4. Aufbau und Funktion

D

4.1 Kurzbeschreibung

Das modular aufgebaute Kalibriersystem Typ BCS10 dient der Druckerzeugung und

Überprüfung von mechanischen und elektronischen SF

gasdichtemessgeräten durch

6

Vergleichsmessungen bei 20 °C.

Die Prüfpumpe ermöglicht eine Druckerzeugung von 0 ... 35 bar. Durch ein Feinregelventil können die einzelnen Messpunkte hochgenau angefahren werden.

Über das verbaute Digitalmanometer können die Messungen in einer von 21 E

inheiten

oder auch in kundenspezischen Einheiten angezeigt werden.

4.2 Lieferumfang

■

Präzisions-Digitalmanometer Typ CPG1000 mit angebauter pneumatischer

Prüfpumpe Typ CPP30

■

Prüflingsadapter mit Schnellkupplung für G ½

■

Prüflingsadapter mit Schnellkupplung für G ¾

■

Prüflingsadapter mit Schnellkupplung für M30 x 2

■

Einstellbares Überdruckventil

■

Metallflexschlauch zum Anschluss des Prüflings, Länge 2 m

■

Kunststoffkoffer inkl. Schaumstoffeinlage und Betriebsanleitung

Lieferumfang mit dem Lieferschein abgleichen.

14051046.01 10/2012 GB/D/F/E

37WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

Page 38

4. Aufbau und Funktion

4.3 Aufbau des Kalibriersystems

1) Digitalmanomter

2) Feinregulierventil

3) Druckablassventil

4) Umschaltung zwischen Druckund Vakuumerzeugung

D

5) Pumpengrie

6) Verstellbare Rändelmutter zur

Einstellung der Pumpleistung

(Überdruckschutz)

1

8

2

3

7) Metallschutzschlauch zum

7

Prüingsanschluss, beidseitig

mit Schnellkupplung, Länge 2 m

8) Einstellbares Überdruckventil

4.4 Batterielebensdauer

Die Batterielebensdauer beträgt ca. 1.500 Betriebsstunden (ohne Hintergrundbeleuchtung). In der oberen linken Ecke der Digitalanzeige bendet sich ein Symbol für die

Batteriekapazität. Dieses Symbol erscheint, wenn die Batteriespannung zu niedrig ist.

Hinweise zur Batterie siehe Kapitel 3 „Technische Daten“.

Für den Batteriewechsel siehe Kapitel 6.8 „Batteriewechsel“.

4.5 Serielle Schnittstelle

Das Digitalmanomter besitzt standardmäßig eine serielle Schnittstelle. Die serielle Datenübertragung kann zur Konguration, Kalibrierung und zur Übertragung von

Messwerten des Messgeräts verwendet werden.

4

5

6

38 WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

14051046.01 10/2012 GB/D/F/E

Page 39

5. Transport, Verpackung und Lagerung

5. Transport, Verpackung und Lagerung

5.1 Transport

Das Kalibriersystem auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

siehe Kapitel 3 „Technische Daten“

Folgende Einüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

Das Kalibriersystem im Originalkoer an einem Ort lagern, der die oben gelisteten

Bedingungen erfüllt. Wenn die Originalverpackung nicht vorhanden ist, dann das Gerät

wie folgt verpacken und lagern:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

3. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der

Verpackung beilegen.

D

14051046.01 10/2012 GB/D/F/E

39WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

Page 40

6. Inbetriebnahme, Betrieb

6. Inbetriebnahme, Betrieb

Die Inbetriebnahme darf nur von geschultem Fachpersonal durchgeführt werden. Das

Kalibriersystem wurde ab Werk komplett auf Dichtheit überprüft.

WARNUNG!

Prüf- und Kalibriersysteme nur im drucklosen Zustand montieren bzw.

demontieren.

D

6.1 Ein- und Ausschalten

Zum Einschalten des Kalibriersystems,

die Einschalttaste (1) drücken. Erneutes Drücken der Einschalttaste schaltet

das Kalibriersystem wieder aus.

