Page 1

INSTRUCTIONS

FOR USE AND CARE OF

White

Rotary Electric

Sewing Machines

MODEL NUMBER 45

MODEL NUMBER 41

WHITE SEWING MACHINE CORP.

White Sewing Machine Products Limiter

CLEVELAND I, OHIO

Page 2

Wherever a reference is made to turning disc wheel, of

sewing: that is with the top of the dise wheel turnin

screw and press it to the left to permit the shank of the NEEDLE

- the NEEDLE being flattened

The needle, when descending, should pass CENTRAL

the needle hole from FRONT to REAR. but close to the right

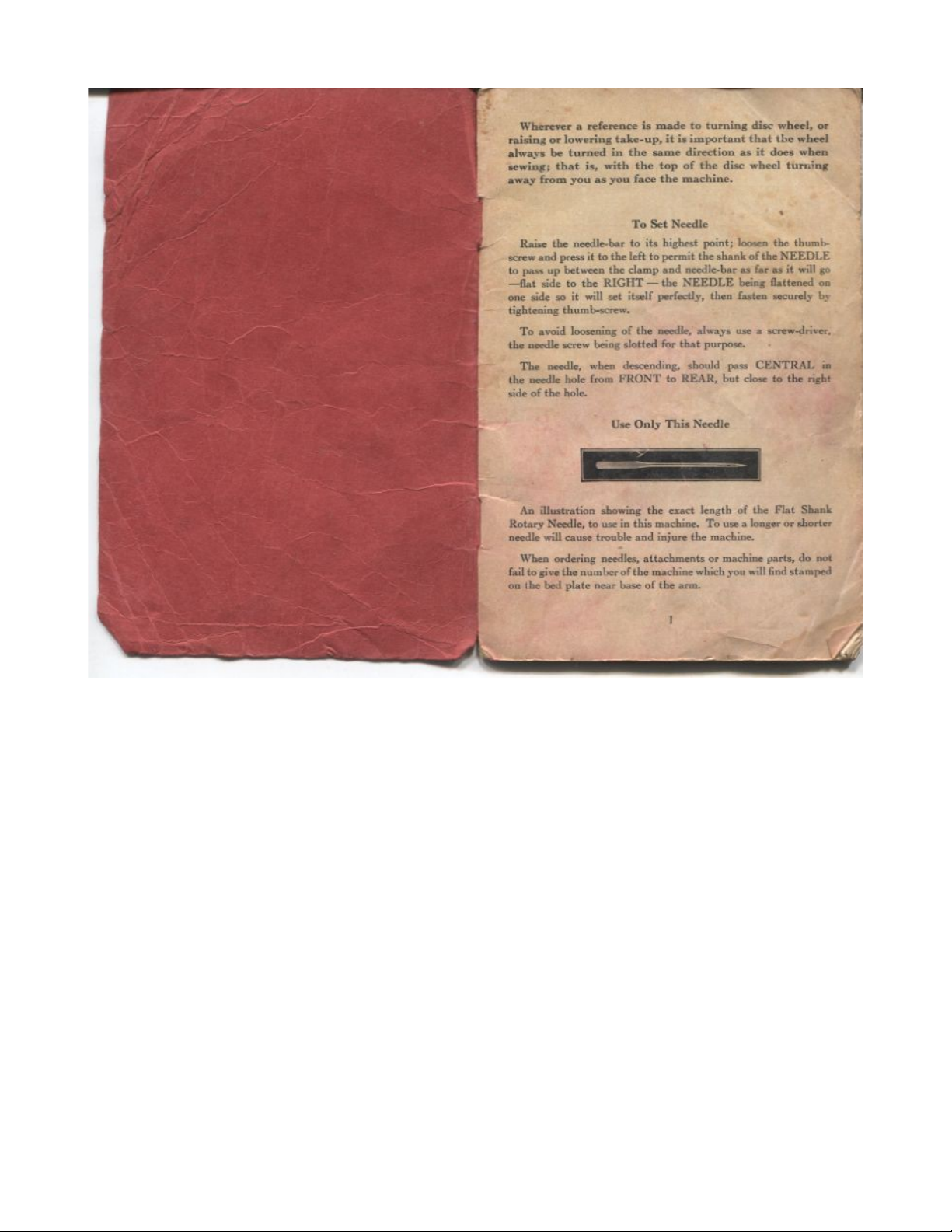

Use Only This Needle

An illustration showing the exact length of the Flat Shank

fail to give the number of the machine

To uses ioneeror.

