Page 1

INDUSTRIAL

WHITE-RODGERS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

White-Rodgers Industrial Temperature Controls are suitable for most high temperature applications.

On small electric ovens, these controls may be used to

operate ovens directly. On ovens requiring a current

greater than the capacity of the control, these controls

may be used for controlling the pilot circuits of operating

relays.

These controls may also be used for controlling electrically operated gas valves on gas fired equipment.

TEMPERATURE CONTROL

INSTALLATION INSTRUCTIONS

DESCRIPTION

THESE CONTROLS MUST BE INSTALLED BY A

QUALIFIED INSTALLER.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical

codes and ordinances.

This control is a precision instrument, and should be

handled carefully. Rough handling or distorting components could cause the control to malfunction.

This control has been accurately calibrated at the factory.

Any attempt to calibrate this control will void the WhiteRodgers warranty.

ELECTRICAL DATA

Switch Action: S.P.S.T. – Open on Rise

Switch Rating:

25A. 120V.A.C., 20A. 240V.A.C. NON-IND.

2.9A., 25V.A.C., 120V.A.C.

125V, PILOT DUTY 600V.A.C.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, FAX (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, FAX (905) 475-4625

Printed in U.S.A.

PRECAUTIONS

CAUTION

To prevent electrical shock and/or equipment

damage, disconnect electric power to system at

main fuse or circuit breaker box until installation

is complete.

WARNING

Do not use on circuits exceeding specified voltages. Higher voltages will damage control and

could cause shock or fire hazard.

SPECIFICATIONS

THERMAL DATA

Range: 100° to 500°F (38° to 260°C)

Differential: 15°F (8°C) Fixed

Capillary Length: 6 Ft. (1.8 m)

Bulb Size: 3/16" x 9-7/8"

PART NO. 37-1896C

Replaces 37-1896B & 37-9103

9548

Page 2

INSTALLATION

For all normal installations, the sensitive bulb should be located

so as to be in the average temperature of the controlled medium

where there is a good air circulation around the bulb. The bulb

should not be attached directly to a wall or surface, but should

be held away by mounting brackets. A minimum amount of

capillary should be in the controlled area.

The bulb may be mounted in any normal atmosphere, but it

should be remembered that the copper element should not be

installed in a corrosive atmosphere such as may be found in

certain applications.

ANTICIPATION

Anticipation is a factor introduced into the performance of a

control to reduce its natural differential. The sensitive bulb of

industrial temperature controls can be located to obtain anticipation by placing it in a position close to the source of the heat. This

causes the sensitive bulb to receive heat quicker than the oven

proper, causing the control to turn the heat off sooner, thus

reducing the differential.

The proper location of the sensitive bulb depends on the

equipment design and can be determined only by trial. Care

should be taken so as not to put the bulb too close to the source

of the heat as this may subject the bulb to damaging temperatures.

The switch mechanism may be located in any position provided

that it will not be subjected to a temperature above 150°F.

Excessive capillary should be coiled and secured close to the

switch mechanism and should be handled with reasonable care

to prevent breaking of the seals, kinking or smashing.

CAUTION

Do not dent the sensitive bulb of this control. A

dent or a sharp bend will change the calibration

and cause the control to cycle at a temperature

lower than the dial setting.

Equipment that is controlled by anticipated controls does not

reach its final or constant temperature on the first cycle of the

control. There is a tendency for the temperature to continue to

rise after the control first starts cycling. After several cycles, the

temperature becomes constant. The greater the amount of

anticipation, the greater the tendency toward preliminary upward cycling.

The amount of anticipation as measured by the change in

calibration caused by the anticipated location should not exceed

25°. Thus, if the control is set to open the circuit at 300°F, the

temperature, when it becomes constant, should not be lower

than 275°F.

WIRING

All wiring should be done in accordance with local and national electrical codes and ordinances.

If the manufacturer of the heating equipment has supplied

a wiring diagram, follow such recommendations.

If none is offered, this diagram shows a suggested circuit.

