Page 1

*

e

Page 2

of

Glossary

Glossary of

Machine

Accessories

Detaching

Connecting

Changing

Changing

Bobbin

Inserting

Adju

Upper

Drawing

Adjusting

Adjusting

Fabric,

Setting

Presser

Cloth

Basting

Staystitching

Zigzag

Edge

Interfacing

Bartack

Shell

Satin

Stretch

Rick

Topstitching

Seaming

Gathering

Lace

Making

Cutting

Corded

SewingonButtons

Blind

Zipper

Mending/Patching

Mending

Darning

Lapped

Applique

Sewing

Sewing

Identification

Extension

Foot

Presser

Needle

Winding

Bobbin

Lower

sting

Threading

Up

Pressure on

Upper

Needle

the

Stitch

Foot

Guide

Stitching

Finishing

Darts

Edging

Stitch

Stitch

Stitching

Stretch

Rack

Knits

Over

Applications

Buttonholes

Buttonholes

Buttonholes

Hem

Stitch

Sewing

Rip

a

Seam

Work

Lower

&

Lifter

Sewing

Embroidery

Maintenance/Cleaning

Oiling

Trouble

Changing

Chart

Light

Control

Foot

Tension

&

Thread

Length

Stitch

Cord

Bulb

Terms

Machine

Table

Thread

Fabric

Lower

CONTENTS

Features

Tensions

Table

Page

1A

18

2

3

4

5

6

7

8,

9,

11

12

13

14

15

16

17

18

19

20

21

21

22

23

23

23

23

23

24

25

26

27

27

27

28,

30

30

31

32

33

34

34

35

36

37

38

39

40

41,42

42

10

29

Page 3

GLOSSARY

1.

APPLIQUE

BASTING

HEM

BLIND

BUTTONHOLE

COUCHING

DARNING

EMBROIDERY

FACING

GATHERING

HEM

MONO.

GRAMMING

OVERCASTING

OVERLOCK

ISTRETCHI

PATCHING

SEWING

OF

Applying

another

onto

zag

Or

zg

with

sew

To

removed

the

using

top

your

in,ofstitches.

and

loose

you

allows

by

thread

the

cut

to

for

easier

variation

A

Item

finish

a

holding

stitch.

means

A

in

cloth

hole

button.

a

To

fasten

lace,

nbbon

method

A

stitching

To

decorate

or

straight

addItion

The

increase

to

Forming

separate

or

any

Another

sewn

fold,

A

Using

a

stitching

The

use

or

edge

loos,

of

a

A

stretch

triple

or

stretch

as

Same

piece

a

with

material

a

material

stitch.

temporary

a

with

longest

tension

th,

be

to

pullIng.

lower

removal.

of

where

of

strengthening

by

down

with

of

the

over

with

zig

zag

of

the

zig

a

for

term

down

straight

form

to

zig

of

a

cloth,

of

weave

buttonholes.

darning

of

TERMS

with

ease.

straight

on

The

bottom

able

It

thread

zig

the

zig

a

another

a

repairIng

flew.

stitching,

stitch.

another

body

stitch

zag

material.

shining.

en

stitch

design.

a

sthrji

zag

to

or

cloth.

pattern

but

cloth.

by

This

“0”

to

you

fine

or

edge

a

using

stitch

top

ttltch

remove

may

at

zag

can

zag

a

piece

edge

over

tracery

for

prevent

used

covering

specific

that

i.

possibl,

stitch,

bnd

stitch

be

different

stitch

control

the

stitch

material,

zig

zag

or

rip

using

of

cord,

of

cloth.

finish

to

the

finish

to

design

straight

a

can

setting

sewing

will

tight;

the

necessary

points

used

sides

to

stitch.

tear

either

material

of

material.

elastic,

zig

or

a

revelling

the

this

lower

of

hold

like

seam

seams

the

be

by

be

zag

hole

a

to

a

a

by

a

STITCH

SATIN

SEAM

TUCK

SHELL

SlURRING

STRAIGHT

STITCH

STRETCH

STITCH

TACKING

TAPERING

SHANK

THREAD

TOPSTITCHING

TRIPLE

STRETCH

solid

A

zig

zag

A

line

material

The

use

zig

the

the

to

gather

To

thread*

A

forward

which

per

inchto‘0’

combination

A

forward

stitches

the

on

stretch

lingerie,

A

series

A

tn.

narrow

A

space

button

buttonhole

lineorseries

A

zag

sewing

the

stitching

term

A

formed

ward

of

line

stitch

when

formed

together.

the

of

stitch

zag

of

material.

edge

cloth

together.

Or

reverse

vary

tidy

bedtward

and

to

materials,

arc.

of

stitches

of

zig

wide

toe

composed

and

cloth

bulky

on

which

a

for

used

forward,

a

by

combination

zig

sewn

by

stitches.

of

flex

zag

range.

of

raised

stretch

zag

very

sewing

zig

zag

to

drawing

single

from

stitches

and

double

lock

to

sewing

of

to

material.

lines

enhances

affect.

of

stitches.

stitching

close

or

give

6

motion

not

thread.

thread

engage

of

patterns,

sideward

two

variation

shell

a

two

line

to

formed

which

break,

knits,

varying

between

straight

bonder

a

formed

tcgetlter,

peces

or

of

8

button

a

and

effect

more

sewing

stitches

by

atows

used

tricot.

from

or

giving

pattern

back

by

of

of

a

the

to

zig

QUILTING

RACK

RICK

Joining

bulk

triple

A

give

to

cover

several

stretch

a

RiCk

which

side

creates

width

cloths

for

beds,

pattern

RACK

furniture

using

effect.

or

clothing.

zig

zag

basic

a

ZAG

ZIG

a

form

to

together

A

motion

to

straight

of

lire

sewing.

needle

describes

which

term

side

to

the

—1A—

Page 4

GLOSSARY

2.

ACCESSORY

BOXJTRAY

TEN.

