Page 1

WHITE-RODGERS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

These controls are designed for use on hot water heating

installations. They have open-on-rise switch action and

are available with either fixed or adjustable differential.

Models are available with either horizontal or vertical well.

Some of these models also have excess capillary stored

within the enclosure, permitting them to be used with wells

having either a standard or extended shank.

Another model, ideal for replacement purposes, has a

slotted case and excess capillary stored within the enclosure. This control can be used with either a standard or

extended shank well, on either horizontal or vertical well

installations.

THESE CONTROLS MUST BE INSTALLED BY A

QUALIFIED INSTALLER.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical

codes and ordinances.

This control is a precision instrument, and should be

handled carefully. Rough handling or distorting components could cause the control to malfunction.

This control has been accurately calibrated at the factory.

Any attempt to calibrate this control will void the WhiteRodgers warranty.

WARNING

Do not use on circuits exceeding specified

voltages. Higher voltages will damage control

and could cause shock or fire hazard.

11B18

HOT WATER CONTROL

Open on Rise, Well-Immersion

INSTALLATION INSTRUCTIONS

DESCRIPTION

PRECAUTIONS

CAUTION

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation.

Following installation or replacement, follow

appliance manufacturer’s recommended installation and/or service instructions to insure proper

operation.

CAUTION

To prevent electrical shock and/or equipment

damage, disconnect electric power to system, at

main fuse or circuit breaker box, until installation

is complete.

Shut off main gas to heating system until installation is complete.

Convertible controls have a Knockout Plate on back of

case (secured by Hex Nut on Horizontal models, and by

Knockout Plug on Vertical models). To convert from

Horizontal to Vertical:

1. Remove control cover. Then remove bottom knockout.

2. Remove Hex Nut (inside control) from Well Mounting

Stem. (To loosen, hold Hex Nut inside while turning

Hex Nut on back of control counterclockwise.)

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, FAX (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, FAX (905) 475-4625

Printed in U.S.A.

CONVERTIBLE CONTROLS

3. Pull Well Mounting Stem away from case and remove

Knockout Plate.

4. Swing capillary down through slot into bottom knockout.

5. Secure Knockout Plate to back of case by using

Knockout Plug provided in envelope.

6. Insert Well Mounting Stem into bottom knockout and

tighten Hex Nut (inside control) securely.

PART NO. 37-2068B

Replaces 37-2068A & 37-9199

9545

Page 2

CONVERTIBLE CONTROLS CONT.

NOTE

To convert from Vertical to Horizontal model, remove

Knockout Plug and Plate. Remove Hex Nut (inside control) and swing capillary upward into back knockout. Place

Knockout Plate beneath Hex Nut on back of control and

tighten Hex Nut (inside control). If bottom knockout is not

used for wiring, insert Knockout Plug.

EXTENDING CAPILLARY

Some controls have excess stored capillary which may be

extended for use with an extended shank well. Use reasonable care when straightening and forming the capillary.

INSTALLATION

If the boiler manufacturer recommends a control location,

follow such recommendations. If none is offered, the

following information gives suggested locations.

When used for high limit service, the control should be

installed in the riser close to the boiler, or in a boiler

tapping that is near the top or hottest section of the boiler.

If the boiler is also used to heat domestic hot water, make

sure that the high limit control is not located in the section

of the boiler that contains the heat exchanger or piping for

domestic hot water.

