Page 1

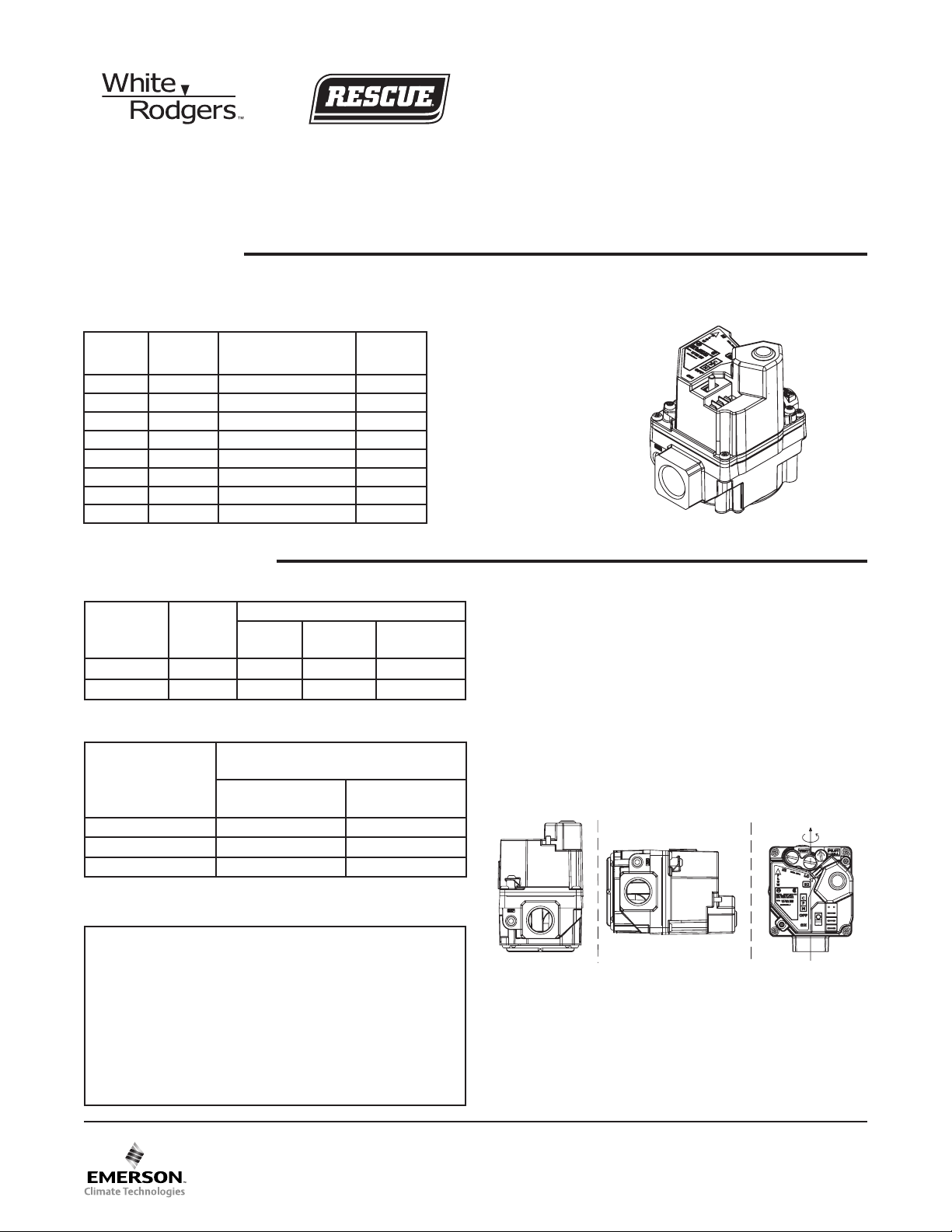

36H SERIES

360˚

Combination Gas Valve

INSTALLATION INSTRUCTIONS

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL INJURY

AND/OR PROPERTY DAMAGE.

DESCRIPTION

The 36H series combination gas valve is designed with redundant and main solenoid valves that control gas flow to the main

burners, a pressure regulator to maintain a constant outlet pressure, and a two position on/off switch for electrical shutoff.

Model numbers below include features as described:

Model

No.

36H22 1 Fast NO

36H23 1 Slow NO

36H32 1 Fast YES

36H33 1 Slow YES

36H54 2 Fast NO

36H55 2 Slow NO

36H64 2 Fast YES

36H65 2 Slow YES

# of

Stages

Open

Characteristics

Proven

Pilot

SPECIFICATIONS

Pressure Regulator Setting: (“ W.C.)

Two Stage

Single

Stage

Natural Gas 2.5 - 5.0 1.0 - 3.5 2.5 - 5.0 1.5

LP Gas 7.0 - 12.0 4.0 - 9.5 8.0 - 12.0 2.5

PIPE SIZES/CAPACITIES

Pipe Sizes

Available (inches)

3/4” x 3/4” NPT 300,000 486,000

1/2” x 3/4” NPT 260,000 421,000

1/2” x 1/2” NPT 170,000 275,400

Low High

Capacity (BTU/hr) at 1”

pressure drop across valve

AGA Std. Nat. Gas

(1,000 btu/cu. ft.)

Min Diff.

Low to High

LP. Gas

(2,500 btu/cu. ft.)

Type of Gas: Natural Gas

Ambient Temperature: -40° to 175°F

Pressure Rating: 14” W.C. (1⁄2 PSI) max.

Voltage: 24 VAC

Frequency: 50/60 Hz

Current: Single Stage - .410A

Two-Stage - .540A

MOUNTING POSITIONS:

Upright, or 0° to 90° from upright

UPRIGHT

LEFT or RIGHT

INLET BOSS

VERTICAL

CONTENTS

Description ................................................................. 1

Specifications ............................................................. 1

Precautions ................................................................ 2

Installation .................................................................. 3

System Wiring

Adjustment ................................................................. 4

Pressure Regulator Adjustment

Lighting Instructions .................................................... 6

www.white-rodgers.com

www.emerson.com

Figure 1. Gas valve mounting positions

PART NO. 37-6632B

Replaces 37-6632A

0927

Page 2

PRECAUTIONS

WARNING

!