Nach dem Einschalten wird für ca.

1 Sekunde die Firmwareversion im

Display angezeigt.

1

6.2 Nullpunkteinstellung

Um den angezeigten Wert als Nullpunkt

festzulegen, nur die ZERO-Taste (3)

drücken. Die Anzeige wechselt sofort

auf den Wert 0.

6.3 MIN-/MAX-Wert

Das Digitalmanometer speichert den

Minimal- und Maximaldruck.

Bei einmaliger Betätigung der

MAX-/MIN-Taste (4) wird der Maximaldruck aus dem Speicher angezeigt. Bei erneuter

Betätigung der MAX/MIN-Taste wird der Minimaldruck aus dem Speicher angezeigt.

Nach 2 Sekunden schaltet die Anzeige wieder zurück auf den Betriebsmodus. Zum

Löschen des MIN-/MAX-Speichers, die MAX-/MIN-Taste (4) mindestens 2 Sekunden

drücken, bis die Meldung „CLr“ angezeigt wird.

Die Bargraphanzeige am unteren Rand des Displays zeigt den anliegenden Druck im

Verhältnis zum Gesamtmessbereich.

Durch eine mögliche Tara-Einstellung kann der angezeigte Druckwert vom

anliegenden Druck abweichen.

40 WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

2

5

4

3

14051046.01 10/2012 GB/D/F/E

Page 41

6. Inbetriebnahme, Betrieb

6.4 Hintergrundbeleuchtung

Die Hintergrundbeleuchtung dient der besseren Ablesbarkeit der Digitalanzeige. Über

die ENTER-Taste (5) lässt sich die Hintergrundbeleuchtung ein- und ausschalten.

6.5 Konguration

Das Kalibriersystem Typ BCS10 arbeitet in zwei verschiedenen Modi, dem Betriebsmodus und dem Kongurationsmodus.

Im Betriebsmodus erfasst das Digitalmanomter den Druck und stellt diesen auf der

Digitalanzeige dar.

Der Kongurationsmodus dient der Einstellung des Systems.

Folgende Einstellungen lassen sich verändern:

■

Einheiten

■

Automatische Abschaltung

■

Dämpfung

■

Abtastrate

■

Tarafunktion

■

Funktionssperre

Die genaue Funktionsbeschreibung der einzelnen Punkte siehe Kapitel 6.6 „Funktionen“.

Kongurationsmenü

Um das Kongurationsmenü des Digitalmanometers aufzurufen, die CONFIG-Taste (2)

drücken.

D

Die einzelnen Menüpunkte werden über die ZERO-Taste (3) und die MAX-/MIN-Taste (4)

eingestellt. Zum schnelleren scrollen die Taste gedrückt halten.

Um alle Änderungen zu speichern und das Kongurationsmenü zu verlassen, die

ENTER-Taste (5) drücken.

Über die ENTER-Taste kann das Kongurationsmenü jederzeit varlassen

werden. Dabei werden alle Änderungen gespeichert und das Kalibriersystem kehrt in den Betriebsmodus zurück.

14051046.01 10/2012 GB/D/F/E

41WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

Page 42

6. Inbetriebnahme, Betrieb

Menüführung

Betriebsmodus

Einheitenauswahl

UNITS SET

D

Automatische

Abschaltung

SET AUTO-

Batteriestatus

Temperaturanzeige

OFF

BAR

PSI

MPA ...

OFF

1 ... 30 Min

°C

°F

Dämpfung

SET DAMP

nächste Seite

ON

OFF

42 WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

14051046.01 10/2012 GB/D/F/E

Page 43

6. Inbetriebnahme, Betrieb

Abtastrate

SET RATE

Tarafunktion

SET TARE

Funktionssperre

LOCK

FUnC

Betriebsmodus

0,5/SEC

1/SEC

3/SEC

10/SEC

Werte sind

abhängig von

der gewählten

Einheit

Passwortabfrage:

101 eingeben

Nullpunkteinstellung

(ZERO-Taste)

Sperren/Entsperren

D

Das Passwort 101 ist werkseingestellt und kann nicht verändert

werden.

