__________________________

To

reduce

has

a

other).

one

way.

reverse

qualified

not

change

POLARIZED

the

polarized

This

the

If

plug

the

plug.

electrician

the

Record

and

The

The

Serial

Model

Retain

risk

plug

in

Model

Serial

Model

No.

No.

these

of

plug

will

does

If

it

to

plug

SEWING

space

provided

No.

of

No.

is

No.islocated

1919

numbers

PLUG

electric

(one

fit

in

stifl

install

in

any

MACHINE

this

appliance.

located

for

CAUTION

shock,

blade

polarized

a

not

fit

does

the

way.

below

Rear

of

Rear

of

future

is

fully

not

proper

the

Serial

arm.

arm.

reference.

this

wider

in

fit,

No.

applianc

than

outlet

the

contact

outlet.

t

on

outl€

C

IMPORTANT

SAFETY

INSTRUCTIONS

an

When

followed,

using

including

Read

all

appliance).

DANGER——To

appliance

An

appliance

WARN

electric

1.

2.

3.

4.

5.

6.

7.

8.

9.

not

Do

is

used

Use

attachments

Never

properly,

appliance

electrical

Never

ings

of

and

dust,

Never

not

Do

not

Do

being

To

disconnect,

outlet.

Do

not

should

the

from

ING

shock,

to

allow

near

or

by

this

appliance

recommended

operate

has

it

if

the

to

mechanical

or

sewing

loose

or

outdoors.

the

insert

operate

the

drop

use

operate

administered.

unplug

this

cloth.

by

electrical

the

appliance,

following:

instructions

reduce

never

electric

——To

or

usedasa

be

children.

only

appliance

been

nearest

appliance

machine

any

where aerosol

all

turn

pulling

left

be

outlet

immediately

reduce

injury

toy.

its

intended

for

the

by

if

it

dropped

authorized

adjustment.

with

and

into

object

(spray)

controls

cord.

on

unattended

Close

or

foot

to

basic

the

after

the

to

persons:

attention

use

manufacturer

a

damaged

has

damaged,

dealer

any

To

air

controller

any

products

off

the

unplug,

or

openings

opening.

(“0”)

safety

precautions

before

risk

of

plugged

when

using

risk

necessary

is

described

as

as

contained

cord or

or

dropped

service

free

are

grasp

center

blocked,

from

being

position,

the

using

electric

in.

and

before

of

burns,

when

in

this

in

plug,

into

for

Keep

the

accumulation

usedorwhere

then

plug, not

should

always

shock:

Always

unplug

cleaning.

fire,

this

manual.

manual.

this

ifitis

not

water.

examination,

remove

Return

ventilation

plug

cord.

the

(this

this

appliance

Use

only

working

the

repair,

open

of

lint,

oxygen

from

be

is

DANGER

1.

2.

3.

Always

Do

Do

Do

unplug before

not

reach

place

not

place

not

water

Replace

that

where

or

has

other

bulb

fallen

it

can

liquid.

with

into

fall

same

water.

or

be

type

Unplug

pulled

rated

15

immediately.

into

tuborsink.

a

watts.

relamping.

appliance

for

an

store

drop

appliance

into

or

or

in

WARNING

fingers

Keep

1.

machine

Always

2.

3.

Do

4.

Do

break.

Switch

5.

area,

presser

Always

6.

lubricating,

instruction

Never

7.

may

needle.

use

use

not

pullorpush

not

the

such

foot,

unplug

operate

blocked.

be

the

bent

sewing

as

etc.

or

manual.

away

proper

needles.

threading

sewing

when

onasoft

from

all

needle

fabric

machine

machine

making

moving

while

off

needle,

any

surface

parts.

plate.

stitching.Itmay

(“0’)

changing

from

other

The

such

wrong

when

the

user

as

Special

plate

making any

needle,

electrical

servicing

bedorcouch

a

care

can

deflect

threading

outlet

adjustments

is

required

cause

the

adjustments

when

where

around

the

needle

bobbin,

removing

mentioned

needle

causing

in

the

air

the

to

the

changing

or

openings

sewing

break.

it

to

needle

covers

the

in

SAVE

THESE

INSTRUCTIONS

NAMES

1.

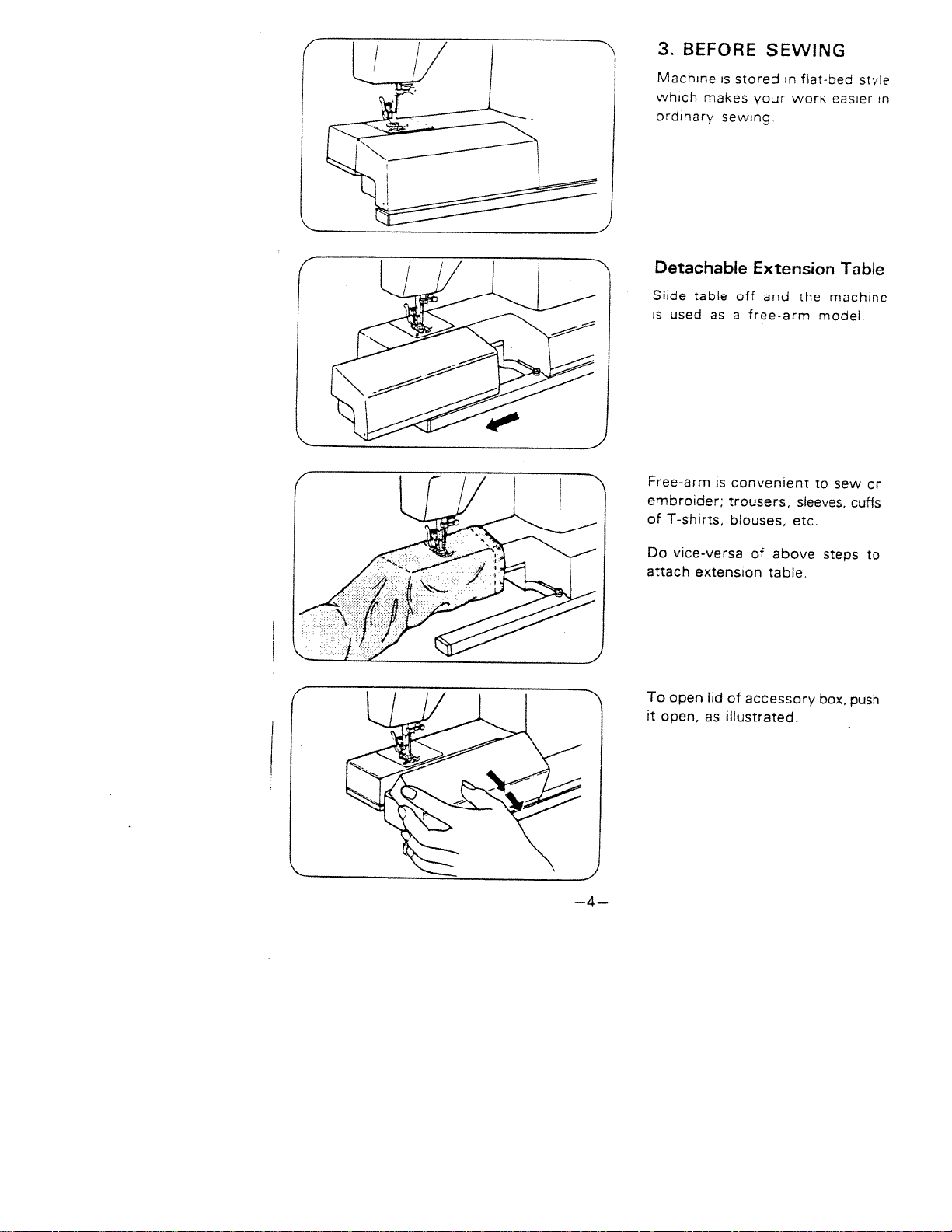

ACCESSORIES

2.

BEFORE

3.

STARTING

4.

STRAIGHT

5.

ZIGZAG

6.

MAKING

7.

OVERCASTING

8.

BLIND

9.

10.

SHELL

11.

MENDING

STRETCH

12.

13.

STRETCH

14.

LAPPED

15.

BRIAR

OVERLOCKING

16.

17.

SEWING

18.

ZIPPER

19.

