Whirlpool WFC7500VW0 User Manual

CONSUMER CARE TECHNICAL

EDUCATION GROUP PRESENTS

JOB AID

Part No. 8178738

L-83

Model WFC7500VW0

2008

24” FRONT-LOADING

AUTOMATIC WASHER

FORWARD

This Whirlpool Job Aid, “2008 24" Front-Loading Automatic Washer” (Part No. 8178738), provides the In-Home Service Professional with information on the installation, operation, and service of the 2008 24" Front-Loading Automatic Washer. For specific information on the model

being serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided with the washer.

The Wiring Diagram used in this Job Aid is typical and should be used for training purposes only.

Always use the Wiring Diagram supplied with the product when servicing the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide information that will enable the In-Home Service Professional to properly diagnose malfunctions and repair the 2008 24" Front-Loading Automatic

Washer.

The objectives of this Job Aid are to:

Understand and follow proper safety precautions.•

Successfully troubleshoot and diagnose malfunctions.•

Successfully perform necessary repairs.•

Successfully return the washer to its proper operational status.•

WHIRLPOOL CORPORATION assumes no responsibility for any repairs

made on our products by anyone other than In-Home Service Professionals.

Copyright © 2008, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

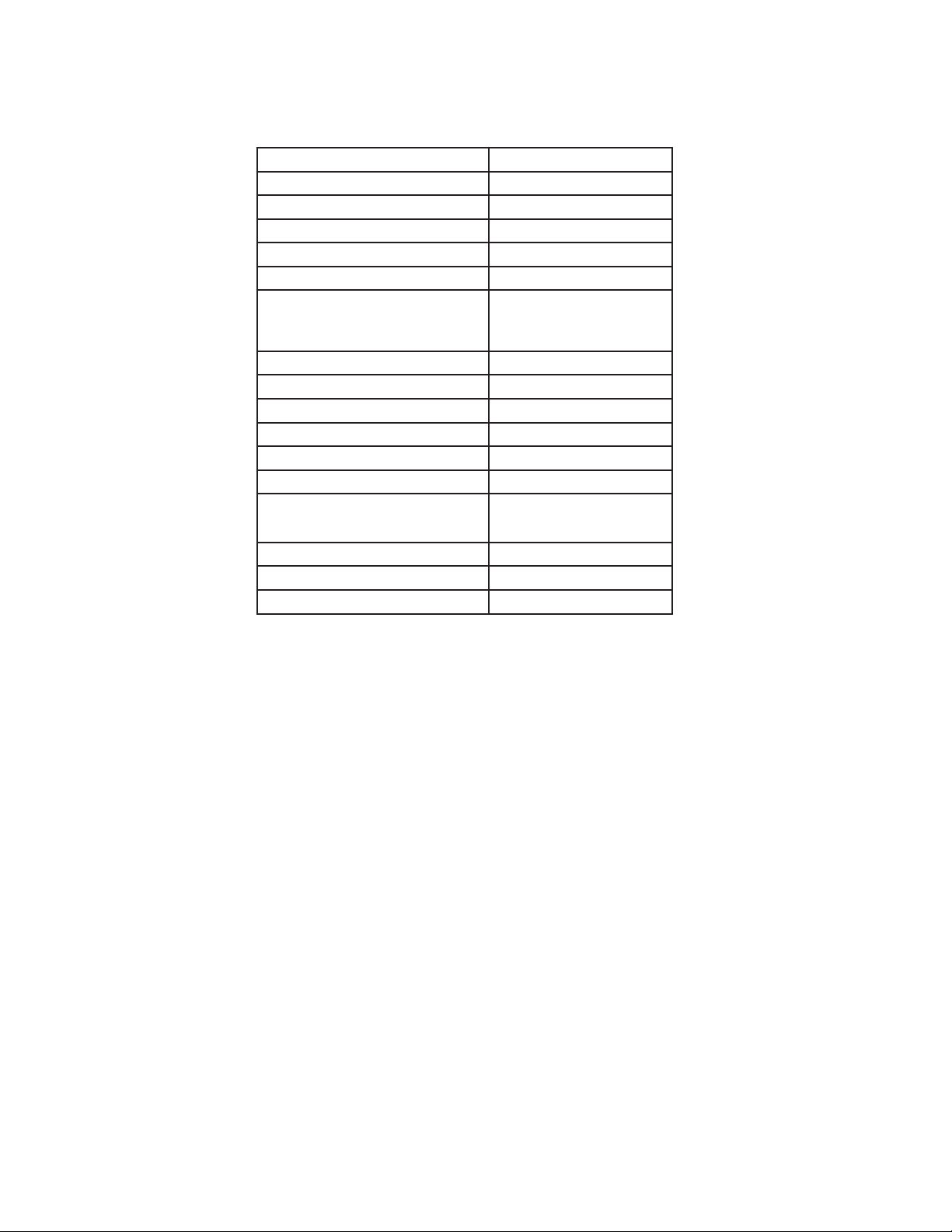

TABLE OF CONTENTS

Page

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Washer Safety .......................................................... 1-1

Model & Serial Number Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Model & Serial Number Label And Tech Sheet Locations ......................... 1-3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

INSTALLATION INFORMATION ............................................. 2-1

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

PRODUCT OPERATION .................................................... 3-1

Features And Benefits .................................................... 3-1

Washer Use ............................................................ 3-2

Washer Care ...........................................................3-11

Troubleshooting ........................................................ 3-14

COMPONENT ACCESS .................................................. 4-1

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Removing The Console,The Touchpad/LED Assembly And Central Control Unit ....... 4-2

Removing The Water Inlet Valve ............................................ 4-4

Removing The Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Removing The Line Filter & Power Supply Cord ................................ 4-6

Removing The Detergent Dispenser Assembly ................................. 4-8

Removing The Detergent Dispenser Motor .................................... 4-9

Removing The Door Switch Assembly And The Bellows ..........................4-11

Removing The Drain Pump ............................................... 4-14

Removing The ECO Valve ................................................ 4-16

Removing The Motor Control Unit .......................................... 4-17

Removing The Temperature Sensor ........................................ 4-19

Removing The Drive Belt And Motor ........................................ 4-20

Removing The Basket Drive Pulley ......................................... 4-22

Removing The Tub And Basket ............................................ 4-23

COMPONENT TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Inlet Cold/Bleach Water Valve Solenoids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Inlet Hot Water Valve Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Pressure Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Line Filter .............................................................. 5-4

Door Switch ............................................................ 5-5

Drain Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Temperature Sensor ..................................................... 5-7

Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

- iii -

Page

DIAGNOSTICS & TROUBLESHOOTING ...................................... 6-1

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Diagnostic Guide ...................................................... 6-1

Failure Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Universal Diagnostics Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Quick Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

Electronic Assemblies - Removal Or Replacement ........................... 6-12

Troubleshooting Guide .................................................. 6-13

WIRING DIAGRAMS ....................................................... 7-1

Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

- iv -

GENERAL

WARNING

DANGER

WASHER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance.

Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and

others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the

chance of injury, and tell you what can happen if the instructions are not followed.

1-1

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER W F W 7 5 00 V W 0

BRAND

W = WHIRLPOOL

ACCESS

F = FRONT LOAD T = TOP LOAD

PRODUCT

W = WASHER

SERIES

5=Whirlpool Leap 6=Oasis

7=24" Front Load 8=Mid Line Front Load

9=Duet Front Load

PRICE POINT LEVELS (1-9)

TRADE PARTNER ID (00 = BRANDED)

YEAR OF INTRODUCTION

V = 2008

COLOR CODE

T = Biscuit

ENGINEERING CHANGE (0, 1, 2, ETC.)