LOWER

SPRING

SION

BOBBIN

TENSION

BOBBIN

WIND#iG

BOBBIN

WINDING

COVER

FACE

DOG

FEED

FOOT

CONTROL

HANDWH

NEEDLES

NEEDLE

NEEDLE

THUMB

NEEDLE

PORTABLE

COVER

PRESSER

PRESSER

PRESSER

UFTER

SCREW

SPINDLE

STOP

EEL

CLAMP

CLAMP

SCREW

PLATE

BAR

FOOT

FOOT

OF

storage

For

and

arm

of

Balances

To

winding

For

For

capacity.

opan

easy

asa.cnbly

For

For

amount

pedal

plug

For

needle

wheel

Used

variations

leather,

For

end

For

For

plate

receptacle

A

whar

Controls

materials

control

When

mteml&

For

and

is

engaged.

is

SEWING

of

acceseor

larger

for

a

upper

the

adust

bobbin

automatically

changing

for

accela

for

materiel

feeding

activating

preeaur.

of

corrtrola

machine

into

tumnetg

take

and

toward

turns

form

to

are

etc.

attaching

needle

the

of

fastening

supporting

merited

is

In

not

the

being

lever.

towered

against

raising

presser

released

estra

Also

lee.

work

and

tension

with

stopping

needle,

to

oIling.

power

th,

end

mechanism

up

todr

a

many;

the

bar.

needle

material

to

protect

use,

pressure

sewn.

onto

the

towering

or

When

foot.

when

and

MACHINE

neadles,

feet,

used

ace.

strrf

tension

tower

of

thread.

bulb

the

and

through

to

exerted

speed:

socket.

well

by

high

to

operator.

on

stitch

example:

needle

into

whan

several

for

sawing

a

exerted

Can

material

dog.

feed

the

raised,

lowered,

estensron

55

bobbin

bobbin

provklea

presser

machine.

the

on

attached

hand

poertion.

your

sharp,

to

needle

sewing.

hem

on

be

it

presser

the

the

FEATURES

bobbins

threads.

case.

full

at

bar

machine,

foot

the

wirea

bring

to

This

machine.

ball,

lower

in,

clamp.

This

sizes.

machine

various

varied

holds

tension

tension

by

the

bar

FOOT

PRESSER

SCREWtotire

THUMB

REVERSE

SEWING

BUTTON

SOCKET

PIN

SPOOL

IRETRACTABLE)

STITCH

LENGTH

DIAL

UP

TAKE

LEVER

THREAD

CUTTER

GUIDE

THREAD

FOR

WINDING

BOBBIN

GUIDE

THREAD

UPPER

FOR

THREADING

THREAD

UPPER

TENSION

THREAD

UPPER

DIAL

TENSION

ZiGZAG

DIAL

WIDTH

tastenirtg

For

presser

changing

For

direction,

continued

Located

the

light

for

On.

changing

For

forward

For

drawingupthe

a

tight

stitch.

cutting

For

and

back

Holds

thread

Guides

tension.

for

Use

control

to

Used

setting

For

may

width

width.

reverse

under

bulb.

sewing

and

into

thread

single

thread

change

button

reverse

excess

taut

width

be

presser

bar.

from

the

the

the

from

or

lock.

varied

must

sewing.

face

and

length

direction,

thread,

presser

for

two

upper

zigzag

of

foot

even

from

attachments

end

forwardtoreverse

for

top

be

cover

winding

of

thread

located

bar.

stitch

held

to

in

change

bobbin.

in

to

on

either

form

winding.

to’

pins

spool

helps

sewing,

thread

tension

Zigzag

stitching.

to

5mm

width

0

for

the

the

1

—

B—

Page 5

Machine

identification

28

71

12

73

14

—

15/6

18

1

2.

3.

.3

4

6

7

9

10

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15. Bed

16.

17.

18.

19.

20.

21.

22.

23.

24

25.

26.

27.

28.

‘

1

Bobbin

Bobbin

motion

Stop

wheel

Hand

Stitch

lengtl

Reverse

Connector

Stitch

pattern

plate

Base

Thread

Thread

Thread

tension

Top

cover

Extension

Handle

Faceplate

Set

screw

Presser

Needle

dogs

Feed

Needle

Needle

Presser

Presser

Extension

plate.

Top

winder

winder

stitch

guide

take-up

guide

plate

for

foot

plate

clamp

foot

foot

plate

stop

knob

knob

button

knob

face

lifter

holder

guide

plate

screw

pin

Spool

1.

20

27

22

yq

23

24

25

-26

27

—2—

Page 6

ACCESSORIES

uttonoie

Zigzag

(on

Button

foot

Zipper

foot

machine)

foot

sewing

foot

Bobbins

pcs.)

(3

Accessories

compartment

table

sion

are

stored

at

front

in

of

built-in

exten

Ordinary

needles

Screw

14

Oiler

drivers

—3—

Page 7

BEFORE

Machine

makes

which

ordinary

SEWING

stored

is

your

sewing.

flat-bed

in

work

ea&er

style

in

\cLJ

Detaching

up

Pick

machine

model.

Free-arm

embroider;

T-shirts,

of

vice-versa

Do

attach

open

To

open,

it

Extension

slide

and

used

is

convenient

is

trousers,

blouses,

of

extension

lidofaccessory

illustrated.

as

off

it

as

sleeves,

etc.

above

table.

and

free-arm

a

to

steps

Table

sew

cuffs

box,

the

or

to

lift

—4--

Page 8

Connecting

and

Power

Foot

Cord

Controller

Connect

power

cord

Before plugging

be

sure

that

of

your

plate

a

*

Specifications

to

at

country.

Always unplug

in

not

The

the

use.

more

faster

WARNING:

THE

FOOT

ATTACHED

MACHINE

DESIGNATED

MODEL

FOR

THIS

221N

YOUR

FOOT

SEWING

APPLIANCE

221N.

foot

controller

CD

in

your

that

voltage

machine.

back

vary

press

you

machine

the

CONTROLLER,

ON

MODEL

FOR

ONLY.

SAFETY,DONOT

CONTROLLER TO

MACHINE

OTHER

is

(written

of

machine)

from

machine

foot

THE

SEWING MACHINE

THAN

machine,

same

country

when

controller,

runs.

FOR

WHICH

SEWING

221N,

APPLY

AND/OR

MODEL

and

as

on

IS

ANY

productisequipped

This

plug

power

the

having

to

plug

outlet.

outlet

insert

(a

the

unable

If

obsolete

plug.

POLARIZED

blade

one

only

the

still

should

Do

with

wider

one

way.

plug fully

fall

to

defeat

not

PLUGS

polarized

a

than

into

contact

fit,

the

the

This

the

safety

other).

is

outlet,

CAUTION

alternating

This plug

safety

a

an

feature.

try

electrIcian

purpose

current

reversing

to

of

the

line

will

fit

If

you

the

replace

polarized

plug

into

are

plug.

the

Page 9

Changing

presser

Raise

needle

Set

position

towards

by

you

Foot

foot

in

turning

.

