Page 1

Save these instructions for future use!

q

)

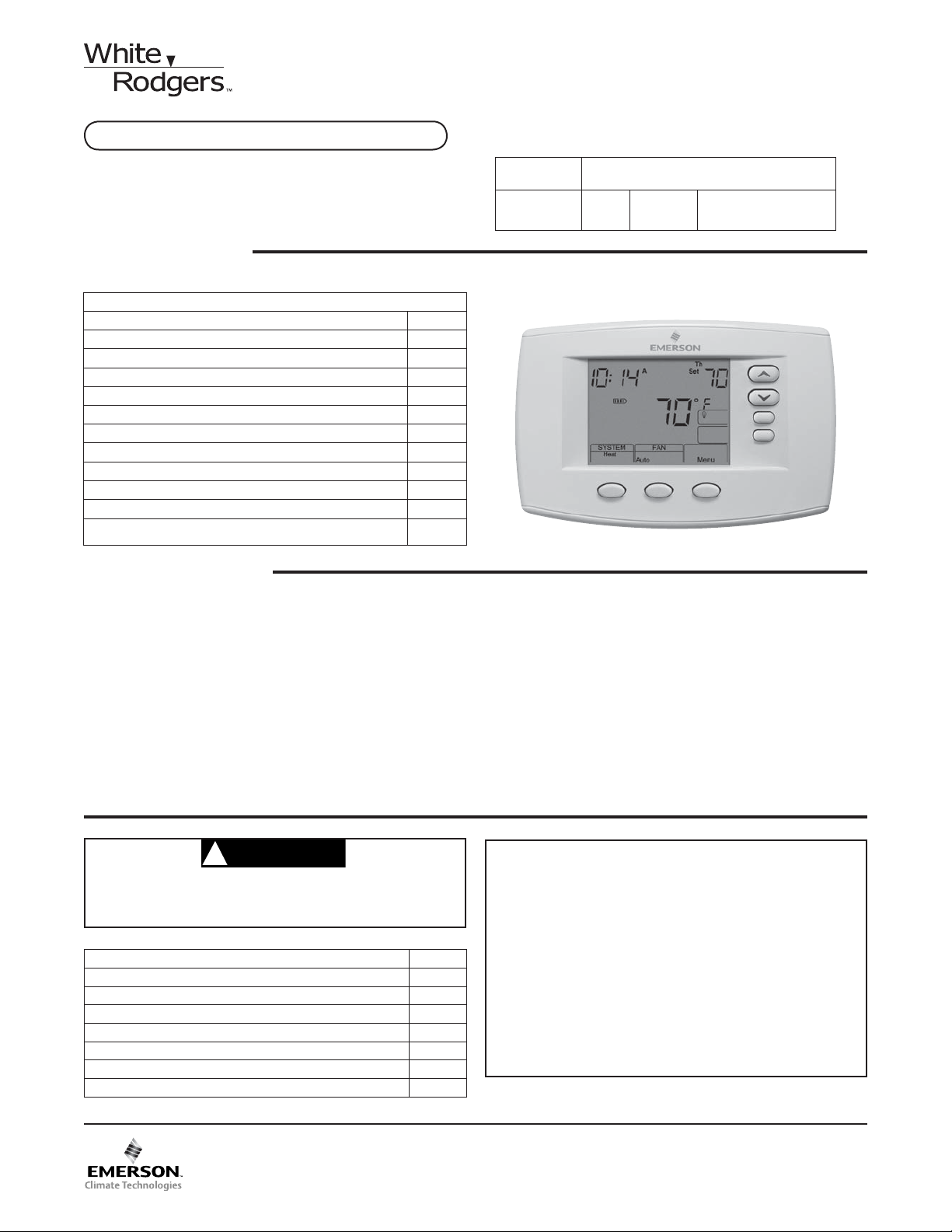

Blue Universal Thermostat

with Automatic Heat/Cool

Changeover Option

Single Stage, Multi-Stage, Heat Pump

Installation and Operating Instructions for Model:

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS

CAREFULLY BEFORE INSTALLING OR OPERATING THIS

CONTROL COULD CAUSE PERSONAL INJURY AND/OR

PROPERTY DAMAGE.

Model Programming Choices

1F95-0671

7 Day 5/1/1 Day Non-Programmable

APPLICATIONS

THERMOSTAT APPLICATION GUIDE

Description

Heat Pump (No Aux. or Emergency Heat) Yes

Heat Pump (with Aux. or Emergency Heat) Yes

Systems with up to 4 Stages Heat, 2 Stages Cool Yes

Heat Only Systems Yes

Millivolt Heat Only Systems – Floor or Wall Furnaces Yes

Cool Only Systems Yes

Gas or Oil Heat Yes

Electric Furnace Yes

Hydronic (Hot Water) Zone Heat – 2 Wires Yes

Hydronic (Hot Water) Zone Heat – 3 Wires Yes

Wired Remote Temperature Sensor (Indoor or Outdoor) Yes

Dual Fuel Feature (Heat Pump Mode, Outdoor Remote

uired

Re

Ye s

1F95-0671 Universal Thermostat

SPECIFICATIONS

Electrical Rating:

Battery Power. . . . . . . . . . . . . . . . . . . . . . . . . . mV to 30 VAC, NEC Class II, 50/60 Hz or DC

Input-Hardwire . . . . . . . . . . . . . . . . . . . . . . . . . 20 to 30 VAC

Terminal Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5A per terminal, 2.5A maximum all terminals combined

Setpoint Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 to 99°F (7 to 32°C)

Differential (Single Stage) . . . . . . . . . . . . . . . . . . . . Heat 0.6°F; Cool 1.2°F

Differential (Multi-Stage) . . . . . . . . . . . . . . . . . . . . . Heat 0.6°F; Cool 1.2°F

Differential (Heat Pump) . . . . . . . . . . . . . . . . . . . . . Heat 1.2°F; Cool 1.2°F

Operating Ambient. . . . . . . . . . . . . . . . . . . . . . . . . . 32°F to +105°F (0 to +41°C)

Operating Humidity . . . . . . . . . . . . . . . . . . . . . . . . . 90% non-condensing max.

Shipping Temperature Range . . . . . . . . . . . . . . . . . -40 to +150°F (-40 to +65°C)

Dimensions Thermostat. . . . . . . . . . . . . . . . . . . . . . 4.2"H x 6.4"W x 1.7"D

CAUTION

!

To prevent electrical shock and/or equipment damage,

disconnect electric power to system at main fuse or

circuit breaker box until installation is complete.

Index Page

Installation 2

Wiring Diagrams 3

Thermostat Quick Reference 5

Installer Confi guration Menu 6

Operating Your Thermostat 9

Programming 10

Troubleshooting 14

ATTENTION: MERCURY NOTICE

This product does not contain mercury. However, this product may replace a product that contains mercury.

Mercury and products containing mercury must not be

discarded in household trash. Do not touch any spilled

mercury. Wearing non-absorbent gloves, clean up any

spilled mercury and place in a sealed container. For proper

disposal of a product containing mercury or a sealed

container of spilled mercury, place it in a suitable shipping

container. Refer to www.white-rodgers.com for location to

send product containing mercury.

PART NO. 37-6979A

www.white-rodgers.com

0908

Page 2

INSTALLATION

WARNING

!

Thermostat installation and all components of the

control system shall conform to Class II circuits per

the NEC code.

Remove Old Thermostat

Before removing wires from old thermostat, mark wires for

terminal identifi cation so the proper connections will be made

to the new thermostat.

Installing New Thermostat

1. Pull the thermostat body off the thermostat base. Forcing

or prying on the thermostat will cause damage to the unit.

2. Place base over hole in wall and mark mounting hole

locations on wall using base as a template.

3. Move base out of the way. Drill mounting holes. If you

are using existing mounting holes and the holes drilled

are too large and do not allow you to tighten base snug ly, use plastic screw anchors to secure the base.

4. Fasten base snugly to wall using mounting holes shown

in Figure 1 and two mounting screws. Leveling is for

appearance only and will not affect thermostat operation.

5. Connect wires to terminal block on base using appropriate

wiring schematic.

6. Push excess wire into wall and plug hole with a fi re re sistant material (such as fi berglass insulation) to prevent

drafts from affecting thermostat operation.

7. Carefully line the thermostat up with the base and snap

into place.