When used for low limit or operator service, the control

should be located near that section of the boiler that

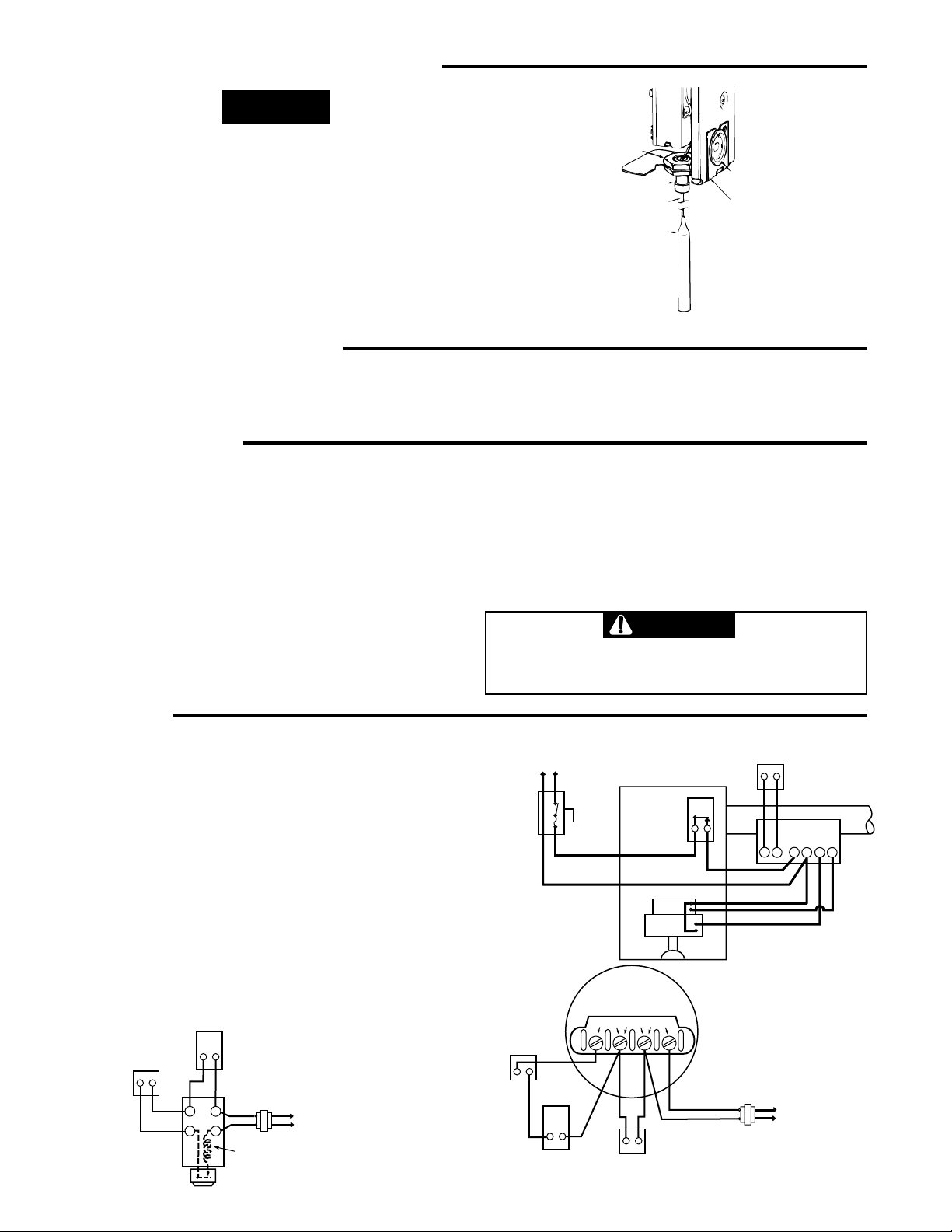

HEX NUT

MOUNTING STEM

CAPILLARY

BULB

KNOCKOUT PLUG

KNOCKOUT PLATE

Convertible Control converted to Vertical Model.

With the capillary fully extended, the bulb should slide all

the way to the end of the well.

contains the heat exchanger or piping for domestic hot

water.

To remove the well from the control, loosen the set screw

in the large nut, then slide the well off to expose the bulb.

Screw the well into the proper tapping. Slide the bulb back

into the well, making sure that the bulb enters the well as

far as it will go and tighten the set screw.

CAUTION

Do not dent or bend the bulb as this will prevent

it from fitting into the well properly.

WIRING

All wiring should be done in accordance with local and national electrical codes and ordinances.

If the boiler or burner manufacturer recommends a wiring

diagram, then follow such recommendations.

If none is offered, these diagrams show suggested circuits.

HIGH

LIMIT

Used as high limit control

THERMOSTAT

SILENT KNIGHT

GAS VALVE

AUX

2 3

TH TR

1 4

with Silent Knight gas

valve with plug-in pilot

TRANSFORMER

COIL

PLUG-IN

PILOT

TO

LINE

LINE

GND HOT

Used as high limit

control with

oil burner control

THERMOSTAT

LIMIT

CONTROL

2

FUSED

LINE

SWITCH

THERM PILOT

INTERMITTENT IGNITION

OIL BURNER CONTROL

LIMIT

CONTROL

TRANS

MOTOR

DIAPHRAGM

GAS VALVE

TRANS

AUTOMATIC

IF AUTOMATIC PILOT IS NOT USED,

CONNECT A JUMPER BETWEEN

PILOT

THE PILOT TERMINALS

THERMOSTAT

STACK

1

4

2

T

3

T

Used as high limit

control with

diaphragm gas valve

TRANSFORMER

TO

LINE

Page 3

SETTING THE CONTROL

CONTROLS WITH ADJUSTABLE DIFFERENTIAL

The movable indicator points to the temperature at which

the contacts open. The fixed indicator points to the temperature at which the contacts close. The difference

between these two indicators is the differential.

