Whirlpool WFM18, WFD18 Installation Instructions

80% SINGLE-STAGE MULTISPEED GAS FURNACE

INSTALLATION INSTRUCTIONS

Table of Contents

GAS FURNACE SAFETY................................................................2

INSTALLATION REQUIREMENTS................................................4

Tools and Parts ............................................................................4

Electrostatic Discharge (ESD)......................................................4

Location Requirements................................................................4

Installation Configurations ...........................................................7

Ductwork Requirements ..............................................................8

Electrical Requirements ...............................................................8

Gas Supply Requirements...........................................................9

Venting Requirements..................................................................9

INSTALLATION INSTRUCTIONS................................................10

Inspect Shipment.......................................................................10

Plan Vent System.......................................................................10

Install Ductwork..........................................................................14

Filter Specifications....................................................................15

Make Electrical Connections .....................................................16

115-Volt Line Connection of Accessories—

Electronic Air Cleaner.................................................................18

Make Gas Connections..............................................................18

Start-Up Procedure and Adjustment.........................................22

Complete Installation..................................................................26

Furnace Shutdown.....................................................................26

SEQUENCE OF OPERATION ......................................................27

Power Up....................................................................................27

Heating Mode—Mode DIP Switch Set to 1 STG Position.........27

Heating Mode—Mode DIP Switch Set to 2 STG Position.........27

Cooling Mode.............................................................................27

Fan Only Mode...........................................................................27

OPERATIONAL CHECKS.............................................................28

Burner Flame ..............................................................................28

Auxiliary Limit Control ................................................................28

Circulator Blower Speed ............................................................28

MAINTENANCE ............................................................................31

Annual Inspection.......................................................................31

Filters ..........................................................................................31

TROUBLESHOOTING ..................................................................32

Resetting from Lockout..............................................................34

ASSISTANCE OR SERVICE.........................................................36

Accessories ................................................................................36

ATTENTION INSTALLATION PERSONNEL

As a professional installer, you have an obligation to know the product better than the customer. This includes all

safety precautions and related items. Prior to actual installation, thoroughly familiarize yourself with this instruction

manual. Pay special attention to all safety warnings. Often during installation or repair, it is possible to place

yourself in a position which is more hazardous than when the unit is in operations.

Remember, it is your responsibility to install the product safely and to know it well enough to be able to instruct a

customer in its safe use. Safety is a matter of common sense...a matter of thinking before acting. Most dealers have

a list of specific good safety practices...follow them.

The precautions listed in this installation manual are intended as supplemental to existing practices. However, if

there is a direct conflict between existing practices and the content of this manual, the precautions listed here take

precedence.

Placeholder

Whirlpool® Model

WFM18, WFD18

WPIO-359B

Whirlpool® Home Cooling and Heating

14610 Breakers Drive

Jacksonville, Florida 32258

GAS FURNACE SAFETY

Recognize this symbol as a safety precaution.

Please adhere to the following warnings and cautions when installing, adjusting, altering, servicing or operating the furnace.

WARNING

Hazards or unsafe practices could result in property

damage, product damage, severe personal injury or death.

Goodman 1

CAUTION

Hazards or unsafe practices may result in property

damage, product damage, personal injury or death.

IMPORTANT SAFETY INSTRUCTIONS

Use only with type of gas approved for this furnace.

■

Refer to the furnace rating plate.

Install this furnace only in a location and position

■

as specified in the “Location Requirements” section

of these instructions.

Provide adequate combustion and ventilation air to

■

the furnace space as specified in the “Venting

Requirements” section of these instructions.

■

Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system

only, as specified in the “Venting Requirements”

section of these instructions.

Never test for gas leaks with an open flame. Use a

■

commercially available soap solution made

specifically for the detection of leaks to check all

connections, as specified in the “Make Gas

Connections” section of these instructions.

Adequate clearance must be provided around the

■

vent-air intake terminals.

ANSI Box Install G 2009 in Goodman Folder

CAUTION

Hazards or unsafe practices may result in property

or product damage.

Always install furnace to operate within the furnace’s

■

intended temperature-rise range with a duct system

which has an external static pressure within the

allowable range, as specified in the “Complete

Installation” section of these instructions. See

furnace rating plate.

■

When a furnace is installed so that supply ducts

carry air circulated by the furnace to areas outside

the space containing the furnace, the return air

shall also be handled by duct(s) sealed to the

furnace casing and terminating outside the space

containing the furnace.

A gas-fired furnace for installation in a residential

■

garage must be installed as specified in the

“Location Requirements” section of these

instructions.

The furnace shall be installed so the electrical

■

components are protected from water.

■ Furnaces for indoor installation on combustible

flooring shall not be installed directly on carpeting,

tile or other combustible material other than wood

flooring.

Goodman 9

SAVE THESE INSTRUCTIONS

To the Installer

Before installing this unit, please read this manual thoroughly to familiarize yourself with specific items which must be adhered to,

including but not limited to: unit maximum external static pressure, gas pressures, Btu imput rating, proper electrical connections,

circulating air temperature rise, minimum or maximum CFM and motor speed connections and venting. These furnaces are designed

for Category I venting only.

2

WARNING

WARNING

If the information in these instructions is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

Goodman 42

DANGER

CARBON MONOXIDE POISONING HAZARD

Special Warning for Installation of Furnace or Air Handling

Units in Enclosed Areas such as Garages, Utility Rooms or

Parking Areas.

Possible property damage, personal injury or death due

to fire, explosion, smoke, soot, condensation, electrical

shock or carbon monoxide may result from improper

installation, repair, operation or maintenance of this

product.

WARNING

To prevent property damage, personal injury or death due

to fire, do not install the furnace in a mobile home, trailer

or recreational vehicle.

WARNING

To prevent personal injury or death due to improper

installation, adjustment, alteration,

refer to this manual. For additional assistance or

information, consult a qualified installer, service agency

or the gas supplier.

Goodman 44

service

or

maintenance,

WARNING

This product contains or produces a chemical or

chemicals which may cause serious illness or death and

which are known to the State of California to cause

cancer, birth defects or other reproductive harm.

