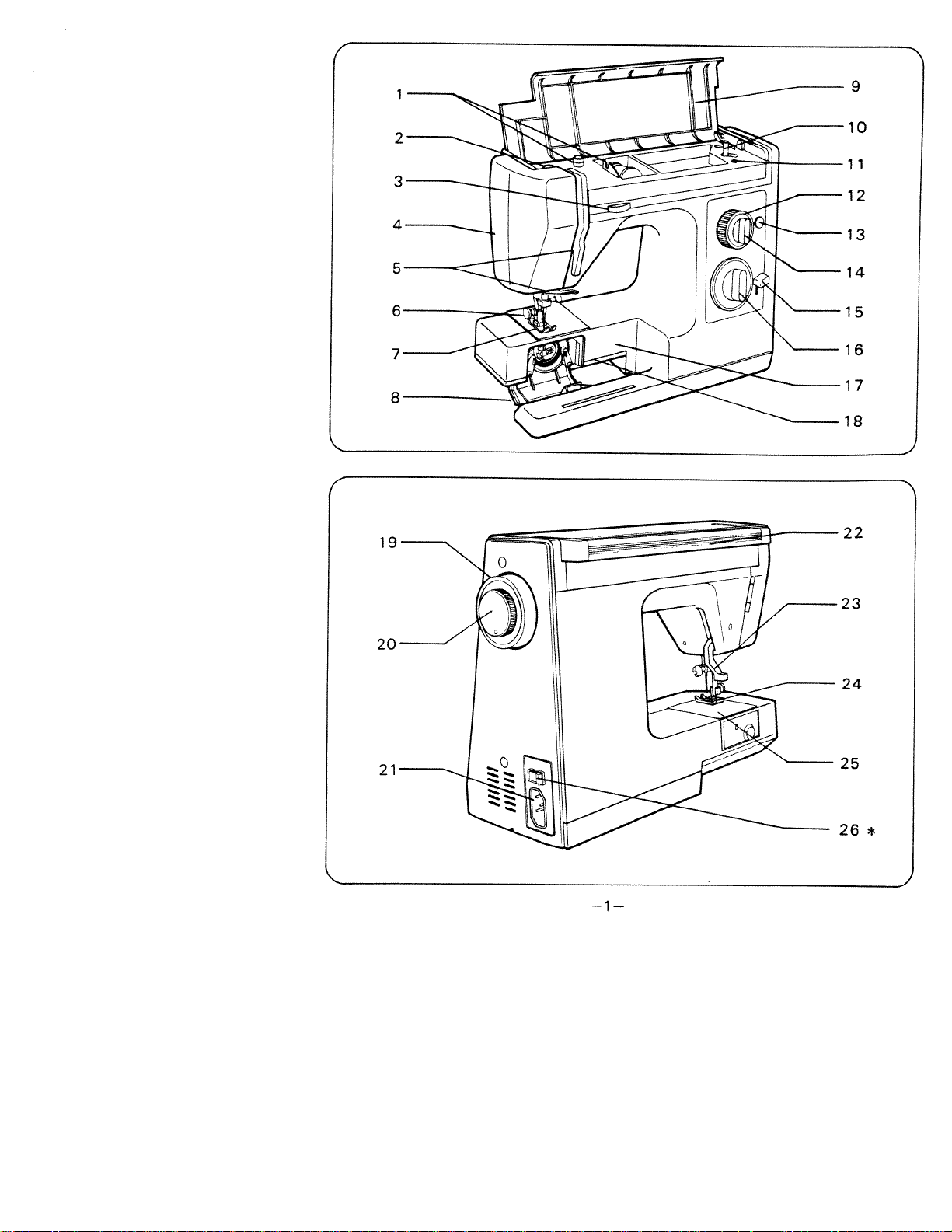

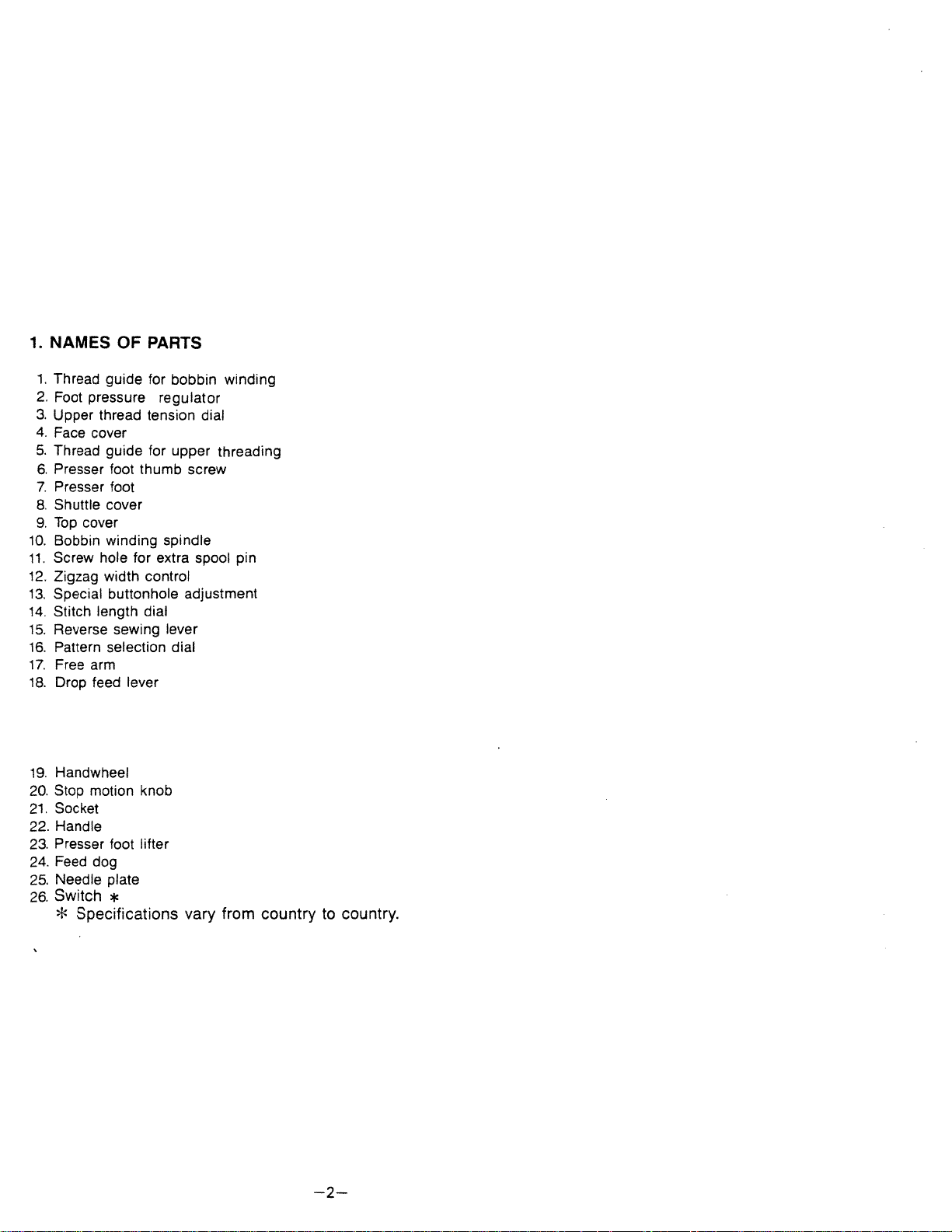

Specifications and Main Features

