Page 1

Hot Water Controls

WHITE-RODGERS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

These hot water controls were designed for use on hot water

heating installations but they may be used on other heating

applications to control the temperature of other fluids. The fluid

they are to be used with must not be corrosive to copper.

These controls have capillary tubing between the temperature

sensitive bulb and the switch mechanism so that the switch

mechanism can be mounted at any convenient location while

the temperature sensitive bulb is located in the fluid to be

controlled.

These controls have special contacts which are suitable for use

on low voltage and millivolt (thermocouple generator type)

circuits as well as line voltage equipment such as gas valves, oil

burner motors, etc.

THESE CONTROLS MUST BE INSTALLED BY A QUALIFIED

INSTALLER

Do not exceed the specification ratings.

All wiring must conform to local and national electrical codes and

ordinances.

This control is a precision instrument, and should be handled

carefully. Rough handling or distorting components could cause

the control to malfunction.

This control has been accurately calibrated at the factory. any

attempt to calibrate this control will void the White-Rodgers

warranty.

WARNING

Do not use on circuits exceeding specified voltage.

Higher voltage will damage control and could cause

shock or fire hazard.

Remote T ype

INSTALLATION INSTRUCTIONS

DESCRIPTION

PRECAUTIONS

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous operation.

Following installation or replacement, follow appliance

manufacturer's recommended installation and/or service instructions to insure proper operation.

CAUTION

To prevent electrical shock and/or equipment damage,

disconnect electric power to system at main fuse or

circuit breaker box until installation is complete.

Shut off main gas to heating system until installation is

complete.

If the equipment manufacturer recommends a control location,

follow such recommendations. If none is offered, the following

recommendations should be observed.

When used to control the temperature of a vat or tank, locate the

control bulb in a place representative of the average temperature. Make certain that the fluid being controlled is not injurious

to the copper element.

When used for high limit service on a heating boiler, the control

should be installed in the riser close to the boiler, or in a boiler

tapping that is near the top or hottest section of the boiler. If the

boiler is also used to heat domestic hot water, make sure that the

high limit control is not in that section of the boiler that contains

the heat exchanger or piping for domestic hot water.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, FAX (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, FAX (905) 475-4625

Printed in U.S.A.

INSTALLATION

When used for low limit or operator service, the control should

be located near that section of the boiler that contains the heat

exchanger or piping for domestic hot water.

Be careful to avoid damage to the capillary tubing between the

control and the temperature sensitive bulb. This tubing should

be led over a path that will protect it from cuts, blows, wear due

to vibration, etc.

CAUTION

Do not dent or bend the bulb as this will change the

control calibration and cause it to cycle at a temperature lower than the dial setting.

