Page 1

WHITE-RODGERS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

These relay-hot water controls combine a high limit control, a

transformer, a circulator relay, and wiring terminals into a single

unit. They are suitable for use on boilers equipped with a 24 volt

or millivolt gas valve.

These controls are designed primarily for use on boilers that do

not supply domestic hot water. (However, they are equipped

with an extra terminal to permit them to be used on boilers with

a tankless domestic coil by the addition of a separate SPDT low

limit-circulator control on systems using a 24 volt gas valve.)

The internal transformer supplies power for operating a gas

valve as well as the relay coil. On systems zones with motorized

water valves, the internal transformer may also be used for

powering some (or all) of the water valves.

8J48A

Relay-Hot Water Control

For use with 24 VAC or Self-Generating Gas Valve

(Suitable for External Zone Valve Load)

INST ALLA TION INSTRUCTIONS

DESCRIPTION

If in doubt about whether your wiring is millivolt, line, or low

voltage, have it inspected by a qualified heating and air conditioning contractor, electrician, or someone familiar with basic

electricity and wiring.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical codes

and ordinances.

This control is a precision instrument, and should be handled

carefully. Rough handling or distorting components could cause

the control to malfunction.

ELECTRICAL RATINGS

Input Voltage: 120 VAC, 60 Hz

Circulator Motor: 8.0 Amps Full Load Current (120 VAC)

48.0 Amps Locked Rotor Current (120 VAC)

Gas Valve: 24.0 VAC, 0.65 Amp OR

Millivolt Systems (0.25 to 1.0 VDC, 0.25 Amp)

Combined Load of Zone Valves:

Internal transformer (terminals TV and Z) may be used for

supplying power to four W-R Type 1311 or three Type 1361

zone Valves. (For other zone valves, total zone valve load is not

to exceed 1.2 Amp.)

PRECAUTIONS

CAUTION

!

To prevent electrical shock and/or equipment damage,

disconnect electric power to system, at main fuse or

circuit breaker box, until installation is complete.

WARNING

!

Do not use on circuits exceeding specified voltage.

Higher voltage will damage control and could cause

shock or fire hazard.

Do not short out terminals on gas valve or primary

control to test. Short or incorrect wiring will burn out

heat anticipator. Personal injury and/or property damage may result from shorted or incorrect wiring.

SPECIFICATIONS

ROOM THERMOSTAT

Set adjustable heater (anticipator) at 0.25, or use a fixed heater

with a 0.25 Amp rating.

HOT WATER CONTROLS

Range: High Limit – 140° to 240°F. (Some models have a

Preset Dial Stop. Adjustments should be made by

authorized service personnel only.)

Differential: High Limit – 8°F Fixed

Switch Action: High Limit – Open on rise

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS ROAD

ST. LOUIS, MISSOURI 63123-5398

Printed in U.S.A.

