Whirlpool W11114976B Service Data Sheet

FOR SERVICE TECHNICIAN’S USE ONLY

Voltage Measurement Safety Information

When performing live voltage measurements, you must do the following:

Verify the controls are in the off position so that the appliance does not start when energized.

Allow enough space to perform the voltage measurements without obstructions.

Keep other people a safe distance away from the appliance to prevent potential injury.

Always use the proper testing equipment.

After voltage measurements, always disconnect power before servicing.

IMPORTANT: Electrostatic Discharge (ESD) Sensitive Electronics

ESD problems are present everywhere. Most people begin to feel an ESD discharge at

approximately 3000V. It takes as little as 10V to destroy, damage, or weaken the main control

assembly. The new main control assembly may appear to work well after repair is finished,

but a malfunction may occur at a later date due to ESD stress.

Use an anti-static wrist strap. Connect wrist strap to green ground connection point or

unpainted metal in the appliance

-OR Touch your finger repeatedly to a green ground connection point or unpainted metal

in the appliance.

Before removing the part from its package, touch the anti-static bag to a green ground

connection point or unpainted metal in the appliance.

Avoid touching electronic parts or terminal contacts; handle electronic control assembly

by edges only.

When repackaging main control assembly in anti-static bag, observe above instructions.

This service data sheet is intended for use by persons having electrical, electronic, and

mechanical experience and knowledge at a level generally considered acceptable in the

appliance repair trade. Any attempt to repair a major appliance may result in personal injury

and property damage. The manufacturer or seller cannot be responsible, nor assume any

liability for injury or damage of any kind arising from the use of this data sheet.

Contents

IMPORTANT SAFETY NOTICE — “For Technicians only”

Control Panels .........................................2–5

Diagnostic Guide .........................................6

Fault/ Error Codes (Washer).........................7

Washer Troubleshooting Guide ................8, 9

Manual Test Mode (Washer) ......................10

PART NO. W11114976B

User Interface/Control Board (Washer) ......11

Rear View of Washer .................................12

Dryer Troubleshooting Guide .....................13

Dryer Troubleshooting Tests ................14–17

Wiring Diagrams .................................18–20

PAGE 1

FOR SERVICE TECHNICIAN’S USE ONLY

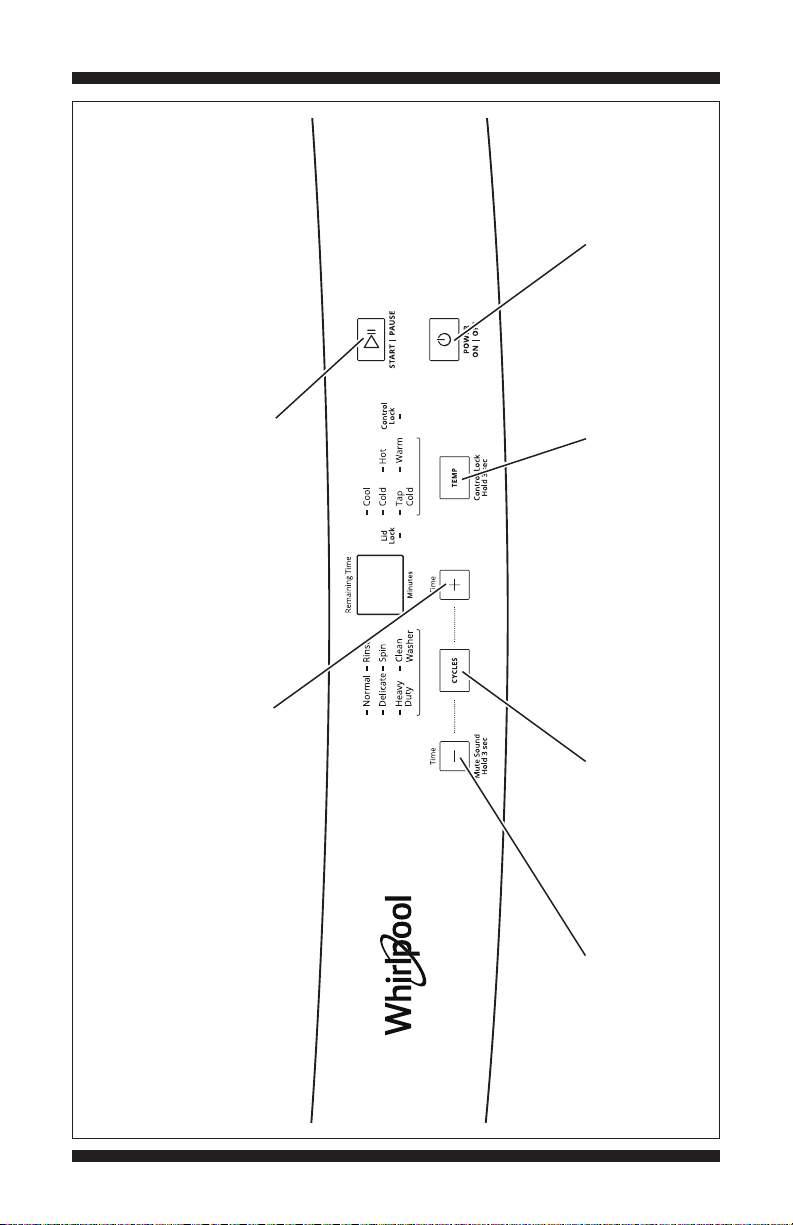

button exits the

Pressing the Power

UI/LED Test Mode.

the indicator.

