Whirlpool WFC7500VW1 Parts Diagram

FOR SERVICE

T

A

r

c

u

A

a

r

TECHNICIAN

ONLY

- DO NOT

REMOVE OR

DESTRO

Electrostatic Discharge (ESD)

ESD problems are

weaken the

assembly may appear to work

failure may occur at a later date due to ESD stress.

Use

ground connection point or unpainted

appliance

T

ouch your finger repeatedly to a green ground

point or unpainted

Before removing

anti-static bag to a green ground connection point or

unpainted

A

void touching electronic parts or

handle electronic control assembly by edges only.

When repackaging

anti-static bag,

electronic control assembly.

an

anti-static

metal in the

IMPOR

NT

Sensitive Electronics

present

everywhere. ESD may damage or

well

after

wrist strap.

metal in the

the

Connect

-OR-

appliance.

part from

appliance.

its

terminal

failed

observe above

electronic control assembly in

instructions.

The

new c

ontrol

repair is finished,

wrist strap to green

metal in the

connection

package, t

ouch

contacts;

DIAGNOSTIC GUIDE

Before

servicing,

Make sure there is power at

Has a household fuse blown or circuit

delay fuse?

Are both hot and cold water

unobstructed?

All tests/checks should be made with a VOM or DVM having a

sensitivity of 20,000 ohms per

Check all connections before replacing components. Look

broken or loose wires,

connections

A potential

connections.

ohmmeter.

Connectors: Look at top of connector.

wires. Check

engage

Resistance checks must be made with power cord unplugged

outlet, and with wiring harness or connectors disconnected.

check

far enough.

cause of a

Observe connections and check

for

metal

wires not pressed into connector far enough to

barbs.

the

following:

failed terminals, or

control not functioning is corrosion on

the wall

outlet.

breaker

faucets

open and water supply

volt DC or greater.

wires not pressed into

Check

tripped? T

for

continuity with

for

broken or loose

the

ime

for

Y

but

hoses

an

from

POURLETECHNICIEN

Circuits é lectroniques sensibles

aux dé

Le

risque de dé

décharge é

composants é

l’impression

charge é

lectrostatique peut endommager ou

lectroniques. La nouvelle

qu’elle fonctionne correctement après la

réparation, mais une décharge é

fait subir des

plus tard.

Utiliser un bracelet de décharge é

le

bracelet à la vis verte de

dommages

métallique non peinte de

T

oucher

plusieurs fois du

ou

terre

une surface métallique non peinte de

A

vant de retirer la pièce de

antistatique en contact avec la vis verte de

une surface métallique non peinte de

É viter de toucher les composants é

broches de contact; tenir la

par les bords seulement

Lors du ré

défaillante dans

instructions

GUIDE

vant d

’entreprendre

Vérifier que la prise de

F

usible grillé ou

Robinets d

d’eau exempts d

Utiliser pour tous les contrô

dont la résistance

ou plus.

Contrô ler

Rechercher

cosses

Le

non-fonctionnement d’un

corrosion des pièces de

ler la

Connecteurs :

des fils brisés ou

mal branchées.

Lors de

d’alimentation

faisceaude câ

emballage

le sachet

ci-dessus.

DE

DIAGNOSTIC

une réparation, contrô ler ce

disjoncteur ouvert? Fusible

’eau chaude et d

’obstruction?

de connexion dété

continuité

toute mesure de résistance, vérifier que

interne est de 20 000

toutes les

des

fils brisés ou mal connectés, ou des bornes ou

avec un

Examiner

mal connectés; rechercher également des cosses

est débranché de la

blage ou

SEULEMENT- NEP

IMPORT

charges é

lectrostatique

AS ENLEVERNIDÉTRUIRE

ANT

lectrostatiques

est permanent. Une

carte peut

lectrostatique peut

qui

provoqueront

lectrostatique. Connecte

liaison à la

l’appareil

-OU-

terre ou sur une surfa

doigt la vis verte de

son sachet,

placer

l’appareil.

lectroniques ou les

lors

d’une

carte de

carte de

circuits é

des manipulations.

circuits é

antistatique, appliquer les

courant

connexions

est alimentée.