WARNING

!

CAUTION

!

DO NOT BEGIN INSTALLATION UNTIL YOU READ

THE FOLLOWING PRECAUTIONS.

If you do not follow these instructions exactly, a fire or explosion may

result, causing property damage, personal injury or loss of life.

1. Failure to turn off electric or main gas supply to

heating system could cause personal injury and/

or property damage by shock, gas suffocation, fire,

and/or explosion.

2. Do not use this control on circuits exceeding specified voltage. Higher voltage will damage the control

and may cause shock or fire hazard.

3. NEVER USE FLAME OR ANY KIND OF SPARK TO

CHECK FOR GAS LEAKS–COULD CAUSE FIRE AND/

OR EXPLOSION.

4. DO NOT USE WIRE JUMPER on pilot systems, such

as standing pilot, proven pilot, or spark-to-pilot

ignition–a fire and/or explosion may result.

Properly install gas piping to control.

• Do not remove protective inlet or outlet caps until

ready to connect supply pipe to gas valve.

• Use new supply pipe, properly threaded, reamed,

de-burred, and cleaned.

• Use backup wrench, applied only to provided wrench

flats on inlet boss, when tightening the supply pipe.

Do not grip bracket, solenoid or any other part of

control.

• Do not over-tighten pipe to control (50ft-lbs max.)

• Always install sediment trap in the gas supply line

to prevent contamination of gas valve.

5. Do not use a control set for natural gas with LP gas,

or a control set for LP gas with natural gas. Personal

injury and/or property damage, gas suffocation, fire,

and/or explosion may result.

6. Do not use a gas valv e w h i c h a p p ears

to be damaged. A damaged valve may cause

personal injury and/or property damage due to shock,

gas suffocation, fire and/or explosion. Contact supplier to replace any valve that appears to have been

damaged.

7. Do not use a gas valve that has been in direct contact

with water. Water entering gas valve may result in concealed internal damage to gas valve. Personal injury

and/or property damage, gas suffocation, fire and/or

explosion may result.

1. Do not short out terminals on gas valve or primary

control to test. Short or incorrect wiring can cause

equipment damage, property damage, and/or personal injury.

2. This control is not intended for use in locations

where it may come in direct contact with water.

Suitable protection must be provided to shield the

control from exposure to water (dripping, spraying,

rain, etc.).

3. Clean gas piping of contaminants, cutting fluid, or

other chemicals which might react harmfully with

the gas valve components before install.

Failure to install properly can cause gas leakage resulting in injury due to fire or explosion.