Pressing the Start/Pause

test. Press once to turn off

button begins or continues the

Pressing the “+” button

turns on/off the 7-segment display.

Pressing the

Pressing the

Pressing the “–” button

temperature

Temp button

corresponding

turns on/off each

Cycles button

corresponding

cycle indicator.

turns on/off each

and lid lock indicators.

turns on/off the control lock

indicator.

WHIRLPOOL WASHER CONTROL PANEL

PAGE 2

Figure 1a - User Interface Test, Whirlpool Washer

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

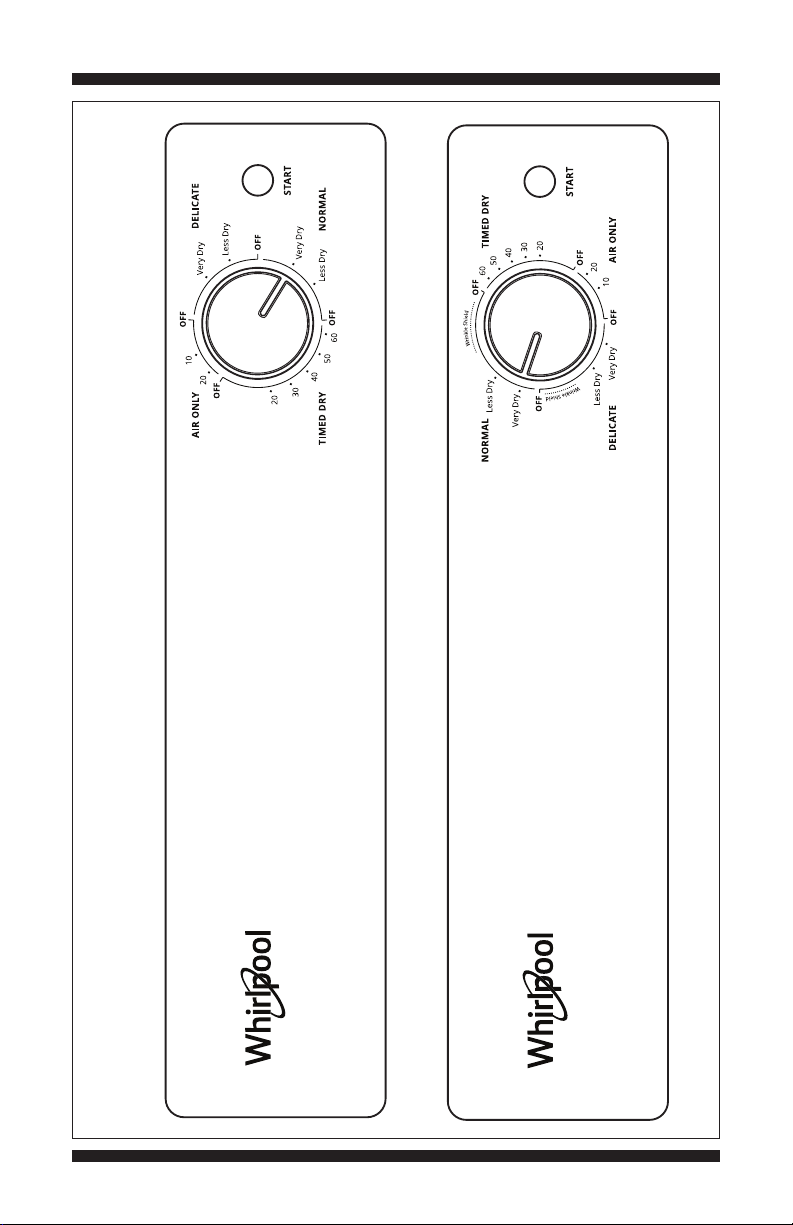

240V MODEL

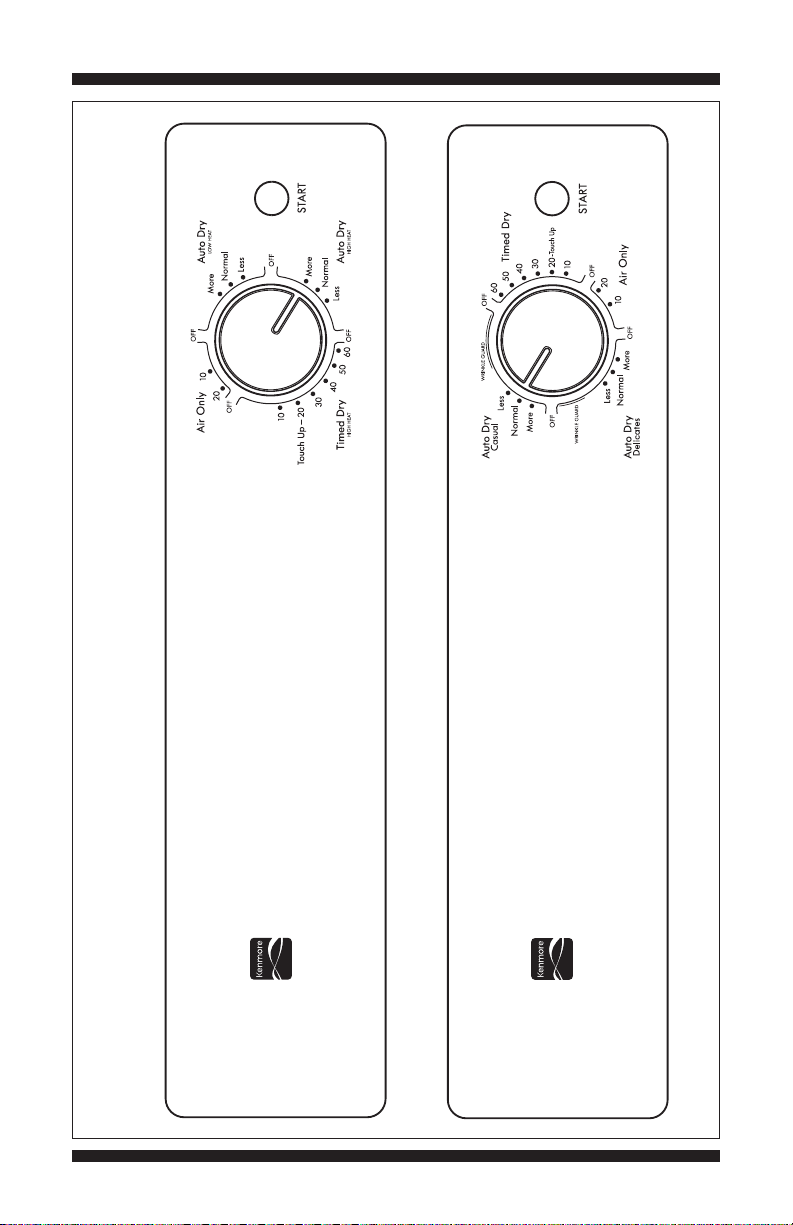

WHIRLPOOL DRYER CONTROL PANEL (appearance may vary)

DO NOT REMOVE OR DESTROY

120V MODEL

Figure 1b - User Interface Test, Whirlpool Dryer

PAGE 3

FOR SERVICE TECHNICIAN’S USE ONLY

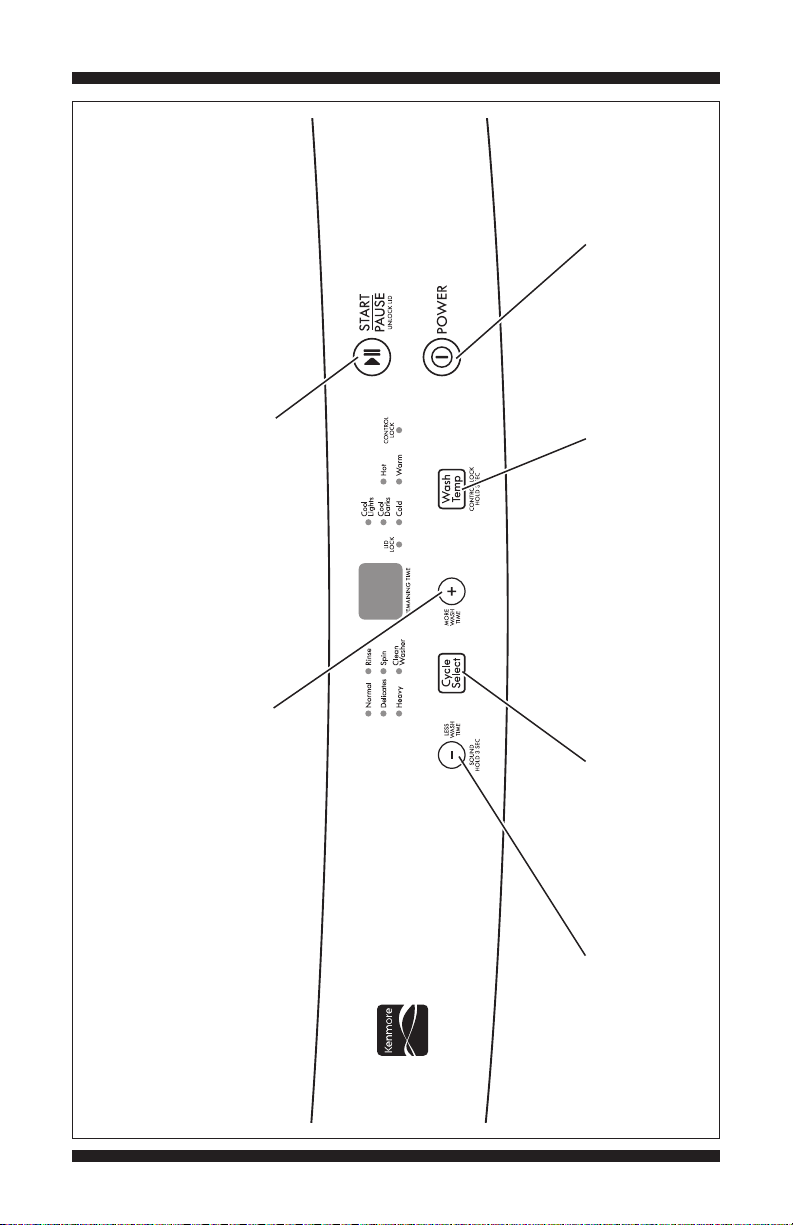

button exits the

Pressing the Power

UI/LED Test Mode.

the indicator.

