Whirlpool WOD51EC7HS, WOD51EC0HS, WOS51EC0HS, WOS51EC7HS INSTALLATION INSTRUCTIONS AND OPERATION MANUAL

INSTALLATION INSTRUCTIONS

IMPORTANT:

Sa

IMPOR

À conserver pour consultation par l'inspecteur local des installations électriques.

27" (68.6 CM) AND 30" (76.2 CM) ELECTRIC

SINGLE AND DOUBLE BUILT-IN OVEN

FLUSH INSTALLATION KIT

INSTRUCTIONS D’INSTALLATION

ENSEMBLE D’INSTALLATION EN AFFLEUREMENT

POUR FOUR ÉLECTRIQUE ENCASTRÉ SIMPLE ET

DOUBLE DE27"(68,6 CM) ET 30" (76,2 CM)

Flush Installation Kit Part Number

Ensemble d'installation en

affleurement référence

W11173681 27” (68.6 cm), white WOS51EC7HW, WOD51EC7HW

W11173683 30” (76.2 cm), white

W11173685 27” (68.6 cm), black

W11173691 30” (76.2 cm), black

W11173693 27” (68.6 cm), stainless steel

W11123003 30” (76.2 cm), stainless steel

W11173700 27” (68.6 cm), black stainless WOS72EC7HV, WOD77EC7HV

W11173703 30” (76.2 cm), black stainless WOS72EC0HV, WOD77EC0HV

W11123005 30” (76.2 cm), bronze WOSA2EC0HN, WODA7EC0HN

Size and Color

Dimensions et couleur

UL Listed for Model Numbers

Homologation UL pour les modèles

numéro

WOS51EC0HW, WOD51EC0HW,

WOS72EC0HW, WOD77EC0HW

WOS51EC7HB, WOD51EC7HB,

WOS72EC7HB, WOD77EC7HB

WOS51EC0HB, WOD51EC0HB,

WOS72EC0HB, WOD77EC0HB

WOS51EC7HS, WOD51EC7HS,

WOS72EC7HS, WOD77EC7HS

WOS51EC0HS, WOD51EC0HS,

WOS72EC0HS, WOD77EC0HS,

WOS97EC0HZ, WOSA2EC0HZ,

WOD97EC0HZ, WODA7EC0HZ

Table of Contents/Table des matières

BUILT-IN OVEN SAFETY ................................................................2

INSTALLATION REQUIREMENTS

Tools and Parts

Location Requirements

INSTALLATION INSTRUCTIONS

Prepare Built-In Oven

Remove Oven Door(s)

Replace Oven Door(s)

Positioning Oven Feet

Replace Plastic Spacers

Install Oven

Install Deector Kit Bracket

Complete Installation

.............................................................................2

................................................................2

...................................................................5

..................................................................5

..................................................................6

..................................................................6

..............................................................7

...................................................................................8

...................................................................9

.................................................2

...................................................5

.........................................................9

SÉCURITÉ DU FOUR ENCASTRÉ

EXIGENCES D’INSTALLATION

Outillage et pièces

Exigences d’emplacement

INSTRUCTIONS D’INSTALLATION

Préparation du four encastré

Dépose de la/des porte(s) du four

Réinstallation de la/des porte(s) du four

Positionnement des pieds du four

Remplacement des cales d’espacement en plastique

Installation du four

Installation du support de la trousse du déecteur

Achever l’installation

......................................................................11

......................................................................17

..................................................................19

..............................................10

...................................................11

.........................................................11

.............................................14

.....................................................14

.............................................14

.............................................15

....................................14

.............16

...................18

ve for local electrical inspector's use.

TANT :

W11115048A

BUILT-IN OVEN SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed here.