PART NO. 37-4013C

Replaces 37-4013B

9522

Page 2

INSTALLATION

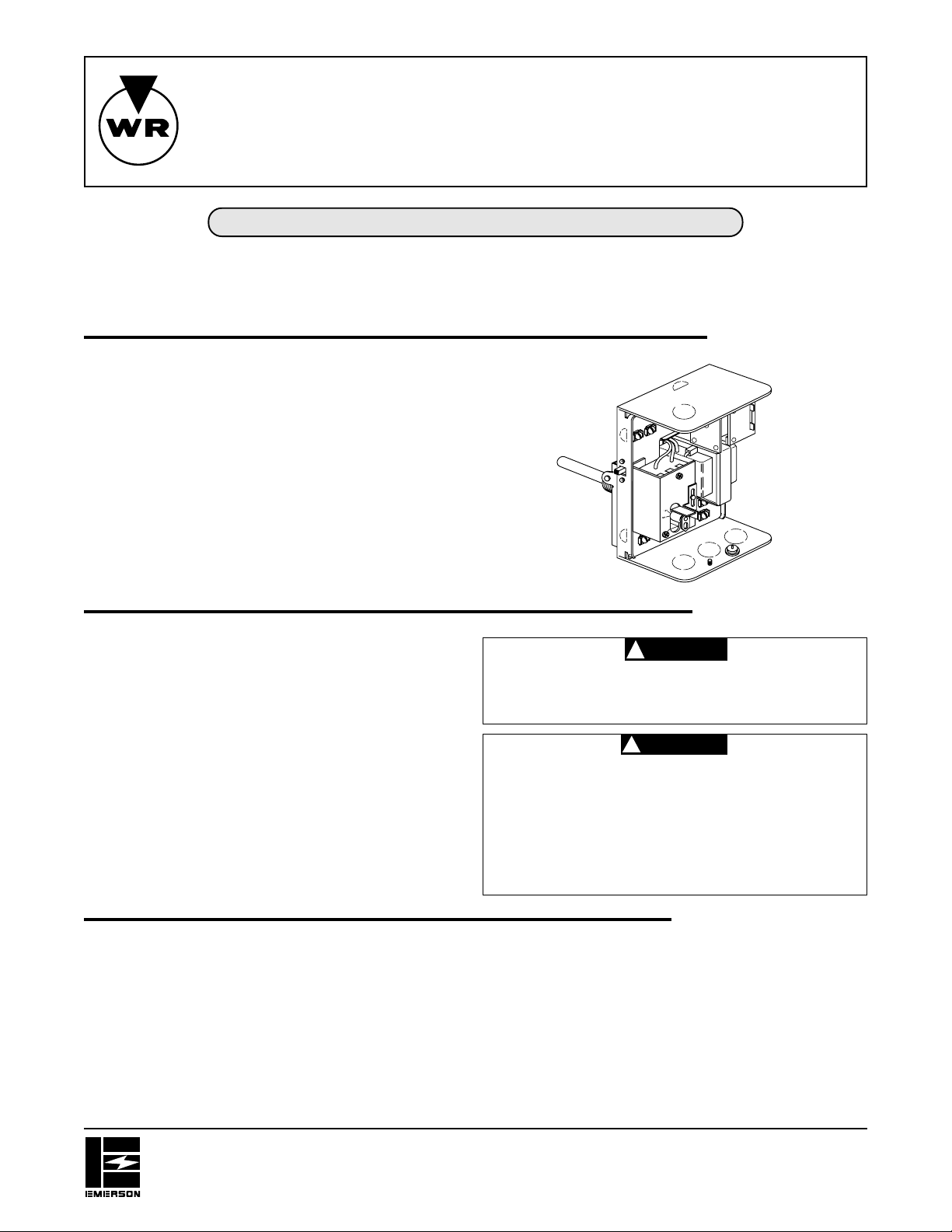

NOTE

If the boiler manufacturer recommends a control location, then

follow such recommendations. Otherwise, locate the control as

close to the top of the boiler as possible, but not in the same

section of the boiler that has fittings for domestic hot water.

Never locate the control near a return pipe to the boiler.

PREPARING TO MOUNT CONTROL

This control can be mounted vertically or horizontally.

1. Loosen the set-screw holding the well in place (see fig. 1).

2. Push down and out on the well and carefully slide the

capillary tube in slot.

3. Place the well in new notch and tighten the set-screw to

secure the well in the new position.

MOUNTING THE CONTROL

1. Disconnect electrical power to the boiler.

2. Completely drain the boiler.

3. If a well tapping is not provided, prepare one near the top of

the boiler.

4. Sparingly apply pipe joint compound to the well threads and

install well.

NOTE

Use hex on well for tightening the well. Do not attempt to tighten

by using the case as a handle.

5. Refill the boiler and check for water leaks.

6. Insert the bulb element into the well until it bottoms.

7. Locate and secure the coil of excess tubing so that it cannot

touch electrical components.

