Page 1

37E73A-918, 921, 922 or 927 INTELLI-VENT™

WARNING

!

WARNING

!

WARNING

!

Water Heater Thermostat Control Installation Instructions

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

The 37E73A-9XX INTELLI-IGNITION™ control is a

combination gas valve, ignition control, and thermostat for

use on Power Vented water heaters. The microcomputer in

the control supervises the ignition sequence and timings

for the water heater, and provides diagnostic codes in case

of system malfunction. The control provides direct burner

ignition using the White-Rodgers’ Silicon Nitride ignitor. The

control uses the INTELLI-IGNITION™ technology to greatly

extend the ignitor’s life.

Adjustable Regulator Controls: The gas regulator on this

control requires no field service. The regulator is factory

adjustable for the proper burner gas pressure.

For Natural Gas Only

DESCRIPTION

“WHAT TO DO IF YOU SMELL GAS”

•Do not try to light any appliance.

•Do not touch any electrical switch; do not use any

phone in your building.

•Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s Instructions

•

If you cannot reach your gas supplier, call the fire

department.

Do not use this Natural Gas control on LP Gas water

heater. Improper operation could occur, resulting in

personal injury and/or death due to Carbon Monoxide

(CO) poisoning, fire, or explosion. Check for proper

gas type as listed on the rating plate affixed to the

water heater.

.

CONTENTS

Description ............................................................. 1

Precautions ............................................................ 1

Specifications ......................................................... 2

Installation .............................................................. 2

Operation ................................................................ 7

Wiring ..................................................................... 6

Troubleshooting ...................................................... 8

PRECAUTIONS

FIRE, SHOCK AND EXPLOSION HAZARDS

• Shutoffmaingastoapplianceforserviceoruntil

installation is complete.

• Disconnectelectricpowerbeforeservicing.

• Donotexceedthespeciedvoltage.

• Replace existing control with recommended

model.

• Protectthecontrolfromdirectcontactwithwater

(dripping, spraying, rain, etc.)

• Ifthecontrolhasbeenindirectcontactwithwater,

replace the control.

• Labelallwiresbeforedisconnectionwhenservicing controls. Wiring errors can cause improper and

dangerous operation.

• Routeandsecurewiringawayfromame.

• Ensureproperearthgroundingofappliance.

• Ensureproperconnectionoflineneutralandline

hot wires.

• Donotusetoolstooperatethiscontrol.

• Donottakecontrolapart,therearenoserviceable

parts inside.

• Donotusecontrolifithasbeenooded.

• Neverstandonthecontroloruseasastep.

www.white-rodgers.com

www.emersonclimate.com

PART NO. 37-7110A

0950

Page 2

SPECIFICATION

NOTE

NOTE

ELECTRICAL RATINGS:

Input and Frequency: 120 VAC, 60 Hz

Output Ratings:

Ignitor Load: 2 Amps maximum

Inducer Draft Motor: 3 Amps Full Load, 4 Amps Locked

Rotor

Current: 0.2 Amps @ 120 VAC

Range of Regulation (Btu/Hr)

Minimum: 30,000 Maximum: 150,000

Pressure Regulator Setting: Factory set to 3.5” or 4.0” W.C.

Adjustable 2.5” to 5.0” W.C.

1.0” Pressure Drop Capacity

100,000 Btu/Hr

a

Based on 1000 Btu/ft3, 0.64 specify gravity natural gas

Maximum Inlet Pressure: 1/2 PSI maximum

Ambient Temperature Rating:

32oF to 160oF (0oC to 70oC )

a

Automatic High Temperature Cutoff:

Single-Use Type, 185oF(82oC)

Prepurge Time: 5 Seconds

Ignitor Warm-up Time: 20 Seconds

Trial for Ignition Period: 4 Seconds

Inter-purge Time: 5 Seconds

Post-purge Time: 5 Seconds

Ignition Retries: 2 Retries; 3 Trials before lockout

Ignition Recycles: 2 Recycles, 3 Losses of flame before

lockout

BODY CONFIGURATION:

Right angle with a 1/2” NPT inlet and a 1/2” inverted flare

outlet

MOUNTING:

Limited Horizontal/Vertical

INSTALLATION

Dirt or contamination in the gas line can block the control

from operating creating a risk of explosion, injury, or death.

1. This control must be installed or serviced only by a

professional.

2. For your safety, this control is supplied with tamper

resistant screws. Do not attempt to repair or adjust

the control. If you experience problems, replace the

control immediately. Continuing to use a damaged

control could result in fire and/or explosion.

3. An odorant has been added to the gas to help you

detect it. Before lighting, search for the odor of gas by

snifngatoorlevelaroundthewaterheater.