PART NO. 37-0882C

Replaces 37-0882B & 37-9025

9546

Page 2

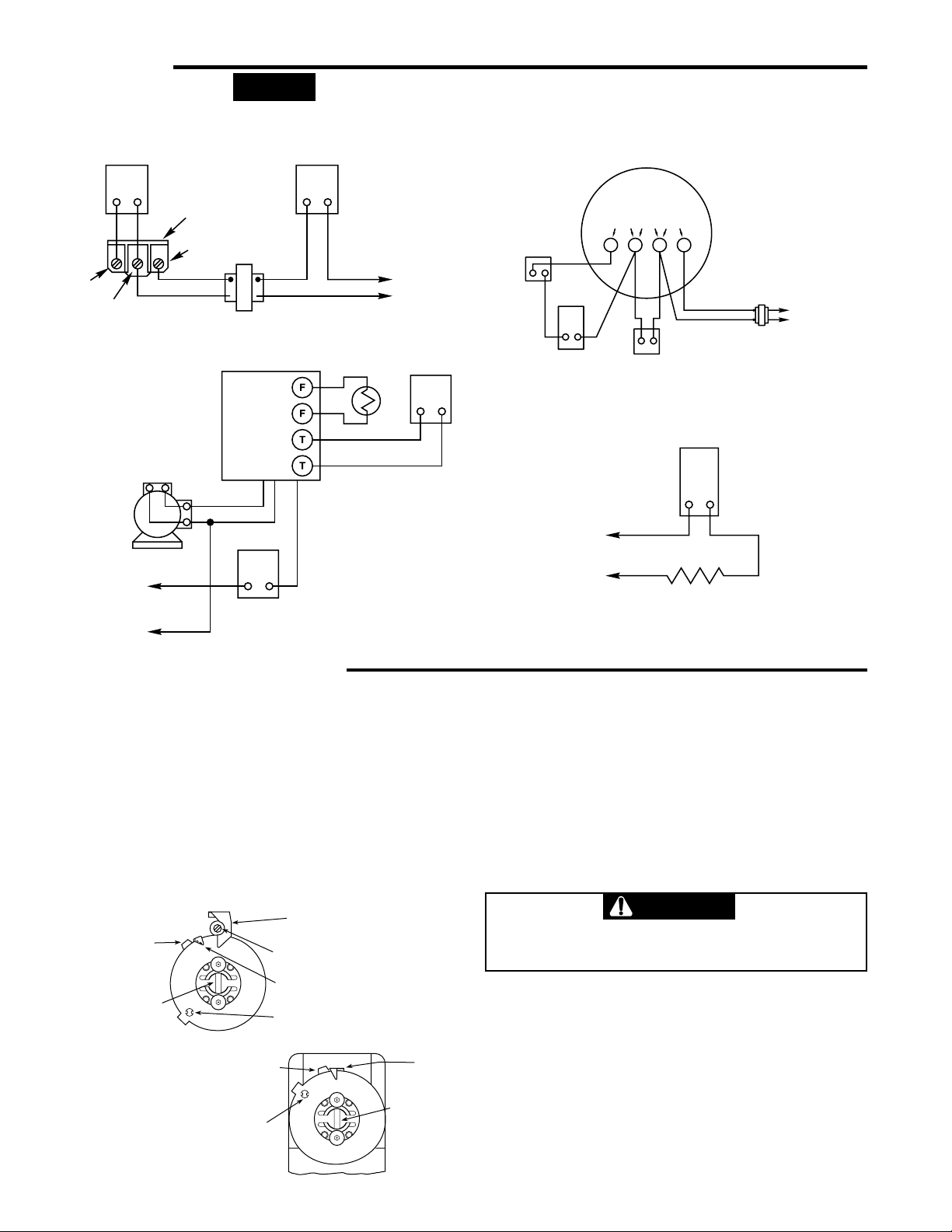

WIRING

NOTE

All wiring should be done according to local and national

electrical codes.

THERMOSTAT HIGH LIMIT

GAS VALVE

TERMINAL PANEL

TR

TH

TH-TR

24VAC

TRANSFORMER

Used as high

limit control with

36C03 Type Gas

Valve

HOT

LINE

N

If the boiler or burner manufacturer recommends a wiring

diagram, then follow such recommendations.

If none is offered, these diagrams show suggested circuits.

DIAPHRAGM

THERMOSTAT

GAS VALVE

THERM PILOT TRANS

1234

Used as high limit

control with

diaphragm gas valve

TRANSFORMER

TO

LINE

TYPE 668

HOT

N

IGNITION

TRANSF.

BURNER

MOTOR

LINE

OIL BURNER CONTROL

ORANGE

WHITE

LIMIT

CONTROL

Used as high

limit control with

BLACK

oil burner control

THERMOSTAT

SETTING THE CONTROL

CONTROLS WITH ADJUSTABLE DIFFERENTIAL

The movable indicator points to the temperature at which the

contacts open. The fixed indicator points to the temperature at

which the contacts close. The difference between these two

indicators is the differential.

To set the control:

1. Use a screwdriver in the adjusting slot (A) on the front of the

control to turn the dial so that the fixed indicator (B) points

to the temperature at which the contacts will close.

2. Turn the differential adjusting screw (C) until the movable

indicator (D) points to the temperature at which the contacts

will open.

“F” Stop tab

“A” Adjusting

slot

ADJUSTABLE DIFFERENTIAL

“F” Stop tab

“B” Fixed indicator

(cut-in point)

“C” Differential adjusting

screw

“D” Movable indicator

(cut-out point)

“E” Stop screw

“B” Fixed

indicator

LIMIT

CONTROL

AUTOMATIC

IF AUTOMATIC PILOT IS NOT USED,

CONNECT A JUMPER BETWEEN

PILOT

THE PILOT TERMINALS

Used as operating control

for electrically heated tank

TYPE

230-19

TEMPERATURE

CONTROL

HOT

LINE

N

LOAD

CONTROLS WITH A FIXED DIFFERENTIAL

The indicator (B) points to the temperature at which the contacts

open.

To set the control:

Use a screwdriver in the adjusting slot (A) on the front of the

control to rotate dial until the desired temperature at which

the contacts will open is positioned directly under the

indicator (B).

CONTROLS WITH ADJUSTABLE STOPS

CAUTION

Setting stop higher than control being replaced could

cause personal injury and/or property damage.