2

Page 3

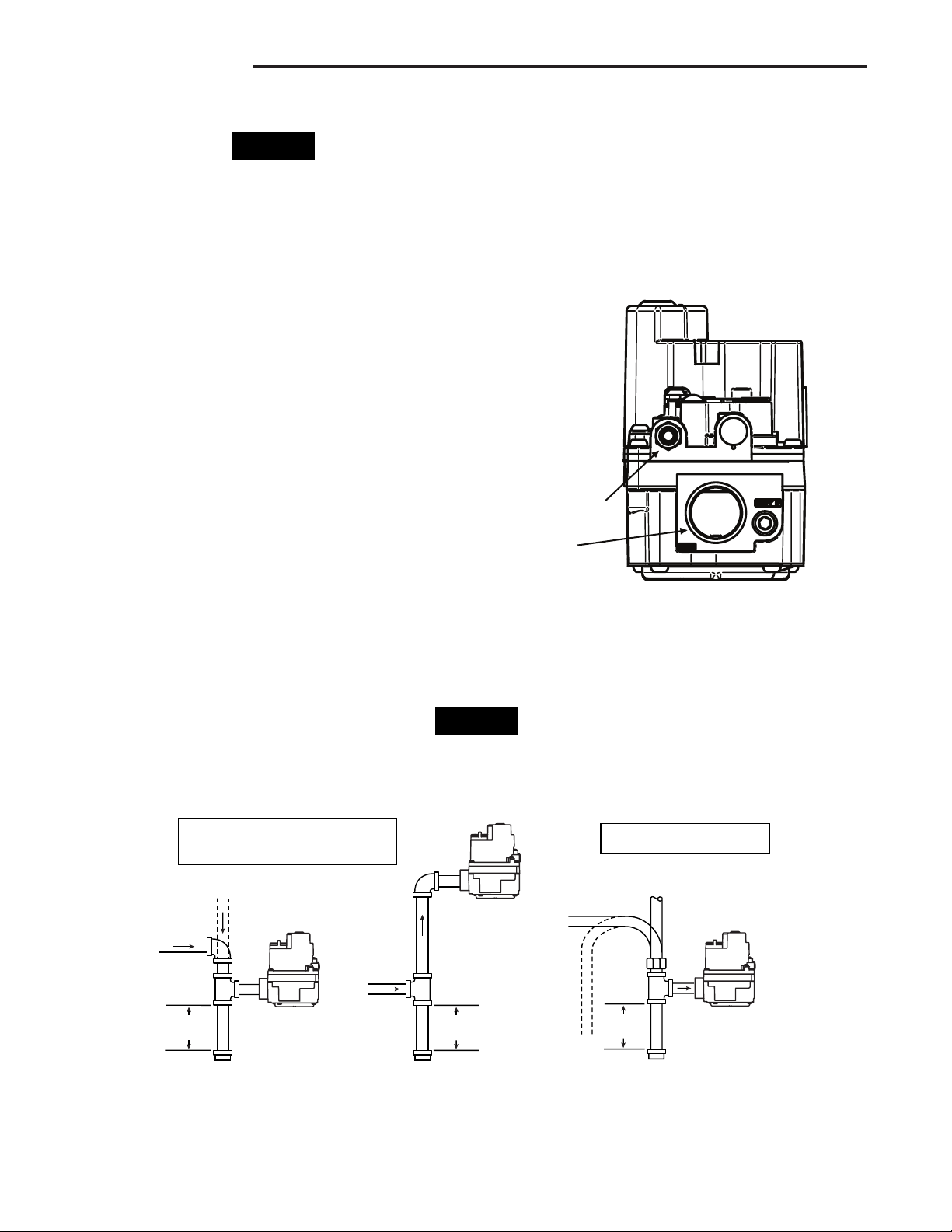

INSTALLATION

Piped Gas

Supply

Piped Gas

Supply

Tubing Gas

Supply

NOTE: ALWAYS INCLUDE A

DRIP LEG IN PIPING

NOTE: A MANUAL SHUTOFF VALVE

MUST BE INSTALLED WITHIN

6 FEET OF THE EQUIPMENT

Horizontal

Drop

Gas Valve

3 in.

minimum

Gas Valve

Riser

3 in.

minimum

Drop

Horizontal

Riser

Gas Valve

3 in.

minimum

Pilot Gas Outlet

Gas Outlet

NOTE

NOTE

MAIN PIPING CONNECTIONS

Re fer to wa r nin gs an d cau tion s on p age 2 before

attempting installation. All piping must comply with local codes,

ordinances, and/or national fuel gas codes.

1. Turn off electrical power to the system at the fuse box or

circuit breaker. Also turn off the main gas supply.

2. If replacing an existing valve, disconnect all plumbing and

electrical connections from the old control.

3. This valve may be installed upright, + or – 90˚ from upright,

or vertical (refer to figure 1). The arrows on the valve identification label and on the bottom plate indicate direction of

gas flow through the valve

4. You should use new pipe that is properly chamfered, reamed,

and free of burrs and chips. If you are using old pipe, be

sure it is clean and free of rust, scale, burrs, chips, and old

pipe joint compound.

5. Apply pipe joint compound (pipe dope) or teflon tape that is

approved for all gases, only to the male threads of the

pipe joints. DO NOT apply compound or teflon tape to the

first two threads (see fig. 3 for typical piping connections).

6. Do not tighten piping excessively, as this may damage the

valve (50ft lbs max).

7. See SYSTEM WIRING when making electrical connections.

After all gas and electrical connections are completed, turn

gas on and check for gas leaks with leak detection solution

or soap suds. Bubbles forming indicate a leak. SHUT OFF

GAS AND FIX ALL LEAKS IMMEDIATELY.

PILOT GAS CONNECTION

MODELS 36H3X AND 36H6X REQUIRE A PILOT

CONNECTION.

Loosen the pilot fitting until it is finger-tight.

Insert clean, deburred tubing all the way through the fitting.

While holding the tubing securely, slowly tighten fitting until

you feel a slight “give”. Tighten the fitting an additional 1 1/2

turns.

Figure 2. gas valve outlet end

All piping must comply with local codes, ordinances, and/

or national fuel gas codes.

Figure 3. typical gas valve piping

3

Page 4

INSTALLATION

Redundant

Coil

(+)

(-)

SW1

SW1

SW2

P

C

Main

Coil

(+)

(-)

M

SW2

Two-Stage

Coil

(+)

(-)

RECTIFIER

Rectifier

Rectifier

HI

Two Stage Models Only

Rectifier

SW1

SW1

SW2

SW2

(+)

(-)