Page 3

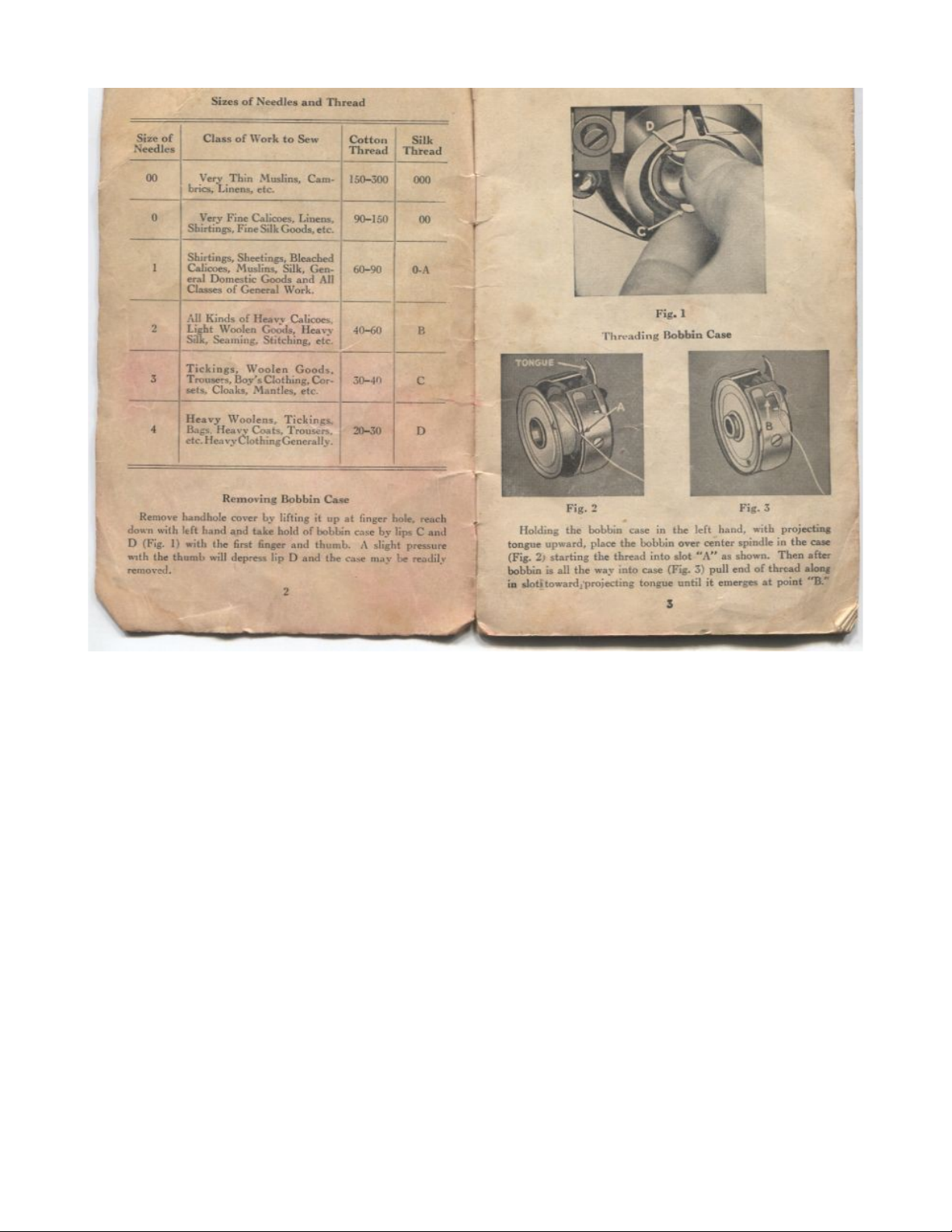

Sizes of Needles and Thread

Size of

Class of Work to Sew

VerY Thin Muslins, Cam-

Very Fine Calicoes, Linens,

Shirtings Starting flinched

Work.