SERIAL NUMBER CK T 41 01002

DIVISION RESPONSIBILITY

C = CLYDE, OH K = SHANGHAI, CHINA

YEAR OF PRODUCTION

T = 2006 U = 2007

WEEK OF PRODUCTION

41 = 41ST WEEK

PRODUCT SEQUENCE NUMBER

1-2

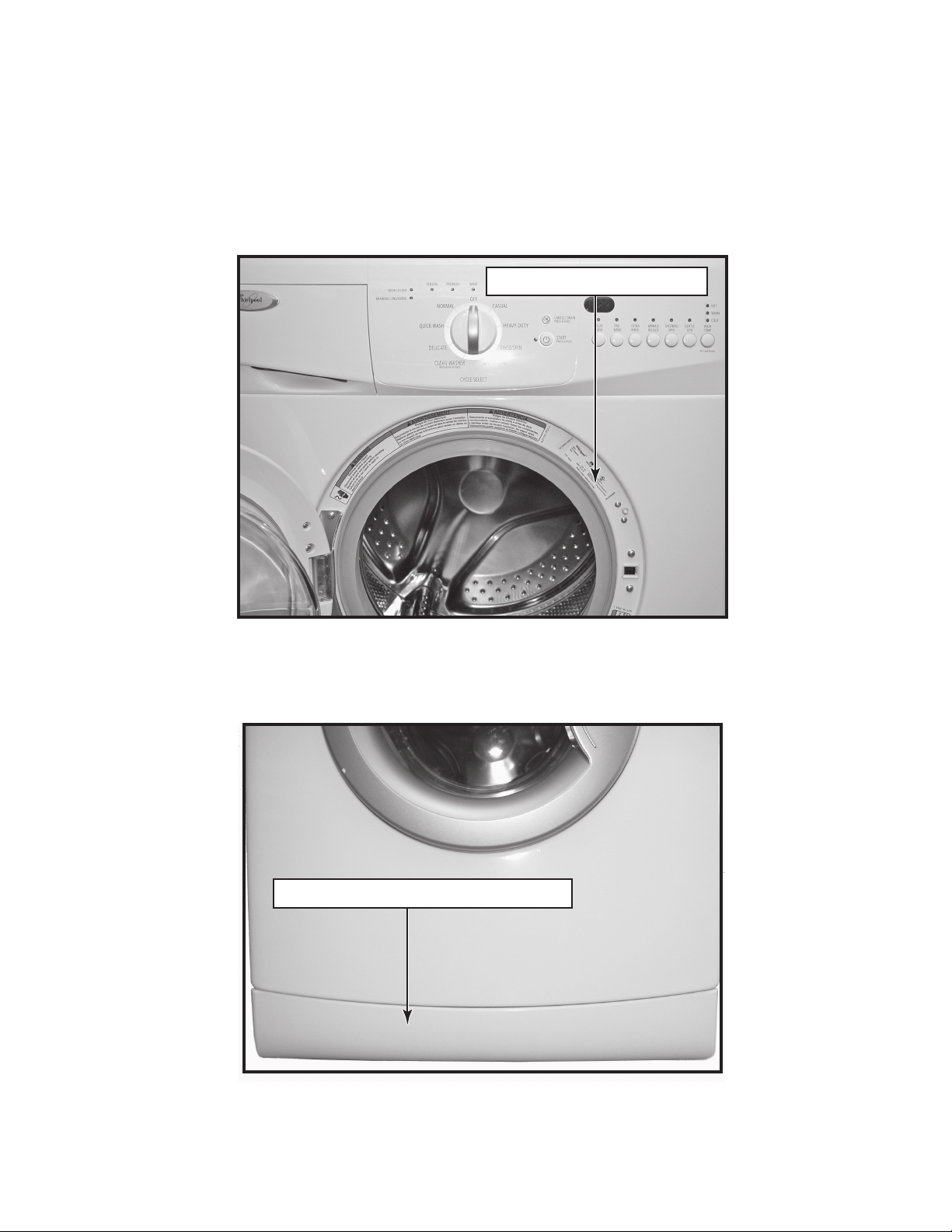

MODEL & SERIAL NUMBER LABEL

AND TECH SHEET LOCATIONS

The Model & Serial Number Label and Tech Sheet locations are shown below.

Model & Serial Number Label

Tech Sheet (Behind Lower Access Panel)

1-3

SPECIFICATIONS

Model Number WFC7500VW0

Model Description Front Load Washer

Color White

Capacity (IEC Equivalent) 2.3

Temperature Control Thermist

Heater No

Sensors Suds Sensor,

NTC (Thermistor),

Water Level Sensor

Tumble Speed Variable

Spin Speed 1200 RPM Maximum

Motor Variable Speed; 1/3 HP

Voltage 120V

Frequency 60 Hz

Amps 15 Amp

Water Consumption Average

DOE (Gallons-Per-Cycle)

Height 33.5"

Install Depth: Min - Max 23.5"

Width 23.5"

Variable per Load

CEE Tier II Qualied

1-4

INSTALLATION INFORMATION

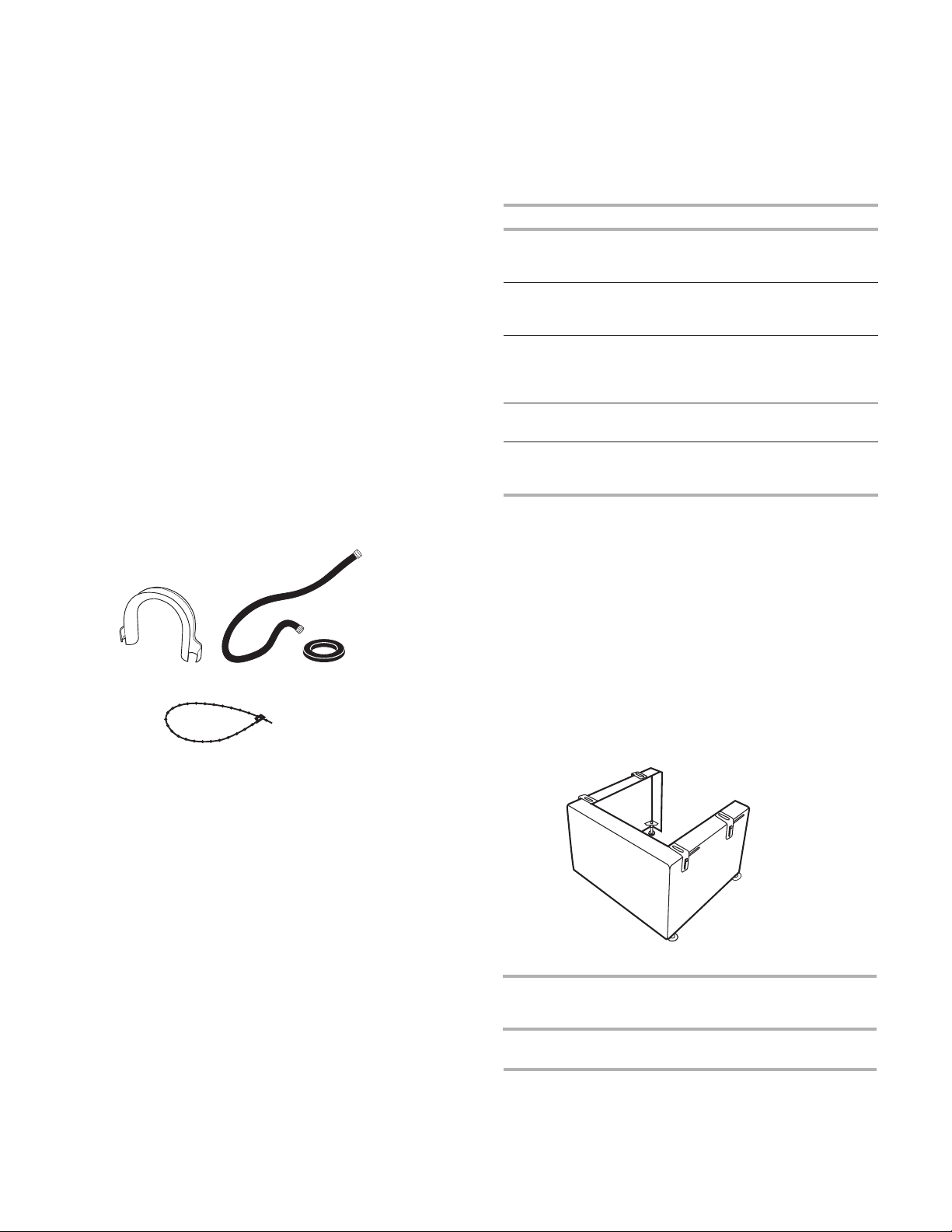

A. U-shaped hose form

B. Water inlet hoses (2)

C. Inlet hose washers (4)

D. Beaded tie strap

ABC

D

Optional pedestal

If Yo u Have Yo u Will Need to Buy

Laundry tub or

standpipe taller

than 55" (1.4 m)

Sump pump system (if not alre ady

available)

Overhead sewer Standard 20 gal. (76 L), 30" (76.2cm) tall

drain tub or utility sink and sump pump

(available from local plumbing suppliers)

Floor drain Siphon break, Part Number 285834;

additional drain hose

Part Number8318155; and c onnector kit,

Part Number285835

Drain hose too

short

4ft (1.2 m) drain hose extension kit,

Part Number 285863

Water faucets

beyond reach of ll

hoses

2 longer water ll hoses:

6ft (1.8m) Part Number 76314

10 ft (3.0 m) PartNumber350008

Pedestal

Height

Approximate

Height with

Washer

ColorModel

Number

11.8" (30.0cm) 44.7" (113.5 cm)White LAB0050PQ

INSTALLATION REQUIREMENTS

TOOLS AND PARTS

Gather the required tools and parts before

starting installation. The parts supplied are in

the washer drum.