Goodman 45

WARNING

Carbon monoxide producing devices (such as an

automobile, space heater, gas water heater, etc.) should

not be operated in enclosed areas such as unventilated

garages, utility rooms or parking areas because of the

danger of carbon monoxide (CO) poisoning resulting from

the exhaust emissions. If a furnace or air handler is

installed in an enclosed area such as a garage, utility room

or parking area and a carbon monoxide producing device is

operated therein, there must be adequate, direct outside

ventilation.

This ventilation is necessary to avoid the danger of CO

poisoning which can occur if a carbon monoxide producing

device continues to operate in the enclosed area. Carbon

monoxide emissions can be (re)circulated throughout the

structure if the furnace or air handler is operating in any

mode.

CO can cause serious illness including permanent brain

damage or death.

Goodman 38

WARNING

Should overheating occur or the gas supply fail to shut

off, turn off the manual gas shutoff valve external to the

furnace before turning off the electrical supply.

Goodman 43

To prevent possible personal injury or death due to

asphyxiation, this furnace must be Category I vented.

Do not vent using Category III venting.

Provisions must be made for venting combustion

products outdoors through a proper venting system.

The length of flue pipe could be a limiting factor in

locating the furnace.

Goodman 66

WARNING

To prevent possible property damage, personal injury or

death due to electrical shock, the furnace must be located

to protect the electrical components from water.

Goodman 46

3

WARNING

Heating unit should not be utilized without reasonable,

routine inspection, maintenance and supervision. If the

building in which any such device is located will be

vacant, care should be taken that such device is

routinely inspected, maintained and monitored. In the

event that the building may be exposed to freezing

temperatures and will be vacant, all water-bearing pipes

should be drained, the building should be properly

winterized and the water source closed. In the event

that the building may be exposed to freezing

temperatures and will be vacant, any hydronic coil units

should be drained as well, and, in such case, alternative

heat sources should be utilized.

Goodman 47

INSTALLATION REQUIREMENTS

These instructions are intended as a general guide only for use by

qualified persons and do not supersede any national or local

codes in any way. Compliance with all local, state, or national

codes pertaining to this type of equipment should be determined

prior to installation.

Read this entire instruction manual, as well as the instructions

supplied in separate equipment, before starting the installation.

The installation of the furnace, wiring, warm air ducts, venting,

etc., must conform to the requirements of the National Fire

Protection Association; the National Fuel Gas Code, ANSI

Z223.1/NFPA No. 54 (latest edition) and the National Electrical

Code, ANSI/NFPA No. 70 (latest edition) in the United States, and

any state laws, local ordinances (including plumbing or

wastewater codes), or local gas utility requirements.

Local authorities having jurisdiction should be consulted before

installation is made. Such applicable regulations or requirements

take precedence over the general instructions in this manual.

This furnace design is certified by CSA International as a

Category I furnace in compliance with the latest edition of

American National Standard Z21.47/CSA Standard 2.3 for GasFired Central Furnaces, for operation with Natural gas or

propane. Consult the rating plate on the furnace for gas type

before installing.

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Too ls n eeded

■ Pipe wrench

■ Screwdriver

■ Tape measure

■ Thread sealant

■ Level

Parts needed

Check local codes and with gas supplier. Check existing gas

supply, electrical supply, and venting, and read “Ductwork

Requirements,” “Electrical Requirements,” “Gas Supply

Requirements” and “Venting Requirements” before purchasing

parts.

■ Noncorrosive leak check solution

■ Test g auge wi th ¹⁄₈" NPT connection

(for measuring gas supply pressure)

■ Allen wrench

Additional Safety Considerations

■ This furnace is approved for Category I venting only.

■ Provisions must be made for venting combustion products

outdoors through a proper venting system. The length of the

flue pipe could be a limiting factor in locating the furnace.

Electrostatic Discharge (ESD)

NOTE: Discharge static electricity accumulated in the body

before touching the unit. An electrostatic discharge can adversely

affect electrical components.

Use the following steps during furnace installations and servicing

to avoid damage to the integrated control module. By putting the

furnace, the control and the person at the same electrostatic

potential, these steps will help avoid exposing the integrated

control module to electrostatic discharge. This procedure is

applicable to both installed and non installed (ungrounded)

furnaces.

1. Disconnect all power to the furnace. Do not touch the

integrated control module or any wire connected to the

control prior to discharging your body’s electrostatic charge

to ground.

2. Firmly touch a clean, unpainted, metal surface of the furnace

near the control. Any tools held in a person’s hand during

grounding will be discharged also.

3. Service the integrated control module or connect wiring after

following the discharge process in Step 2.

NOTE: Do not recharge your body with static electricity by

moving or shuffling your feet or touching ungrounded

objects. Repeat Step 2 if you touch an ungrounded object.

4. Follow steps 1 through 3 before removing a new control from

its container or installing the control on a furnace. Return any

old or new controls to their containers before touching any

ungrounded object.

Location Requirements

This furnace is primarily designed for residential home-heating

applications. It is not designed or certified for use in mobile

homes, trailers or recreational vehicles. Neither is it designed or

certified for outdoor applications. The furnace must be installed

indoors (for example: attic space, crawl space or garage area

provided the garage area is enclosed with an operating door).

4

This furnace can be used in the following non-industrial

commercial applications:

■ Schools

■ Office buildings

■ Churches

■ Retail stores

■ Nursing homes

■ Hotels/motels

■ Common or office areas

WARNING

To prevent property damage, personal injury or death due

to fire, do not install the furnace in a mobile home, trailer

or recreational vehicle.

In such applications , the furnace must be installed with the

following stipulations:

■ It must be installed according to the installation instructions

provided and according to local and national codes.

■ It must be installed indoors in a building constructed on site.

■ It must be part of a ducted system and not used in a free air

delivery application.

■ It must not be used as a “makeup” air unit.

■ All other warranty exclusions and restrictions apply.

This furnace may be used as a construction site heater only if the

following conditions are met:

■ The vent system is permanently installed according to these

installation instructions.

■ A room thermostat is used to control the furnace. Fixed

jumpers that provide continuous heating cannot be used.

■ Return air ducts are provided and sealed to the furnace.

■ A return air temperature range between 60ºF (16ºC) and 80ºF

(27ºC) is maintained.

■ Air filters are installed in the system and maintained during

construction, replaced as appropriate during construction

and, upon completion of construction, are replaced.

■ The input rate and temperature rise are set according to the

furnace rating plate.