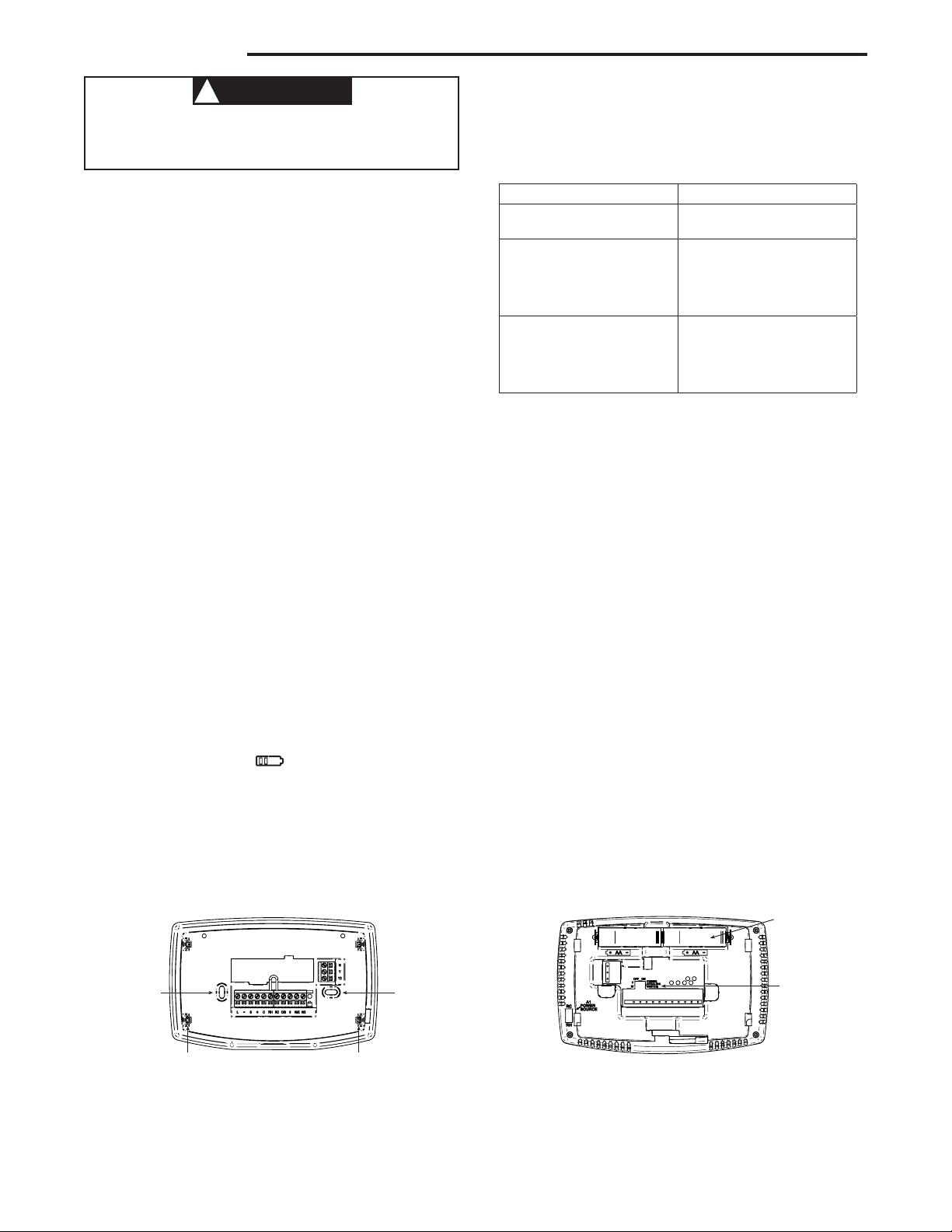

Battery Location

2 "AA" alkaline batteries are included in the thermostat at the

factory with a battery tag to prevent power drainage. Remove

the battery tag to engage the batteries.

To replace batteries, set system to OFF, remove thermostat

from wall and install the batteries in the rear along the top of

the thermostat (see Figure 1). For best results, use a premium brand "AA" alkaline battery such as Duracell

®

gizer

. If the home is going to be unoccupied for an extended

period (over 3 months) and

is displayed, the batteries

should be replaced before leaving.

®

or Ener-

Power Stealing Switch

The Power Stealing Switches (Figure 1, rear view) should be

left in the "On" position for most systems. The information in

the following table details the thermostat power method and

switch options.

Thermostat Power Method Switch Position/Description

Battery Powered, no 24 Volt

system power available.

Hardwired with Battery

Back-up, for 24 Volt systems

with common connection from

transformer to "C" terminal on

thermostat.

*Battery Powered with Power

Stealing Assist, for 24 Volt

systems with no common

connection from transformer to

"C" terminal on thermostat.

*Power Stealing Assist is very reliable to increase battery life,

but on a small number of heating or cooling systems with high

impedance electronic modules you may observe one of the following conditions:

1. The furnace draft inducer motor may run with no call for heat.

2. The furnace fan may turn on with no call for heat or may not

turn off.

3. The furnace may not turn off when the call for heat ends.

4. The air conditioner may not turn off when the call for cool ends.

If the Power Stealing Assist method is not compatible with your

system, place the Power Stealing Switches to "Off". This cancels

Power Stealing Assist, operates the thermostat on batteries and

corrects the condition.

Switches "On", thermostat runs

on batteries.

Switches "On", thermostat

runs on power directly from

transformer with battery backup.

Switches "On", thermostat runs

on batteries and supplemental

power drawn through the heat

or cool circuit.

Figure 1 – 1F95-0671

Rear view of thermostat

*

* A1 For Damper Control Not Applicable To This Model.

2 "AA" Batteries

Power Stealing

Switches

Mounting

Hole

Place Level

across Mounting Tabs

(for appearance only)

Thermostat Base

across Mounting Tabs

(for appearance only)

Place Level

Mounting

Hole

2

Page 3

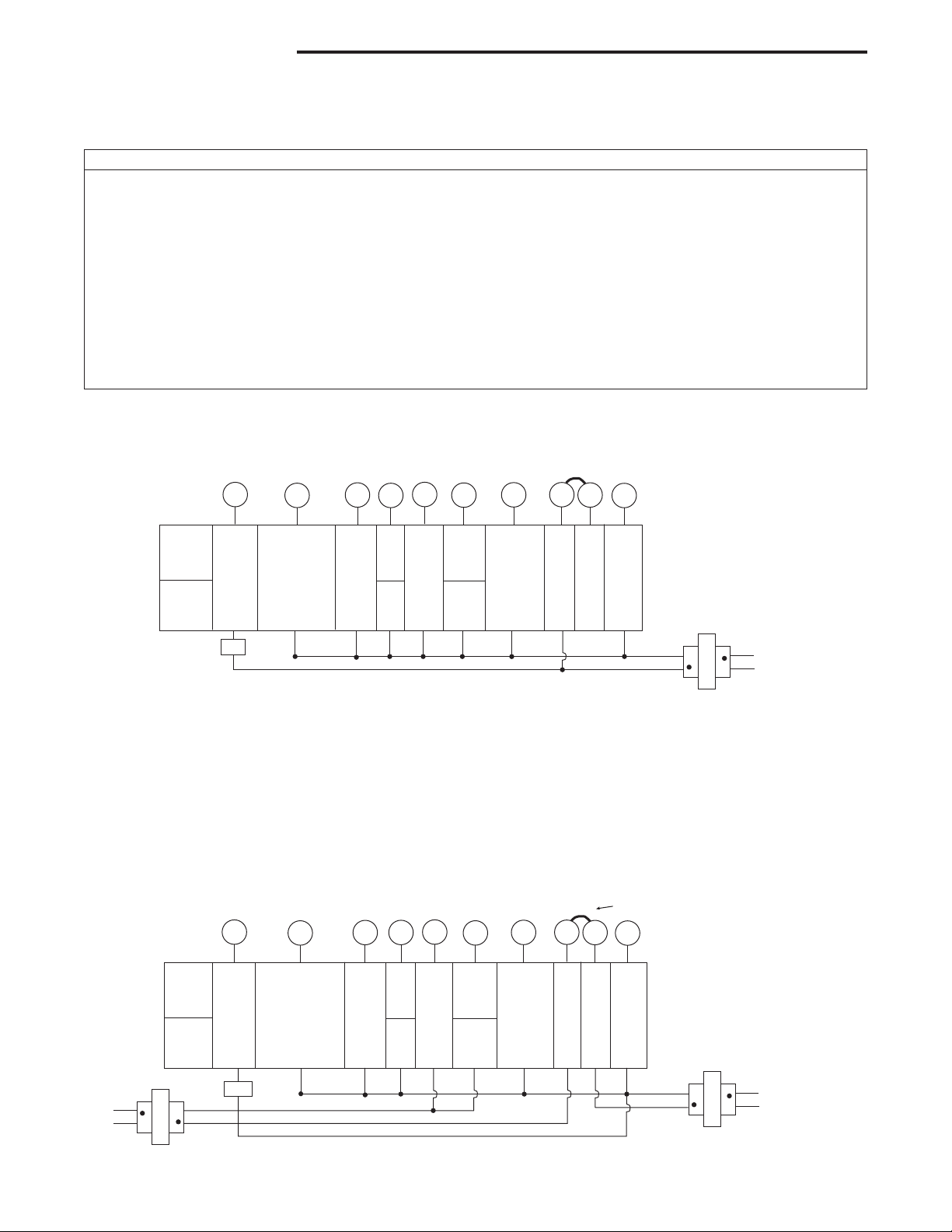

WIRING DIAGRAMS

Refer to equipment manufacturers' instructions for specifi c

system wiring information. After wiring, see CONFIGURA-

Wiring diagrams shown are for typical systems and describe

the thermostat terminal functions.