4. In some situations, the gas may lose its odor. To

detect unodorized gas, you must have a gas detector,

which can be purchased from your gas company. If

you do not have a detector and have the slightest

suspicion that gas may be present, get out of the

house and call the gas company. DO NOT RELY

TOTALLY ON YOUR NOSE.

REMOVING THE OLD CONTROL

1. Shut off the gas to the water heater

2. Turn off electrical power to the water heater.

3. Remove the two plastic wire connectors that plug

into the bottom of the control. The connectors have

latches which must be depressed. DO NOT FORCE

THE CONNECTORS, DAMAGE TO THE WIRING MAY

RESULT.

4. Shut off the water at the cold water inlet.

5. Connect a hose to the water heater drain cock. Drain the

water to a nearby drain. Open a hot water faucet for faster

draining.

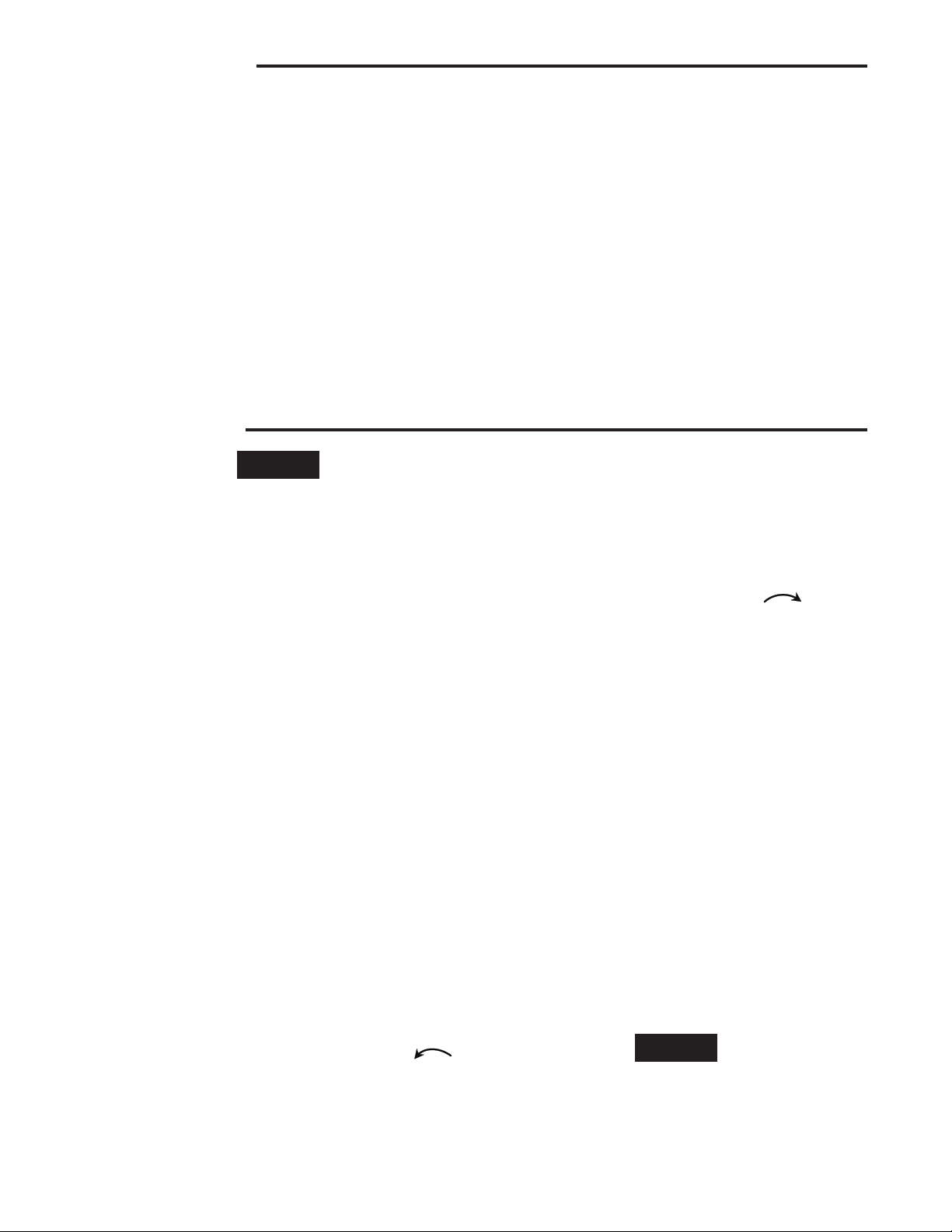

6. Disconnect the gas line at the union (Figure 1). Remove

the piping from the old control.