Pressing the Start/Pause

test. Press once to turn off

button begins or continues the

Pressing the “+” button

turns on/off the 7-segment display.

Pressing the

Pressing the

Pressing the “–” button

temperature

corresponding

turns on/off each

Wash Temp button

corresponding

cycle indicator.

turns on/off each

Cycle Select button

and lid lock indicators.

turns on/off the control lock

indicator.

KENMORE WASHER CONTROL PANEL

PAGE 4

Figure 1c - User Interface Test, Kenmore Washer

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

240V MODEL

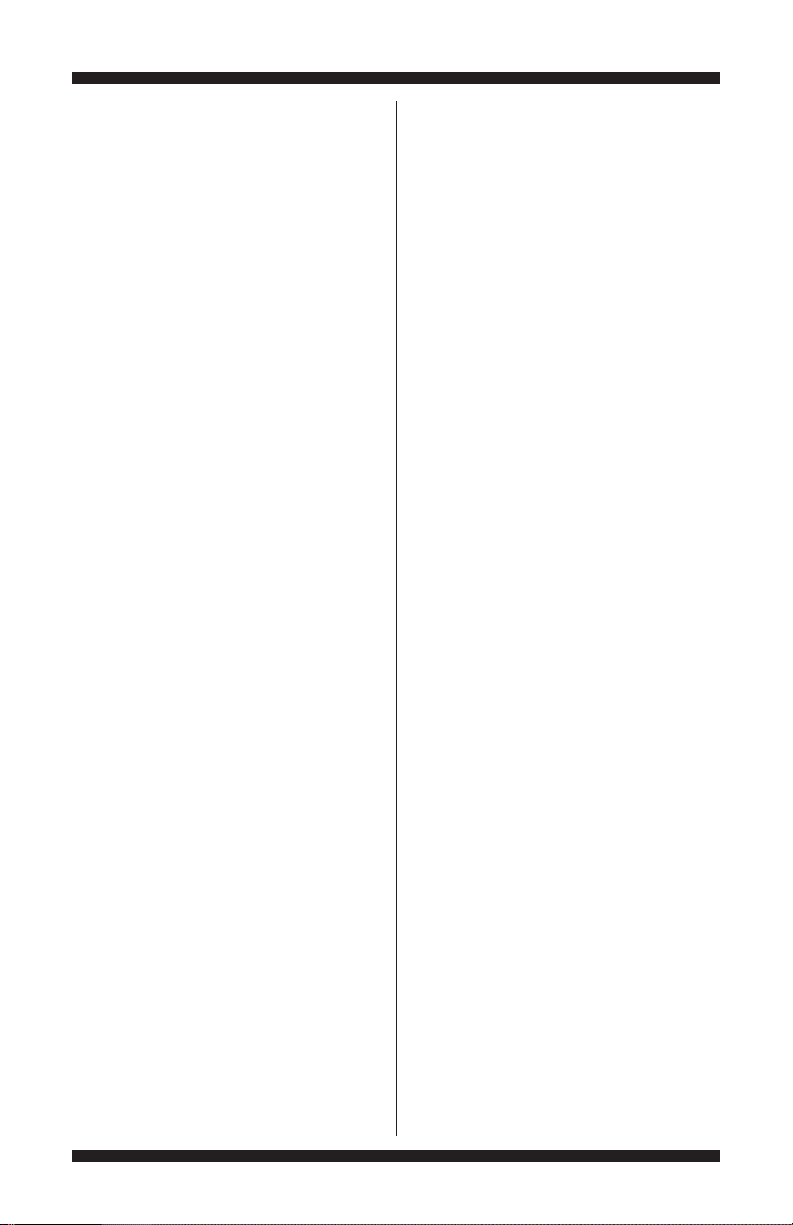

KENMORE DRYER CONTROL PANEL (appearance may vary)

DO NOT REMOVE OR DESTROY

120V MODEL

Figure 1d - User Interface Test, Kenmore Dryer

PAGE 5

FOR SERVICE TECHNICIAN’S USE ONLY

DIAGNOSTIC GUIDE

Before servicing, check the following:

Make sure there is power at the wall outlet.

Has a household fuse blown, or circuit

breaker or GFCI tripped? Was a regular fuse

used? Inform customer that a time-delay fuse

is required.

Is dryer vent properly installed and clear

of lint or obstructions?

Make sure both hot and cold water faucets

are open and water supply hoses are

unobstructed.

Make sure drain hose is not sealed into

drain pipe, and that there is an air gap for

ventilation. See Installation Instructions for

other drain hose installation considerations.

All tests/checks should be made with a

VOM (volt-ohm-milliammeter) or DVM

(digital-voltmeter) having a sensitivity of

20,000 Ω per volt DC or greater.

Resistance checks must be made

with washer/dryer unplugged or power

disconnected.

IMPORTANT: Avoid using large

diameter probes when checking harness

connectors as the probes may damage

the connectors upon insertion.