TION section for proper thermostat confi guration.

TERMINAL DESIGNATION DESCRIPTIONS

Terminal Designation Description

O/B ........................................... Changeover valve for heat pump energized constantly in cooling and off/heating

Y2 ............................................ 2nd Stage Compressor

Y ............................................ Compressor Relay

G ............................................ Fan Relay

RC ............................................ Power for Cooling

RH ............................................ Power for Heating

C ............................................ Common wire from secondary side of cooling (Optional). Required for fault indication, continuous back-

light operation or remote temperature sensor operation 6 Powered closed 3rd wire for 3-wire zone valve

W/E ........................................... Heat Relay/Emergency Heat Relay (Stage 1) (3rd Stage Heat in HP2)

W2 ............................................ 2nd Stage Heat (4th Stage Heat in HP2)

- ............................................ Common (DC) for wired remote temperature sensor

S ............................................ Frequency signal from remote temperature sensor

+ ............................................ Power (DC) to remote temperature sensor

L ............................................ Compressor diagnostic indicator for systems with diagnostic connection typically found on Heat pump

systems or with Copeland's Comfort Alert

Figure 2 – Single Stage or Multi-Stage System (No Heat Pump)

with Single Transformer

Jumper

System

Single

Stage 1

(SS1)

MultiStage 2

(MS2)

Comfort Alert II Module

or Similar System

Diagnostic Module

See Module Instructions

for details

L

Diagnostic

Indicator

Input

or

System

Malfunction

Switch

Input

O/B

O

Energized Constantly

in

Cool Mode

B

Energized Constantly

in Heat, Off,

Emergency

Mode

Y

Cool Mode

1st Stage

Y2

No

Output

Cool

Mode

2nd

Stage

W/E

Heat

Mode

1st Stage

W2

No Output

Heat Mode

2nd Stage

G

Blower/

Circulator

Fan Energized

on Call for

Cool (and

Heat if

configured

for Electric

Heat)

RH

24 Volt

(Hot)

Heat

* Common connection required for diagnostic or malfunction indication.

RC

24 Volt

(Hot)

Cool

C

Optional*

24 Volt

(Com-

mon)

NEUTRAL

24VAC

HOT

CLASS II

TRANSFORMER

120VAC

Single Stage and Multi-Stage Connections

Refer to equipment manufacturers' instructions for specifi c

system wiring information.

This thermostat is designed to operate a single-transformer

or two-transformer system.

You can confi gure the thermostat for use with the following

systems:

Figure 3 – Single Stage or Multi-Stage System (No Heat Pump)

with Two Transformers

O/B

O

Energized Constantly

in

Cool Mode

B

Energized Constantly

in Heat, Off,

Emergency

Mode

Y

Cool Mode

1st Stage

No

Output

Cool

Mode

2nd

Stage

120VAC

HEATING

System

Single

Stage 1

(SS1)

MultiStage 2

(MS2)

CLASS II

TRANSFORMER

NEUTRAL

24VAC

HOT

L

Diagnostic

Indicator

(Optional)

SINGLE STAGE (SS 1) gas, oil or electric.

MULTI-STAGE (MS 2) gas, oil or electric.

After wiring, see INSTALLER CONFIGURATION section for

proper thermostat confi guration.

Jumper

RH

W/E

Y2

Heat

Mode

1st Stage

W2

No Output

Heat Mode

2nd Stage

G

Blower/

Circulator

Fan Energized

on Call for

Cool (and

Heat if

configured

for Electric

Heat)

24 Volt

(Hot)

Heat

Remove Jumper Wire

between RH & RC

RC

Optional

24 Volt

24 Volt

(Hot)

(Com-

Cool

mon)

C

NEUTRAL

24VAC

HOT

CLASS II

TRANSFORMER

120VAC

COOLING

3

Page 4

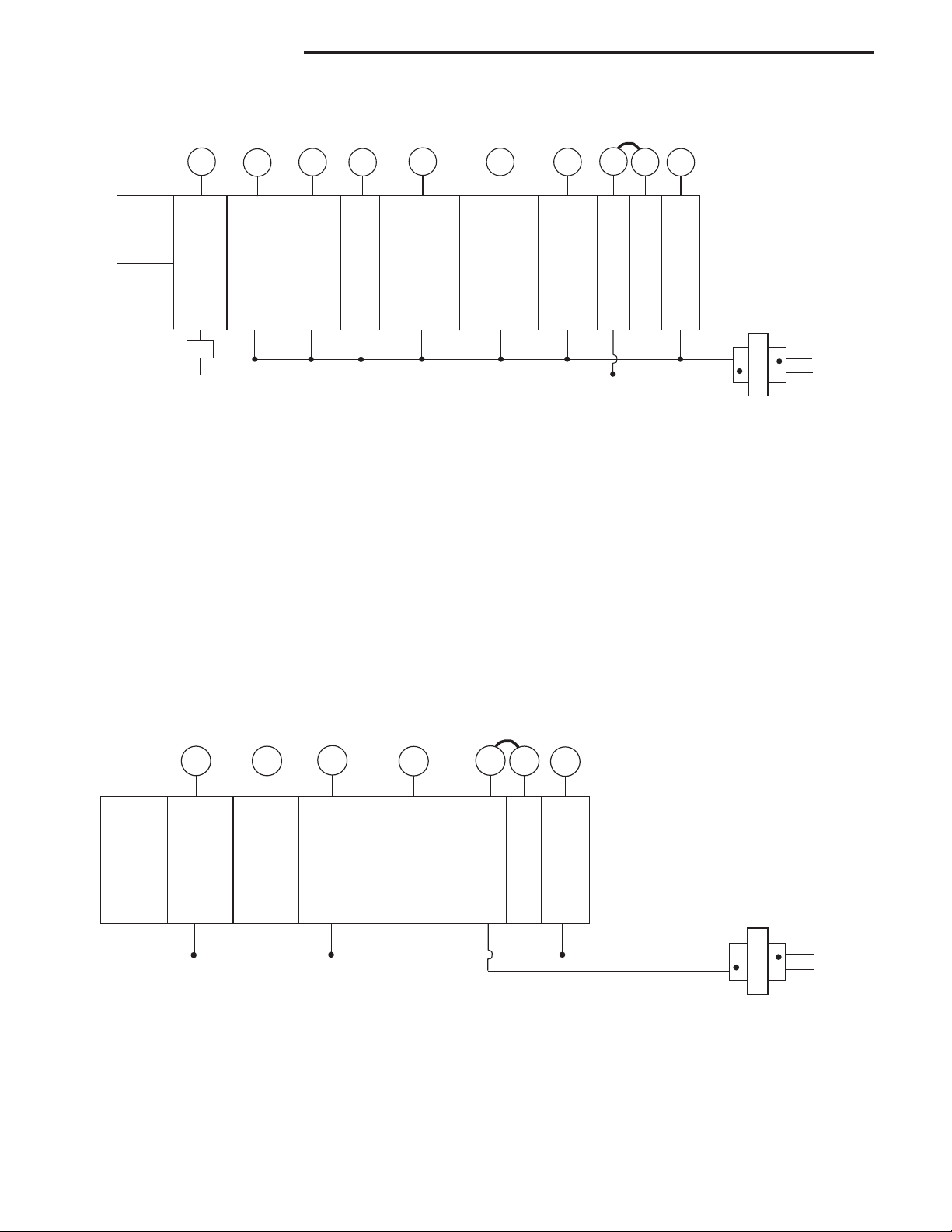

WIRING DIAGRAMS

System

Heat Pump 1

(HP1)

Heat Pump 2

(HP2)

Comfort Alert II Module

or Similar System

Diagnostic Module

See Module Instructions

for details

L

Diagnostic

Indicator

or System

Malfunction

Switch

O/B

O

Energized in

Cool Mode

B

Energized in

Heat, Off,

Emergency

Mode

* Common connection required for diagnostic or malfunction indication.

+

Dual Fuel option, if selected turns off compressor(s) when Auxiliary stages energize.

Y

Heat and

Cool Mode

1st Stage

(Compressor)

Figure 4 – Heat Pump Systems

Y2

No

Output

2nd

Stage

(Compressor)

+

W/E

Heat Mode - 2nd

Stage, Emergency

Mode - 1st Stage

+

Note: Dual Fuel option

de-energizes Heat mode

stage 1 (compressor)

when auxiliary heat

is energized

Heat Mode - 3rd

Stage, Emergency

Mode - 1st Stage

+

Note: Dual Fuel option

de-energizes Heat mode

stage 1 (compressor)

when auxiliary heat

is energized

+

W2

Heat Mode - 3rd

Stage, Emergency

Mode - 2nd Stage

+

Note: Dual Fuel option

de-energizes Heat mode

stage 1 (compressor)

when auxiliary heat

is energized

Heat Mode-4th

Stage. Emergency

Mode - 2nd Stage

+

Note: Dual Fuel option

de-energizes Heat mode

stage 1 (compressor)

when auxiliary heat

is energized

G

Blower/

Circulator Fan

Energized on

Call for Heat

or Cool.