ROLL

20.

QUILTING

EMBROIDERY

21.

MAINTENANCE

22.

TROUBLE

23.

Detachable

Connecting

Setting

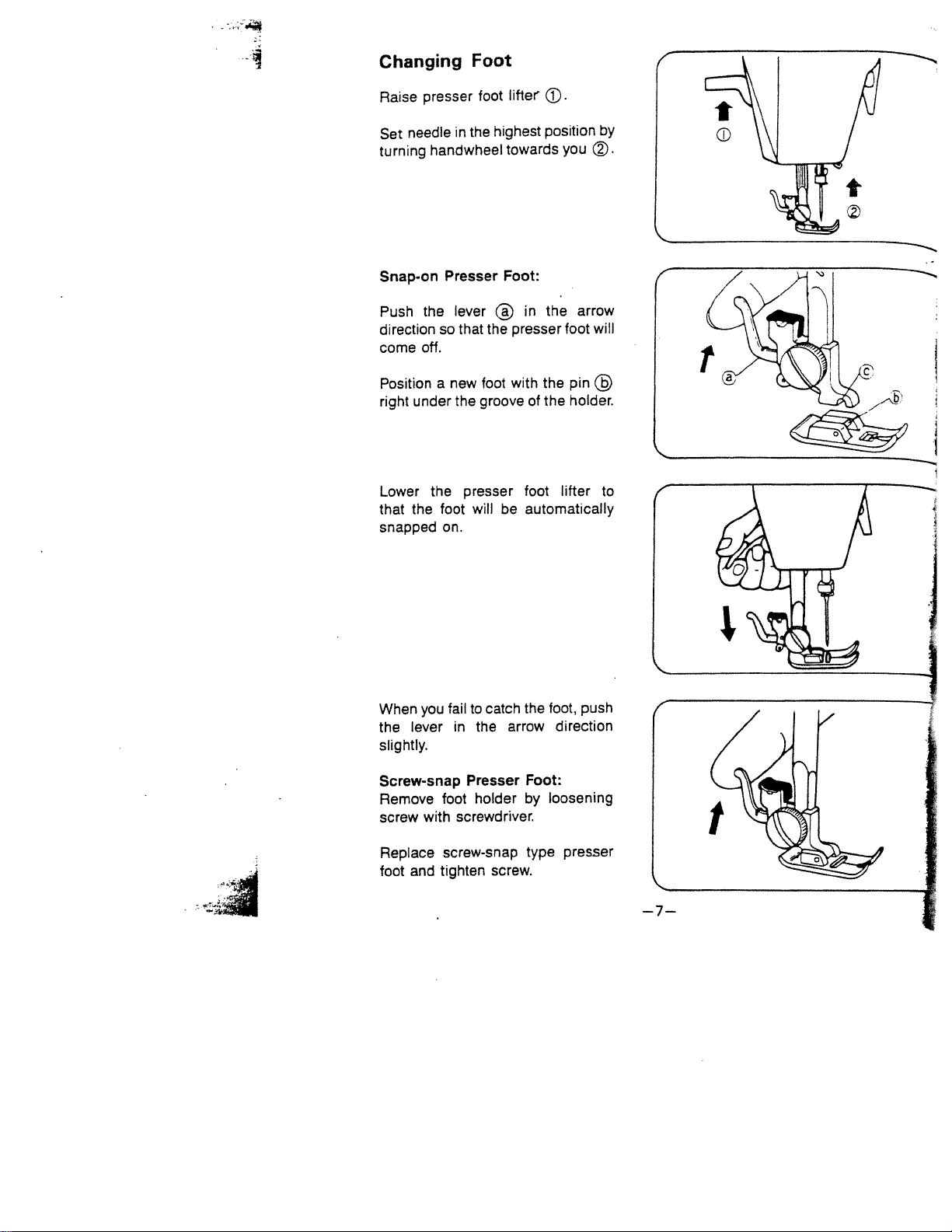

Changing

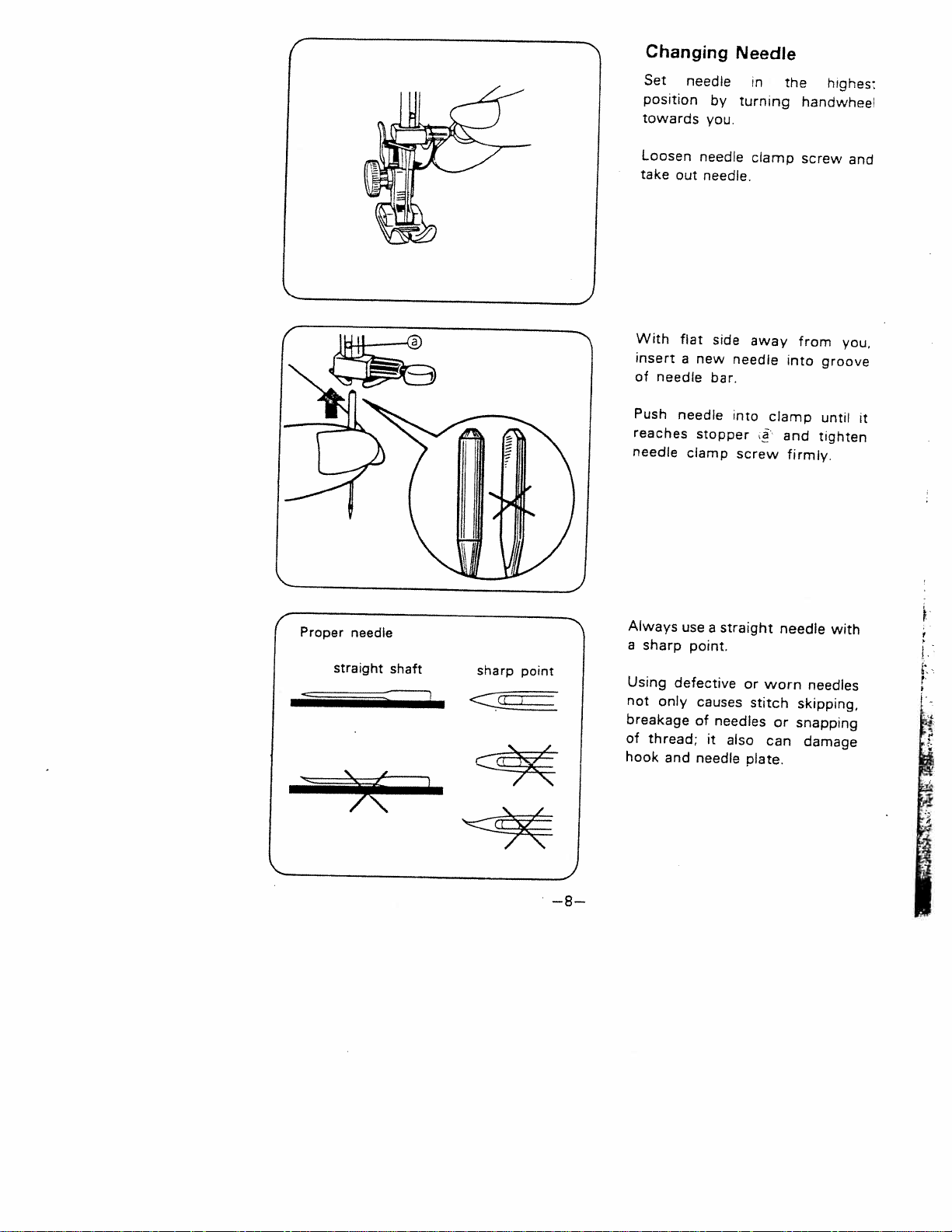

Changing

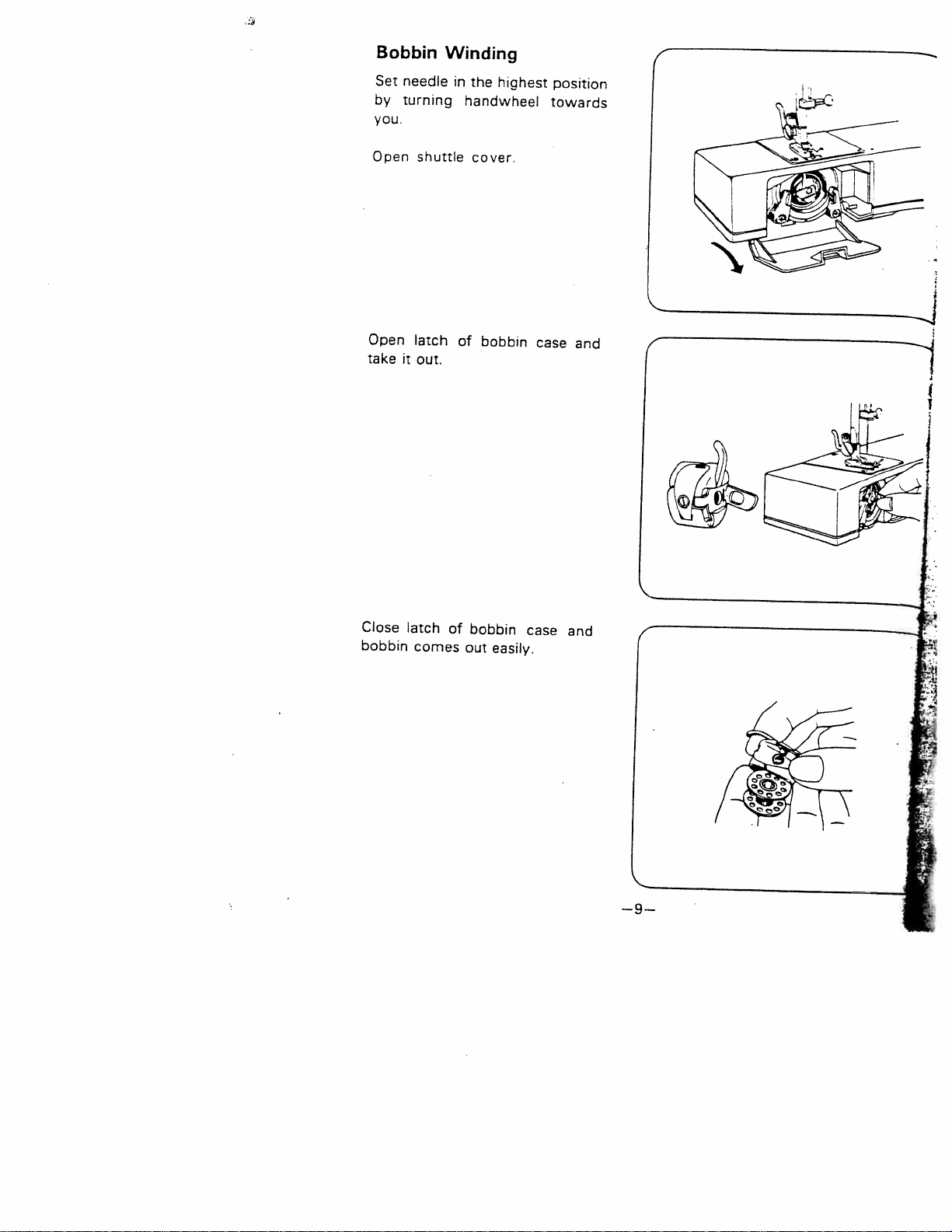

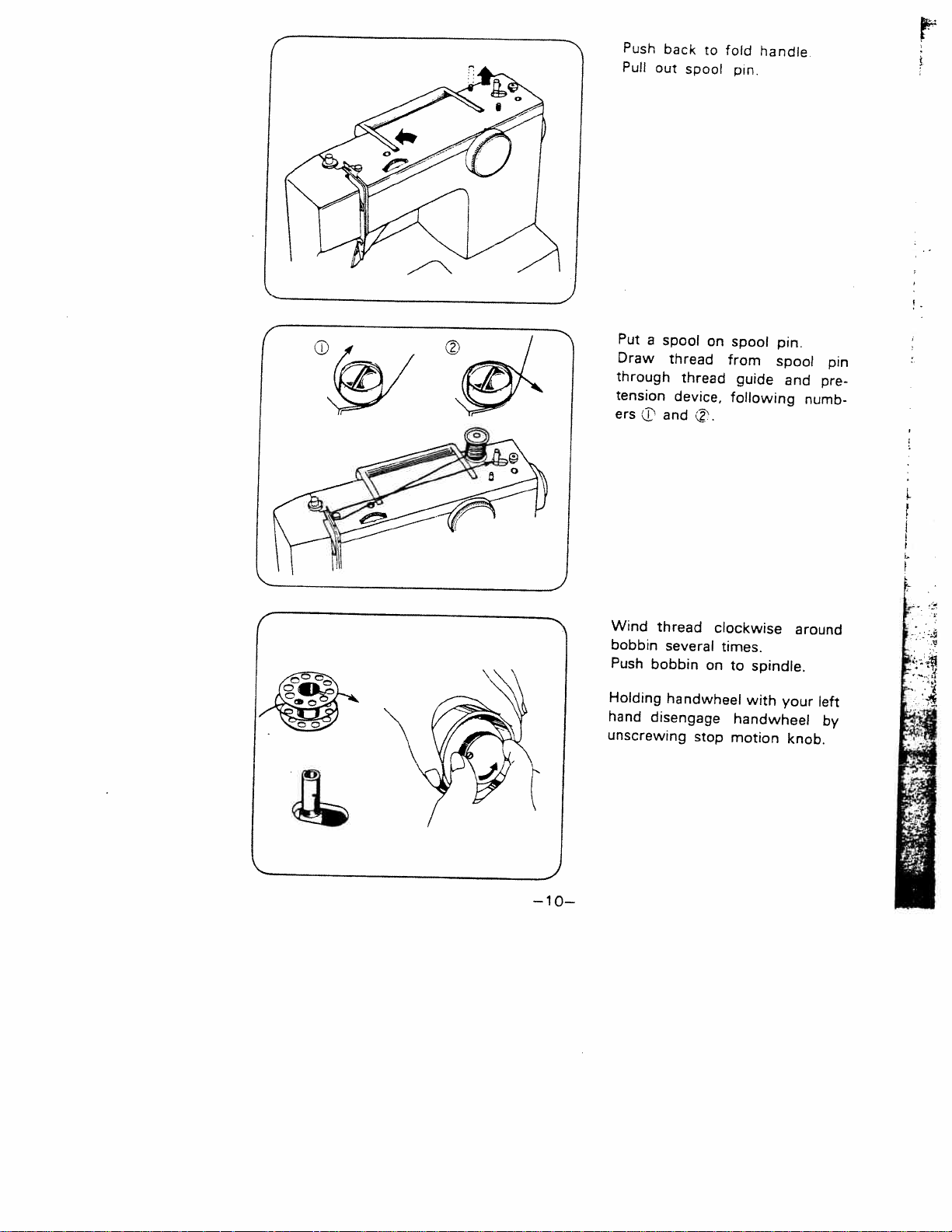

Bobbin

Inserting

Adjusting

Darning

Threading

Drawing

Foot

Fabric,

Turning

Pattern

Starting

Double

Reverse

Cloth

Adjusting

Thread

Determine

Left

Cutting

Corded

HEM

Elastic

STITCHING

Mending

Adjusting

Straight

Rick-Rack

STRETCH

HEMMING

Cleaning

Oiling

Changing

OF

PARTS

SEWING

Spool

Foot

Needle

Winding

Bobbin

Lower

Plate

Upper

Up

Pressure

Thread

TO

SEW

a

Square

Selection

Sew

to

Presser

Sewing

Guide

Thread

SEWING

SEWING

Tension

BUTTONHOLES

Length

and

Right

Buttonholes

Buttonholes

STITCH

Blind

Rip

a

STITCHING

Stretch

SEAMS

Stretch

Stretch

SEAM

ON

BUTTONS

SEWING

CHART

Light

CONTENTS

Extension

Foot

SEWING

Controller

Pins

Tension

Tension

Lower

and

Foot

for

Side

Hem

Stitching

Bulb

Tension

Needle

Corner

Dial

Lifter

Tension

Zigzag

Balance

Stitch

Stitch

Stitching

Table

and

Table

Stitch

of

Balance

Power

Buttonhole

Cord

40

40

41

42

43

32

33

34

34

35

36

37

38

39

32

32

28

29

30

30

31

31

22

22

24

25

25

26

27

20

21

21

21

1

20

1

1

17

1

18

1

1

1

15

1

1

1

14

3

4

4

5

6

7

8

9

2

3

3

5

6

7

9

9

9

16

17

1

19

20

21

22

23

24

25

26.

