White 1599 User Manual

Blue

Jeans

‘

Machine

WHITE

BEWINQ

MACHINE

CONTENTS

1. |

NAMES OF PARTS |

2 |

2. |

ACCESSORIES |

3 |

3. |

BEFORE SEWING |

4 |

|

Detaching Extension Table |

4 |

|

Connecting Foot Controller and Power Cord |

5 |

|

Changing Needle |

6 |

|

Changing Foot |

7 |

|

Bobbin Winding |

8 |

|

Inserting Bobbin |

11 |

|

Adjusting Lower Tension |

12 |

|

Drop Feed Lever |

12 |

|

Threading Upper Thread |

13 |

|

Twin Needle Threading |

14 |

|

Decorative Tucks or Designs |

14 |

|

Drawing Up Lower Thread |

15 |

|

Foot Pressure |

15 |

|

Fabric, Thread and Needle Table |

16 |

|

Pattern Setting |

17 |

4. |

STRAIGHT SEWING |

18 |

|

Pattern Selection Dial |

18 |

|

Stitch Length Dial |

18 |

|

Starting to Sew |

19 |

|

Double Presser Foot Lifter |

19 |

|

Cloth Guide |

20 |

|

Adjusting Thread Tension |

20 |

|

Applications of Straight Stitch |

21 |

5. |

ZIGZAG SEWING |

22 |

|

Zigzag Width Control |

22 |

|

Thread Tension for Zigzag Stitch |

22 |

6. |

MAKING BUTTONHOLES |

23 |

|

Determine Length |

23 |

|

Determine Width |

23 |

|

Buttonhole Density Adjustment |

25 |

|

Cutting Buttonholes |

26 |

7. |

SEWING ON BUTTONS |

27 |

8. |

OVERCASTING |

28 |

9. |

OVERLOCKING |

29 |

|

Application of Rick-Rack |

31 |

|

Application of Decorative Fun Patterns |

32 |

10. |

STRAIGHT STRETCH STITCH |

30 |

|

Adjusting Stretch Stitch Balance |

30 |

11. |

BLIND HEM STITCH |

33 |

|

Elastic Blind Hem Stitch |

34 |

12. |

STRETCH SEAM |

35 |

13. |

ZIPPER SEWING |

36 |

14. |

SHELL STITCHING |

38 |

15. |

PIN TUCKING |

|

16. |

QUILTING |

39 |

17. |

MENDING |

40 |

|

Patching |

40 |

|

40 |

|

|

Mending a Rip |

|

18. |

DARNING |

41 |

19. |

APPLIQUE WORK |

42 |

20. |

MAINTENANCE |

44 |

|

Cleaning |

44 |

|

Oiling |

|

21. |

TROUBLE CHART |

47 |

|

Changing Light Bulb |

0 |

CD |

|

M |

N) |

N) |

N) |

|

0) |

01 |

|

c.) |

N) |

C..) N)-. 0 |

* |

|

|

|

|

|

|

|

|

|

|

I

1. NAMES OF PARTS

1.Thread guide for bobbin winding

2.Foot pressure regulator

3.Upper thread tension dial

4.Face cover

5.Thread guide for upper threading

6.Presser foot thumb screw

7.Presser foot

8.Shuttle cover

9.Top cover

10.Bobbin winding spindle

11.Screw hole for extra spool pin

12.Zigzag width control

13.Special buttonhole adjustment

14.Stitch length dial

15.Reverse sewing lever

16.Pattern selection dial

17.Free arm

18.Drop feed lever

19.Handwheel

20.Stop motion knob

21.Socket

22.Handle

23.Presser foot lifter

24.Feed dog

25.Needle plate

26.Switch *

*Specifications vary from country to country.

—2—

2. ACCESSORIES

,—

Felts (2 pcs.)

c

Buttonhole foot

Button sewing foot

N

‘J (

Zipper foot

Darning foot

(

Quilting guide

Cloth guide

Buttonhole cutter

—3—

Bobbins (3

Needles

Ordinary needles (3 pcs.)

Bail point needle (1 pc.)

Twin needle (1 pc.)

Extra spool pin (For twin needle sewing).

Spool cover

Oiler

Screw drivers

(small)

(large)

3.

BEFORE

SEWING

Machine is stored which makes your ordinary sewing.

in flat-bed style work easier for

Detaching

Extension

Table

Slide as a

off, and free-arm

the machine model.

is

used

J

To open top cover of accessory push open, as illustrated.

box,

Do vice-versa of above tach extension table.

steps

to

at

Free-arm is convenient to sew or embroider; trousers, sleeves, cuffs,

T-shirts,

blouses,

etc.