PM

C

HI

Main

Coil

Redundant

Coil

Two-stage

Coil

Two Stage Models Only

NOTE

NOTE

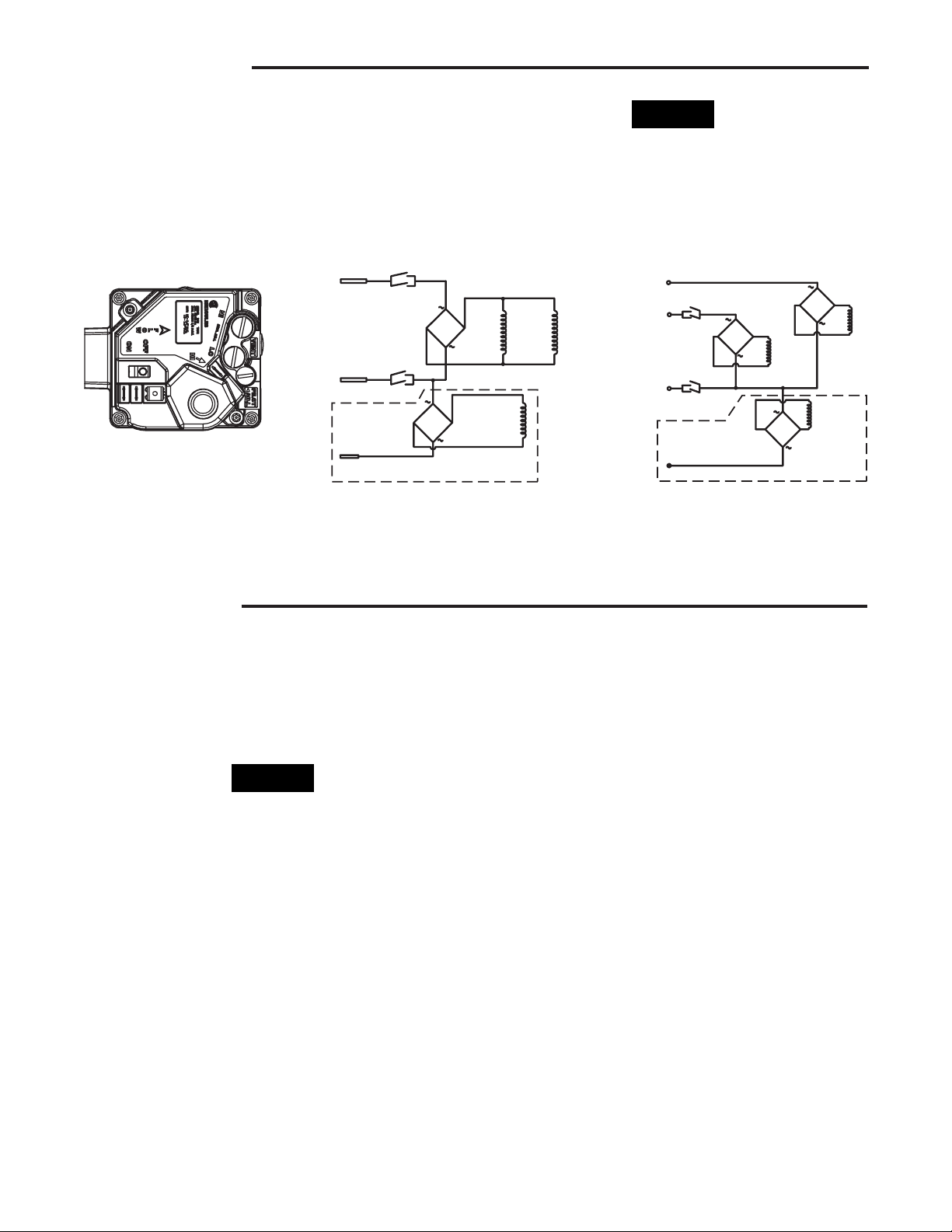

SYSTEM WIRING

REFER TO AND FOLLOW THE APPLIANCE MANUFACTURER’S WIRING DIAGRAM. REFER TO FIG. 4

FOR TERMINAL IDENTIFICATION.

WIRING DIAGRAM - HSI MODELS

36H2X & 36H5X

Figure 4. System Wiring

All wiring should be installed in accordance with local and national electrical codes and ordinances.

Always check that the electrical power supply used agrees with

the voltage and frequency shown on the gas control.

WIRING DIAGRAM -

PILOTED MODELS

36H3X & 36H6X

ADJUSTMENT

PRESSURE REGULATOR ADJUSTMENT

These controls are shipped from the factory with the regulator

set as specified on the control label. Consult the appliance rating plate to ensure burner manifold pressure is as specified. If

another outlet pressure is required, follow these steps.

Natural Gas: Two-Stage Models - Low outlet pressure will

be factory-adjusted in the 1 to 3.5” W.C. range and high outlet

pressure will be factory-adjusted in the 2.5 to 5” range. The

valve cannot be adjusted outside this range and the high outlet

pressure setting must always be set at least 1.5” above the low

outlet pressure setting.

Single Stage Models- Outlet pressure will be factory-adjusted

in the 2.5” to 5” range. The valve cannot be adjusted outside

this range.

LP Gas: Two-Stage Models - Low outlet pressure will factoryadjusted in the 4” to 9.5” W.C. range and high outlet pressure

will be adjusted in the 8 to 12” W.C. range. The valve cannot

be adjusted outside this range and the high outlet pressure

setting must always be set at least 2.5” above the low outlet

pressure setting.

Single Stage Models - Outlet pressure will be factory-adjusted

in the 7 to 12” range. The valve cannot be adjusted outside this

range.

4

Page 5

Low regulator cover screw

(two stage only)

Regulator adjust screw

Regulator spring

Pilot cover screw

Pilot gasket

Pilot adjust screw

Regulator spring

Regulator adjust screw

Single stage and two stage

high regulator cover screw

Outlet pressure tap

ADJUSTMENT

NOTE

OUTLET PRESSURE ADJUSTMENT

1. Turn off all electrical power to the system.

2. Remove plug and install hose barb fitting and manometer

to pressure tap on outlet end of valve. See fig. 5.

3. Turn on system power. Set thermostat to call for heat (low

stage for two-stage systems). Main burner should light.

Proceed to step 6 for single stage systems.

4. (2-stage only) Remove regulator cover screw from the

low outlet pressure regulator adjust tower (fig. 5) and turn

screw clockwise ( ) to increase pressure, or counterclockwise ( ) to decrease pressure. Always adjust

regulator according to original equipment manufacture’s

specifications listed on the appliance rating plate. Replace

regulator cover screw.

5. (2-stage only) Set thermostat to call for high stage.

6. Remove regulator cover screw from the single stage or

high outlet pressure regulator adjust tower (fig. 5) and turn

screw clockwise ( ) to increase pressure, or counterclockwise ( ) to decrease pressure. Always adjust

regulator according to original equipment manufacturer’s

specifications listed on the appliance rating plate. Replace

regulator cover screw.

Figure 5. Pressure Adjustment

7. Turn off all electrical power to the system.

8. Remove manometer hose and fitting from outlet pressure

tap.

9. Replace outlet pressure tap plug and tighten (clockwise

40-60 in-lb.)

10. Turn on system power and set thermostat to call

for heat.

11. Using a leak detection solution or soapsuds, check for

leaks at pressure tap plug. Bubbles forming indicate a leak.

SHUT OFF GAS AND FIX ALL LEAKS IMMEDIATELY.

PILOT FLAME ADJUSTMENT

(Models 36H3X and 36H6X only)

If the pilot frame is low and does not engulf the bulb of the

mercury flame sensor, the system will not energize the main

valve. If pilot gas pressure is too high, gas will sputter past the

ignition electrode, and may not ignite. High pilot gas pressure

may also cause the flame to lift off the burner, causing the

flame sensor bulb to sense “low” heat.

To adjust the pilot gas pressure, remove the cover screw (See

fig. 5). To REDUCE pilot pressure, turn the pilot adjust screw

(beneath the cover screw) clockwise ( ) . To INCREASE

pilot pressure, turn the pilot adjust screw counterclockwise (

). Replace and tighten cover screw.