1

14

15

1.

4

5

6

7

8

9

10

11

12

3

8

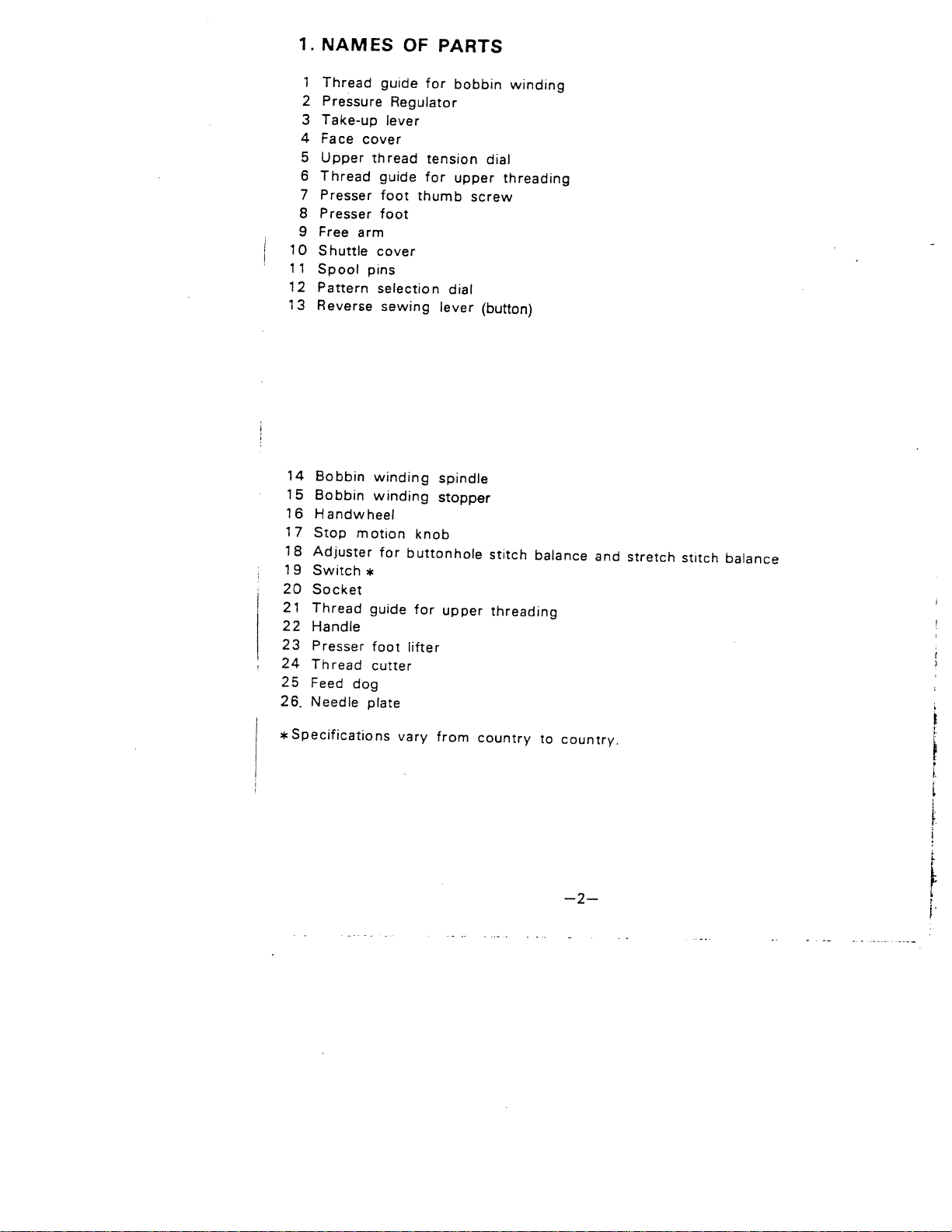

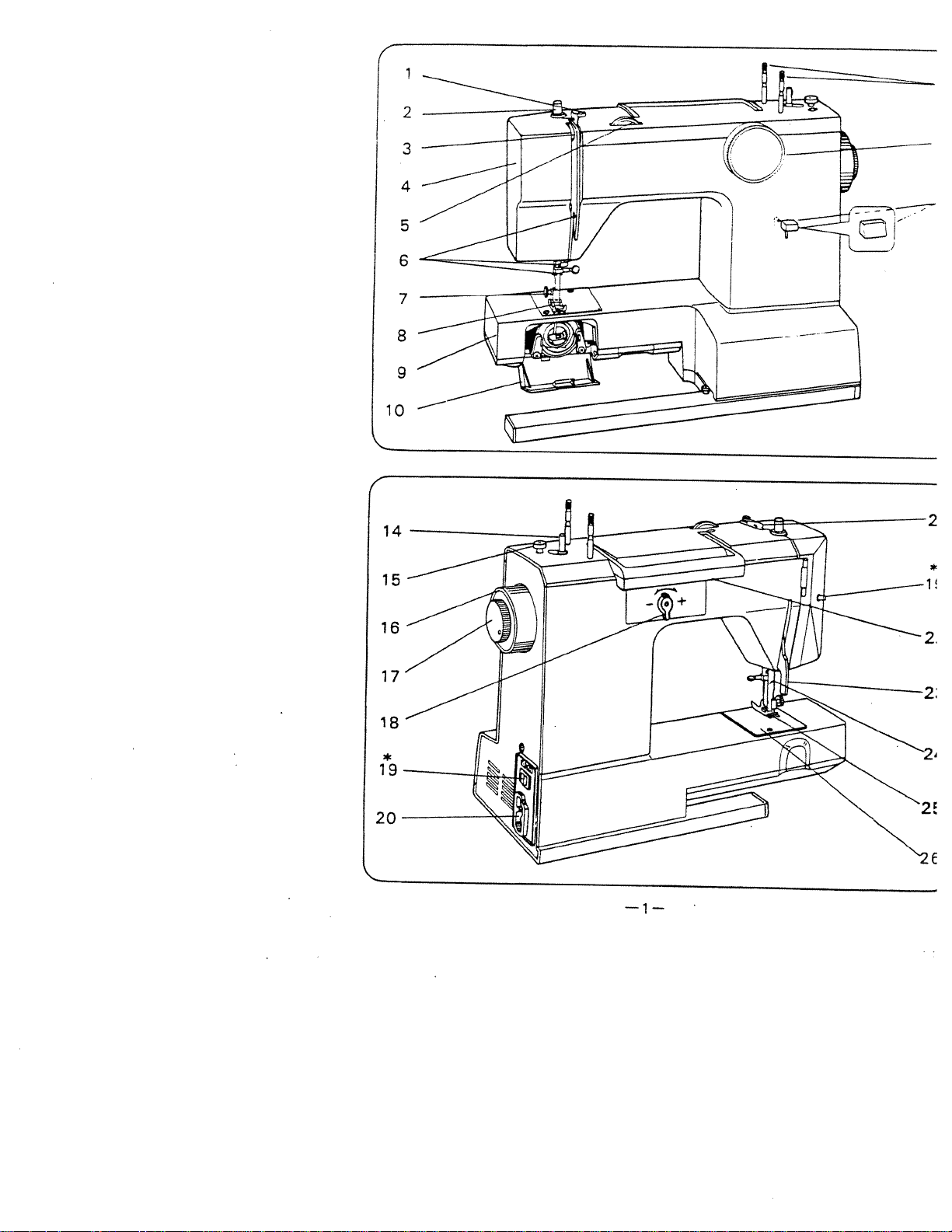

NAMES

1

Thread

2

Pressure

Take-up

3

Face

Upper

Thread

Presser

Presser

Free

Shuttle

Spool

Pattern

Reverse

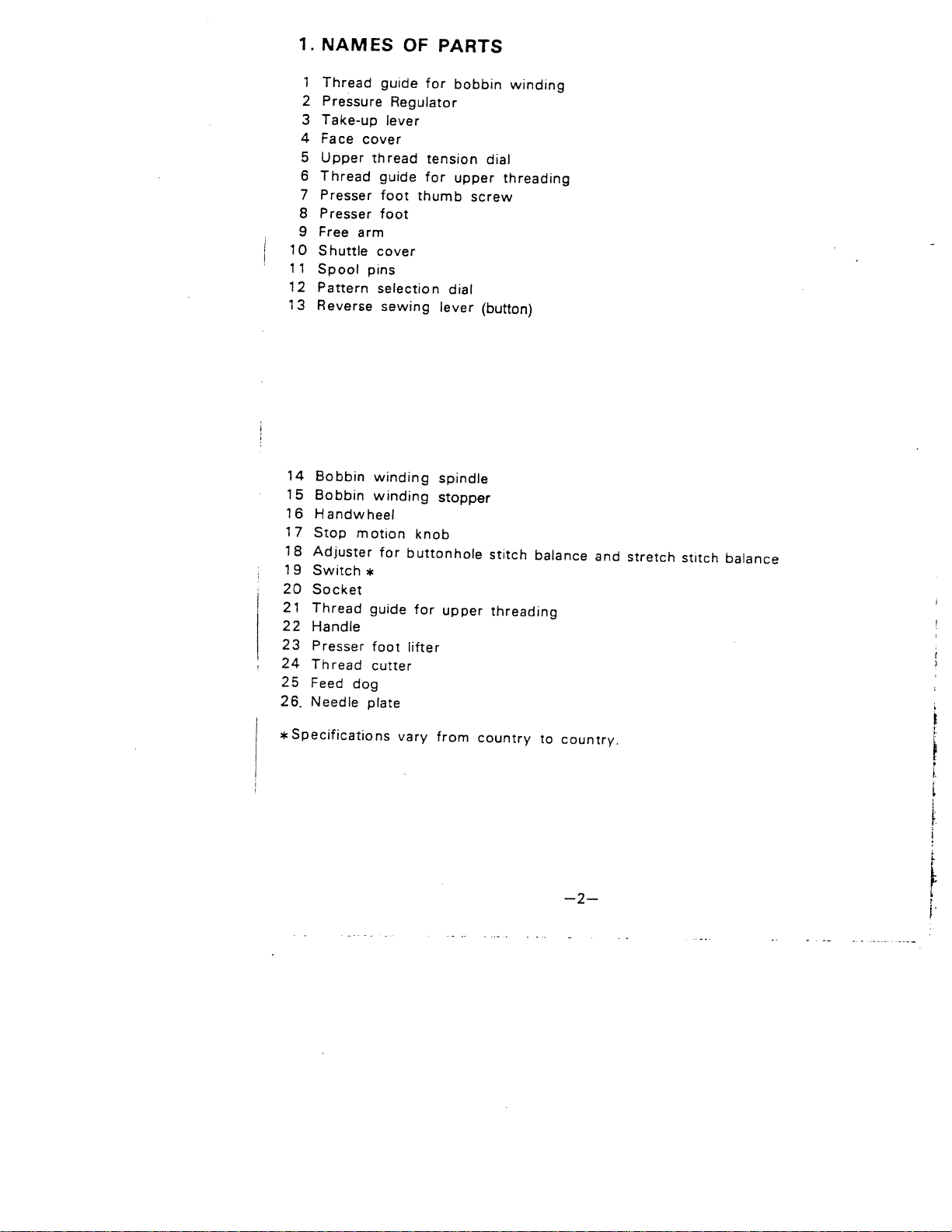

Bobbin

Bobbin

Handwheel

Stop

Adjuster

Switch*

Socket

Thread

Handle

Presser

Thread

Feed

Needle

cover

thread

arm

cover

pins

selection

winding

winding

motion

guide

foot

cutter

dog

plate

OF

guide

Regulator

lever

guide

foot

foot

sewing

for

buttonhole

lifter

for

tension

for

thumb

knob

for

PARTS

bobbin

upper

screw

dial

lever

(button)

spindle

stopper

upper

winding

dial

threading

stitch

threading

balance

and

stretch

stitch

balance

*Specifications

vary

from

country

to

country.

