Page 1

WARNING

!

WHITE-RODGERS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

These water valves provide a low cost system of zoned temperature control wherever hot water is the heating medium. In

new construction, the heating piping system can be laid out to

produce any number of independent temperature controlled

zones by use of these valves.

In existing buildings, a variety of zone heating combinations can

be obtained, depending on the particular -piping lay-outs. Each

zone requires one water valve and one thermostat, but only

one circulator is required for the entire system. New construction properly piped, will not require flow control valves,

since the water valve itself performs this function.

Existing construction, where flow control valves have been

installed, will operate quite satisfactorily without removing the

existing flow control valves.

TYPE 1361

HYDRONIC ZONE VALVES

(2 WIRE)

INST ALLA TION INSTRUCTIONS

DESCRIPTION

If in “Closed” position, valve may be opened by turning dial

clockwise with your thumb until word “Open” appears. When

power is resumed, valve will automatically return to command of

room thermostat.

This zone valve motor is intended for use with a low voltage

system; do not use this zone valve with a millivolt or line voltage

system. If in doubt about whether your wiring is millivolt, line or

low voltage, have it inspected by a qualified heating contractor

or electrician.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical codes and

ordinances.

CAUTION

!

To prevent injuries from scalding always drain system

before unlatching valve assembly from body.

All guarantees are void if these specifications are exceeded.

Maximum water temperature: 240°F (115°C)

Maximum system pressure: 50 PSI

Differential across valve: 15 PSI

Electrical Rating:

Valve motor: .2 Amp. Max at 25 VAC

(.40 Amp.) when valve is in open position.

Auxiliary Contacts: Do not exceed 2.0 Amp. at

25 VAC (Terminals 2 and 3)

NOTE: The valve motor draws more than .2 Amp. while it is

opening. For this reason, do not use more than the

The zone valve is designed to turn in one direction, stopping

every 90° in either the open or closed position, depending on

thermostat demand. The motor position is controlled by a wafer

switch attached to the motor shaft.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, Fax (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, FAX (905) 475-4625

Printed in U.S.A.

PRECAUTIONS

CAUTION

!

To prevent electrical shock and/or equipment damage,

disconnect electric power to system at main fuse or

circuit breaker box until installation is complete.

Do not use on circuits exceeding specified voltages.

Higher voltages will damage control and could cause

shock or fire hazard.

SPECIFICATIONS

recommended number of valves per transformer as

shown on pages 3 and 4.

Thermostat: Use two-wire thermostat with .2 Amp. anticipator

Timing: From full close to full open–Approx. 45 seconds

From full open to full close–Approx. 60 seconds

Friction loss equivalents:

3/4" valves – 2-1/2 ft. copper tubing

1" valves – 4 ft. copper tubing

1-1/4" valves – 7 ft. copper tubing

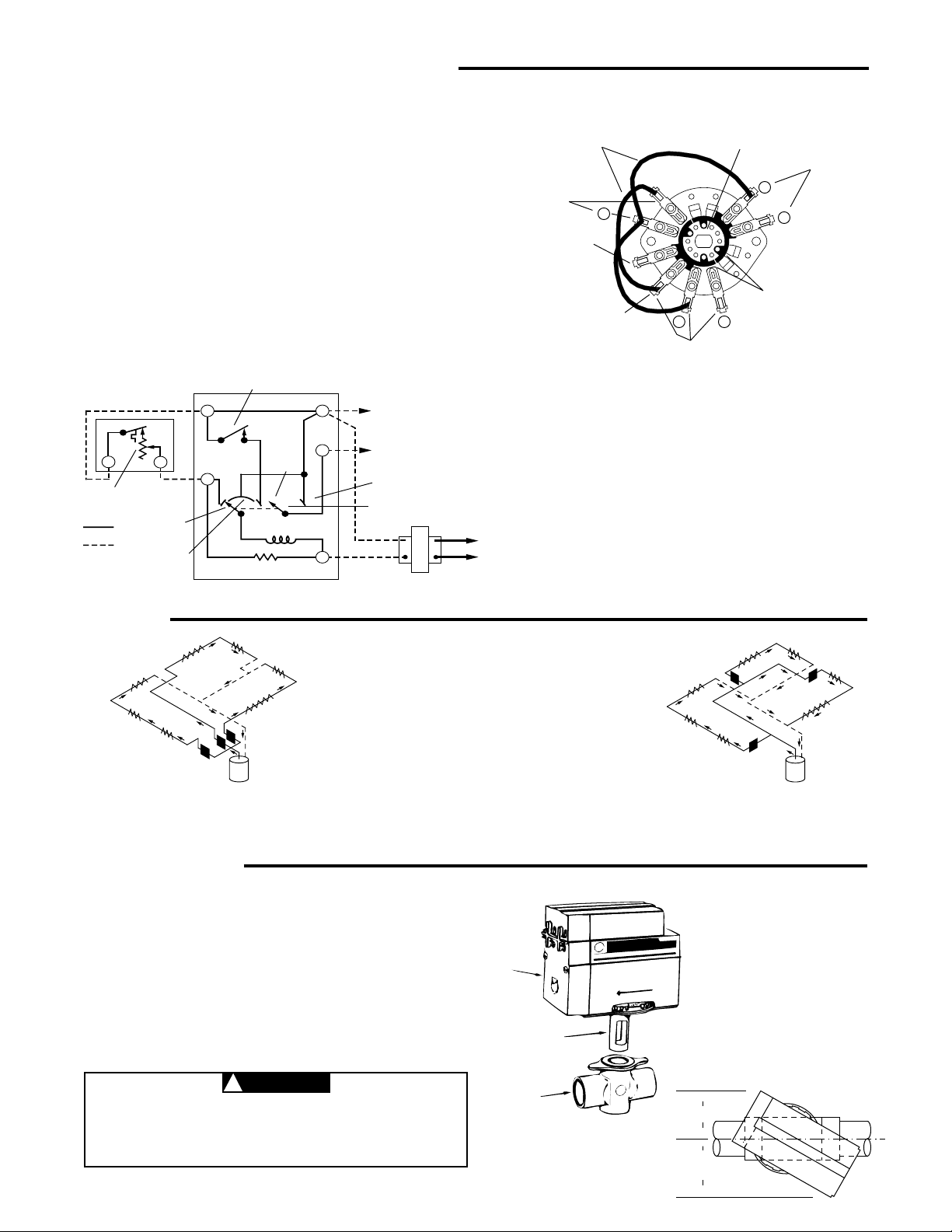

PRINCIPLE OF OPERATION

The contact arrangement of the switch is constructed so that

when the shaft of the motor revolves 90° a new set of stationary

and moving contacts makes, while the old set breaks. Fig.1.

The schematic shows the valve in the closed position. As the

PART NO. 37-5422B

Replaces 37-5422A

9812

Page 2

PRINCIPLE OF OPERATION (CONT.)

thermostat calls for heat, the valve motor is energized by a

circuit made through side “A” of the motor switch to terminal “4”.

Fig. 2. (At the same time, a circuit is made through the warp

switch heater.) As the valve begins to open, side “A” of the motor

switch makes with a “holding” contact and then breaks from the

stationary contact wired to terminal “4”. The “holding” contact

provides a circuit which prevents the valve from stopping part

way through its cycle if the thermostat is changed to the satisfied

position. As the valve reaches the full open position, side “B” of

the motor switch closes, providing a low voltage auxiliary circuit

for starting the burner or circulator. At the same time side “A” of

the motor switch makes a circuit through the warp switch

contacts to terminal “2”. The valve does not continue to rotate

since the warp switch opened its contacts before the valve

reached the full open position. The warp switch heater remains

energized as long as the thermostat calls for heat.

WARP SWITCH

THERMOSTAT

HEAT

ANTICIPATOR

INTERNAL WIRING

EXTERNAL WIRING

TYPE 1E/F30

▼

SIDE “A” OF

MOTOR

SWITCH

HOLDING

CONTACT

CONTACTS

NORMALLY CLOSED

5

▼

SIDE “A”

4

WARP SWITCH HEATER

OPEN

POSITION

▼

▼

▼

MOTOR

Fig. 2

2

3

▼

▼

1

TO AUXILIARY CIRCUIT

(NOTE: IF SAME

TRANSFORMER POWERS BOTH THE AUXILIARY CIRCUIT AND THE

WATER VALVE, CONNECT AUXILIARY CIRCUIT TO TERMINALS 1

AND 3 INSTEAD OF 2

AND 3.)

OPEN POSITION

MOTOR SWITCH

SIDE “B”

SIDE “B” OF

TRANSFORMER

NOTE: INTERNAL PARTS AND

WIRING OF WATER VALVE.

STATIONARY CONTACTS

(TERMINALS 2 & COM.)

SWITCH CONTACTS)

JUMPER WIRES

(2 THRU WARP

▼

2

COMMON

▼

▼

▼

▼

▼

▼

▼

STATIONARY CONTACTS

(TERMINALS 2, 4 & COM.)

MOTOR SHAFT:

Revolves in 90° intervals

with each thermostat cycle.

▼

▼

▼

2

▼

▼

4

2

ROTATING BOARDS:

Each Board makes/breaks

1 set of contacts with each

90° revolution of motor

shaft on thermostat

demand.

(Valve is shown in the open position)

Fig. 1

When the thermostat is satisfied, the circuit through the warp

switch heater is broken, allowing the heater to cool. When the

warp switch contacts close, the valve motor is energized, and

drives the valve to the closed position. As the valve begins to

move to the closed position, side “A” of the motor switch makes

the holding circuit. Then side “B” of the motor switch breaks the

auxiliary circuit and side “A” of the motor switch makes contact

“4” then breaks the holding circuit stopping the valve (in a fully

LINE

closed position).

STATIONARY CONTACTS

(TERMINALS 2 & 3)

▼

▼

3

PIPING

The two most commonly used piping systems are

shown below. Plan 1 is popular for new installations,

while plan 2 is frequently used when converting twopipe systems.

This valve does not seal completely. A small amount of

leakage through valve is permitted. The amount depends on valve size and pressure differential across

PLAN 1

Water valves installed at the boiler

header to provide a separate supply to each zone.

Fig. 3

closed valve. Do not use if your application requires

complete seal off. Maximum leakage at rated differen-

tial is two, four or six gal. per hour for 3/4", 1" or 1-1/4"

valves, respectively.

PLAN 2

A common main supplies all

zones, with a water valve installed

on the riser to each zone.