Set Elect/Gas

Option for

Emergency

mode

Jumper

RH

24 Volt

(Hot)

Heat

RC

24 Volt

(Hot)

Cool

C

Optional*

24 Volt

(Com-

mon)

NEUTRAL

24VAC

HOT

CLASS II

TRANSFORMER

120VAC

Heat Pump Connections

Refer to equipment manufacturers' instructions for specifi c

system wiring information.

This thermostat is designed to operate a single-transformer

or two-transformer system.

You can confi gure the thermostat for use with the following

systems:

Figure 5 – 3-Wire (SPDT) Heat Only Zone Valve Wiring

W

Opens

Val ve

(4)

G

Blower/Circulator

Fan Energized

System

Single Stage

3-wire

Zone Valve

application

6

Closes

Val ve

(6)

Y

HEAT PUMP TYPE 1 (HP 1). Single stage compressor

system; gas or electric backup.

HEAT PUMP TYPE 2 (HP 2). Multi-stage compressor or two

compressor system with gas or electric backup.

After wiring, see INSTALLER CONFIGURATION section for

proper thermostat confi guration.

Jumper

RC

C

Constant

24 Volt

(Com-

mon)

RH

24 Volt

(Hot)

Heat

(5)

24 Volt

(Hot)

Cool

NEUTRAL

24VAC

HOT

CLASS II

TRANSFORMER

120VAC

4

Page 5

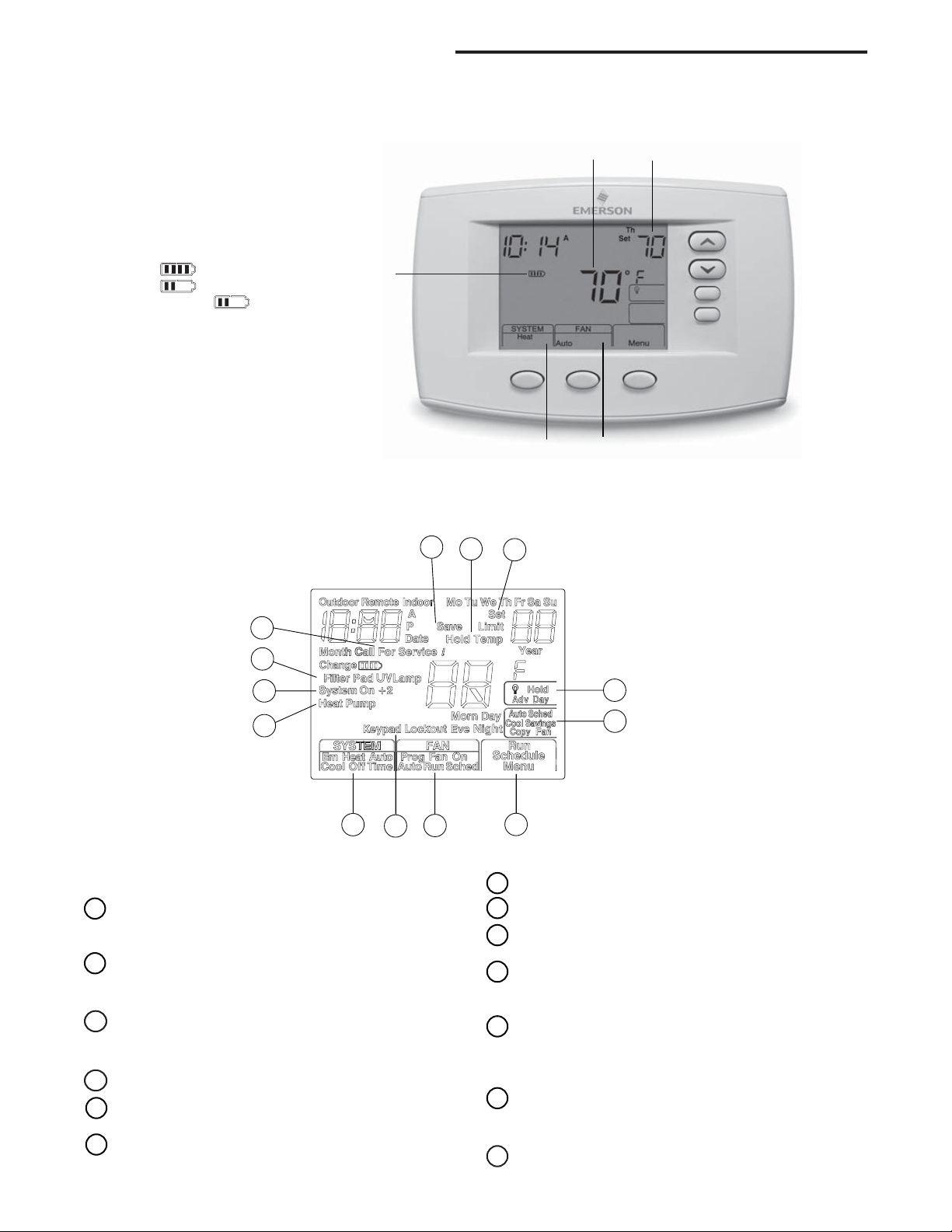

THERMOSTAT QUICK REFERENCE

Home Screen Description

Figure 5 – Home Screen Display

Battery Level Indicator

Indicating the current power level

of the 2 “AA” batteries:

Full power remaining.

Half power remaining

Change The batteries should

be replaced at this time with 2 new

premium brand “AA” Alkaline batteries.

(See page 2 for more details)

Room

Temperature

Setting

Temperature

Figure 6 – Programming & Confi guration Items

8

12

3

1

9

5

13

6

Programming and Confi guration Items

"System On" indicates when heating or cooling stage

1

is energized. "System On +2" indicates when addi

tional stages are on.

2

The word "Hold" is displayed when the thermostat is

in the HOLD mode. "Temp" is displayed when the

thermostat is in a Temporary HOLD mode.

Displays "Change Filter" when the system has run for

3

the programmed fi lter time period as a reminder to

change or clean your fi lter.

4

Displays "Set" for setpoint when in Run Program mode.

Displays System Mode (Heat, Em, Auto, Cool, Off)

5

or Time in menu mode.

Displays Fan mode (On, Auto) "Prog FAN On" or

6

"Run Sched" in Menu mode.

System

Indicator

2

4

7

7

Displays "Run Schedule", "Schedule", or "Menu".

8

Displays "Save" when Cool Savings

Displays "Heat Pump" when system is confi gured

9

as Heat Pump thermostat.

Displays "Hold" in programmable mode when not in

10

Hold mode. Displays Light Bulb in non-program-

mable mode.

Initially displays "Auto Sched". If Auto Schedule had

11

been used or disabled, then it displays "Cool Savings"

when in the Cool Mode. Displays "Copy" in Schedule

mode and "Fan" in Fan Schedule mode.

"Call For Service" indicates a diagnostic fault in the

12

heating/cooling system, it does not indicate a fault in the

thermostat.

"Keypad Lockout" in Menu mode when selecting key-

13

pad Lockout or in RUN when a keypad Lockout is active.

Fan

Indicator

10

11

TM

is working.

5

Page 6

INSTALLER/CONFIGURATION MENU

Thermostat must be in Heat, Cool or Auto. Press and hold the Menu button for at least 5 seconds. The display will show item

#1 in the table below. Press Menu to advance to the next menu item. Press

INSTALLER/CONFIGURATION MENU

Menu

HP SS Press

Ref.

1 1 1 MENU (MS 2) HP 1, HP 2, SS 1 Selects Multi-Stage (MS 2 No Heat Pump),

2 2 2 MENU (GAS) for SS or MS

3 3 3 MENU CS (3) 0, 1, 2, 4, 5, 6 Selects Cool Savings

4 4 4 MENU E (On) OFF Selects Energy Management Recovery (EMR)

5 – 5 MENU CR Heat (ME) SL, FA Selects Adjustable Anticipation, cycle rate, Heat

6 5 – MENU CR Heat Pump

7 6 6 MENU CR Cool (ME)

8 7 7 MENU CL (OFF) CL On Compressor Lockout Time

9 8 8 MENU Em Heat, Auto

Button

Displayed

(Factory Default)

(ELE) for HP

(ME)

or

CR AU (FA)

Cool Off

or

Heat, Auto,Cool Off

Press

to select from listed

Heat Cool Off,

Heat Off with Fan icon,

Heat Off without Fan icon

Cool Off, Auto Off

or

options

ELE GAS setting: furnace controls the blower

SL, FA Selects Adjustable Compressor Anticipation

SL, FA

SL

or to change a menu item options.

Comments

Heat Pump 1 (HP 1, 1 compressor),

Heat Pump 2 (HP 2, 2 compressor or 2

speed compressor), or Single Stage (SS 1)

ELE setting: thermostat controls the blower

Value 1 (low) to 6 (high),

Value 0 disables feature

On or OFF.