Tools Needed

■ Phillips screwdriver

■ Measuring tape

■ Drill (for wall cabinet installations)

1

■

/8" (3 mm) drill bit (for wall cabinet installations)

■ Level

■ Flat-blade screwdriver

Parts Needed

■ #8-14 x 1" screws - (2) single ovens, (4) double ovens

included with built-in oven

■ (2) #8-18 x

built-in oven

■ (4) #8-18 x

built-in oven

■ Bottom vent included with built-in oven

■ (2) feet double oven included with built-in oven

■ (2) front feet double oven included with built-in oven

Parts Supplied

■ Deector bracket

3

/8" screws - bottom vent included with

3

/8" screws - double oven feet included with

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

NOTE: Refer to the following “Location Requirements” and the

“Location Requirements” section of the Installation Instructions

provided with your built-in oven.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions provide minimum clearance with oven.

■ Recessed installation area must provide complete enclosure

around the recessed portion of the oven.

■ Oven support surface must be solid, level, and ush with

bottom of cabinet cutout.

■ Floor must be able to support a single oven weight of

129lbs (59 kg) for 27" (68.6 cm) models or 154 lbs (70 kg)

for30"76.2 cm) models.

■ Floor must be able to support a double oven weight of

251lbs (114 kg) for 27" (68.6 cm) models or 288 lbs (131 kg)

for 30" (76.2 cm) models.

IMPORTANT: To avoid damage to your cabinets, check with

your builder or cabinet supplier to make sure that the materials

used will not discolor, delaminate, or sustain other damage. This

oven has been designed in accordance with the requirements

of UL and CSA International and complies with the maximum

allowable wood cabinet temperatures of 194°F (90°C).

■ Plastic spacers - (2) single ovens, (4) double ovens

■ #8-18 x

(76.2 cm) models

2

1

/8" screws - (2) for 27" (68.6 cm) models), (4) for 30"

