WARNING

!

WHITE-RODGERS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

The type 668 Oil Burner Control provides safe operation

of oil burners on heating plants where ignition during the

entire burner cycle is desired.

The 668 is used with the 956 Flame Detector

* Formerly called constant ignition.

If in doubt about whether your wiring is millivolt, line, or

low voltage, have it inspected by a qualified heating and

air conditioning contractor, electrician, or someone familiar with basic electricity and wiring.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical

codes and ordinances.

This control is a precision instrument, and should be

handled carefully. Rough handling or distorting components could cause the control to malfunction.

TYPE 668

Intermittent Ignition* – Non Recycling

OIL BURNER CONTROL

With Series 956 Flame Detector

INSTALLATION INSTRUCTIONS

DESCRIPTION

PRECAUTIONS

CAUTION

!

To prevent electrical shock and/or equipment

damage, disconnect electric power to system, at

main fuse or circuit breaker box, until installation

is complete.

Do not use on circuits exceeding specified voltages. Higher voltages will damage control and

could cause shock or fire hazard.

Electrical Data

Input voltage: 668 120V. AC, 60Hz.

668H 220V. AC, 50/60Hz.

Maximum Load Current:

Oil Burner Motor (Orange Wire):

10 Amps F.L. 60 Amps L.R.

Ignition Transformer:

360VA (3.0 Amps)

Relay Voltage: 668 24 Volts AC, 60Hz.

668H 24 Volts AC, 50/60Hz

The proper Location and Mounting of the primary oil

burner control panel on the burner and the flame detector

with respect to the oil flame shall be determined by the

furnace, boiler, or burner manufacturer.

If this control, supplied as part of a furnace, boiler or

burner, is wired to the equipment or if the manufacturer

of such equipment provides instructions for wiring this

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, Fax (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, FAX (905) 475-4625

Printed in U.S.A.

SPECIFICATIONS

Room Thermostat:

Set adjustable heat anticipator at 0.4 Amps. For fixed

anticipation thermostats, use 0.35 to 0.45 Amp.

heater.

Safety Timing:

668, 668H-401 to 499: 45 seconds

668, 668H-501 to 599: 30 seconds

668, 668H-601 to 699: 15 seconds

INST ALLATION AND WIRING

control, then follow his recommendations. If no special

wiring instructions are given, then follow the electrical

connections shown on this diagram for a simple system.

For more complicated systems, especially for hot water

heating, consult the manufacturer of the heating plant for

full details of the desired sequence of control operation.

PART NO. 37-5456A

Replaces 37-1794 &

37-9517

9510

INSTALLATION AND WIRING CONT.

All wiring should be done in accordance with local and national electrical codes and ordinances.