(This item only appears when MS 2 or SS 1 is

selected above)

(Heat Pump) This item only appears when

HP 1, HP 2 is selected above

Selects Adjustable Anticipation, cycle rate, cool

(when MS 2 or SS 1 is selected above.) or

Selects the cycle rate for Auxiliary stage (when

HP 1 or HP 2 is selected above)

System Mode Confi guration

with Automatic Changeover capability

10 9 9 MENU dL (On) dL OFF Selects Display Light On or OFF

11 10 10 MENU 0

(current temperature)

12 11 11 MENU °F °C Selects Fahrenheit/Celsius Temperature Display

13 12 12 MENU (On) b OFF May select Beeper OFF to stop audible

14 13 13 MENU P (7) 3, 0 Defaults 7-day programming (P7) but non-

15 14 14 MENU PS (4) 2 Selects Program periods per day:

16 15 15 MENU Heat AS (On) OFF Automatic Schedule for heat mode

17 16 16 MENU Cool AS (On) OFF Automatic Schedule for cool mode

18 17 – MENU Heat FA (On) OFF Fast Heat option may be disabled by

19 18 – MENU Cool FA (On) OFF Fast Cool option may be disabled by

20 19 17 MENU Remote (OFF) On Selects Remote Sensor On/OFF

MENU Remote

(In)

MENU Indoor Loc

(On)

1 HI, 2 HI, 3HI, 4 HI,

1 LO, 2 LO, 3 LO, 4 LO

Outdoor Selects Remote Sensor to outdoor

OFF Selects Local Sensor (in thermostat) to OFF.

Adjustable Ambient Temperature Display

key feedback

programmable (0) or 5/1/1 programming (P3)

is available on most models.

4 = Morn, Day, Eve, Night

2 = Day, Night

selecting OFF. NA to SS or HP1 confi g.

selecting OFF. NA to SS or HP1 confi g.

NA is Remote Sensor OFF

N/A if Remote is selected to Outdoor

6

Page 7

INSTALLER/CONFIGURATION MENU

21 20 18 MENU dS (On) Off Selects Automatic Daylight Saving Time option

22 21 19 MENU (OFF)

Keypad Lockout

MENU (000)

Keypad Lockout

23 22 20 MENU L Heat

(99)

24 23 21 MENU L Cool

(45)

25 24 – MENU CO

(05)

MENU (dF) EA Selects between dF (dual Fuel) or EA (Electric

MENU Cd

(60)

26 25 – MENU AO

(80)

27 26 22 MENU Change Filter (OFF) On Selects Filter Change-out Indicator On or OFF.

MENU Change Filter (200 h) 25-1975 h Change Filter time in 25 hour increments. This

28 27 23 MENU (OFF)

Change UV Lamp

MENU (350)

Change UV Lamp

29 28 24 MENU Cool On (o) Heat On (b) Selects operation of the reversing valve terminal

30 29 27 MENU RUN SCHED Returns to Normal Operation

L, P, Limit Selects one of 3 Keypad Lockout confi gurations

L - Total Keypad Lockout

P - Partial Keypad Lockout

(Up and Keys still work)

Limit - Limited Temperature Range

1-999 Selects personal lockout code. 000 is NOT A

VALID CODE.

L 62 to L 98 Select Limited HEAT Range Temperature

L 46 to L 82 Select Limited COOL Range Temperature

06-50 Selects outdoor Compressor OFF temperature

(Balance Point temperature). 05 disables fea-

ture. Outdoor Remote required

Aux) only available if CO is greater than 05

Selects Compressor delay OFF time in seconds

(only if dF is selected)

Selects AO (Auxiliary OFF) temperature. Fea-

ture disabled if 80 is selected. Outdoor Remote

required

menu only appears if On is selected in above.

On Selects UV Lamp

Timer: On/OFF

25-1975 Selects number of Days between

changing UV Lamp

(O/B) output as an O or B terminal

1) This control can be confi gured for:

MS 2 – Multi-Stage System (no heat pump)

HP 1 – Heat Pump with one stage of compressor

HP 2 – Heat Pump with two stage compressor or two

compressor system, Gas or Electric backup

SS 1 – Single Stage System

2) GAS or Electric (ELE) fan operation. If the heating system

requires the thermostat to energize the fan, select ELE.

Select GAS if the heating system energizes the fan on a

call for heat.

3) Select Cool Savings™ value – Selects the amount of

adjustment for the Cool Savings™ feature in Cool mode

with 1 (1°) being the least amount of adjustment and 6

(6°) being the most amount of adjustment. Default value

is 3. Cool Savings is an optional energy saving feature that

can reduce your cooling costs. It is based on the principal

that lower indoor humidity makes a slightly higher temperature feel more comfortable. Cool Savings operates

during periods of high demand which normally occur on

the hottest summer days when a cooling system may run

for hours to reach the thermostat setting. Long cooling

run times also lower the indoor humidity. Cool Savings,

very slowly, adjusts the setpoint temperature to make the

setpoint closer to the displayed room temperature, to a

maximum of the number of degrees you select. Adjusting the setpoint temperature over a long cooling run time

allows the system to reach your set temperature and turn

off. The room temperature will actually be higher than the

thermostat displays but the reduction in humidity will allow

comfort at the slightly higher temperature.

To turn this feature on in the Cool mode press Cool

Savings. The display will show “Save” next to the set-

point temperature. When Cool Savings is making adjustments to the room temperature display “Save” will be

fl ashing and the displayed room temperature may vary

within the adjustment range you selected.

If "Save" is not displayed and this feature is OFF, no

change will occur when the cooling system is continuously

running during periods of high demand.

4) Energy Management Recovery: (this step is skipped if

confi gured to be non-programmable).

Energy Management Recovery (E) On enables the ther-

mostat to start heating or cooling early to make the building

temperature reach the program setpoint at the time you

specify. Heating will start approximately 5 minutes early

(15 minutes for heat pump) for every 1° of temperature

required to reach setpoint.

Example: E On is selected and your heating is pro-

grammed to 65° at night and 70° at 7 AM. If the building

temperature is 65°, the difference between 65° and 70° is

5°. Allowing 5 minutes per degree, the thermostat setpoint

will change to 70° at 6:35 AM. Cooling allows approximately 15 minutes per degree, because it takes longer to

reach set temperature.

7

Page 8

INSTALLER/CONFIGURATION MENU

5, 6 & 7) Cycle Rate Selection – The factory default setting for

Heat and Cool modes, SS1, MS2, is medium cycle (ME).

For Heat Pump, HP1, HP2, the default setting is medium

(ME). For Emer (Aux) the default setting is fast cycle (FA).

To change cycle rate, press the

Cycle rate differentials for different settings are:

MODE Fast Medium Slow

FA ME SL

Heat (SS1, MS2) 0.4°F 0.6°F 1.7°F

Cool (SS1, MS2) 0.9°F 1.2°F 1.7°F

Heat Pump (HP1, HP2) 0.9°F 1.2°F 1.7°F

Emer (HP1, HP2) 0.6°F - 1.7°F

8) Select Compressor Lockout CL OFF or ON – Selecting

CL ON will cause the thermostat to wait 5 minutes between cooling cycles. This is intended to help protect the

compressor from short cycling. Some newer compressors

already have a time delay built in and do not require this

feature. Your compressor manufacturer can tell you if the

lockout feature is already present in their system. When

the thermostat compressor time delay occurs, it will fl ash

the setpoint for up to fi ve minutes.

9) System Mode Confi guration – This thermostat is confi g-

ured for Heat and Cool (SYSTEM switch with Cool Off

Heat) default. It can also be confi gured for Heat and Cool

with Auto changeover (Heat, Auto, Cool, Off), Heat only

with fan (Off Heat), Heat only without fan, Auto only

(Auto Off), and Cool only (Cool Off).

10) Select Backlight Display – The display backlight improves

display contrast in low lighting conditions. When the "C"

terminal is powered, selecting backlight CdL ON will keep

the light on continuously. Select backlight OFF will turn the

light on momentarily after any button is pressed. When the

"C" terminal is not powered, the light will be on momentarily

after any button is pressed no matter whether the backlight

is selected ON or OFF.

11) Select Temperature Display Adjustment 4 LO to 4 HI –

Allows you to adjust the room temperature display up to 4°

higher or lower. Your thermostat was accurately calibrated

at the factory, but you have the option to change the display temperature to match your previous thermostat. The

current or adjusted room temperature will be displayed.

12) Select F° or C° Readout – Changes the display readout

to Celsius or Fahrenheit as required.

13) Select Audio Prompting (Beeper) On or Off – Factory

default setting is on (b, On). If you wish to turn off the

beeper select OFF.

14) Program Options: Selects confi guration for 7 day (7) or

5/1/1 day (3) programming or non-programming (0) mode.

The default setting is 7, indicating 7 day programming.

The programs per week can be changed to 3 or 0 by

pressing the

non-programmable will eliminate the need for EMR, and

that step in the menu will be skipped.