‘ifter

the

handwheel

D.

highest

Remove

screwdriver.

with

Replace

screw.

foot

new

loosening

by

foot

and

screw

tighten

9

—6—

Page 10

Changing

needle

Set

position

towards

by

you.

Needle

in

turning

the

handwheel

highest

Loosen

take

With

insert

needle

of

Push

stopper

clamp

out

fiat

a

needle

screw

needle

needle.

face

new

bar.

®

needle

and

firmly.

clamp

away

until

tighten

screw

from

into

it

and

you,

groove

reaches

needle

Always

sharp

a

Using

only

not

breakage

of

thread;

hook

use

a

point.

defective

causes

of

and

needle

straight

needles

it

also

or

stitch

worn

or

can

plate.

needle

needles

skipping,

snapping

damage

with

—7—

Proper

__

l,rrIrrrf721r?Jf

needle

straight

f

If

I

11

shaft

I

point

sharp

I

I

IJ

I

LJ

1

Page 11

Bobbin

Set

position

towards

Winding

needle

by

you.

in

turning

-

the

handwheel

highest

Open

Open

take

shuttle

latch

it

out.

cover.

of

bobbin

case

and

—8—

Close

bobbin

latch

comes

of

bobbin

out

easily.

case

and

Page 12

Push

out

Pull

Put

a

Draw

through

numbers

back

spoolpin.

spool

thread

fold

to

spoolpin.

on

pretension

D

handle.

from

spoolpin

device,

following

Wind

bobbin

Push

Holding

hand

unscrewing

thread

several

bobbin

disengage

clockwise

times.

on

handwheel

stop

spindle.

to

with

haridwheel

motion

around

your

knob.

left

by

—9—

Page 13

Push

down

bobbin

foot

rightand

to

controller.

press

P.achine

when

Push

Take

cut

and

Retighten

winding

bobbin

off

thread.

stop

stops

to

bobbin

autornaticlly

full.

is

left.

from

motion

spindle

knob.

touble

correction

fjt

—=

j4’

—10—

bobbin

If

shown,

as

loosen

bobbin

driver

is

remove

set-screw

winding,

adjust

and

wound

of

by

unevenly

top

the

using

height.

cover

guide

and

for

screw

Page 14

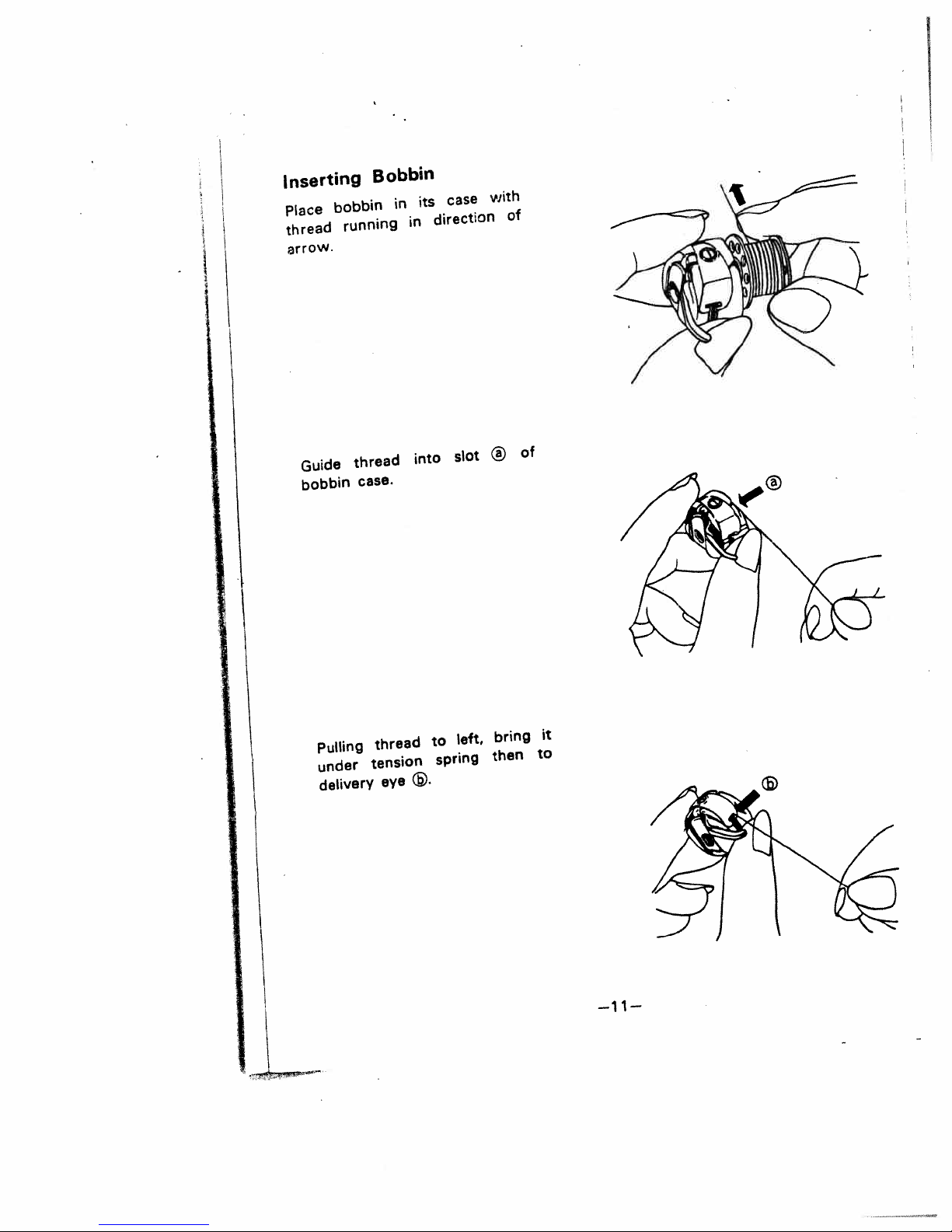

Inserting

Place

thread

bobbin

arrow.

Bobbin

running

in

its

in

case

direCtiOfl

with

of

Guide

bobbin

Pulling

under

delivery

thread

case.

thread

tension

eye

intO

slot

to

spring

left,

®

bring

then

of

it

tO

—11—

Page 15

Adjusting

To

test

shake

At

proper

will

gradually

amount.