’eau froide ouverts et tuyaux d

les un voltmètre ou autre instrument

avant de remplacer un composant.

riorées.

organe de

connexion. Inspecter

ohmmètre.

le

sommet d

le

connecteur est débranché.

prise de

temporisé

ohms

commande

les

’un connecteur; rechercher

courant, et

affaiblir les

donner

lui avoir

une défaillance

liaison à

l’appareil.

le sachet

liaison à la

terre

lectroniques

lectroniques

qui suit :

par volt CC

grillé?

peut être dû à

connexions

le

cordon

que

’arrivée

le

la

et

o

l

cont

PART

NO.

46197042905

PAGE

1

Date : 14-Feb-2008

FOR SERVICE

TECHNICIAN

ONLY

- DO NOT

REMOVE OR

DESTRO

Y

POURLETECHNICIEN

SEULEMENT- NEP

TROUBLESHOOTING GUIDE

NOTE: After problem(s) are fixed, please run the diagnostic test to ensure that there have no other issues.

POSSIBLE CAUSE/TEST PROBLEM

NOTE: Possible Cause/Tests must be performed in the sequence shown for each problem.

WON'T POWER UP

(buttons do not respond when

pressed)

WON'T START CYCLE

WON’T SHUT OFF

CONTROL WON'T ACCEPT

SELECTIONS

1. Check that the unit is plugged into a working outlet and for blown fuses.

2. Check for power going to Central Control Unit (CCU) by listening for a click in the CCU when unit is plugged in. If no

click, replace CCU.

3. Unplug washer or disconnect power.

4. Check continuity of line cord and line filter.

5. Check harness connections to CCU.

6. Plug in washer or reconnect power.

7. Check the button/LED assembly by selecting different cycles and changing the modifiers and options available to

confirm the button/LED assembly is responding.

8. Check the connection of the power cord to the line filter and at the CCU. Check to confirm the door closes fully.

1. Open and close the door. The door has to be opened between consecutive wash cycles.

2. Check the door switch/lock unit using the diagnostics. See Quick Diagnostic Test.

3. If door is locked, drain the unit.

4. Unplug washer or disconnect power.

5. Check the wire harness connections.

6. Plug in washer or reconnect power.

7. Check the button/LED assembly by selecting different cycles and changing the modifiers and options available to

confirm the button/LED assembly is responding.

1. Check for a Fault/Error Code on the display.

2. Switch knob to OFF position.

3. Check the button/LED assembly by selecting different cycles and changing the modifiers and options available to

confirm the button/LED assembly is responding.

4. Unplug washer or disconnect power.

5. Check that the drain hose and drain pump filter are clear of foreign objects and not plugged.

6. Plug in washer or reconnect power.

7. Check drain pump.

8. Verify CCU operation by running a Quick Diagnostic Test or any cycle.

9. Check Knob assembly on the CCU to ensure the direction is properly oriented. See page 9.

1. Switch knob to OFF position.

2. Drain the unit, and then check that the drain hose and drain pump filter are clear of foreign objects.

3. Check the button/LED assembly by using the Universal test mode.

4. Unplug washer or disconnect power.

5. Check harness connections.

6. Plug in washer or reconnect power.

7. Verify CCU operation by running a Diagnostic Test or any cycle.

AS ENLEVERNIDÉTRUIRE

WON'T DISPENSE

WON'T FILL

OVER FILLS

DRUM WON'T ROTATE

1. Verify the unit is level.

2. Verify dispenser drawer is not clogged with detergent.

3. Check water connections to the unit and within the unit. Check for plugged screen in water source.

4. Check the water supply and the water valve.

5. Unplug washer or disconnect power.

6. Check harness connections.

7. Plug in washer or reconnect power.

8. Verify CCU operation by running a Quick Diagnostic Test or any cycle.

1. Check installation. Verify hot and cold water faucets are open.

2. Check inlet valves.

3. Unplug washer or disconnect power.

4. Check water connections to the unit and within the unit. Make sure water supply hoses are unobstructed. Check for

plugged screen.

5. Plug in washer or reconnect power.

6. Check operating pressure switch.

7. Check drain pump motor.

8. Verify CCU operation by running a Quick Diagnostic Test or any cycle.

9. Check the steps listed under WON'T DISPENSE.

1. Verify the unit is level.

2. Check pump drain system – this could indicate a failure to drain.

3. Unplug washer or disconnect power.

4. Check operating pressure switch.

5. Check pressure switch hose.

6. Plug in washer or reconnect power.

7. Verify flow meter operation by blowing air though the part and measuring the resistance.

8. Verify CCU operation by running a Quick Diagnostic Test or any cycle.

1. Check drive belt.

2. Check drive motor.

3. Unplug washer or disconnect power.

4. Check wire harness connections.

5. Plug in washer or reconnect power.

6. Perform the Motor Continuity Test.

PART

NO.