15) Program Steps per day – This control can be confi gured

for 4 or 2 program steps per day. Default is "4 PS" and

can be toggled between 4 PS and 2 PS.

16 & 17) Select Automatic Schedule – With just one touch

of the Auto Schedule key this feature allows you to program a desired comfort temperature into all the program

periods along with a 6° set back for night periods of both

Heat and Cool programs. Factory default is "On" for both.

When Heat AS On and Cool AS On are activated while

in Heat or Cool mode, select desired setpoint temperature

and press Auto Schedule. This value will be copied into

all the morning, day and evening program periods. The

night program periods will have a 6°F set back.

or buttons. A selection of 0 days for

or button.

18 & 19) Select Fast Second Stage ON or OFF – Heat

pump or Multi-stage only, in the run mode, with the fast

Heat feature enabled (FA Heat On), if the Heat setpoint

temperature is manually raised by 3°F (2°C) or more

above the actual temperature using

will energize immediately. With FA OFF, second stage will

not energize until the setpoint temperature is 1°F or more

above actual temperature for more than ten minutes. The

Fast Cool feature (FA Cool) provides the same controls

when the setpoint temperature is lowered.

20) Select Remote Temperature Sensor – This control

allows one wired remote temperature sensor (indoor,

F145-1328, or outdoor, F145-1378) be connected to it and

indicates the measured temperature in clock digits. This

menu enables you to select the remote sensor and also

confi gure it as indoor or outdoor temperature sensor. Factory default is off. Select Remote On and Remote in (for

indoor) or Outdoor Remote.

Local Temperature Sensor disable – This is applicable

only when indoor remote temperature sensor is enabled.

Factory default is Loc On. You can make it Loc Off if you

desire by using

remote temperature reading will be used for control

21) Select Daylight Saving Time Calculation – This feature

will allow the thermostat to calculate the DST automatically and apply it to the Real Time Clock display. Default

On. Use or touch keys to select the feature OFF.

22) Keypad Lockout – This step allows you to select the type

of lockout or limited range security required. If no lockout or limited range security is required, press MENU to

advance the menu.

Three security settings are available in this menu item.

Use the

Lockout selections are:

"Keypad Lockout and L" = Total Lockout. Total Lockout

locks all keys.

"Keypad Lockout and P" = Partial Lockout. Partial Lock-

out allows only the

your set temperature limits.

"Keypad Lockout and Limit" prevents changing the

temperature limits in the Confi guration Menu.

Press Menu after selecting the type of lockout.

"Keypad Lockout Combination Number Selection"

Display will read "000" "Keypad Lockout". Note: "000" is

not a valid combination choice.

Skip this step and continue through the remaining confi gu-

ration menu items if you require an Air Filter Change out

indicator or Humidifi er Pad Change out indicator by pressing the MENU button to advance.

Return to this point when you are ready to start your

selected lock-out and continue by:

Press

Pressing

out combination number.

Record the number you select for future use.

Press MENU or RunSched to exit the menu. The security

feature you select will start. The system button will remain

active for 10 seconds to allow setting Heat, Off, Cool or

Auto.

23) Limited Heat Range – This feature provides a maximum

setpoint temperature for heat. The default setting is 99°F.

It can be changed between 62°F and 98°F by pressing the

. Display will read "001".

or button.

or buttons. Then, only the indoor

or buttons to select the lockout desired.

or buttons to operate within

or buttons to select your keypad lock-

the second stage

8

Page 9

INSTALLER/CONFIGURATION MENU

24) Limited Cool Range – This feature provide a minimum

setpoint temperature for cool. The default setting is 45°F. It

can be changed between 46°F and 82°F by pressing the

or button.

25) Select Compressor Off (CO) Feature Using Outdoor

Sensor – This feature is applicable only in heat pump

modes and with an outdoor sensor installed and enabled.

When CO is enabled by selecting a temperature >05°F

(-15°C), the thermostat will use the outdoor sensor temperature to determine when to switch to gas heat and shut

down the compressor.

When the outdoor temperature goes below the selected

temperature, the gas heat will begin. Default is 05 (Off or

disabled), but can be set in the range of 06 to 50 using the

or buttons.

Select dF or EA – If CO is set > 05°F (-15°C), select dF

(default) if your system has a fossil fuel (gas or oil) Auxiliary heat. Select EA if your system has Electric Auxiliary

heat and you want the compressor to continue to run

while calling for Auxiliary stage.

Select Compressor Delay (Cd) – If dF is selected, after

the auxiliary heat is turned on, the compressor(s) shut

down is delayed for the time selected (in seconds). This

delay is factory set to 60, but can be set in the range of 0

to 99 using

26) Select Auxiliary Off (AO) – This feature is applicable only

in heat pump modes and with an outdoor sensor installed

and enabled. Select the temperature that will inhibit the

auxiliary heating stage. As long as the outdoor temperature is above the setpoint, the auxiliary heat will not turn

on. The default setting is 80, but can be set in the range of

35 to 79. A setting of 80 disables this feature.

27) Select Filter Replacement Reminder and Set Run Time

Select the "Change Filter" reminder On or OFF. If selected On, press MENU to select the time period from 25

to 1975 hours in 25 hours increments. In a typical system,

200 hours (default) of run time is approximately 30 days.

After the selected time of blower operation, the thermostat

will display "Change Filter" as a reminder to change or

or buttons.

clean your air fi lter. When "Change Filter" is displayed,

press MENU or RUN SCHED button to clear the display

and restart the time to the next fi lter change.

28) Change UV Lamp – This feature allows the thermostat to

display the words "Change UV Lamp" (Call for Service

of UV bulb) after a set time of UV bulb operation. This is

a reminder to maintain your UV system at optimum level

of operation. When enabled the factory set interval for

"Change UV Lamp" to be displayed is 350 days of UV

bulb operation and can be adjusted in 25 day increments.

This should be adjusted with respect to the bulb's recommended maintenance schedule.

When "Change UV Lamp" is displayed, you can clear it

by pressing MENU.

29) Select Reversing Valve Output – The O/B option is

factory set at "O" position. This will accommodate the

majority of heat pump applications, which require the

changeover relay to be energized in COOL. If the thermostat you are replacing or the heat pump being installed

with this thermostat requires a "B" terminal, to energize

the changeover relay in HEAT, the O/B option should be

set at "B" position.

OPERATING YOUR THERMOSTAT

Check Thermostat Operation

NOTE

To prevent static discharge problems, touch side of

thermostat to release static build-up before touching

any keys.

If at any time during testing your system does not operate

properly, contact a qualifi ed service person.

Fan Operation

If your system does not have a G terminal connection, skip to

Heating System.

1. Turn on power to system.

2. Press FAN button to select ON. The blower should begin

to operate.

3. Press FAN button to select AUTO. The blower should

stop immediately.

CAUTION

!

Do not allow the compressor to run unless the compressor oil heaters have been operational for 6 hours

and the system has not been operational for at least

5 minutes.

Heating System

1. Press SYSTEM button to select Heat. If the auxiliary

heating system has a standing pilot, be sure to light it.

2. Press to adjust thermostat setting to 1° above room

temperature. The heat pump system should begin to operate. The display should show “System On”. However, if

the system confi guration is set to HP1 or HP2 and setpoint

temperature display is fl ashing, the 5 minute compressor

lockout feature is operating (see Confi guration menu,

item 11).

3. Adjust temperature setting to 3° above room temperature.

If your system confi guration is set at MS2, HP2 or HP1,

the auxiliary heat system should begin to operate and

the display will show “System On +2”.

4. Press to adjust the thermostat below room temperature. The heating system should stop operating.

9

Page 10

OPERATING YOUR THERMOSTAT

Emergency System

EM bypasses the Heat Pump to use the heat source wired to

terminal W/E on the thermostat. EM is typically used when

compressor operation is not desired, or you prefer back-up

heat only.

1. Press SYSTEM button to select EM. “EM” will fl ash

on the display.

2. Press

temperature. The Emergency heating system will begin to

operate. The display will show "System On" and fl ashing

"EM" to indicate that the Emergency system is operating.

3. Press to adjust the thermostat below room temperature. The Emergency heating system should stop operating.

To prevent compressor and/or property damage, if the

outdoor temperature is below 50°F, DO NOT operate

the cooling system.

to adjust thermostat setting above room

CAUTION

!

Cooling System

1. Press SYSTEM button to select Cool.

2. Press to adjust thermostat setting below room temperature. The blower should come on immediately on high

speed, followed by cold air circulation. The display should

show “System On”. If the setpoint temperature display is

fl ashing, the compressor lockout feature is operating (see

Confi guration menu, item 5).

3. Adjust temperature setting to 3° below room temperature.

The second stage cooling should begin to operate and

the display should show “System On +2”.

4. Press to adjust the temperature setting above room

temperature. The cooling system should stop operating.

Choose the Fan Setting (Auto or On)

Fan Auto is the most commonly selected setting and runs the

fan only when the heating or cooling system is on.

Fan On selection runs the fan continuously for increased air

circulation or to allow additional air cleaning.