Deflector Bracket Dimensions

AA

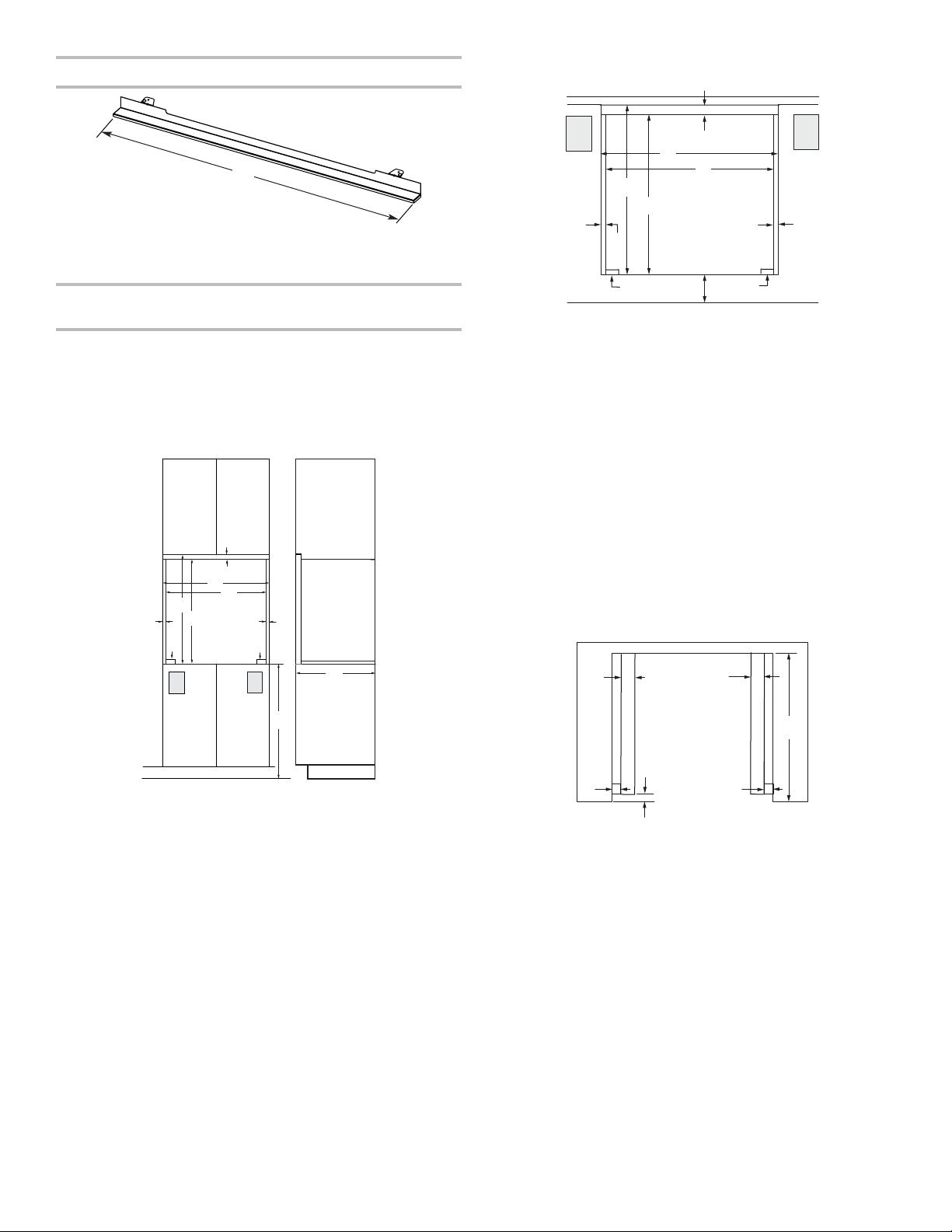

Single Ovens Undercounter - Flush Installations

(without cooktop installed above)

A

27" (68.6 cm) Models

A. 2615/16" (68.4 cm) overall width

30" (76.2 cm) Models

15

A. 29

/16" (76.0 cm) overall width

Cabinet Dimensions - Single Ovens,

Flush Installations

A 25" (63.5 cm) minimum cutout depth is required.

These dimensions will result in a 1/4" (6 mm) reveal on the top,

a1/4" (6 mm) reveal on the sides, and a 1/8" (3 mm) reveal on

thebottom of the wall oven.

The front face of the cleats and platform will be visible and

should be treated as a nished surface.

Single Ovens Installed in Cabinet - Flush Installation

A

B

C

D

E

F

G

F

G

A

B

A

C

D

E

F

G

G

H

Front View

27" (68.6 cm) Models

A. Recommended junction box

location

3

B.

/4" (19 mm) top cleat*

1

C. 27

/4" (69.2 cm) minimum

width of ush inset cutout

7

D. 25

/8" (65.7 cm) minimum

width of opening

1

E. 29

/4" (74.3 cm) minimum

height of ush inset cutout

2

F. 28¹/

" (72.4 cm)

recommended cutout height

5

G.

/8" (17 mm) side cleat*

1

H.

/2" x 2" (13 mm x 51 mm)

spacer the entire depth of

the cabinet*

5

I. 4

/8" (11.7 cm) bottom of

cutout to oor

* Cleats and spacers must be recessed 13/8" (3.5 cm) from the

front of the cabinet.

H

I

30" (76.2 cm) Models

A. Recommended junction box

location

3

B.

/4" (19 mm) top cleat*

4

C. 30¹/

" (76.8 cm) minimum

width of ush inset cutout

7

D. 28

/8" (73.3 cm) minimum

width of opening

1

E. 29

/4" (74.3 cm) minimum

height of ush inset cutout

1

F. 28

/2" (72.4 cm)

recommended cutout height

11

G.

/16" (17 mm) side cleat*

1

H.

/2" x 2" (13 mm x 51 mm)

spacer the entire depth of

the cabinet*

5

I. 4

/8" (11.7 cm) bottom of

cutout to oor

H

H

Front View Side View

27" (68.6 cm) Models

3

A.

/4" (19 mm) top cleat*

1

B. 27

/4" (69.2 cm) minimum

width of ush inset cutout

7

C. 25

/8" (65.7 cm) minimum

width of opening

1

D. 29

/4" (74.3 cm) minimum

height of ush inset cutout

1

E. 28

/2" (72.4 cm)

recommended cutout height

11

F.