For gas to gas conversion, consult your dealer for appropriate

conversion kit.

5

Page 6

LIGHTING INSTRUCTIONS

WARNING

!

FOR YOUR SAFETY READ BEFORE OPERATING

If you do not follow these instructions exactly, a fire or explosion

may result, causing property damage, personal injury or loss of life.

A. HSI MODELS: This appliance does not have a pilot. It is

equipped with an ignition device which automatically lights

the burner. Do not try to light the burner by hand.

PROVEN PILOT MODELS: This appliance is equipped with

an intermittent ignition device which automatically lights the

appliance. Do not try to light the pilot by hand.

B. BEFORE OPERATING smell all around the appliance area

for gas. Be sure to smell next to the floor because some gas

is heavier than air and will settle on the floor.

FOR YOUR SAFETY

“WHAT TO DO IF YOU SMELL GAS”

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on this label.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. HSI MODELS: This appliance is equipped with an ignition

device which automatically lights the burner. Do not try to light

the burner by hand.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re department.

C. Use only your hand to move the gas control switch. Never

use tools. If the switch will not move by hand, don’t try to

repair it, call a qualified service technician. Force or attempted

repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician

to inspect the appliance and to replace any part of the control

system and any gas control which has been

under water.

5. PROVEN PILOT MODELS: This appliance is equipped with an

ignition device which automatically lights the pilot. Do not try

to light the burner by hand.

6. Remove control access panel.

7. Wait five (5) minutes to clear out any gas. If you then smell

gas, STOP! Follow “B” in the safety information above on this

label. If you don’t smell gas, go to the next step.

8. Push gas control switch to “ON.”

NOTE: Do not force.

9. Replace control access panel.

10. Turn on all electric power to the appliance.

11. Set thermostat to desired setting.

12. If the appliance will not operate, follow the instructions “To Turn

Off Gas To Appliance” and call your service technician or gas

supplier.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is to be

performed.

White-Rodgers is a division

of Emerson Electric Co.

The Emerson logo is a

trademark and service mark

of Emerson Electric Co.

www.white-rodgers.com

www.emerson.com

3. Remove control access panel.

4. Push gas control switch to “OFF.” Do not force.

5. Replace control access panel.

Page 7

PARA APAGAR EL GAS QUE LLEGA AL ARTEFACTO

PARA SU SEGURIDAD LEA ANTES DE USAR

INSTRUCCIONES DE USO

www.emerson.com

¡ADVERTENCIA!

!

Si no sigue estas instrucciones al pie de la letra, puede producirse un

incendio o una explosión y, como consecuencia, daños materiales,

lesiones personales o la pérdida de vidas.

www.white-rodgers.com

5. Vuelva a colocar el panel de acceso del control.

fuerce.

4. Coloque el interruptor del control de gas en “OFF”. No lo

llame a su técnico o proveedor de gas.

sección “Para apagar el gas que llega al artefacto” y

12. Si el artefacto no funciona, siga las instrucciones de la

11. Ajuste el termostato al valor deseado.

10. Encienda toda la alimentación eléctrica al artefacto.

9. Vuelva a colocar el panel de acceso del control.

NOTA: no lo fuerce.

8. Coloque el interruptor del control de gas en “ON”.

Si no huele gas, continúe con el paso siguiente.

de seguridad que se encuentra arriba de esta etiqueta.

gas, ¡DETÉNGASE! Siga el punto “B” de la información

7. Espere cinco (5) minutos para eliminar el gas. Si huele

6. Retire el panel de acceso del control.

quemador a mano.

automáticamente el piloto. No intente encender el

cuenta con un dispositivo de encendido que enciende

5. MODELOS CON PILOTO PROBADO: Este artefacto

Emerson Electric Co.

comercial y una marca de servicio de

El logotipo de Emerson es una marca

Emerson Electric Co.

White-Rodgers es una división de

3. Retire el panel de acceso del control.

realizar alguna tarea de reparación.

2. Apague toda la alimentación eléctrica al artefacto si debe

1. Ajuste el termostato al valor más bajo.

quemador a mano.

automáticamente el quemador. No intente encender el

un dispositivo de encendido que enciende

4. MODELOS HSI: Este artefacto cuenta con

3. Apague toda la alimentación eléctrica al artefacto.

2. Ajuste el termostato al valor más bajo.

encuentra arriba de esta etiqueta.

1. ¡ALTO! Lea la información de seguridad que se

que haya estado bajo el agua.

partes del sistema de control y cualquier control de gas

calicado para que inspeccione el artefacto y cambie las

el agua. Llame inmediatamente a un técnico de servicio

D. No utilice este artefacto si alguna parte ha estado bajo

explosión.

intento de reparación pueden producir un incendio o una

Llame a un técnico calicado. El uso de fuerza o cualquier

interruptor no se mueve a mano, no intente repararlo.

de gas. No utilice herramientas en ningún caso. Si el

C. Utilice sólo la mano para mover el interruptor de control

llame a los bomberos.

• Si no logra contactarse con su proveedor de gas,

proveedor de gas.

el teléfono de un vecino. Siga las instrucciones del

• Llame inmediatamente a su proveedor de gas desde

ningún teléfono en su edificio.

“QUÉ HACER SI HUELE GAS”

PARA SU SEGURIDAD

pesados que el aire y se depositan sobre el suelo.

también al ras del suelo ya que algunos gases son más

para detectar si hay olor a gas. Asegúrese de oler

encender el piloto a mano.

que enciende automáticamente el artefacto. No intente

cuenta con un dispositivo de encendido intermitente

quemador a mano.

automáticamente el quemador. No intente encender el

Cuenta con un dispositivo de encendido que enciende

• No toque ningún interruptor eléctrico. No utilice

• No intente encender ningún artefacto.