Check all harnesses and connections

before replacing components. Look for

connectors not fully seated, broken or

loose wires and terminals, pin insertion,

or wires not pressed into connectors

far enough to engage metal barbs.

A potential cause of a control not

functioning is corrosion or contamination on

connections. Use an ohmmeter to check for

continuity across suspected connections.

PAGE 6

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

FAULT/ERROR CODES (WASHER) – The fault codes below may be indicated

under various conditions.

Display Explanation and Recommended Procedure

EA Water Level Sensor

This error code will appear if the pressure sensor is damaged (outside a

specific frequency range). The washer will beep and this error code will

appear when the water level reaches approximately 3/4" (18 mm) below

the overflow point for 3 seconds. It will then pause, drain the water to the

highest load size level, then turn off the pump. The lid will remain locked.

Check connections between UI and water level sensor. Test water level

sensor in Manual Load Test, page 10.

E1 Low/No Water Fill

This error code will appear if the water level in the washer does not reach

the lowest level within 10 minutes or the set level within 20 minutes of

starting a cycle. Check water valve connections. Test water valves and

water level sensor in Manual Load Test, page 10.

E2 Abnormal Drain

This error code will appear if the washer fails to reach the reset level after

draining the water for 8 minutes. Check installation of drain hose, check

drain hose for obstructions, and check connections between UI and drain

pump. Test drain pump in Manual Load Test, page 10.

E3 Abnormal Spin

This error code will appear if the tub strikes the tub switch several times

without balancing itself. In a spin only cycle, the error code will appear the

first time the tub strikes the tub switch. See Spin Test, page 10.

EC Abnormal Circuit Motor Pulse Detection

The motor functions, but the circuit cannot detect the motor pulses.

The lid will remain locked for 5 minutes.

E4 Lid Open

This error code will appear if the washer lid is opened or if the lid switch

is open at the start of the spin during a rinse and spin cycle. Close lid.

See Lid Switch Test, page 10.

EL Lid Lock Malfunction

This error code will appear if the washer makes 10 unsuccessful attempts

to lock the lid or if the lid is detected as open during the wash or spin phase

where it must be closed and locked. Check for interference with lid or lid

lock mechanism. See Manual Load Test and Lid Switch Test, page 10.

E5 Class B Software Error

Any class B software error will display E5.

EP EEPROM Abnormal

EEPROM is corrupted.

DO NOT REMOVE OR DESTROY

PAGE 7

FOR SERVICE TECHNICIAN’S USE ONLY

WASHER TROUBLESHOOTING GUIDE NOTE: Always check for error codes first (pg. 7).

Problem Possible Cause Checks & Tests

Won’t Power Up No power to washer. Check power at outlet, check circuit breakers, fuses,

• No operation or junction box connections. If fuse or circuit breaker

• No button response blows repeatedly, washer capacitor or motor may be

• No LEDS or display defective. If so, replace it.

Connection problem between Check the AC power cord for continuity.

AC plug and UI.

User Interface/Control problem. See UI/LED Test, page 10.

Won’t Start Cycle Lid lock mechanism not 1. Lid not closed due to interference.

No response when functioning. 2. Lock not closed due to interference.

Start is pressed 3. See Lid Switch Test, page 10.

4. Check lid lock solenoid in Manual Load Test, page 10.

User Interface/Control problem. See UI/LED Test, page 10.

UI Won’t Accept User Interface/Control problem. See UI/LED Test, page 10.

Selections

Some or all buttons

non-responsive

No Sounds When Button sounds are turned off. Press “–” for 3 seconds to turn on button sounds.

Buttons Are Pressed

Won’t Fill No water supplied to washer. 1. Check water connections to washer.

2. Verify that hot and cold water supply is on.

Plugged filter/screen. Check for plugged filter or screen in the water valve

or hoses.

Water valve problem. Check water valve connections. If good, check function

of hot and cold water valves in Manual Load Test, page 10.

User Interface/Control problem. See UI/LED Test, page 10.

Overfills Pressure hose problem. Check pressure hose connections. Make sure hose is

routed correctly and not pinched. Check hose for leaks.

Replace hose if needed.

Water level sensor problem. Replace water level sensor.

Water valve problem. Check function of hot and cold water valves in Manual

Load Test, page 10.

Drain hose incorrectly installed. The top of the standpipe must be at least 39" (991 mm)

high and no higher than 72" (1.8 m) from the bottom

of the washer.

User Interface/Control problem. See UI/LED Test, page 10.

Incorrect Water Water hose installation. Make sure inlet hoses are connected properly.

Temperature

or hoses.

Water valve problem. Check water valve connections. If good, check function

of hot and cold water valves in Manual Load Test, page 10.

User Interface/Control problem. See UI/LED Test, page 10.

Won’t Agitate Lid not closed/lid lock 1. Lid not closed due to interference.

mechanism not functioning. 2. Lid lock not closed due to interference.

3. See Lid Switch Test, page 10.

4. Check lid lock solenoid in Manual Load Test, page 10.

Harness connections. Check harness connections between UI

and drive system.

Shifter problem. See Spin Test, page 10.

Motor problem. See Spin Test, page 10.

User Interface/Control problem. See UI/LED TEST, page 10.