To

adjust

screw

with

bobbin

bobbin

tension,

Lower

tension,

case

tension

small

Tension

hang

as

shown.

bobbin

drop

screwdriver.

turn

a

adjusting

and

case

small

Raise

position.

Leave

cm

(4”)

Take

bobbin

Release

is

fully

needle

end

from

hold

case

latch

inserted

of

thread

of

into

when

in

bobbin

latch

hook.

the

of

about

case.

and

bobbin

highest

10

push

case

—12—

Page 16

UPPER

THREADING

Turn

1.

you

to

Place

2.

spool

Lead

3.

top

Down

4.

discs,

Draw

5.

check-spring

tug

Up

6.

up

Lead

7.

thread

the

the

the

Thread

8.

the

to

highest

its

a

pin.

the

thread

and

from

the

into

and

level

thread

threading

needle

back.

FRONT

through

Hold

thread

hand

the

down

thread

upper

pulled

thread

and

the

threads

long.

hand

raise

spool

thread

guides.

between

right

thread

the

through

from

guide

the

TO

about

the

loosely

wheel

needle

and

loop

thread

out

ends

draw

machine,

wheel

take-up

the

position.

thread

of

to

up

and

hook.

the

right

down

at

slot,

thread

bar

needle

BACK,

end

toward

goes

comes

will

which

straight.

under

toward

three

through

the

left.

through

with

eye

to

through

the

then,

or

3

of

and

all

form

or

toward

on

tension

a

of

left.

bottom

through

guide

drawing

4

the

turn

you

the

back

then

Place

presser

the

leaving

four

lever

the

the

the

slight

take-

the

from

FROM

inches.

upper

up.

over

can

back

of

it

the

until

way

A

the

be

both

foot

of

both

inches

—13—

Page 17

Drawing

Hold

left

hand.

Turn

you

until

up

again.

Pull

upper

lower

in

loop.

a

Pull

out

cm

(6’)

under

Up

end

of

handwheel

needle

thread

thread

both

threads

and

place

presser

upper

will

foot

Lower

slowly

moves

be

to

them

on

thread

towards

down

slowly

brought

about

together

left

Thread

with

and

and

up

1

5

—14—

Page 18

ADJUSTING

PRESSURE

ON

FABRIC

GENERAL

•

Usually

heavy

very

fabrics

knit

press

short.

pin

position.

table.

outer

the

center

lower

below

the

for

normal

arid

of

(B)

ring

center

SEWING

sewing,

bulky

medium

the

of

exceotioria)

For

reduce

To

of

(A>

pin

fabrics

and

pressure

half

the

down

(B)

except

arid

very

control

the

pressure

again

for

very

light

fabrics,

pressure,

control,

sewing

stretchy

weight,

be

refer

halfway

to

the

at

press

then

on

its

to

Ordinary

stretchy

Very

fabric

Heavy

Medium

Light

Heavy

Medium

Light

of

and

weight

weight

fabrics

and

weight

weight

Fabric

less

bulky

soft

bulky

and

elasticity:

fabrics

fabrics

fabrics

knits:

and

ones

ones

sheer

ones

—15—

Pressure

fabric

Half

Full

Full

Full

Half

Half

on

Page 19

CONTROLS:

ADJUSTING

STRAIGHT

THREAD

STITCH:

TENSIONS

GREEN

AREA

Always

tension

as

the

raised.

upper

the

control

to

turn

tension

the

machine

is

It

the

however,

bobbin

screw

clockwise

to

wise

When

balanced,

formed

fabric

ing

in

the

When

bobbin

the

upper

the

the

on

When

loose,

the

the

over

fabric

the

the

When

tensions

puckered

fabrics,

sheer

Loosen

tight.

adjust

with

tension

To

to

the

is

threaded

seldom

bobbin

when

thread

on

side

to

loosen.

both

a

with

upper

thread

fabric

the

upper

bobbin

(C).

upper

are

in

the

is

increase

thread,

right.

the

left.

be

required

necessary

tension,

of

tighten,

tensions

perfect

both

(A).

tension

thread

(B).

upper

balanced

sewing

both

both

the

presser

released

the

Before

sure

properly.

thread

the

threads

is

which

tension

thread

thread

and

tensions

tensions

upper

turn

counterclock

stitch

pulled

bobbin

foot

when

tension

To

decrease,

adjusting

that

to

tension,

to

turn

bobbin

are

properly

will

interlock

is

too

up

is

lying

forms

lying

but

fabric

direction

are

evenly.

thread

down,

tension

adjust

change

is

flat

thread

it

the

small

case

tight,

over

flat

too

loops

on

on

too

is

on

be

is

tC)

It

is

tension

stitch

stitching

broidery

thread

ZIG

ZAG

zag

Zig

red

area

recommended

balance

length.

buttonholes

for

slightly

tension.

TENSIONS:

requires

stitch

smoother

for

a

under

In

loosen

to

case

adjust

the

less

flat

the

medium

of satin

em

and

upper

tension

top

appearing

so

pattern.

—16-—

we

recommend

you

turn

your

tension

dial

to

Page 20

Fabric

,Thread

and

Needle

Table

FABRIC

SHEER;

VERY

Chiffon,

Voile.

Blouse

SHEER;

Organdy.

Lawn.

LIGHT-WEIGHT;

Brocade.

Wool.

MEDIUM;

Linen.

Faille.

HEAVY;

Sailcloth

EXTRA

Upholstery.

Awning

(KNITS)

LIGHT-WEIGHT;

Power

MEDIUM-WEIGHT;

Jersey,

Power

HEAVY-WEIGHT;

knit,

Wool.

Velvatten.

Terrycloth

Denim,

HEAVY;

net

Double

Net

Power

FAKE-FURS,

Canvas.

lace,

Net

Crepe,

Taffeta

Crepe.

Velvet

Silk,

PIque,

Duck.

Tricot

Knit,

Double

Nat

VELOURS

European

Cotton

70

50—70

30

30

30

30

50—70

30

30

30

THREAD

Mercerized

Cotton

6D

60

50

50

Heavy

Duty

Heavy

Duty

80

50

50

Heavy

Duty

Cotton

Covered

Polyester,

Nylon

Silk,

Silk

Nylon

Silk

Nylon

Silk

Silk

C.C.Poly.

CC.Poly.

Silk

Nylon

Silk

Nylon

C.C.Poly.

Silk

Nylon

C.C

CCPoiy.

PoIy.