46197042905

PAGE

2

Date : 14-Feb-2008

FOR SERVICE

TECHNICIAN

ONLY

- DO NOT

REMOVE OR

DESTRO

Y

POURLETECHNICIEN

SEULEMENT- NEP

AS ENLEVERNIDÉTRUIRE

MOTOR OVERHEATS

WON'T DRAIN

MACHINE VIBRATES

INCORRECT WATER

TEMPERATURE

DISPLAY FL ASHING

1. Check drive motor.

2. Unplug washer or disconnect power.

3. Check wire harness connections.

4. Check drive belt.

5. Plug in washer or reconnect power.

6. Check for obstruction between the spin basket and the outer tub.

1. Unplug washer or disconnect power.

2. Check wire harness connections.

3. Check drain pump.

4. Check drain pump motor.

5. Check that the drain hose and drain pump filter are clear of foreign objects.

6. Plug in washer or reconnect power.

7. Verify CCU operation by running a Quick Diagnostic Test or any cycle.

1. Remove shipping system.

2. Check installation.

3. Check leveling feet.

1. Check that the inlet hoses are connected properly.

2. Unplug washer or disconnect power.

3. Check water temperature sensor for an abnormal condition. See the Water Temperature Sensor section, page 10.

4. Plug in washer or reconnect power.

5. Verify CCU operation by running a Diagnostic Test or any cycle.

See Failure/Error Display Codes.

DIAGNOSTIC TEST

The two test modes contain three modes of operation.

Test modes:

Universal test mode, with additional user interface test at the beginning

Quick test mode

Operation modes:

User interface test

Automated test

Loads tests to assist in diagnosing potentially non-electrical issue

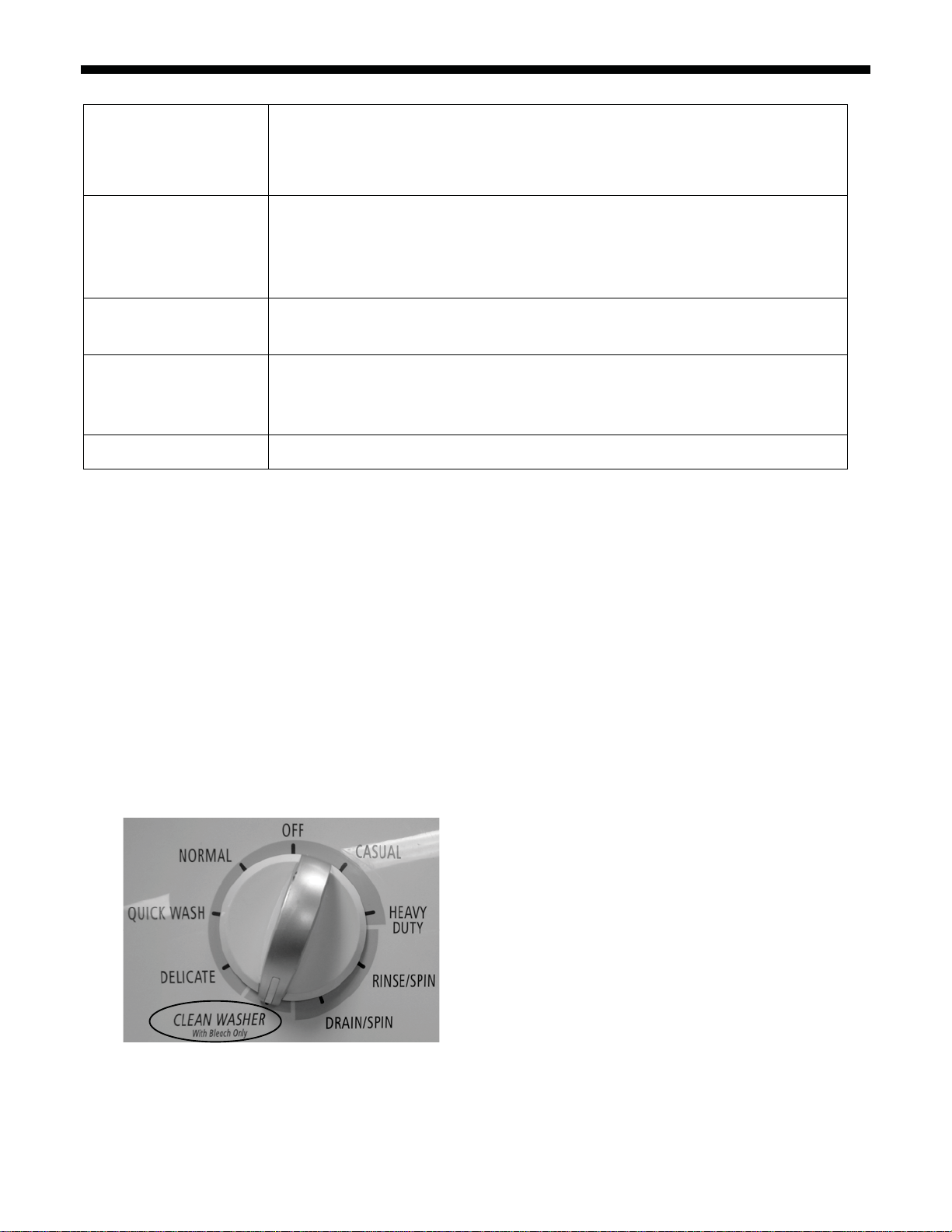

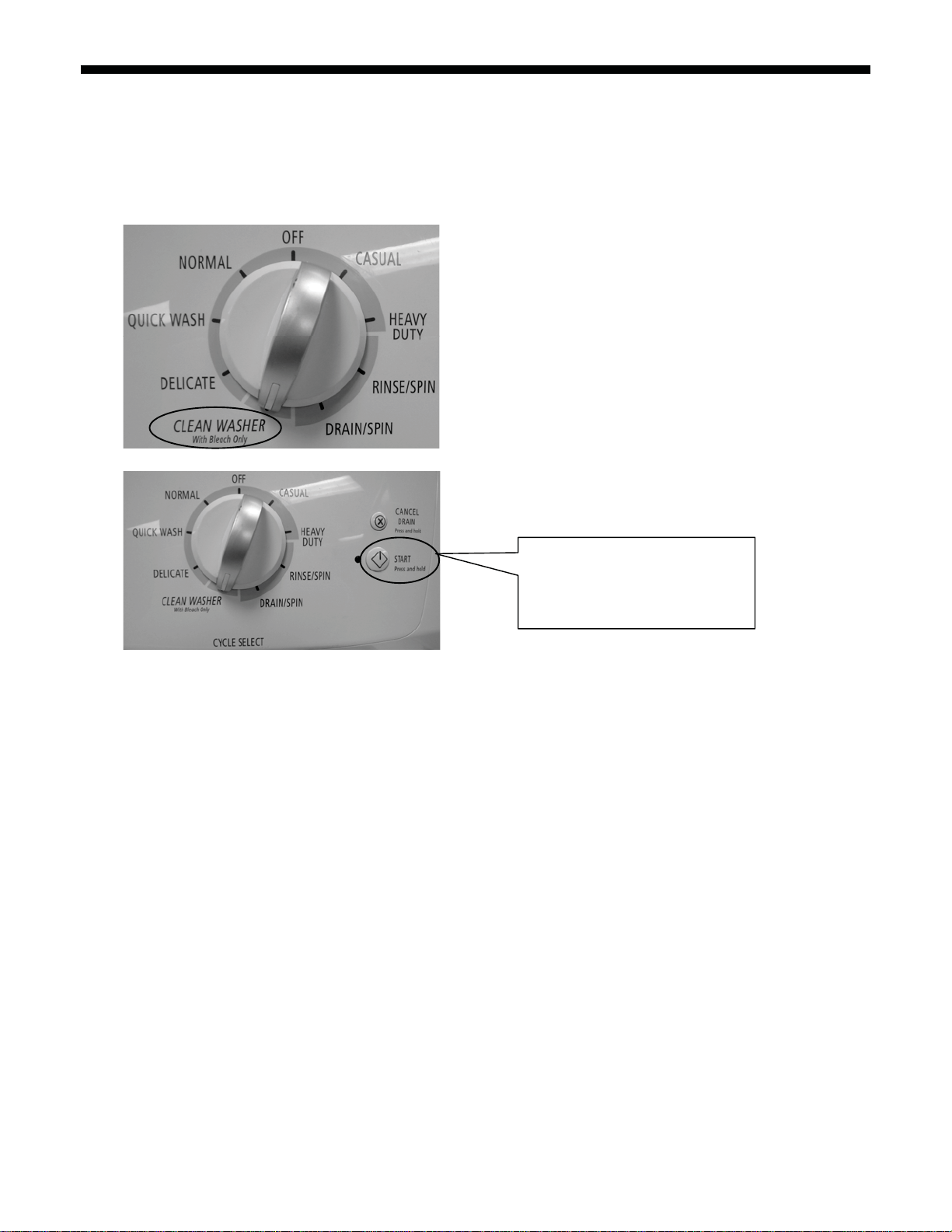

Startin g Univ ers al Test Mode

1. Close the door

2. Rotate the knob and select the CLEAN WASHER cycle. (See picture below)