B. ANTES DE UTILIZAR el artefacto huela a su alrededor

MODELOS CON PILOTO PROBADO: Este artefacto

A. MODELOS HSI: Este artefacto no tiene piloto.

INSTRUCCIONES DE ENCENDIDO

Page 8

5

To rnillo de cubierta del regulador

de mínima (sólo dos etapas)

To rnillo de ajuste del regulador

Resorte del regulador

To rnillo de

cubierta de piloto

Junta de piloto

To rnillo de

ajuste de piloto

Resorte del regulador

To rnillo de ajuste del regulador

To rnillo de cubierta del regulador

de máxima de una sola etapa

y de dos etapas

Grifo de presión de salida

NOTA

el kit de conversión adecuado.

Para la conversión gas a gas, consulte a su distribuidor sobre

( ). Vuelva a colocar el tornillo de la cubierta y ajústelo.

ajuste del piloto en sentido contrario a las agujas del reloj

Para AUMENTAR la presión del piloto, gire el tornillo de

cubierta) en el sentido de las agujas del reloj ( ).

gire el tornillo de ajuste del piloto (debajo del tornillo de la

cubierta (vea la g. 5). Para REDUCIR la presión del piloto,

Para ajustar la presión del gas del piloto, retire el tornillo de la

del regulador.

del artefacto. Vuelva a colocar el tornillo de la cubierta

equipo original indicadas en la placa de especicaciones

acuerdo con las especicaciones del fabricante del

( ) para reducirla. Ajuste siempre el regulador de

presión, o en sentido contrario a las agujas del reloj

detecte calor “bajo”.

levante el quemador y que el bulbo del sensor de la llama

de gas del piloto es alta, también puede hacer que la llama

encendido y es posible que no lo encienda. Si la presión

es demasiado alta, el gas pasará de largo el electrodo de

energizará la válvula principal. Si la presión del gas del piloto

el bulbo del sensor de llama de mercurio, el sistema no

Si la llama del piloto está baja y no encierra completamente

(Sólo modelos 36H3X y 36H6X)

AJUSTE DE LA LLAMA DEL PILOTO

sentido de las agujas del reloj ( ) para aumentar la

presión de salida de mínima (g. 5) y gire el tornillo en el

regulador desde la torre de ajuste del regulador de

4. (sólo 2 etapas) Retire el tornillo de la cubierta del

Siga con el paso 6 para sistemas de una sola etapa.

dos etapas). El quemador principal debería encenderse.

para una llamada de calor (etapa baja para sistemas de

3. Encienda la alimentación al sistema. Ajuste el termostato

extremo de salida de la válvula. Vea la gura 5.

manguera y el manómetro al grifo de presión en el

2. Retire el tapón e instale el conector de púa de la

1. Apague toda la alimentación eléctrica al sistema.

PÉRDIDAS INMEDIATAMENTE.

AJUSTE DE PRESIÓN DE SALIDA

indica una pérdida. CIERRE EL GAS Y REPARE LAS

el tapón del grifo de presión. La formación de burbujas

espuma de jabón, verique que no haya pérdidas en

11. Utilizando una solución de detección de pérdidas o

Figura 5. Ajuste de presión

termostato para una llamada de calor.

10. Encienda la alimentación al sistema y ajuste el

lb.)

ajuste (en el sentido de las agujas del reloj, 40-60 pulg./

9. Vuelva a colocar el tapón del grifo de presión de salida y

de presión de salida.

8. Retire la manguera del manómetro y el conector del grifo

7. Apague toda la alimentación eléctrica al sistema.

del regulador.

del artefacto. Vuelva a colocar el tornillo de la cubierta

equipo original indicadas en la placa de especicaciones

acuerdo con las especicaciones del fabricante del

( ) para reducirla. Ajuste siempre el regulador de

presión, o en sentido contrario a las agujas del reloj

) para aumentar la

sentido de las agujas del reloj (

máxima o de una sola etapa (g. 5) y gire el tornillo en el

la torre de ajuste del regulador de presión de salida

6. Retire el tornillo de la cubierta del regulador desde

etapa alta.

5. (sólo 2 etapas) Ajuste el termostato para una llamada de

AJUSTE

Page 9

4

NOTA

Serpentín

redundante

(+)

(-)

SW1

SW1

SW2

P

C

Serpentín

principal

(+)

(-)

M

SW2

Serpentín

de dos

etapas

(+)

(-)

RECTIFICADOR

Rectificador

Rectificador

ALTO

Sólo modelos de dos etapas

DIAGRAMA DE CONEXIONES - MODELOS CON PILOTO

Rectificador

SW1

SW1

SW2

SW2

(+)

(-)

PM

C

ALTO

Serpentín

principal

Serpentín

redundante

Serpentín

de dos

etapas

Sólo modelos de dos etapas

DIAGRAMA DE CONEXIONES - MODELOS HSI

NOTA

pulg. por encima de la presión de salida mínima.

ajustarse fuera de este rango.

de fábrica en el rango de 7 pulg. a 12 pulg. La válvula no puede

Modelos de una sola etapa - La presión de salida viene ajustada

la presión de salida máxima siempre debe estar al menos 1.5

válvula no puede ajustarse fuera de este rango y el ajuste de

pulg. W.C. y la máxima en el rango de 2.5 pulg. a 5 pulg. La

mínima viene ajustada de fábrica en el rango de 1 pulg. a 3.5

menos 2.5 pulg. por encima de la presión de salida mínima.

Gas natural: modelos de dos etapas - La presión de salida

el ajuste de la presión de salida máxima siempre debe estar al

pulg. W.C. La válvula no puede ajustarse fuera de este rango y

pulg. a 9.5 pulg. W.C. y la máxima en el rango de 8 pulg. a 12

de salida mínima viene ajustada de fábrica en el rango de 4

Gas de petróleo licuado: modelos de dos etapas - La presión

a continuación.