European

705

65—70

65—7O

75—80

80—90

100

120

70

70—80

80—90

90—100

NEEDLE

U.SSize

15x1

9

9

1

1

11—14

16

19

9

9—10

11—14

14—16

Point

Style

Regular

-

-

Light

Ball

Light

toMedium

Ball

Medium

Heavy

to

Ball

Ball

Sharp

REMARKS

Loosen

per

or

up.

tension

[LEATHER

VINYLS

LIGHT-TO-MEDIUM-

WEIGHT

HEAVY

[DECORATIVE

STITCHING

TOP

MACHINE

FILMS

LEATHER

TOUCHES]

EMBROIDERY

Silk

Size

30

30

30

twist

50—70

50

50

Heavy

Duty

C.CPoly.

C.CPoly.

C.C.PoIy.

—17--

90

90—100

100—110

100—110

65—80

14

14—16

16—f

16—18

9—11

Wedge

Wedge

Wedge

B

Regular

Regular

Page 21

STRAIGHT

The

normal

is

between

should

usage.

longer

require

and

length.

control

depend

stitches,

shorter

bias

Be

at

Usually,

cut

“o”

STITCH:

stitch

2-4

on

and

stitches.

areas

sure

line.

length

but the

fabric

the

heavier

lighter weight

For

use

to

set

the

for

length

fabrics

a

shorter

most

artd

curved

stitch

fabrics

chosen

area

require

fabrics

seams

stitch

width

of

The

length

is

shortest stitch

the

between

lengthen

Figures

Approx.

When

of

seam,

a

backward

of

marking

andtothe

indicator

on

Number

you

press

long

as

the

of

wish

in

as

SETTING

stitch

and

variety

for

a

left

to

STITCH

stitches

sew

to

the

push

the

button

THE

regulated

is

is

the

5

longest,

of lengths.

shorten the

LENGTH

per

inch

SEWING

backward

button

is

held

STITCH

by

the

But

Turn

stitch.

CHART

0

No

Feeding

IN

REVERSE

tie

to

as

far

in.

—18-—

LENGTH

stitch

length

the

control

the

(Approximate)

1

30

the

threads

as

it

will

control

2

15

at

go.

control

may

dial

the

The

dial.

be

set

to

3

10

beginning

machine

at

the

4

7

any

right

or

will

Near

5

6

0

spot

to

end

sew

Page 22

Place

cm

Lower

fabric

(0.4”)

inside

presser

under

foot

the

foot

lifter.

edge.

about

1

4’

Presser

order

In

when

firmly

far

as

reinforce

To

wards

pushing

button.

using

push

as

to

Foot

to

very

presser

it

the

down

obtain

will

Lifter

thick

go.

seam,

edge

reverse

wider

materials,

foot

sew

of

lifter

fabric

sewing

gap

up

back

by

—19—

Release

forward

hand

Never

as

pull

button

sewing

is

it

material.

fed.

‘and

guiding

commence

fabric

by

Page 23

Cloth

Use

cloth

long

from

Set

guide

of

needle

distance.

Run

machine

touching

Position

to

sew

Sew

reverse

forcement

Draw

is

finished.

Cut

threads

behind

Guide

seam

edge

a

fabric

presser

guide

in

guide.

cloth

curved

at

of

of

hole

plate,

with

‘guide

stitches

end

to

with

when

regular

material.

on

edge

seam.

of

left

when

thread

bar.

arm,

and

at

seam.

sewing

distance

at

of

an

for

sewing

cutter.

a

right

adjust

fabric

angle

rein

-20—

Page 24

asting

B

useful

very

for

and

stitch

at

Choose

your

lower

trial

5.

is

guide

hems.

possible,

Loosen

fabric

can

upper

thread.

fittings,

lines,

tension

thread

so

be

thread,

Machine

joining

ing

basting

Use

stitch

upper

t

contrast

easily

Basting

easily

pulling

basting

seams

construction

pleats

longest

length

thread.

with

seen.

stitches

clipping

by

out

for

mark

and

setting

on

color

can

it

removed

then

to

be

Staystitching

Staystitching

a

as

acts

that

before

ing

Staystitch

always

grain.

the

seamline

from

12

Use

fabrics.

curved

stitching

stitches

joining

edge

prevents

guideline

edges.

stretch

might

final

the

single

a

on

Place

in

for

stitching.

the

in

stitches

seam

the

per

stretching

clipping

Staystitch

during

layer

direction

inch

and

and

any

handl

fabric,

of

away

1/8”

allowance.

most

for

of

1

I

—21—

Page 25

ZIG-ZAG

STITCHING

Machine

Setting

MvvAWvW

%4%WMW

/W\’W\

—22—

sure

Be

You

nations

stitch

turned

However,

raise

before

Tension

needs

zig-zag,

Stitches

fabric

Zig-zag

Seam

Use

fabrics

during

open and

Adjust

fabric.

the

the

stitched

and

fabric.

Use

•

•

to

make

can

by

length.

while

needle

adjusting

on

tobeloosened.

the

should

without

stitching

Finishing

to

“overcast”

that

wear

stitch

stitch

Choose

open

most

fabric

edges

show

one of

seam

Trim

stitching

for

best

Place

stitching

allowance

after

fabric

fabrics

weight fabrics,

roll.

use

zig-zag

any

adjusting

machine

if

machine

to

upper

looser

causing

fray

and

each

width

setting

stitch

edges.

a

ridge

two

methods:

edge

over

firmly

and

stitching

which

number

stitch

Both

its

highest

stitch

lie

flat

has

many

seam

prevent

to

washing.

side

and

Avoid

which

on

evenly

raw

edge

woven

near

trim

fray

and

foot.

width

knobs

is

is

not

width

thread

The

wider

the

against

any

puckering.

uses:

Press

separately.

length

that

and still

harsh,

become

right

and

of

fabrics.

edge

away

.

-

easily,

knits

of

combi

can

running.

running,

position

knob.

usually

tension.

edges

raveling

seam

to

will

secure

over-

side

place

fabric-

of

seam

excess

best

light

which

and

be

the

the

in

suit

give

stiff

of

-

for

1

Page 26

Edge

Finishing

Usetofinish

edges

to

prevent

nate

bulk

firm

fabrics,

or

facing.

fabrics,

then

stitch

‘trim

of

stitch

For

fabric

hem

edges

raveling

turned-in

along

loosely

about

close

and

woven

W’

to

and

edges.

edge

from

stitching.

to

of

facing

elimi

For

hem

soft

or

edge,

4..