—2—

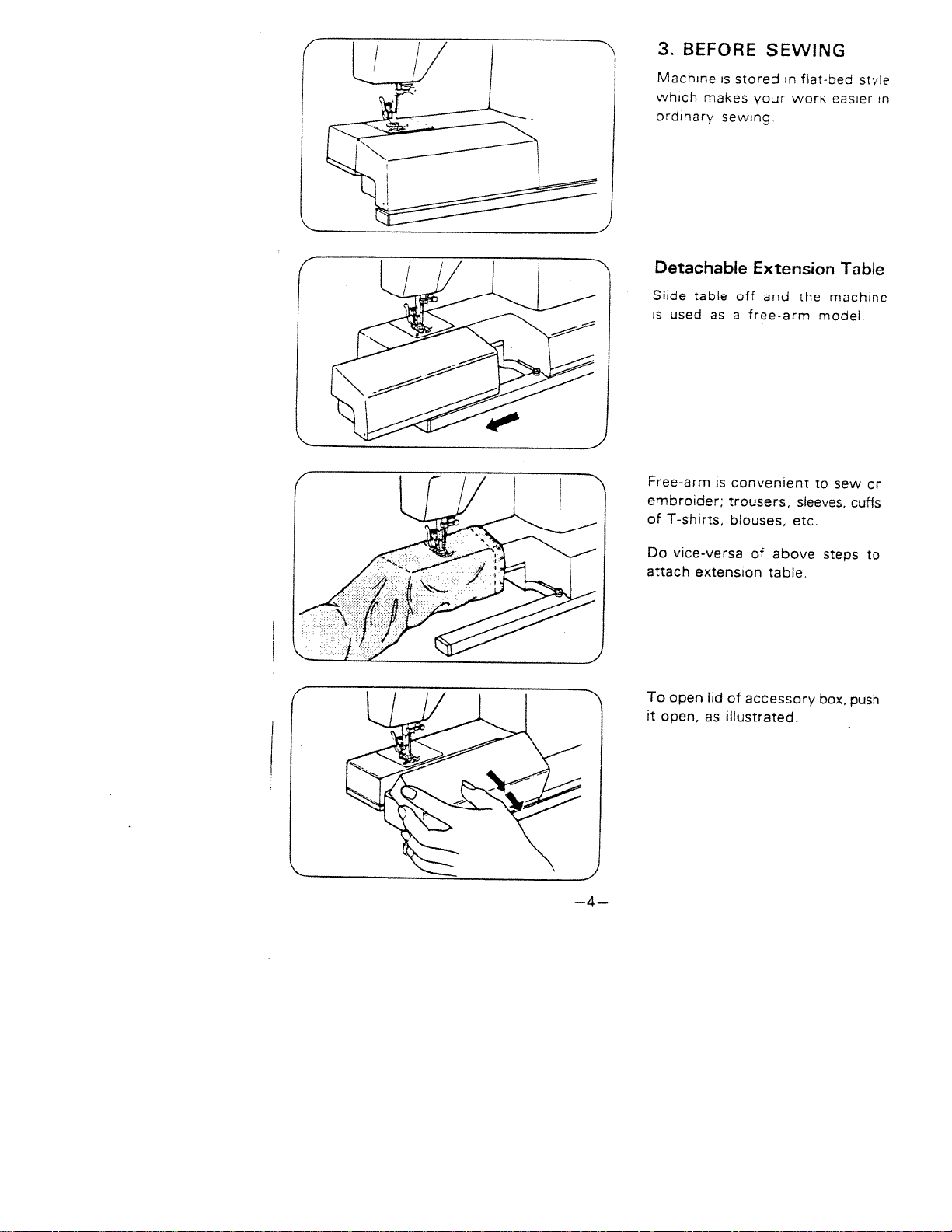

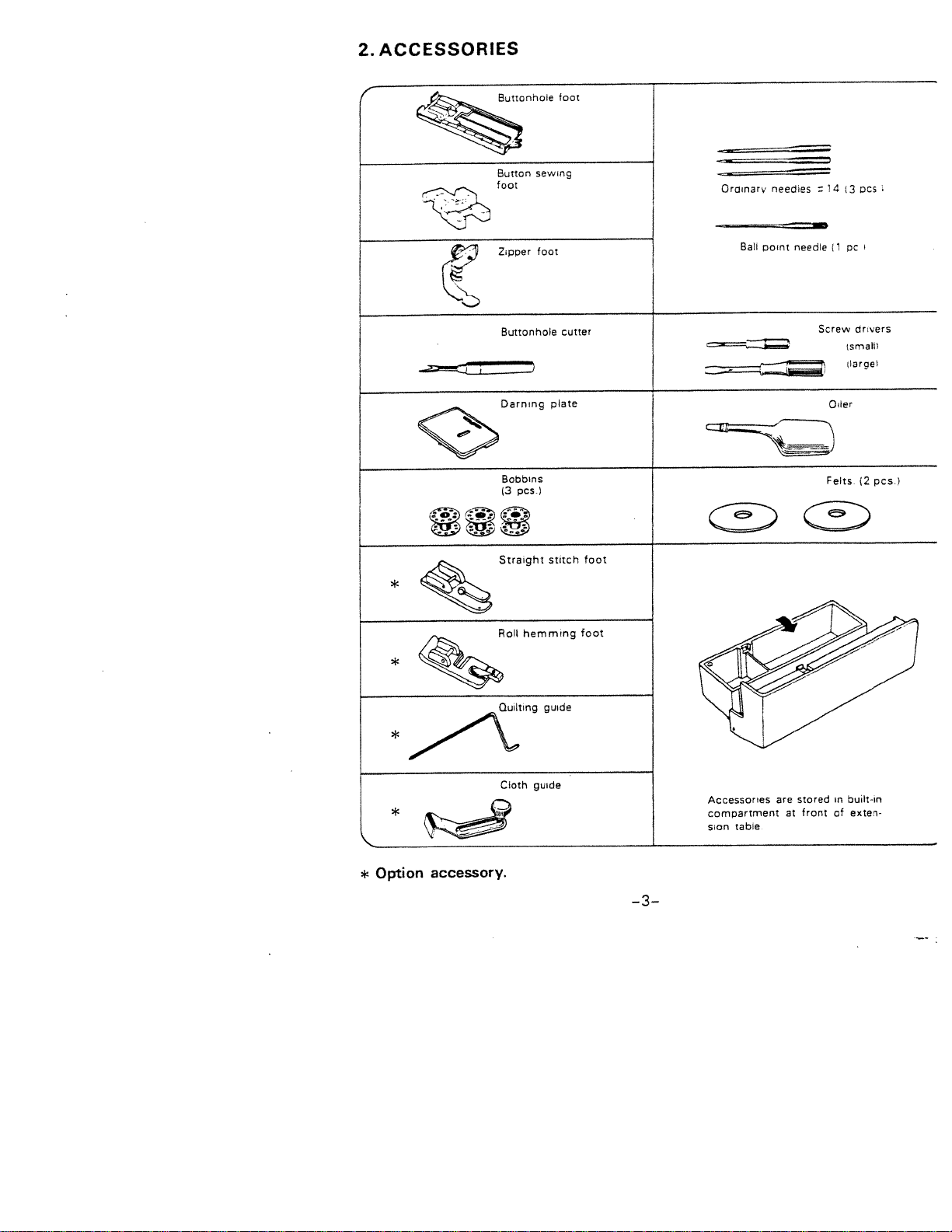

3.

BEFORE

SEWING

Machine

which

ordinary

makes

Detachable

Siide

table

is

used

Free-arm

embroider;

of

T-shirts,

is

stored

sewing

off

as

a

is

convenient

trousers,

blouses,

in

flat-bed

your

work

Extension

and

the

free-arm

sleeves,

etc.

easier

machine

model

to

sew

style

in

Table

or

cuffs

—4—

Do

attach

To

it

open,

vice-versa

extension

open

lid

as

of

above

table.

of

accessory

illustrated.