7. Remove the control by turning it counterclockwise ( ).

INSTALLING THE NEW CONTROL

All piping must comply with local and state ordinances or

with the National Fuel Gas Code (ANSI Z223.1-NFPA 54),

whichever applies.

2

To protect the control from dirt and contamination, a drip leg

or sediment trap (see Figure 1) must be installed in the piping

leading to the control.

1. Apply pipe compound to the male threads of the pipe that

goes into the control, leaving the first two or three threads

clean.

2. Install control in the tank. Turn clockwise (

short piece of pipe to help in turning. Align the control so

that the burner tube may be connected.

3. Make the main burner connection. Do not use pipe joint

compound or Teflon tape.

4. Connect the gas line. Use new black iron pipe that has

been properly reamed. If old pipe is used, be sure it

is clean and free from rust and scale. Use pipe joint

compound on male threads only. (Use pipe joint compound

approved for natural and LP gas service.) Do not use

TEFLON tape. Do not apply compound to the first two

threads.

5. DO NOT use joint compound or tape on the union

connection.

6. Make the electrical connections to the control. There are

two plastic connectors that plug into the bottom of the

control. The connectors are “keyed” so that they can only

be inserted one way. Make sure that the connectors

are properly aligned before attempting to insert. DO

NOT FORCE THE CONNECTORS; DAMAGE TO THE

CONTROL WILL RESULT.

7. To fill the water heater with water:

a. Close the water heater drain valve by turning the

handle to the right (clockwise). The drain valve is on

the lower front of the water heater.

The cold water supply valve must be left open when the

water heater is in use.

b. Open the cold water supply valve to the water heater.

c. To ensure complete filling of the tank, let air exit by

opening the nearest hot water faucet. Allow water to

run until a constant flow is obtained. This will let air out

of the water heater and the piping.

). Use a

Page 3

GROUND JOINT UNION

INTELLI-VENT™

CONTROL

GAS SUPPLY

PIPE

TEE

DRIP LEG

(SEDIMET TRAP)

3" MINIMUM

(MANDATORY)

PIPE CAP

SHUT-OFF VALVE

CAUTION

!

Never use this water heater unless it is completely

NOTE

filled with water. To prevent damage to the tank, the

tankmustbelledwithwater.Watermustowfrom

the hot water faucet before turning ON gas to the

water heater.

Figure 1. Typical gas connection

d. Check all new water piping for leaks. Repair as needed.

8. Open the gas shutoff valve.

9. BEFORE TURNING ON THE APPLIANCE, CHECK THE

GAS LINES FOR LEAKS.

a. Use a soapy water solution. DO NOT test for gas leaks

using a match or open flame.

b. Brush the soapy water solution on all gas pipes, joints,

and fittings. Use care that excess solution does not

enter the control’s plastic housing.

c. Check for bubbling soap. This means you have a leak.

Turn OFF the gas and make the necessary repairs.

d. Turn on the gas and recheck for leaks. Repeat this

process until you are sure the system is gas-tight. If

repeated work on a part does not stop the leak, the

part must be replaced.

e. Rinse off the soapy solution and wipe all the plumbing

parts dry.