PART

NO.

46197042905

PAGE

3

Date : 14-Feb-2008

FOR SERVICE

TECHNICIAN

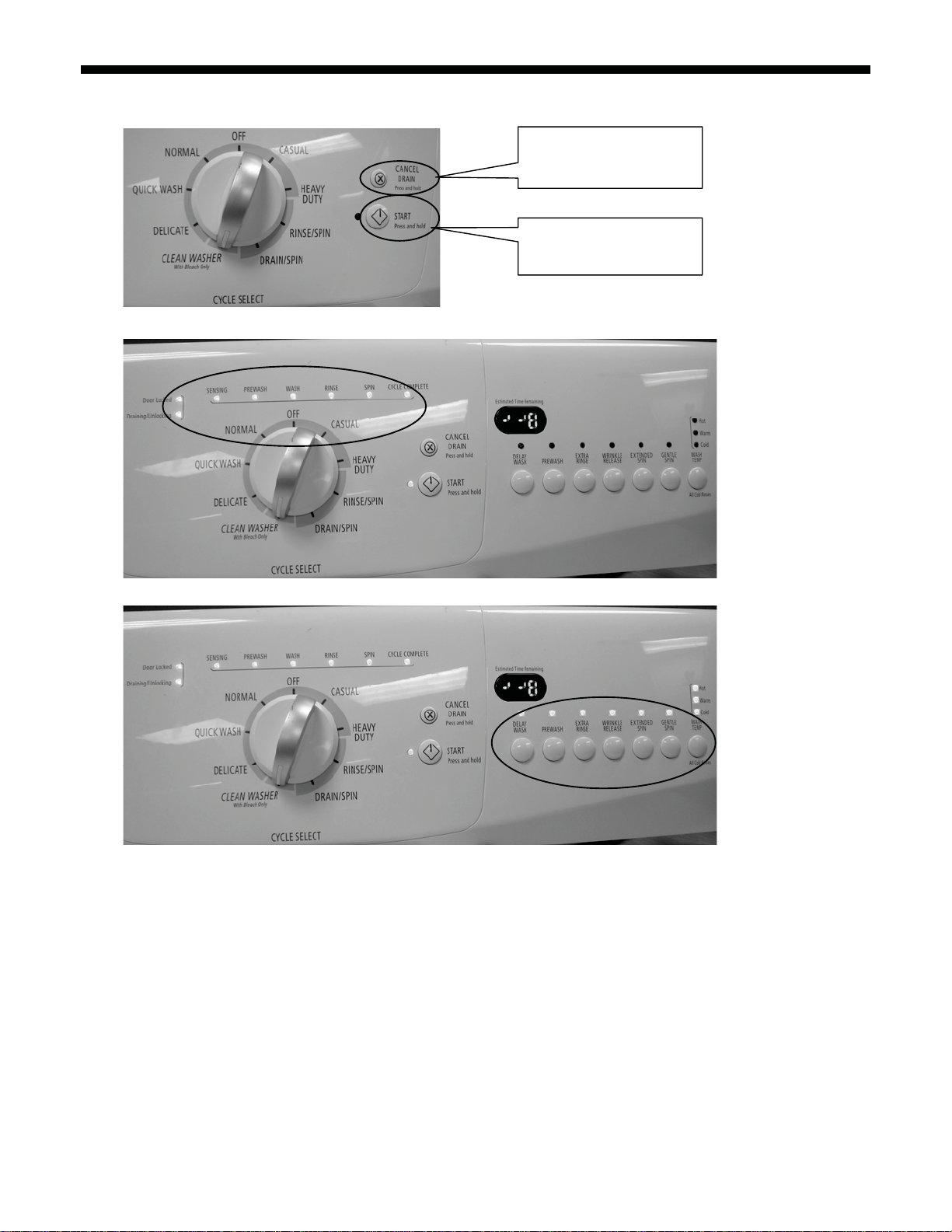

3. Press “CANCEL/DRAIN” button for 2 times, and then press “START” button for 2 times within 5 seconds. (See pictures below)

