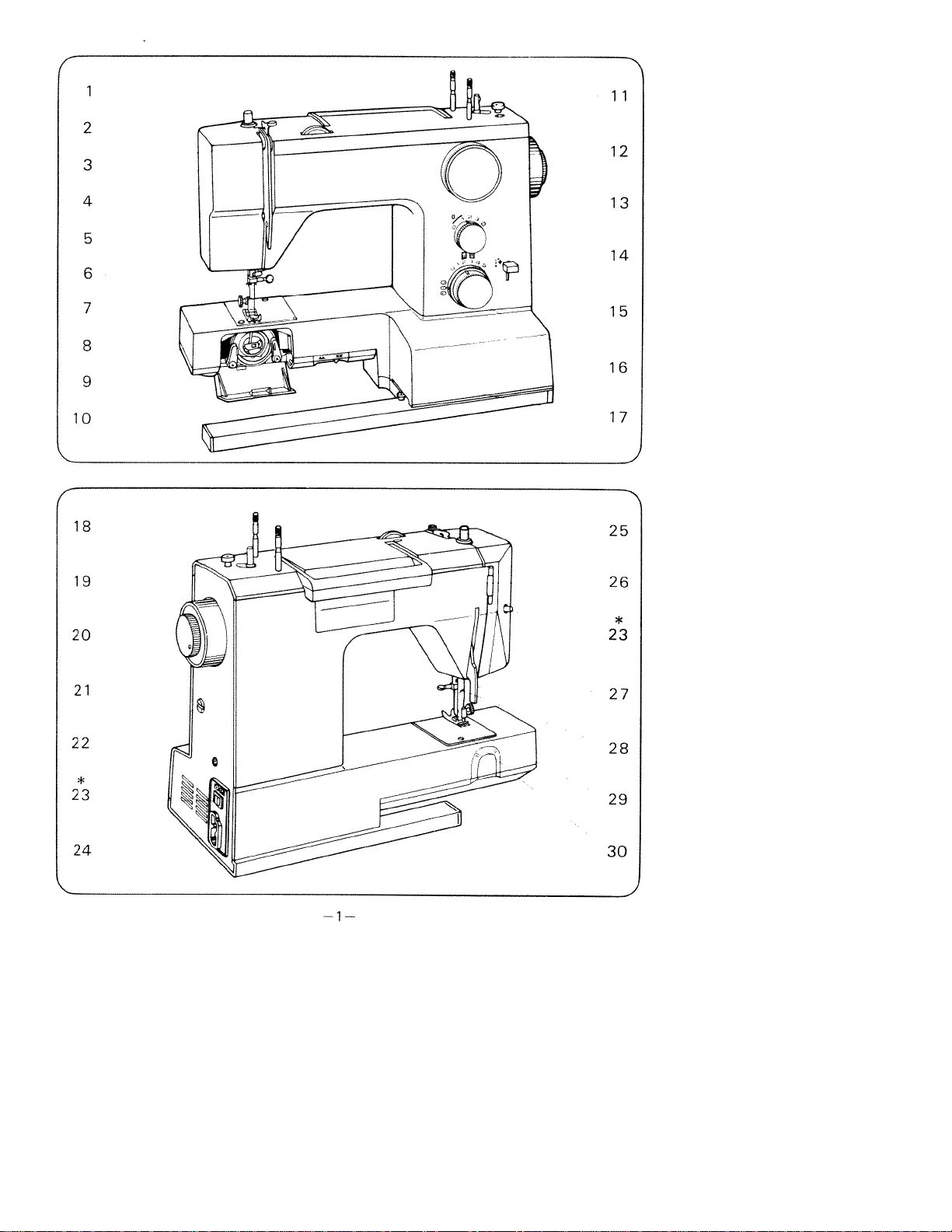

Specifications and Main Features

- Model Number: 1899

- Place of Serial