Fan Prog On indicates that the fan is programmed to be on

for the entire period. The Prog Fan On can be overridden

to have the fan cycle with the system. Press the FAN button to change the fan to Auto. The fan programming will be

overridden until the next program period begins or until Run

Schedule is pressed.

Choose the System Setting

(Cool, Off, Heat, Em, Auto)

Press the SYSTEM button to select:

Heat: Thermostat controls only the heating system.

Off: Heating and Cooling systems are off.

Cool: Thermostat controls only the cooling system.

Auto: Auto Changeover is used in areas where both heating

and cooling may be required on the same day. AUTO allows

the thermostat to automatically select heating or cooling

depending on the indoor temperature and the selected heat

and cool temperatures. When using AUTO, be sure to set the

Cooling temperatures more than 1° Fahrenheit higher than

the heating temperature.

Em: Setting is available only when the thermostat is confi gured in HP1 or HP2 mode.

Manual Operation for

Non-Programmable Mode

Press the SYSTEM button to select Heat or Cool and use

the buttons to adjust the temperature to your desired setting.

After selecting your desired settings you can also press the

SYSTEM button to select AUTO to allow the thermostat to

automatically change between Heat and Cool.

Manual Operation (Bypassing the Program)

Programmable Mode

Adjust the temperature wherever you like and then press

the HOLD button. This will override the program. The HOLD

feature bypasses the program and allows you to adjust the

temperature manually, as needed. Whatever temperature

you set in HOLD will be maintained 24 hours a day, until you

manually change the temperature or press Run Schedule to

cancel HOLD and resume the programmed schedule.

Program Override (Temporary Override)

Press the or button to adjust the temperature. This

will override the temperature setting for a two hour override

period.

Example: If you turn up the heat during the morning program,

it will be automatically lowered later, when the temporary hold

period ends. To cancel the temporary setting at any time and

return to the program, press Run Schedule.

If the SYSTEM button is pressed to select AUTO the

thermostat will change to Heat or Cool, whichever ran last. If

it switches to heat, but you want cool, or it changes to cool,

but you want heat, press both buttons simultaneously to

change to the other mode.

PROGRAMMING

Set Current Time and Day

1) Press Menu button to enter installer menu. Then press

Time button once to indicate hour & AM or PM designa tion in clock display.

2) Press and hold either the

reach the correct hour and AM or PM designation.

3) Press Time again to display minutes only in clock

display.

4) Press and hold either the

reach the correct minutes.

5) Press Time once again to display year.

6) Press and hold either the

reach the correct year.

10

or button until you

or button until you

or button until you

7) Press Time once again to display month.

8) Press and hold either the

reach the correct month.

9) Press Time once again to display date of the month

along with day of the week at top row (which is automatic).

10) Press and hold either the

reach the correct day of the month and day of the week

is automatically calculated and displayed at the top row.

11) Press RunSched button once; now the display will show

the correct time and room temperature.

or button until you

or button until you

Page 11

PROGRAMMING

Energy Saving Factory Pre-Program

The 1F95-0680 thermostats are programmed with the energy saving settings shown in the table below for all days of the week.

If this program suits your needs, simply set the thermostat clock and press the RunSched button.

The table below shows the factory set heating and cooling schedule for all days of the week.

* Wake Up

(Morn)

Heating

Program

Cooling

Program

* You can eliminate these two program periods in the confi guration menu (reference #15) if the building is occupied all day.

Day period will change to 6:00 AM and 70° and can be programmed as required.

6:00 AM 70°F 8:00 AM 62°F 5:00 PM 70°F 10:00 PM 62°F

6:00 AM 75°F 8:00 AM 83°F 5:00 PM 75°F 10:00 PM 78°F

Leave For Work

(Day)

* Return Home

(Eve)

Go To Bed

(Night)

Planning Your Program – Important

The Heating and Cooling Program schedules below allow you to pencil in your own program times and temperatures.

The 1F95-0680 comes confi gured for 7 day programming and can also be confi gured for 5+1+1 programming (see confi guration section).

Factory settings are listed on Monday, Saturday and Sunday. If you are re-programming a 5+1+1 day schedule, pencil in your

own times and temperatures directly below the factory times and temperatures.

If you are re-programming a 7 day schedule, fi ll in all lines with the times and temperatures you want.

Keep the following guidelines in mind when planning your program.

• In Heating, lower temperatures will save energy.

• In Cooling, higher temperatures will save energy.

• If you plan on using Auto Changeover, do not program the heating temperature higher than the cooling temperature.

Worksheet for Re-Programming 5+1+1 and 7 Day Program

Heating

Program

MON

Wake Up

(Morn)

6:00 AM 70°F Auto 8:00 AM 62°F Auto 5:00 PM 70°F Auto 10:00 PM 62°F Auto

Leave For Work

Fan

(Day)

Fan

Return Home

(Eve)

Fan

Go To Bed

(Night)

Fan

TUE

WED

THU

FRI

SAT

SUN

Cooling

Program

MON

TUE

WED

THU

FRI

SAT

SUN

6:00 AM 70°F Auto 8:00 AM 62°F Auto 5:00 PM 70°F Auto 10:00 PM 62°F Auto

6:00 AM 70°F Auto 8:00 AM 62°F Auto 5:00 PM 70°F Auto 10:00 PM 62°F Auto

Wake Up

(Morn)

6:00 AM 75°F Auto 8:00 AM 83°F Auto 5:00 PM 75°F Auto 10:00 PM 78°F Auto

6:00 AM 75°F Auto 8:00 AM 83°F Auto 5:00 PM 75°F Auto 10:00 PM 78°F Auto

6:00 AM 75°F Auto 8:00 AM 83°F Auto 5:00 PM 75°F Auto 10:00 PM 78°F Auto

Leave For Work

Fan

(Day)

Fan

Return Home

(Eve)

Fan

Go To Bed

(Night)

Fan

11

Page 12

PROGRAMMING

Automatic Daylight Saving Calculation

The Real Time Clock will adjust automatically for daylight savings time, in the following manner:

Increment one hour at 2 AM on the second Sunday of March

and decrement one hour at 2 AM on the fi rst Sunday of November. (New DST effective 2007).

The daylight saving feature can be enabled or disabled in

installer confi guration menu. Default is DS ON (enabled).

After entering installer confi guration mode, momentarily

press MENU button until the display indicates dS (in actual

temperature digits) and on (default – in clock digits).

buttons will toggle display and operation from on to OFF.

or

Programming Tip: Copy Program

When programming your thermostat, you may copy the program from one day to another day or group of days using the

Copy key. In 7 day programming mode, a day can be copied

to another day or all six other days. In 5/1/1 day programming

mode the weekday (Mon – Fri) program can be copied into

Sat and Sun or either Sat or Sun.

To copy a program from one day to another:

1) In Set Schedule mode, enter the program for the day or

select the day you wish to copy by pressing Advance Day.

2) Press Copy. On the display, "Copy" will begin to fl ash.

The day of the week being copied will show.

3) Press Advance Day. The day being copied will be indi-

cated and the other days will be fl ashing.

4) If you wish to copy to all days skip to next step or press

Advance Day until the day you wish to copy to is fl ashing.

5) Press Copy. “Copy” will be on, the day you copied from

will disappear and the day(s) you copied to will be on.

6) If you wish to copy this same program into other days,

press Copy and repeat steps 2 through 5.

7) Press RunSched to return to normal operation.

Fill in the blank schedule on the next page then:

Enter the Heating Program

1) Press SYSTEM button to select Heat in the system switch

area indicating the active mode being programmed.

2) Press the Menu button and then press Schedule.

3) The top of the display will show the day(s) being pro-

grammed. The fi rst period to be programmed will appear.

The set temperature will also be displayed and the time

will be fl ashing to indicate that the time can be changed.

4) Press

period. The time will change in 15 minute increments.

5) Press the System Time button to change to the tempera-

ture fl ashing.

6) Press or buttons to change the temperature to

your selected temperature for the fi rst heating period.

7) After you have set the time and temperature for the fi rst

period, press Schedule to advance to the next program

period.

8) Repeat steps 4 through 7 until all of the program times

and temperatures are entered for all program periods for

that day.

9) Press Schedule button to change to the next day and

repeat steps 4 through 8 until all program days and periods are entered.

10)When programming is complete and all of the times and

temperatures match your desired heating schedule, press

RunSched. The thermostat will now run your program.

or buttons to adjust the start time for the

Enter the Cooling Program

1) Press the SYSTEM button until the Cool icon appears.

2) Follow Enter Heating Program instructions for entering

cooling times and temperatures.

Automatic Schedule

This feature provides a method to program every day with the

most popular time and temperature settings using one key.

For this feature to be available, the Auto Schedule options

(Installer/Confi guration menu item 16, AS Heat, or item 17,

AS Cool) must be selected On.

To use Auto Schedule, press RunSched to be sure you are in

normal operating mode. In SYSTEM Heat mode, use the keys

to select your “Comfort Temperature”. When your “Comfort

Temperature” is selected, press Auto Sched button. The

Auto Schedule key will disappear to indicate that the Auto

Schedule command has been accepted.