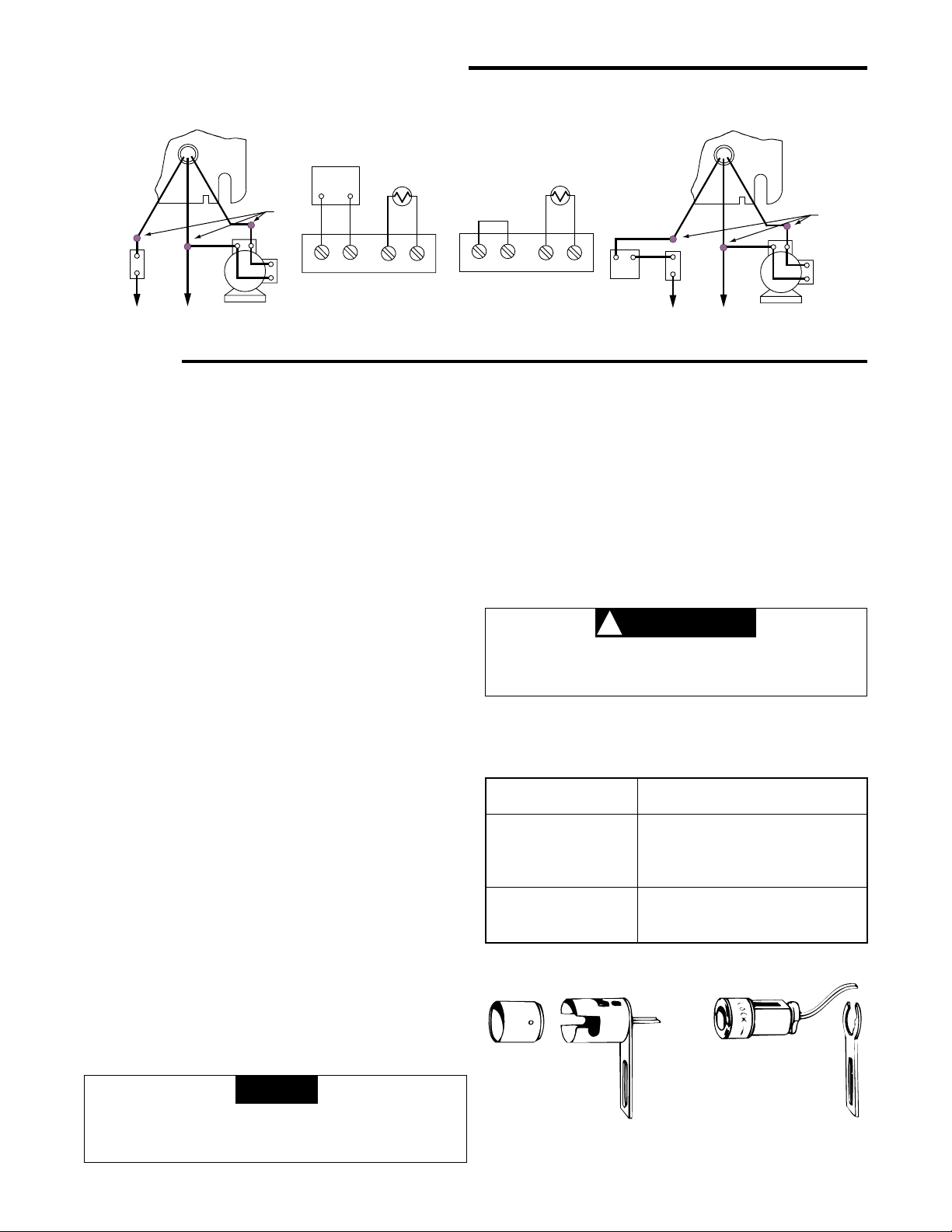

LOW VOLTAGE PRIMARY CONTROL

LINE VOLTAGE PRIMARY CONTROL

PRIMARY

CONTROL

BLACK

WHITE

LIMIT

LINE

HOT

External Line Voltage Wiring

ORANGE

IGN.

TRANS.

BURNER

N

MOTOR

THERMOSTAT

DETECTOR

WIRE

NUTS

T

TFF

FLAME

TESTING

The following control checks should be made after each

installation to insure that the controls are correctly wired

and functioning properly.

1. Open the main line switch.

2. Adjust thermostat or operating control to call for heat.

3. Operate the manual reset button on top of control.

4. Make certain that high limit control is set at the correct

temperature.

5. Open the hand valve in the oil line. The system is now

ready for the following tests.

A. NORMAL CYCLE:

Close the line switch. The burner should start and

continue to run normally. (If burner starts, establishing flame, but then locks out on safety, make “Flame

Detector Check” at this time.

B. SAFETY TIMING:

1. Let the burner run for about 5 minutes. Then remove

one of Flame Detector leads from the “F” terminals.

After a time period corresponding to the safety timing

has elapsed, the control should lock out on safety,

stopping the burner.

2. Open the line switch.

3. Replace Flame Detector lead removed in step 1.

4. Wait about 3 minutes. Then operate the manual reset

button on top of control.

C. HIGH LIMIT AND THERMOSTAT CHECK:

1. Close the line switch to start the burner.

2. Lower the setting of the high limit control to its lowest

setting. This should stop the burner, unless furnace or

boiler temperature is below the minimum setting of the

high limit.

3. Return high limit control to its proper setting. Burner

should restart.

4. With the burner running, turn thermostat to its lowest

setting. This should stop the burner, unless actual

room temperature is below the lowest setting of the

thermostat.

NOTE

On systems supplying domestic hot water, burner

will continue to run if low limit control is not

satisfied.

PRIMARY

FLAME

DETECTOR

FIELD

INSTALLED

JUMPER

T

TFF

LINE VOLTAGE

THERMOSTAT OR

OPERATING

CONTROL

CONTROL

BLACK

WHITE

LIMIT

LINE

HOT

External Line Voltage Wiring

ORANGE

BURNER

N

MOTOR

IGN.

TRANS.

WIRE

NUTS

5. Return thermostat to its proper setting.

D. FLAME DETECTOR CHECK: (This test is not re-

quired if the control performs as described in test

A.)

If the burner starts but the control locks out (stopping the

burner), check the flame detector as follows:

1. Open the line switch.

2. Connect one end of a wire jumper to one of the “F”

terminals.