number: Rear of arm

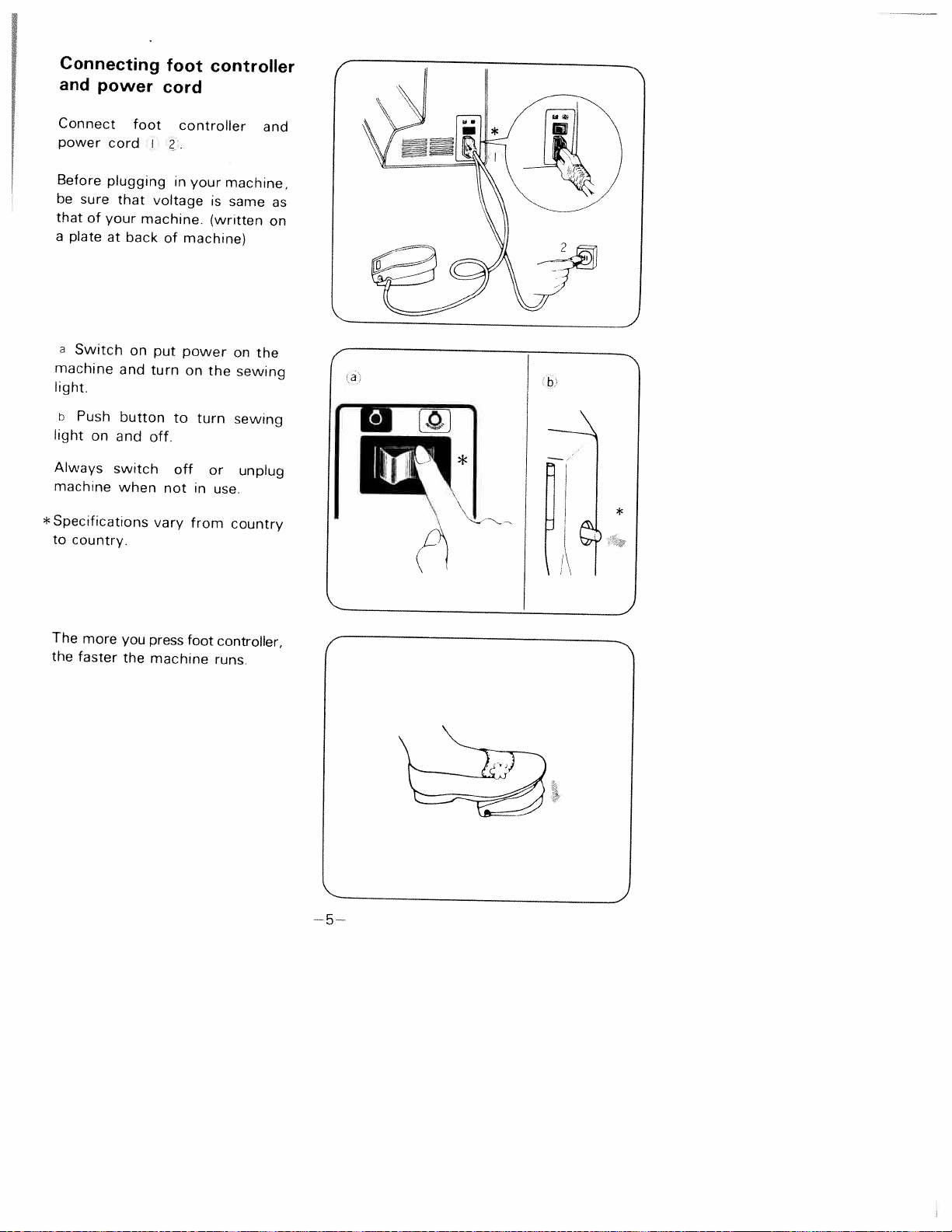

- Foot Controller: YC-482

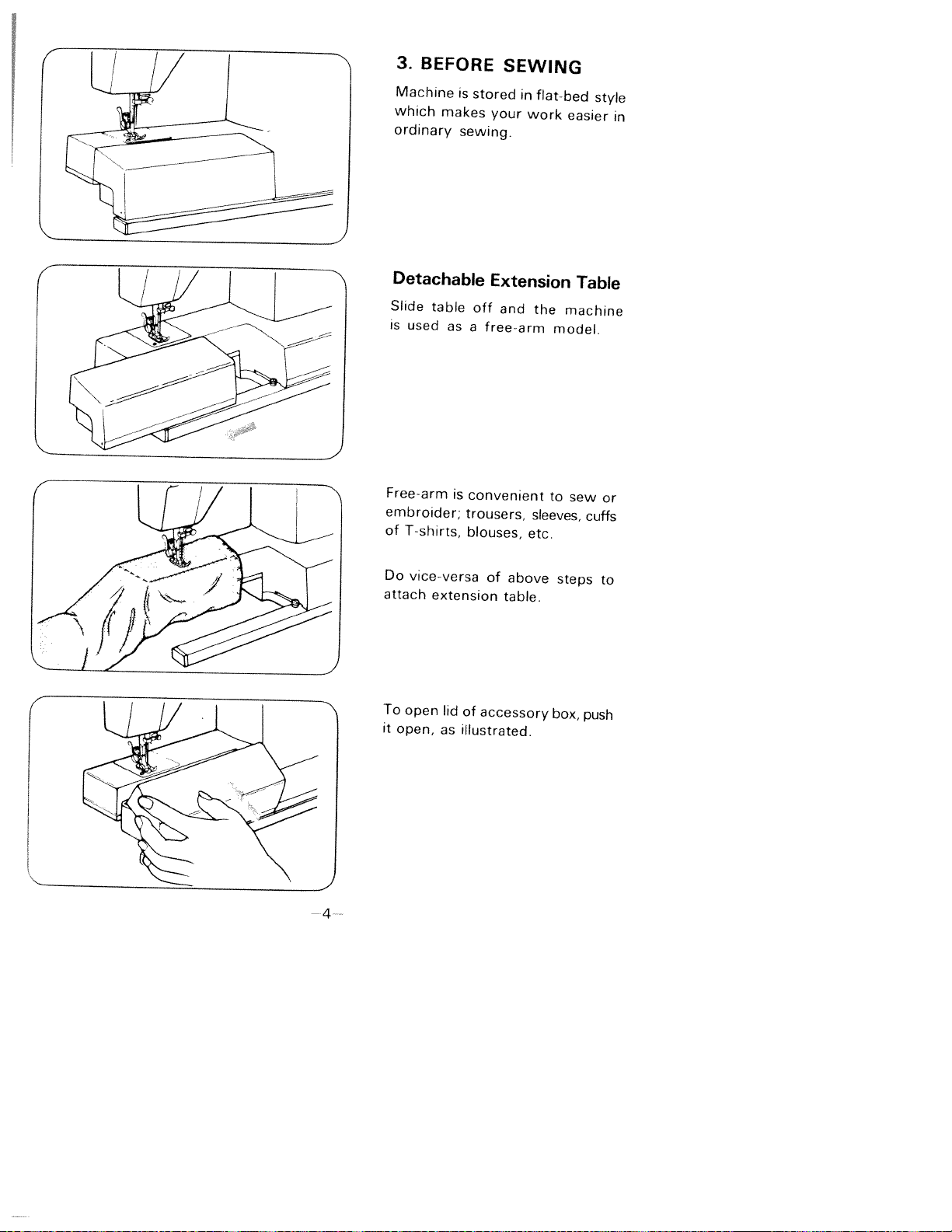

- Type of sewing machine: Flat-bed style with an extension table that can be detached for free arm sewing.