UnLOC

LOC

14051046.01 10/2012 GB/D/F/E

Einheitenauswahl

Sperren/Entsperren

Automatische

Abschaltung

Sperren/Entsperren

nächste Seite

UnLOC

LOC

UnLOC

LOC

43WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

Page 44

6. Inbetriebnahme, Betrieb

D

Dämpfung

Sperren/Entsperren

Abtastrate

Sperren/Entsperren

Tarafunktion

Sperren/Entsperren

Benutzerdenierte

Einheit (Skalierung

einstellen)

SET FACTR

UnLOC

LOC

UnLOC

LOC

UnLOC

LOC

Einstellung

siehe Kapitel 6.7

Betriebsmodus

44 WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

14051046.01 10/2012 GB/D/F/E

Page 45

6. Inbetriebnahme, Betrieb

6.6 Beschreibung der Menüpunkte

Druckeinheiten

Das Kalibriersystem ist ab Werk eingestellt (siehe Lieferschein).

Eine Liste der verfügbaren Einheiten siehe Kapitel 3 „Technische Daten“.

Details über die Konguration benutzerdenierter Einheiten siehe Kapitel 6.7 „Konguration der Funktionssperre“.

Automatische Abschaltung

Die automatische Abschaltung kann in Minutenschritten im Bereich von 1 ... 30 Minuten

eingestellt werden. Um das Gerät im Dauerbetrieb zu nutzen, diesen Menüpunkt mit

„OFF“ deaktivieren.

Batteriespannung anzeigen

Es wird der aktuelle Batteriestatus als Spannungswert sowie als Balkengrak angezeigt.

Temperaturanzeige

Dieser Menüpunkt zeigt die vom internen Sensor gemessene Temperatur an. Der Wert

kann in °F oder °C angezeigt werden.

Dämpfung

Bei eingeschalteter Dämpfung werden die Messwerte von pulsierenden Druckquellen

geglättet.

D

Abtastrate

Legt fest, in welchem Intervall der Druck gemessen und die Anzeige aktualisiert wird.

0,5 Messungen pro Sekunde entsprechen 30 Messungen in der Minute.

TARE (Tarafunktion)

Unter diesem Menüpunkt kann ein konstanter Osetwert eingestellt werden, der von

dem gemessenen Druck subtrahiert wird.

Der Wert TARE hängt von der gewählten Einheiten und kann auf den maximalen Anzeigebereich eingestellt werden.

Die Balkengrak zeigt immer den tatsächlichen Druck in Abhängigkeit vom gesamten

Messbereich, unabhängig von der Taraeinstellung an. Dies erfolgt aus Sicherheitsgründen, damit auch bei der Anzeige „0“ zu erkennen ist, ob das Kalibriersystem unter Druck

steht.

Beispiel:

Ist TARE beispielsweise auf 30 bar eingestellt und es wird ein Druck von 37 bar gemessen, wird als Messwert 7 bar angezeigt. Ein Druck von 27 bar würde dann als -3 bar

angezeigt werden.

14051046.01 10/2012 GB/D/F/E

45WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

Page 46

6. Inbetriebnahme, Betrieb

Funktionssperre

Das Kalibriersystem Typ BCS10 wird ab Werk so ausgeliefert, dass der Zugang zu allen

Einstellungen freigegeben ist und diese geändert werden können.

Der Zugri auf die einstellbaren Parameter kann eingeschränkt oder ganz untersagt

werden, um Änderungen der Konguration durch Unbefugte zu verhindern.

Erreicht wird dies durch die Funktionssperre.

Desweiteren können hier benutzerdenierte Einheiten skaliert werden.

Die Konguration des Funktionssperre siehe Kapitel 6.7 „Konguration der Funktions-

D

sperre“

6.7 Konguration der Funktionssperre

Zu dem Menüpunkt „FUnC

Digitalanzeige erscheint die Meldung „0PWRD“. Nun das Passwort „101“ eingeben. Das

Passwort ist ab Werk vordeniert und kann nicht geändert werden.