Si se requiere otra presión de salida, siga los pasos indicados

que la presión del múltiple del quemador sea la especicada.

puede ajustarse fuera de este rango.

ajustada de fábrica en el rango de 2.5 a 5 pulg. La válvula no

Modelos de una sola etapa - La presión de salida viene

placa de especicaciones del artefacto para asegurarse de

según lo especicado en la etiqueta del control. Consulte la

Estos controles se envían de fábrica con el regulador ajustado

AJUSTE DE REGULADOR DE PRESIÓN

36H3X y 36H6X

CON PILOTO

DIAGRAMA DE CONEXIONES - MODELOS

36H3X y 36H6X

AJUSTE

Figura 4. Conexiones eléctricas

36H2X y 36H5X

MODELOS CON PILOTO

DIAGRAMA DE CONEXIONES - MODELOS HSI

36H2X y 36H5X

MODELOS HSI

el control de gas.

utilizado concuerde con el voltaje y la frecuencia indicados en

Verique siempre que el suministro de alimentación eléctrica

normas y leyes eléctricas locales y nacionales.

Todas las conexiones deben realizarse de conformidad con las

4 PARA LA IDENTIFICACIÓN DE LAS TERMINALES.

FABRICANTE DEL ARTEFACTO. REFIÉRASE A LA FIGURA

REFIÉRASE AL DIAGRAMA DE CONEXIONES DEL

CONEXIONES ELÉCTRICAS

INSTALACIÓN

Page 10

NOTA

Suministro de

gas por tubería

Suministro de

gas por tubería

Suministro de

gas por tubería

NOTA: INCLUYA SIEMPRE UNA PATA

DE GOTEO EN LAS TUBERÍAS

Figure 2. Typical gas valve piping

NOTA: DEBE HABER UNA VÁLVULA DE CIERRE

MANUAL INSTALADA DENTRO DE UNA

DISTANCIA DE 6 PIES DEL EQUIPO

Horizontal

Caída

Válvula de gas

3 pulg.

mínimo

Válvula de gas

Elevador

3 pulg.

mínimo

Caída

Horizontal

Elevador

Válvula de gas

3 pulg.

mínimo

3

NOTA

Salida de gas de piloto

Salida de gas

Figura 3. Tubería de válvula de gas típica

y/o con las normas relativas a gas combustible nacionales.

Todas las tuberías deben cumplir con las normas y leyes locales

Figura 2. Extremo de la salida de la válvula de gas

conector girándolo una vuelta y media más.

conector hasta que sienta que cede ligeramente. Ajuste el

Mientras sostiene el tubo con rmeza, ajuste lentamente el

Introduzca un tubo limpio sin rebaba hasta el nal del conector.

mano.

Aoje el conector del piloto hasta que quede bien ajustado a

las conexiones correspondientes. Una vez realizadas

7. Vea la sección CONEXIONES ELÉCTRICAS para realizar

dañar la válvula (50 pies/lbs máx).

6. No ajuste las tuberías de forma excesiva, ya que podría

g. 3 las conexiones de tuberías típicas).

ni cinta de teón a las primeras dos roscas (vea en la

roscas macho de las uniones. NO aplique compuesto

aprobada para todos los tipos de gases, sólo a las

5. Aplique compuesto sellador para tuberías o cinta de teón

viejo.

óxido, sedimentos, rebaba, astillas y compuesto sellador

tuberías viejas, asegúrese de que estén limpias y libres de

biseladas, fresadas y libres de rebaba y astillas. Si utiliza

4. Se recomienda utilizar tuberías nuevas debidamente

ujo de gas a través de la válvula.

de la válvula y de la placa inferior indican la dirección del

a la gura 1). Las echas de la etiqueta de identicación

respecto de la posición recta, o en posición vertical (reérase

3. Esta válvula puede instalarse en posición recta, + o – 90˚

tuberías y conexiones eléctricas del control viejo.

2. Si cambia una válvula existente, desconecte todas las

de gas principal.

fusibles o en el disyuntor. Apague también el suministro

1. Apague la alimentación eléctrica al sistema en la caja de

CONEXIÓN CON PILOTO.

LOS MODELOS 36H3X Y 36H6X REQUIEREN UNA

CONEXIÓN PARA GAS CON PILOTO

combustible nacionales.

las normas y leyes locales y/o con las normas relativas al gas

de realizar la instalación. Todas las tuberías deben cumplir con

Reérase a las advertencias y precauciones de la página 2 antes

PÉRDIDAS INMEDIATAMENTE.

indica una pérdida. CIERRE EL GAS Y REPARE LAS

de pérdidas o espuma de jabón. La formación de burbujas

y verique que no haya pérdidas con solución de detección

todas las conexiones de gas y eléctricas, encienda el gas

PRINCIPALES

CONEXIONES DE LAS TUBERÍAS

INSTALACIÓN

Page 11

¡ADVERTENCIA!

!

Si no sigue estas instrucciones al pie de la letra, puede producirse un

incendio o una explosión y, como consecuencia, daños materiales,

lesiones personales o la pérdida de vidas.

¡PRECAUCIÓN!

¡ADVERTENCIA!

2

instalarla.

con los componentes de la válvula de gas antes de

químicas que podrían reaccionar de forma nociva

taminantes, líquidos de corte u otras sustancias

3. Limpie las tuberías de gas para eliminar los con-

exposición al agua (goteo, rocío, lluvia, etc.).

protección adecuada para proteger el control de la

directamente con el agua. Debe proporcionarse la

en lugares en los que pueda entrar en contacto

2. Este control no está diseñado para ser utilizado

lesiones personales.

producir daños en el equipo, daños materiales y/o

cortocircuitos o las conexiones incorrectas pueden

gas ni del control principal para probarlos. Los

1. No cortocircuite las terminales de la válvula de

incendio o explosión.

pérdida de gas y lesiones como consecuencia de

Si no se instala correctamente, puede producirse una

de la válvula de gas.

de suministro de gas para evitar la contaminación

• Instale siempre el ltro de sedimentos en la línea

pies/libra máx.).