/16" (17 mm) side cleat*

1

G.

/2" x 2" (13 mm x 50.8 mm)

spacer the entire depth of the

cutout*

H. Recommended junction box

location

5

I. 4

/8" - 32" (11.7 cm -

81.3cm) bottom of cutout to

oor

J. 25" (63.5 cm) minimum depth

of cutout

J

I

30" (76.2 cm) Models

3

A.

/4" (19 mm) top cleat*

1

B. 30

/4" (76.8 cm) minimum

width of ush inset cutout

7

C. 28

/8" (73.3 cm) minimum

width of opening

1

D. 29

/4" (74.3 cm) minimum

height of ush inset cutout

1

E. 28

/2" (72.4 cm)

recommended cutout height

11

F.

/16" (17 mm) side cleat*

1

G.

/2" x 2" (13 mm x 51 mm)

spacer the entire depth of

the cutout*

H. Recommended junction box

location

5

I. 4

/8" - 32" (11.7 cm -

81.3cm) bottom of cutout

to oor

J. 25" (63.5 cm) minimum

depth of cutout

B

C

D

D

Top View

27" (68.6 cm) Models

1

A.

/2" x 2" (13 mm x 51 mm)

spacer the entire depth of

the cutout*

B. 25" (63.5 cm) depth of

cutout

3

C. 1

/8" (3.5 cm) recess from

front of cabinet

11

D.

/16" (17 mm) side cleat*

30" (76.2 cm) Models

1

A.

/2" x 2" (13 mm x 51 mm)

spacer the entire depth of

the cutout*

B. 25" (63.5 cm) depth of

cutout

3

C. 1

/8" (3.5 cm) recess from

front of cabinet

11

D.

/16" (17 mm) side cleat*

* Cleats and spacers must be recessed 13/8" (3.5 cm) from

thefront of the cabinet.

* Cleats and spacers must be recessed 13/8" (3.5 cm) from the

front of the cabinet.