Woolen Goods, Heavy

ings, Woolen Goods

Boy's Clothing, Cor

Woolens, Tickings

oats,

90-150

30-40

Silk

Thread

Fig. 1

Threading Bobbin Ca

Fig. 3

tongue upward, place the bobbin over center spindle in the cast

(Fig. 2) starting the thread into slot "A"

bobbin is all the war into case (ic. gl pull end of thread alo

Page 4

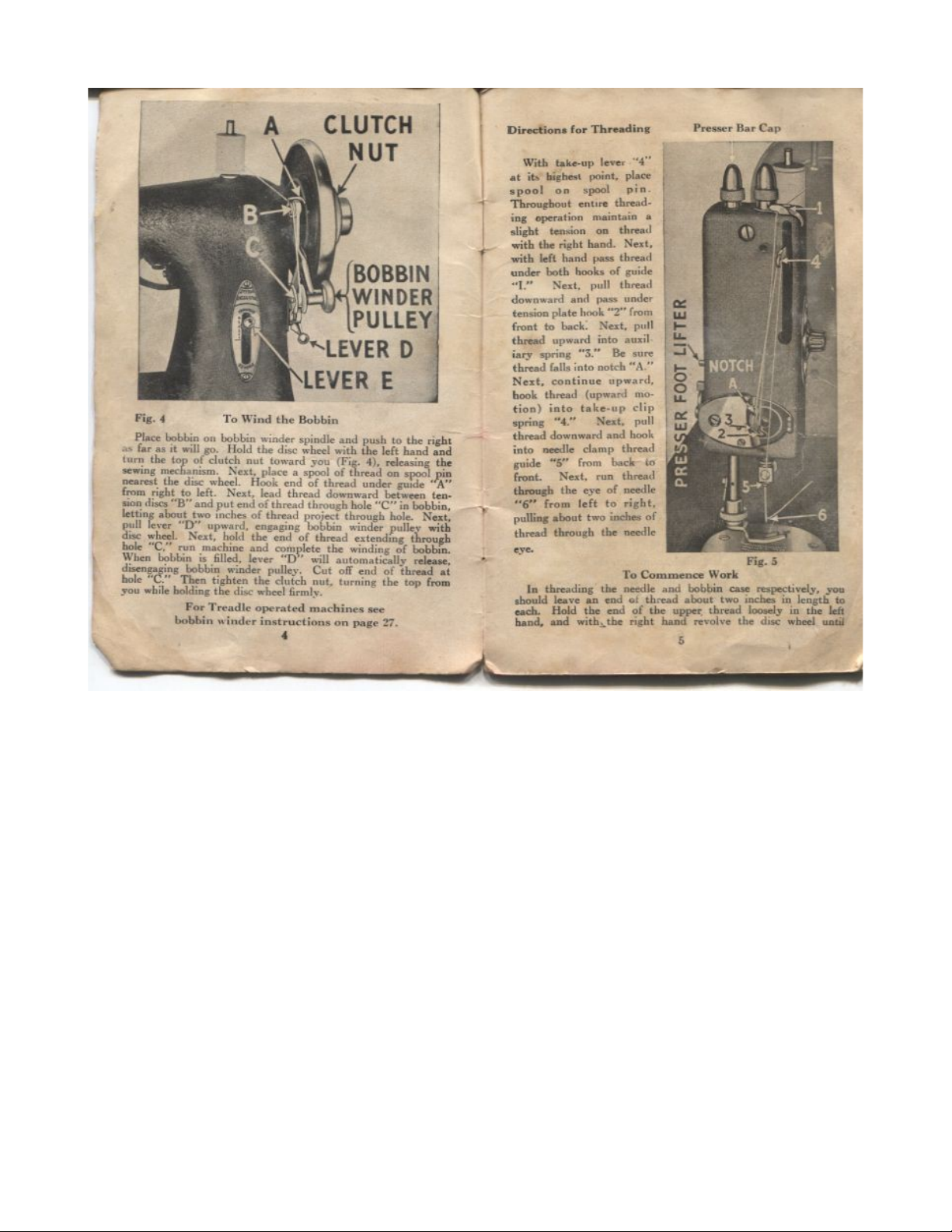

A CLUTCH

NUT

BOBBIN

*WINDER

PULLEY

OLEVER D

LEVER E

PRESSER FOOT LIFTER

Hir

LEnT

Page 5

Take the

Turn the disc wheel until the take-up

in presser-foot slot),