- Item Number: WHITE Sewing Machine

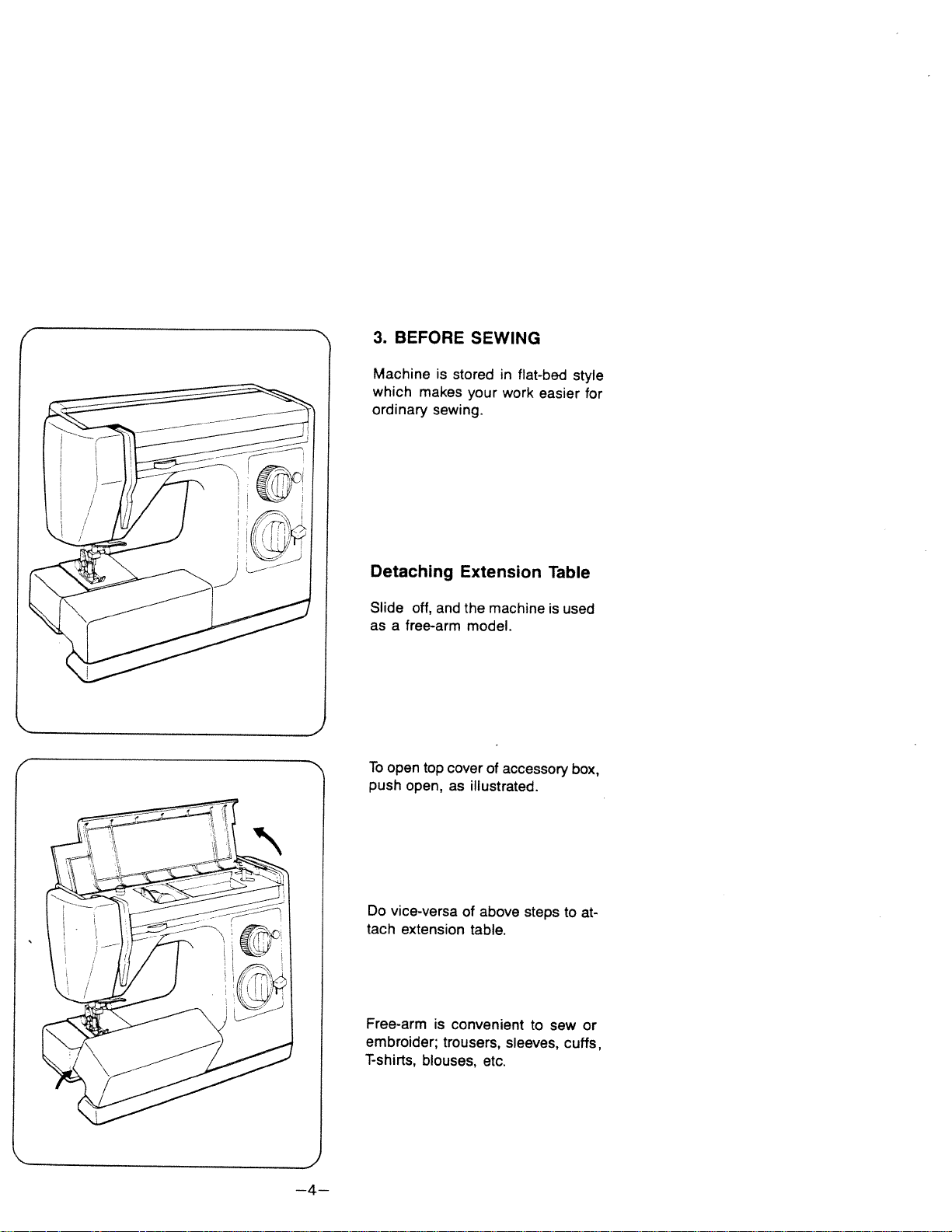

- Category: Free-arm