HOT

LINE

N

Connections for direct control of heaters.

LOAD

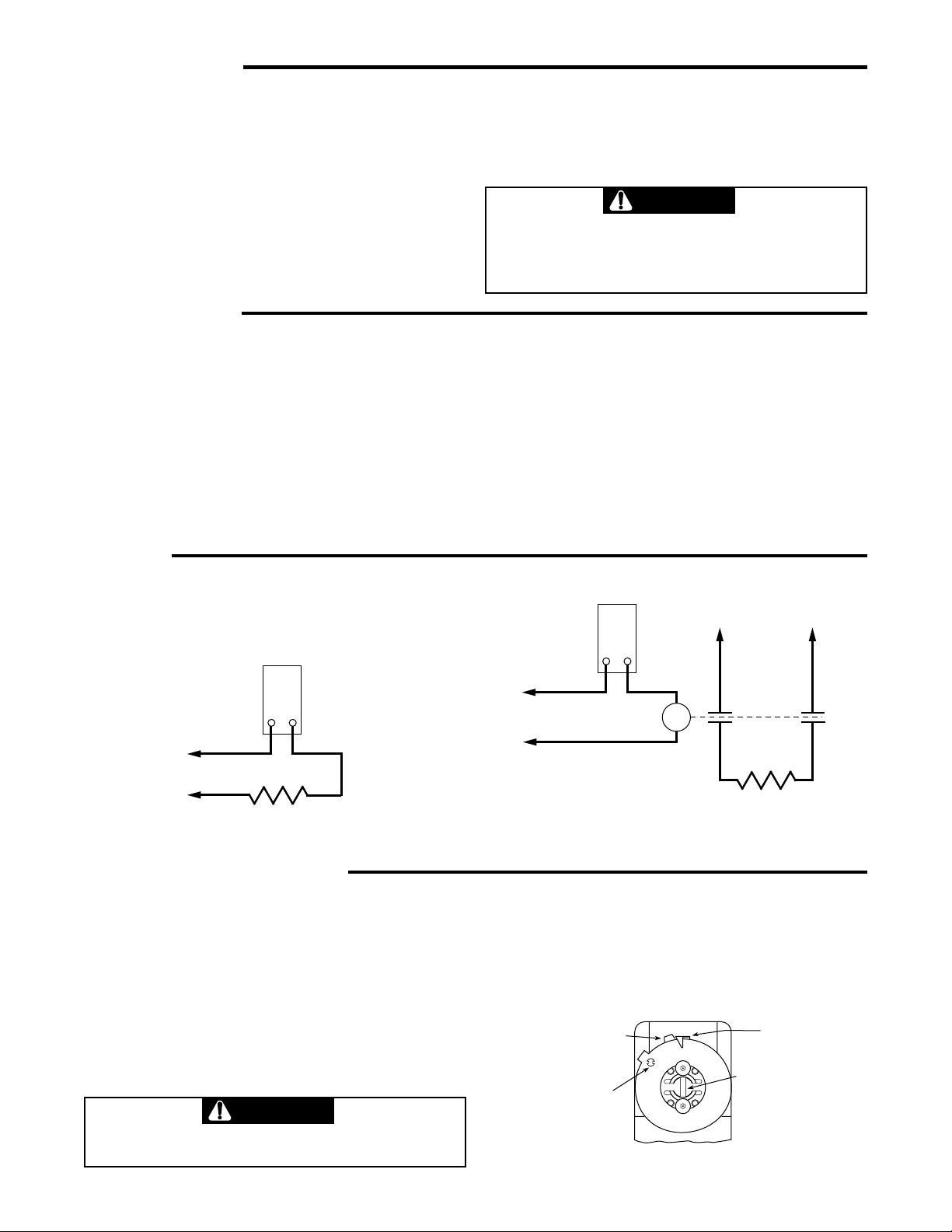

SETTING THE CONTROL

CONTROLS WITH A FIXED DIFFERENTIAL

The indicator (B) points to the temperature at which the contacts

open.