Die Funktionen, die gesperrt bzw. entsperrt werden können sind:

- Nullpunkteinstellung (ZERO-Taste)

- Einstellung der Einheiten

- Einstellungen der automatischen Abschaltung

- Einstellung der Dämpfung

- Einstellung der Abtastrate

- Tara-Einstellung

Der Befehl LOC sperrt die jeweilige Fuktion und UnLOC entsperrt diese wieder.

Gesperrte Funktionen werden im Kongurationsmenü nicht mehr angezeigt und können

somit auch nicht mehr verändert werden.

Einstellung einer benutzerdenierten Einheit oder eines benutzerdenierten

Messbereichs:

Über den Menüpunkt SET FACTOR lässt sich ein Multiplikator zwischen 0,001 und 100

für einen benutzerdenierten Messbereich einstellen. Der denierte Faktor wird mit dem

gemessenen Druckwert in psi multipliziert. Das Ergebnis wird angezeigt.

Beispiel: 40 psi entsprechen 1.000 g eines Produkts in einem Tank. Auf der Anzeige soll

das Gewicht des Produkts erscheinen.

Wenn als Multiplikator 25 deniert wird, entspricht ein Druck von 40 psi dem Wert 1.000

(40 x 25). Als technische Einheit wird auf dem Gerät „CUST“ angezeigt.

LOCK

“ scrollen und die ENTER-Taste drücken. Auf der

46 WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

14051046.01 10/2012 GB/D/F/E

Page 47

6. Inbetriebnahme, Betrieb

6.8 Batteriewechsel

1. Die Blende des Digitalmanometers ca. 90° nach links drehen und abnehmen.

2. Die Frontplatte des Digitalmanometers abnehmen, somit ist das Batteriefach

zugänglich.

3. Die Batterien tauschen. Nur 1,5 V AA-Alkalibatterien verwenden.

4. Gerät wieder verschließen. Sicherstellen, dass die Vorderseite korrekt ausgerichtet

ist.

6.9 Messaufbau und Einrichtung

WARNUNG!

Prüf- und Kalibriersysteme nur im drucklosen Zustand montieren bzw.

demontieren.

1) Gerät ein- und ausschalten

2) Nullpunktabgleich durchführen

1

3) Feinregulierventil

8

4) Druckablassventil

2

5) Umschaltventil Druck-/Vakuumer-

3

4

zeugung

6) Pumpengrie

D

9

14051046.01 10/2012 GB/D/F/E

7) Verstellbare Rändelmutter zur

5

Einstellung der Pumpleistung

(Überdruckschutz)

8) Einstellbares Überdruckventil

6

9) Metallexschlauch zum

7

Prüingsanschluss, beidseitig mit

Schnellkupplung, Länge 2 m

47WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

Page 48

6. Inbetriebnahme, Betrieb

D

Passendes Adapterstück auswählen

und mit dem Prüing verschrauben.

Prüing über die Schnellkupplung mit

dem Metallexschlauch verbinden.

Die andere Seite des Metallexschlauches über die

Schnellkupplung mit dem Kalibriersystem verbinden.

Prüfen ob die Umschaltung für Druck- oder

Vakuumerzeugung (Pfeil) auf Druck eingestellt ist.

Das Kalibriersystem ist nur für die Druckerzeugung

geeignet.

WARNUNG!

Der Aufbau des Kalibriersystems ist nicht für die Vakuumerzeugung

ausgelegt. Das Umschaltventil in jedem Fall auf Druckerzeugung eingestellt lassen.

Umschaltventil niemals verstellen, während das System unter Druck steht

Umschalten nur bei geönetem Ablassventil.

Druckablassventil schließen.

Druckablassventil im Uhrzeigersinn drehen, bis das

Ventil geschlossen ist. Es ist kein harter Anschlag

spürbar.

48 WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

14051046.01 10/2012 GB/D/F/E

Page 49

6. Inbetriebnahme, Betrieb

Kalibriersystem einschalten.

Der Messaufabau sollte nun der Abbildung

entsprechen.