Tools needed for connecting the water inlet hoses

Pliers (that open to 1-9/16• ˝ [39.5 mm])

Flashlight (optional)•

Tools needed for installation

Open end wrenches 13 mm and 12 mm•

Level•

Wood block•

Ruler or measuring tape•

Parts supplied

Alternate parts

OPTIONS

Pedestal

You have the option of purchasing pedestals

of different heights separately for this washer. You may select a 11˝ (30.0 cm) pedestal.

The pedestal will add to the total height of the

washer.

2-1

Stack Kit

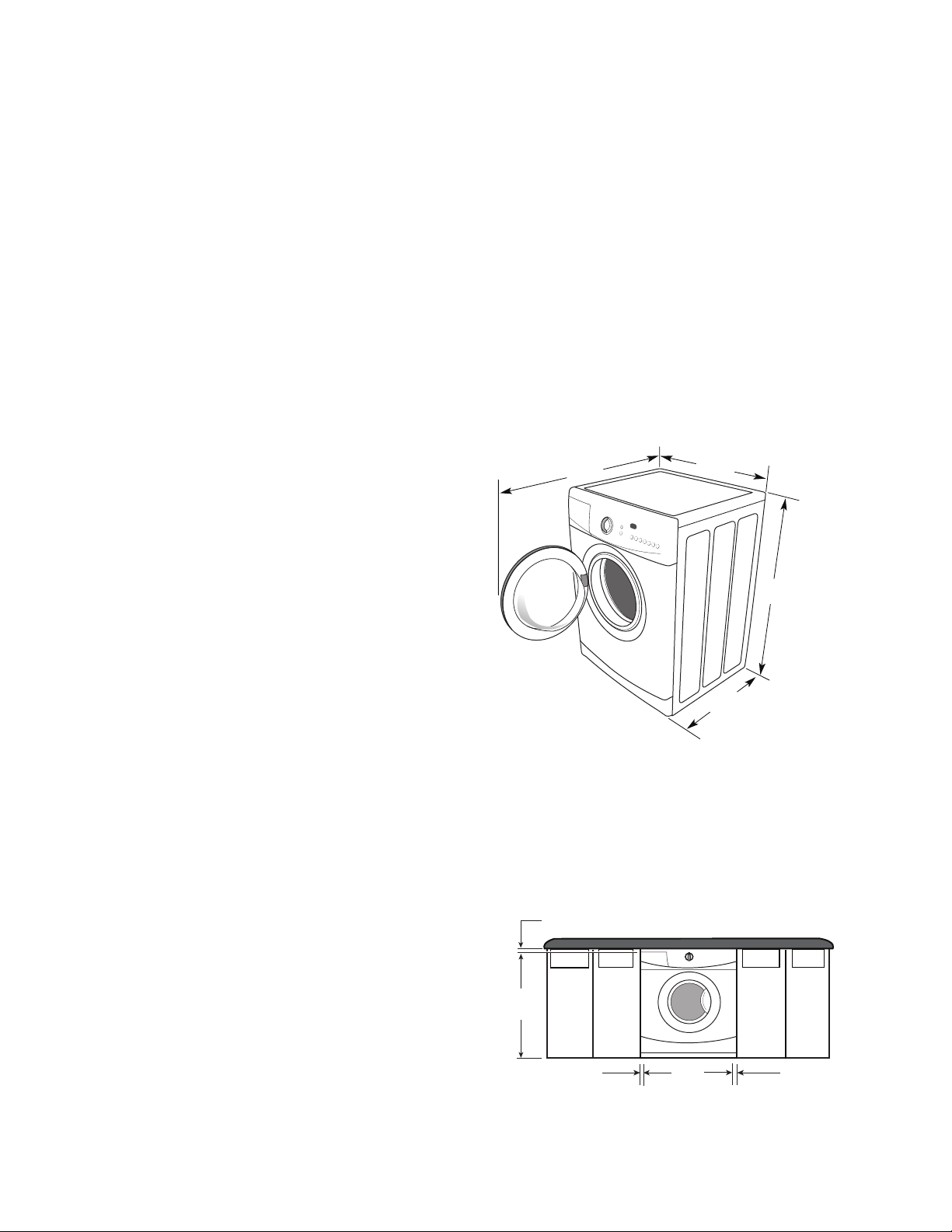

36.2

(92 cm)

23.4"

(59.5 cm)

"

32.9"

(83.5 cm)

20.1"

(51 cm)

1"

(2.5 cm)

1"

(2.5 cm)

32.9" min.

(83.5 cm)

23.4"

(59.5 cm)

2" (5 cm)

Installation Clearances

Are you planning to stack your washer and

dryer? To do so you will need to purchase a

Stack Kit.

To order, call the dealer from whom you purchased your washer or refer to the “Assistance or Service” section. Ask for Part Number W10178021.

LOCATION REQUIREMENTS

Selecting the proper location for your washer

improves performance and minimizes noise

and possible washer “walk.”

The washer can be installed under a custom

counter, in a basement, laundry room, closet,

or recessed area. See “Drain System,” page

2-4.

Companion appliance location requirements

should also be considered. Proper installation

is your responsibility.

You will need

The location must be large enough to allow •

the washer door to be fully opened.

Additional spacing should be considered •

for ease of installation and servicing. The

door opens more than 90°, and it is not reversible.

Additional clearances might be required for •

wall, door, and floor moldings.

Additional spacing of 1• ˝ (2.5 cm) on all

sides of the washer is recommended to reduce noise transfer.

Companion appliance spacing should also •

be considered.

Washer Dimensions

A water heater set to deliver 120• °F (49°C)

water to the washer.

A grounded electrical outlet located within •

5.4 ft (1.65 m) of where the power cord is

attached to the back of the washer. See

“Electrical Requirements,” page 2-5.

Hot and cold water faucets located within •

4 ft (1.2 m) of the hot and cold water fill

valves, and water pressure of 20-100 psi

(137.9-689.6 kPa).

A level floor with a maximum slope of •

1˝(2.5 cm) under entire washer. Installing

the washer on soft floor surfaces, such as

carpets or surfaces with foam backing, is

not recommended.

A sturdy and solid floor to support the •

washer with a total weight (water and load)

of 400 lbs (180 kg).

Do not operate your washer in temperatures

below 32°F (0°C). Some water can remain

in the washer and can cause damage in low

temperatures.

Recommended installation spacing for

custom undercounter installation

The dimensions shown are for the recommended spacing.

Custom undercounter installation Washer only

2-2

Recommended installation spacing for re-

A. Side view - closet or conned area

B. Closet door with vents

34"

(86.4 cm)

A

B

3"

(7.6 cm)

3"

(7.6 cm)

1"

(2.5 cm)

4"

(10.2 cm)

20.1"

(51.0 cm)

48 in.

2

(310 cm2)

24 in.

2

(155 cm2)

A. Recessed area

B. Side view - closet or conned area

1"

(2.5 cm)

20.1"

(51.0 cm)

1"

(2.5 cm)

1"

(2.5 cm)

23.4"

(59.5 cm)

4"

(10.2 cm)

18" min.

(45.7 cm)

BA

*Min. top and bottom air openings for closet door.

**External exhaust elbow requires additional space.

†Wall, door and oor molding may require additional spacing.