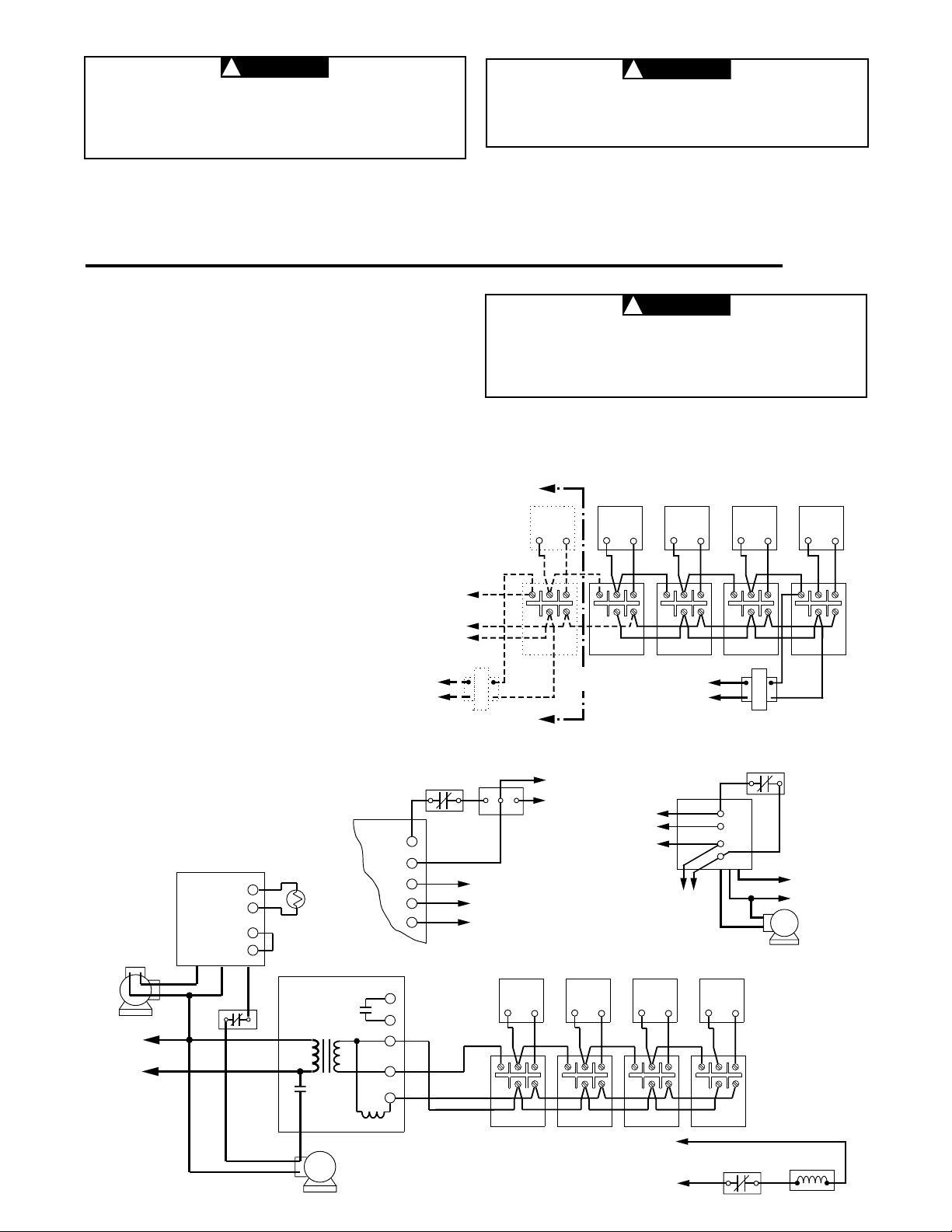

INSTALLATION

ALL GUARANTEES ARE VOID IF THE VALVE IS NOT ASSEMBLED ACCORDING TO THESE INSTRUCTIONS.

1. Remove body assembly only from shipping carton. Valve

head and stem should be left in carton at this time for

protective purposes. Do not assemble head to body before

attaching body into line.

2. Mount the valve body in the line in any desired position

except upside down. CAUTION: Provide the necessary

clearances for turning valve head sideways when assembling it to valve body (see fig. 5). Note that terminal end of

valve head requires more clearance.

CAUTION

!

Use only silicone grease, water, or soap suds on O-ring

or Valve Body to facilitate assembly. Use of vaseline or

any petroleum grease or oil will cause O-ring to deteriorate.

2

VALVE

HEAD

BODY

STEM

Fig. 5

2" MINIMUM

CLEARANCE

▼

2-3/4" MINIMUM

CLEARANCE

▼

Clearances required for

assembling valve head to

valve body.

▼

▼

729

Fig. 4

Page 3

T2

T1-V1

V2-L1

Z-L2

CAUTION

CAUTION

!

!

Be sure that bayonet lock securely latches mounting

plate to body. Failure to do so could allow valve head

to separate from body and result in scalding injuries

and/or water damage.

3. Be sure that any excess solder, flux, or other foreign matter

is thoroughly removed from the valve bore.

4. With valve body mounted in the line, remove the head

assembly from the carton, and carefully wipe stem with a soft

cloth to remove any dust or grit.

All wiring should be done according to local and national electrical codes

For best connections, use #18 Thermostat wire. #16 will also

work satisfactorily.

Make connections to screw terminals according to wiring diagram.

NOTE: To check motor operation without thermostat con-

nected, jumper 2 and 4 to open valve; remove jumper

to close valve.

If the boiler manufacturer recommends a wiring diagram, follow

his instructions. If none are available, the following diagrams

show suggested circuits for Type 1361 Water Valves in conjunc-

to prevent injuries from scalding always drain

system before unlatching valve assembly from

body.

5. The valve head may now be assembled to the valve body.

With valve head positioned as shown in figure 5, insert valve

stem into valve bore, push downward, and turn valve head

until it locks to valve body.

6. Support piping with a pipe hanger on each side of valve. The

valve is now ready to be wired.

WIRING

CAUTION

!

Do not attempt to wire two or more zone valves in

parallel to operate from a single thermostat. (If valves

are wired in parallel, the motors may run continuously,

due to feedback between the motor holding circuits.)

tion with two-wire thermostat (.2 Amp. anticipator) and other

related controls.