sewing machine

- Power Supply Per Country: Dependent on the country

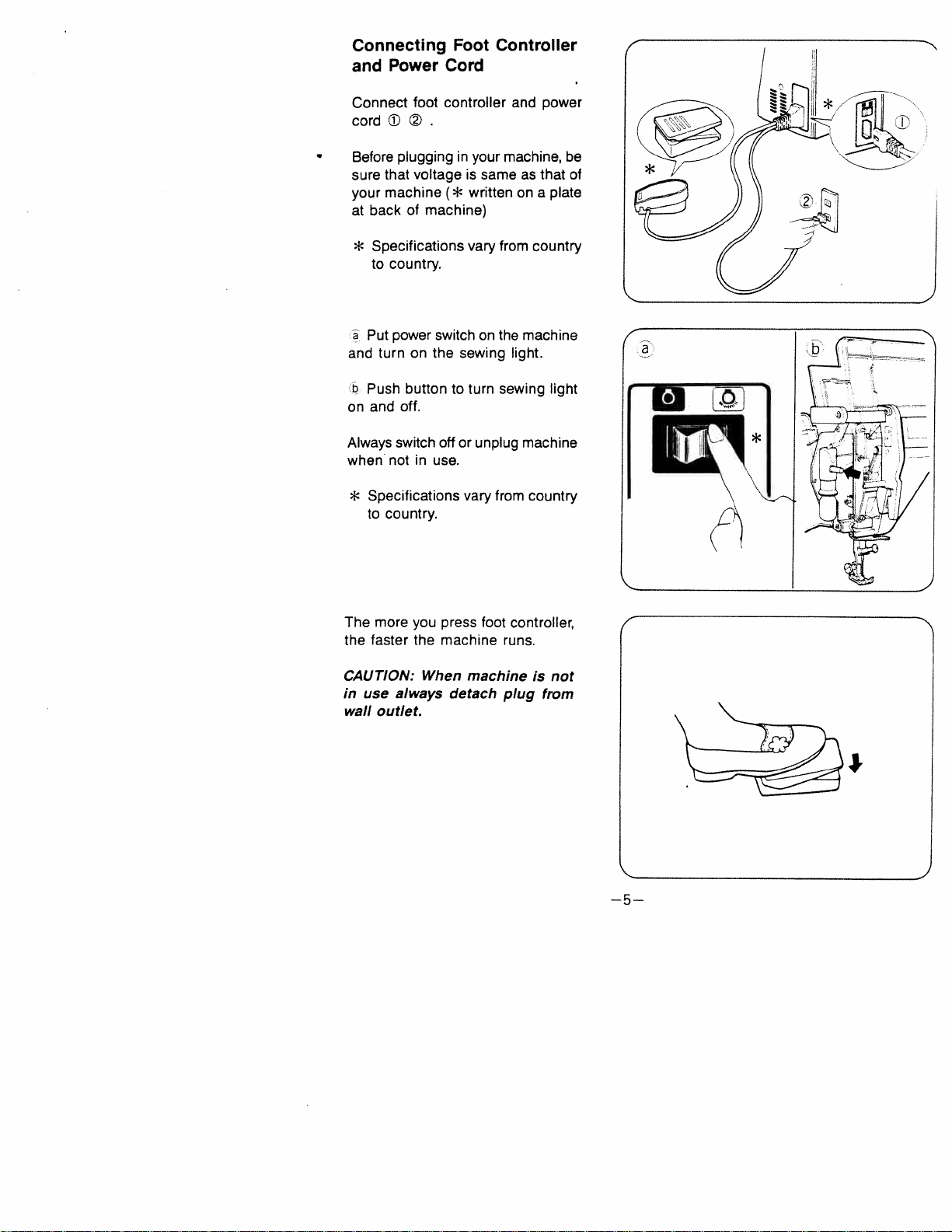