Die Pumpengrie mehrmals betätigen, bis der

gewünschte Druck leicht überschritten ist.

Um die maximale Pumpleistung zu erreichen, sollte die Feder oberhalb

der Rändelmutter entspannt sein.

Bei Prüingen mit niedrigen Messbereichen, kann durch Drehen der

Rändelmutter der Hubweg verkürzt werden. Dadurch wird der Druckanstieg pro Hub geringer und die Gefahr eines Überdrückens minimiert.

D

Den gewünschten Druck über das Feinregulierventil

(Pfeil) einstellen.

Die Prüfung erfolgt normalerweise bei fallendem

Druck, da die Gasdichteinstrumente in der Regel so

speziziert und justiert sind.

Um den Druck zu verringern, das Feinregulierventil

entgegen dem Uhrzeigersinn drehen.

Eine weitere Druckreduzierung ist über das Druckablassventil möglich.

Um den Druck zu erhöhen, das Feinregulierventil im Uhrzeigersinn drehen.

Den eingestellten Druck über das Digitalmanometer ablesen.

14051046.01 10/2012 GB/D/F/E

49WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

Page 50

6. Inbetriebnahme, Betrieb

Zur besseren Lesbarkeit des Displays lässt sich über die ENTER-Taste

D

die Hintergrundbeleuchtung aktivieren.

Den Anzeigewert des Prüings mit dem Anzeigewert

des Digitalmanometers vergleichen und protokollieren.

Nach erfolgter Kalibrierung das Druckablassventil

önen, um das System drucklos zu schalten.

Der Prüing kann vom Kalibriersystem getrennt

werden.

Das Kalibriersystem kann nun in umgekehrter

Reihenfolge demontiert werden.

WARNUNG!

Nur im drucklosen Zustand demontieren.

50 WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

14051046.01 10/2012 GB/D/F/E

Page 51

7. Wartung und Reinigung / 8. Störungen

7. Wartung und Reinigung

7.1 Wartung

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

7.2 Reinigung

VORSICHT!

■

Das Gerät mit einem feuchten Tuch reinigen.

■

Elektrische Anschlüsse nicht mit Feuchtigkeit in Berührung bringen.

■

Messstoreste am Kalibriersystem können zur Gefährdung von

Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

Hinweise zur Rücksendung des Gerätes siehe Kapitel 9.2 „Rücksendung“.

7.3 Rekalibrierung

DKD/DAkkS-Schein - amtliche Bescheinigungen:

Es wird empfohlen, das Kalibriersystem in regelmäßigen Zeitabständen von

ca. 12 Monaten durch den Hersteller rekalibrieren zu lassen. Jede werksseitige Rekalibrierung beinhaltet außerdem eine umfangreiche und kostenfreie Überprüfung aller

Systemparameter auf Einhaltung der Spezikationen. Die Grundeinstellungen werden

wenn notwendig korrigiert.

D

8. Störungen

8.1 Störung Digitalmanomter

Anzeige auf Display Ursachen Maßnahmen

OL

-OL

Keine Anzeige oder

wirre Zeichen

14051046.01 10/2012 GB/D/F/E

Batteriespannung schwach,

Funktion ist nur noch kurze Zeit

gewährleistet

Messbereich über- bzw.

unterschritten

Batterie ist leer

Netzgerät falsch eingestellt oder

verpolt

Systemfehler

Gerät defekt

Alkalibatterien austauschen

Systemdruck auf zulässigen

Bereich einstellen

Alkalibatterien austauschen

Netzgerät korrekt einstellen und

polen

Gerät ausschalten,kurz warten

und wieder einschalten

Zur Reparatur an Hersteller

senden.

51WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

Page 52

8.

Störungen / 9. Demontage, Rücksendung ...

VORSICHT!

Können Störungen mit Hilfe der oben aufgeführten Maßnahmen nicht

beseitigt werden, ist das Kalibriersystem unverzüglich außer Betrieb zu

setzen, sicherzustellen, dass kein Druck bzw. Signal mehr anliegt und

gegen versehentliche Inbetriebnahme zu schützen.

