White Rodgers 50T35-743 User Manual

50T35-743

Integrated Furnace Control

INSTALLATION INSTRUCTIONS

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

DESCRIPTION

The 50T35-743 is an automatic gas interrupted ignition control that employs a microprocessor to continually monitor, analyze, and

control the proper operation of the gas burner, inducer, and fan. Signals interpreted during continual surveillance of the thermostat

and flame sensing element initiate automatic ignition of the burner, sensing of the flame, and system shut-off during normal

operation. This control incorporates system fault analysis for quick gas flow shut-off, coupled with automatic ignition retry upon

sensing a fault correction. It is designed as a replacement for the following controls:

Model Replaces

White-Rodgers 50T35-743 Goodman B18099-06

Goodman B18099-08

Goodman B18099-10

Goodman B18099-13

PRECAUTIONS

Installation should be done by a qualified heating and air

conditioning contractor or licensed electrician.

If in doubt about whether your wiring is millivolt, line, or low

voltage, have it inspected by a qualified heating and air conditioning contractor or licensed electrician.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical codes

and ordinances.

This control is a precision instrument, and should be handled

carefully. Rough handling or distorting components could cause

the control to malfunction.

Following installation or replacement, follow manufacturer’s

recommended installation/service instructions to ensure proper

operation.

CAUTION

Do not short out terminals on gas valve or primary

control. Short or incorrect wiring may damage the

thermostat.

Index Page

Description 1

Precautions 1

Specifications 2

Installation 3

Typical System Wiring 5

Failure to comply with the following

warnings could result in personal injury

or property damage.

FIRE HAZARD

• Do not exceed the specified voltage.

• Protect the control from direct contact with water

(dripping, spraying, rain, etc.).

• If the control has been in direct contact with water,

replace the control.

• Label all wires before disconnection when servicing controls. Wiring errors can cause improper

and dangerous operation.

• Route and secure wiring away from flame.

SHOCK HAZARD

• Disconnect electric power before servicing .

• Ensure proper earth grounding of appliance.

• Ensure proper connection of line neutral and line

hot wires.

EXPLOSION HAZARD

• Shut off main gas to appliance until installation is

complete.

WARNING

www.white-rodgers.com

PART NO. 37-6533B

Replaces 37-6533A

0614

SPECIFICATIONS

ELECTRICAL RATINGS [@ 77°F (25°C)]:

Input Voltage: 25 VAC 60 Hz

OPERATING TEMPERATURE RANGE:

-40° to 175°F (-40° to 80°C)

Max. Input Current @ 25 VAC:

0.5 amp + Main Value Load

Relay Load Ratings:

HUMIDITY RANGE:

5% to 93% relative humidity (non-condensing)

Valve Relay: 1.5 amp @ 24 VAC 60 Hz 0.6 pf

Ignitor Relay: 5.0 amp @ 120 VAC 60 Hz

(resistive)

MOUNTING:

Surface mount multipoise

Circulator Relay: 11 FLA–26.0 LRA @ 120 VAC

Humidifier Load Rating: 0.5A @ 24 VAC

1.0A @ 120 VAC

Electronic Air Cleaner Load Rating: 1A @ 120 VAC

Flame Current Requirements:

Timing Specs:

maximum

Flame Establishing Time: 0.8 sec

Flame Failure Response Time: 2.0 sec

Minimum current to insure flame detection: 1 µa DC*

Maximum current for non-detection: 0.1 µa DC*

Maximum allowable leakage resistance: 100 M ohms

Gases Approved: Natural, Manufactured, Mixed, Liquified

Petroleum, and LP Gas Air Mixtures are all approved for

use.