4. Upon release, and after door locked, all console LED lights will turn ON except option LED. (See pictures below)

5. Press the option buttons, one at a time, to check the User Interface

6. Following steps are automatically driven, or they can be manually advanced by pressing the Cancel/Drain button 2 time. See table

UNIVERSAL DIAGNOSTICS TEST” on next page.

“

ONLY

- DO NOT

REMOVE OR

DESTRO

Y

POURLETECHNICIEN

First press “CANCEL/DRAIN”

button for 2 times

Then press “START” button for

2 times within 5 seconds.

SEULEMENT- NEP

AS ENLEVERNIDÉTRUIRE

NOTES:

To cancel out of this mode rotate the selector knob. (This exits you out of the program.)

Press “CANCEL/DRAIN” button 2 times can advance to the next step of the procedure.

If the starting procedure fails, switch the knob and back to the CLEAN WASH cycle, the repeat the starting procedure.

PART

NO.

46197042905

PAGE

4

Date : 14-Feb-2008

FOR SERVICE

TECHNICIAN

ONLY

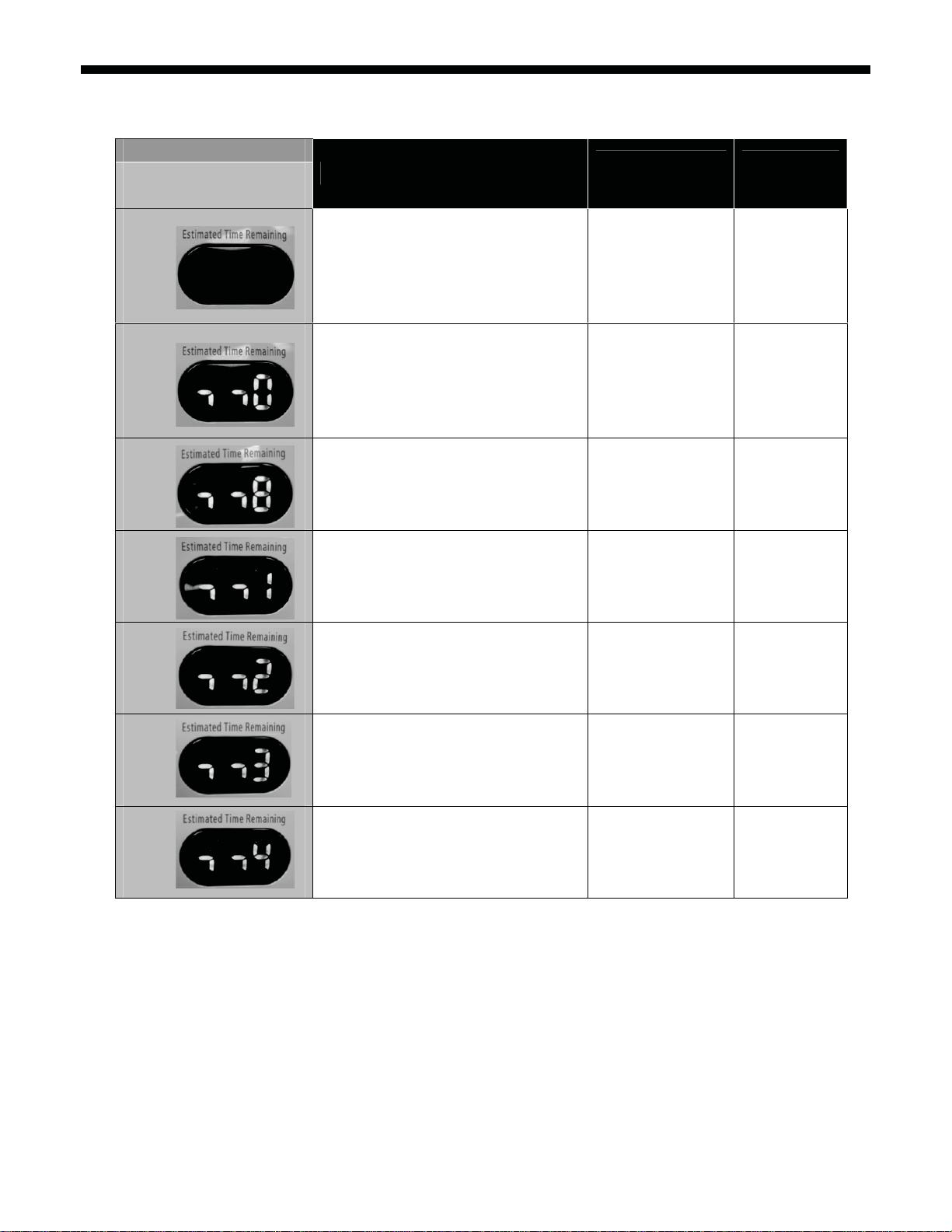

UNIVERSAL DIAGNOSTICS TEST

- DO NOT

REMOVE OR

DESTRO

Y

POURLETECHNICIEN

SEULEMENT- NEP

AS ENLEVERNIDÉTRUIRE

Indication

Factory Test Display

(7-SEGMENT LED)

OFF

0 (Phase LED rolling)

8

1

2

3

4

Control Action

Door locks Door lock system F13

Checks the EEPROM data’s validity

Pump turns ON if the water level is detected to be

above the wash level

All display led are turned on

UI option led will be turned on after options are

pushed.

Turns hot valve inlet on (About 15s)

Turns bleach valve inlet on (About 15s)

Turns cold valve inlet on (About 15s)

Fill by cold water inlet valve to Level_wash

Motor reverse. Runs at normal washing speed.

(About 15s)

Pump turns ON to drain the washer Drain system F03, F21

Drive motor to max speed Motor speed

Actuators to be

Checked

Drain system

EEPROM test

User interface F21, F25

Hot Water inlet valve

Cold Water inlet valve

Bleach inlet valve

Reversing relay