Won’t Spin Lid not closed/lid lock 1. Lid not closed due to interference.

mechanism not functioning. 2. Lock not closed due to interference.

3. See Lid Switch Test, page 10.

4. Check lid lock solenoid in Manual Load Test, page 10.

Harness connections. Check harness connections between UI

and drive system.

Shifter problem. See Spin Test, page 10.

Motor problem. See Spin Test, page 10.

User Interface/Control problem. See UI/LED TEST, page 10.

User Interface/Control problem. See UI/LED Test, page 10.

Plugged filter/screen. Check for plugged filter or screen in the water valve

PAGE 8

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

WASHER TROUBLESHOOTING GUIDE (cont.) NOTE: Always check for error codes first

(pg. 7).

Problem Possible Cause Checks & Tests

Won’t Drain Drain hose incorrectly installed. The top of the standpipe must be at least 39" (991 mm)

high and no higher than 72" (1.8 m) from the bottom

of the washer. Make sure that drain hose is not sealed

into drain, and that there is an air gap for ventilation.

Plugged drain hose. Check drain hose for obstructions.

Harness connections. Check connections between UI and drain pump.

Drain pump problem. Check drain pump in Manual Load Test, page 10.

Drain pump is defective. Replace drain pump.

User Interface/Control problem. See UI/LED Test, page 10.

Cycle Time Oversuds. 1. Verify use of HE detergent.

Longer Than 2. Excessive detergent usage.

Expected

Drain hose incorrectly installed. The top of the standpipe must be at least 39" (991 mm)

high and no higher than 72" (1.8 m) from the bottom

of the washer. Make sure that drain hose is not sealed

into drain, and that there is an air gap for ventilation.

Draining slowly. Check for drain hose obstructions.

Water pressure drop. Results in longer fill time.

Poor Wash Oversuds. 1. Verify use of HE detergent.

Performance 2. Excessive detergent usage.

Please reference

Use & Care Guide

Clothes wet after cycle 1. Overloaded washer.

is complete (not water 2. Oversuds (see above).

saturated, but very damp). 3. Weak suspension.

4. Shifter not moving into position. See Spin Test,

page 10.

Load not rinsed. 1. Check proper water supply.

2. Not using HE detergent.

3. Washer not loaded properly.

4. Shifter not moving into spin position. See Spin Test,

page 10.

Not cleaning clothes. 1. Washer not loaded properly.

2. Not using HE detergent.

3. Not using correct cycle.

4. Shifter not moving into position. See Spin Test,

page 10.

Fabric damage. 1. Washer overloaded.

2. Bleach added incorrectly.

3. Sharp items in tub.

Wrong option or cycle Refer customer to Use and Care Guide.

selection.

Unusual Noise Drain pump starting. This is normal. To reduce the noise, raise the drain hose

to at least 39½" (1 m) above the floor (but not more than

47¼" [1.2 m] above the floor).

Squealing/buzzing/rattling Loose belt or pulley. Adjust, tighten, or replace.

during wash or rinse.

Squealing/buzzing/rattling Worn bearings/suspension, or load is out of balance.

during spin.

Load is unbalanced. Rearrange load evenly in tub.

Load is tangling. Washer not loaded properly.

Incorrect water level. See “Won’t Fill” and “Overfills,” page 8.

DO NOT REMOVE OR DESTROY

PAGE 9

FOR SERVICE TECHNICIAN’S USE ONLY

MANUAL TEST MODE (WASHER)

Manual Load Test

NOTE: The tub must be empty of clothes

and water before running this test.

To activate Manual Load Test, press and

hold CYCLES or CYCLE SELECT, then press

POWER. While continuing to press and hold

CYCLES or CYCLE SELECT, press START

three times. A tone will sound for 1 second

to indicate successful entering of the Manual

Load Test. The “Control Lock” indicator will

be lit and “CL” will appear in the display.

Instructions: Press CYCLES or CYCLE

SELECT to select the Load to test. Press

and hold START to apply power to the Load.

The Load will be powered as long as the

Start button is pressed. Release the

START button to turn off power to the Load.

NOTE: The speaker will beep on and off

as long as the Start button is depressed.

See the chart below.

j

Press

CYCLES

or CYCLE

SELECT

Until

Following Press and 7-Segment

Indicator Hold START Display

Is Lit: to Initiate: Shows:

Normal Clockwise Model

rotation of Number

the motor

Delicate Counter- Software

clockwise version

rotation of number

the motor

Heavy Activation of Voltage/

or Heavy the retractor frequency

Duty motor

Rinse Activation Size of tub/

of the cold up drain

water valve

Spin Activation Water level/

of the hot frequency

water valve

Clean Activation Washer

Washer of the lid serial

lock solenoid number

(lid will lock)

(Release of

Start will

unlock the lid)

Press POWER to exit the test.

k

Spin Test

Press POWER to turn on the washer.

Press and hold “+” while pressing START

three times. A tone will sound for 1 second

to indicate successful entering of the Spin Test.

The display will indicate “3” if there is no water

in the tub, “4” if there is water in the tub. The

“Normal” indicator will be flashing. When water

in the tub reaches the “RESET” level, the washer

will start to spin (continuous for 1 minute, off for

1 minute). The washer will then turn off.