I

—4—

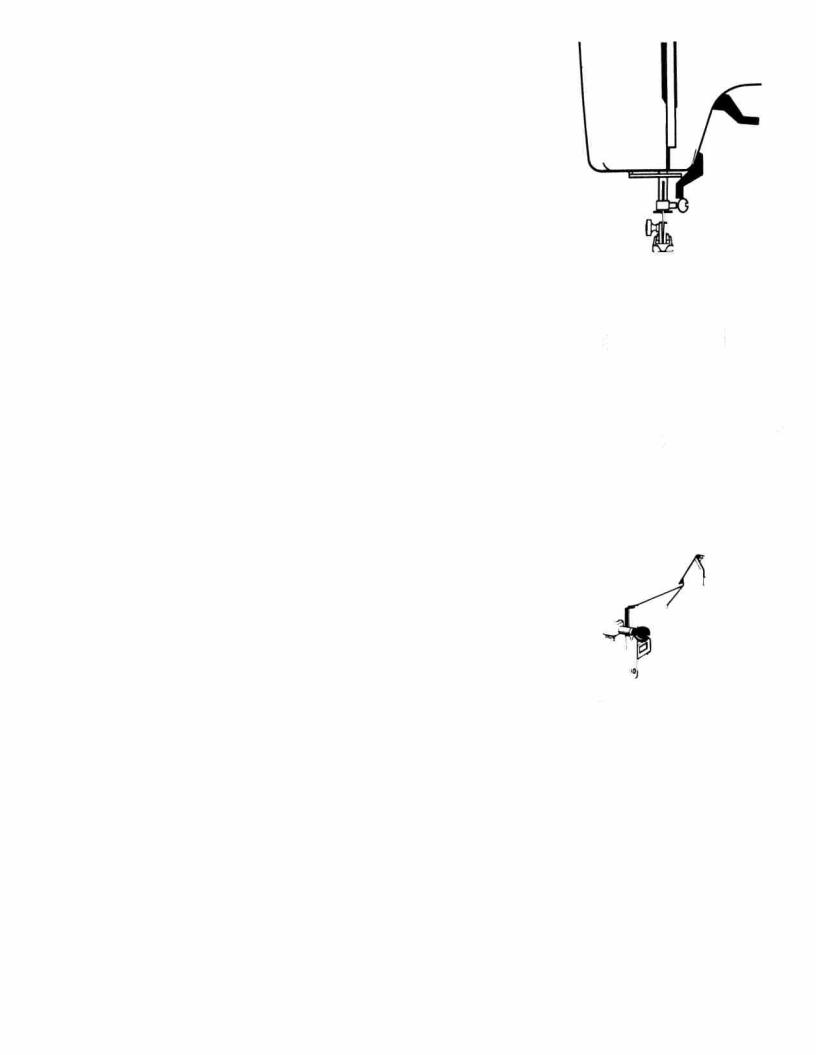

Changing

Foot

Raise

presser

foot

lifter.

Set

needle

in

the

highest

position

by

turning haridwheel towards

you.

(1)

Push

button

of

holder towards

you

and

foot

will

come

off.

(2)

Position

a

new

foot

by

aligning

holding foot.

groove

of

shank

with

pin

of

(3) Lower presser foot lifter so that holder catches presser foot.

Jr

—7—

Push back to fold handle.

Open top cover.

Put a spooi on spool pin. |

|

4 |

|

|

Draw thread from spool pin through |

© |

© |

||

thread guide and pretension device, |

||||

|

|

|||

following numbers |

and, |

|

|

|

Caution:

Spool should be put on spool pin in the manner of its thread being drawn from under side of spool.

Wind thread clockwise around bob bin several times.

Push bobbin onto spindle.

Holding handwheel with your left hand disengage handwheel by unscrewing stop motion knob.

—9—

Push bobbin to right and press down foot controller.

Machine stops automatically when bobbin is full.

Push bobbin to left, to disengage from wheel.

1

Take off bobbin from spindle and cut thread.

Retighten stop motion knob.

If bobbin is wound unevenly as shown, open top cover and use screw driver to adjust the guide for

bobbin winding.

,—

trouble 4c

correction

—10—

r

__j

Adjusting Lower Tension

To test bobbin tension, hang and shake bobbin case as shown.

At proper tension bobbin case will gradually drop a small amount.

To adjust tension, turn adjusting screw with small screwdriver.

Raise needle to highest position.

Leave end of thread of about 10 cm (4”) from bobbin case.

Take hold of latch and push bobbin case into hook.

Release latch when bobbin case is fully inserted.

J

|

Drop Feed Lever |

|

The lever is in the right side of |

|

shuttle cover. For normal sewing, |

|

move the lever to AAA position. |

v: 1/ |

To lower feed dog, move the lever |

to II position. |

|

|

This position is used for button |

|

sewing, darning and embroidery. |

‘—

—12—

Loading...

Loading...