To set the control:

1. Use a screwdriver in the adjusting slot (A) on the front

of the control to turn the dial so that the fixed indicator

(B) points to the temperature at which the contacts will

close.

2. Turn the differential adjusting screw (C) until the

movable indicator (D) points to the temperature at

which the contacts will open.

“B” Fixed indicator

“F” Stop tab

“A” Adjusting

slot

ADJUSTABLE DIFFERENTIAL

(cut-in point)

“C” Differential adjusting

screw

“D” Movable indicator

(cut-out point)

“E” Stop screw

CONTROLS WITH A FIXED DIFFERENTIAL

The indicator (B) points to the temperature at which the

contacts open.

To set the control:

Use a screwdriver in the adjusting slot (A) on the front

of the control to rotate dial until the desired temperature at which the contacts will open is positioned

directly under the indicator (B).

CONTROLS WITH ADJUSTABLE STOPS

CAUTION

Setting stop higher than control being replaced

could cause personal injury and/or property damage.

1. Loosen stop screw (E) with enclosed wrench.

2. Set dial to original equipment manufacturer's specification.

3. Without moving the dial, move stop tab (F) against

indicator.

4. Retighten stop screw (E).

“F” Stop tab

“E” Stop screw

“A” Adjusting

FIXED DIFFERENTIAL

“B” Fixed

indicator

slot

3

Page 4

WHITE-RODGERS

Utilisateur: conservez ces instructions pour vous y référer au besoin!

SI VOUS NE LISEZ PAS ATTENTIVEMENT CES INSTRUCTIONS AVANT

D’INSTALLER ET D’UTILISER LA COMMANDE, VOUS RISQUEZ DE CAUSER

DES BLESSURES ET DES DOMMAGES MATÉRIELS.

Cette commande a été conçue pour servir avec un

système de chauffage à eau chaude. Elle est dotée d’un

commutateur ouvert sur hausse. Le différentiel peut être

fixe ou réglable, selon le modèle.

Ils existe des modèles qui conviennent aux gaines

verticales et horizontales. Certains des modèles sont

aussi dotés dans le boîtier d’un surplus de capillaire qui

permet de les utiliser avec une gaine normale ou longue.

Un autre modèle, idéal comme remplacement, est doté

d’un boîtier à rainure et d’un surplus de capillaire. Il peut

ainsi servir avec une gaine normale ou longue montée

verticalement ou horizontalement.

11B18

COMMANDE D’EAU CHAUDE

Ouverture sur hausse, avec gaine

INSTALLATION INSTRUCTIONS

DESCRIPTION

LA PRÉSENTE COMMANDE DOIT ÊTRE INSTALLÉE

PAR UN TECHNICIEN QUALIFIÉ.

Ne dépassez pas les charges nominales.

Tout le câblage doit être conforme aux codes et règlements

locaux et nationaux qui régissent les installations

électriques.

Cette commande est un instrument de précision qui doit

être manipulé avec soin. Elle peut se détraquer si elle est

manipulée de façon négligente ou si des composantes

sont déformées.

La commande a été calibrée avec précision lors de la

fabrication. Toute tentative de calibrer l’appareil annulera

la garantie de White-Rodgers.

AVERTISSEMENT

N’installez pas cet appareil sur des circuits qui

dépassent la tension nominale. Une tension trop

élevée peut endommager la commande et poser

des risques de chocs électriques et d’incendie.

Les commandes convertibles sont dotées à l’arrière

d’une plaque de conversion (tenue par un écrou hexagonal

sur les modèles horizontaux et par un bouchon de

conversion sur les modèles verticaux). Pour convertir la

commande de l’horizontale à la verticale :

1. Retirer le couvercle de la commande. Retirer ensuite

la plaque inférieure.

2. Retirer l’écrou hexagonal (à l’intérieur de la commande)

de la tige de montage de la gaine. (Pour desserrer

l’écrou, le tenir tout en tournant à gauche l’écrou

hexagonal qui se trouve à l’arrière de la commande).