■ 100% outside air is provided for combustion air requirements

during construction. Temporary ducting can be used.

NOTE: Do not connect the temporary duct directly to the

furnace. The duct must be sized according to the instructions

under Section V, Combustion and Ventilation Air

Requirements, Section 5.3.3.

■ The furnace heat exchanger, components, duct system, air

filters and evaporator coils are thoroughly cleaned following

final construction cleanup.

■ All furnace operating conditions (including ignition, input rate,

temperature rise and venting) are verified according to these

installation instructions.

NOTE: The Commonwealth of Massachusetts requires that the

following additional requirements must also be met:

■ Gas furnaces must be installed by a licensed plumber or gas

fitter.

■ A T-handle gas cock must be used.

■ If the unit is to be installed in an attic, the passageway to and

the service area around the unit must have flooring.

To ensure proper installation and operation, thoroughly read this

manual for specifics pertaining to the installation and application

of this product.

To ensure proper furnace operation, install, operate and maintain

the furnace in accordance with these installation and operation

instructions, all local building codes and ordinances. In their

absence, follow the latest edition of the National Fuel Gas Code

(NFPA 54/ANSI Z223.1), and/or CAN/CSA B149 Installation

Codes, local plumbing or waste water codes, and other

applicable codes.

A copy of the National Fuel Gas Code (NFPA 54/ANSI Z223.1)

can be obtained from any of the following:

American National Standards Institute

1430 Broadway

New York, NY 10018

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley

Cleveland, OH 44131

A copy of the CAN/CSA B149 Installation Codes can also be

obtained from:

CSA International

178 Rexdale Boulevard

Etobicoke, Ontario, Canada M9W 1R3

The rated heating capacity of the furnace should be greater than

or equal to the total heat loss of the area to be heated. The total

heat loss should be calculated by an approved method or in

accordance with “ASHRAE Guide” or “Manual J-Load

Calculations” published by the Air Conditioning Contractors of

America.

In the U.S.A., this furnace must be installed in accordance with

the latest edition of the ANSI Z223.1 booklet entitled “National

Fuel Gas Code” (NFPA 54), and the requirements or codes of the

local utility or other authority having jurisdiction. In Canada, this

furnace must be installed in accordance with the current CAN/

CGA-B149.1 & 2 Gas Installation Codes, local plumbing or waste

water codes and other applicable codes. Additional helpful

publications available from the NFPA are, NFPA 90A—Installation

of Air Conditioning and Ventilating System and NFPA 90B—Warm

Air Heating and Air Conditioning System.

All venting shall be in accordance with PART 7, Venting of

Equipment, of the National Fuel Gas Code, ANSI Z223.1, or

applicable local building and/or air conditioning codes. These

publications are available from:

National Fire Protection Association, Inc.

1 Batterymarch Park,

Quincy, MA 02269

NOTE: Furnaces with NOx screens meet the California NOx

emission standards and California seasonal efficiency standards.

Annual inspections of the furnace and its vent system is strongly

recommended.

Your unit model type determines which installation procedures

must be used. For WFM18 models, you must follow instructions

for horizontal left, horizontal right or upflow installations only.

WFM18 furnaces are not approved for downflow installations.

WARNING

Possible property damage, personal injury or death due

to fire, explosion, smoke, soot, condensation, electrical

shock or carbon monoxide may result from improper

installation, repair, operation or maintenance of this

product.

Goodman 48

5

WARNING

To prevent possible equipment damage, property damage,

personal injury or death, the following bullet points must

be observed when installing the unit.

Follow the instructions listed below when selecting a furnace

location. Refer also to the guidelines provided in “Combustion

and Ventilation Air Requirements.”

■ Centrally locate the furnace with respect to the proposed or

existing air distribution system.

■ Check that the temperature of the return air entering the

furnace is between 55°F and 100°F (13ºC and 38ºC) when the

furnace is heating.

■ Provide provisions for venting combustion products outdoors

through a proper venting system. Special consideration

should be given to the vent/flue pipe routing and the

combustion air intake pipe when applicable. Refer to “Vent/

Flue Pipe and Combustion Air Pipe—Termination Locations”

for appropriate termination locations and to determine if the

piping system from the furnace to the termination can be

accomplished within the guidelines given.

NOTE: The length of flue and/or combustion air piping can be

a limiting factor in the location of the furnace.

■ Check that adequate combustion air is available for the

furnace. Improper or insufficient combustion air can expose

building occupants to gas combustion products that could

include carbon monoxide. Refer to “Combustion and

Ventilation Air Requirements.”

■ Set the furnace on a level floor to enable proper condensate

drainage. If the floor becomes wet or damp at times, place

the furnace above the floor on a concrete base sized

approximately 1¹⁄₂" (3.8 cm) larger than the base of the

furnace. Refer to “Horizontal Applications and

Considerations” for leveling of horizontal furnaces.

■ Check that the upflow or horizontal furnaces are not installed

directly on carpeting, or any other combustible material.

NOTE: The only combustible material allowed is wood.

■ Exposure to contaminated combustion air will result in safety

and performance-related problems.

NOTE: Do not install the furnace where the combustion air is

exposed to the following substances:

Chlorinated waxes or cleaners

Chlorine-based swimming pool chemicals

Water softening chemicals

Deicing salts or chemicals

Carbon tetrachloride

Halogen-type refrigerants

Cleaning solutions (such as perchloroethylene)

Printing inks

Paint removers

Var nishes

Hydrochloric acid

Cements and glues

Antistatic fabric softeners for clothes dryers

Masonry acid washing materials

Goodman 50

■ If the furnace is used in connection with a cooling unit, install

the furnace upstream or in parallel with the cooling unit.

Premature heat exchanger failure will result if the cooling unit

is placed ahead of the furnace.

■ If the furnace is installed in a residential garage, position the

furnace so that the burners and ignition source are located

not less than 18" (45.7 cm) above the floor. Protect the

furnace from physical damage by vehicles.

■ If the furnace is installed horizontally, the furnace access

doors must be vertical so that the burners fire horizontally

into the heat exchanger.

NOTE: Do not install the unit with the access doors on the

“up/top” or “down/bottom” side of the furnace.

■ Do not connect this furnace to a chimney flue that serves a

separate appliance designed to burn solid fuel.