3" (7.6 cm)

12" (30.5 cm)

23.4"

(59.5 cm)

3" (7.6 cm)

1" (2.5 cm)

1"

†

(2.5 cm)

1"

†

(2.5 cm)

48 in.2 *

(310 cm

2

)

24 in.

2

*

(155 cm

2

)

7" (17.8 cm)

9"

(22.9 cm)

7" (17.8 cm)

4"

(10.2 cm)

20.7"

(52.5 cm)

23.4"

(59.5 cm)

1"

(2.5 cm)1"(2.5 cm)

1"

(2.5 cm)

cessed or closet installation, with or without a pedestal

The dimensions shown are for the recommended spacing.

Recessed area or closet installation

Recessed or closet installation Washer on pedestal

Recommended installation spacing for recessed or closet installation, with stacked

washer and dryer

The dimensions shown, at the top of the right

column, are for the recommended spacing.

Recommended installation spacing for

cabinet installation

The dimensions shown are for the recommended spacing.

For cabinet installation with a door, the

minimum ventilation openings in the top

are required.

2-3

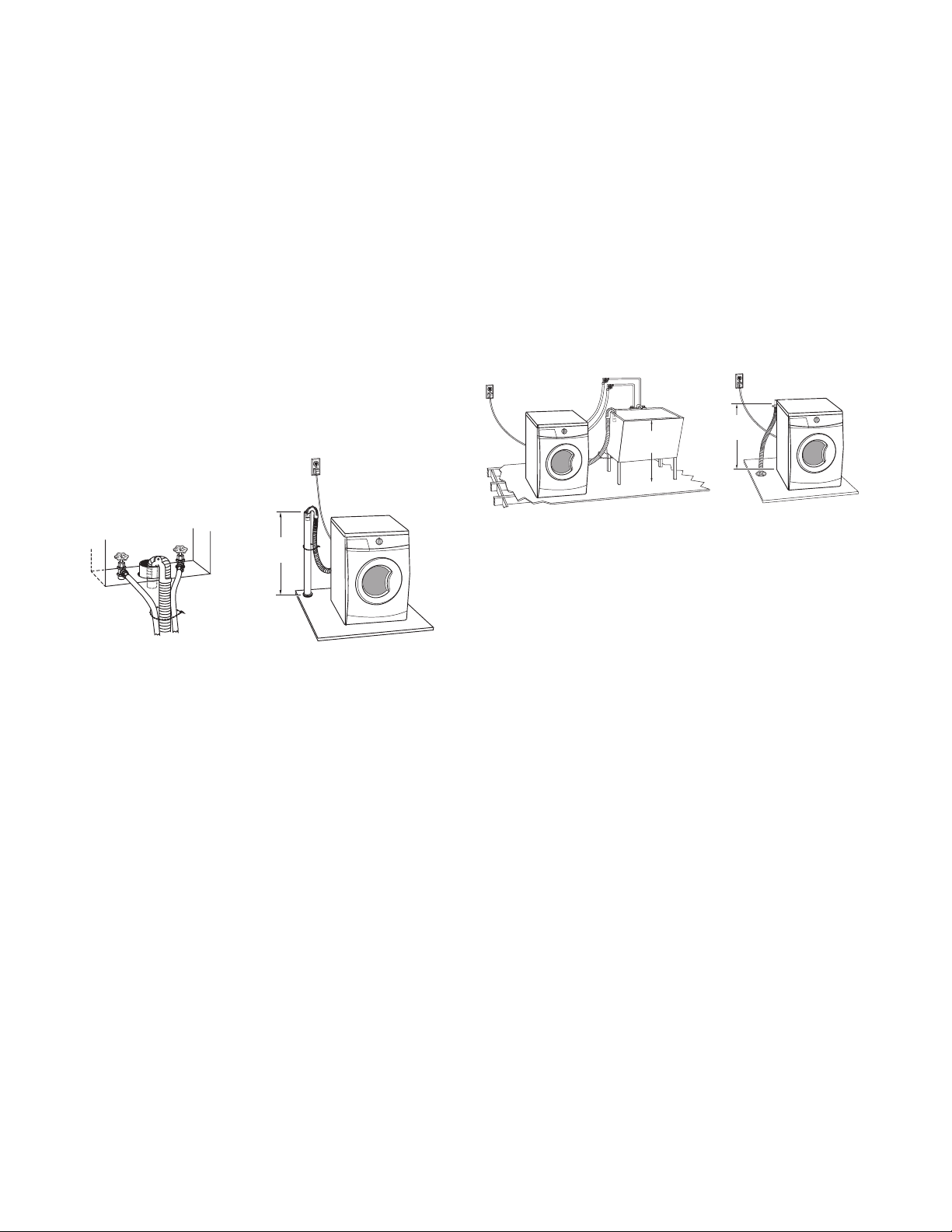

DRAIN SYSTEM

30" min.

(76.2 cm)

A

B

DC

30" min.

(76.2 cm)

26" min.

(66 cm)

The washer can be installed using the standpipe drain system (floor or wall), the laundry

tub drain system or the floor drain system.

Select the drain hose installation method you

need. See “Tools and Parts,” page 2-1.

Standpipe drain system - wall or floor

(views A & B)

The standpipe drain requires a minimum

diameter standpipe of 2˝ (5 cm). The minimum carry-away capacity can be no less than

17 gal. (64 L) per minute.

The top of the standpipe must be at least 30˝

(76.2 cm) high and no higher than 55˝ (1.4 m)

from the bottom of the washer.

Laundry tub drain system (view C)

The laundry tub needs a minimum 20 gal.

(76 L) capacity. The top of the laundry tub must

be at least 30˝ (76.2 cm) above the floor.

Floor drain system (view D)

The floor drain system requires a siphon break

that may be purchased separately. See “Tools

and Parts,” page 2-1.

The siphon break must be a minimum of 26˝

(66 cm) from the bottom of the washer. Additional hoses might be needed.

2-4

WARNING

ELECTRICAL REQUIREMENTS

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

A 120 volt, 60 Hz., AC only, 15- or 20-•

amp, fused electrical supply is required. A

time-delay fuse or circuit breaker is recommended. It is recommended that a separate circuit serving only this appliance be

provided.

This washer is equipped with a power sup-•

ply cord having a 3 prong grounding plug.

To minimize possible shock hazard, the •

cord must be plugged into a mating,

3 prong, grounding-type outlet, grounded

in accordance with local codes and ordinances. If a mating outlet is not available,

it is the personal responsibility and obligation of the customer to have the properly grounded outlet installed by a qualified

electrician.

GROUNDING INSTRUCTIONS

For a grounded, cord-connected washer:

This washer must be grounded. In the

event of a malfunction or breakdown,

grounding will reduce the risk of electrical

shock by providing a path of least resistance for electric current. This washer is

equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed

and grounded in accordance with all local

codes and ordinances.

WARNING: Improper connection of the

equipment-grounding conductor can result

in a risk of electric shock. Check with a

qualified electrician or serviceman if you

are in doubt as to whether the appliance is

properly grounded.

Do not modify the plug provided with the

appliance – if it will not fit the outlet, have a

proper outlet installed by a qualified electrician.

For a permanently connected washer:

This washer must be connected to a

grounded metal, permanent wiring system, or an equipment-grounding conductor

must be run with the circuit conductors and

connected to the equipment-grounding

terminal or lead on the appliance.

If codes permit and a separate ground wire •

is used, it is recommended that a qualified

electrician determine that the ground path

is adequate.

Do not ground to a gas pipe.•

Check with a qualified electrician if you are •

not sure the washer is properly grounded.

Do not have a fuse in the neutral or ground •

circuit.

2-5

INSTALLATION INSTRUCTIONS

WARNING

A. Coupling

B. Washer

AB

REMOVE TRANSPORT SYSTEM

Excessive Weight Hazard

Use two or more people to move and

install washer.

Failure to do so can result in back or

other injury.

IMPORTANT: Position the washer so that the

rear of the unit is within approximately 3 ft

(90 cm) of the final location.

There are 4 bolts in the rear panel of the

washer that support the suspension system

during transportation. These bolts also retain

the power cord inside the washer until the

bolts are removed.

4. Close the bolt holes with the 4 transport

bolt hole plugs.