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, FAX (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, FAX (905) 475-4625

Imprimé aux É.-U.A.

PRÉCAUTIONS

ATTENTION

Prenez soin d’identifier les fils avant de débrancher

ou de réviser la commande. Les erreurs de

raccordement peuvent entraîner un fonctionnement incorrect ou dangereux de la commande.

Pour assurer le bon fonctionnement de la

commande après l’avoir installée, veuillez suivre

les directives d’installation ou de révision du

fabricant de l’équipement.

ATTENTION

Afin de prévenir les chocs électriques et les

dommages matériels pendant l’installation,

coupez l’alimentation électrique au panneau de

distribution principal.

Coupez le gaz qui alimente le système de

chauffage pendant toute la durée de l’installation.

COMMANDES CONVERTIBLES

3. Dégager la tige de montage de la gaine et retirer la

plaque de conversion.

4. Glisser le capillaire dans la rainure jusqu’à la plaque

inférieure.

5. Fixer la plaque de conversion à l’arrière de la commande

à l’aide du bouchon de conversion qui se trouve dans

l’enveloppe.

6. Introduire la tige de montage de la gaine dans la

plaque inférieure et serrer solidement l’écrou hexagonal

(à l’intérieur de la commande).

PIÈCE No 37-2068B

Remplace 37-2068A & 37-9199

9545

Page 5

COMMANDES CONVERTIBLES (suite)

NOTE

Pour convertir la commande de la verticale à l’horizontale,

retirer d’abord le bouchon et la plaque de conversion.

Retirer l’écrou hexagonal (à l’intérieur de la commande)

et glisser le capillaire dans la rainure jusqu’à la plaque

arrière. Placer la plaque de conversion sous l’écrou

hexagonal à l’arrière de la commande et serrer l’écrou

hexagonal (à l’intérieur de la commande). Si l’ouverture

de la plaque inférieure ne sert pas au câblage,y poser le

bouchon de conversion.

EXTENSION DU CAPILLAIRE

Certaines commandes ont un surplus de capillaire qui

peut être allongé afin de servir avec une gaine allongée.

Procéder soigneusement pour redresser et former le

capillaire.

INSTALLATION

Si un emplacement de la commande est recommandé par

le fabricant de la chaudière, alors veuillez vous y conformer.

Si aucun emplacement n’est suggéré, veuillez suivre les

conseils suivants.

Lorsque la commande est utilisée comme limiteur à

maximum, elle doit être installée près de la chaudière,

sur la colonne montante, ou dans une ouverture taraudée

qui est située dans la partie supérieure ou dans la section

la plus chaude de la chaudière. Si la chaudière sert aussi

pour l’eau chaude domestique, s’assurer que le limiteur à

maximum n’est pas installé dans la partie de la chaudière

où se trouvent l’échangeur de chaleur ou les canalisations

d’eau chaude domestique.

Lorsque la commande sert de limiteur à minimum ou

d’actionneur, elle doit alors être installée dans la partie

ÉCROU HEXAGONAL

TIGE DE MONTAGE

CAPILLAIRE

CAPTEUR

BOUCHON DE

CONVERSION

PLAQUE DE

CONVERSION

Commande convertie en modèle vertical.

Une fois le capillaire complètement allong, le capteur doit

glisser jusqu’au fond de la gaine.

de la chaudière où se trouvent l’échangeur de chaleur ou

les canalisations d’eau chaude domestique.

Pour séparer la gaine de la commande, desserrer d’abord

la vis de réglage du gros écrou, puis glisser la gaine pour

exposer le capteur. Visser la gaine dans l’ouverture

taraudée qui convient. Réintroduire ensuite le capteur

dans la gaine en prenant soin qu’il soit bien au fond. Serrer

la vis de réglage.

ATTENTION

Ne pas plier ou bosser le capteur, car il serait

alors impossible de l’introduire correctement dans

la gaine.

CÂBLAGE

Tout le câblage doit être conforme aux codes et règlements

locaux et nationaux qui régissent les installations

électriques.

Si le fabricant de la chaudière ou du brûleur recommande

un schéma de câblage, alors veuillez vous y référer.

Dans le cas contraire, voici quelques schémas de circuits

recommandés.