3

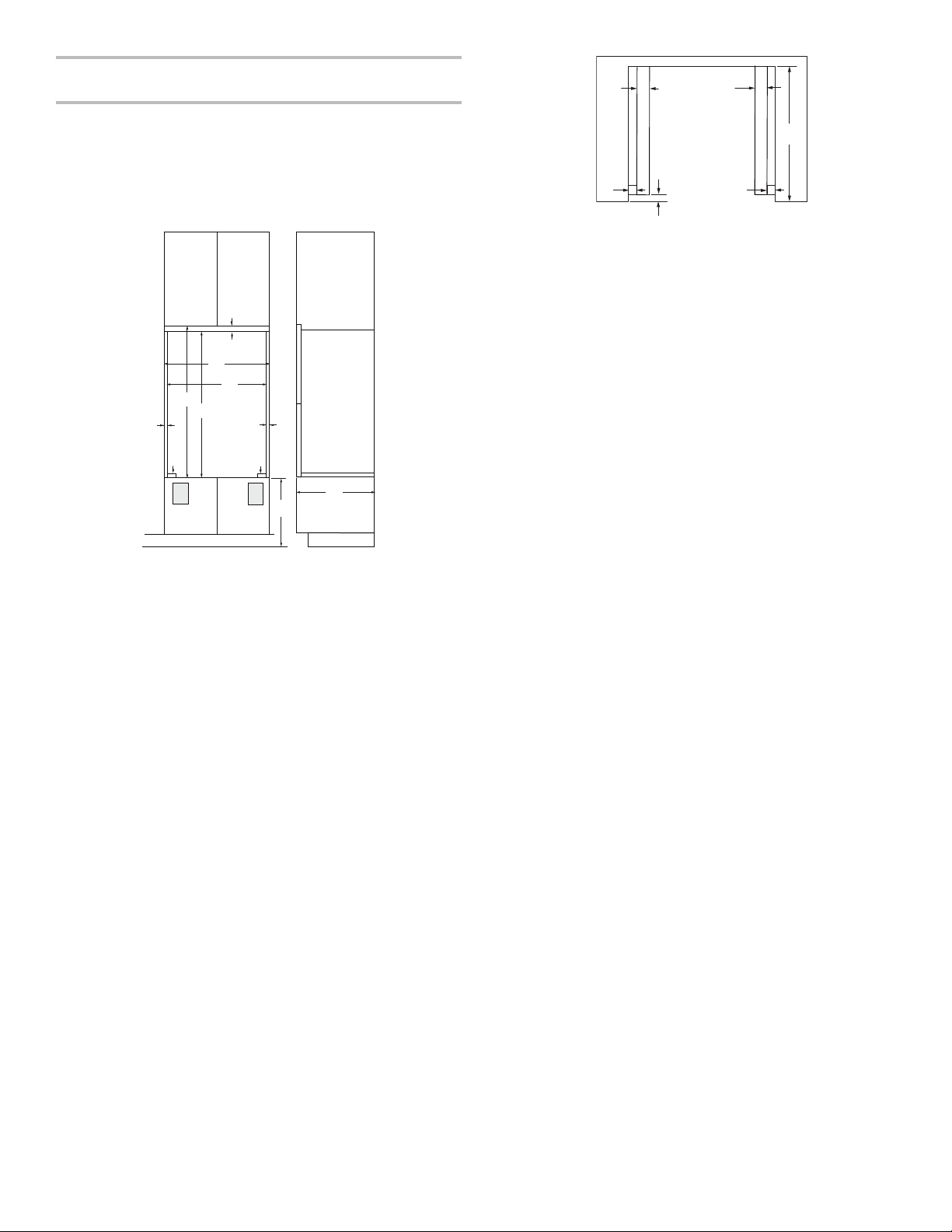

Cabinet Dimensions - Double Ovens,

AA

Flush Installations

A 253/8" (64.4 cm) minimum cutout depth is required.

These dimensions will result in a 1/4" (6 mm) reveal on the top,

a1/4" (6 mm) reveal on the sides, and a 1/8" (3 mm) reveal on

thebottom of the wall oven.

The front face of the cleats and platform will be visible and

should be treated as a nished surface.

Double Ovens Installed in Cabinet - Flush Installations

A

B

C

D

F

E

F

G G

B

C

D

D

Top View

27" (68.6 cm) Models

1

A.

/2" x 2" (13 mm x 51 mm)

spacer the entire depth of

the cutout*

3

B. 25

/8" (64.4 cm) depth of

cutout

3

C. 1

/8" (3.5 cm) recess from

front of cabinet

11

D.

/16" (17 mm) side cleat*

30" (76.2 cm) Models

1

A.

/2" x 2" (13 mm x 51 mm)

spacer the entire depth of

the cutout*

3

B. 25

/8" (64.4 cm) depth of

cutout

3

C. 1

/8" (3.5 cm) recess from

front of cabinet

11

D.

/16" (17 mm) side cleat*

* Cleats and spacers must be recessed 13/8" (3.5 cm) from the

front of the cabinet.

H

H

J

I

Front View Side View

27" (68.6 cm) Models

9

A.

/16" (14 mm) top cleat*

1

B. 27

/4" (69.2 cm) minimum

width of ush inset cutout

7

C. 25

/8" (65.7 cm) minimum

width of opening

D. 52" (132.1 cm) minimum

height of ush inset cutout

7

E. 51

/16" (130.6 cm)

recommended cutout height

11

F.

/16" (17 mm) side cleat*

1

G.

/2" x 2" (1.3 cm x 5.1 cm)

spacer the entire depth of

the cutout*

H. Recommended junction box

location

5

I. 4

/8" - 143/4" (11.7 cm-

37.5cm) bottom of cutout to

oor

3

J. 25

/8" (64.4 cm) minimum

depth of cutout

30" (76.2 cm) Models

9

A.

