Page 1

11D06, 11D37, 11D82

CAUTION

WHITE-RODGERS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

These controls are designed for use on hot water heating

installations. They have; open on rise, close on rise, or S.P.D.T.

switch action and are available with either fixed or adjustable

differential.

These controls are equipped with remote bulb feature for ease

of installation in hard to reach locations.

REMOTE BULB

HOT WATER CONTROL

INSTALLATION INSTRUCTIONS

DESCRIPTION

THESE CONTROLS MUST BE INSTALLED BY A QUALIFIED

INSTALLER.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical codes

and ordinances.

This control is a precision instrument, and should be handled

carefully. Rough handling or distorting components could cause

the control to malfunction.

This control has been accurately calibrated at the factory. Any

attempt to calibrate this control will void the White-Rodgers

warranty.

If the boiler manufacturer recommends a control location, follow

such recommendations. If none is offered, the following information gives suggested locations.

When used for high limit service, the control should be installed in the riser close to the boiler, or in a boiler tapping that

is near the top or hottest section of the boiler. If the boiler is also

used to heat domestic hot water, make sure that the high limit

control is not located in the section of the boiler that contains the

heat exchanger or piping for domestic hot water.

When used for low limit or operator service, the control should

be located near that section of the boiler that contains the heat

exchanger or piping for domestic hot water.

PRECAUTIONS

To prevent electrical shock and/or equipment damage, disconnect electric power to system, at main fuse

or circuit breaker box, until installation is complete.

WARNING

Do not use on circuits exceeding specified voltages.

Higher voltages will damage control and could cause

shock or fire hazard.

INSTALLATION

To remove the well from the control, loosen the set screw in the

large nut, then slide the well off to expose the bulb. Screw the

well into the proper tapping. Slide the bulb back into the well,

making sure that the bulb enters the well as far as it will go and

tighten the set screw.

CAUTION

Do not dent or bend the bulb as this will prevent it from

fitting into the well properly.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, FAX (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, FAX (905) 475-4625

Printed in U.S.A.

PART NO. 37-2562B

Replaces 37-2562 & 37-9460

9548

Page 2

WIRING

All wiring should be done in accordance with local and national electrical codes and ordinances.

11D06 .................... OPEN ON RISE

11D37 .................... CLOSE ON RISE

11D82 .................... S.P.D.T.

SETTING THE CONTROL

CONTROLS WITH ADJUSTABLE DIFFERENTIAL

1. Insert a screwdriver in the centre slot and turn the dial until

the right hand indicator “B” points to the lowest temperature

of the cycle.

2. Turn the differential adjusting screw “C” until the left hand

indicator “D” points to the highest temperature of the cycle.

The left-hand indicator points to the temperature at which the

contacts open on high limit and low limit applications. On

circulator applications, the left-hand indicator points to the

temperature at which the circulator will start.

On combination low limit and circulator applications, the

left-hand indicator points to the temperature at which the low

limit stops the burner and permits the circulator to run.

“B” FIXED INDICATOR

RED

COMMON

CLOSE ON RISE

OF TEMPERATURE

WHITE

BLUE

OPEN ON RISE

OF TEMPERATURE

CONTROLS WITH FIXED DIFFERENTIAL

Insert a screwdriver in centre slot “A” and turn the dial until the

fixed indicator “B” points to the highest desired temperature of

the cycle.

The fixed indicator points to the temperature at which the

contacts open on high limit and low limit applications. On

circulator applications, the fixed indicator points to the temperature at which the circulator will start.

On combination low limit and circulator applications, the

fixed indicator points to the temperature at which the low limit

stops the burner and permits the circulator to run.