If the lid is opened during the spin, the display

will indicate “E4” and the washer will stop

spinning. If the lid is closed again, the washer

will resume spinning. If the tub switch detects

an unbalance during the spin, “E3” will show

on the display and the motor will stop.

Press POWER to clear the error and exit the test.

Lid Switch Test

Press POWER to turn on the washer.

Press and hold CYCLES or CYCLE SELECT

while pressing START three times. A tone will

sound for 1 second to indicate successful

entering of the Lid Switch Test.

The “Normal” indicator will be lit, and the

washer tub will begin to rotate clockwise.

If the lid is opened, the tub will stop; if it is

closed again, the tub will resume rotation.

The tub will not rotate if it contains water.

Press POWER to exit the test.

UI/LED Test

Press POWER to turn on the washer.

Press and hold TEMP or WASH TEMP while

pressing START three times. A tone will sound

for 1 second to indicate successful entering

of the UI/LED Test. The display will indicate

“8.8.” and all indicators will be off.

Press “–.” The Control Lock and Lid Lock

indicators will be lit. Press “–” again. The

Control Lock and Lid Lock indicators will

turn off.

Press CYCLES or CYCLE SELECT. All of the

Cycle indicators will be lit. Press CYCLES or

CYCLE SELECT again. The Cycle indicators

will turn off.

Press “+.” The 7-segment display showing

“8.8.” will turn off. Press “+” again. The

7-segment display will turn on.

Press TEMP or WASH TEMP. All of the Temp

indicators will be lit. Press TEMP or WASH

TEMP again. The Temp indicators will turn off.

Press POWER to exit the test.

PAGE 10

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

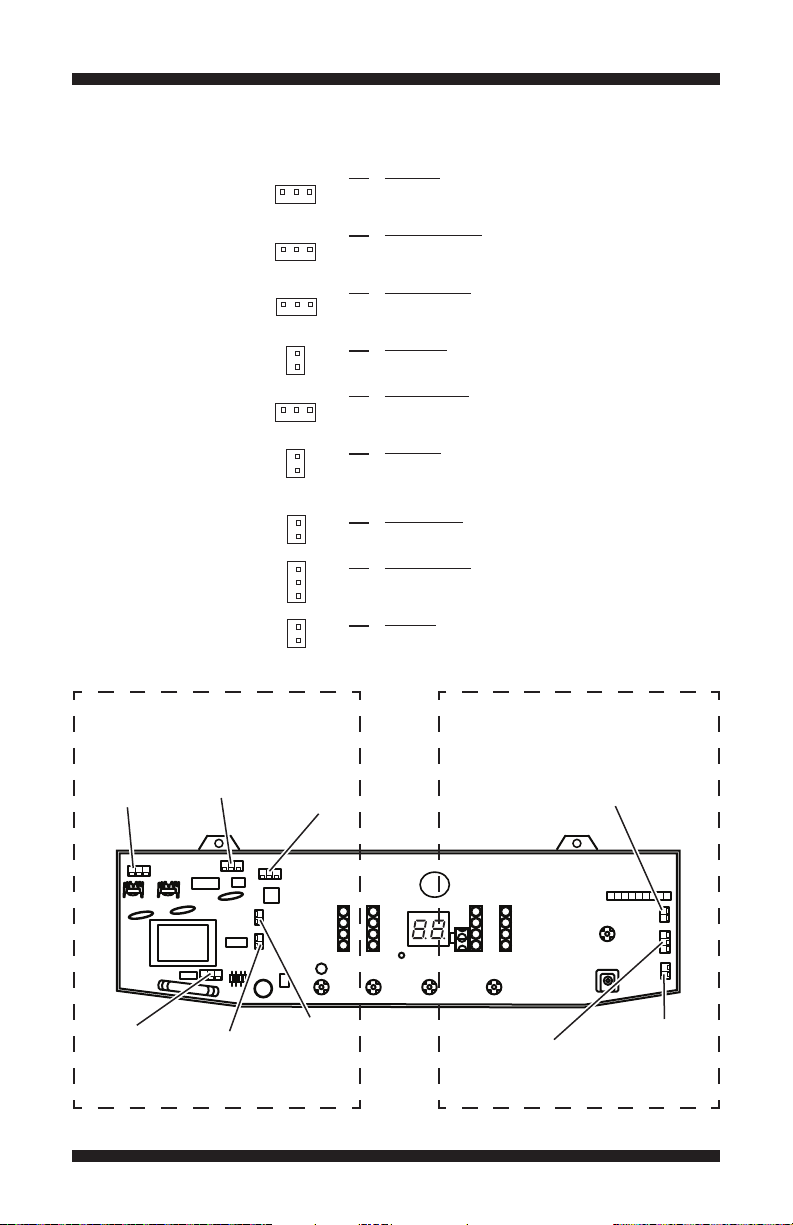

USER INTERFACE/CONTROL BOARD (WASHER)

Board Connectors

and Pinouts

(Figure 2)

CN2

Motor

and

Capacitor

CN5

Lid Lock

Solenoid

1 2 3

Red

1 2 3

White

1 2 3

Yellow

1 2

White

1 2 3

Blue

1 2

Red

2 1

Red

3 2 1 2 1

White

White

CN3

Water Inlet

Valves

High Voltage Connections

CN1 Power Cord

CN1-1 Black L1

CN1-2 Open

CN1-3 Lt Blue Neutral

CN2 Motor and Capacitor

CN2-1 Yellow Main Drive Motor, Right (CW)