3. Start the burner by closing the line switch. As soon as

the flame has been established, connect the other end

of the wire jumper to the other “F” terminal.

WARNING

!

The control provides no safety protection with

this jumper installed. Do NOT leave burner in this

condition except for making this check.

If the control still locks out with the jumper installed, the

control should be replaced. If the control does not lock out,

however, check the operation of the 956 flame detector as

follows:

Possible Cause of Correction

Trouble

Open circuit in Cell Replace Cell (or Cell Assembly)

of 956 Flame Detector. Do not

disturb position of bracket or

socket assembly.

Flame detector Locate flame detector according

improperly positioned. to the burner manufacturer’s

specifications.

TYPE 956 FLAME DETECTORS

OLD STYLE

CELL

2

SOCKET

ASSEMBLY

Rotate Cell Assembly counterclockwise to remove it.

To replace it insert end

through notched opening in

bracket and rotate clockwise. NOTE: If bracket is

ever removed from burner,

Cell Assembly will not fit if

bracket is reinstalled backwards.

NEW STYLE

CELL ASSEMBLY

BRACKET

TESTING CONT.

WARNING

!

PART No. OF REPLACEMENT PART

F142-0006 Cell only (Old Style)

4. If safety lockout problem is of an occasional nature

the following additional check may be made to

insure that flame detector location is not a marginal

one:

a. Disconnect flame detector leads from “F” terminals.

b. Attach a jumper wire to one “F” terminal. Start burner.

Then immediately connect jumper wire to the other “F”

terminal. Burner should continue to run.

c. With burner running, attach flame detector leads to an

accurate ohmmeter. Reading of ohmmeter should be

below 1000 ohms, and preferably as low as 500 ohms.

NOTE

If indicator of ohmmeter remains steady, readings

up to 2000 ohms should also be acceptable. Generally, though, the lower the reading, the better the

application, and less likely the chance of a variation

in the burner flame causing a safety lock-out.

d. If resistance of flame detector is over 1000 ohms, it may

not be able to see the burner flame properly. Check

alignment of the flame detector through the hole in the

static pressure disc. Clean this hole if it is blocked by

foreign matter. Check for broken “F” wires.

e. If flame detector alignment is good but resistance is still

high, readjustment of burner flame and/or nozzle replacement may be necessary (according to burner

manufacturer’s instructions).

Be sure to remove wire jumper after finishing this

flame detector check.

3

WHITE-RODGERS

AVERTISSEMENT

Utilisateur : conservez ces instructions pour vous y référer au besoin !

SI VOUS NE LISEZ PAS ATTENTIVEMENT CES INSTRUCTIONS AVANT

D’INSTALLER ET D’UTILISER LA COMMANDE, VOUS RISQUEZ DE CAUSER DES

BLESSURES ET DES DOMMAGES MATÉRIELS.

La commande de brûleur à mazout modèle 668 assure le

fonctionnement sécuritaire des brûleurs d’installations de

chauffage qui demandent un allumage durant tout le cycle du

brûleur.

Le modèle 668 est employé avec le détecteur de flamme 956.

COMMANDE DE BRÛLEUR À MAZOUT

à allumage intermittent et sans remise en route

MODÈLE 668

avec détecteur de flamme Série 956

DESCRIPTION

Si vous n’êtes pas certain de la tension du câblage de votre

système (soit en millivolts, à basse tension ou à la tension du

secteur), faites inspecter celui-ci par un électricien, un entrepreneur agréé en chauffage et climatisation ou une personne

qui a des connaissances de base en électricité et en câblage.

Ne dépassez pas les charges nominales.

Tout le câblage doit être conforme aux codes et règlements

locaux et nationaux qui régissent les installations électriques.

Votre commande est un appareil de précision qui doit être

manipulé avec soin. Elle peut se détraquer si elle est manipulée

de façon négligente ou si des composantes sont endommagées.

Charges électriques

Tension absorbée : 668 120 V c.a., 60 Hz;

668H 220 V c.a., 50/60 Hz.

Courant maximum en charge :

Moteur de brûleur à mazout (fil orange) :

10 A F.L.; 60 A L.R.

Transformateur d’allumage :

360 VA (3,0 A).

Tension du relais : 668 24 V c.a., 60 Hz;

668H 24 V c.a., 50/60 Hz

La fabricant de l’appareil de chauffage ou du brûleur déterminera

où et comment installer le panneau de commande sur le brûleur

à mazout et le détecteur de flamme par rapport à la flame.