“B” FIXED

INDICATOR

“A” ADJUSTING

SLOT

SERVICING

CAPILLARY

“C” DIFFERENTIAL

ADJUSTING SCREW

“D” MOVABLE INDICATOR

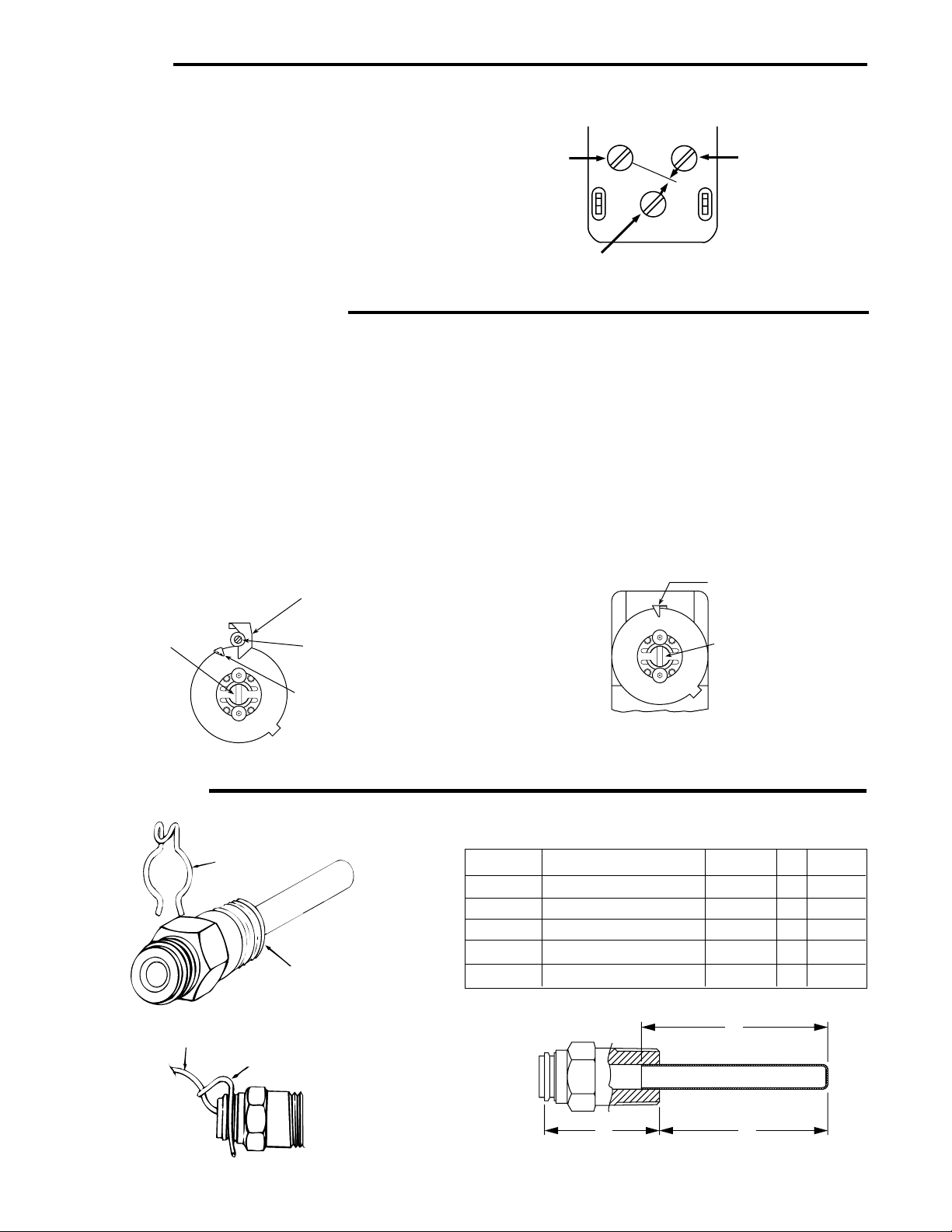

Order wells and heat conductive grease No. 145-0163 separately.

RETAINER CLIP

Well No. Description A B C

89-0211 1/2" Std. Shank 1-13/16" 3" 3-5/16"

89-0212 1/2" Std. Ext. Shank 3-5/16" 3" 3-5/16"

89-0213 3/4" Std. Shank 1-13/16" 3" 3-5/16"

89-0214 3/4" Std. Ext. Shank 3-5/16" 3" 3-5/16"

IMMERSION WELL

RETAINER CLIP

89-0215 3/4" Extra Ext. Shank 4-13/16" 3" 3-5/16"

“A” ADJUSTING

SLOT

C

A

B

2

Page 3

11D06, 11D37, 11D82

WHITE-RODGERS

Utilisateur: conservez ces instructions pour vous y référer au besoin!

SI VOUS NE LISEZ PAS ATTENTIVEMENT CES INSTRUCTIONS AVANT

D’INSTALLER ET D’UTILISER LA COMMANDE, VOUS RISQUEZ DE CAUSER

DES BLESSURES ET DES DOMMAGES MATÉRIELS.

Ce régulateur a été conçu pour servir avec des équipements de

chauffage à eau chaude. Il est doté d’un commutateur à ouverture

sur hausse, à fermeture sur hausse ou unipolaire bidirectionnel.

Le différentiel peut être fixe ou réglable.

La commande est dotée d’un capteur à distance, facilitant son

installation dans les endroits difficiles d’accès.

RÉGULATEUR D’EAU CHAUDE AVEC

CAPTEUR À DISTANCE

INSTRUCTIONS D’INSTALLATION

DESCRIPTION

LA PRÉSENTE COMMANDE DOIT ÊTRE INSTALLÉE PAR

UN TECHNICIEN QUALIFIÉ.

Ne dépassez pas les charges nominales.

Tout le câblage doit être conforme aux codes et règlements

locaux et nationaux qui régissent les installations électriques.

Cette commande est un instrument de précision qui doit être

manipulé avec soin. Elle peut se détraquer si elle est manipulée

de façon négligente ou si des composantes sont déformées.

La commande a été calibrée avec précision lors de la fabrication.

Toute tentative de calibrer l’appareil annulera la garantie de

White-Rodgers.

Si un emplacement de la commande est recommandé par le

fabricant de la chaudière, alors veuillez vous y conformer. Si

aucun emplacement n’est suggéré, veuillez suivre les conseils

suivants.