- Point of Supply: Foot controller, Power cord

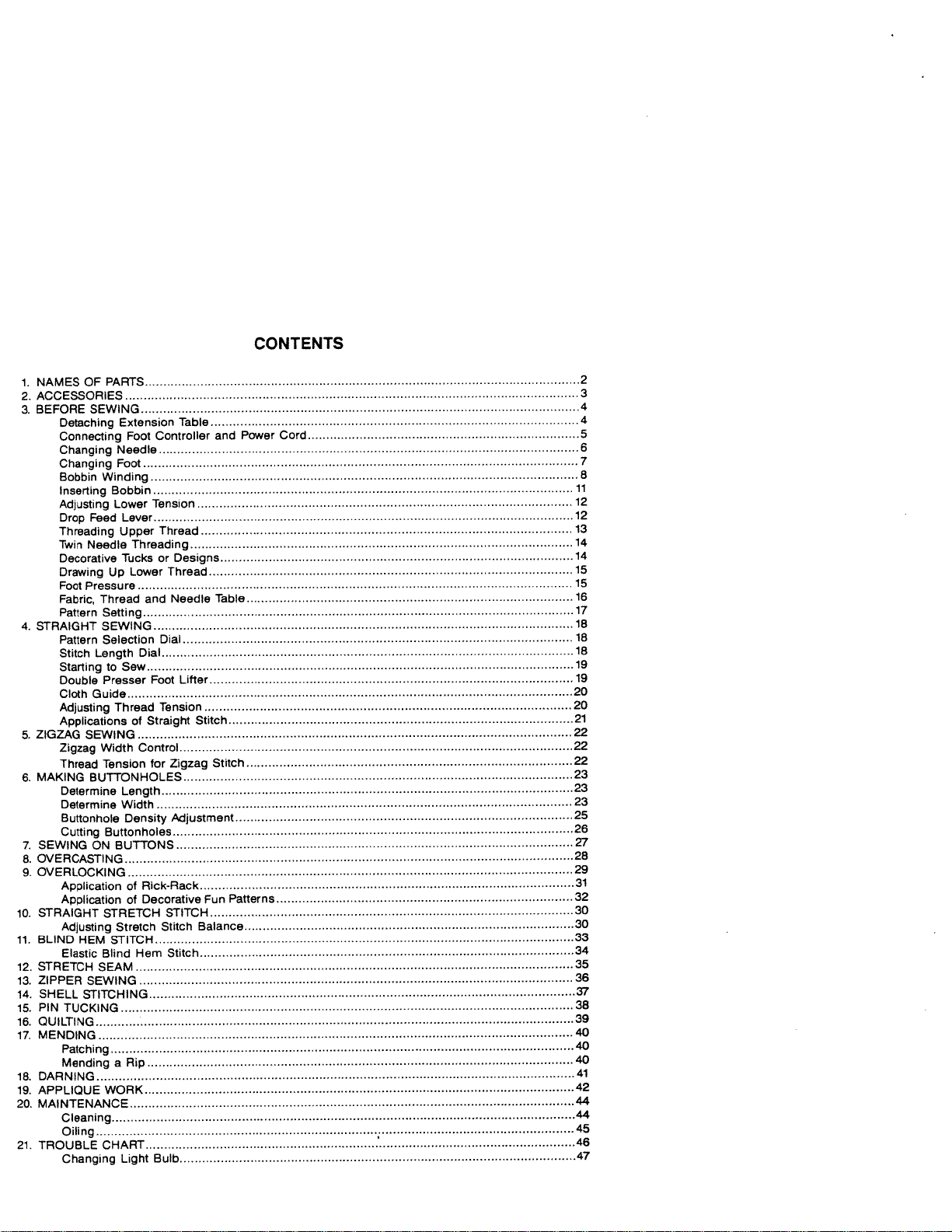

- Available Stitch Patterns: Straight, Zigzag, Buttonhole, Blind Hem, Stretch, Overlock, Shell Stitching and others