1

I

Interfacing

to

Use

dart

in

center

edges

dart

along

through

closetostitching.

B

artacks

Use

to

as

corners

zipper

stitch

Set

zig-zag

5.

sIieu

Stitch

for

Use

for

lingerie

under

length

thread

upper

in

pull

edge.

under

folded

so

along

folded

Darts

reduce

interfacing

of

dart

matching

line

point.

reinforce

of

openings,

width

or

wider

Edging

a

decorative

and

edge

between

tension

fabric,

Place

presser

edge

edge.

of

bulk

fabrics.

to

point;

dart

from

Trim

points

pockets,

and

knàb

and

soft

fabric.

4

forming

edge

foot

isonthe

when

wide

both

lingerie

stitch

edge

and

so

of

from

stitching

Cut

overlap

lines.

endofdart

raw

of

strain

belt

medium

at

length

treatment

fabrics.

Set

Tighten

5.

stitches

scalloped

a

folded

the

left.

a

down

cut

Zig-zag

edges

such

loops,

straps.

at

Fold

stitch

will

fabric

right,

Stitch

1

—23—

Satin

Closely

form

called

grams,

stitch

Set

1.

and

feed

not

one

in

thread.

looser

Stitch

spaced

smooth,

a

satin

appliques

If

too

spot.

the

stitches.

length

close

but.will

Loosen

The

tension.

zig-zag

satin-like

and

knob

to

wider

stitches

Use

embroidery.

between

machine

0

continue

tension

the

surface

for

mono

sewing

of

stitch,

which

are

0

will

upper

the

Page 27

sewing

When

to

seam

polyester

and

give

especially

stretch

or

is

on

knitted

along

cotton

designed

lightweight

covered

STRETCH

stretch

or

with

knits

for

knits.

fabrics,

fabric,

the

polyester

and

STITCHING

stretch

a

use

without

thread

stretch

which

fabrics.

stitch

breaking

has

Use

the

an

a

which

thread.

extra

ball

allows

amount

point

the

Select

of

needle,

Machine

Setting-

STRETCH

RI

III

UI

STRAIGHT

STITCH

Stretch

stitch.

strength.

Use

knits

woven

In

seams

when

seams,

and

Also

want

out

Guide

machine

stitches

straight

combining

stitching

for

stretch

and

that

worn

and

children’s

in

for

use

heavier

a

buttonhole

using

fabric

to

that

stitch

fabrics.

fabrics,

receive

as

such

armholes

clothes.

topstitching

row

make

give

triple

a

is

stretchability

regular

use

side

gently,

the

stretch

seams

for

of

lot

a

seams,

sportswear

in

when

stitching

of

thread.

twist

back-and-forth

to

lock

and

stitching

strain

crotch

you

with

allowing

seam,

the

I

in

—24—

Page 28

Machine

Setting

RICKRACK

STRETCH

STITCH

Foot

4

Pattern

Dial

I

Rickrack

resembles

sible,

right

It

purpose

stitch

stitches,

nence.

adjusted

Use

and

keep

Also

fabrics

Use

and

Place

together

stitches

then

you

Can

looking

and

can

be

consists

from

overcast

to

hems

light

suitable

such

for

garment

elastic

to

stretch

sew.

also

be

Stitch

stitch

rickrack

wrong

used

strtch

giving

Width

narrow

to

prevent

weight

as

attaching

waistline

at

the

anchor

elastic

used

Length

I

is

a

trim.

the

same

sides.

as

stitch.

of

strength

of

edges

knits

for

overcasting

woolens

elastic.

over

markings.

elastic

for

decorative

triple

heavy.duty

a

three

the

zigzag

wide.

to

of

seams,

raveling

from

and

fourths.

in

fabric

between

Tension

zig-zag

is

It

on

both

Each

threads

and

terrycloth.

Mark

and

Take

to

pins

stitching.

I

that

rever

the

zig-zag

perrha

can

facings

and

rolling.

heavy

elastic

pin

a

few

fabric,

all

or

be

to

as

—25—

Page 29

DECORATIVE

decorative

stitch

a

borders

of

and

pattern

trims,

variety

great

A

of

rows

decorative

ii

stitching

by

or

monograms,

STITCHING

can

combining

appliques

TOP

You

with

along

edges,

hems.

•

•

created

be

different

and

STITCHING

can

one

collars,

pockets,

straight

Use

tailored

twist

hole

Use

heavier

regularthread

•

Use

stitching,

use

Or

page,

ing

special

by

stitches—top

embroidery.

accent

more

or

look,

for

stretch

row

satin

of

one

effects.

using.ore

lines

rows

lapels,

cuffs,

stitch

sewing

added

straight

stitching

of

for

stitch

especially

stitches

the

varying

or

stitching,

garment

a

of

topstitching

of

yokes,

seams

for

with

emphasis.

stitch

even

wider

for

on

width

the

more

facing

and

more

a

button.

for

with

row

borders.

follow.

a

of

for

—26--

Page 30

Seaming

The

narrow

in

seams

added

open

Tinyzigzag

be

when

G

Ordinary

basting

while

small

as

thread,

cord

into

have

the

order

strength.

seam

seen

stretched.

athering

pulling

zigzag

o-ochet

for

fabrics.

been

cord

to

Knits

zigzag

of

stitches

the

and

Over

gathering

stitch

across

thread

gives

gathering

stitched

can

eliminate

firm

and

in

a

much

Once

be

can

After

press

can

seam

Cord

often

fullness.

a

the

pulled

bulk.

be

knits

sewing,

will

with

cord

or

stronger

fullness

gathers

in

used

for

flat.

hardly

give

breaks

such

carpet

place,

out

a

A

in

—27—

Lace

Applications

lace

edge

When

lace

laces

touch

where

line

follow

for

easing

lace

using

an

Attaching

special

dresses,orlinens.

lacesinplace

corners

straight

convenient

sewing.

edged

the

application.

trims

or

to

Pin

or

necessary.

or

braid

to

follow

a

the

almost

adds

lingerie,

or

baste

mitering

has

when

scalloped

design

invisible

a

A

a

of

Page 31

MAKING

BUTTONHOLES

Determine

button

bar

buttonhole

diameter

tacks.