Si la commande est utilisée comme limiteur à maximum, elle

doit être installée près de la chaudière, sur la colonne montante,

ou dans une ouverture taraudée qui est située dans la partie

supérieure ou dans la section la plus chaude. Si la chaudière

sert aussi pour l’eau chaude domestique, s’assurer que le

limiteur à maximum n’est pas installé dans la partie de la

chaudière où se trouvent l’échangeur de chaleur ou les canalisations d’eau chaude domestique.

Si la commande sert de limiteur à minimum ou d’actionneur,

elle doit alors être installée dans la partie de la chaudière où se

trouvent l’échangeur de chaleur ou les canalisations d’eau

chaude domestique.

PRÉCAUTIONS

ATTENTION

Afin de prévenir les chocs électriques et les dommages

matériels pendant l’installation, coupez l’alimentation

électrique au panneau de distribution principal.

AVERTISSEMENT

N’installez pas cet appareil sur des circuits qui dépassent la tension nominale. Une tension trop élevée peut

endommager la commande et poser des risques de

chocs électriques et d’incendie.

INSTALLATION

Pour séparer la gaine de la commande, desserrer d’abord la vis

de réglage du gros écrou, puis glisser la gaine pour exposer le

capteur. Visser la gaine dans l’ouverture taraudée qui convient.

Réintroduire ensuite le capteur dans la gaine en prenant soin

qu’il soit bien au fond. Serrer la vis de réglage.

ATTENTION

Ne pas plier ou bosser le capteur, car il serait alors

impossible de l’introduire correctement dans la gaine.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, Télécopieur (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, Télécopieur (905) 475-4625

Imprimé aux É.-U.A.

PIÈCE No 37-2562B

Remplace 37-2562 & 37-9460

9548

Page 4

CÂBLAGE

N

Tout le câblage doit être conforme aux codes et règlements locaux et nationaux qui régissent les installations électriques.

11D06....................................... OUVERTURE SUR HAUSSE

11D37....................................... FERMETURE SUR HAUSSE

11D82................... UNIPOLAIRE BIDIRECTIONNEL (SPDT)

RÉGLAGE DE LA COMMANDE

COMMANDES À DIFFÉRENTIEL RÉGLABLE

1. Introduire la pointe d’un tournevis dans la fente de réglage

(A). Tourner le cadran pour que l’indicateur du côté droit (B)

indique la température la plus basse du cycle.

2. Tourner la vis de réglage du différentiel (C) jusqu’à ce que

l’indicateur du côté gauche (D) indique la température la plus

élevée du cycle.

L’indicateur du côté gauche indique la température à laquelle les

contacts seront ouverts lorsque la commande sert de limiteur

à maximum ou de limiteur à minimum. Lorsque la commande

sert de circulateur, l’indicateur du côté gauche indique la

température de mise en marche du circulateur.

Lorsque la commande sert de circulateur avec limiteur à

minimum, l’indicateur du côté gauche indique la température à

laquelle le limiteur à minimum arrêtera le brûleur tout en

permettant au circulateur de fonctionner.

(B) INDICATEUR FIXE

RED

ROUGE BLEUE

Common

NEUTRE

FERMETURE SUR HAUSSE

Close on rise

DE TEMPÉRATURE

of temperature

BLUE

BLANCHE

WHITE

OUVERTURE

Open on rise

SUR HAUSSE DE

of temperature

TEMPÉRATURE

COMMANDES À DIFFÉRENTIEL FIXE

Introduire la pointe d’un tournevis dans la fente de réglage (A).

Tourner le cadran pour que la température maximale souhaitée

du cycle se trouve directement sous l’indicateur fixe (B).

L’indicateur fixe indique la température à laquelle les contacts

seront ouverts lorsque la commande sert de limiteur à maximum

ou de limiteur à minimum. Lorsque la commande sert de

circulateur, l’indicateur fixe indique la température de mise en

marche du circulateur.

Lorsque la commande sert de circulateur avec limiteur à

minimum, l’indicateur fixe indique la température à laquelle le

limiteur à minimum arrêtera le brûleur tout en permettant au

circulateur de fonctionner.

(B) INDICATEUR FIXE

I

(A) FENTE DE

RÉGLAGE

RÉVISION

TUBE CAPILLAIRE

ING

(C) VIS DE RÉGLAGE

DU DIFFÉRENTIEL

(D) INDICATEUR MOBILE

Commander séparément les gaines et la graisse themoconductrice no 145-0163.

ATTACHE

No de gaine

Description A B C

89-0211 Tige standard 1/2" 1-13/16" 3" 3-5/16"

89-0212 Tige standard allongée 1/2" 3-5/16" 3" 3-5/16"

89-0213 Tige standard 3/4" 1-13/16" 3" 3-5/16"

89-0214 Tige standard allongée 3/4" 3-5/16" 3" 3-5/16"

GAINE D’IMMERSION

ATTACHE

89-0215 Tige surallongée 3/4" 4-13/16" 3" 3-5/16"

(A) FENTE DE

RÉGLAGE

C

A

B

2

Loading...

Loading...