A 40 VA transformer will handle up to four (4) water valves. A

20 VA transformer will handle a maximum of two (2) 1361 series

valves.

DIAGRAM FOR SYSTEMS WHERE BURNER AND

CIRCULATOR OPERATION IS INDEPENDENT OF

THERMOSTAT

Fig. 6 Using Type 1361 Zone Valve

123

452

ADDITIONAL

ZONES

123

452

452

123

HOT

LINE

N

123

TRANSFORMER

452

123

DIAGRAM FOR SYSTEMS WHERE INTERNAL TRANSFORMER OF RELAY CONTROL SUPPLIES POWER

FOR ZONE VALVES

Alternate Wiring for using

750 Mv. Gas Valve

BURNER CONTROL

IGNITION

TRANS.

ORANGE

WHITE

BURNER

MOTOR

N

LINE

HOT

Fig. 7 Diagram

for Oil-fired

System using

8A03A-2

WHITE

BLACK

TYPE 668 OIL

HIGH LIMIT

F

F

T

T

BLACK

TYPE 956

FLAME DETECTOR

TYPE 8A03A-2

RELAY CONTACTS

(24V OR 750 MV)

TRANSFORMER

RELAY

CONTACTS

(LINE

VOLTAGE)

ORANGE

CIRCULATOR MOTOR

TYPE 8A03A-2

V1

V2

1

2

3

RELAY COIL

V1

V2

1

2

3

HIGH LIMIT

MUST BE N.E.C.

CLASS 1 WIRING

750 MV

GAS VALVE

TH

PG

TH PG

1

TO ZONE VALVES

2

}

3

452

123

Fig. 7a Diagram for

Gas-Fired System

3

750 MV

POWER

GENERATOR

TO ZONE

VALVES

1

2

{

3

MUST BE N.E.C.

CLASS 1 WIRING

Alternate Connections

For Type 8A02A Relay

452

123

TYPE 8A02A-1

TO 24 VOLT

GAS VALVE

452

123

1

MUST BE N.E.C.

CLASS 1 WIRING

3

YELLOW

452

123

HIGH LIMIT

HIGH LIMIT

CIRCULATOR

MUST BE N.E.C.

CLASS 1 WIRING

HOT

LINE

N

MOTOR

GAS VALVE

24 VAC

452

Page 4

WIRING – Continued

DIAGRAM FOR SYSTEMS WHERE INTERNAL TRANSFORMER OF RELAY-HOT WATER CONTROL

SUPPLIES POWER FOR ZONE VALVES

TO LOW VOLTAGE

GAS VALVE

V1

V2

TYPE 842A-16

1

C1 C2

HOT

LINE

2

N

123

T3

T1

T2

452

452

123

452

123

452

123

452

123

ADDITIONAL

ZONES

Fig. 8 Diagram for Gas-Fired

System using 842A-16

N

LINE

HOT

CIRCULATOR

MOTOR

TYPE 8F42A

1

2

C1 C2

3

TO ZONE VALVES

T2

T1

Z

V1

V2

V3

B

W

5

}

1

TO 24 VAC

GAS VALVE

Alternate Connections

For Type 8F42A

CIRCULATOR

MOTOR

N

LINE

HOT

CIRCULATOR

MOTOR

TYPE 8F43A

1

2

C1 C2

3

T2

T1

Z

V1

V2

5

}

1

TO 24 VAC

GAS VALVE

Alternate Connections

For Type 8F43A

DIAGRAM FOR SYSTEMS WHERE EXTERNAL TRANSFORMER REQUIRED FOR POWERING ZONE VALVES

2

TO ZONE

VALVES

{

3

452

123

ADDITIONAL

ZONES

123

Fig. 9 Diagram for Gas-Fired System using

842A-1 or 843A-1

Alternate Connections

For Type 809A Relay

TO ZONE

VALVES

{

2

3

TYPE 809A RELAY

1 2 L L

TO GAS VALVE

AND TRANSFORMER

OR OIL BURNER

CONTROL

TO ZONE

VALVES

CIRCULATOR

MOTOR

{

123

TYPE 956 FLAME

DETECTOR

FD

FD

T

T

CIRCULATOR

MOTOR

452

C1 C2

B1

HOT

LINE

452

2

3

N

Alternate Connections

For Type 692 or 693

452

123

TRANSFORMER

TYPE 692 OR 693 OIL

BURNER HOT WATER

CONTROL

1

2

B2

BURNER

IGN.

TRANS.

MOTOR

123

TO ZONE

VALVES

HOT

LINE

N

TYPE 842A OR

T1

{

CIRCULATOR

2

3

T2

MOTOR

CIRCULATOR

TYPE 956 FLAME

DETECTOR

T

FD

MOTOR

452

Alternate Connections

For Type 6C92 or 6C93

843A

1 2

C1

B1 B2

BURNER

CONTROL

TYPE 6C92 OR 6C93 OIL

1

C1 C2

B1

HOT

LINE

N

C2

BURNER HOT WATER

CONTROL

2

B2

IGN.

TRANS.

BURNER

MOTOR

N

LINE

HOT

CIRCULATOR

MOTOR

Alternate Connections

For Type 8B42A or 8B43A

Alternate Connections

HOT

LINE

TO ZONE

VALVES

For Type 829A Relay

N

2

{

3

TO GAS VALVE AND

TRANSFORMER OR

C1 C2

B1

TYPE 829A RELAY

OIL BURNER

CONTROL

TYPE 8B42A

OR 8B43A

1

THERM

163

452

MANUAL OPERA TION

Use manual operator only in case of power failure, or for testing

system prior to wiring. If power fails, valve may be in either

“Open” or “Closed” position.

