Whirlpool KGCR055G, KGCT305G, KGCT365G, KGCS105G, YKGCT305G Owner's Manual

...

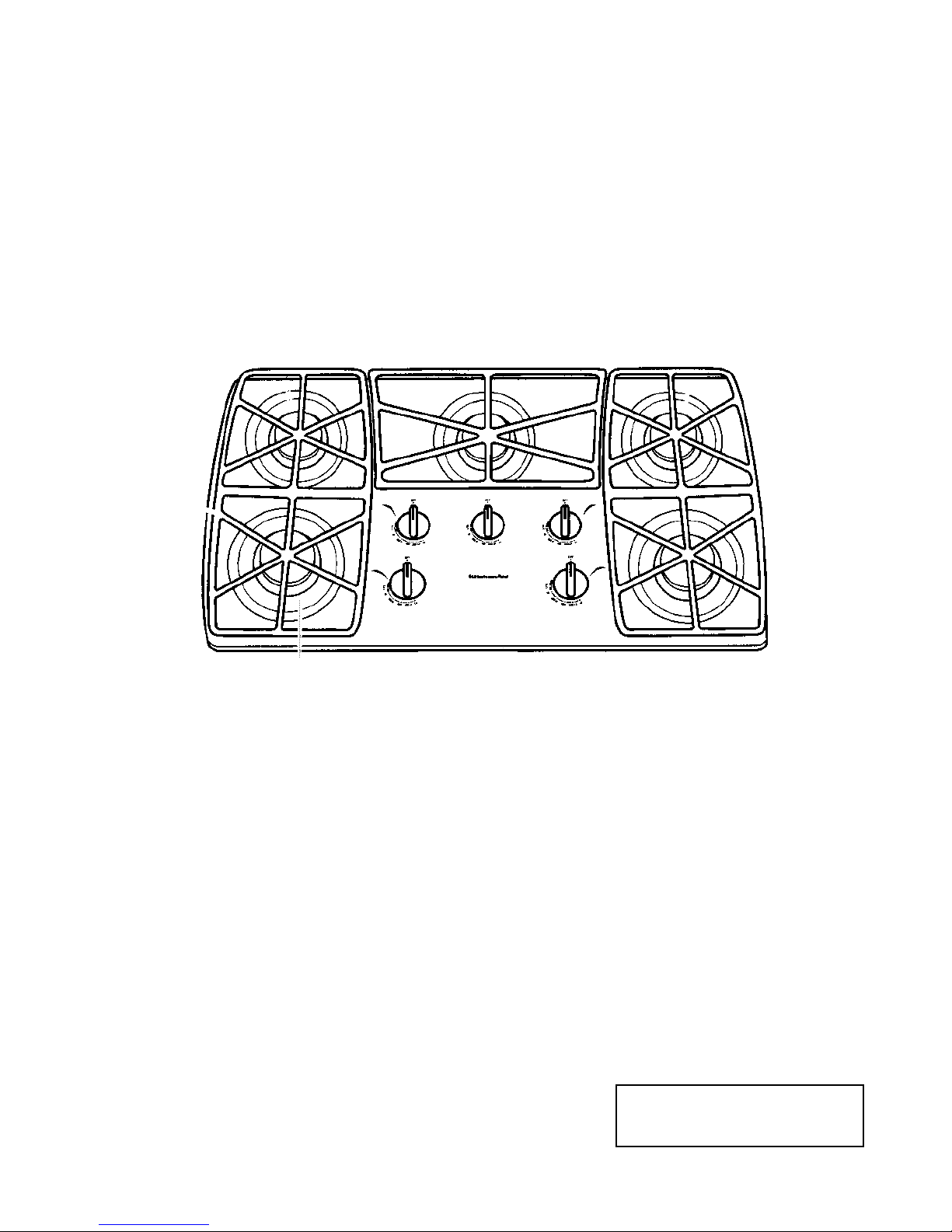

WHIRLPOOL & KITCHENAID

BUILT-IN GAS COOKTOPS

JOB AID

Part No. 4317256

FORWARD

This Job Aid, “Built-In Gas Cooktops,” (Part No. 4317256), provides the technician with information on the installation, operation, and service of KitchenAid & Whirlpool Built-In Gas Cooktops. It

is to be used as a training Job Aid and Service Manual. For specific information on the model

being serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided with the cooktop.

The Wiring Diagrams and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair Built-In Gas Cooktops.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the cooktop to proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repair

made on our products by anyone other than Authorized Factory Service

Technicians.