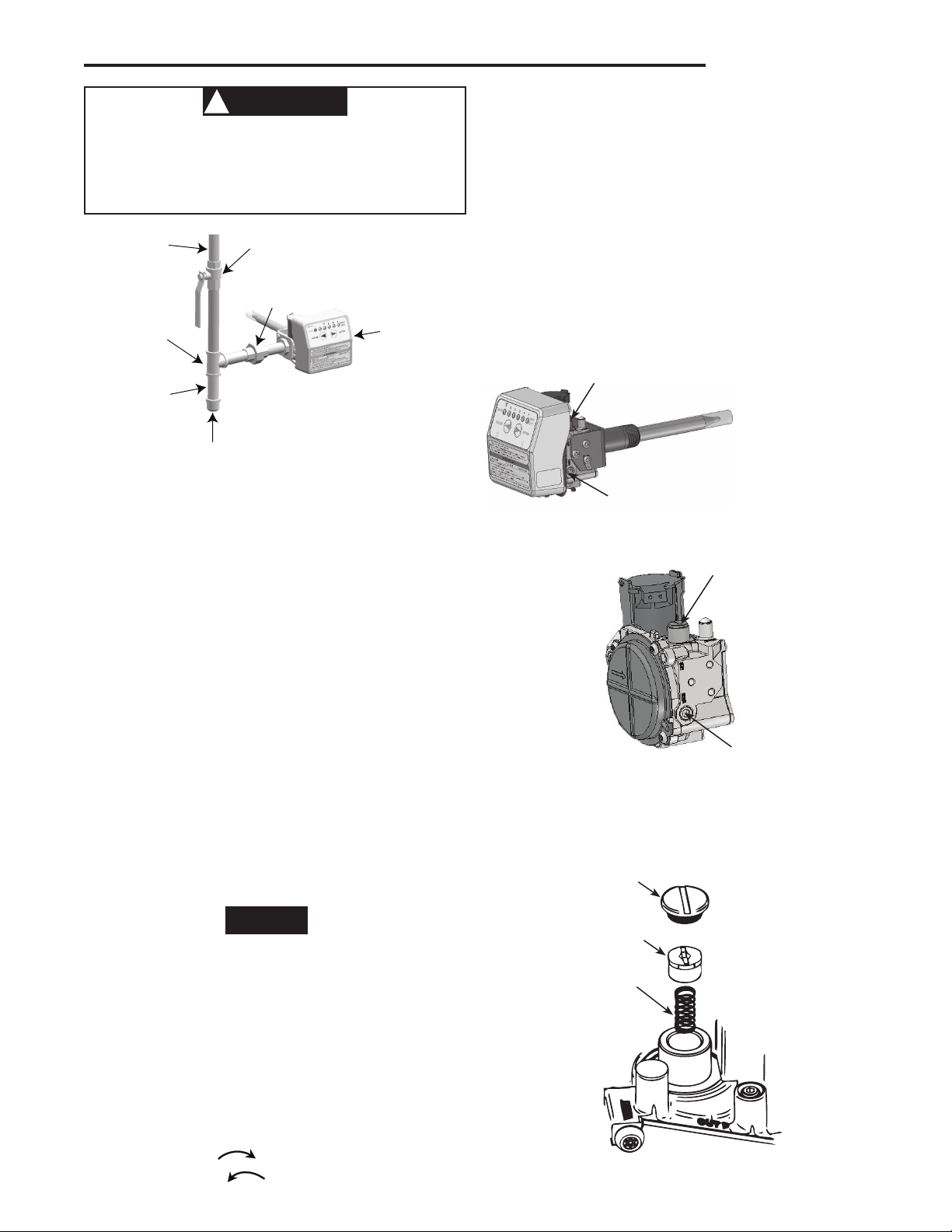

PRESSURE REGULATOR ADJUSTMENT

These controls are shipped from the factory with the regulator

set as specified on the control label. Consult the appliance

rating plate to ensure burner manifold pressure is as specified.

If another outlet pressure is required, follow these steps.

INSTALLATION

fig. 3). Always adjust regulator to provide the correct

pressure according to the original equipment manufacturer’s

specifications listed on the appliance rating plate. Replace

regulator cover screw.

6. Turn off all electrical power system to the system.

7. Remove manometer hose from outlet pressure tap.

8. Remove hose fitting and re-install the 1/8 NPT pressure

tap plug. Tighten to 60 in-lb max.

9. Turn on electrical power to the system.

10. Turn on system power and energize valve.

11. Using a leak detection solution or soap suds, check

for leaks at pressure boss screw or pressure tap plug.

Bubbles forming indicate a leak. SHUT OFF GAS AND FIX

ALL LEAKS IMMEDIATELY.

Outlet Pressure

Regulator Adjust

Tower

1/8 Threaded Outlet

Pressure Tap

37E Intelli-Vent™ Control

Outlet Pressure

Regulator Adjust

Tower

1/8 Threaded Outlet

Pressure Tap

36G Valve

Figure 2. Pressure port and regulator adjust locations

Regulator

Cover Screw

If a valve has been factory-adjusted for the 2.5 to 5 inches

W.C. range, it cannot be field-adjusted outside that range.

1. Turn off all electrical power to the system

2. These models have 1/8 NPT threaded taps. The outlet

pressure tap plug will need to be removed and a separate

hose fitting installed.

3. Attached a hose and manometer to the separate hose

fitting which has been installed in place of the 1/8 NPT

threaded tap.