machine, and it is reads

thread with

Proper Adjust

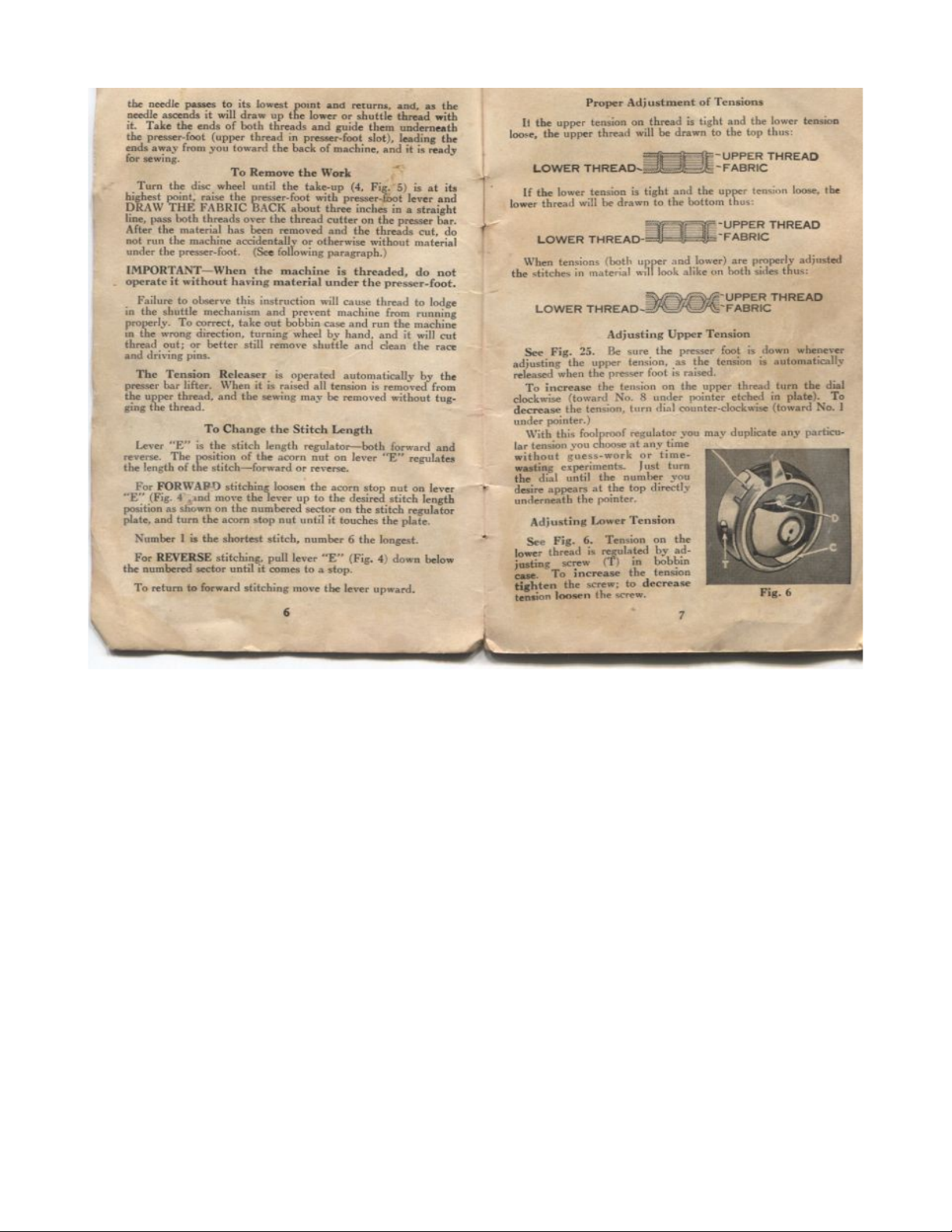

It the upper tension on thread is tight and the lower tension

LOWER THREAD-

If the lower tension is tight and the upper tension loose, the

lower thread will be drawn to the bottom t

LOWER THREAD-

nenE Of Lensions

TE UPPER THREAD

§-FABRIC

IF -UPPER THREAD

E°FABRIC

machine is threaded.

To Change the Stitch Length

eleven The pothe stinch, lensch. regal tar leboth, formard and

tength or the stich of die are or rest on.!

For FORWAPD stitching loosen the

(Fig.