■ Counterflow installation over a noncombustible floor—Before

setting the furnace over the plenum opening, check that the

surface around the opening is smooth and level. A tight seal

should be made between the furnace base and floor by using

a silicon rubber caulking compound or cement grout.

■ Counterflow installation over a combustible floor—If

installation over a combustible floor becomes necessary, use

an accessory subbase (see Specification Sheet applicable to

your model for details). A special accessory subbase must be

used for upright counterflow unit installations over any

combustible material including wood. Follow the instructions

with the subbase for proper installations.

NOTES:

■ Do not install the furnace directly on carpeting, tile or

other combustible material other than wood flooring.

■ The subbase will not be required if an air conditioning coil

is installed between the supply air opening on the furnace

and the floor.

■ Adequate combustion/ventilation air must be supplied to the

closet or enclosure.

■ Furnace must be completely sealed to the floor or base.

Combustion/ventilation air supply pipes must terminate 12"

(30.5 cm) from the top of the closet or enclosure and 12"

(30.5 cm) from the floor of the closet or enclosure.

NOTE: Do not remove the solid base plate for the side return.

■ Return air ducts must be completely sealed to the furnace

and terminate outside the enclosure surfaces.

6

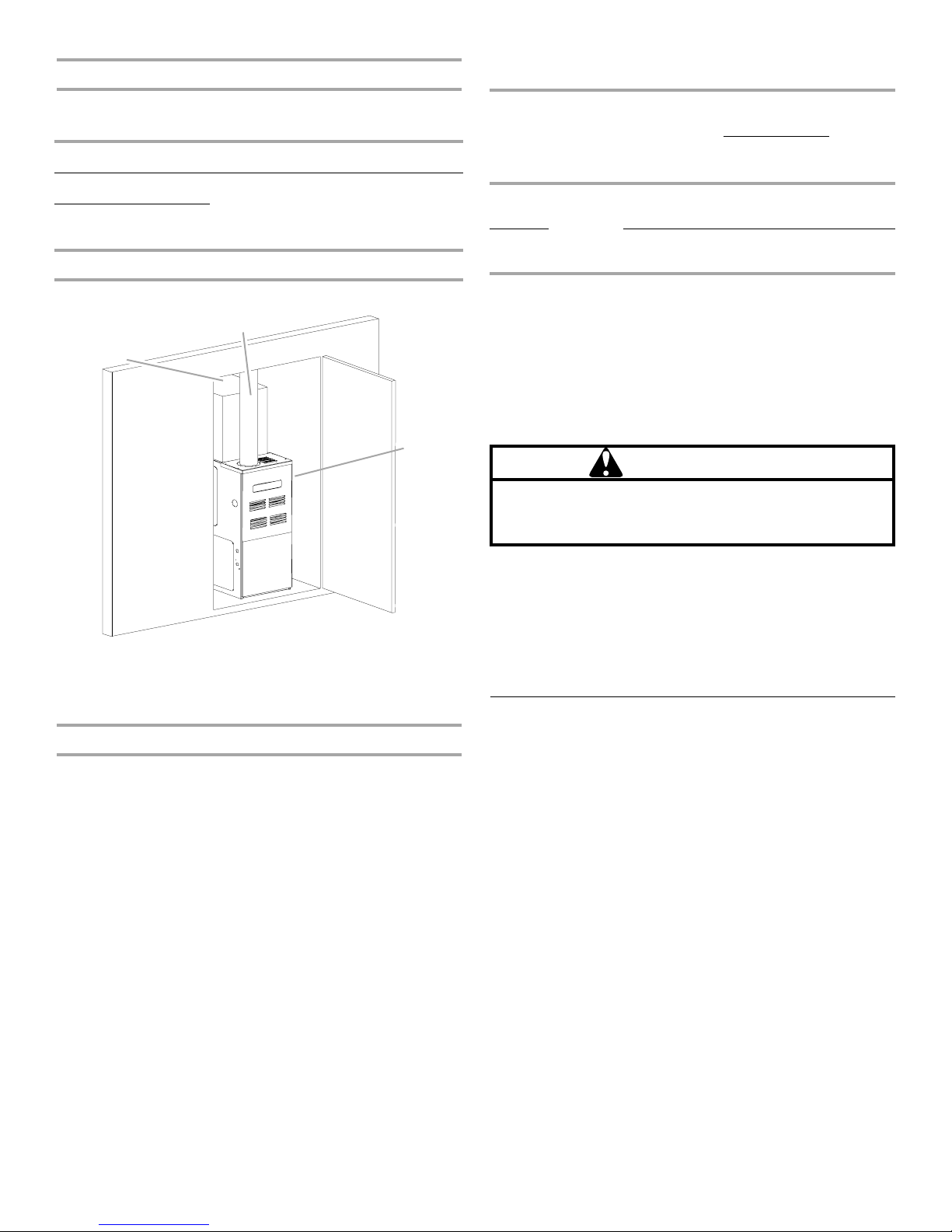

Installation Clearances and Accessibility

D

For installations above 7,000 ft (2,133.6 m), refer to your local

distributor for required kit(s).

Unobstructed front clearance of 24" (61 cm) for servicing is

recommended.

Clearances to Combustibles—in. (cm)

Vent Pipe

B1-Vent Single Wall

Connector Sides Front Back Top (Plenum)

1 (2.5) 6 (15.2) 1 (2.4) 3 (7.6) 0 1 (2.5)

NOTE: Top clearance for horizontal configuration is 1" (2.5 cm).

B

A

C

Manifold

Pressure

Pressure

High

Stage

Natural

0 to

Propane LPM-

NOTE: In Canada, gas furnaces are only certified to 4,500 ft

(1,371.6 m).

Contact your local distributor for a tabular listing of appropriate

manufacturer’s kits for propane gas and/or high altitude

installations. The indicated kits must be used to insure proper

furnace operation. All conversions must be performed by a

qualified installer or service agency.

7,000 ft

(2,133.6 m)

None #43 3.5"

W.C.

#55 10.0"

03B

W.C.

Low

Stage

1.9"

W.C.

6.0"

W.C.

Switch

ChangeGas Altitude Kit Orifice

None

None

Propane Gas Conversion

WARNING

Failure to follow these instructions can result in bodily

injury or death. Carefully read and follow all instructions

given in this section.