- Dial for Adjustments: Custom stitches length adjustment feature

- Width Control: Stitching width variation feature

- Tension Setting: Upper and Lower thread tension adjustment feature

- Needle: Sewing machine needle qualified alternative

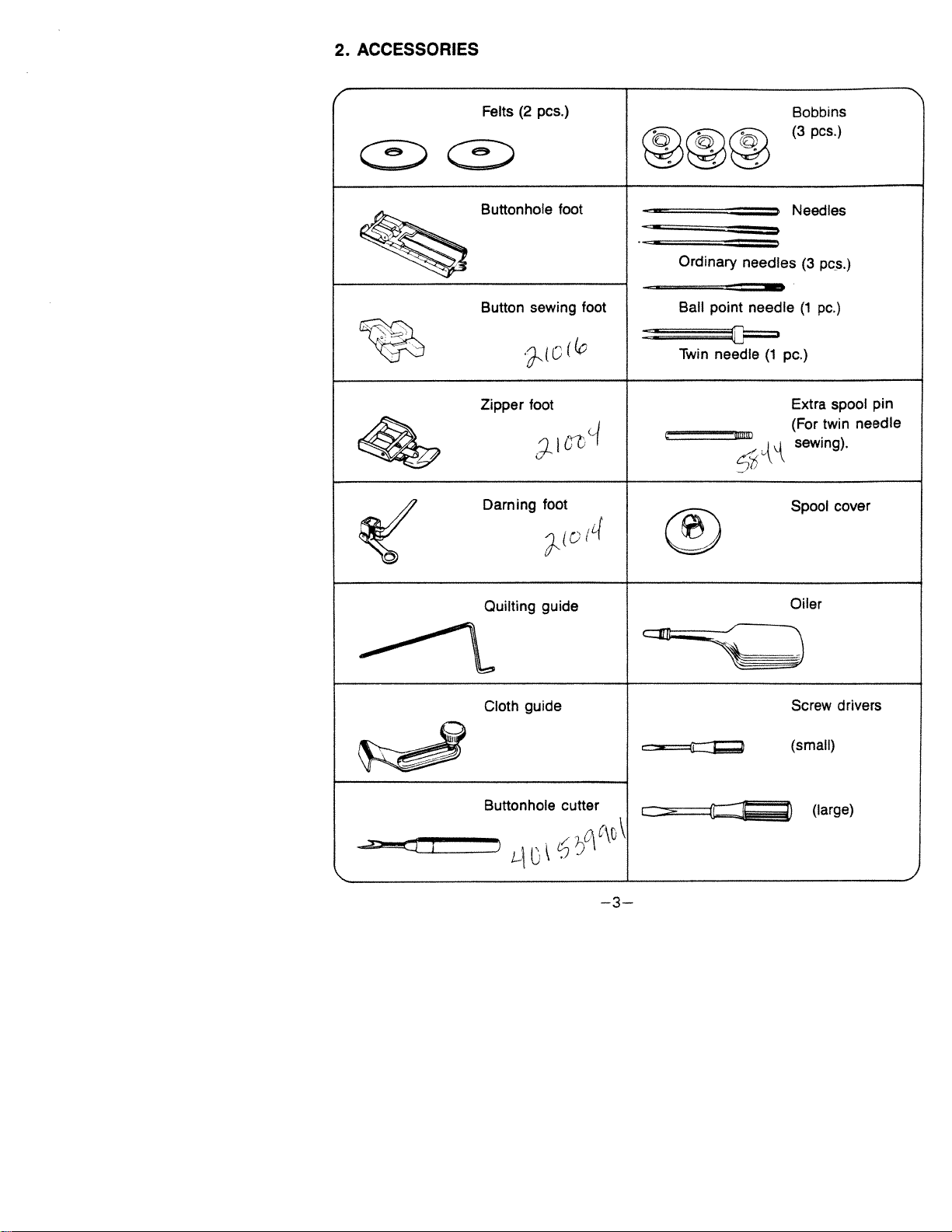

- Other Tools: Supping of presser feet, bobbins, needle pack, button hole cutter, quilting guide etc

- Maintenance: Oiling points and cleaning mechanisms for effecting maintenance

- Special Features: Pattern selection dial, dual presser foot lifter, a drop feed lever for darning and embroidery

- Weight: Not Provided

- Sizes: Not Provided

---

Frequently Asked Questions

Q1: Is it possible to sew any kind of fabrics using this sewing machine?

A1: This sewing machine is capable of sewing many kinds of fabrics including lightweight sheer fabrics, medium weight wool, polyester, majiic wool, and heavy duty denim and upholstery fabrics.