CN2-2 Open

CN2-3 Red Main Drive Motor, Left (CCW)

CN3 Water Inlet Valves

CN3-1 Violet Water Inlet Valve, Hot

CN3-2 Open

CN3-3 Orange Water Inlet Valve, Cold

CN4 Torque Motor

CN4-1 Open

CN4-2 Pink Torque Motor

CN5 Lid Lock Solenoid

CN5-1 Gray Interlock

CN5-2 Open

CN5-3 White Interlock

CN9 Drain Pump

CN9-1 Open

CN9-2 Violet Water Pump

Logic/Low Voltage Connections

CN6 Pressure Sensor

CN6-2 White Gnd

CN6-1 Blue Water Level Sensor

CN7 Lid/Lock Switches

CN7-3

Black & Blue

CN7-2 Black Lid Switch ON/OFF

CN7-1 Blue Lock Switch ON/OFF

CN8 Tub Switch

CN8-2 Gray Tub Switch

CN8-1 Gray +5V

+5V

Logic/Low Voltage ConnectorsHigh Voltage Connectors

CN8

Tub Switch

CN1

Power Cord

CN4

Torque Motor

Drain Pump

DO NOT REMOVE OR DESTROY

CN9

Figure 2 - User Interface

CN7

Lid/Lock

Switches

CN6

Pressure

Sensor

PAGE 11

FOR SERVICE TECHNICIAN’S USE ONLY

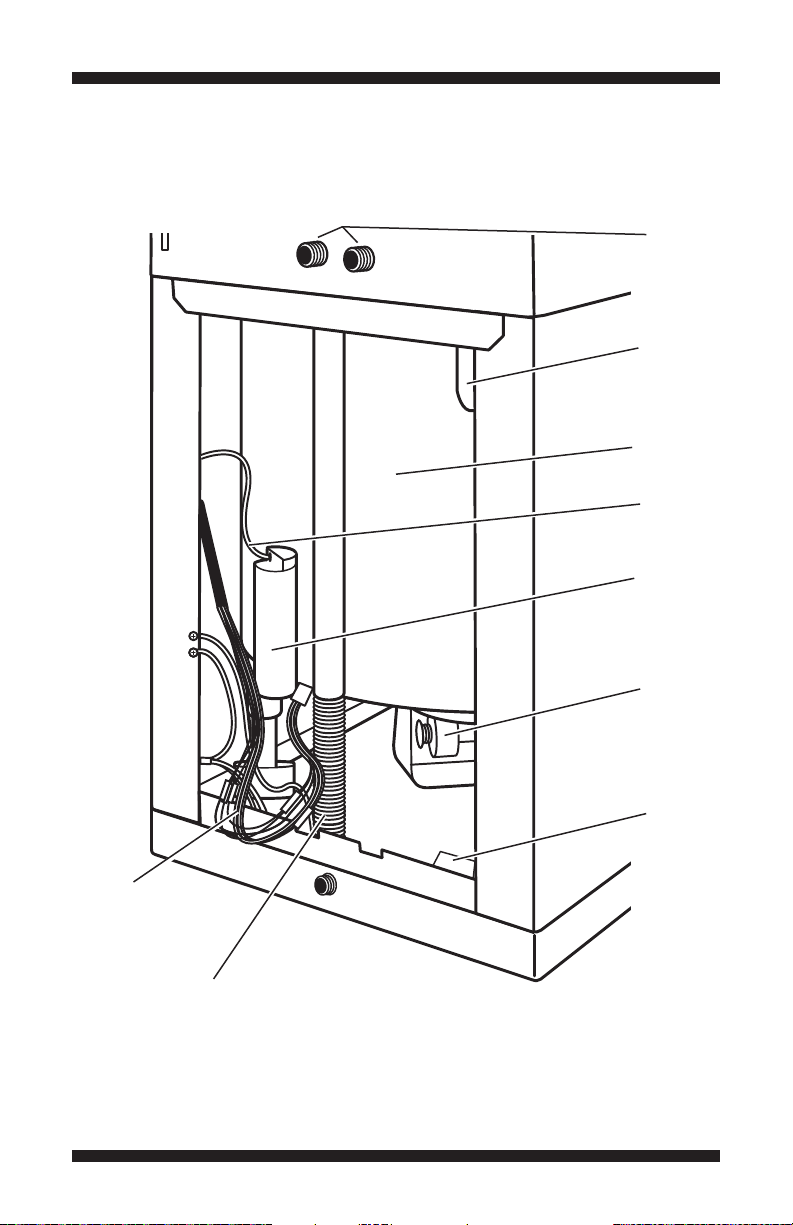

REAR VIEW OF WASHER

Water

Inlet

Valves

Tub

Switch

Tub

Assembly

Pressure

Hose

Pressure

Dome

Connector

Bundle

PAGE 12

Motor &

Retractor

Drain

Pump

Drain

Hose

Figure 3 - Rear View of Washer

DO NOT REMOVE OR DESTROY

Loading...

Loading...