In diesem Falle Kontakt mit dem Hersteller aufnehmen.

Bei notwendiger Rücksendung die Hinweise unter Kapitel 9.2 „Rücksendung“ beachten.

8.2 Störung Prüfpumpe

D

Störung Ursachen Maßnahmen

Die Prüfpumpe ist undicht Druckablassventil oen

Druckablassventil schließen

Die Pumpengrie sind

schwergängig

Umschaltung für Druck und

Vakuum ist nicht richtig geschaltet

(Umschalter bendet sich in Mittelstellung)

Pumpe wurde längere Zeit nicht

benutzt

Schalthebel in Richtung Druckerzeugung umlegen.

Pumpe so lange betätigen bis

diese leichtgängig wird

VORSICHT!

Können Störungen mit Hilfe der oben aufgeführten Maßnahmen nicht

beseitigt werden, ist das Kalibriersystem unverzüglich außer Betrieb zu

setzen, sicherzustellen, dass kein Druck bzw. Signal mehr anliegt und

gegen versehentliche Inbetriebnahme zu schützen.

In diesem Falle Kontakt mit dem Hersteller aufnehmen.

Bei notwendiger Rücksendung die Hinweise unter Kapitel 9.2 „Rücksendung“ beachten.

9. Demontage, Rücksendung und Entsorgung

WARNUNG!

Messstoreste am Kalibriersystem können zur Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

9.1 Demontage

Messaufbauten nur im drucklosen Zustand demontieren!

52 WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

14051046.01 10/2012 GB/D/F/E

Page 53

9. Demontage, Rücksendung und Entsorgung / 10. Zubehör

9.2 Rücksendung

WARNUNG!

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoen (Säuren,

Laugen, Lösungen, etc.) sein.

Zur Rücksendung des Gerätes die Originalverpackung oder eine geeignete Transportverpackung verwenden.

Um Schäden zu vermeiden:

1. Das Kalibriersystem in eine antistatische Plastikfolie einhüllen.

2. Das Kalibriersystem mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

3. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung beifügen.

4. Sendung als Transport eines hochempndlichen Messgerätes kennzeichnen.

Hinweise zur Rücksendung benden sich in der Rubrik „Service“ auf

unserer lokalen Internetseite.

9.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

D

Bei Geräten mit dieser Kennzeichnung wird darauf hingewiesen, dass

diese nicht in den Hausmüll entsorgt werden dürfen. Die Entsorgung

erfolgt durch Rücknahme bzw. durch entsprechende kommunale Stellen

(siehe EU-Richtlinie 2002/96/EC).

10. Zubehör

Zur Verwendung des Kalibriersystems Typ BCS10 mit der Datenlogger-Auswertesoftware CPGlog siehe Bedienungsanleitung „Datenlogger-Software“ unter www.wika.de

Bestellnummer des Datenloggers CPGlog ist dem Datenblatt SP 60.08 zu entnehmen.

14051046.01 10/2012 GB/D/F/E

53WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

Page 54

Anlage 1: Konformitätserklärung Typ BCS10

D

54 WIKA Betriebsanleitung Kalibriersystem, Typ BCS10

14051046.01 10/2012 GB/D/F/E

Page 55

Sommaire

Sommaire

1. Généralités 56

2. Sécurité 57

3. Spécications 61

4. Conception et fonction 63

5. Transport, emballage et stockage 65

6. Mise en service, exploitation 66

7. Entretien et nettoyage 77

8. Dysfonctionnements 77

9. Démontage, retour et mise au rebut 78

10. Accessoires 79

Annexe 1: Déclaration de conformité CE type BCS10 80

Déclarations de conformité se trouvent sur www.wika.fr.