If in “Open” position, valve will remain open until power is

resumed.

If in “Closed” position, valve may be opened by turning dial

clockwise with your thumb until word “Open” appears. When

power is resumed, valve will automatically return to command of

room thermostat.

OPEN

4

Fig. 10

TO ZONE VALVES

T1T2

2

B2

IGN.

TRANS.

BURNER

MOTOR

CIRCULATOR

MOTOR

HOT

LINE

N

Page 5

WHITE-RODGERS

Utilisateur : conservez ces instructions pour vous y référer au besoin !

SI VOUS NE LISEZ PAS ATTENTIVEMENT CES INSTRUCTIONS AVANT

D’INSTALLER ET D’UTILISER LA COMMANDE, VOUS RISQUEZ DE CAUSER DES

BLESSURES ET DES DOMMAGES MATÉRIELS.

Ces robinets constituent un système économique de régulation

par zones de la température des installations de chauffage à

l’eau chaude. Dans un nouveau bâtiment, la tuyauterie de

chauffage peut être installée de façon à créer, à l’aide de ces

robinets, un certain nombre de zones de réglage de la

température.

Dans les bâtiments existants, le réseau de zones qui peut être

créé dépend de la disposition de la tuyauterie en place. Chaque

zone nécessite un robinet et un thermostat, mais un seul

circulateur est requis pour l’ensemble du système. Les

nouveaux bâtiments dont la tuyauterie est adéquate ne

nécessiteront pas de robinets de réglage de débit, puisque les

robinets de zones remplissent cette fonction.

Dans les bâtiments existants qui sont déjà dotés de robinets de

réglage de débit, le système fonctionnera adéquatement sans

nécessiter leur démontage.

TYPE 1361

ROBINETS DE ZONE HYDRONIQUES

(À 2 FILS)

INSTRUCTIONS D’INST ALLA TION

DESCRIPTION

Si le robinet est fermé, vous pouvez l’ouvrir en tournant

l’actionneur avec le pouce de façon à exposer le mot « OPEN ».

Une fois le courant rétabli, le robinet se remettra automatiquement

sous la commande du thermostat d’ambiance.

Le moteur du robinet de zone a été conçu pour fonctionner sur

un système à basse tension : ne vous en servez pas avec un

système en millivolts ou à la tension du réseau. Si vous n’êtes

pas certain de la tension du câblage de votre système (soit en

millivolts, à basse tension ou à la tension du réseau), faites

inspecter celui-ci par un électricien ou un entrepreneur agréé en

chauffage.

Ne dépassez pas les charges nominales.

Tout le câblage doit être conforme aux codes et règlements

locaux et nationaux qui régissent les installations électriques.

ATTENTION

ATTENTION

!

!

Dans le but de prévenir les brûlures, vidangez toujours

le système avant de séparer la tête du corps du robinet.

Toutes les garanties seront nulles si les charges ci-dessous ne sont pas respectées.

Température maximum de l’eau : 115°C (240°F)

Pression maximum du système : 50 PSI

Différence de pression de part et d’autre du robinet : 15 PSI

Charges électriques :

Moteur du robinet : 0,2 A maxi à 25V c.a. (0,40 A) lorsque le

robinet est ouvert

Contacts auxiliaires : Ne pas dépasser 2,0 A à 25 V c.a.

(Bornes 2 et 3)

NOTE : Le moteur du robinet absorbe plus de 0,2 A lorsqu’il

s’ouvre. Par conséquent, n’utilisez pas avec un transformateur

plus de robinets que le nombre recommandé aux pages 3 et 4.

Le robinet de zone a été conçu pour tourner dans un seul sens,

s’arrêtant après 90° en position ouverte ou fermée, selon l’état

du thermostat. La position du moteur est commandée par un

commutateur à galettes étagées qui est fixé à l’arbre du moteur.

PRÉCAUTIONS

ATTENTION

ATTENTION

!

!

Pour prévenir les risques d’électrocution et de dommages

matériels, coupez l’alimentation du système au panneau de

distribution électrique principal pendant toute la durée de

l’installation.

AVERTISSEMENT

!

N’installez pas cet appareil sur des circuits qui dépassent

la tension nominale. Une tension trop élevée peut endommager la commande et poser des risques d’électrocution et

d’incendie.

SPÉCIFICATIONS

Thermostat : Servez-vous d’un thermostat à 2 fils avec

anticipateur de 0,2 A.

Minutage : Entre la fermeture complète et l’ouverture complète :

Equivalents de perte par frottement :

Soupapes de 3/4" : 75 cm (2,5 pi.) de tuyau de cuivre

Soupapes de 1" : 120 cm (4 pi.) de tuyau de cuivre

Soupapes de 1 1/4" : 215 cm (7 pi.) de tuyau de cuivre

Environ 45 secondes;

Entre l’ouverture complète et la fermeture complète :

Environ 60 secondes.

PRINCIPE DE FONCTIONNEMENT

Les bornes du commutateur sont disposées de façon à assurer,

avec chaque rotation de 90° du moteur, la fermeture de nouveaux

circuits fixes et mobiles ainsi que l’ouverture des circuits

précédents. Fig.1.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, Télécopieur (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, Télécopieur (905) 475-4625

Imprimé aux États-Unis

NO DE PIÈCE 37-5422B

Remplace 37-5422A

9812

Page 6

PRINCIPE DE FONCTIONNEMENT (suite)

Le schéma montre le robinet en position fermée. Lorsque le

thermostat déclenche un appel de chaleur, le moteur du robinet

est mis sous tension par la fermeture d’un circuit reliant le côté

A du moteur à la borne 4 (fig. 2). (En même temps, le circuit de

l’élément chauffant du commutateur à bilame est fermé.) Alors

que le robinet commence à ouvrir, le côté A du commutateur du

moteur ferme le circuit de maintien, puis ouvre le circuit fixe relié

à la borne 4. Le circuit de maintien empêche le robinet de

s’arrêter au milieu de son cycle si l’appel de chaleur du thermostat

est satisfait. Lorsque le robinet est complètement ouvert, le côté

B du commutateur du moteur ferme un circuit auxiliaire à basse

tension qui sert à mettre en marche le brûleur ou le circulateur.