NOTE: If the washer is to be transported at

a later date, call your local service center.

To avoid suspension and structural damage,

your machine must be properly set up for relocation by a certified technician.

CONNECT THE INLET HOSES

Insert new flat washers (supplied) into each

end of the inlet hoses. Firmly seat the washers in the couplings.

Connect the inlet hoses to the water faucets

Make sure the washer drum is empty.

1. Using a 12 mm wrench, loosen each of

the bolts.

2. Once the bolt is loose, move it to the center of the hole and completely pull out the

bolt, including the plastic spacer covering

the bolt.

3. Once all 4 bolts are removed, discard the

bolts and spacers. Then pull the power

cord through the opening of the rear panel and close the hole with the attached

cap.

1. Attach a hose to the hot water faucet.

Screw on coupling by hand until it is seated on the washer.

2. Attach a hose to the cold water faucet.

Screw on coupling by hand until it is seated on the washer.

3. Using pliers, tighten the couplings with

an additional two-thirds turn.

NOTE: Do not overtighten or use tape

or sealants on the valve. Damage to the

valves can result.

2-6

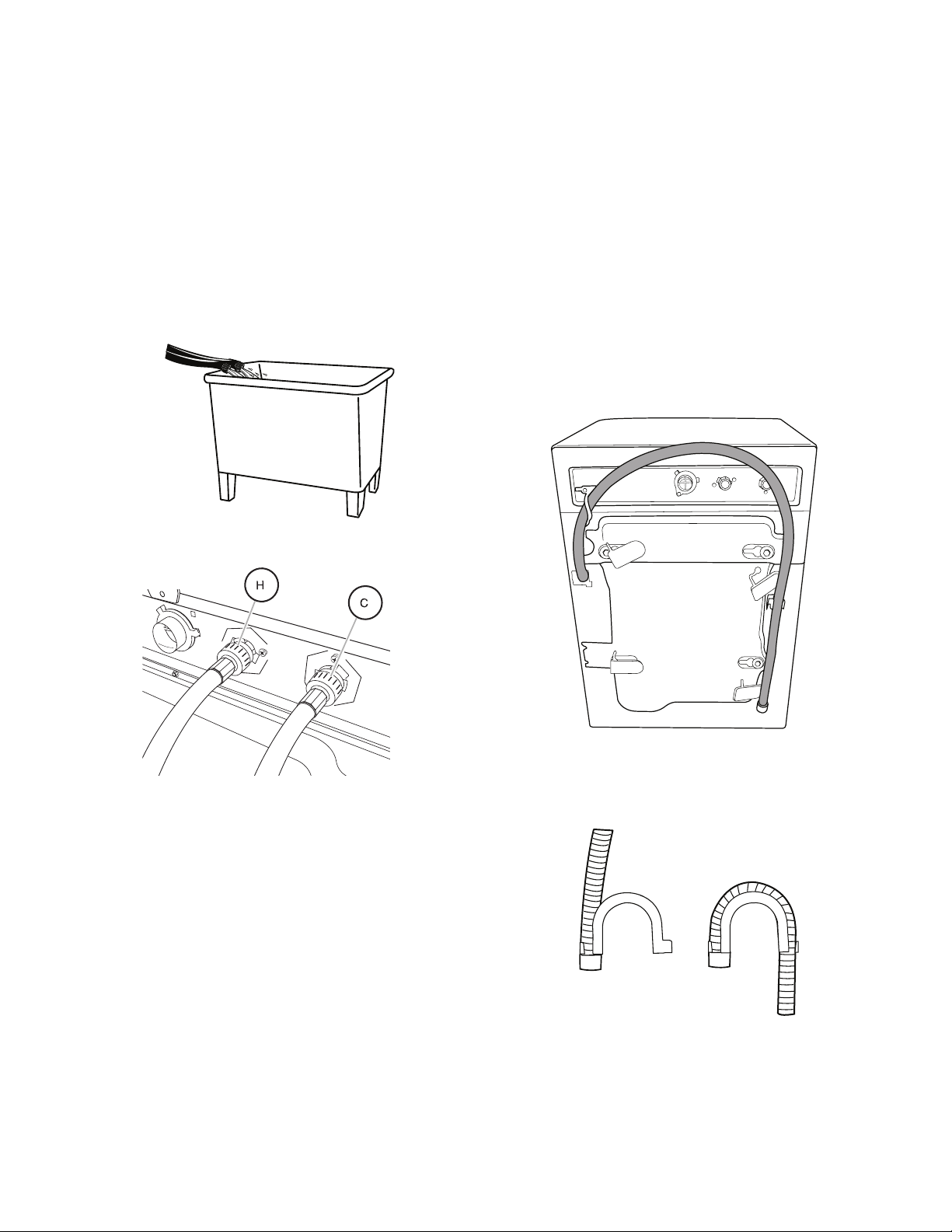

Clear the water lines

H. Hot water inlet

C. Cold water inlet

A.Snap either end of the drain hose form to the drain hose at

the point where the corrugation begins.

B. Bend drain hose over drain hose form and snap into place.

AB

1. Run water through both faucets and inlet hoses, into a laundry tub, drainpipe or

bucket, to get rid of particles in the water lines that might clog the inlet valve

screens.

NOTE: Replace inlet hoses after 5 years of

use to reduce the risk of hose failure. Record

hose installation or replacement dates on the

hoses for future reference.

Periodically inspect and replace hoses if bulges, kinks, cuts, wear, or leaks are found.

2. Check the temperature of the water to

make sure that the hot water hose is connected to the hot water faucet and that

the cold water hose is connected to the

cold water faucet.

Connect the inlet hoses to the washer

ROUTE THE DRAIN HOSE

Proper routing of the drain hose protects your

floors from damage due to water leakage.

Read and follow these instructions.

Remove drain hose from the washer

Gently pull the corrugated drain hose from the

shipping clips.

1. Attach the hot water hose to the washer’s hot (H) water inlet valve. Screw on

coupling by hand until it is seated on the

washer.

2. Attach the cold water hose to the washer’s

cold (C) water faucet. Screw on coupling

by hand until it is seated on the washer.

3. Using pliers, tighten the couplings with

an additional two-thirds turn.

NOTE: Do not overtighten. Damage to

the coupling can result.

4. Turn on the water faucets completely and

check for leaks.

Laundry tub drain or standpipe drain

Connect the drain hose form to the corrugated

drain hose.

2-7

To keep drain water from going back into

AB C

the washer:

Do not straighten the drain hose, and do •

not force excess drain hose into standpipe.

Hose should be secure, but loose enough

to provide a gap for air.

Do not lay excess hose on the bottom of •

the laundry tub.

Floor drain

You may need additional parts. See Floor

Drain under “Tools and Parts,” page 2-1.

SECURE THE DRAIN HOSE

1. Drape the power cord over the washer

top.

2. Move the washer to its final location.

3. Place the drain hose in the laundry tub or

standpipe. See illustrations A and B.

LEVEL THE WASHER

Properly leveling your washer avoids excessive noise and vibration.

1. Check the levelness of the washer by

placing a level on the top edge of the

washer, first side to side, then front to

back.

If the washer is against a wall, move the

washer out slightly before tipping back.

First prop the front with a wood block and

adjust the feet as necessary; then prop

the back and adjust feet as necessary.

Repeat this step until washer is level.

4. If the washer faucets and the drain standpipe are recessed, put the hooked end of

the drain hose in the standpipe. See illustration C.

NOTES:

Do not force excess drain hose back into •

the rear of the washer.

To prevent siphoning, do not seal the drain •

hose into the standpipe.

2. Make sure that all four feet are stable and

resting on the floor. Then check that the

appliance is perfectly level (use a level).

3. After the washer is level, use a 13 mm

open-end wrench to turn the nuts on the

feet tightly against the washer cabinet.

IMPORTANT: All four feet must be tight-

ened. If the nuts are not tight against the

washer cabinet, the washer may vibrate.

4. Slide the washer to its final location.

5. The washer should not move front to

back, side to side, or diagonally when

pushed on its top edges.

6. Confirm the levelness of the washer.

2-8

COMPLETE INSTALLATION

WARNING

Use only HE High Efficiency detergent.