F

14051046.01 10/2012 GB/D/F/E

55WIKA mode d'emploi système d’étalonnage, type BCS10

Page 56

1. Généralités

1. Généralités

■

Le transmetteur de pression décrit dans les instructions d'étalonnage a été conçu

et fabriqué selon les dernières technologies en vigueur. Tous les composants sont

soumis à des critères de qualité et d'environnement stricts durant la fabrication. Nos

systèmes de gestion sont certiés selon ISO 9001 et ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant l'utilisation de l'instrument. Il est possible de travailler en toute sécurité avec ce produit en respectant

toutes les consignes de sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les accidents et les

prescriptions générales de sécurité en vigueur pour le domaine d‘application de

l'instrument.

F

■

Le mode d'emploi fait partie du produit et doit être conservé à proximité immédiate

de l'instrument et être accessible à tout moment pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération, avoir lu soigneusement et compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de dommages provoqués par une utilisation non conforme à l'usage prévu, de non respect de ce mode

d'emploi, d'utilisation de personnel peu qualié de même qu'en cas de modications

de l'instrument eectuées par l'utilisateur.

■

Les conditions générales de vente mentionnées dans les documents de vente

s'appliquent.

■

Sous réserve de modications techniques.

■

Les étalonnages d'usine et les étalonnages DKD/DAkkS (Service allemand d'étalonnage) sont eectués conformément aux normes internationales.

■

Pour obtenir d'autres informations :

- consulter notre site internet : www.wika.fr

- che technique correspondante : SP 60.08

- conseiller applications :

Tel. : (+33) 1 343084-84

Fax : (+33) 1 343084-94

E-Mail : info@wika.fr

56 WIKA mode d'emploi système d’étalonnage, type BCS10

14051046.01 10/2012 GB/D/F/E

Page 57

1. Généralités / 2. Sécurité

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer la mort ou des blessures graves si elle n'est pas évitée.

ATTENTION !

… indique une situation potentiellement dangereuse et susceptible de

provoquer de légères blessures ou des dommages matériels et pour

l'environnement si elle n'est pas évitée.

Information

… met en exergue les conseils et recommandations utiles de même

que les informations permettant d'assurer un fonctionnement ecace et

normal.

2. Sécurité

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement, s'assurer

que le système d'étalonnage a été choisi de façon adéquate en ce qui

concerne la plage de mesure, la version et les conditions de mesure

spéciques.

Un non-respect de cette consigne peut entraîner des blessures corporelles graves et/ou des dégâts matériels.

F

Vous trouverez d'autres consignes de sécurité dans les sections individuelles du présent mode d'emploi.

14051046.01 10/2012 GB/D/F/E

57WIKA mode d'emploi système d’étalonnage, type BCS10

Page 58

2. Sécurité

2.1 Utilisation conforme à l'usage prévu

Le système d'étalonnage type BCS10 sert à l'inspection d'instruments de mesure de la

densité de gaz SF

L'instrument est conçu et construit exclusivement pour une utilisation conforme à l'usage

prévu décrit ici et ne doit être utilisé qu'en conséquence.

Les spécications techniques mentionnées dans ce mode d'emploi doivent être respectées. En cas d'utilisation inadéquate ou de fonctionnement de l'instrument en dehors

des spécications techniques, un arrêt et contrôle doivent être immédiatement eectués par un collaborateur autorisé du service de WIKA.

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à l'usage

prévu.

Traiter l'instrument de mesure et de précision électronique avec le soin requis (protéger

F

l'instrument contre l'humidité, les chocs, les forts champs magnétiques, l'électricité

statique et les températures extrêmes, n'introduire aucun objet dans l'instrument ou les

ouvertures). Il est impératif de protéger les connecteurs et les prises contre les salissures.

Si l'instrument est transporté d'un environnement froid dans un environnement chaud, la

formation de condensation peut provoquer un dysfonctionnement fonctionnel de l'instrument. Il est nécessaire d'attendre que la température de l'instrument se soit adaptée à la

température ambiante avant une nouvelle mise en service.

.

6

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à l'usage

prévu.

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants dommages

corporels et matériels.

■

Les opérations décrites dans ce mode d'emploi ne doivent être eectuées que par un personnel ayant la qualication décrite ci-après.

■

Tenir le personnel non qualié à lécart des zones dangereuses.

Personnel qualié