steps

box,

to

push

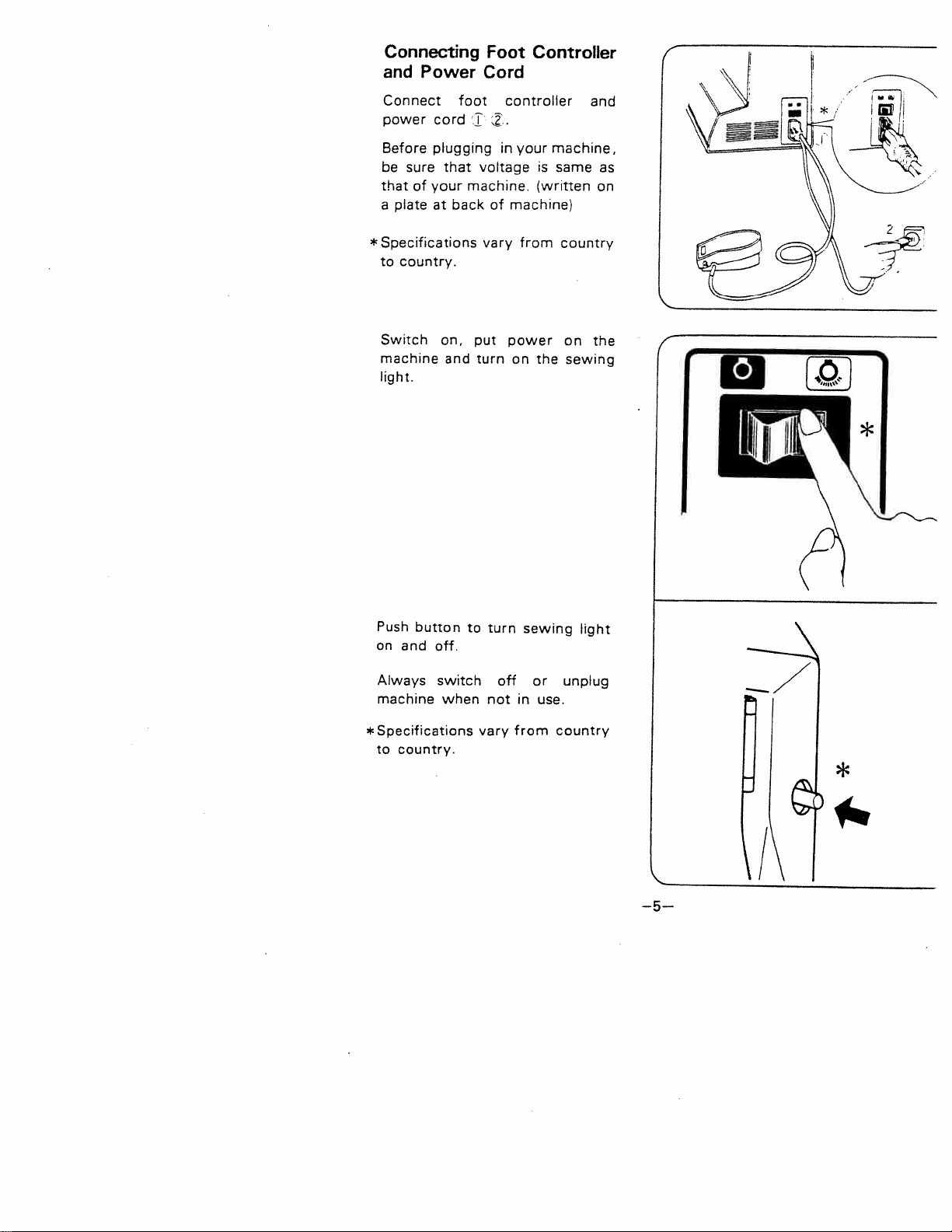

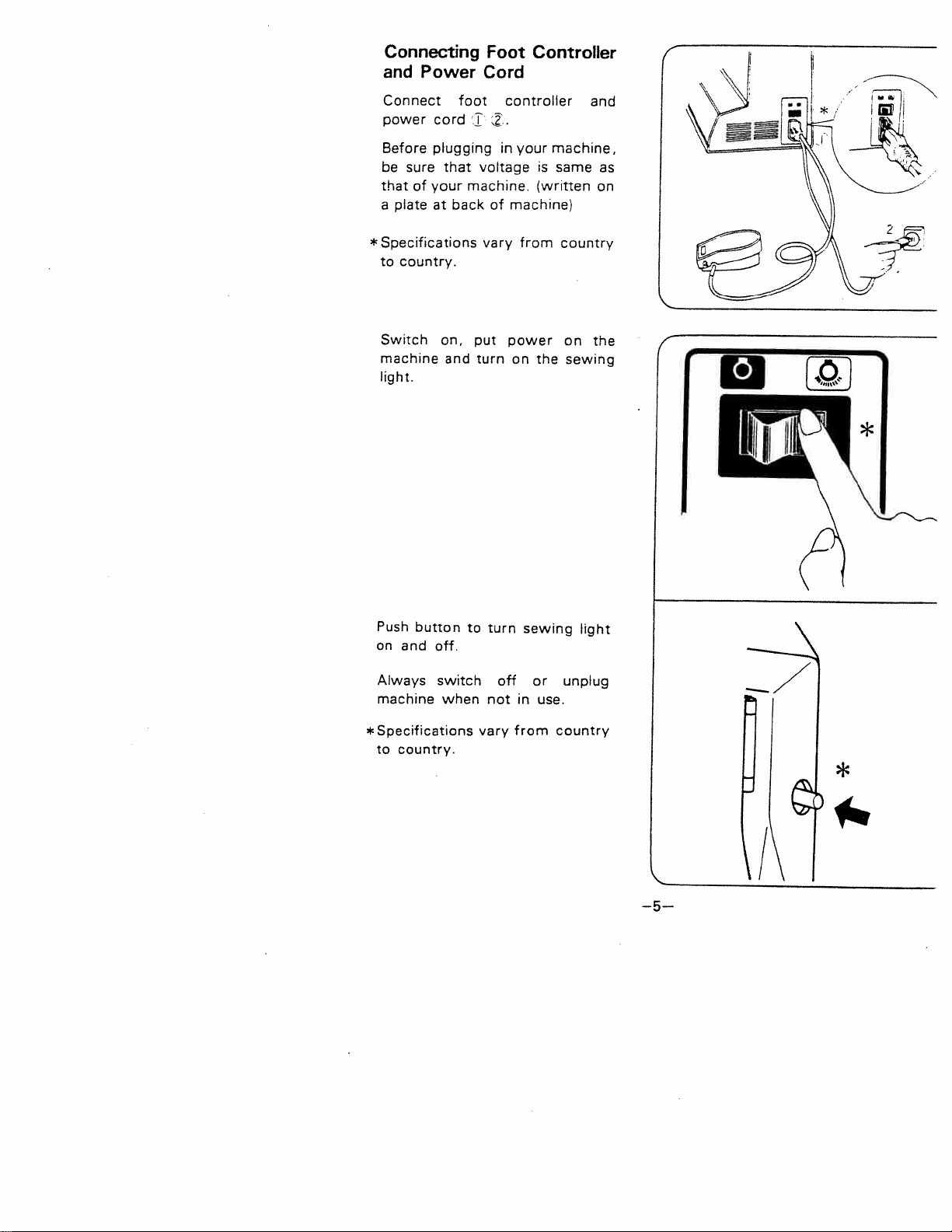

Connecting

and

Power

Foot

Cord

Controller

F

Connect

power

Before

sure

be

thatofyour machine. (written

plateatbackofmachine>

a

*

Specifications

to

country.

Switch

machine

light.

foot controller

cord

plugging

that

voltage

vary

on,

put

and

turn

in

your

power

on

is

from

the

and

machine,

same

country

on

sewing

on

the

as

I

Push

button

on

and

off.

Always

machine

*Specifications

to

switch

when

country.

to

turn

not

vary

off

sewing

or

in

from

light

unplug

use.

country

*

)

—5—

Drawing

Hold

hand.

left

Turn

until

you

again.

up

Pull

upper

lower

in

loop.

a

Pull

out

cm

(6”)

under

Up

end

of

handwheel

needle

thread

thread

both

threads

and

place

presser

upper

will

foot

Lower

thread

slowly

moves

slowly

brought

be

to

them

on

Thread

towards

down

about

together

left.

with

and

and

up

1

5

Foot

Push

down

regulator.

the

presser

push

down

is

obtained.

Insufficient

feeding

difficulty

or

presser

reduce

When

fabnc,

pressure

fabrics.

Pressure

the

This

foot.

inner

of

the

in

guiding

foot

the

pressure.

sewing

reduce

when

outer

will

To

pin

pressure

fabric,

marks

multiple

the

release

Increase

until

the

sewing

ring

may

skipped

fabric.

appear

thickness

pressure.

of

the

the

suitable

cause

on

lighter

the

pressure

pressure.

pressure

stitches,

If

feed

the

or

Increase

pressure

on

poor

or

dogs

fabric.

heavy

weight

—15—

Fabric,

Thread

and

Needle

Table

FABRIC

VERY

SHEER;

Voile.

Chiffon,

SHEER:

Blouse

Lawn.

Organdy,

LIGHT-WEIGHT:

Wool.

Brocade,

MEDIUM;

Linen,

Faille,

HEAVY;

Sailcloth

EXTRA

Upholstery.

[KNITSJ

LIGHT-WEIGHT;

Power

MEDIUM-WEIGHT:

Jersey,

Power

HEAVY-WEIGHT;

knit,

FAKE-FURS,

ILEATHERI

VINYLS

LIGHT-TO-MEDIUM-

WEIGHT

HEAVY

fDECORATIVE

TOP

MACHINE

Wool,

Velvetteri.

Terrycloth

Denim.

HEAVY:

Canvas,

net

Double

Net

Power

Net

VELOURS

FILMS

LEATHER

TOUCHES)

STITCHING

EMBROIDERY

Knit.

Lace,

Net

Crepe,

Taffeta

Crepe,