8. Fit the back of the case into the well and tighten using the setscrew on the back panel.

Slot

Capillary

Tube

Well

Set-screw

Figure 1

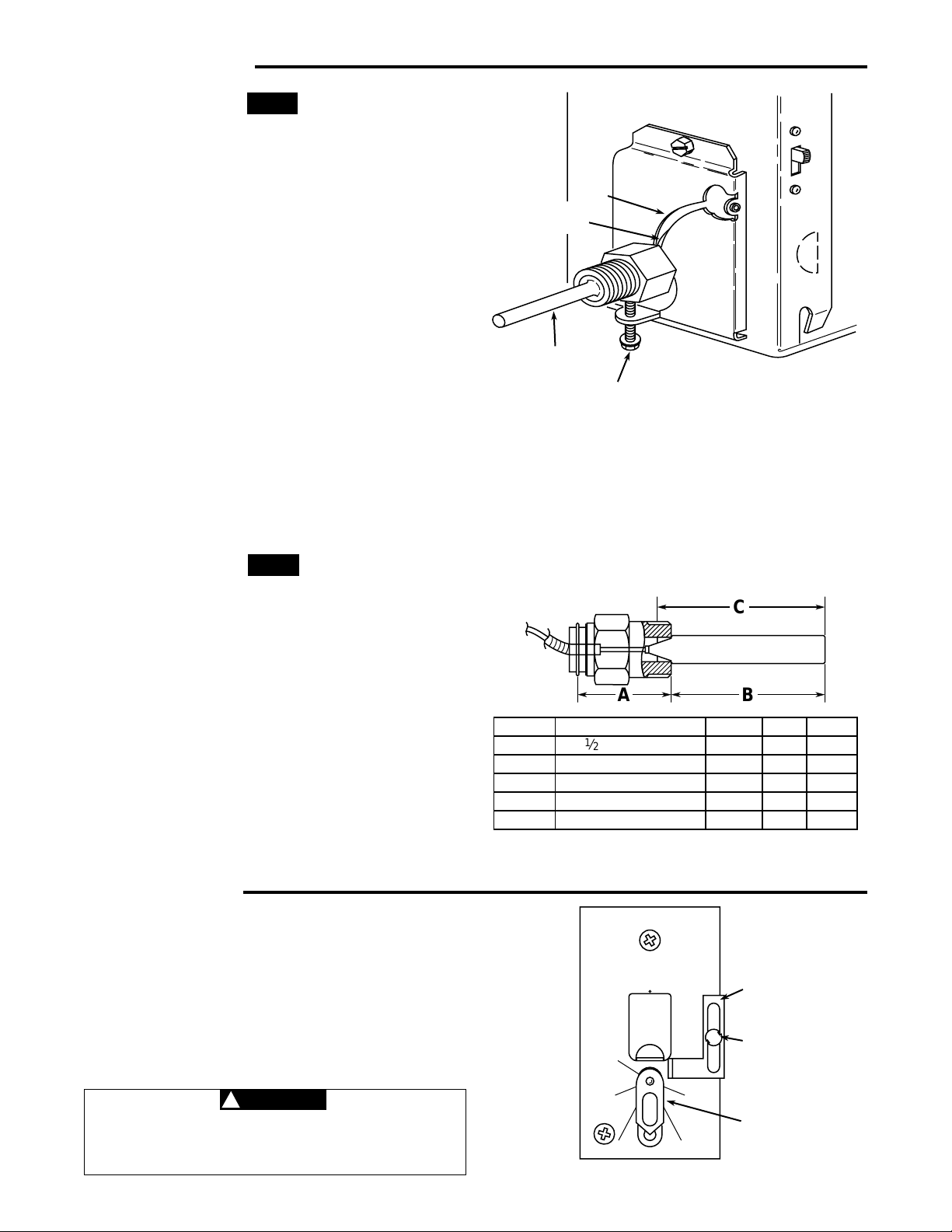

MOUNTING TO EXISTING WELL

(For use with well adaptor, which may be ordered separately.)

For best control performance, a well comparable to that shown

in fig. 2 is recommended. However, by using a heat conductive

grease, these controls will give satisfactory performance when

used with large-diameter existing wells. If desired, both the

conductive grease and replacement wells may be ordered

separately (see fig. 2).

C

AB

Well No. Description A B C

89-0211

89-0212

89-0213

89-0214

89-0215

Conductive Grease No. 145-0163

1

⁄2” Std. Shank

1

⁄2” Std. Ext. Shank

3

⁄4” Std. Shank

3

⁄4” Std. Ext. Shank

3

⁄4” Extra Ext. Shank

13

⁄16”

1

5

3

⁄16”

13

1

⁄16”

5

3

⁄16”

13

4

⁄16”

3”

3”

3”

3”

3”

5

3

⁄16”

5

3

⁄16”

5

3

⁄16”

5

3

⁄16”

5

3

⁄16”

DIAL SETTING

When replacing an existing control, adjust the setting of the high

limit to correspond with that of the old control.

Set the pointer to the temperature at which the contacts of the

high limit are to open (see fig. 3)

Models with a preset dial stop are to be adjusted by authorized

service personnel only.

To reset the dial stop, loosen the stop adjust screw and reposition the stop to the desired setting.

Retighten the stop adjust screw.

WARNING

!

DO NOT set the stop higher than the original

manufacturer’s recommended setting. Personal injury

and/or property damage may result.