4. Turn on system power and energize valve.

5. Remove regulator cover screw and turn regulator adjust

screw clockwise (

) to increase pressure, or

counterclockwise ( ) to decrease pressure (see

Plastic

Adjust Screw

Regulator

Spring

Figure 3

3

Page 4

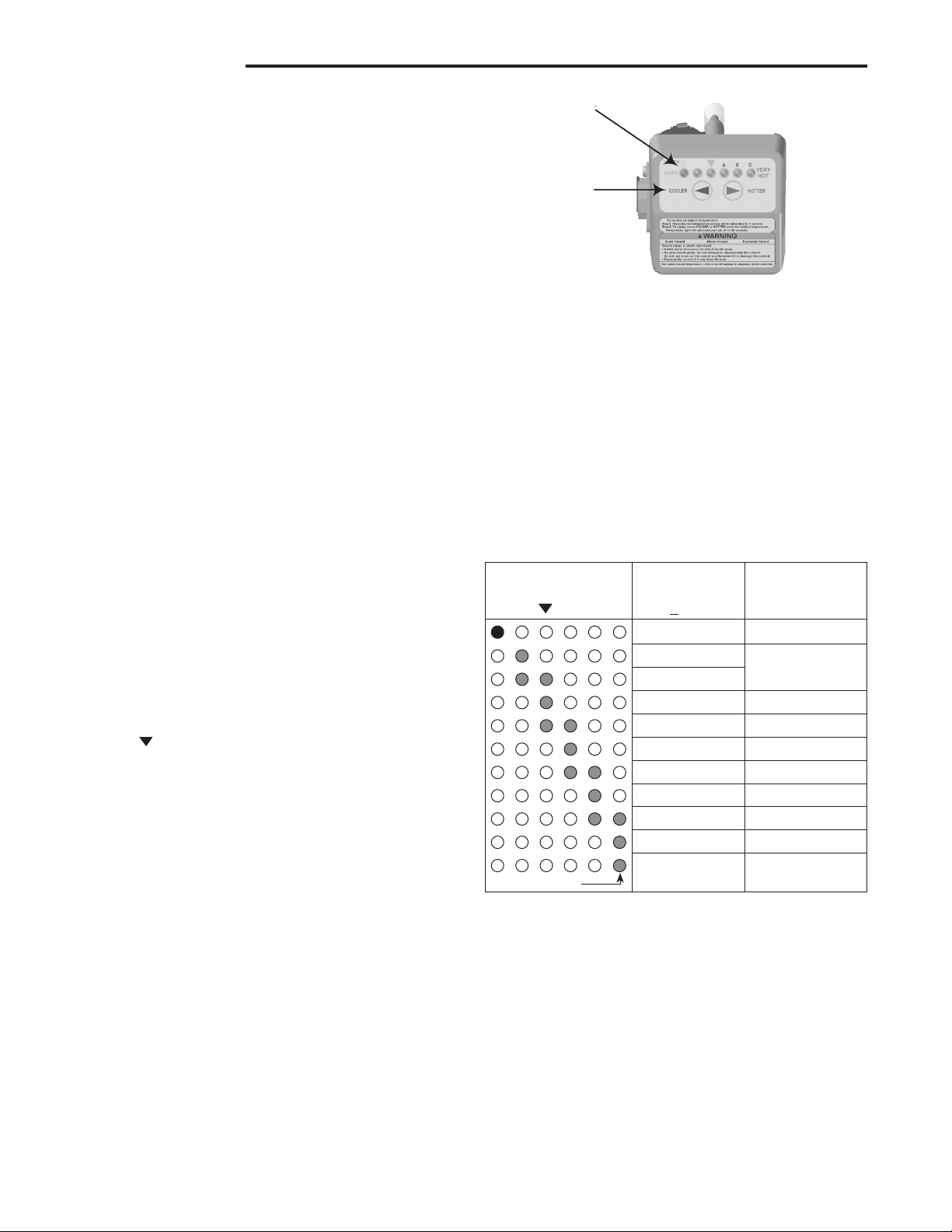

TEMPERATURE

INDICATORS

TEMPERATURE

ADJUSTMENT

BUTTONS

70 (Vacation)

N/A

INSTALLATION

OPERATING INSTRUCTIONS

1. The control uses an automatic ignition system to light

the burner. DO NOT TRY TO MANUALLY LIGHT THE

BURNER.

2. Wait at least five (5) minutes to clear out any gas, and

then smell around the appliance area near the floor. If you

smell gas, STOP! Follow the instructions “What to do if

you smell gas” on the first page of this instruction sheet.

If you do not detect gas, continue with the next step.

3. Make sure that both the inner and outer doors are in place.

These doors are located where the burner tube enters the

water heater at the bottom. Both doors must be in place

for safe operation.

4. Turn on power to the water heater. This can be done either

by turning on the disconnect switch to the water heater,

or plugging in the water heater to a nearby outlet. The installer should have made this provision for you, and it must

meet local and state ordinances or the National Electric

Code, whichever applies.

5. For a brief time (one to five seconds) all of the indicators

on the front of the control should come on, and then turn

off. This indicates that the control has completed the selfdiagnostic test, and is ready for operation. If any combination of indicators remain illuminated, either refer to the

troubleshooting section of this manual, or contact a qualified service person.

6. The water heater is now ready for operation, and will

begin to heat the water to the factory default setting of

approximately 70°F. If an alternate temperature setting is

required, please refer to the following section “Temperature

Regulation”.

Figure 4. Temperature Indicators and Adjustment

b. To increase the temperature press and release the

HOTTER button once. The temperature indicators will

now display the new temperature setting.