Measure

of

for

Mark

Determine

Determine

diameter

kind

and

Attach

Completely

®

Place

marking

through

®

of

buttonhole

buttonhole

of

material

foot

of

marking.

and

width

button,

of

material.

of

push

of

center

indicates

Length

and

0.3cm

add

size

Width

according

its

foot.

back

foot.

under

buttonhole

foot

of

beginning

thickness

material.

on

thickness,

sliding

foot

and

(1/8”)

part

that

so

passes

arrow

to

line

1

of

length

buttonhole

marking

3cm(i/8”J

a

diameter

thickness

I.

—28—

Page 32

the

line

fabric

sure

1.

2.

3.

4.

5.

6.

7.

6.

9.

10.

seam

the

sheer

zer

be

MAKING

First,

buttonhole

tailor’s

or

(following

machine

Replace

foot

which

piling

buttonhole

Set

stitch

length

Lower

on

fabric

buttonhole.

the

end

tionl),Stop

fabric

at

Lift

the

needle

around

Lower

wheel

just

of

fabric.

foot

guide

six

stitches

tration

Turn

tion

five

(Illustration

Raise

stitch

length

Stitch

(Illustration

Stitch

above

Cut

If

stitch

and

or

needle

width

near

second

bar

(Illustration

the

ripper,

stitching.

you

plan

or

or

paper,

torn

away

2).

six

buttonhole

BUTTONHOLES

mark

presser

up

knob

needle

of

right

presser

as

end

presser

set

soft

beginning

the

on

fabric

chalk.

directions

adjustments

foot

is

grooved

of

thread.

foot

guide

width

near

0.

carefully

indicating

Stitch

the

button

machine

side

of

foot

a

pivot,

for

end.

foot

enough

stitches

“0”.

tack

Push

the

to

form

to

length

zigzag

2).

out

at

2

side

3)

by

being

to

make

material,

under

after

to

sliding

rear.

dial

width

to

and

repeating

4)

opening

careful

fabric

stitching.

Make

of

buttonholes

with

below)

are

with

at

2

into

the

beginning

to

the

hole,

with

stitching.

and

turn

and

raise

Take

bar

to

form

fabric,

return

of

buttonhole,

not

place

which

and

end

a

basting

one

on

to

correct

buttonhole

to

prevent

Push

sliding

to

the

and

stitch

the

mark

mark

(Illustra

needle

using

the

fabric

turn

hand

needle

buttonhole

five

tack

(Illus

“0”

posi

to

5.

Take

bar

tack

reset

sttch

step

with

the

to

cut

on

stabili.

a

can

scrap

rear.

of

for

in

the

out

or

6

—29—

be

of

S

P

1

p...

2—

7

sf

:

p

igfl

ft

p

j

T

Page 33

Cutting

a

Stick

prevent

to

buttonhole

Cut

buttonhole

Buttonholes

needle

through

over-cutting.

cutter.

along

bar

centre

tacks

with

Corded

stretch

For

corded

a

keep finished

to

shape.

in

filler

Hook

ends

lead

and

taut,

notches

Proceed

regular

When

pull

the

on

buttonhole

Thread

side

cord.

Buttonholes

fabrics

buttonhole

cord

cord

of

hook

shown.

as

with

buttonholes.

buttonhole

cord

filler

other

ends

tie,

and

such

buttonhole

top

on

under

them

stitching

ends

disappears

end

stitching.

cord

of

cut

or

as

effective

is

spur

foot,

to

completed,

is

that

so

to

both

knits,

and

pull

bottom

as

loop

reverse

ends

for

into

of

—30—

Page 34

SEWING

stitch

Set

Position

under

foot.

left

to

Raise

width

right

side

needle

so

hole

length

a

that

of

ON

button

When

of

stitch,

and

button.

needle

BUTTONS

at

“0”

and

material

needle

adjust

comes

lower

zigzag

comes

foot.

to

machine

Run

and

sew

machine

Stop

upper

®

and

unstitching.

OR

®

threads.

wrong

Set

Draw

position.

zigzag

sew

Draw

thread

side

5-6

3-4

out

at

zigzag

when

width

stitches

work

ends

and

medium

stitches.

needle

control

and

through

tie

a

to

knot.

speed

is

to

prevent

cut

in

0

off

to

—31—

Page 35

BLIND

blind

The

finish

drapes,

straight

practice

application

pairing.

Procedure:

Prepare

(1)

such

pinked,

Fold

(2)

inch

Fold

(3)

leaving

Guide

(4)

cut

of

the

zigzag

into

When

(5)

from

cnmpleted

When

basting

ironing

an

seams.

basing

tape.

then

HEM

hem

that

and

slightly

or

will

it

and

as

hem

from

hem

the

the

of

stitch

the

center

the

stitching

machine

hemming

stitch

board,

Ease

thread.

Baste

continue

STITCH

stitch

almost

is

curtains.

be

the

edge

raw

overcast,

tape,

hem

up

upper

back

about

fold

presser

cut

wide

fold

hem.

along

in

Press

or

into

curved

a

desired

edge.

toward

1/4

of

comes

of

bite

the

of

is

and

A-line

an

the

fold

the

with

hem

pin

step

provides

invisible

is

It

hems.

quick

very

wilt

hem

hem

of

114

just

or

length.

Press

inch

fabric

the

so

foot

just

presser

the

should

fabric

completed,

turn

skirt,

raw

the

up

excess

steam,

1/2”

3.

a

done

never

desired

in

stitched

inch

plain.

Baste

in

right

extended.

that

slightly

catch

the

at

right

to

place

edge

hem,

fabric

from

durable

on

easily

With

and

(Step

place.

side

into

the

to

foot

left.

remove

of

matching

by

then

hem

garments,

with

little

a

hem

easy

need

manner,

under

1)

pin

or

(Step

fabric

of

(Step

center

the

zigzag

left

the

and

barely

just

fabric

side.

machine

a

hem.

the

pulling

apply

taped

re

1/2

2)

3)

bite

to

the

Press

At

the

hem

edge,

or,

STEP

STEP

STEP

1

2

STEP

5

—32—-

Page 36

ZIPPER

using

By

sliding

can

be

turning

Loosen

that

needle

Tighten

®.

SEWING

special

adjuster,

easily

fabric.

screw

comes

screw.