Velvet

Silk.

Cotton

Duck,

Tricot

Double

50—70

Silk

Size

European

Cotton

70

5070

30

30

30

30

30

30

30

30

30

30

twist

50—70

THREAD

Mercerized

Cotton

60

60

I

I

50

50

Heavy

Duty

Heavy

Duty

60

50

50

Heavy

Duty

50

50

Heavy

Duty

Cotton

Covered

Polyester,

Silk.

Silk

Nylon

Silk

Nylon

Silk

Silk

C.C,Poly.

CC.Poly.

Silk

Nylon

Silk

Nylon

C.CPoly.

Silk

Nylon

C.CPoly.

c.c

Poly

C.CPoly.

C.C.Poly.

C.CPoIy.

Nylon

European

705

65—70

65—70

75—80

80—90

100

120

70

70—80

80—90

90—

100

90

90—100

100—110

100—110

65—80

i

11—14

14—16

I

14—16

16—18

16—18

9—11

NEEDLE

U.SSize

15x1

9

9

11

1

1-’-14

16

19

9—10

14

to

Regular

[

Regular

Regular

Light

Ball

Light

Medium

Ball

Medium

to

Heavy

Ball

Ball

Sharp

Wedge

Wedge

Wedge

Point

Style

-

or

REMARKS

Loosen

per

tension

one

or

points

[_

up-

two

—16—

r

Cloth

*

Option

Use

long

from

Set

of

cloth

seam

edge

guide

needle

Guide

accessory.

guide

of

of

in

hole

plate,

when

regular

material.

on

arm,

and

sewing

distance

at

right

adjust

a

distance.

Run

—

,—

machine

touching

Position

to

sew

Sew

a

reverse

forcement

Draw

fabric

is

finished.

‘—

Cut

threads

behind

presser

guide.

cloth

curved

at

to

with

with

guide

stitches

end

left

bar.

edge

seam.

of

when

thread

at

an

for

seam.

of

fabric

angle

rein

sewing

cutter

—20—

Adjusting

Test

stitch

scrap

to use.

With

correct

and

lower

equal

and

both

threads

If

upper

(loose),

straight

surface

by

turning

of

upper

of

Thread

performance

material

threads

strong

in

tension

(lower)

along

fabric

tension

you

tension

enough

center.

upper

(.©).

is

dial.

Tension

are

),

(.

tension

to

too

thread

(lower)

Correct

on

going

upper

lock

tight

lies

a

is

STRAIGHT

5.

machine

Set

*

Option

kinds

3

can

be

accessory.

straight

of

selected

as

as

SEWING

shown.

stitch

shown

lengths

below.

-

5,

6,

7,

--.

:$:_

Stitch

ZIGZAG

6.

machine

Set

prevent

To

ing.

stitch

beginning

4

kinds

patterns

No.11

*

2640

Selector

No.

No.