1. Check the electrical requirements. Be

sure that you have the correct electrical

supply and the recommended grounding

method. See “Electrical Requirements,”

page 2-5.

2. Check to be sure all parts are now installed. If there is an extra part, go back

through the steps to see which step was

skipped.

3. Check that you have all of your tools.

4. Dispose of or recycle all packaging materials.

5. Check that the water faucets are on.

6. Check for leaks around faucets and inlet

hoses.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

7. Plug into a grounded 3 prong outlet.

8. Read “Washer Use,” page 3-2.

9. To test and to clean your washer, use

1/2 the manufacturer’s recommended

amount of detergent for a medium sized

load. Pour the detergent into the detergent dispenser. Select NORMAL/CASUAL, and then select START. Allow the

washer to complete one whole cycle.

2-9

— NOTES —

2-10

PRODUCT OPERATION

Use only HE High Eciency detergent.

FEATURES AND BENEFITS

The front-loading high efciency washer was

designed to conserve resources and lower your

water and energy bills. The washer is designed

to determine and then provide the amount of

water needed for the best performance. The

time of operation may be greater for this new

system than for a conventional washer.

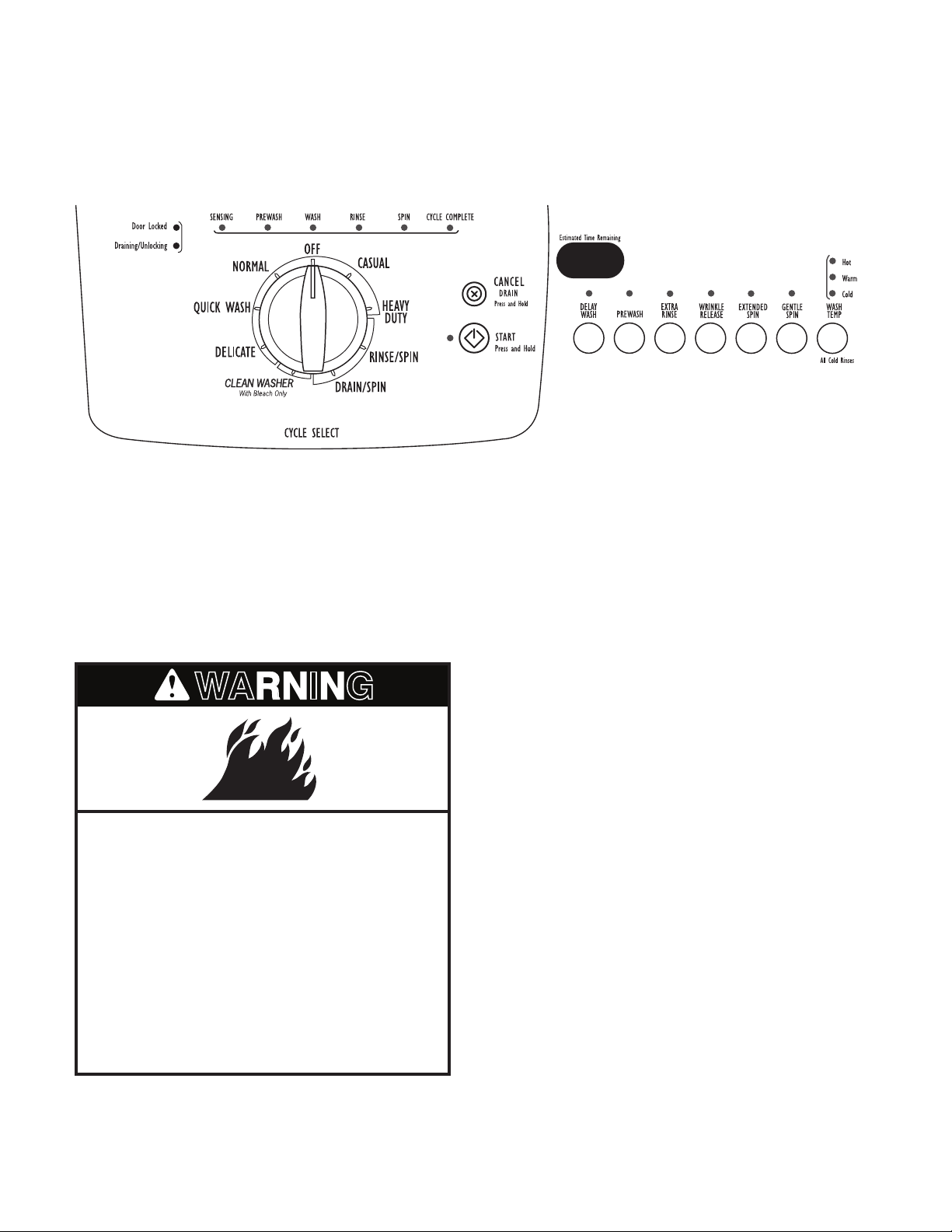

ELECTRONIC CONTROLS

Flexible electronic controls are easy to use

whether you are a beginner or an expert.

AUTO WATER LEVEL

Adjusting to the size of the load, this feature

allows the washer to use the minimal amount

of water needed to clean and rinse the clothes.

With a low water level, you can obtain the

same results with smaller amounts of additives.

Because only the required amount of water is

used, the washer saves energy, too. You can

obtain the same washing results for small and

large loads size.

SUSPENSION SYSTEM

To reduce washer “walk” and “off-balance”

conditions, your new washer combines:

2 Springs to isolate vibration•

2 shock absorbers at the washer base to •

minimize movement

SPIN SPEEDS

This washer automatically selects the spin

speed based on the cycle selected.

DYNAMIC BALANCE

A precision balancing system allows the washer

to reach high-speed spins. The washer spins

faster so that clothes coming out of the washer

will have less moisture than with traditional top

load machines. In addition, if the Dynamic Balance system detects off-balance loads during

spinning, it redistributes the clothes so that they

are evenly balanced.

SMART DISPENSERS

The three compartments in the dispenser

allow loading of all laundry products before

the washer is started. The products will be

dispensed into the wash at the optimal time

for high performance cleaning. The bleach

release system is included in the detergent

advantage system. The detergent is added at

the beginning of the cycle, and the bleach is

added after the enzymes have had a chance

to do their cleaning. The fabric softener is

dispensed in the rinse cycle or in the EXTRA

RINSE, if selected. The Detergent Advantage

System Dispenser tray is easily removed for

cleaning.

STAINLESS STEEL DRUM

The stainless steel drum eliminates corrosion

and enables higher spin speeds for more water

extraction, reducing drying time.

ADAPTIVE VARIABLE

SPEED MOTOR

The motor adapts to the load size and to the

cycle selected to give the optimum cleaning,

rinsing, and spinning conditions. The motor can

handle slow speeds needed for delicate items

and is powerful enough to drive an average

clothes load up to a high-speed spin.

3-1

WARNING

WASHER USE

STARTING THE WASHER

Fire Hazard

Never place items in the washer that

are dampened with gasoline or other

ammable uids.

No washer can completely remove oil.

Do not dry anything that has ever had

any type of oil on it (including cooking

oils).

Doing so can result in death, explosion,

or re.

The following is a guide to using the washer.

Please refer to specic sections of this manual

for more detailed information.

Do not store laundry products on the top surface of this washer. Vibration is normal during

operation.

3-2

USING THE PROPER DETERGENT

Use only HE High Efficiency detergent.

Use only High Efciency detergents. The package for this type of detergent will be marked

“HE” or “High Efciency.” This wash system,

along with less water, will create too much

sudsing with a regular non-HE detergent. Using regular detergent will likely result in washer

errors, longer cycle times, and reduced rinsing

performance. It may also result in component

failures and noticeable mold or mildew. HE detergents are made to produce the right amount

of suds for the best performance. Follow the

manufacturer’s instructions to determine the

amount of detergent to use.

First Wash Cycle Without Laundry

Before washing clothes for the rst time, if not

completed during the nal installation step,

choose the Normal/Casual cycle and run it

without clothes. Use only HE High Efciency

detergent. Use 1/2 the manufacturer’s recommended amount for a medium-sized load. This

initial cycle serves to ensure the interior is clean

before washing clothes.

For All Wash Cycles

1. To load washer

Open the washer door by pulling on the

handle. Sort laundry according to color and

type of fabric. Place a load of sorted clothes

in the washer. Do not overload washer.