/16" (14 mm) top cleat*

1

B. 30

/4" (76.8 cm) minimum

width of ush inset cutout

7

C. 28

/8" (73.3 cm) minimum

width of opening

D. 52" (132.1 cm) minimum

height of ush inset cutout

7

E. 51

/16" (130.6 cm)

recommended cutout height

11

F.

/16" (17 mm) side cleat*

1

G.

/2" x 2" (1.3 cm x 5.1 cm)

spacer the entire depth of

the cutout*

H. Recommended junction box

location

5

I. 4

/8" - 143/4" (11.7 cm-

37.5cm) bottom of cutout to

oor

3

J. 25

/8" (64.4 cm) minimum

depth of cutout

* Cleats and spacers must be recessed 13/8" (3.5 cm) from the

front of the cabinet.

4

INSTALLATION INSTRUCTIONS

Locked

Prepare Built-In Oven

NOTES:

■ Refer to the following “Installation Instructions” and

the “Installation Instructions” section of the Installation

Instructions provided with your built-in oven.

■ Refer and adhere to the “Electrical Requirements”

section,and complete the instructions in the “Make

Electrical Connection” section of the Installation

Instructionsprovidedwith your built-in oven.

1. Decide on the nal location for the oven. Avoid drilling

orcutting into house wiring during installation.

WARNING

Excessive Weight Hazard

Use two or more people to move and install oven.

Failure to do so can result in back or other injury.

2. To avoid oor damage, set the oven onto cardboard prior

to installation. Do not use handle or any portion of the front

frame for lifting.

3. Remove the shipping materials and tape from the oven.

Remember to keep the corner posts and other materials

thatmay be needed for installation.

4. Remove the hardware package from inside the bag

containing literature.