Number I is the shortest stitch, number 6 the longest.

for REYERSE stitching.pull lever "E" (Fig, 4) down below

m on the

acorn stop nut until it touches the plate.

scorn stop nut on lever

up to the

• desired. enoth

sector on the stitch regulator

When tensions (both upper and lower) are, proper adjusted

LOWER THREAD.)

Adjusting Upper Tension

& YABER THREAD

the upper thread turn the dial

maw dunicate any particu

Page 6

RACE

niter proud, being(SR

(DP)

and without forcing allowing

sim and

Page 7

that knurled thumb-screw is tightened securely

• making a

With the rich

(right side down) in

"the decodile hole,

Page 8

ATT

scroll

The Five-Stitch Ruffler

NICENTESTA

Page 9

Page 10

Directions for Using the Shirring Foot

Remove the presser-toot and replace with the Shirrine Foot

Fig 15

To Gather, Puff or

Place the goods under the foot the same as in ordinars

For fine gather use a short stitch.

Combination

When sewing materials together, it i is better

When the attachment is properly adjusted, the most inexperi-

enced operator may

no difficulty.

that the attachment is adjusted

sachs, "Tin lithe the right until the braiding guide

Page 11

For cutting bands of various widths, either straight or bias

The sliding scale is adjustable for the widths of band desired.

1¼ inch indicates the proper

width for a bias fold, which is to

be inch wide when fished

One inch indicates the width

One-half inch is for corded or plain piping.

Fig. 20

the cloth in the gauge and proceed to cut the The tape

1; ship the edge of

which

Page 12

o chance the stitchine

time, the wider inside

The Combination Adjustable Zipper

Attaching and Cording Foot

can be adjusted for stitching estbe

seam or for stitching right or left

Adjust by loosening thumb screw

Inserting Cording

For smooth operation and good results it is neces-

sary to use high grade oil.

Oil is

SewinG Machine

Page 13

Attaching

Remove the regular presser foot and attach the Combination

ahment in its place. Loosen the thumb screw on the attach.

ment and move the foot to the right or left as desired. See that

The needle holes on either side are cut deep enough to allow

Side Fastener

will not catch in the slide pull as it

ELECTRICAL EQUIF

Fig. 23

Cording

Fig. 24

The toilet contenti

Page 14

TAKE-UP

DOWN

FOIL

OIL TOIL BoIL

OIL

OIL-

To. I ig

donnie Machine

at all points indicated.

dry and oil carefully with White Sewing Machine Oil

Do not allow agents or unauthorized repairmen to

Fig;

26

Page 15

thread uneven and the

• that the thread slims

than likelv caused by pulline

It the stitches are not even, it may be caused by the presser.

the labnc sewed, or by the stitcl

SUPPLEMENTARY INSTRUCTIONS

for

TREADLE OPERATED MACHINE

In general, this machine is the same as the

one illustrated and described throughout this

book (except for electrical equipment), so all

instructions will apply, except for "Winding

the Bobbin" (Fig. 4 page 4), which directions

are given in this supplement.

When referring to this instruction book you

will notice that a few illustrations (Figs. 4, 24,

and 25) do not look exactly like your machine

due to the absence of the built in sewing light

and motor (on electric machines only), but in

all other respects they are the same.

WINDING THE BOBBIN

(TREADLE OPERATED MACHINE)

Slip a bobbin onto bobbin winder spindle

and push to right as far as it will go. Hold the

disc wheel with the left hand and loosen the

clutch nut, releasing the drive pulley so it will

run without operating the sewing mechanism.

Next, place spool of thread on bobbin winder

spool pin. Next, slip thread under guide

(A) and continue downward between tension

27

Page 16

Instructions for Treadle Operated Machine

discs (B), then

put end of thread

through hole (C)

in bobbin, from

inside, leaving

about two inches

of thread extend-

ing outside of

bobbin.

Next, pull lever

(D) upward en-

DISC WHEEL CLUTCHNUT

BOBBIN

WINDER

PULLEY

gaging bobbin

winder pulley

with disc wheel.

LEVER D

Hold the end of

the thread ex-

tending through

hole (C) and operate foot treadle until bob.

bin is wound, Lever (D) will automatically

release disengaging bobbin winder pulley when

bobbin is filled.

Remove bobbin from spindle, cut thread at

spool; then cut off the other end of thread at

hole

(C). Tighten clutch nut, turning the

top from you while holding the disc whee

firmly.

Loading...

Loading...