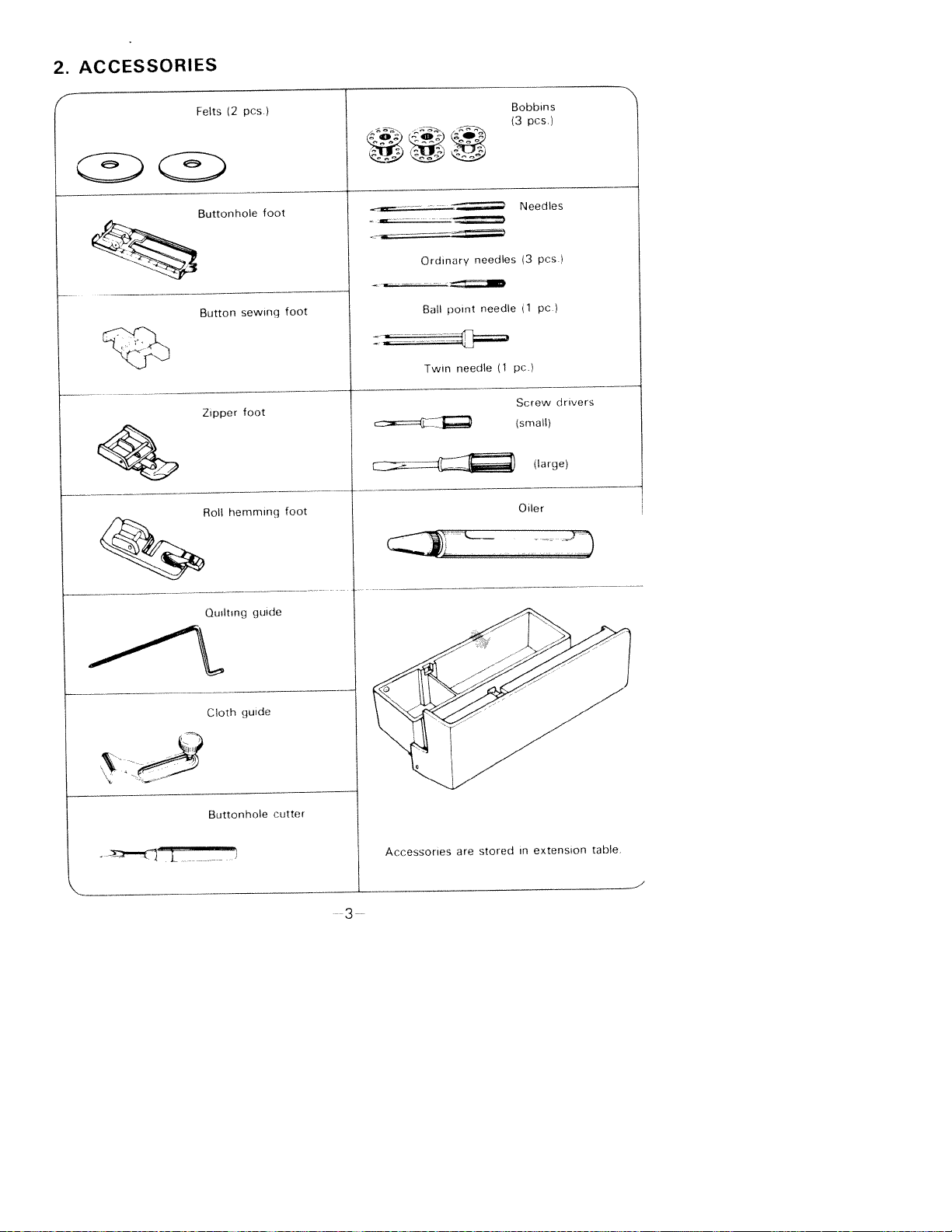

- Position of Accessories: Accessories are housed in the extension table.

- Needles that are Suppled:

- Ordinary needles (3 pcs)

- Ball point needle (1 pc)

- Twin needle (1 pc)

- The Set Includes:

- Button sewing foot

- Three bobbins

- Buttonhole foot

- Zipper foot

- Roll hemming foot

- Quilting guide

- Cloth guide

- Buttonhole cutter

- Multifunctional Accessories Such As:

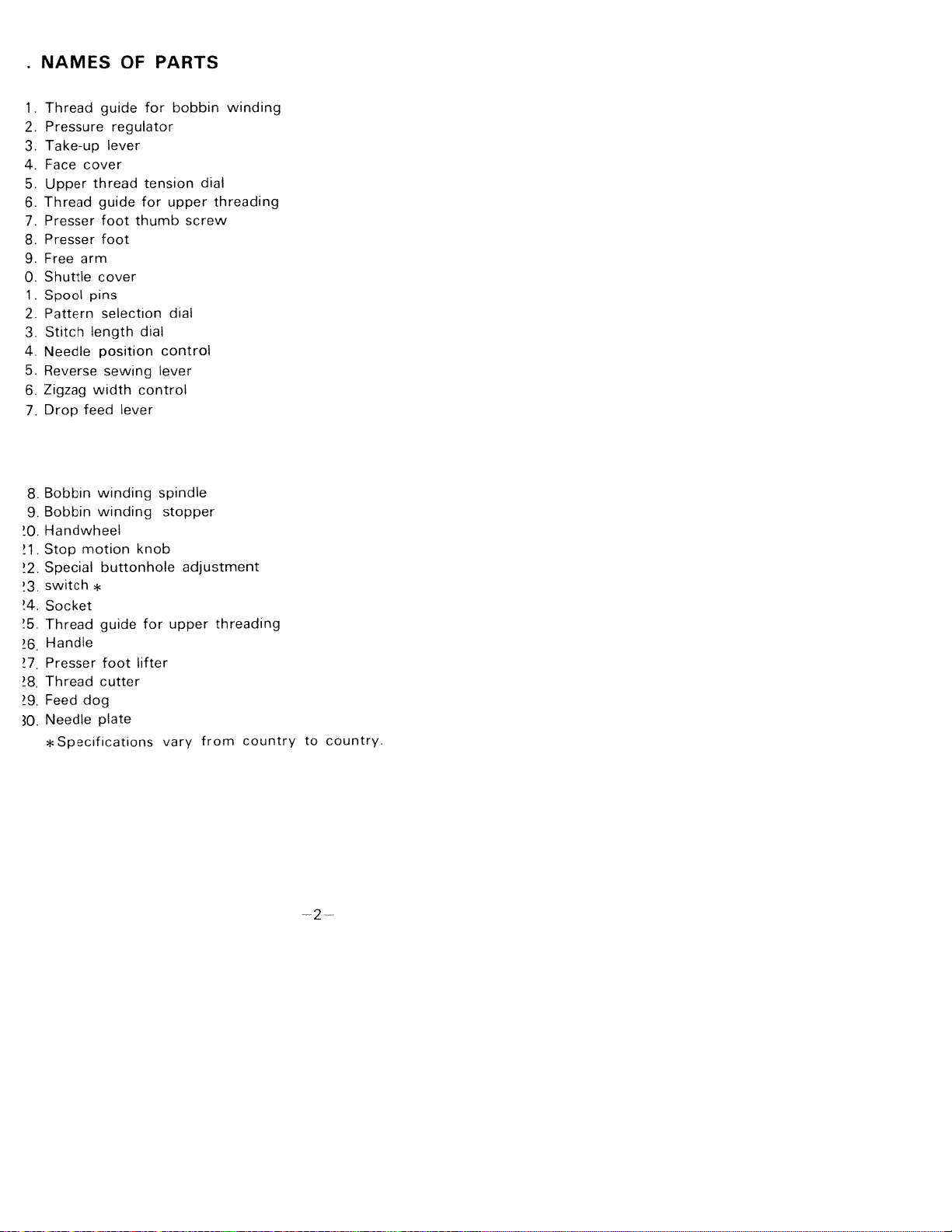

- Continuous regulatory of stitch length

- Control of the width of the zigzag

- Control of the position of the needle

- Regulation of the thread tension

- Regulation of the foot pressure.

- Stitching Skills:

- Stright stitching

- Stitching zig-zag

- Stitching buttonholes

- Sewing overcast

- Deal with blind hemming

- Scoffing

- Making embroidery patterns

- Sewing decorated tucks or designs

- Stitching twin needles

- Stress-Free Features:

- Polarized plug which reduces the chances of electric shock.

- The machine should not be left running while unattended.

- After use of the machine, disconnect the plug before cleaning.

- Maintenance and Cleaning:

- Need proper system of stuffing and oiling.

- When in constant use it is advisable to clean it once a month.

Frequently Asked Questions

Q: Can I know the model number of the machine?

A: The number in question is 1899.

Q: What’s the typical location for the serial number?

A: The serial number can be found on the back side of the arm.

Q: Does this sewing machine requires a specific type of foot controller?

A: This machinery makes use of a YC-482 type foot controller.

Q: I need to ask if this machine can sew thick materials?

A: Yes, if the foot pedal can be adjusted set right, it can sew thick materials.