Si la commande, ayant été livrée avec un appareil de chauffage,

est raccordée à l’appareil, ou encore si le fabricant a fourni des

directives pour son raccordement, veuillez alors suivre ces

PRÉCAUTIONS

ATTENTION

Pour prévenir les risques d’électrocution et de dommages

matériels, coupez l’alimentation du système au panneau

de distribution électrique principal pendant toute la durée

de l’installation.

N’installez pas cet appareil sur des circuits qui dépassent

la tension nominale. Une tension trop élevée peut endommager la commande et poser des risques d’électrocution et

d’incendie.

SPÉCIFICATIONS

Thermostat d’ambiance :

Réglez l’anticipateur à 0,4. Pour les thermostats à anticipation

fixe, assurez-vous que l’anticipation se trouve entre 0,35 et

0,45 A.

Délais de sécurité :

Modèles 668-401 à -499 : 45 secondes

Modèles 668-501 à -599 : 30 secondes

Modèles 668-601 à -699 : 15 secondes

INSTALLATION ET CÂBLAGE

recommandations. Si aucune directive de câblage n’a été

fournie, veuillez vous fier au schéma de câblage ci-dessous

dans le cas d’un système simple.

Pour un système plus complexe, en particulier en ce qui a trait

au chauffage à l’eau chaude, veuillez obtenir du fabricant de

l’appareil de chauffage tous les détails du cycle de commande.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, Télécopieur (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, Télécopieur (905) 475-4625

Imprimé aux États-Unis

No de pièce 37-5456A

Remplace : 37-1794 &

37-9517

9510

INSTALLATION ET CÂBLAGE (SUITE)

AVERTISSEMENT

T

TFF

T

TFF

ORANGE

MARRETTES

THERMOSTAT

DÉTECTEUR

DE FLAMME

DÉTECTEUR

DE FLAMME

CAVALIER INSTALLÉ

SUR PLACE

THERMOSTAT OU

COMMANDE À LA

TENSION DU

RÉSEAU

TRANSFO

D’ALLUMAGE

COMMANDE

PRINCIPALE

BLANC

NOIR

LIMITEUR

RÉSEAU

SOUS

TENSION

N

MOTEUR DE

BRÛLEUR

MARRETTES

TRANSFO

D’ALLUMAGE

MOTEUR DE

BRÛLEUR

ORANGE

COMMANDE

PRINCIPALE

BLANC

NOIR

LIMITEUR

RÉSEAU

SOUS

TENSION

N

Tout le câblage doit être conforme aux codes et règlements locaux et nationaux qui régissent les installations électriques.

COMMANDE PRINCIPALE À LA TENSION DU RÉSEAU

COMMANDE PRINCIPALE À LA TENSION DU RÉSEAU

Câblage externe à la tension du réseau

ESSAIS

Une fois l’installation complétée, il est recommandé de mettre

le système à l’essai pour s’assurer de son bon fonctionnement.

1. Ouvrez l’interrupteur principal.

2. Réglez le thermostat ou la commande principale de façon

3. Appuyez sur le bouton de remise en route manuel situé sur

4. Assurez-vous que le point de consigne du limiteur à

5. Ouvrez le robinet d’alimentation en mazout. Vous êtes

A. CYCLE NORMAL :

B. DÉLAI DE SÉCURITÉ :

1. Laissez le brûleur fonctionner pendant environ 5 minutes.

2. Ouvrez l’interrupteur principal.

3. Rebranchez le fil du détecteur de flamme que vous avez

4. Attendez environ 3 minutes, puis appuyez sur le bouton de

C. VÉRIFICATION DU LIMITEUR À MAXIMUM ET DU

1. Fermez l’interrupteur principal afin de mettre le brûleur en

2. Réglez le limiteur au point de consigne le plus bas possible.

3. Réglez maintenant le limiteur au point de consigne normal.

4. Alors que le brûleur est en marche, réglez le thermostat au

Dans les installations qui fournissent l’eau chaude domestique, le brûleur restera en marche si le limiteur à minimum

n’a pas été satisfait.

5. Réglez maintenant le thermostat au point de consigne

à engendrer un appel de chaleur.

le dessus de la commande.

maximum est réglé à la bonne température.

maintenant prêt à procéder aux essais suivants.

Fermez l’interrupteur principal. Le brûleur devrait se mettre

en marche et fonctionner normalement. (Si le brûleur

démarre et allume la flamme, puis engage le blocage de

sécurité, procédez immédiatement à la « Vérification du

détecteur de flamme ».)