Press and release the HOTTER button until you have

reached the desired setting. HOLDING DOWN THE BUTTON

WILL NOT CONTINUE TO RAISE THE SETTING. The Button

must be pressed and released for each temperature change

desired.

To avoid scald injury, set the control to the lowest setting

which will deliver your needed hot water. Refer to Table 1 to

determine the approximate temperature setting, and the approximate time for scald injury at that temperature.

Table 1. Temperature Settings

Display

A B C

Approximate

Temperature

(+10

o

F)

Approximate

Time to Cause

Injury

TEMPERATURE REGULATION

After the gas and electrical connections are made and the

water heater tank is full of water, the control will now start to

heat the water to the factory default setting of approximately

70°F. If a higher setting is desired, start with the setting at the

triangle ( ). This is approximately the 120°F setting, and the

safest and most economical setting for the water heater.

To change the temperature setting for either cooler or warmer

water, the following steps are necessary:

1. “Wake up” the temperature indicators by pressing the

COOLER and HOTTER temperature adjustment buttons at

the same time and releasing after one second (see Figure

4). One or two of the temperature indicators will light up.

These indicators will only remain on for 30 seconds if no

further buttons are pressed. After 30 seconds the control

will go back to “Sleep” mode, and both buttons will again

have to be pressed to see the water temperature setting.

2. If this is the first time that the control has been used, the

leftmost green indicator will be illuminated indicating the

water temperature setting of approximately 70°F. See Table

1 for an explanation of what each of the temperature indicators mean.

a. To decrease the temperature press and release the

COOLER button once. The temperature indicators will

now display the new temperature setting. Press and

release the COOLER button until you have reached the

desired setting. HOLDING DOWN THE BUTTON WILL

NOT CONTINUE TO LOWER THE SETTING. The

Button must be pressed and released for each temperature change desired.

110

115

120

5 minutes

125

130

30 seconds

135

140

5 seconds

145

Flashing

150

160 Under 1 second

1.5 seconds

3. When you have completed setting the control wait 30

seconds to see that the temperature indicators go off and

the control enters “Sleep” mode. ALL OF THE TEMPERA-

TURE INDICATORS WILL BE OFF DURING NORMAL

OPERATION. If any time you see the indicators on, there

may be a system error and you should consult the “Troubleshooting” section of this document, or contact a trained

service professional.

If you use hot water frequently and in short spurts, water temperature can occasionally exceed the temperature setting by

up to 30°F because of the dynamics of the appliance. Keep

this in mind when you are selecting a temperature higher than

the factory default setting.

Be sure to protect babies and the infirm or others with impaired mobility who cannot get out of the hot water quickly.

4

Page 5

WARNING

!

WARNING

!

Scald burns occur in under one second with 160°F

water, which this thermostat will deliver if the

temperature is set at “VERY HOT”. Lower settings of

the temperature will reduce the risk of scald and will

reduce your fuel bill.

They are the people most commonly hurt in scald injuries

and in need of lower temperature and other protection like

supervision, point-of-use temperature control equipment or a

system mixing valve. A point-of-use valve or system mixing

valve can be obtained from your local plumber.

Checking the temperature setpoint may be performed at any

time by the procedure described on step 1 of “Temperature

Regulation” on page 4. No other action is needed for checking temperature setpoint.

SHUTTING OFF THE APPLIANCE

Vacation Shutdown

INSTALLATION

2. Press and release the COOLER button as many times as

needed until the green leftmost indicator is only lit. This

temperature setting is approximately 70°F. Leave the gas

turned on.

3. When returning from vacation reset the temperature to

that you noted in step 1.

Complete Shutdown

1. Turn off the electrical disconnect on the appliance, or

remove the plug from the receptacle, whichever applies.

(Don’t worry; the Intelli-Vent™ control will remember your

correct temperature setting.)

2. Turn off the gas supply to the water heater. The water

heater is now completely shut down.

3. To restart the water heater, follow the instructions in the

section “Operating Instructions”.

There are no user serviceable parts in this control. The

control is supplied with tamper resistant screws. DO NOT

attempt to repair or adjust the control. If you experience problems, discontinue use and replace the control immediately.

Continuing to use a damaged control could result in fire

and/or explosion.

Never allow small children to use a hot water tap, or

to draw their own bath water. Never leave a child or

impaired person unattended in a bathtub or shower.

Scald burns can result

1. “Wake up” the temperature indicators by holding down both

the COOLER and HOTTER temperature adjustment buttons at the same time for one second (see Figure 2). One

or two of the temperature indicators will light up. Make a

note as to which indicators are illuminated so that you can

reset the control to the same setting when you return from

vacation.