2

Figure 2

140

160 220

200180

Figure 3

Stop

Stop

Adjust

Screw

Pointer

Page 3

WIRING AND OPERATION

All wiring should be installed according to local and national electrical codes and ordinances.

Figure 4 shows wiring connections for a typical installation using

the 8J48A with a 36C03 or a 36C53 24V manifold gas valve.

Figure 5 shows wiring connections for the 8J48A with a 36C03U

or 36C53U self-generating gas valve. Operation is as follows:

As the room thermostat contacts close, the relay coil is energized and closes its two sets of relay contacts. The manifold gas

valve opens as the no. 1 relay contacts close, while the circulator

motor starts as the no. 2 relay contacts close.

When the room thermostat opens its contacts, the manifold gas

valve closes and the circulator motor stops.

If the boiler temperature exceeds the setting of the high limit

while the thermostat is calling for heat, the high limit will close the

gas valve but permit the circulator to run as long as the

thermostat is calling for heat.

Transformer

No. 2 Relay

Contacts

Hot

C1

L1

120 VAC

Room Thermostat

L2

Neutral

C2

AUTO/MANUAL SWITCH

NOTE

For manual operation of self-generating millivolt systems

only.

The manual switch, located on the outside of the controls case,

allows operation of the burner during power failures. When the

switch is set to MANUAL, the burner will operate continuously

until the high limit temperature is reached. The circulator, which

requires line voltage to operate, will not function in MANUAL

mode. When power is restored, reset the switch to AUTO to

resume automatic operation.

Factoryinstalled

Jumper

Z W TP

Low Voltage

Field-

installed

Jumper

T

TV

Manual

Switch

High

Limit

B

No. 1 Relay

Contacts

36C

Gas Valve

TH TH-TR TR

B2

INTERNAL WIRING

EXTERNAL WIRING

Hot

L1

120 VAC

L2

Neutral

INTERNAL WIRING

Line Voltage

Low Voltage

EXTERNAL WIRING

Line Voltage

Low Voltage

Line Voltage

Low Voltage

Line Voltage

Low Voltage

C1

C2

No. 2 Relay

Contacts

Circulator

Motor

Figure 4. 24 Volt AC Gas Valve

Factoryinstalled

Transformer

Jumper

Z W TP

Low Voltage

Room Thermostat

Circulator

Motor

Figure 5. Millivolt Gas Valve

T

TV

B3

B3

Manual

Switch

No. 1 Relay

Contacts

B2

High

Limit

B

36C

Gas Valve

TH TH-PG PG

B1

To 750 MV

Thermopile

B1

3

Page 4

WIRING AND OPERATION (cont’d)

Figure 7. Alternate Connections for using Separate

Low Limit-Circulator Control on

Boiler with Tankless Domestic Coil

Z

BL

W

RWB

Low Limit

Circulator

Control

NOTE: Remove external jumper

between W and Z terminals

Thermostat

8J48A

W-R

1361

Zone

Valves

2

13

TV

Z

24V

Gas

Valve

T

B3B1

Hot

Figure 6. Typical Connections for

Zoning with 2-Wire Zone Valves

LINE

C2C1

L2L1

Neutral

Circulator

Motor

Line Voltage

Low Voltage

36C Series

Gas Valve

Thermostat

Zone 1

FactoryInstalled

Jumper

TR TH-TR TH

TWTV

B1 B2 B3 L1 L2

BZTP

8J48A

C1

C2

Thermostat

829A

Relay

Circulator

Zone 1

Zone 2

531

246

Circulator

Field-

Installed

Jumper

Zone 2

Figure 8. 8J48A - 24 Volt Systems Zoned with Circulators

Thermostat

Zone 1

Thermostat

Zone 2

829A

Relay

Thermostat

Zone 3

531

24

6

Circulator

Thermostat

Zone 3

Field-

Installed

Jumper

Zone 3

Neutral

120 V

Hot

TWTV

B1

B2 B3 L1 L2

FactoryInstalled

Jumper

To 750 MV

Thermopile

Line Voltage

Low Voltage

36C Series

Gas Valve

PG TH-PG TH

Figure 9. 8J48A - Millivolt Systems Zoned with Circulators

BZTP

8J48A

C1

C2

829A

Relay

Circulator

Zone 1

531

246

Circulator

Field-

Installed

Jumper

Zone 2

829A

Relay

531

24

6

Circulator

Field-

Installed

Jumper

Zone 3

Neutral

120 V

Hot

Loading...

Loading...