1. Loosen stop screw (E) with enclosed wrench.

2. Set dial to original equipment manufacturer's specification.

3. Without moving the dial, move stop tab (F) against indicator.

4. Retighten stop screw (E).

“E” Stop screw

“A” Adjusting

FIXED DIFFERENTIAL

slot

2

Page 3

WHITE-RODGERS

Utilisateur: conservez ces instructions pour vous y référer au besoin!

SI VOUS NE LISEZ PAS ATTENTIVEMENT CES INSTRUCTIONS AVANT

D’INSTALLER ET D’UTILISER LA COMMANDE, VOUS RISQUEZ DE CAUSER

DES BLESSURES ET DES DOMMAGES MATÉRIELS.

Ces commandes ont été conçues pour servir avec des systèmes

de chauffage à eau chaude. Elles peuvent cependant servir à

d’autres applications de régulation de température d’un liquide.

Ce liquide ne doit pas corroder le cuivre.

Les commandes sont dotées d’un tube capillaire qui relie le

capteur thermosensible au commutateur. Celui-ci peut ainsi

être installé dans un endroit pratique alors que le capteur baigne

dans le liquide dont la température doit être contrôlée.

Les commandes sont dotées de bornes spéciales qui permetent

de les utiliser avec des circuits à basse tension et à millivolts

(avec générateur à thermocouple) ainsi qu’avec des équipements

à la tension du réseau, comme des robinets à gaz, des moteurs

de brûleurs à mazout, etc.

LA PRÉSENTE COMMANDE DOIT ÊTRE INSTALLÉE PAR

UN TECHNICIEN QUALIFIÉ.

Ne dépassez pas les charges nominales.

Tout le câblage doit être conforme aux codes et règlements

locaux et nationaux qui régissent les installations électriques.

Cette commande est un instrument de précision qui doit être

manipulé avec soin. Elle peut se détraquer si elle est manipulée

de façon négligente ou si des composantes sont déformées.

La commande a été calibrée avec précision lors de la fabrication.

Toute tentative de calibrer l’appareil annulera la garantie de

White-Rodgers.

AVERTISSEMENT

N’installez pas cet appareil sur des circuits qui dépassent la tension nominale. Une tension trop élevée peut

endommager la commande et poser des risques de

chocs électriques et d’incendie.

Commande d’eau chaude

AVEC CAPTEUR À DISTANCE

INSTRUCTIONS D’INSTALLATION

DESCRIPTION

PRÉCAUTIONS

ATTENTION

Prenez soin d’identifier les fils avant de débrancher ou

de réviser la commande. Les erreurs de raccordement

peuvent entraîner un fonctionnement incorrect ou

dangereux de la commande.

Pour assurer le bon fonctionnement de la commande

après l’avoir installée, suivre les directives d’installation ou de révision du fabricant de l’équipement.

ATTENTION

Afin de prévenir les chocs électriques et les dommages

matériels pendant l’installation, coupez l’alimentation

électrique au panneau de distribution principal.

Coupez le gaz qui alimente le système de chauffage

pendant toute la durée de l’installation.

Si un emplacement de la commande est recommandé par le

fabricant de l’équipement, alors veuillez vous y conformer. Si

aucun emplacement n’est suggéré, veuillez suivre les conseils

suivants.

Si la commande est utilisée pour contrôler la température d’un

bassin ou d’un réservoir, alors placer le capteur là où la température du liquide correspond à la moyenne. S’assurer que le

liquide à contrôler ne cause aucun dommage au cuivre.

Si la commande est utilisée comme limiteur à maximum sur une

chaudière de chauffage, elle doit être installée près de celle-ci,

sur la colonne montante, ou dans une ouverture taraudée qui est

située dans la partie supérieure ou dans la section la plus

chaude. Si la chaudière sert aussi pour l’eau chaude domestique,

s’assurer que le limiteur à maximum n’est pas installé dans la

partie de la chaudière où se trouvent l’échangeur de chaleur ou

les canalisations d’eau chaude domestique.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, Télécopieur (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, Télécopieur (905) 475-4625

Imprimé aux É.-U.A.

INST ALLATION

Si la commande sert de limiteur à minimum ou d’actionneur, elle

doit alors être installée dans la partie de la chaudière où se

trouvent l’échangeur de chaleur ou les canalisations d’eau

chaude domestique.

Prendre soin de ne pas endommager le tube capillaire qui relie

la commande et le capteur thermosensible. Acheminer ce tube

de façon à ce qu’il soit protégé contre les coupures, les coups,

l’usure due aux vibrations, etc.