• No ajuste excesivamente la tubería al control (50

control.

en la abrazadera, el solenoide ni otras partes del

incendio y/o explosión.

personales y/o daños materiales, asfixia con gas,

visibles en la válvula. Éstos pueden causar lesiones

la válvula de gas puede producir daños internos no

contacto directo con agua. El ingreso de agua en

7. No utilice una válvula de gas que haya estado en

válvula que presente daños.

contacto con su proveedor para cambiar cualquier

asfixia con gas, incendio y/o explosión. Póngase en

nales y/o daños materiales debido a electrocución,

Una válvula dañada puede causar lesiones perso-

6. No utilice una válvula de gas que presente daños.

para ajustar la tubería de suministro. No la utilice

de la llave suministradas en la saliente de entrada,

• Utilice la llave auxiliar sólo en las partes planas

roscadas, fresadas, sin rebaba y limpias.

• Utilice tuberías de suministro nuevas, debidamente

de suministro a la válvula de gas.

salida hasta que esté listo para conectar la tubería

• No quite las tapas protectoras de la entrada y la

cuada.

Instale las tuberías de gas al control de forma ade-

una explosión.

a piloto, ya que podría producirse un incendio y/o

espera, piloto comprobado o encendido de chispa

mas con piloto, como los sistemas con piloto en

4. NO UTILICE UN CABLE DE PUENTE en los siste-

UN INCENDIO Y/O UNA EXPLOSIÓN.

DE PÉRDIDAS DE GAS YA QUE PODRÍA CAUSAR

DE CHISPERO PARA VERIFICAR LA PRESENCIA

3. NO UTILICE NUNCA UNA LLAMA NI NINGÚN TIPO

electrocución o de incendio.

dañarán el control y pueden causar riesgos de

voltaje especificado ya que los voltajes más altos

2. No utilizar este control en circuitos que excedan el

riales, asfixia con gas, incendio y/o explosión.

producirse lesiones personales y/o daños mategas de petróleo licuado con gas natural. Pueden

gas de petróleo licuado o un juego de control para

5. No utilice un juego de control para gas natural con

gas, incendio y/o explosión.

como consecuencia de electrocución, asfixia con

ducirse lesiones personales y/o daños materiales

principal al sistema de calefacción, podrían pro-

1. Si no se apaga el suministro eléctrico o de gas

SIGUIENTES PRECAUCIONES.

ANTES DE INICIAR LA INSTALACIÓN LEA LAS

PRECAUCIONES

Page 12

0927

360˚�

Reemplaza 37-6632A

Nº DE PIEZA 37-6632B

DE ENTRADA

SALIENTE VERTICAL

IZQUIERDA o DERECHA

www.emerson.com

www.white-rodgers.com

Figura 1. Posiciones de montaje de la válvula de gas

Instrucciones de encendido ........................................ 6

Ajuste .......... ............................................................... 5

Ajuste del regulador de presión

Ajuste ........ ................................................................. 4

Conexiones eléctricas

Instalación .................................................................. 4

Instalación .................................................................. 3

Precauciones ............................................................. 2

Especicaciones ........................................................ 1

RECTA

Recta, o de 0° a 90° respecto de la posición recta

CONTENIDO

Descripción ................................................................ 1

POSICIONES DE MONTAJE:

1/2 pulg. x 1/2 pulg. NPT 170,000 275,000

1/2 pulg. x 3/4 pulg. NPT 260,000 421,000

3/4 pulg. x 3/4 pulg. NPT 300,000 486,000

(1,000 btu/pies cúbicos) (2,500 btu/pies cúbicos)

Gas natural estándar AGA Gas de petróleo licuado

(pulg.)

Tamaños de tuberías disponibles de presión de 1 pulg. a través de la válvula

Capacidad (BTU/hora) a una caída

Dos etapas - .540A

Corriente: Una sola etapa - .410A

Frecuencia: 50/60 Hz

Voltaje: 24 VCA

Presión nominal: 14 pulg. W.C. (1⁄2 PSI) máx.

Temperatura ambiente: -40° a 175°F

Tipo de gas: Gas natural

de bajo a alto

Dif. mínimo

Bajo Alto

Dos etapas

TAMAÑOS/CAPACIDADES DE LAS TUBERÍAS

etapa

Una sola

licuado

Gas de petróleo 7.0 - 12.0 4.0 - 9.5 8.0 - 12.0 2.5

Gas natural 2.5 - 5.0 1.0 - 3.5 2.5 - 5.0 1.5

Ajuste del regulador de presión: (pulgadas W.C.)

ESPECIFICACIONES

36H65 2 Lento SÍ

36H64 2 Rápido SÍ

36H55 2 Lento NO

36H54 2 Rápido NO

36H33 1 Lento SÍ

36H32 1 Rápido SÍ

36H23 1 Lento NO

36H22 1 Rápido NO

MODELO ETAPAS ABIERTAS PROBADO

Nº DE Nº DE CARACTERÍSTICAS PILOTO

características indicadas en cada caso:

de encendido y apagado de dos posiciones para el cierre eléctrico del equipo. Los modelos enumerados a continuación incluyen las

el ujo de gas a los quemadores principales, un regulador de presión para mantener una presión de salida constante y un interruptor

La válvula de gas combinada serie 36H está diseñada con una válvula de solenoide principal y válvulas redundantes que controlan

DESCRIPCIÓN

PERSONALES Y/O DAÑOS MATERIALES.

DE INSTALAR O UTILIZAR ESTE CONTROL PODRÍA CAUSAR LESIONES

EL NO LEER Y SEGUIR CON CUIDADO TODAS LAS INSTRUCCIONES ANTES

INSTRUCCIONES PARA LA INSTALACIÓN

Válvula de gas combinada

SERIE 36H

Loading...

Loading...