5. Move oven and cardboard close to the oven’s nal location.

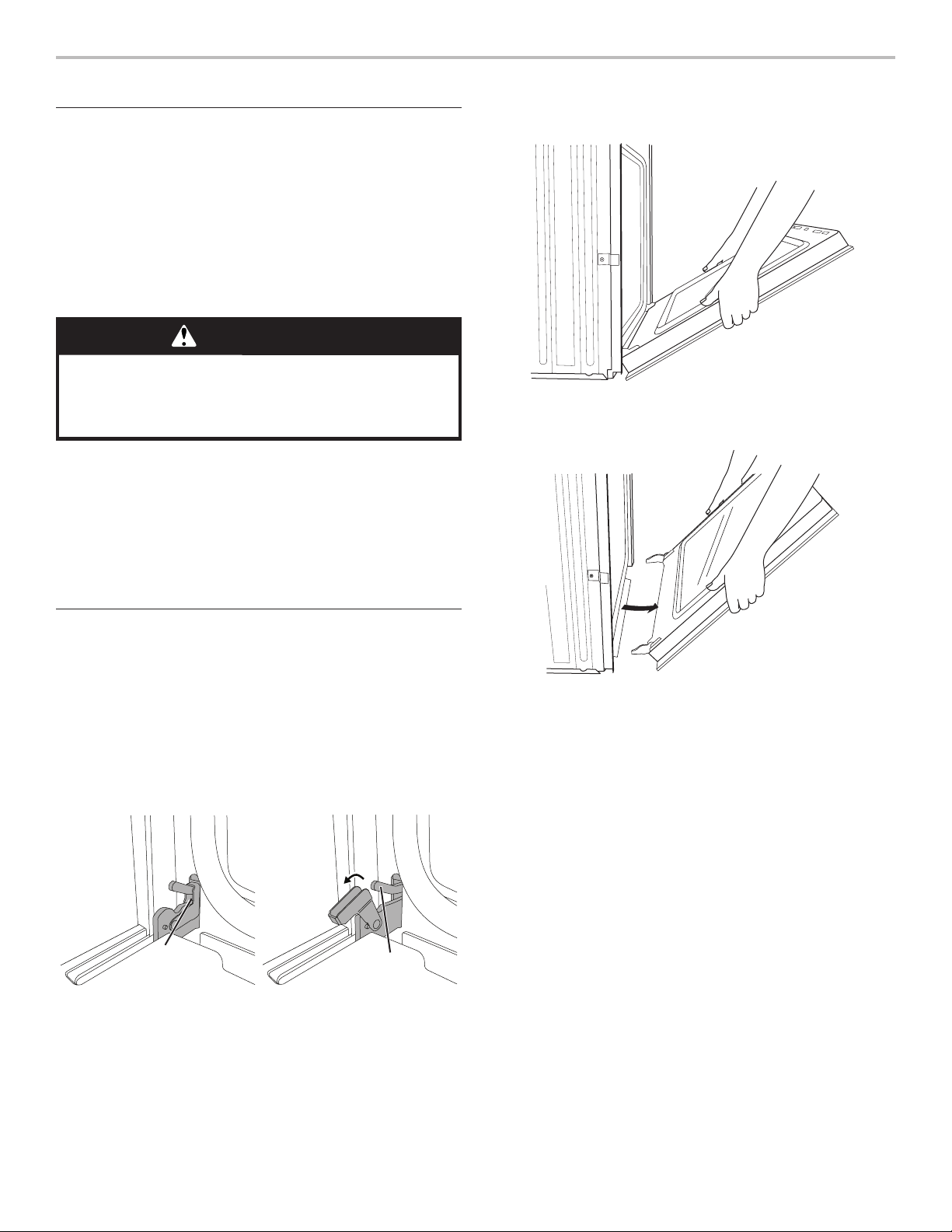

4. Partially close the door to engage the door latch locks. The

door will stop at this point.

5. Using two hands, grasp the edges of the oven door. Lift and

pull the oven door toward you, and remove. You may need to

gently shift door from side to side as you pull.