ATTENTION

Ne pas plier ou bosser le capteur, car l’étalonnage en

serait alors modifié, entraînant la mise en marche de

l’équipement à une température inférieure au point de

consigne.

PIÈCE No 37-0882C

Remplace 37-0882B & 37-9025

9546

Page 4

CÂBLAGE

NOTE

Tout le câblage doit être conforme aux codes et règlements

locaux et nationaux qui régissent les installations électriques.

THERMOSTAT

TH

TH-TR

TRANSFORMATEUR

D’ALLUMAGE

SOUS TENSION

MOTEUR DE

BRÛLEUR

SECTEUR

N

ORNIER DU

ROBINET À GAZ

TR

24VAC

TRANSFORMATEUR

COMMANDE DE BRÛLEUR

ORANGE

BLANC

LIMITEUR À MAXIMUM

À MAZOUT

LIMITEUR

Utilisée comme

limiteur à

maximum avec

robinet à gaz

Type 36C03

THERMOSTAT

Utilisée comme

limiteur à maximum

avec commande de

NOIR

brûleur à mazout

SOUS TENSION

SECTEUR

N

Si le fabricant de la chaudière ou du brûleur recommande un

schéma de câblage, alors veuillez vous y référer.

Dans le cas contraire, voici quelques schémas de circuits

recommandés.

ROBINET À GAZ

DIAPHRAGM

À MEMBRANE

THERMOSTAT

LIMITEUR

CONTROL

LIMIT

SOUS

TENSION

RÉSEAU

GAS VALVE

THERM PILOT TRANS

1234

VEILLEUSE

AUTOMATIC

AUTOMATIQUE

PILOT

N

Utilisée comme limiteur

Used as high limit

à maximum avec robinet

control with

à gaz à membrane

diaphragm gas valve

TRANSFORMATEUR

TRANSFORMER

SI UNE VEILLEUSE AUTOMATIQUE N’EST PAS

IF AUTOMATIC PILOT IS NOT USED,

CONNECT A JUMPER BETWEEN

UTILISÉE, RACCORDER LES DEUX BORNES DE

THE PILOT TERMINALS

LA VEILLEUSE À L’AIDE D’UN CAVALIER.

RÉGULATEUR DE

TEMPÉRATURE

CHARGE

TO

SECTEUR

LINE

TYPE 230-19

COMMANDES À DIFFÉRENTIEL RÉGLABLE

L’indicateur mobile donne la température à laquelle les contacts

seront ouverts. L’indicateur fixe donne la température à laquelle

les contacts seront fermés. La différence entre les deux indicateurs représente le différentiel.

Pour régler la commande :

1. Introduire la pointe d’un tournevis dans la fente de réglage

(A) qui se trouve à l’avant de la commande. Tourner le

cadran pour que l’indicateur fixe (B) indique la température

à laquelle les contacts devront être fermés.

2. Tourner la vis de réglage du différentiel (C) jusqu’à ce que

l’indicateur mobile (D) indique la température à laquelle les

contacts devront être ouverts.

B INDICATEUR FIXE

F BUTÉE

A FENTE DE

RÉGLAGE

(POINT D’ENCLENCHEMENT)

C VIS DE RÉGLAGE

DU DIFFÉRENTIEL

D INDICATEUR MOBILE

(POINT DE

DÉCLENCHEMENT)

E VIS DE

BUTÉE

DIFFÉRENTIEL RÉGLABLE

F BUTÉE

E VIS DE

BUTÉE

B INDICATEUR FIXE

(POINT D’ENCLENCHEMENT)

A FENTE DE

RÉGLAGE

RÉGLAGE DE LA COMMANDE

COMMANDES À DIFFÉRENTIEL FIXE

L’indicateur (B) donne la température à laquelle les contacts

seront ouverts.

Pour régler la commande :

Introduire la pointe d’un tournevis dans la fente de réglage

(A) qui se trouve à l’avant de la commande. Tourner le cadran

pour que la température à laquelle les contacts devront être

ouverts se trouve directement sous l’indicateur (B).

COMMANDES À BUTÉES RÉGLABLES

ATTENTION

Il y a un risque de blessures et de dommages matériels

si la butée est réglée à un point de consigne plus élevé

que celle de la commande qui est remplacée.

1. Desserrer la vis de butée (E) à l’aide de la clé fournie.

2. Régler le cadran selon les recommandations du fabricant de

l’équipement.

3. En prenant soin de ne pas déplacer le cadran, accoter la

butée (F) contre l’indicateur.

4. Serrer à nouveau la vis de butée (E).

DIFFÉRENTIEL FIXE

2

Loading...

Loading...