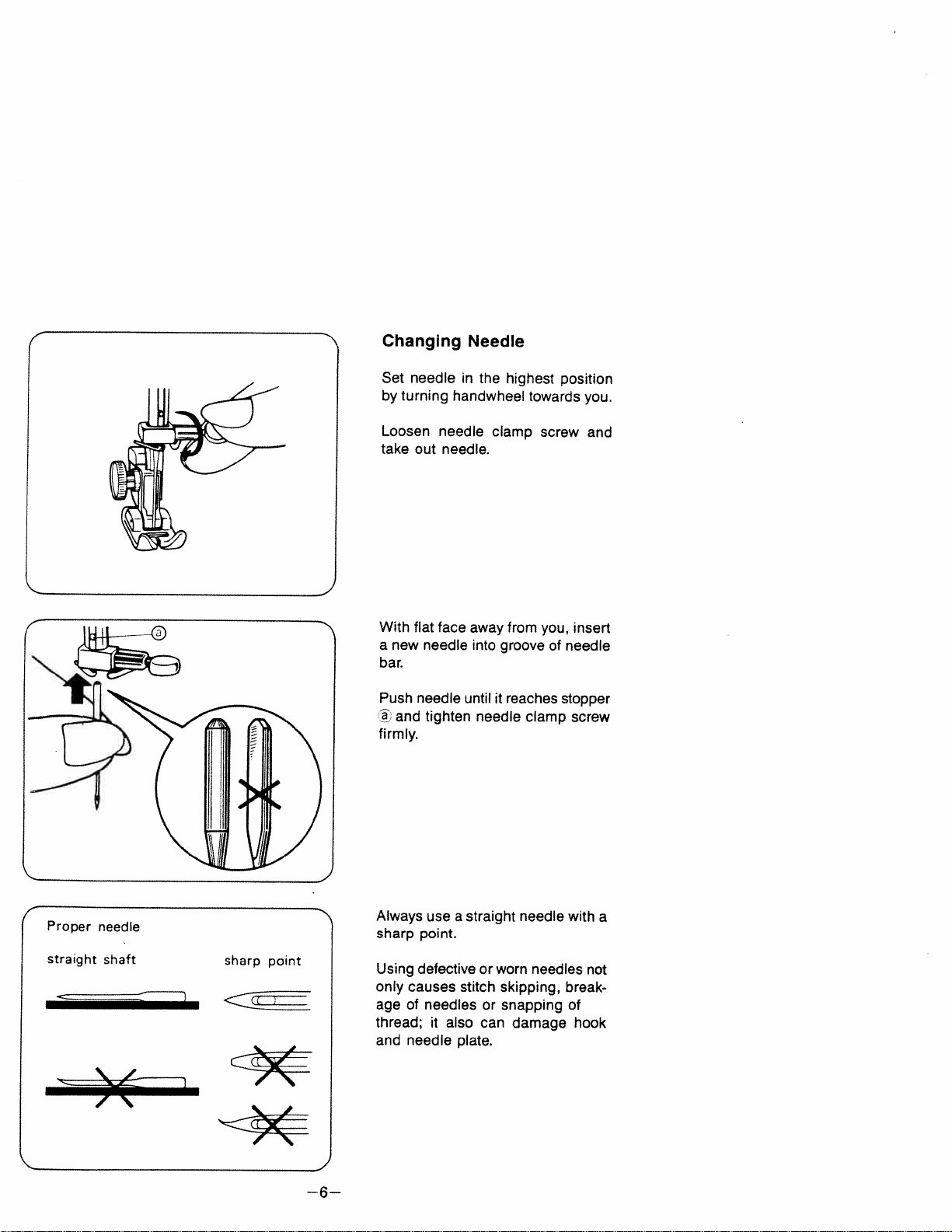

Q2: I want to change my sewing needle, how can I achieve this?

A2: To do this start by using the handwheel to set the needle into its highest available position, Next move on to loosening the needle clamp screw and removing the old sewing needle, after this you are to insert the new needle while keeping the flat side of the sewing needle facing you, and finally tighten the clamp screw.

Q3: Is it possible to use different kinds of threads?

A3: Certainly, when it comes to threads there are different kinds that can be used depending on the fabric suitable for sewing, depending on the fabric you can use cotton, silk or polyester threads.

Q4: The thread is breaking quite frequently, I do not know what to do.

A4: To avoid breaking the thread be sure to check if the sewing needle is set in the correct position or its bent, also check if the thread is properly threaded and finally check if the upper and lower tensions are correctly set.

Q5: I want to know if it’s necessary if I want to oil the machine.

A5: To oil or not to oil is a major question many people ask, While it is not compulsory recommended though is to do regular oiling if you wish to retain the performance of the machine, your best bet would be to oil the machine after cleaning it every few hours.

Q6: Can you tell me the process by which a buttonhole can be made?

A6: To get the process started attach the buttonhole to the foot, afterwards set the selection of the pattern settings to buttonhole, to select the size make use of the button and finally follow what the buttonhole sewing instructions of the machine provide you with.

Q7: What is the best method to clean my sewing machine?

A7: To clean up your sewing machine, begin by removing the foot and the needle, thereafter use a cleaning brush to get rid of any dust or lint, don’t forget the interior of the bobbin area as well.

Q8: Please advise on what I should do if my machine is running too loud?

A8: In case your machine is running loud, have a look if there are any threads that are stuck within the race, if there are then carefully remove them. Additionally however, make sure that the entire machine is properly assembled.

User Manual

Loading...

Loading...