HIGH

LIMITEUR À

LIMIT

THERMOSTAT

THERMOSTAT

ROBINET À GAZ

SILENT KNIGHT

SILENT KNIGHT

GAS VALVE

MAXIMUM

AUX

2 3

TH TR

1 4

Utilisée comme limiteur à

Used as high limit control

maximum avec robinet à

gaz Silent Knight à

with Silent Knight gas

veilleuse enfichable

valve with plug-in pilot

TRANSFORMATEUR

TRANSFORMER

BOBINE

COIL

VEILLEUSE

PLUG-IN

ENFICHABLE

PILOT

TO

SECTEUR

LINE

SECTEUR

LINE

NEUTRE

SOUS TENSION

GND HOT

COMMUTATEUR

DE SECTEUR

À FUSIBLE

FUSED

LINE

SWITCH

Utilisée comme

limiteur à maximum

Used as high limit

avec commande de

control with

brûleur à mazout

oil burner control

THERMOSTAT

LIMIT

LIMITEUR

CONTROL

2

COMMANDE DE BRÛLEUR À

INTERMITTENT IGNITION

MAZOUT À ALLUMAGE

OIL BURNER CONTROL

INTERMITTENT

LIMIT

CONTROL

LIMITEUR

TRANS

MOTEUR

MOTOR

ROBINET À GAZ

DIAPHRAGM

À MEMBRANE

GAS VALVE

VEILLEUSE

AUTOMATIC

AUTOMATIQUE

PILOT

TRANS

THERM PILOT

THERMOSTAT

1

2

T

T

Utilisée comme limiteur

Used as high limit

à maximum avec robinet

control with

à gaz à membrane

diaphragm gas valve

TRANSFORMATEUR

TRANSFORMER

SI UNE VEILLEUSE AUTOMATIQUE N’EST PAS

IF AUTOMATIC PILOT IS NOT USED,

UTILISÉE, RACCORDER LES DEUX BORNES DE

CONNECT A JUMPER BETWEEN

LA VEILLEUSE À L’AIDE D’UN CAVALIER.

THE PILOT TERMINALS

TO

SECTEUR

LINE

CHEMINÉE

4

3

STACK

Page 6

RÉGLAGE DE LA COMMANDE

COMMANDES À DIFFÉRENTIEL RÉGLABLE

L’indicateur mobile donne la température à laquelle les

contacts seront ouverts. L’indicateur fixe donne la température à laquelle les contacts seront fermés. La différence

entre les deux indicateurs représente le différentiel.

Pour régler la commande :

1. Introduire la pointe d’un tournevis dans la fente de

réglage (A) qui se trouve à l’avant de la commande.

Tourner le cadran pour que l’indicateur fixe (B) indique

la température à laquelle les contacts devront être

fermés.

2. Tourner la vis de réglage du différentiel (C) jusqu’à ce

que l’indicateur mobile (D) indique la température à

laquelle les contacts devront être ouverts.

B INDICATEUR FIXE

F BUTÉE

A FENTE DE

RÉGLAGE

DIFFÉRENTIEL RÉGLABLE

(POINT D’ENCLENCHEMENT)

C VIS DE RÉGLAGE

DU DIFFÉRENTIEL

D INDICATEUR MOBILE

(POINT DE DÉCLENCHEMENT)

E VIS DE BUTÉE

COMMANDES À DIFFÉRENTIEL FIXE

L’indicateur (B) donne la température à laquelle les

contacts seront ouverts.

Pour régler la commande :

Introduire la pointe d’un tournevis dans la fente de

réglage (A) qui se trouve à l’avant de la commande.

Tourner le cadran pour que la température à laquelle

les contacts devront être ouverts se trouve directement

sous l’indicateur (B).

COMMANDES À BUTÉES RÉGLABLES

ATTENTION

Il y a un risque de blessures et de dommages

matériels si la butée est réglée à un point de

consigne plus élevé que celle de la commande

qui est remplacée.

1. Desserrer la vis de butée (E) à l’aide de la clé fournie.

2. Régler le cadran selon les recommandations du

fabricant de l’équipement.

3. En prenant soin de ne pas déplacer le cadran, accoter

la butée (F) contre l’indicateur.

4. Serrer à nouveau la vis de butée (E).

F BUTÉE

E VIS DE BUTÉE

B INDICATEUR FIXE

A FENTE DE

DIFFÉRENTIEL FIXE

(POINT D’ENCLENCHEMENT)

RÉGLAGE

3

Loading...

Loading...