Goodman 53

E

A. Top clearance—1" (2.5 cm)

B. Vent pipe clearance—6" (15.2 cm)

for single wall connector, 1"

(2.5 cm) for B-1 vent

C. Back clearance—0"

D. Side clearance—1" (2.5 cm)

E. Front clearance—3" (7.6 cm)

High Altitude Installations

High Altitude Derate

IMPORTANT: The furnace will naturally derate itself with altitude.

Do not attempt to increase the firing rate by changing orifices or

increasing the manifold pressure. This can cause poor

combustion and equipment failure.

High altitude installations may require both a pressure switch and

an orifice change. These changes are necessary to compensate

for the natural reduction in the density of both the gas fuel and

the combustion air at higher altitude.

This unit is configured for Natural gas. The appropriate

manufacturer’s propane gas conversion kit must be applied for

propane gas installations.

Contact your local distributor for a tabular listing of appropriate

manufacturer’s kits for propane gas and/or high altitude

installations. The indicated kits must be used to insure safe and

proper furnace operation. All conversions must be performed by

a qualified installer or service agency.

Installation Configurations

Horizontal Installation

Line contact to framing is permitted when installed in the

horizontal configuration. Line contact is defined as the portion of

the cabinet that is formed by the intersection of the top and side.

IMPORTANT: Accessibility clearance, where greater, should take

precedence over minimum fire protection clearance.

A gas-fired furnace for installation in a residential garage must be

installed so that the ignition source and burners are located not

less than 18" (45.7 cm) above the floor and are protected or

located to prevent physical damage by vehicles.

A gas furnace must not be installed directly on carpeting, tile, or

other combustible materials other than wood flooring.

7

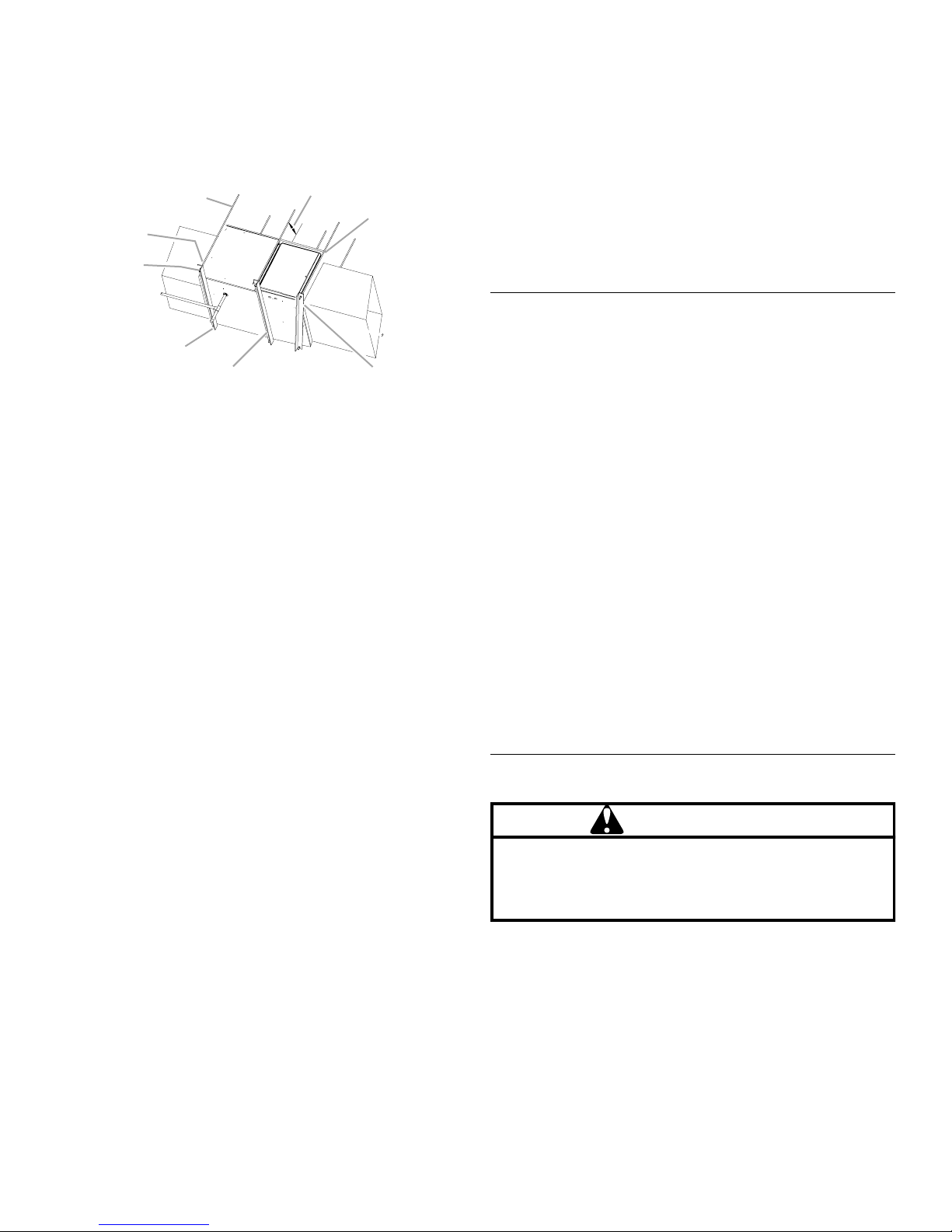

Furnace Suspension

If you are suspending the furnace from the rafters or joists, use a

³⁄₈" (1 cm) threaded rod and 2" x 2" x ³⁄₈" (5.1 cm x 5.1 cm x 1 cm)

angle iron as shown below. The length of the rod will depend on

the application and the clearances necessary.

Suspended Furnace

A

H

G

F

A.

³⁄₈

" (1 cm) diameter threaded

rod (6)

B. 8" (20.3 cm) minimum

clearance between center rod

and furnace cabinet to allow for

circulator blower removal.

C. Level furnace end to end, slight

forward tilt with front 0" to

(1.9 cm) below back.

³⁄₄

"

D. Tilt outward to allow for door and

E. Position as close as possible to

F. 2" x 2" x

G. Support nuts

H. Hold down nuts

B

C

DE

circulator blower removal.

blower deck to allow for circulator

blower removal.