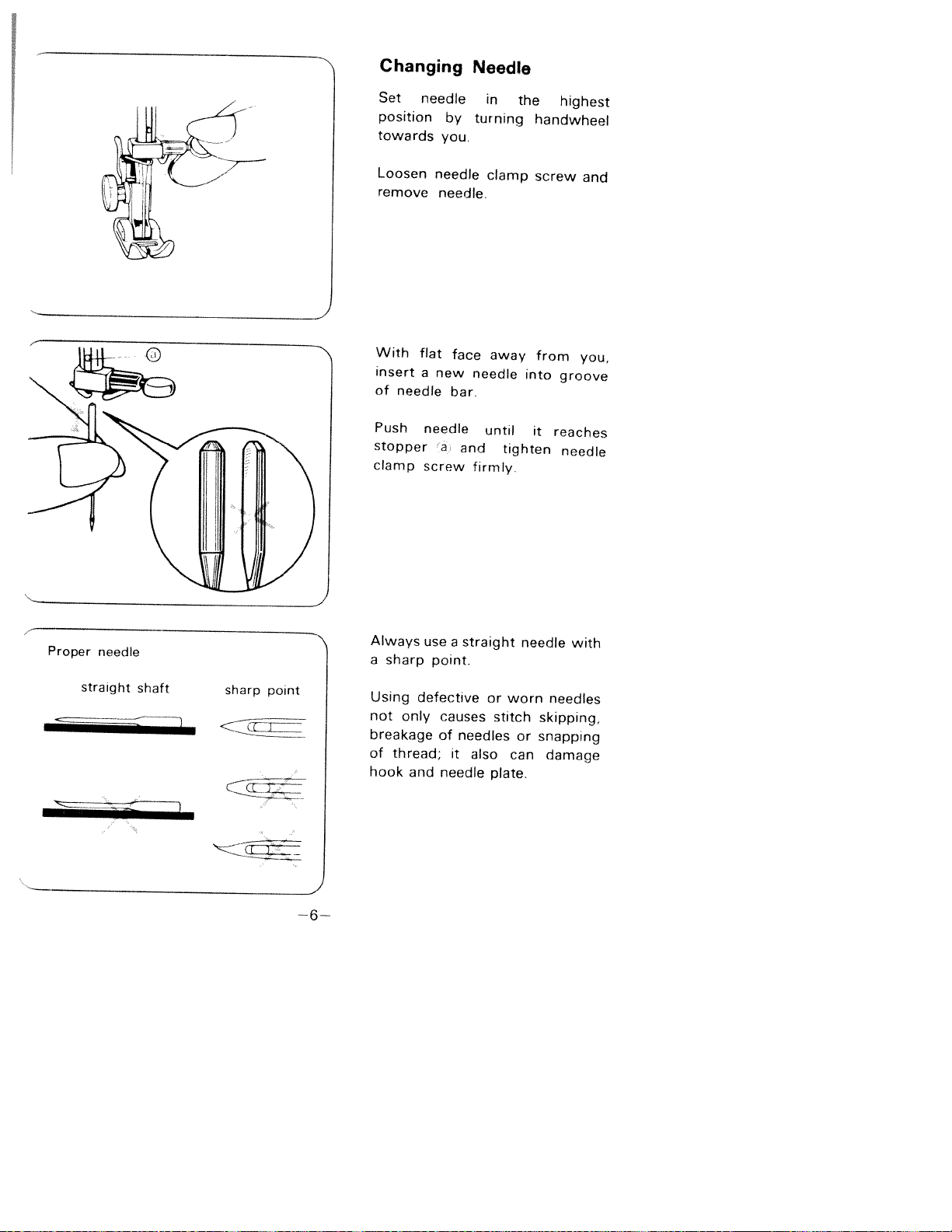

Q: Lia how do I change the needle?

A: Bring the needle to the highest position, turn and remove the screw that holds the needle clamp, bring out the old needle and insert the new one while ensuring that the flat side is facing away from you, Finally turn the screw and lock it firmly.

Q: Is it advisable to leave the machine plugged when not in use?

A: Certainly not, it is highly unsafe. The device must always remain unplugged when not in operation for the device is prone to electric shocks.

Q: I want to know how frequently should I expect to clean the machine?

A: If the device is operated for few hours daily then it only needs to be cleaned and oiled once a month.

Q: To what extent can this sewing machine allow me to stitch?

A: This sewing machine is capable of creating decorative stitches, automatic button holes, zigzag stitches, and of course, straight stitches.

User Manual

Loading...

Loading...