En même temps, le côté A du commutateur du moteur ferme un

circuit qui passe par l’élément chauffant du commutateur à

bilame et la borne 2. Le robinet ne continue pas à tourner

puisque le circuit du commutateur à bilame a été ouvert avant

que le robinet soit complètement ouvert. L’élément chauffant du

commutateur à bilame reste sous tension tant que l’appel de

chaleur du thermostat n’est pas satisfait.

THERMOSTAT

TYPE 1E/F30

▼

ANTICIPATEUR

DE CHAUFFAGE

CÂBLAGE INTERNE

CÂBLAGE EXTERNE

CÔTÉ A DU

COMMUTATEUR

DU MOTEUR

BORNE DU

CIRCUIT DE

MAINTIEN

COMMUTATEUR À BILAME

BORNES NORMALEMENT

FERMÉES

5

▼

CÔTÉ A :

POSITION

4

ÉLÉMENT CHAUFFANT DU

COMMUTATEUR À BILAME

OUVERTE

▼

▼

▼

▼

MOTEUR

Fig. 2

1

VERS LE CIRCUIT

AUXILIAIRE.

(NOTE : SI LE MÊME

TRANSFORMATEUR

ALIMENTE LE CIRCUIT

AUXILIAIRE ET LE

ROBINET, BRANCHEZ LE

CIRCUIT AUXILIAIRE SUR

LES BORNES 1 ET 3 AU

LIEU DE 2 ET 3.)

CÔTÉ A :

POSITION OUVERTE

CÔTÉ B DU

COMMUTATEUR

DU MOTEUR

TRANSFORMATEUR

2

3

▼

NOTE : PIÈCES ET

CÂBLAGE INTERNES

DU ROBINET

BORNES FIXES

(BORNES 2 , 6 ET COM.)

CAVALIERS

▼

2

▼

6

COMMUN

▼

▼

▼

▼

▼

▼

▼

ARBRE DU MOTEUR :

Il tourne de 90° à chaque

cycle du thermostat.

▼

▼

▼

▼

▼

4

2

BORNES FIXES

(BORNES 2, 4 ET COM.)

BORNES FIXES

(BORNES 2 ET 3)

▼

2

▼

3

PLAQUES ROTATIVES :

Chaque plaque ouvre ou

ferme un jeu de contacts à

chaque rotation de 90° du

moteur, qui est commandé

par le thermostat.

(Le robinet est illustré complèlement ouvert)

Fig. 1

Lorsque le thermostat est satisfait, le circuit qui passe par

l’élément chauffant du commutateur à bilame est ouvert, ce qui

permet à l’élément de refroidir. Lorsque le circuit du commutateur

à bilame est fermé, le moteur du robinet est mis sous tension et

ferme le robinet. Lorsque le robinet commence à se refermer, le

côté A du commutateur du moteur ferme le circuit de maintien.

Le côté B du commutateur du moteur ouvre le circuit auxiliaire

et le côté A du commutateur établit le contact avec la borne 4,

puis ouvre le circuit de maintien, ce qui arrête le robinet lorsqu’il

RÉSEAU

est complètement fermé.

TUYAUTERIE

Les deux systèmes de tuyauterie les plus communs

sont illustrés ci-contre. Le plan 1 est populaire pour les

nouvelles installations tandis que le 2 sert souvent pour

la conversion de systèmes à deux tuyaux.

Le robinet n’est pas parfaitement étanche : il laisse

s’écouler un peu d’eau. Le volume de cet écoulement

dépend de la grosseur du robinet et de la différence de

pression de part et d’autre. Ne pas utiliser ce robinet

PLAN 1

Les robinets sont installés à la tête

de la chaudière afin d’alimenter

séparément chacune des zones.

Fig. 3

si votre système nécessite l’étanchéité parfaite.

L’écoulement maximum à la différence de pression

nominale est de 7,5, 15 et 22,5 litres (deux, quatre et six

gallons) par heure pour les robinets de 3/4", 1" et 1 1/4"

respectivement.

PLAN 2

Une conduite prinicipale alimente

toutes les zones et un robinet est

installée sur la colonne montante

de chaque zone.

Fig. 4

729

INSTALLATION

TOUTES LES GARANTIES SONT NULLES SI LE ROBINET N’EST PAS INSTALLÉ CONFORMÉMENT AUX DIRECTIVES SUIVANTES.

1. Sortez uniquement le corps de la boîte. Laissez la tête et la

tige du robinet dans la boîte pour l’instant afin d’éviter de les

endommager. Ne montez pas la tête sur le corps avant

d’avoir inséré le corps dans la conduite.

2. Montez le corps du robinet dans la conduite dans n’importe

quelle position, sauf à l’envers. ATTENTION : Assurez le

dégagement nécessaire pour tourner la tête du robinet

lorsque vous le montez sur le corps (voir fig. 3). Veuillez noter

que la partie où est situé le bornier nécessite plus de

dégagement.

ATTENTION

ATTENTION

!

!