To set the control:

Use a screwdriver in the adjusting slot (A) on the front of the

control to rotate dial until the desired temperature at which

the contacts will open is positioned directly under the

indicator (B).

CONTROLS WITH ADJUSTABLE STOPS

CAUTION

Setting stop higher than control being replaced could

cause personal injury and/or property damage.

L1

HOT

LINE

N

Diagram of connections for operating heating

1. Loosen stop screw (E) with enclosed wrench.

2. Set dial to original equipment manufacturer's specification.

3. Without moving the dial, move stop tab (F) against indicator.

4. Retighten stop screw (E).

“F” STOP TAB

“E” STOP SCREW

COIL

LOAD

load through a contactor.

“A” ADJUSTING

FIXED DIFFERENTIAL

L2

“B” FIXED

INDICATOR

SLOT

2

Page 3

WHITE-RODGERS

Utilisateur: conservez ces instructions pour vous y référer au besoin!

SI VOUS NE LISEZ PAS ATTENTIVEMENT CES INSTRUCTIONS AVANT

D’INSTALLER ET D’UTILISER LA COMMANDE, VOUS RISQUEZ DE CAUSER

DES BLESSURES ET DES DOMMAGES MATÉRIELS.

Les régulateurs de température industriels de WhiteRodgers sont adaptés à la plupart des applications à

température élevée.

Ces régulateurs peuvent être utilisés pour commander

directement des petits fours électriques. Dans le cas de

fours qui exigent un courant supérieur à la capacité des

régulateurs, ces derniers peuvent commander les circuits

des relais de fonctionnement.

Ces régulateurs peuvent également être utilisés pour commander les robinets à gaz électriques d’équipements à gaz.

RÉGULATEUR DE TEMPÉRATURE

INDUSTRIEL

INSTRUCTIONS D’INSTALLATION

DESCRIPTION

LA PRÉSENTE COMMANDE DOIT ÊTRE INSTALLÉE

PAR UN TECHNICIEN QUALIFIÉ.

Ne dépassez pas les charges nominales.

Tout le câblage doit être conforme aux codes et règlements

locaux et nationaux qui régissent les installations

électriques.

Cette commande est un instrument de précision qui doit

être manipulé avec soin. Elle peut se détraquer si elle est

manipulée de façon négligente ou si des composantes

sont déformées.

La commande a été calibrée avec précision lors de la

fabrication. Toute tentative de calibrer l’appareil annulera

la garantie de White-Rodgers.

FICHE ÉLECTRIQUE

Commutation : Unipolaire unidirectionnelle (SPST)

à ouverture sur hausse.

Charges du commutateur :

25 A, 120V C.A.; 20 A, 240 V C.A.; NON-IND.;

2,9 A, 25 V C.A., 120 V C.A.;

125 V, CHARGE DE VEILLEUSE 600 V C.A.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, TÉLÉCOPIEUR (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, TÉLÉCOPIEUR (905) 475-4625

Imprimé aux É.-U.A.

PRÉCAUTIONS

ATTENTION

Afin de prévenir les chocs électriques et les

dommages matériels pendant l’installation,

coupez l’alimentation électrique au panneau de

distribution principal.

AVERTISSEMENT

N’installez pas cet appareil sur des circuits qui

dépassent la tension nominale. Une tension trop

élevée peut endommager la commande et poser

des risques de chocs électriques et d’incendie.

SPÉCIFICA TIONS

FICHE THERMIQUE

Plage : 38° à 260°C (100° à 500°F).

Différentiel : Fixé à 8°C (15°F).

Longueur du capillaire : 1,8 m (6 pi.).

Grosseur du capteur : 4,8 mm x 251 mm

(3/16" x 9-7/8").

PIÈCE No 37-1896C

Remplace 37-1896B & 37-9103

9548

Page 4

INSTALLATION

Normalement, le capteur doit être situé là où il sera

soumis à la température moyenne du milieu contrôlé et là

où l’air circulera bien autour. Ne pas fixer le capteur

directement au mur ou sur une surface; le tenir à l’écart à

l’aide de supports. Ne laisser qu’un minumum de capillaire

dans la zone contrôlée.