Overloading can cause poor cleaning.

The washer can be fully loaded, but •

not tightly packed. Washer door should

close easily.

Mix large and small items. Avoid wash-•

ing a single item. Load evenly.

Wash small items such as infant socks •

in mesh garment bags. It is recommended that more than one garment bag be

used and that each garment bag be

lled with equal amounts of material.

When unloading garments, occasionally •

check under the rubber rim at the front

of the tub for small items.

2. Close the washer door by pushing it rmly

until the lock clicks. The washer door will

remain locked during the wash cycle.

NOTE: There is a routine at the beginning

of each cycle to avoid unintended use of

the washer. This routine will take approximately 1 minute to complete before the

selected wash cycle begins.

3. Open the dispenser drawer and add laundry additives to the detergent, bleach,

or fabric softener compartments. Close

drawer slowly to avoid spills. See “Using

the Dispenser.”

4. Turn on the washer by turning the cycle

selector and selecting one of the cycles.

The indicator light for the selected cycle

will illuminate. When selecting a Wash

Cycle, the preset Modiers, Options and

Water Temp for the selected cycle will illuminate. The preset settings provide the

recommended fabric care for the selected

cycle. See “Cycles.”

5. Select the desired OPTIONS. Not all Options are available with all cycles. See

“Options.”

6. To begin the wash cycle immediately

Select and hold START (for approximately

3 seconds).

If you do not select START within 5 •

minutes of choosing a cycle, the washer

display automatically shuts off.

When the wash cycle is complete, the •

CYCLE COMPLETE status light illuminates, the door unlocks and the wash

load can be removed from the washer.

The washer goes into standby mode

automatically after the door is opened

or 1 hour after the cycle is complete and

all displays will go off.

To power down the washer manually •

after the wash cycle is complete, switch

knob to Off position.

3-3

Use only HE High Efficiency detergent.

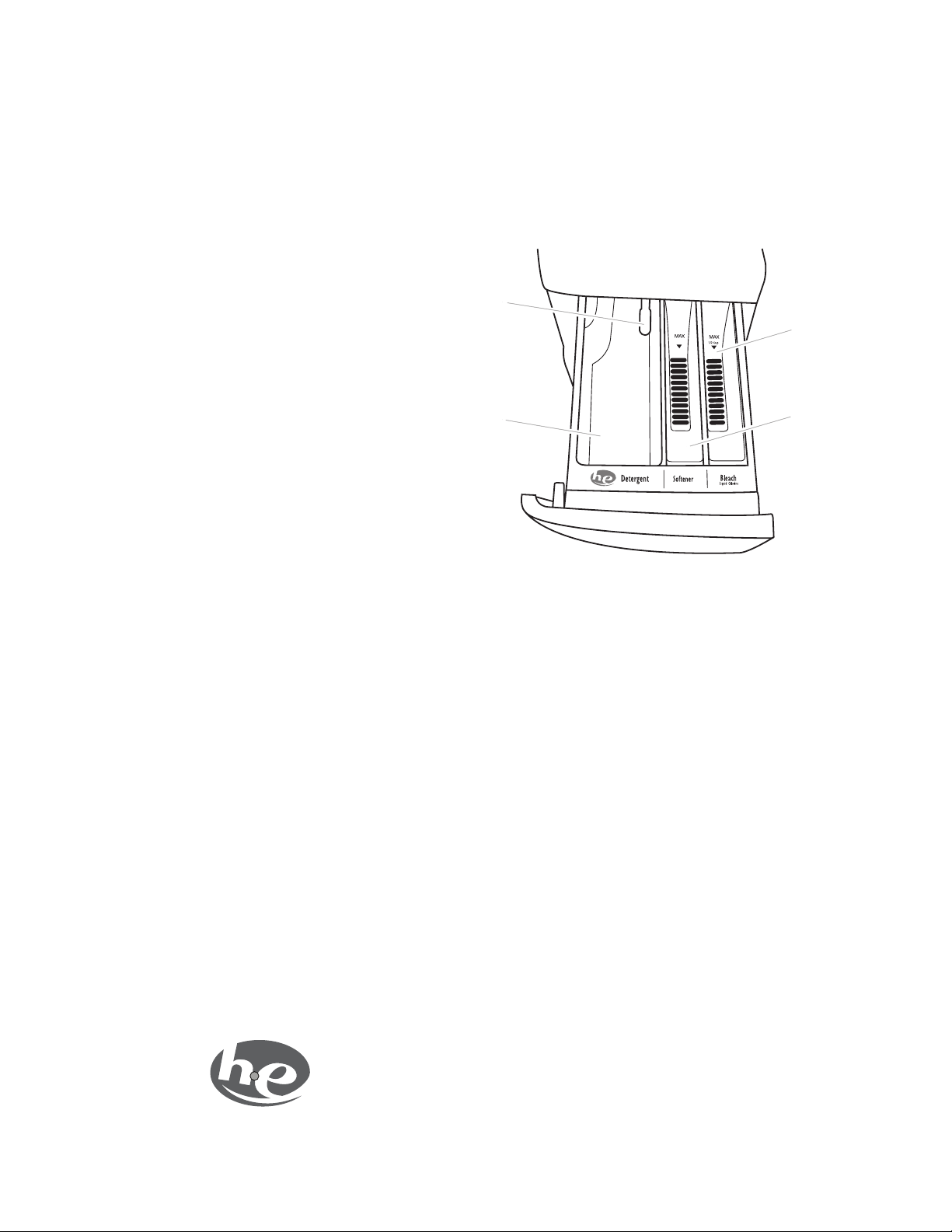

Dispenser

A. Dispenser release lever

B. Main Wash detergent compartment

C. Liquid chlorine bleach compartment

D. Fabric softener compartment

A

B

C

D

7. To begin the wash cycle later Select

DELAY WASH until the desired delay time

(in hours) is displayed. Select START. The

countdown to the wash cycle will show in

the display window.

IMPORTANT: When delaying a cycle, use

only powdered detergents in the main wash

compartment since liquid detergents may

seep out of the compartment during Delay

before the wash cycle begins.

USING THE DISPENSER

The washer has a dispenser drawer with

three separate compartments for your laundry

additives—one is for detergent, one is for liquid chlorine bleach, and one is for liquid fabric

softener. Laundry additives are diluted and

dispensed automatically at the proper time

during the wash cycle, making it unnecessary

for you to return to the washer during the cycle

to add them.

To ll dispenser compartments

1. Pull out the dispenser drawer.

2. Add the desired laundry products to the

proper compartment.

3. Push in the dispenser drawer slowly and

completely (to avoid a spill).

It is normal for small amounts of water to remain in the dispensers when the wash cycle

is complete.

Do not put laundry additives directly into the

wash tub. Always use the proper dispensers

when adding laundry additives.

Choosing the Right Detergent

Use only High Efciency detergents. The package for this type of detergent will be marked

“HE” or “High Efciency.” This wash system,

along with less water, will create too much

Main Wash detergent compartment

(Letter B in Dispenser Illustration)

Add liquid or powdered HE detergent to this

compartment for your main wash cycle.

Powdered color-safe bleach may be added •

to the Main Wash compartment along with

the powdered detergent.

sudsing with a regular non-HE detergent. Using regular detergent will likely result in washer

errors, longer cycle times, and reduced rinsing

performance. It may also result in component

failures and noticeable mold or mildew. HE detergents are made to produce the right amount

of suds for the best performance. Follow the

manufacturer’s instructions to determine the

amount of detergent to use.

3-4

Follow the manufacturer’s instructions to •

determine the amount of detergent to use.

NOTE: Overlling could cause an oversudsing

condition.

Chlorine bleach compartment

(Letter C in Dispenser Illustration)

Add NO MORE THAN 1/2 cup (120 mL) liquid

chlorine bleach to this compartment. The bleach

will be automatically diluted and dispensed

at the best time during the rst rinse after the

wash cycle. This compartment cannot dilute

powdered bleach.

Use only liquid chlorine bleach in this dis-•

penser. Do not use this dispenser to add

powdered chlorine or any form of colorsafe

bleach to your load.

Always measure liquid chlorine bleach. Use •

a measuring cup with a pour spout; do not

guess. Follow the manufacturer’s directions

for proper use.