Servez-vous exclusivement de graisse de silicone, d’eau et

de savon pour faciliter le montage de la bague d’étanchéité

ou du corps du robinet. La vaseline ainsi que les huiles et

les graisses de pétrole entraîneront la détérioration de la

bague d’étanchéité.

2

TÊTE DU

ROBINET

CORPS

TIGE

Fig. 5

DÉGAGEMENT

MINIMUM DE 2"

▼

DÉGAGEMENT

MINIMUM DE 2 3/4"

▼

Dégagement requis

pour monter la tête au

corps du robinet.

▼

▼

Page 7

ATTENTION

T2

T1-V1

V2-L1

Z-L2

ATTENTION

!

!

Assurez-vous que le dispositif de blocage retient solidement

la plaque de montage sur le corps, sans quoi la tête du

robinet pourrait se séparer du corps et entraîner des

DANS LE BUT DE PRÉVENIR LES BRÛLURES, VIDANGEZ

TOUJOURS LE SYSTÈME AVANT DE SÉPARER LA TÊTE

DU CORPS DU ROBINET.

ATTENTION

ATTENTION

!

!

brûlures ainsi que des dommages matériels.

5. Vous pouvez maintenant monter la tête au corps du robinet.

3. Assurez-vous que tout excès de métal d’apport, de flux ou de

toute autre corps étranger a été éliminé du passage du

robinet.

4. Une fois le corps du robinet inséré dans la conduite, sortez

la tête de la boîte et essuyez-en attentivement la tige avec un

linge doux afin d’enlever la poussière et les saletés.

Orientez la tête du robinet de la façon illustrée à la figure 5, puis

insérez la tige dans le passage du robinet. Enfoncez et tournez

la tête du robinet jusqu’à ce qu’elle s’engage sur le corps.

6. Renforcez la tuyauterie avec un collier de suspension de

chaque côté du robinet. Vous pouvez maintenant procéder

au câblage.

CÂBLAGE

Tout le câblage doit être conforme aux codes et règlements locaux et nationaux qui régissent les installations électriques.

Pour assurer des raccordements de la meilleure qualité possible,

servez-vous de fil à thermostat #18. Le #16 est aussi adéquat.

Raccordez les conducteurs aux bornes à vis conformément au

schéma de montage.

NOTE : Pour vérifier le fonctionnement du moteur sans brancher

le thermostat, reliez les bornes 2 et 4 avec un cavalier

pour ouvrir le robinet; retirez le cavalier pour le fermer.

Si le fabricant de la chaudière recommande un schéma de

câblage, suivez ces directives. S’il n’y en a pas de disponible,

consultez les schémas de montage qui suivent, qui indiquent les

circuits recommandés pour brancher les robinets de zone de

type 1361 sur des thermostats à deux fils et autres commandes.

N’essayez pas de raccorder en parallèle deux robinets de

zone ou plus pour fonctionner avec un seul thermostat. (Si

les robinets sont montées en parallèle, une rétroaction

risque de s’établir entre les circuits de maintien des

moteurs, ce qui pourrait faire fonctionner ceux-ci de façon

continue.)

Un transformateur de 40 VA peut alimenter un maximum de

quatre (4) robinets. Un transformateur de 20 VA peut alimenter

un maximum de deux (2) robinets de la série 1361.

ATTENTION

ATTENTION

!

!

SCHÉMA POUR LES SYSTÈMES DONT LE BRÛLEUR

ET LE

CIRCULATEUR FONCTIONNENT INDÉPENDAMMENT DU

THERMOSTAT.

Fig. 6 Utilisation d’un robinet de zone type 1361

452

123

ZONES

SUPPLÉMENTAIRES

452

123

123

SOUS

TENSION

CIRCUIT

452

N

SCHÉMA POUR LES SYSTÈMES DONT LE TRANSFORMATEUR INTERNE DU RELAIS DE COMMANDE ALIMENTE

LES ROBINETS DE ZONE

Câblage permettant d’utiliser

un robinet à gaz de 750 mV

COMMANDE DE BRÛLEUR

À MAZOUT TYPE 668

TRANSFO

D’ALLUMAGE

MOTEUR DU

CIRCULATEUR

CIRCUIT

Fig. 7 Schéma

pour un

système

alimenté à

mazout et doté

d’un 8A03A-2

SOUS

TENSION

ORANGE

BLANC

LIMITEUR À

MAXIMUM

N

BLANC

NOIR

LIMITEUR À

MAXIMUM

TYPE 8A03A-2

V1

V2

F

F

T

T

NOIR

DÉTECTEUR DE

FLAMME TYPE 956

TYPE 8A03A-2

BORNES DU LRELAIS

(24V OU 750 MV)

TRANSFORMATEUR

BORNES DU

RELAIS

(TENSION DU

RÉSEAU)

ORANGE

BOBINE DU RELAIS

MOTEUR DU

CIRCULATEUR

1

2

3

V1

V2

1

2

3

CÂBLAGE C.N.É.

CLASSE 1

OBLIGATOIRE

1

2

}

3

3

ROBINET À GAZ DE

750 MV

TH

TH PG

VERS LES

ROBINETS DE ZONE

ALIMENTATION

DE 750 MV

PG

ROBINETS DE ZONE

Câblage pour l’utilisation

avec un relais type 8A02A

452

123

Fig. 7a Schéma pour un

système alimenté à gaz

VERS LES

123

{

CÂBLAGE

C.N.É. CLASSE

1 OBLIGATOIRE

452

TYPE 8A02A-1

1

2

3

VERS LE

ROBINET À GAZ

DE 24 VOLTS

452

123

1

CÂBLAGE

C.N.É. CLASSE

1 OBLIGATOIRE

3

LIMITEUR À

JAUNE

452

123

LIMITEUR À

MAXIMUM

452

123

TRANSFORMATEUR

MAXIMUM

MOTEUR DU

CIRCULATEUR

ROBINET À GAZ

123

CÂBLAGE

C.N.É. CLASSE

1 OBLIGATOIRE

DE 24 V C.A.