1cm) angle iron (3)

³⁄₈

" (5.1 cm x 5.1 cm x

Existing Furnace Removal

NOTE: When an existing furnace is removed from a venting

system serving other appliances, the venting system may be too

large to properly vent the remaining attached appliances.

The following vent testing procedure is reproduced from the

American National Standard/National Standard of Canada for

Gas-Fired Central Furnaces ANSI Z21.47-Latest Edition, CSA-

2.3-Latest Edition Section 1.23.1. The following steps shall be

followed with each appliance connected to the venting system

placed in operation, while any other appliances connected to the

venting system are not in operation.

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required by the National Fuel Gas Code, ANSI

Z223.1 or the CAN/CSA B149 Installation Codes and these

instructions. Determine that there is no blockage or

restriction, leakage, corrosion and other deficiencies which

could cause an unsafe condition.

3. In so far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building. Turn on clothes dryers and any

appliance not connected to the venting system. Turn on any

exhaust fans, such as range hoods and bathroom exhausts,

so they shall operate at maximum speed. Do not operate a

summer exhaust fan. Close fireplace dampers.

4. Follow the lighting instructions. Place the appliance being

inspected in operation. Adjust thermostat so appliance shall

operate continuously.

5. Test for draft hood equipped appliance spillage at the draft

hood relief opening after 5 minutes of main burner operation.

Use the flame of a match or candle.

6. After it has been determined that each appliance connected

to the venting system properly vents when tested as outlined

above, return doors, windows, exhaust fans, fireplace

dampers and any other gas burning appliance to their

previous conditions of use.

7. If improper venting is observed during any of the above tests,

the common venting system must be corrected.

Corrections must be in accordance with the latest edition of the

National Fuel Gas Code NFPA 54/ANSI Z223.1 and/or CAN/CSA

B149 Installation Codes.

If resizing is required on any portion of the venting system, use

the appropriate table in Appendix G in the latest edition of the

National Fuel Gas Code ANSI Z223.1 and/or CAN/CSA B149

Installation Codes.

Ductwork Requirements

■ Install all conditioned air plenums, ducts and air filters (if not

provided on the furnace) in accordance with NFPA 90B

Standard for the Installation of Warm Air Heating and AirConditioning Systems (latest edition).

■ The furnace is provided with flanges for the connection of the

plenum and ducts.

■ All air filters must be listed as Class 2 furnace air filters.

■ All ductwork must be made of materials and insulated to

meet local, state and national codes. Ductwork installed

outdoors must be sealed, weatherproof and kept from

physical damage. Caulking, flashing or other means of

adequately providing a permanent weather seal should be

used where duct penetrates a building or structure opening.

■ A closed return duct system must be used with the return

duct connected to the furnace.

■ Do not attach ductwork to the back of the furnace.

■ Flexible joints may be used for supply and return connections

to reduce noise transmission.

■ A connecting duct must be installed between the furnace and

the utility room wall to keep the blower from interfering with

combustion air or draft when a central return is used.

■ Do not use a room, closet or alcove as a return air chamber.

■ For models with airflow over 1,800 CFM, install a bottom

return, 2 side returns or 1 side and 1 bottom return.

Electrical Requirements

WARNING

To avoid the risk of injury, electrical shock or death, the

furnace must be electrically grounded in accordance with

local codes or, in their absence, with the latest edition of the

National Electric Code (NEC).

■ The furnace must be grounded and wired in accordance with

local codes or, in the absence of local codes, with the

National Electrical Code ANSI/NFPA No. 70 (latest edition).

■ In all instances, other than wiring for the thermostat, the

wiring to be done and any replacement of wire shall conform

with the temperature limitation for Type T wire (63°F [17ºC]

rise).

8

■ The line voltage supply should be routed through a readily

accessible disconnect located within sight of the furnace. A

junction box on the furnace side panel is provided for line

voltage connections. See the Wiring Connection Diagram in

the “Troubleshooting” section for specific connection

information.

■ Proper polarity of the supply connections (“HOT” and

“NEUTRAL”) must be observed to be sure that the control

system provides the damage avoidance intended.

Existing Venting Systems

When an existing furnace is removed or replaced, the original

venting system may no longer be sized to properly vent the

attached appliances. An improperly sized venting system can

result in the spilling of flue products into the living space, the

formation of condensate, leakage, etc. See the “Carbon

Monoxide Poisoning Hazard” for proper test procedure.

Gas Supply Requirements

This unit is equipped for use with Natural gas. A conversion kit is

required for use with propane. To order the correct conversion kit,

see your local distributor.

■ Gas supply piping should be installed in accordance with

local, state and national codes and the regulations of the

utility. Piping must be of adequate size to prevent undue

pressure drop. Consult the local utility or gas supplier for

complete details on special requirements for sizing gas

piping.

■ If local codes allow the use of a flexible gas appliance

connector, use a CSA design-certified outdoor flexible

stainless steel appliance connector or rigid gas supply line as

needed.

Venting Requirements

WARNING

Goodman 51

To avoid property damage, personal injury or death,

sufficient fresh air for proper combustion and ventilation

of flue gases must be supplied. Most homes require

outside air be supplied into the furnace area.

Improved construction and additional insulation in buildings have

reduced heat loss by reducing air infiltration and escape around

doors and windows. These changes have helped in reducing

heating/cooling costs but have created a problem supplying

combustion and ventilation air for gas-fired and other fuel

burning appliances. Appliances that pull air out of the house

(clothes dryers, exhaust fans, fireplaces, etc.) increase the

problem by starving appliances for air.

House depressurization can cause back drafting or improper

combustion of gas-fired appliances, thereby exposing the

building occupants to gas combustion products that could

include carbon monoxide.

If this furnace is to be installed in the same space with other gas

appliances, such as a water heater, ensure there is an adequate

supply of combustion and ventilation air for the other appliances.

Refer to the latest edition of the National Fuel Gas Code NFPA

54/ ANSI Z223.1 (Section 5.3), or CAN/CSA B149 Installation

Codes (Sections 7.2, 7.3, or 7.4), or applicable provisions of the

local building codes for determining the combustion air

requirements for the appliances.

This furnace must use indoor air for combustion. It cannot be

installed as a direct vent (for example, sealed combustion)

furnace. Most homes will require outside air be supplied to the

furnace area by means of ventilation grilles or ducts connecting

directly to the outdoors or spaces open to the outdoors such as

attics or crawl spaces.