Service

If you wish to verify that the water heater is operating properly:

1. Make sure there is power to the water heater.

2. Make sure that the gas is turned on to the water heater.

3. Initiate a call for heat by either drawing hot water from a

nearby faucet or raising the temperature setting (see section “Temperature Regulation”).

4. Watch the ignition sequence and compare it to the “Sequence of Operation” chart on page 7.

5. Note any error codes that appear and proceed to the next

section “Troubleshooting”.

5

Page 6

HIGH

LIMIT

SWITCH

AIR

PRESSURE

SWITCH

COMBUSTION

BLOWER

BLACK

WHITE

GREEN

TO POWER SUPPLY

DISCONNECT

AND OVERLOAD

PROTECTION

IGNITOR AND

FLAME PROBE

ASSEMBLY

INSET

Intelli-Vent™ Wiring Diagram

Typical Installation

(Consult Appliance Manufacturer's Instructions For Details)

BOTTOM VIEW

INTELLI-VENT CONTROL

TM

FLAMMABLE

VAPOR

SENSOR

(IF EQUIPPED)

WIRING DIAGRAM

A typical system wiring diagram is shown below. Use the

water heater manufacturer’s wiring diagram for details of the

installation. Always follow the instructions supplied with the

water heater, and those of the water heater manufacturer.

6

Page 7

SEQUENCE OF OPERATIONS

APPLY POWER TO

APPLIANCE

IS FIELD WIRING

CORRECT?

DISPLAY ERROR CODE

1

OR

2

NO

YES

REQUEST

FOR HEAT

PRESENT?

NO

IS

PRESSURE SWITCH

PROVEN OPEN WITHIN

5

SECONDS?

YES

NO

COMBUSTION

BLOWER ON

YES

IS

PRESSURE SWITCH

PROVEN CLOSED

WITHIN

5

SECONDS?

NO

WAIT FOR PRESSURE

SWITCH TO OPEN

DISPLAY ERROR

NUMBER

3

WAIT FOR PRESSURE

SWITCH TO CLOSE

DISPLAY ERROR

NUMBER

4

PREPURGE

IS

IGNITOR

OKAY?

TURN OFF INDUCER

DISPLAY ERROR CODE

NUMBER

5

NO

IGNITOR ON FOR

WARM-UP TIME

YES

YES

MAIN VALVE OPENS

MAIN

BURNER LIGHTS

AND IS SENSED

DURING TRIAL

FOR

IGNITION

IGNITOR TURNS OFF

YES

NO

IS

FLAME SENSE

LOST?

IS

REQUEST FOR HEAT

SATISFIED?

MAIN VALVE OFF

COMBUSTION

BLOWER OFF AFTER

POST-PURGE DELAY

MAIN VALVE CLOSES

LESS

THAN

3

TRIES

FOR IGNITION?

MAIN VALVE CLOSES

LOST

LESS THAN

3

TIMES?

YES

YES

TURN OFF INDUCER

AFTER POST-PURGE

DISPLAY ERROR

6

ONE HOUR AUTO

LOCKOUT RESET

DELAY

NO

NO

NO

YES

YES

NO

Intelli-Vent™

Sequence of Operation

Please Note:

The control continually monitors

internal circuits and external sensors.

Error codes noted above, and those for

self-diagnostic faults can be found on

pages 8 and 9.

IS

PRESSURE SWITCH

PROVEN OPEN WITHIN

5

SECONDS?

WAIT FOR PRESSURE

SWITCH TO OPEN

DISPLAY ERROR

NUMBER

3

COMBUSTION

BLOWER ON

IS

PRESSURE SWITCH

PROVEN CLOSED

WITHIN

5

SECONDS?

WAIT FOR PRESSURE

SWITCH TO CLOSE

DISPLAY ERROR

NUMBER

4

INTERPURGE

COMBUSTION

BLOWER OFF

YES

NO

NO

YES

YES

7

Page 8

1

An open earth ground circuit to the ignition system

1. Check that the earth ground conductor is properly

connected at the fuse box or breaker panel and the

water heater.

2. Check that the grounding conductors on the water

heater are properly connected and secure.

2

The self diagnostic test

detected a wiring error or

a high resistance to earth

ground

1. Check for proper connection of the line neutral and

line hot wires.

2. Check that the appliance is securely connected to

earth ground.

3

The pressure switch remained closed longer that

5 seconds after the call for

heat began.

1. The pressure switch wiring is incorrect.

2. The pressure switch is defective and must be

replaced.

ABC

4

The pressure switch remained open longer than 5

seconds after the combustion blower was energized

1. The pressure switch wiring is incorrect.

2. The pressure switch tubing is not connected correctly.

3. Obstructions or restrictions in the water heater air

intake or exhaust flue.