*Measured with a DC microammeter in the flame probe

lead

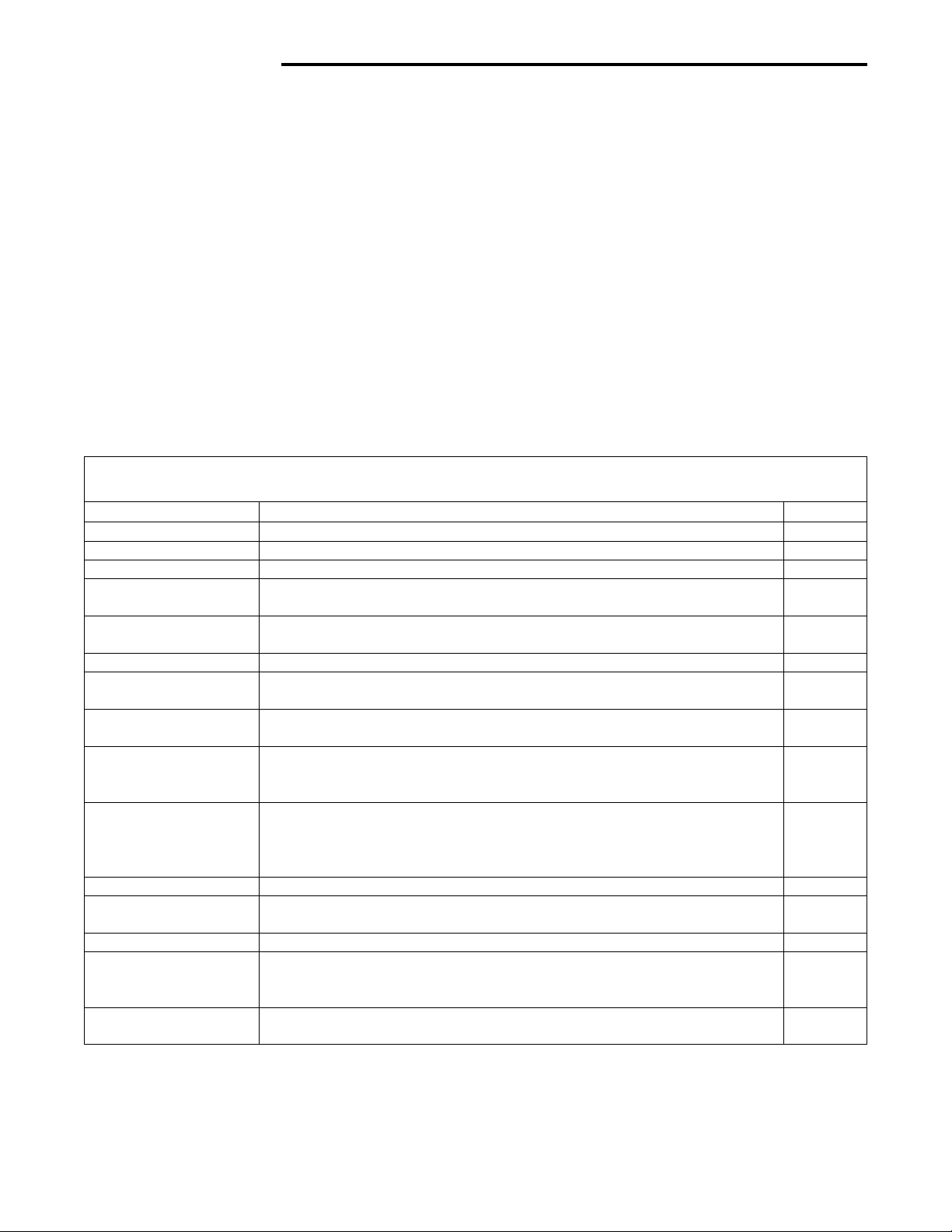

Timing Specifications

(All times are in seconds, unless noted otherwise)

Timing Specification Description 50T35-743

Pre-Purge Initial delay between thermostat contact closure and trial for ignition. 15

Initial Ignitor Warm-Up Duration of ignitor warm-up time on the first 64 attempts. 15

Retry Ignitor Warm-Up Duration of ignitor warm-up time if the control retries. 20

Ignition Activation Period The period of time between energizing the main gas valve and deactivation of 5

the ignition means prior to the lockout time.

Trial for Ignition Period during which the valve and ignition source is activated, attempting to 7

ignite gas at the burner.

Retries Additional ignition attempts if the original ignition attempt is unsuccessful. 2 times

Valve Sequence Period Valve sequence period is the cumulative total amount of time that the gas valve 12

is energized before entering lockout.

Inter-Purge Period between trials for ignition when both the gas valve and ignition source 30

are deactivated to allow unburned gas to escape before the next trial.

Post-Purge After all ignition cycles are complete, the control will enter post-purge. The 25/29

combustion fan will remain on to allow unburned gas to escape. After post-purge (90+ option)

is complete, the combustion fan will turn off.

Lockout Time The period of time between initiation of gas flow and the action to shut off the gas 300

flow in the event of failure to establish proof of the supervised ignition source or

the supervised main burner flame. Reinitiating the lighting sequence requires a

manual operation if ignition is required before Auto reset.

Heat Delay to Fan On Timing to allow the heat to build up in the plenum before turning on the fan. 30

Heat Delay to Fan Off* Timing to allow the fan to run after the call for heat ends. This allows residual heat 90/120/150

to be removed from the heat exchanger and distributed to the conditioned space.

Cool Delay to Fan On Timing to allow the cooling coils to cool off before turning on the fan. 5

Cool Delay to Fan Off Timing to allow the fan to run after the call for cool ends. This allows residual 60

cooling capacity to be removed from the cooling coils and distributed to the

conditioned space.

Auto Reset If shutoff occurs, the control delays for a specific recycle delay period before 60 minutes

beginning another trial for ignition (models with retries only).

* These times will vary depending on option switch position. See INSTALLATION section for further information.

2

Loading...

Loading...