No.

set

and

for

only.

5

6

7

seam

machine

sew

and

or

3

can

model

Stitch

SEWING

shown.

as

ends

for

in

ending

kinds

selected.

be

1510,

length

2%

3%

4%

unravell

straight

reverse

of

of

zigzag

1919

seam.

and

*

\—

1

ZIGZAG

at

Stitch

Selector

No.

No.

No.

*

No.

8

9

10

1

Zigzag

Width

2mm

3mm

4mm

5mm

1

PATTERN

Th

Stitch

Length

1mm

2mm

3mm

4mm

Thread

Stitch

Better-looking

requires

straight

Loosen

less

stitching.

upper

Tension

upper

tension

zigzag

for

stitching

tension

slightly.

Zigzag

than

—21—

back

side

I

right

sid

12.

STRETCH

STITCHING

stitches

The

stretch

with

These

in

selection.

and

are

the

Straight

Rickrack

Briar

Feather

Overcast

2640

Adjusting

Stitch

stretch

In

stretch

usually

(between

sewing

need

to

balance

ance

sake.

special

machine

stretch

For

only.)

Balance

stitch

stitch

be

in

‘+‘

some

adjust

the

stitches

shown

and

for

stretch

briar

stretch

stretch

model

Stretch

adjuster

a

neutral

and

fabrics,

this

are

knit

stitches

your

stretch

1510,

sewing,

“—“).

you

control

for

all

used

fabrics.

built

quick

1919

should

position

When

may

appear

the

to

Ill

III

Ill

iI

Ill

Ill

III

ll

if

I

If

design

illustriations

control

design

design.

If

as

turn

stitching

the

in

slightly

design

the

the

seems

to

looks

appears

right

control

isasyou

open

the

toward

like

hand

toward

like

left,

adjust

“—

the center

tobeclosed

illustrations,

“+“until

desire.

the

the

until

I

+

I

—31—

I

15.

(For

BRIAR

model

STRETCH

1510,

1919

and

2640

only.)

This

stitch

adecorative

lines

and

-I

OVERLOCKING

16.

For

2640

only.)

Overlocking

possible

seams

Set

at

machine

clothes

model

to

the

can

stitch

stitches

sew

same

as

shown.

for

1510,

and

be

on

1919

time.

used

household

children.

and

make

overcast

as

it

—34—

Put

two

with

right

To

prevent

sew

so

drop

outside

Fn

some

stitches

overcasting.

pieces

sides

that

cases

can

edges

right

the

of

facing

edge

be

cloth

and

from

side

of

material.

overlocking

used

together

sew.

fraying,

stitches

for

SEWING

17.

machine

Set

Attach

plate.

(See

Select

sizeofthe button

No.8,9,

darning

Zigzag

and

as

page.13)

widthtosuite

ON

shown,

plate

from

10.

BUTTONS

on

needle

the

pattern

ZIGZAG

PATTERN

*

No.11

2640

Place

under

Sew

Stop

upper

Draw

threads.

Draw

wrong

model

for

only.

button

a

foot.

zigzag

5-6

machine

position.

out

thread

side

work

and

1510,

and

stitches.

when

ends

tie

1919

and

material

needleisin

and

cut

through

a

knot.

off

to

—35—

1

QUILTING

/

20.

Set

*

machine

Option

shown.

as

accessory.

Baste

prevent

you

as

Insert

spring

Mark

tailors

From

following

guide.

Interval

adjusted

direction

ayers

them

sew

the

plate

first

chalk,

second

quitting

on

line

seam

between

by

arrow.

of

of

from

guide

the

with

and

tine,

of

moving

material

slipping

under

holder.

pencil

sew.

just

line

first

seams

can

guide

to

out

the

or

sew,

using

be

in

,

4

I

•‘

.

—

—38-—

EMBROIDERY

21.

machine

Set

as

shown.

ZIGZAG

PATTERN

Remove

To

avoid

pulled

tension.

For

good

important

and

thread.

thin

Use

upper

of

lower

Trace

and

Make

Pull

handwheel

holding

Lower

thread

same

thread.

your

centeritin

sure

out

presser

foot,

lower

up,

reduce upper

embroidery,

to use

embroidery

kind

design

material

lower

towards

upper

and holder

thread

correct

silk

andathinner

and

color

on

material

embroidery

is

taut.

thread

thread

foot

by

you

lightly.

lifter.

screw.

being

thread

it

needles

for

silk

for

hoop.

turning

while

1

LJ

is

F—

Needle

No.

No.

No.

9

11

14

Thread

120—iCC

100—BC

60—50

Hold

sewing

with

satin stitch.

Continue

by

hand.

To

finish

stitches

(Pattern

Lay

typewriting

when

both

threads

along

selector

embroidering

sewing

with

outline

filling,

zigzag

paper

and

guiding

sew

width

dialNo.5,

underneath

sheer

of

start

design

hoop

several

at

6,7>

fabric.

0.

—39—

MAINTENANCE

22.

Your

machine

cleaning

factory

A

machine

few

cleaned

and

sewing

hours

and

Cleaning

requires

oiling

performance.

which

a

day

oiled

is

needs

once

for

used

a

regular

satis

for

to

month.

a

be

off

with

latches

foot

needle

all

cleaning

hook

hook.

Remove

Remove

Brush

dog

Turn

Remove

Remove

withacleaning

cloth.

and

needle.

plate.

dust

and

brush.

outwards.

race

Clean

brush

lint

cover.

hook

andasoft

on

feed

race

—40—

Oiling

oil

Use

for

sewing

oils

mechanism

will

manufactured

machine

eventually

jam.

to

specially

use.

Other

cause

Apply

one

hook

where

face

Open

the

same

Be

careful

oil

oritmay

cause

and

After

oiling,

minutes

to

Remove

screws

screwdriver.

to

every

®

way.

some

part.

top

drop

friction

cover

not

run

allow

cover

and

to

stain

sewing

machine

of

oiltopart

occurs.

and

apply

your

oil

to

by

with

apply

too

much

material

difficulty.

for

penetrate

loosening

large

oil

of

in

1-2

Apply

one

drop

of

oil

lubricating

to

points

—41—

indicated

by

arrows.

23.

TROUBLE

CHART

PROBLEM

Breaking

thread

Skipping

Irregular

The

material

fed

correctly

lower

stitches

stitches

not

Thread

or

not

Lower

Lint

stuck

tension

the

Needle

Needle

Size

or

suitable

Incorrect

Too

much

Incorrect

Upper

Incorrect

Pattern

Lint

stuck

not

drawn

thread

in

not

bent

type

for

upper

oil

size

thread

lower

selection

on

PROBABLE

wound

correctly

up

tension

the

bobbin

spring

fully

inserted

of

needle

the

material

threading

on

the

of

needle

tension

tension

dial

the

feed

evenly

too

and

hook

too

not

dog

CAUSE

on

tight

case

thread

for

the

loose

set

the

bobbin

and

not

material

correctly

inside

CORRECTION

P.11,

P.14

P.13

Remove

and

cleaning

fluff

P.

P.

P

P.14

P.41

P.1

P.20

P.1

P.18

P.40

1

4

2

with

8

8

6

lint

brush

a

—42—

PROBLEM

The

material

puckers

Upper

Stitch

Thread

Incorrect

or

lower

too

too

threading

PROBABLE

thread

long

for

thick

material

upper

of

CAUSE

tension

or

too

tower

tight

thread

CORRECTION

P13.

P.20

P.

1

8

P.16

P.14,

P.12

Breaking

If

trouble

Do

not

try

Changing

Unplug

Open

Remove

in

Install

in

the

face

bulb

counterclockwise.

new

a

clockwise.

needle

is

stilt

correct

to

Light

machine.

cover

by

bulb

Needle

Needle

Needle

Upper

Needle

Dials

the

needle

apparent

fault

Bulb

as

shown.

unscrewing

screwing

by

beni

clamp

thread

too

have

in

not

the

by

correctly

screw

tension

fine

been

was

machine,

yourself.

it

it

for

the

changed

down

I-

inserted

too

loose

too

material

in

the

please

tight

while

material

consult

your

nearest

p

P.

P.

P.20

P.16

P.18

dealer.

8

8

8

—43—

-.

it---

--

2,c--

.

-.

Loading...

Loading...