Do not ll beyond the “MAX” level.•

NOTE: Overlling could cause garment damage.

Fabric softener compartment

(Letter D in Dispenser Illustration)

Add 1/2 cup (120 mL) liquid fabric softener

to this compartment. Fabric softener will be

automatically dispensed in the nal rinse or in

the EXTRA RINSE, if selected.

Do not ll beyond the “MAX” level.•

RESTARTING

To restart the washer at any time, select CANCEL/DRAIN.

CHANGING CYCLES AND OPTIONS

Not all Options are available with all Cycles.

Cycles and Options can be changed anytime

before START is selected.

To stop a cycle and select a new cycle

1. Press and hold CANCEL/DRAIN for 3

seconds.

2. Select desired cycle..

3. Select the desired OPTIONS.

4. Select and hold START (for approximately

3 seconds) to restart the washer at the

beginning of the new cycle.

To cancel a cycle and to drain the washer

manually

1. Press and hold CANCEL/DRAIN for 3

seconds.

2. The pump will turn on to drain out the water

and the door will unlock.

NOTE: t will take approximately 1 minute

for the door to unlock.

3. The washer cycle stops, the door unlocks

and clothes can be removed.

4. To power down the washer manually after

the wash cycle is complete, switch knob

to Off position.

NOTE: If the water level is too high, the

washer will drain automatically before the

door unlocks.

.

STATUS LIGHTS

These lights show which portion of the cycle

the washer is operating.

3-5

Sensing

Cycles

The washer automatically weighs items then

adjusts the Estimated Time Remaining, based

on the cycle selected.

Cycle Complete

The Cycle Complete status light stays on for 1

hour after the cycle is complete. To power down

the washer manually after the wash cycle is

complete, switch knob to Off position.

Estimated Time Remaining

The cycle times vary automatically based on

your water pressure, water temperature, detergent, and clothes load. The cycle time will

be extended if oversudsing occurs or the load

is unbalanced. The oversuds routine removes

extra suds and assures proper rinsing of your

garments. The options you select will also affect the cycle times that are shown in the Preset Cycle Settings table. The Estimated Time

Remaining can change to much longer times

under extreme conditions.

Door Locked

When the Door Locked LED light illuminates,

the door is locked. The door is locked and unlocked automatically, depending on the stage

of the wash cycle. Press and hold CANCEL/

DRAIN for 3 seconds to unlock the door manually. It will take approximately 1 minute for the

door to unlock..

Wash Cycles

Choose Wash Cycles by rotating the Cycle selector knob to the desired cycle. The indicator

light for the cycle selected will illuminate. Each

cycle is designed for different types of fabric

and soil levels.

Each cycle has a default cycle time, WASH •

TEMP, and may have preset Options. The

preset settings provide the recommended

fabric care for the selected cycle.

The preset settings can be changed anytime •

before START is selected. Not all Options

and Modiers (WASH TEMP, spin options)

are available with all Cycles. Select and

hold START (for approximately 3 seconds)

to continue the cycle.

3-6

Preset Cycle Settings

Cycle

Estimated

Time*

(hr:min)

Wash T e mp Spin Sp eed

Normal 0:50 Warm High

Quick Wash

(2-3 items)

0:30 Warm High

Delicate 0:37 Warm Low

Clean Washer 1:15 HotHigh

Drain/Spin 0:18 N/AHigh

Rinse/Spin 0:24 ColdHigh

Heavy Duty 1:10 Wa rm High

Casual 0:45 Warm Low

Delicate

Each cycle has a preset Cycle Time and WASH/

RINSE TEMP. The preset settings provide

the recommended fabric care for the selected

cycle. See chart..

* The cycle times vary automatically based

on your water pressure, water temperature,

detergent, and clothes load. The cycle time

will be extended if oversudsing occurs or the

load is unbalanced.

Use this cycle to wash sheer fabrics and lingerie. This cycle has low-speed spin for gentle

fabric care.

Use mesh garment bags to wash undergar-•

ments such as underwire bras, items with

strings, and small items such as socks.

Clean Washer

Use the Clean Washer cycle once a month to

keep the inside of your washer fresh and clean.

This cycle uses a higher water level. Use with

AFFRESH™ washer cleaner tablet or liquid

chlorine bleach to thoroughly clean the inside

of your washing machine.This cycle should not

be interrupted. See “Cleaning Your Washer.”

Drain/Spin

Use this cycle to drain your washer or to drain

and spin your wash load. The spin speed is

preset to HIGH.

Rinse/Spin

Normal

Use this cycle to wash loads of normally soiled

cottons and linens. This cycle has high-speed

spin.

Quick Wash

Use this cycle to wash small loads of 2-3 lightly

soiled garments that are needed in a hurry.

This cycle combines a shortened wash time

and high-speed spin to shorten drying time.

Large wash loads will result in the machine

increasing the wash time.

Use this cycle to get a rinse and spin only. This

cycle has highspeed spin.

Rinse & Spin is useful for:

Loads that need rinsing only.•

Adding fabric softener to a load using the •

fabric softener dispenser

3-7

Heavy Duty

OPTIONS AND MODIFIERS

Use this cycle to wash loads of sturdy, colorfast

fabrics and Heavy soiled garments. This cycle

combines a longer wash time and high-speed

spin to shorten drying times.

Casual

Use this cycle to wash loads of permanent

press blends and synthetic fabrics. This cycle

has a load cooling process to reduce wrinkling.

NORMAL SOUNDS

As with any new product, you will hear sounds

that you are not accustomed to. You may hear

various sounds when the door is locked or

unlocked, and during the washing, rinsing, or

spinning process. Between changes in wash

actions, there will be momentary pauses. You

will hear water spraying and splashing during

the wash and rinse cycles. These new sounds

and pauses are part of normal washer operation. See “Troubleshooting.”

You can customize your wash by adding options to your cycle selections. Not all Options

are available with all cycles.

See the “Laundry Guide” section for an •

overview of possible options for each Wash

Cycle selection.

If an option is available with a selected cycle, •

the light for that option will illuminate when

selected.

If an option is unavailable with a selected •

cycle, there will be a blinking light. The

light for that option will not illuminate when

selected.

Delay Wash

Use this to begin the wash cycle later.

Select DELAY WASH until the desired time •

(in hours) shows in the Estimated Time Remaining display.

Select START. The countdown to the wash •

cycle will show in the display window.

3-8

Prewash

T

emperature Guide

Wash Water Te mperature Suggested Fabrics

HOT Whites and pastels

Heavy soils

WARM Bright colors

Moderate to light soils

COLD Colors that bleed or fade

Light soils

Prewash is an 18-minute soak phase that is

added before the main wash. During prewash,

there is only a small amount of tumbling.

Extra Rinse

An extra rinse can be used to aid in the removal

of detergent or bleach residue from garments.

This option provides an additional rinse with

the same water temperature as in the normal

rinse. You may select or deselect by pressing

EXTRA RINSE.

Wrinkle Release

Use this option to increase the quantity of

incoming water and decrease the spin speed

and duration in the rinse period. The last spin

phase will have a lower spin speed and last a

shorter time.

Extended Spin

Use this option to increase the nal spin period

by 1 minute during the nal spin.

Gentle Spin

Each cycle has a preset spin speed. To reduce

the nal spin speed, select the GENTLE SPIN

button.

Temperature Guide

In wash water temperatures colder than 60°F

(15.6°C), detergents do not dissolve well. Soils

may be difcult to remove.

Auto Temp Control

ATC (Auto Temp Control) electronically senses

and maintains a uniform water temperature.

ATC regulates incoming hot and cold water.

The ATC is automatically turned ON when a

cycle is selected. See Preset Cycle Settings

table in “Cycles.”

ATC works for the wash temperature with •

Warm and Cold settings.

The Cold rinse temperatures depend on the •

cold water at the faucet.

Wash Temp

Each cycle has a preset water temperature

setting. To change the water temperature, select the WASH TEMP button until the desired

setting is illuminated.

Select a water temperature based on the type

of load you are washing. Use the warmest

wash water safe for fabrics. Follow garment

label instructions.

The water temperature for all rinse cycles is

cold. Cold rinses save energy.

3-9

Loading...

Loading...