WARNING:

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

appliance connected to the venting system being

placed into operation could result in carbon monoxide

poisoning or death.

The following steps shall be followed for each appliance

connected to the venting system being placed into operation,

while all other appliances connected to the venting system are

not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 or the CSA B149.1, Natural Gas and

Propane Installation Codes and these instructions.

Determine that there is no blockage or restriction, leakage,

corrosion and other deficiencies which could cause an

unsafe condition.

3. As far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected to

the venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they are operating

at maximum speed. Do not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so

appliance is operating continuously.

7. Test for spillage from draft hood equipped appliances at the

draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle.

8. If improper venting is observed during any of the above

tests, the venting system must be corrected in accordance

with the National Fuel Gas Code, ANSI Z223.1/NFPA 54

and/or CSA B149.1, Natural Gas and Propane Installation

Codes.

9. After it has been determined that each appliance connected

to the venting system properly vents when tested as

outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas-fired burning

appliances to their previous conditions of use.

9

INSTALLATION INSTRUCTIONS

Inspect Shipment

This furnace is shipped in one package, completely assembled

and wired. The indoor thermostat and accessories are shipped in

a separate carton when ordered.

■ Check the furnace rating plate to confirm specifications are

as ordered.

■ Upon receipt of the furnace, inspect it for possible shipping

damage. Examine the furnace inside the carton if the carton

is damaged.

■ If damage is found, it should be noted on the carrier’s freight

bill. Damage claims should be filed with the carrier

immediately. Claims of shortages should be filed with the

seller within 5 days.

NOTE: If any damages are discovered and reported to the carrier,

do not install the furnace, because your claim may be denied.

Plan Vent System

Category I Venting—Vertical Venting

WARNING

Goodman 66

To prevent possible personal injury or death due to

asphyxiation, this furnace must be Category I vented.

Do not vent using Category III venting.

Provisions must be made for venting combustion

products outdoors through a proper venting system.

The length of flue pipe could be a limiting factor in

locating the furnace.

The minimum vent diameter for the Category I venting system is

as shown in the Minimum Vent chart.

Minimum Vent

Model Upflow Counterflow

45 4" (10.2 cm) 4" (10.2 cm)

70 4" (10.2 cm) 4" (10.2 cm)

90 4" (10.2 cm) 4" (10.2 cm)

115 5" (12.7 cm) 5" (12.7 cm)

140 5" (12.7 cm) N/A

Under some conditions, larger vents than those shown in the

Minimum Vent chart may be required or allowed. When an

existing furnace is removed from a venting system serving other

appliances, the venting system may be too large to properly vent

the remaining attached appliances.

Upflow or horizontal units are shipped with the induced draft

blower discharging from the top of the furnace. (“Top” is as

viewed for an upflow installation.) The induced draft blower can

be rotated 90 degrees for Category I venting. For horizontal

installations, a 4" (10.2 cm) single-wall pipe can be used to

extend the induced draft blower outlet ¹⁄₂" (1.3 cm) beyond the

furnace cabinet. This product is not designed for

counterclockwise induced draft blower rotation.

Vent the furnace in accordance with the National Fuel Gas Code

NFPA 54/ANSI Z223.1—latest edition. In Canada, vent the

furnace in accordance with the National Standard of Canada,

CAN/CSA B149.1 and CAN/CSA B149.2—latest editions and

amendments.

Category I Venting is venting at a non-positive pressure. A

furnace vented as Category I is considered a fan-assisted

appliance. The vent system does not have to be “gas tight.”

NOTE: Single-stage gas furnaces with induced draft blowers

draw products of combustion through a heat exchanger allowing,

in some instances, common venting with natural draft appliances

(for example, water heaters).

All installations must be vented in accordance with National Fuel

Gas Code NFPA 54/ANSI Z223.1—latest edition. In Canada, the

furnaces must be vented in accordance with the National

Standard of Canada, CAN/CSA B149.1 and CAN/CSA B149.2—

latest editions and amendments.

NOTE: The vertical height of the Category I venting system must

be at least as great as the horizontal length of the venting system.

WARNING

To prevent possible personal injury or death, due to

asphyxiation, common venting with other manufacturer's

induced draft appliances is not allowed.

Goodman 67

Venting

NOTE: This furnace is not design certified to be horizontally

vented.

1. Disconnect electrical power from the furnace.

2. Disconnect the induced draft blower power leads, flue pipe

and pressure switch tubing.

3. Remove the round cutout from the right-hand side of the

wrapper.

4. Remove and save the 4 screws that fasten the induced draft

blower to the flue collector box.

5. Remove and save the 3 screws that hold the chimney

assembly to the induced draft blower.

6. Remove and save the 4 screws that fasten the chimney top to

the chimney bottom.

7. Remove the chimney transition bottom from the transition

bottom kit.

8. Install the chimney top with the 4 screws retained from Step

6 onto the new chimney transition bottom from the transition

bottom kit.

9. Install the chimney assembly with the 3 screws retained from

Step 5 onto the induced draft blower.

10. Reinstall the induced draft blower rotating it 90 degrees

clockwise from the original upflow configuration using the

4 screws retained in Step 3. Ensure the gasket located

between the induced draft blower and the collector box is

rotated accordingly.

10

11. Reconnect the induced draft blower power leads.

C

D

E

F

G

H

I

J

K

NOTE: If the wires are not long enough, pull extra wire from

the wire bundle in the blower compartment.

12. Reconnect the flue pipe and the pressure switch tubing.

Ensure that all wires and the pressure switch tubing are at

least 1" (2.5 cm) from the flue pipe, or any other hot surface.

13. Reconnect electrical power to the furnace.

Counterflow units are shipped with the inducted draft blower

discharging from the top (as viewed for a counterflow installation)

of the furnace.

Vent the furnace in accordance with the National Fuel Gas Code

NFPA 54/ANSI Z223.1—latest edition. In Canada, vent the

furnace in accordance with the National Standard of Canada,

CAN/CSA B149.1 AND CAN/CSA B149.2—latest editions and

amendments.

AB

R

Q

P

WARNING

Never allow the products of combustion, including carbon

monoxide, to enter the return ductwork or circulation air

supply.