ABC

5

The self diagnostic test has

detected an error in the Hot

Surface Ignitor circuit.

1. Check that all wiring is correct and secure.

2. Disconnect the ignitor and measure the ignitor resistance with an accurate ohmmeter between pins

1 and 2. Resistance should be between 11.5 and

18.8 ohms. If the reading is incorrect, replace the

Hot Surface Ignitor.

3. If the above checks are good, replace the INTELLIVENT™ control.

ABC

6

The maximum number of

ignition retries or recycle

has been reached and the

system is in lockout

1. Check if the gas supply is off or too low to operate.

2. Check that the flame sense rod to see that it is

located properly and free from contamination.

Reposition the flame sense rod or lightly clean with

an abrasive cloth.

3. The Hot Surface Ignitor may not be positioned correctly. Reposition as necessary.

4. The Hot Surface Ignitor and Flame Sense Rod

wired correctly and in good working condition.

Repair as required.

5. Low voltage to the water heater. Check and repair.

TROUBLESHOOTING

2341

The troubleshooting charts cover the error codes that the

Intelli-Vent™ control can recognize, the potential cause, and

those actions that may help repair the problem. The water

heater manufacturer’s troubleshooting procedure should be

consulted before attempting to repair the appliance. The water heater manufacturer’s instructions take priority over the

instructions here.

If for any reason you question your ability, or feel any doubt

about your ability to perform any of the troubleshooting procedures or repairs recommended. STOP! Contact a trained

and qualified service professional to repair the water

heater.

To troubleshoot the system using the error code indicators:

1. Check that the system is currently active and calling for a

request for heat. You can initiate a call for heat by either

drawing hot water from a nearby faucet or raising the tem-

Error Indication Check, Repair, or Replace

perature setting (see section “Temperature Regulation”).

If you have noted an error code from a previous heating

cycle, this step is not necessary, and you may proceed

with the next step.

2. Refer to the troubleshooting charts on below to find the

error code that is displayed. Check and repair those items

recommended.

3. Once the repair is complete, again initiate a call for heat,

and observe that the ignition sequence complies with that

shown on page 7.

4. After the water heater repair is complete, return the water

heater temperature setting to the original temperature. If

for any reason you cannot remember the original setting,

return the setting to the 120

o

F setpoint. See the section

“Temperature Regulation” for assistance in setting the water temperature setting.

8

Page 9

TROUBLESHOOTING

ABC

7

The self diagnostic test

found a problem with the

gas valve driver circuit

1. Cycle power to the water heater off for 10 seconds

and then back on.

2. If the above step did not cleat the error, the INTELLI-VENT™ control must be replaced

ABC

8

The self diagnostic test has

detected a problem with

the internal microcomputer.

1. Cycle the external power off for 10 seconds and

then back on.

2. If the above step does not clear the error, the

INTELLI-VENT™ control must be replaced.

ABC

9

The self diagnostic test has

detected a problem with

the internal circuit

1. Cycle the external power off for 10 seconds and

then back on.

2. If the above step does not clear the error, the

INTELLI-VENT™ control must be replaced.

ABC

10

Flame signal sensed out of

proper sequence.

1. Replace the INTELLI-VENT™ control.

ABC

11

The high temperature thermal cutoff is open

1. Replace the INTELLI-VENT™ control.

ABC

12

The diagnostic test has detected one of the temperature adjust buttons stuck

closed

1. Make sure that there are no objects leaning against

the front of the control.

2. Lightly press and release each of the buttons once.

3. If the above actions do not clear the error, the

control will continue to regulate water temperature

at the last setting, but you not be able to change

settings unless you replace the INTELLI-VENT™

control.

ABC

13

The self diagnostic test

has detected that the water

temperature sensor is either open or short circuited.

1. Check that all wiring is correct and that there are no

open or shorted circuits.

2. If no wiring problems are found the INTELLIVENT™ control must be replaced by a qualified

service person.

ABC

14

The self diagnostic test

found a problem with the

Flammable Vapor Sensor

1. Check that all wiring is correct and that there are no

open or shorted circuits.

2. If no wiring problems are found the flammable

Vapor Sensor must be replaced.

ABC

15

The control detected the

presence of flammable

vapors near the appliance

and entered lockout.

1. If you smell gas, STOP! Follow the instructions,

“What to do if you smell gas” on page 1 of this

instruction sheet. Otherwise call a qualified service

person for replacement of the control.

Page 10

NOTES

10

Page 11

NOTES

11

Page 12

White-Rodgers is a division

of Emerson Electric Co.

The Emerson logo is a

trademark and service mark

of Emerson Electric Co.

www.white-rodgers.com

www.emersonclimate.com

Loading...

Loading...