Le capteur peut être installé dans toute atmosphère

normale. Il est cependant recommandé de ne pas placer

l’élément de cuivre dans un milieu corrosif.

Le commutateur peut être installé avec n’importe quelle

orientation à condition de ne pas être soumis à une

température supérieure à 65,5°C (150°F).

ANTICIPATION

L’anticipation est un facteur qui sert à diminuer le différentiel

normal d’un régulateur. Pour assurer une forme d’anticipation, le capteur des régulateurs de température industriels peut être placé près de la source de chaleur. Ceci

assure que le capteur détectera le chaleur avant que

celle-ci ne se propage dans le four. Le régulateur coupera

ainsi le chauffage plus rapidement, diminuant effectivement le différentiel.

L’emplacement idéal du capteur dépend de la construction

de l’équipement. Il ne peut être déterminé qu’après essai.

Éviter de placer le capteur trop près de la source de

chaleur, qui pourrait l’endommager.

CÂBLAGE

Tout le câblage doit être conforme aux codes et règlements locaux et nationaux

qui régissent les installations électriques.

Si le fabricant de l’équipement de chauffage recommande

un schéma de câblage, alors veuillez vous y référer.

Dans le cas contraire, le schéma ci-dessous suggère un

circuit.

Enrouler le surplus de tube capillaire et le fixer près du

commutateur. Manipuler le capillaire avec soin afin de ne

pas l’écraser, le plier ni en desceller les joints.

ATTENTION

Ne pas plier ou bosser le capteur sensible du

régulateur. Une bosse un un pli en modifierait

l’étalonnage, entraînant la mise en marche de

l’équipement à une température inférieure au point

de consigne.

L’équipement qui est commandé par des dispositifs à

anticipation n’atteindra pas sa température finale ou

constante dès le premier cycle de marche de la commande.

La température aura tendance à continuer d’augementer

après que le régulateur ait été mis en marche. Après

plusieurs cycles, la température deviendra constante.

Plus l’anticipation est grande, plus la température aura

tendance à être élevée lors des premiers cycles.

Le degré d’anticipation, mesuré par la variation

d’étalonnage qui est occasionnée par le choix d’un

emplacement anticipé, ne doit pas dépasser 13°C (25°F).

Ainsi, si le régulateur est réglé pour ouvrir le circuit à

148°C (300°F), la température, lorsqu’elle devient

constante, ne doit pas être inférieure à 135°C (275°F) .

L1

L2

SOUS

TENSION

RÉSEAU

N

Raccordements pour commander directement les

appareils de chauffage.

CHARGE

RÉGLAGE DE LA COMMANDE

COMMANDES À DIFFÉRENTIEL FIXE

L’indicateur (B) donne la température à laquelle les

contacts seront ouverts.

Pour régler la commande :

Introduire la pointe d’un tournevis dans la fente de

réglage (A) qui se trouve à l’avant de la commande.

Tourner le cadran pour que la température à laquelle les

contacts devront être ouverts se trouve directement

sous l’indicateur (B).

COMMANDES À BUTÉES RÉGLABLES

ATTENTION

Il y a un risque de blessures et de dommages

matériels si la butée est réglée à un point de

consigne plus élevé que celle de la commande

qui est remplacée.

SOUS

TENSION

RÉSEAU

N

Schéma de raccordement pour une charge de chauffage

commandée par un contacteur.

BOBINE

CHARGE

1. Desserrer la vis de butée (E) à l’aide de la clé fournie.

2. Régler le cadran selon les recommandations du

fabricant de l’équipement.

3. En prenant soin de ne pas déplacer le cadran, accoter

la butée (F) contre l’indicateur.

4. Serrer à nouveau la vis de butée (E).

(F) BUTÉE

(E) VIS DE BUTÉE

DIFFÉRENTIEL FIXE

(B) INDICATEUR FIXE

(A) FENTE DE RÉGLAGE

2

Loading...

Loading...