Débranchez ensuite un des fils du détecteur de flamme,

qui sont raccordés aux bornes F. Une fois que le délai de

sécurité s’est écoulé, la commande devrait engager le

blocage de sécurité et arrêter le brûleur.

débranché à l’étape 1.

remise en route manuel qui est situé sur le dessus de la

commande.

THERMOSTAT :

marche.

Le brûleur devrait s’arrêter, sauf si la température de

l’appareil de chauffage est inférieure au point de consigne

minimum du limiteur.

Le brûleur devrait se remettre en marche.

point de consigne le plus bas possible. Le brûleur devrait

s’arrêter, sauf si la température ambiante est inférieure au

point de consigne minimum du thermostat.

normal.

NOTE

Câblage externe à la tension du réseau

D. VÉRIFICATION DU DÉTECTEUR DE FLAMME : (CET

ESSAI EST SUPERFLU SI LA COMMANDE A BIEN

FONCTIONNÉ LORS DE L’ESSAI A.)

Si le brûleur se met en marche, mais la commande engage le

blocage de sécurité (arrêtant ainsi le brûleur), vérifiez le

détecteur de flamme :

1. Ouvrez l’interrupteur principal.

2. Raccordez une extrémité d’un cavalier à une des bornes

F.

3. Mettez en marche le brûleur en fermant l’interrupteur

principal. Dès que la flamme s’allume, raccordez l’autre

extrémité du cavalier sur l’autre borne F.

Lorsque ce cavalier est en place, le blocage de sécurité de

la commande est contourné. NE LAISSEZ PAS le brûleur

fonctionner ainsi, sauf pour effectuer cet essai.

Si le blocage de la commande s’engage de nouveau, veuillez

faire remplacer la commande. Si, au contraire, elle ne s’arrête

pas, veuillez vérifiez de la façon suivante le fonctionnement du

détecteur de flamme 956 :

Cause possible du

problème

Circuit ouvert dans

le détecteur

Détecteur mal

placé

Remplacez le détecteur. Ne

déplacez pas le support ni la douille.

Placez le détecteur conformément

aux directives du fabricant du

Correctif

brûleur.

DÉTECTEURS DE FLAMME MODÈLE 956

DÉTECTEUR

2

ANCIEN MODÈLE

DOUILLE

Pour détacher le module

détecteur, tournez-le à gauche.

Pour le replacer, insérez-le

dans l’encoche du module et

tournez à droite. NOTE : Si le

support est détaché du brûleur,

il faut prendre soin de le

réinstaller dans le même sens,

sans quoi le module ne s’y

adaptera plus.

NOUVEAU MODÈLE

MODULE DÉTECTEUR

SUPPORT

ESSAIS (SUITE)

AVERTISSEMENT

NOS DES PIÈCES DE RECHANGE

F142-0006 Détecteur deul (ancien modèle)

4. Si le problème lié au blocage de sécurité n’est

qu’occasionnel, procédez à l’essai suivant pour vous

assurer que l’emplacement du détecteur est convenable.

a. Débranchez des bornes F les fils du détecteur.

b. Branchez un cavalier sur une des bornes F. Mettez le

brûleur en marche. Raccordez immédiatement l’autre

extrémité du cavalier sur l’autre borne F. Le brûleur

devrait continuer à fonctionner.

c. Avec le brûleur en marche, branchez les fils du

détecteur à un ohmmètre juste. La lecture devrait être

inférieure à 1 000 ohms et se situer de préférence

dans le alentours de 500 ohms.

NOTE

Si l’indicateur de l’ohmmètre est stable, une lecture allant

jusqu’à 2000 ohms devrait être acceptable. Règle générale,

cependant, une faible résistance entraîne une meilleure

installation et diminue le risque qu’une variation de la

flamme du brûleur engage le blocage de sécurité.

d. Si la résistance du détecteur dépasse 1000 ohms, il

est possible que celui-ci ne détecte pas très bien la

flamme du brûleur. Vérifiez son alignement à travers

le trou du disque de pression statique. Si ce trou est

obstrué, nettoyez-le. Assurez-vous que les fils

branchés sur le bornes F sont en bon état.

e. Si le détecteur est bien aligné et la résistance est

toujours élevée, il peut être nécessaire de régler la

flamme du brûleur ou de remplacer la buse

(conformément aux directives du fabricant du brûleur).

Une fois cet essai terminé, vérifiez que vous avez retiré le

cavalier.

3

Loading...

Loading...