®

zipper

zipper

done

and

into

foot

set

with

sewing

without

foot

position

so

parallel

needle

zipper

guiding

right

side

with

comes

the

in

zipper

of

side

right

Sew

that

of

side

so

so

are

foot.

that

©.

of

teeth

left

Re-set

into

Sew

same

carefully

of

edge

foot

position

left

way.

tipper

fabric

C

—33—

Page 37

MENDtNG

Patching

the

Place

part.

along

Sew

right

the

on

part

worn

side.

back

patch

the

side.

close

edge

over

Trim

to

of

the

the

the

away

seam

worn

patch

the

on

vvvvvvv9

A

iA

siii

is

W_V

A

A

A

A

V

V

V

V

V

ls,s

V

V

V

V

A

A

A

A

A

A

V

V

V

V

A

V

V

A

A

A

V

V

V

V

V

V

A

A

A

A

A

A

A

huh

Mending

machine

Set

patching.

for

as

the

Sew

first.

sew

Then

either

piece

A

underneath

side.

a

edges

two

gauze

of

Rip

in

to

same

the

tear

of

more

can

reinforce

together

seams

placed

be

the

way

on

rip.

—34—

Page 38

Darning

Set

stitch

length

at

‘O’

I

_4

_q_:

4_

(‘t

r-

T

hfr1

Stretch

or

to

the

Sew

coseIy

material

By

making

the

darned

and

sew

over

more

fabric

with

part

the

spaced.

back

flexible

free

you

worn-out

and

turning

part

over

armcTh

are

going

stiches

forth

points

becomes

the

according

part

guiding

by

hoop

to

darn.

with

hand.

blunt,

softer

®

—35---

Page 39

LAPPED

SEAM

SEWING

P’ace

another

stitch

of

For

®

(

For

Sew

side.

one

according

non-fray

easy

over

piece

size.

fo’ded

to

of

fabrics.

fray

area

fabric

the

to

fabrics.

from

over

width

right

—36—

Page 40

APPLIQUE

Draw

used

Place

and

Sew

around

stitch

width

size

of

material.

To

change

or

to

sew

machine,

away

from

presser

Lower

sewing.

presser

design

as

an

cut-out

baste

adjusting

according

cut-out

direction

very

positioning

edge

foot

WORK

on

applique

on

it.

outline

stitch

and

small

of

and

turn

foot

material

and

base

with

to

shape

type

at

circles,

needle

cut-out,

and

cut

material

zigzag

length

of

corners.

stop

material.

continue

to

it

and

and

base

just

lift

be

out.

Sew

zigzag

This

a

width

is

few

to

stitches

at

prevent

0.

at

end

with

unstitching.

—37—

Page 41

Needie

Thread

EMBROIDERY

stitch

length

Set

at

“0”

No.

No.

No.

9

11

14

120—100

100—SO

60—50

Remove

avoid

To

pulled

tension.

good

For

important

thread.

and

thin

Use

upper

same

of

lower

Trace

center

and

Make

out

Pull

hand

holding

Lower

foot,

up,

thread

thread.

your

sure

lower

wheel

upper

presser

and

lower

reduce

embroidery,

correct

use

to

embroidery

and

and

kind

design

in

it

embroidery

material

thread

towards

thread

foot

holder

thread

upper

thinner

a

color

on

is

lifter.

screw.

thread

needles

silk

material

taut.

turning

by

you

lightly.

being

it

for

silk

for

hoop.

while

is

—38—

Hold

sewing

satin

with

Continue

hand.

by

finish

To

stitches

typewriting

Lay

when

threads

both

stitch.

sewing

with

outline

filling,

zigzag

along

embroidering

guiding

paper

and

of

several

sew

width

underneath

sheer

start

design

hoop

at

fabric.

0.

Page 42

MAINTENANCE

Your

machine

cIeanng

factory

A

machine

few

cleaned

hours

and

sewing

a

and

Cleaning

off

with

latches

foot

needle

all

dust

cleaning

outwards.

Remove

Remove

Brush

dog

Turn

requires

oiling

performance.

which

day

oiled

and

needle.

plate.

and

brush.

is

needs

once

lint

for

used

a

on

regular

satis

for

to

month.

feed

a

be

Remove

Remove

with

cloth.

a

cleaning

hook

hook.

race

Clean

brush

cover.

hook

and

a

race

soft

—39--

Page 43

Oiling

oil

Use

sewing

for

hook

Open

the

careful

Be

or

oil

and

After

minutes

every

to

Remove

will

one

where

face

same

cause

oiling,

oils

mechanism

Apply

manufactured

machine

eventually

jam.

to

drop

friction

cover

way.

to

not

stain

may

it

some

run

allow

to

part.

top

oil

of

and

apply

your

sewing

machine

oil

specially

use.

part

to

occurs.

apply

too

material

difficulty.

penetrate

to

loosening

by

Other

cause

oil

much

for

of

in

1-2

:4

:

I

11

Apply

one

drop

of

oil

to

lubricating

points

indicated

by

arrows.

Page 44

TROUBLE

CHART

PROBLEM

Breaking

thread

Skipping

Irregular

material

The

correctly

fed

lower

stitches

stitches

not

Thread

not

or

Lower

Lint

stuck

tension

the

Needle

Needle

or

Size

suitable

Incorrect

nuch

Too

Incorrect

Upper

Incorrect

Pattern

not

drawn

thread

in

not

bent

type

for

upper

oil

size

thread

lower

selection

PROBABLE

up

tension

the

needle

of

on

of

tension

evenly

Correctly

bobbin

inserted

material

threading

the

needle

tension

dial

wound

spring

fully

the

CAUSE

too

and

hook

for

too

not

on

tight

case

loose

set

the

and

thread

the

correctly

bobbin

inside

not

material

CORRECTION

P.10,

Remove

and

cleaning

P.12

fluff

P.

P.

P

P.

P.

P.

P.

P

P.

R9

17

13

40

17

13

1

18,

with

7

2

lint

brush

7

22

a

Lint

stuck

on

the

feed

—41--

dog

P.

39

Page 45

Oiling

oil

Use

sewing

for

oils

mechanism

will

one

Apply

where

hook

face

Open

same

the

careful

Be

or

oil

cause

and

After

minutes

every

to

Remove

screws

screwdriver.

manufactured

machine

eventually

jam.

to

drop

friction

cover

way.

to

not

stain

may

it

some

to

®

part.

top

run

allow

cover

and

oiling,

oil

of

and

apply

your

sewing

machine

oil

®

specially

use.

part

to

occurs.

apply

too

material

difficulty.

penetrate

to

loosening

by

with

Other

cause

oil

much

for

of

in

1-2

large

Apply

one

drop

of

oil

to

‘ubricating

—40—

points

indicated

by

arrows.

Loading...

Loading...