Goodman 68

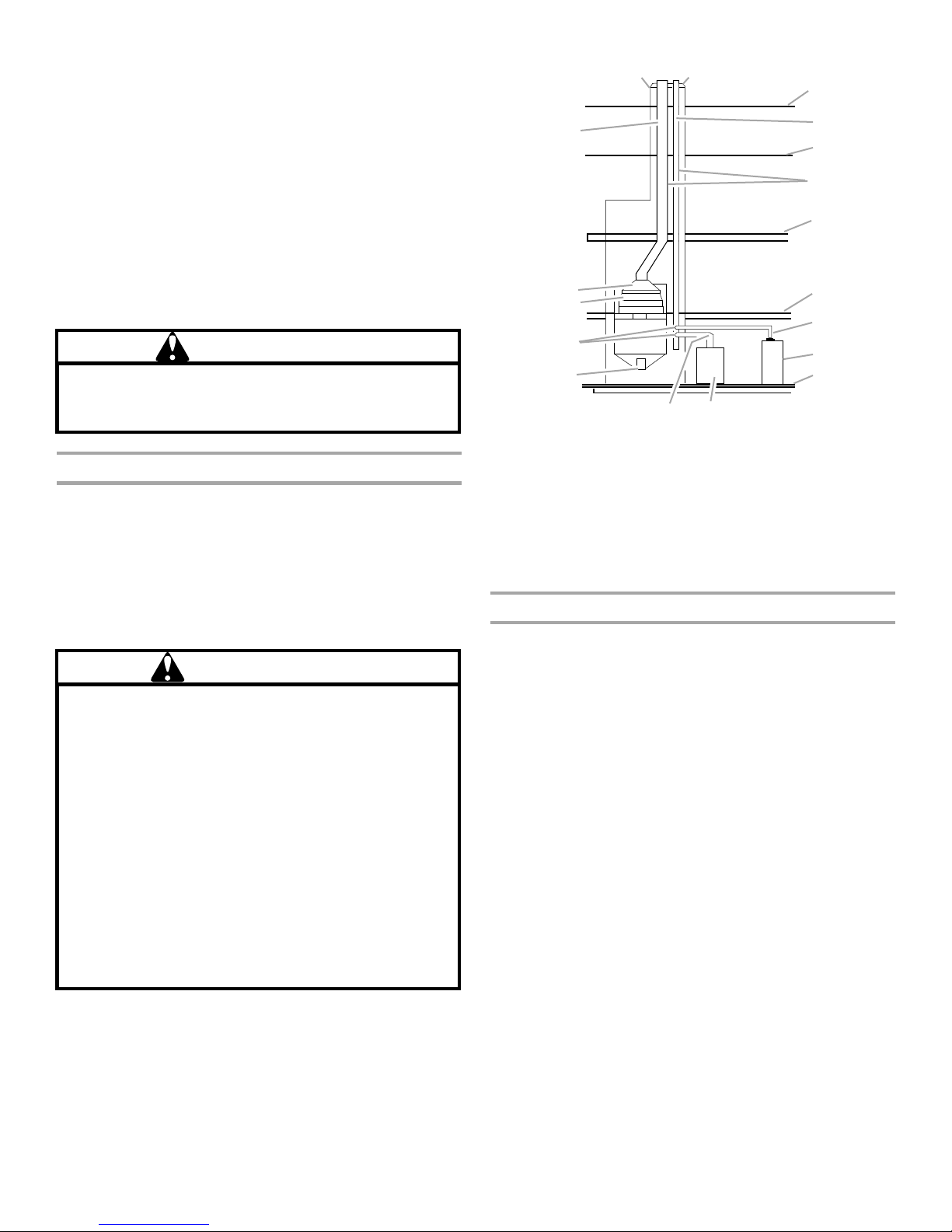

Category I Furnaces Only—Exterior Masonry Chimneys

An exterior masonry chimney is defined as a “Masonry chimney

exposed to the outdoors on one or more sides below the roof

line.” The ability to use a clay-lined masonry chimney depends on

a parameter not associated with interior chimneys. This variable

is the geographic location of the installation. Researchers have

discovered that the winter design temperatures have a direct

impact on the suitability of this type of venting. In most situations,

the existing masonry chimneys will require a properly-sized

metallic liner.

WARNING

Possiblility of property damage, personal injury or death.

Damaging condensation can occur inside masonry

chimneys when a single fan-assisted Category I appliance

(80% AFUE furnace) is vented without adequate dilution

air. Do not connect an 80% furnace to a masonry chimney

unless the furnace is common vented with a draft hood

equipped appliance or the chimney is lined with a metal

liner or Type B metal vent. All installations using masonry

chimneys must be sized in accordance with the

appropriate venting tables. If an 80% furnace is common

vented with a draft hood equipped appliance, the potential

for condensation damage may still exist with extremely

cold conditons, long vent connectors, exterior chimneys

or any combination of these conditions. The risk of

condensation damage is best avoided by using the

masonry chimney as a pathway for properly-sized metal

liner or Type B metal vent.

Goodman 69

O

N

L

M

A. Crown

B. Wash

C. Roof line

D. Clay tile size: 8" x 8" x

12" (24.3 cm x 24.3 cm

x 30.5 cm) (each x 24"

[61 cm] length)

E. Attic floor

F.

¹⁄₂

" to 1 " (1.3 cm to

2.5 cm) air space

G. Second floor

H. First floor

I. Water heater vent

connector

J. Natural draft water

heater

K. Basement floor

L. Fan-assisted

forced air furnace

M. Forced air furnace

vent connector

N. Clean out

O. Breech

P. D am p e r

Q. Throat

R. Clay tile size:

generally 12" x 12"

(30.5 cm x 30.5 cm)

(24" [61 cm] length)

Checklist Summary

This checklist serves as a summary of the items to be checked

before venting an 80+ furnace into a masonry chimney. In

addition, we recommend that a qualified serviceman use this

checklist to perform a yearly inspection of the furnace venting

system.

This checklist is only a summary. For detailed information on

each of the procedures mentioned, see the paragraph referenced

with each item.

This inspection is based upon a draft topical report, “Masonry

Chimney Inspection and Relining,” issued by the Gas Research

Institute. While not yet finalized, we believe this report represents

the best information on this subject which is currently available.

11

Loading...

Loading...