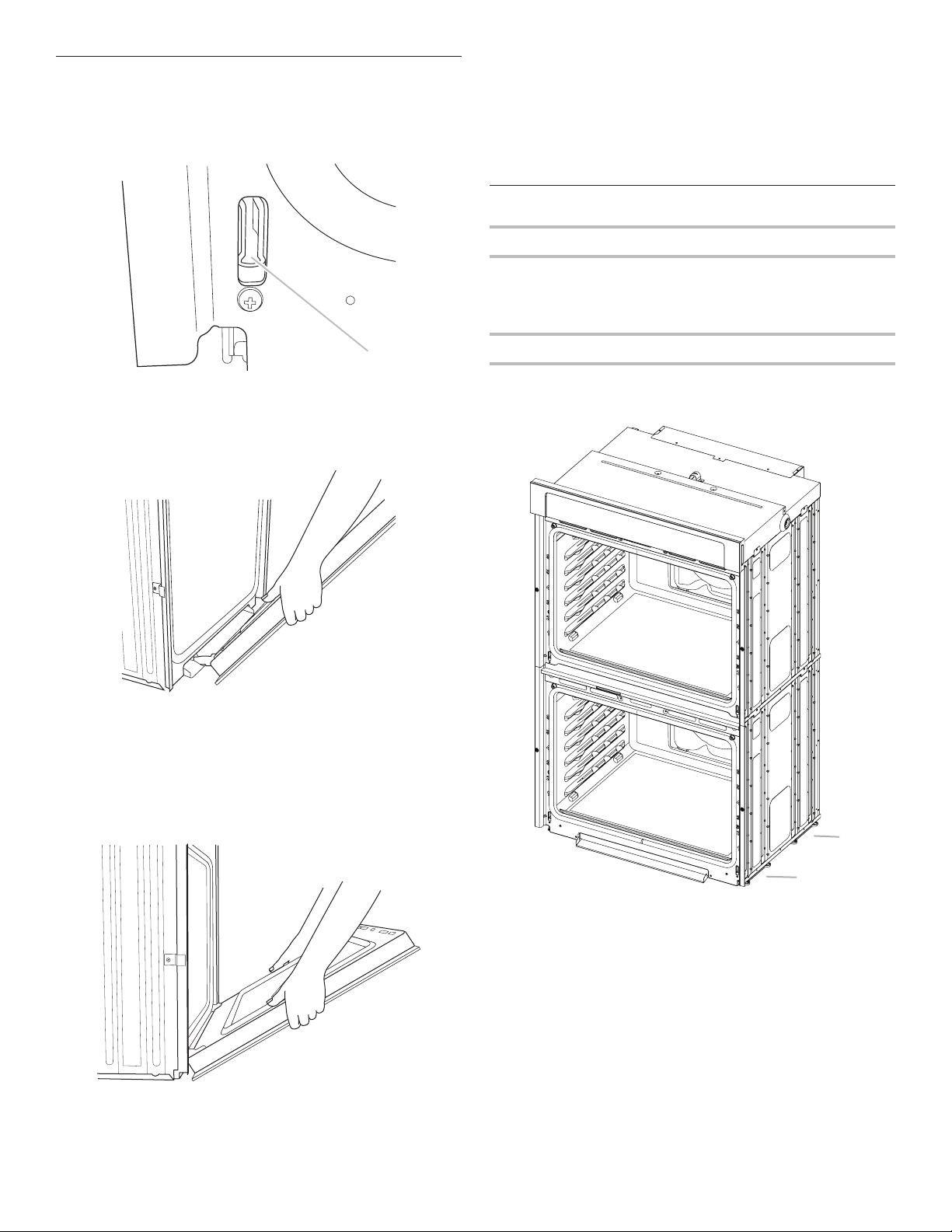

Remove Oven Door(s)

IMPORTANT: Use two hands to remove oven door(s).

1. Prior to removing the oven door, prepare a surface where

you will place it. This surface should be at and covered with

a soft blanket, or use the corner posts from your packaging

material.

2. Open the oven door.

3. Locate the oven door hinge locks in both corners of the oven

door, and rotate the hinge locks toward the oven door to the

unlocked position. If the door hinge lock is not rotated fully

(see illustration B), the door will not remove properly.

position

Grip here

to rotate.

A Oven door hinge lock

in locked position

Unlocked

position

Soft close hinge

arm on select models

B. Oven door hinge lock in

partially unlocked position

6. Set the oven door(s) aside on the prepared covered work

surface with the oven door resting on its handle.

7. To continue with the oven installation, go to the “Positioning

Oven Feet” section.

5

Replace Oven Door(s)

A

A

1. Using two hands, grasp side edges of door at the midpoint.

Face the oven cavity.

2. Locate the slots on each side of the oven cavity for the door

hinge locks.

6. Close the oven door.

7. When the hinges are properly installed and the door closed,

there should be an even gap between the door and the

control panel. If one side of the oven door is hanging lower

than the other, the hinge on that side is not properly installed.

Repeat the steps to remove, then replace the oven door. See

the “Remove Oven Door(s)” and “Replace Oven Door(s).”

sections.

Positioning Oven Feet

Single Ovens

The positioning of the oven feet allows a single oven to be

installed in a recommended cutout height of 281/2" (72.4 cm).

Go to the “Make Electrical Connection” section in the Installation

Instructions provided with your built-in oven.

A

A. Slot in the oven cavity for door hinge lock

3. At a 45° angle, align door hinges with slots in the lower

frontof the oven cavity. Slowly insert door, making sure you

maintain the 45° angle. You will know the door is engaged

inthe slot when you feel a slight drop.

4. Lower the oven door to the fully open position. If the oven

door does not open to a full 90 degrees, repeat steps 1

through 3.

5. Locate the oven door hinge locks in the corners of the oven

door, and rotate the hinge locks toward the oven cavity to

the locked position.

See Step 3 (illustration A) in the “Remove Oven Door(s)”

section for proper locked position.

Double Ovens

The oven feet need to be installed to allow a double oven to be

installed in a recommended cutout height of 517/16" (130.6 cm).

NOTE: Do not remove the spacers.

A. Spacers

6

Loading...

Loading...