In Heat mode the thermostat will maintain your “Comfort Temperature” during the Morning, Day and Evening periods and

setback 6° for the Night. Morning period will begin at 6:30 AM

and Night period will begin at 10:30 PM.

To set the Auto Schedule temperature for Cool mode, press

SYSTEM to change the mode to Cool and repeat setting the

temperature. In Cool mode, the thermostat will maintain your

selected “Comfort Temperature” continuously.

The “Comfort Temperature” can be temporarily overridden

by changing the setpoint temperature using the

buttons. Once Auto Schedule has been set and the key has

disappeared, it can be reset in the Installer/ Confi guration

menu.

or

Entering Fan Program

The fan can be programmed to turn on at the beginning of a

period and remain on through the whole period. In RunSched

mode when the FAN switch indicates Prog Fan On the fan is

programmed to be on for the period.

1) Press System button to select either Heat or Cool.

2) Press Menu button and then press Fan button to the right

of the display.

3) The top of the display will show the day(s) being programmed. The fi rst period to be programmed will appear.

4) Press the Fan button to change from Auto to Prog.

5) Press the Fan button to the right of the display to change

to the next period.

6) Repeat steps 4 and 5 to program the fan for all periods of

the day.

7) Press Fan to advance to the next day of the week and

repeat steps 4 through 7 to program the fan for all days of

the week.

12

Page 13

PROGRAMMING

Wired Remote Temperature Sensing

One remote temperature sensor can be installed indoor or

outdoor and connected to the thermostat by a maximum

cable length of 100 meters (300 feet). Terminals +, S and - on

the terminal block allow connection of the remote sensor.

The thermostat must have 24 VAC Common connection to

terminal C for the remote sensor to operate. The remote sensor can be enabled or disabled in the Installer/Confi guration

menu, item 20.

When remote sensor, Remote, is selected Off (factory default), no remote sensor is enabled. When remote sensor is

selected On, the next step is to select the remote as indoor,

Remote In, or outdoor, Remote Outdoor. If the remote is selected as Remote In, an additional step will be to select if the

temperature shown on the display will be from the thermostat,

Loc On, or the remote sensor Loc Off.

In normal operation, when a remote sensor is enabled the

time digits of the display will alternate between the time and

the remote temperature for three seconds each. Above the

remote temperature will be "Remote", for indoor sensor or

"Outdoor Remote", for outdoor sensor. If the remote sensor

is an indoor sensor and the local display has been disabled,

the temperature displayed as the room temperature will be

the remote sensor temperature.

Sensing Range:

Outdoor temperature range is -40

Indoor temperature range is 32

o

F to 140oF

o

F to 99 oF

The example shows that the weight selected would prioritize

the overall averaged temperature between the two sensors.

The high weight selection caused the remote sensor to have

a higher infl uence in the calculated temperature average than

the local sensor and the low weight selection caused the

remote sensor to have less infl uence.

Dual Fuel Temperature Setpoint

When the thermostat is confi gured for Heat Pump mode

and an outside remote sensor is installed and enabled, the

thermostat can monitor the outside temperature to determine

when to switch to auxiliary heat and shut down the compressor. This eliminates the need for a fossil fuel kit.

The Compressor Off temperature (CO) set in the confi guration menu, item 25, will determine when the auxiliary heat will

start and the compressor will shut off. Default setting is 05°F.

-15°C (feature disabled) and can be set for 06 to 50°. When

the outside temperature falls to the selected temperature, the

auxiliary heat system will begin.

The auxiliary heat system can be fossil fuel (dF) or electric

heat (EA). This is selected after CO is set greater than 05°. If

the auxiliary heat is fossil fuel, (df), a delay time for the compressor shut down (Cd) can be selected. Default for this delay

is 60 seconds but can be set from 0 to 99 seconds. If EA is

selected, there is no selection for Cd because the compressor will shut down immediately.

Weighing of Remote Reading:

The thermostat will weight or average the temperature of the

indoor remote sensor with the local sensor in the thermostat

for each program period. The averaging will be active only

when the local sensor and the indoor remote sensor are both

functional and enabled in the Installer/Confi guration menu.

When the thermostat is in the Set Schedule mode, the weight

of the indoor sensor will be shown in the current temperature

digits of the display. The weight will show as A2 (average and

default), H4 (high) or L1 (low). Pressing the

tons at the same time will change the weight for the program

period. The weight of the thermostat sensor is fi xed.

In normal operation of the thermostat, the current temperature displayed will be the weighted average of the local

sensor and the remote sensor using the formula (local sensor

weight x local sensor temperature) + (remote sensor weight x

remote sensor temperature) / (local sensor weight + remote

sensor weight).

Example: Local sensor temperature is 80° and the remote

sensor is 70°.

If weight is selected H4, the averaged temperature of 72° will

be displayed.

(1 x 80) + (4 x 70) / 5 = 72°

If weight is selected A2, the average temperature of 73° will

be displayed.

(1 x 80) + (2 x 70) / 3 = 73.3°

If weight is selected L1, the average temperature of 75° will

be displayed.

(1 x 80) + (1 x 70) / 2 = 75°

or but-

13

Page 14

TROUBLESHOOTING

Reset Operation

Note: When thermostat is reset, installer confi guration menu settings and programming will reset to factory settings.

If a voltage spike or static discharge blanks out the display or causes erratic thermostat operation, you can reset the thermostat by removing the wires from terminals R and C (do not short them together) and removing batteries for 2 minutes. After

resetting the thermostat, replace the wires and batteries. If the thermostat has been reset and still does not function correctly

contact your heating/cooling service person or place of purchase.

Note: Be sure to review the installer confi guration menu settings.

To reset the programming, clock and confi guration settings, press the

thermostat should go blank and then all segments will be displayed momentarily.

Symptom Possible Cause Corrective Action

No Heat/No Cool/No Fan

(common problems)

No Heat

No Cool

Heat, Cool or Fan

Runs Constantly

Thermostat Setting &

Thermostat Thermometer

Disagree

Furnace (Air Conditioner)

Cycles Too Fast or Too Slow

(narrow or wide

temperature swing)

Forgot Keypad

Lockout Code

1. Blown fuse or tripped circuit breaker.

2. Furnace power switch to OFF.

3. Furnace blower compartment door or

panel loose or not properly installed.

4. Loose connection to thermostat or system.

1. Pilot light not lit.

2. Furnace Lock-Out Condition. Heat

may also be intermittent.

3. Heating system requires service or

thermostat requires replacement.

1. Cooling system requires service or

thermostat requires replacement.

1. Possible short in wiring.

2. Possible short in thermostat.

3. Possible short in heat/cool/fan system.

4. FAN Switch set to Fan ON.

1. Thermostat thermometer setting

requires adjustment.

1. The location of the thermostat and/or

the size of the Heating System may

be infl uencing the cycle rate.

or and SYSTEM button simultaneously. The

Replace fuse or reset breaker.

Turn switch to ON.

Replace door panel in proper position to engage safety

interlock or door switch.

Tighten connections.

Re-light pilot.

Many furnaces have safety devices that shut down when

a lock-out condition occurs. If the heat works intermittently

contact the furnace manufacturer or local HVAC service

person for assistance.

Diagnostic: Set SYSTEM Switch to HEAT and raise the

setpoint above room temperature. Within a few seconds

the thermostat should make a soft click sound. This sound

usually indicates the thermostat is operating properly. If

the thermostat does not click, try the reset operation listed

above. If the thermostat does not click after being reset

contact your heating and cooling service person or place

of purchase for a replacement. If the thermostat clicks,

contact the furnace manufacturer or a HVAC service

person to verify the heating is operating correctly.

Same as diagnostic for No Heat condition except set the

thermostat to COOL and lower the setpoint below the

room temperature. There may be up to a fi ve minute delay

before the thermostat clicks in Cooling.

Check each wire connection to verify they are not shorted

or touching together. No bare wire should stick out from

under terminal block. Try resetting the thermostat as described above. If the condition persists the manufacturer

of your system or service person can instruct you on how

to test the Heat/Cool system for correct operation. If the

system operates correctly, replace the thermostat.

The thermometer can be adjusted +/- 4 degrees. See

Temperature Display Adjustment in the Confi guration

Menu section.

Digital thermostats provide precise control and cycle

faster than older mechanical models. The system turns

on and off more frequently but runs for a shorter time

so there is no increase in energy use. If you would like

an increased cycle time, choose SL for slow cycle in the

Confi guration menu, step 7 (heat) or 8 (cool). If an acceptable cycle rate is not achieved, contact a local HVAC

service person for additional suggestions.

Press the menu button (button will disappear) and hold in

for 20 seconds. This unlocks the thermostat.

14

Page 15

NOTES

15

Page 16

White-Rodgers is a division

of Emerson Electric Co.

The Emerson logo is a

trademark and service mark

of Emerson Electric Co.

HOMEOWNER HELP LINE: 1-800-284-2925

www.white-rodgers.com

Loading...

Loading...