Safety relay

Motor thermistor

Tachometer signal

Tap field relay

Failure code

for failure mode

F03, F05, F14,

F21, F23, F24,

F26, F30

F01, F21, F23,

F24

F06, F07, F21,

F27

F06, F07, F21,

F27, F28

PART

NO.

46197042905

PAGE

5

Date : 14-Feb-2008

FOR SERVICE

TECHNICIAN

ONLY

- DO NOT

REMOVE OR

DESTRO

Y

POURLETECHNICIEN

SEULEMENT- NEP

AS ENLEVERNIDÉTRUIRE

Starting Quick Test Mode

All of the steps below must be done in sequence in order to reach the Diagnostic Test. This executes the automatic test but does not run

the user interface test

1. Close the door

2. Switch the knob and select the CLEAN WASHER cycle. (See picture below)

3. Press “START” button for 4 times within 5 seconds. (See picture below)

NOTES:

Please ensure that current machine status is in PROGRAM (SELECTION) mode.

Otherwise, please follow the instructions below to bring it back to PROGRAM

(SELECTION) mode.

1) PAUSE mode: Press and hold CANCEL/DRAIN button for 3 seconds for

reset, then switch knob to enter PROGRAM mode

2) FAILURE mode: Switch knob to enter PROGRAM mode

3) EXECUTION mode: Press and hold CANCEL/DRAIN button for 3 seconds

for reset, then switch knob to enter PROGRAM mode

4) STANDBY mode: Press START button or switch knob to enter PROGRAM

mode

5) DELAY START mode: Switch knob to enter PROGRAM mode

First press “START” button for 4 times

within 5 seconds

4. Following steps are automatically driven, or they can be manually advanced by pressing the Cancel/Drain button 2 times. See table

“

QUICK DIAGNOSTICS TEST” on next page.

NOTES:

To cancel out of this mode rotate the selector knob. (This exits you out of the program.)

Press “CANCEL/DRAIN” button 2 times can advance to the next step of the procedure.

If the starting procedure fails, switch the knob and back to the CLEAN WASH cycle, the repeat the starting procedure.

PART

NO.

46197042905

PAGE

6

Date : 14-Feb-2008

Loading...

Loading...