452

Page 8

CÂBLAGE (suite)

SCHÉMA POUR LES SYSTÈMES DONT LE TRANSFORMATEUR INTERNE DE LA COMMANDE D’EAU CHAUDE À RELAIS

ALIMENTE LES ROBINETS DE ZONE

VERS LE ROBINET

À GAZ À BASSE

T3

T1

T2

MOTEUR DU

CIRCULATEUR

CIRCUIT

SOUS TENSION

CIRCULATEUR

TENSION

V1

V2

N

MOTEUR DU

TYPE 842A-16

1

C1 C2

TYPE 8F43A

1

C1 C2

SOUS TENSION

CIRCUIT

N

2

T2

T1

Z

V1

V2

2

Câblage pour type 8F43A

3

VERS LES

ROBINETS DE

5

ZONE

}

1

VERS LE ROBINET À

GAZ DE 24 V C.A.

6

Fig. 8 Schéma pour un

système alimenté à gaz

et doté d’un 842A-16

4

56

452

123

6

ZONES

SUPPLÉMENTAIRES

SOUS TENSION

4

56

123

N

CIRCUIT

MOTEUR DU

CIRCULATEUR

4

56

TYPE 8F42A

1

123

2

452

T2

Z

452

61

C1 C2

4

56

2

452

61

3

6

3

5

T1

V1

V2

V3

B

W

}

1

VERS LE ROBINET À

GAZ DE 24 V C.A.

Câblage pour type 8F42A

4

56

2

452

3

VERS LES ROBINETS

DE ZONE

SCHÉMA POUR LES SYSTÈMES QUI NÉCESSITENT UN TRANSFORMATEUR EXTERNE POUR ALIMENTER LES ROBINETS DE

ZONE

DE ZONE

CIRCUIT

N

{

2

3

C1 C2

B1

TYPE 8F42A

OU 8B43A

1

2

B2

TRANSFO

D’ALLUMAGE

T1T2

VERS LES

4

56

452

123

6

4

56

452

123

6

4

56

452

61

123

4

56

2

452

3

61

4

56

2

6

TYPE 842A OU 843A

T1

T2

452

3

1 2

C1

B1 B2

C2

SOUS TENSION

CIRCUIT

N

ROBINETS

SOUS TENSION

ZONES

SUPPLÉMENTAIRES

Fig. 9 Schéma pour un système alimenté à

gaz et doté d’un 842A-1 ou d’un 843A-1

DÉTECTEUR DE

FLAMME TYPE 956

Câblage pour un relais de type 809A

VERS LES

ROBINETS

DE ZONE

2

{

3

VERS LE ROBINET À GAZ ET

LE TRANSFORMATEUR OU

VERS LA COMMANDE DU

BRÛLEUR À MAZOUT

RELAIS TYPE 809

1 2 L L

MOTEUR DU

CIRCULATEUR

VERS LES

ROBINETS

DE ZONE

SOUS TENSION

CIRCUIT

N

{

2

3

FD

FD

T

T

MOTEUR DU

CIRCULATEUR

Câblage pour type 692 ou 693

FONCTIONNEMENT MANUEL

Servez-vous de l’actionneur manuel seulement en cas de

panne de courant ou dans le but de mettre le système à l’essai

avant d’en effectuer le câblage. En cas de panne de courant,

le robinet sera soit ouvert, soit fermé.

S’il est ouvert, il restera ainsi jusqu’à ce que le courant soit

rétabli.

S’il est fermé, vous pouvez l’ouvrir en tournant l’actionneur

avec le pouce de façon à exposer le mot « OPEN ». Une fois

TRANSFORMATEUR

COMMANDE DE BRÛLEUR À

MAZOUT TYPE 692 OU 693 POUR

SYSTÈMES À L’EAU CHAUDE

1

2

C1 C2

B2

B1

TRANSFO

D’ALLUMAGE

MOTEUR DU

BRÛLEUR

MOTEUR DU

CIRCULATEUR

Câblage pour type

8B42A ou 8B43A

Câblage pour relais

de type 829A

RELAIS TYPE 829A-1

2

{

3

VERS LA VALVE DE GAZ

ET LE TRANSFORMATEUR

OU VERS LA COMMANDE

DU BRULEUR A MAZOUT

452

THERM

163

MOTEUR DU

BRÛLEUR

VERS LES

ROBINETS

DE ZONE

MOTEUR DU

BRÛLEUR

2

{

3

SOUS TENSION

CIRCUIT

N

CIRCULATEUR

Câblage pour type

6C92 ou 6C93

COMMANDE DU

BRÛLEUR

DÉTECTEUR DE

FLAMME TYPE 956

COMMANDE DE BRÛLEUR À MAZOUT

SYSTÈMES À L’EAU CHAUDE

T

FD

1

C1 C2

B1

MOTEUR DU

TYPE 6C92 OU 6C93 POUR

2

VERS LES

B2

ROBINETS

DE ZONE

TRANSFO

D’ALLUMAGE

MOTEUR DU

BRÛLEUR

SOUS TENSION

CIRCUIT

N

le courant rétabli, le robinet se remettra automatiquement sous la

commande du thermostat d’ambiance.

OPEN

4

Fig. 10

MOTEUR DU

BRÛLEUR

SOUS TENSION

CIRCUIT

N

Loading...

Loading...