Copyright 1999, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

Table of Contents

PAGE

SPECIFICATIONS .................................................................................................................. 1-1

INSTALLATION HIGHLIGHTS................................................................................................ 2-1

Gas Supply Requirements ................................................................................................. 2-1

Electrical Requirements ..................................................................................................... 2-3

Installation.......................................................................................................................... 2-4

Converting The Cooktop For Use With L.P. Gas ............................................................... 2-6

PRODUCT OPERATION ........................................................................................................ 3-1

Electronic Ignition System ................................................................................................. 3-1

COMPONENT ACCESS ......................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing The Maintop...................................................................................................... 4-2

Removing A Venturi & Spark Ignitor .................................................................................. 4-3

Removing A Spark Module & Power Cord......................................................................... 4-4

Removing An Ignitor Switch & A Gas Valve ...................................................................... 4-5

Removing The Gas Manifold ............................................................................................. 4-6

COMPONENT TESTING ........................................................................................................ 5-1

The Ignitor Switches .......................................................................................................... 5-1

DIAGNOSIS & TROUBLESHOOTING.................................................................................... 6-1

WIRING DIAGRAMS & STRIP CIRCUITS.............................................................................. 7-1

TECH TIPS ............................................................................................................................. 8-1

Surface Burners & Grates.................................................................................................. 8-1

Cleaning The Surface Burners .......................................................................................... 8-2

Requesting Assistance Or Service .................................................................................... 8-3

KitchenAid Gas Cooktop Warranty .................................................................................... 8-4

Whirlpool Gas Cooktop Warranty ...................................................................................... 8-5

- iii -

KITCHENAID MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER

INTERNATIONAL SALES IND.

OR MARKETING CHANNEL

IF PRESENT

K=KITCHENAID BRAND

PRODUCT IDENTIFICATION:

EC=ELECTRIC COOKTOPS

GC=GAS COOKTOPS

MERCHANDISING SCHEME

C=CERAMIC GLASS

D=DOWNDRAFT VENT

G=GRILL/GRIDDLE

M=MODULAR DOWNDRAFT

N=INTERNATIONAL COLLECTION

P=PROFESSIONAL/COMMERCIAL

S=STANDARD/PORCELAIN METAL

T=TEMPERED GLASS

X=208 VOLT

E=ELECTRONICS

CAPACITY/SIZE /SERIES/CONFIG

1ST POSITION 2ND POSITION

1=STANDARD 0=30" WIDE

2=GRILL GRIDDLE 3=33" WIDE

3=TEMPERED GLASS 6=36" WIDE

4=COMMERCIAL 2=42" OR 12" WIDE

5=CERAMIC GLASS 5=15" WIDE

8=MODULAR/DOWNDRAFT

0=2 BURNER/ELEMENT SYSTEM

KGCS127 GBL 0

FEATURES

0=STANDARD ELEMENTS/BURNERS

1=RADIANT ELEMENTS

2=DUAL ELEMENTS

3=

4=

5=SEALED BURNERS/CAST ELEMENTS

6=5 BURNERS/ELEMENTS

7=HALOGEN ELEMENTS/6 BURNERS

8=TOUCH CONTROLS

9=INDUCTION

YEAR OF INTRODUCTION

G=1998 H=1999 J=2000

COLOR CODE

AL = Almond SS = Stainless

BL = Black WH = White

BT = Biscuit

ENGINEERING CHANGE (NUMERIC)

SERIAL NUMBER

SERIAL NUMBER X H 07 1 2 3 4 5

OXFORD

YEAR OF INTRODUCTION:

H = 1998, J = 1999, K = 2000

WEEK OF PRODUCTION

(7th WEEK)

PRODUCT SEQUENCE NUMBER

- iv -

WHIRLPOOL MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

S C S 30 0 4 G Q ----

MODEL NUMBER

INTERNATIONAL SALES IND.

OR MARKETING CHANNEL

IF PRESENT

PRODUCT GROUP:

R = ELECTRIC COOKING PRODUCTS

S = GAS COOKING PRODUCTS

G = WHIRLPOOL GOLD RANGE

PRODUCT IDENTIFICATION:

C = BUILT-IN COOKTOP

J = GOLD ELECTRIC COOKTOP

G = GOLD GAS COOKTOP

CONFIGURATION:

S = PORCELAIN / STEEL TOP

T = TEMPERED GLASS TOP

C = CERAMIC GLASS TOP

M = MODULAR DOWNDRAFT

MODEL SIZE:

20 = 20"

30 = 30"

36 = 36"

FEATURE VARIATIONS:

0 = LOW SPEED COIL ELECTRIC / OPEN-LOW END

BURNER GAS / OPEN BAYS

1 = HIGH SPEED COIL ELECTRIC / SEALED BURNERS

2 = CERAMIC RADIANT ELECTRIC

3 = CERAMIC RADIANT / DUAL

4 = MODULAR

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 0 = NO ELEMENTS / BURNERS

2 = TWO ELEMENT / BURNER

4 = FOUR ELEMENT / BURNER

5 = FIVE ELEMENT / BURNER

YEAR OF INTRODUCTION

G = 1998 H = 1999 J = 2000

COLOR CODE

B = Black S = Stainless Steel

N = Almond Z = Almond on Almond

Q = White on White W = White

ENGINEERING CHANGE (NUMERIC)

SERIAL NUMBER

SERIAL NUMBER X H 07 1 2 3 4 5

OXFORD

YEAR OF INTRODUCTION:

H = 1998, J = 1999, K = 2000

WEEK OF PRODUCTION

(7th WEEK)

PRODUCT SEQUENCE NUMBER

- v -

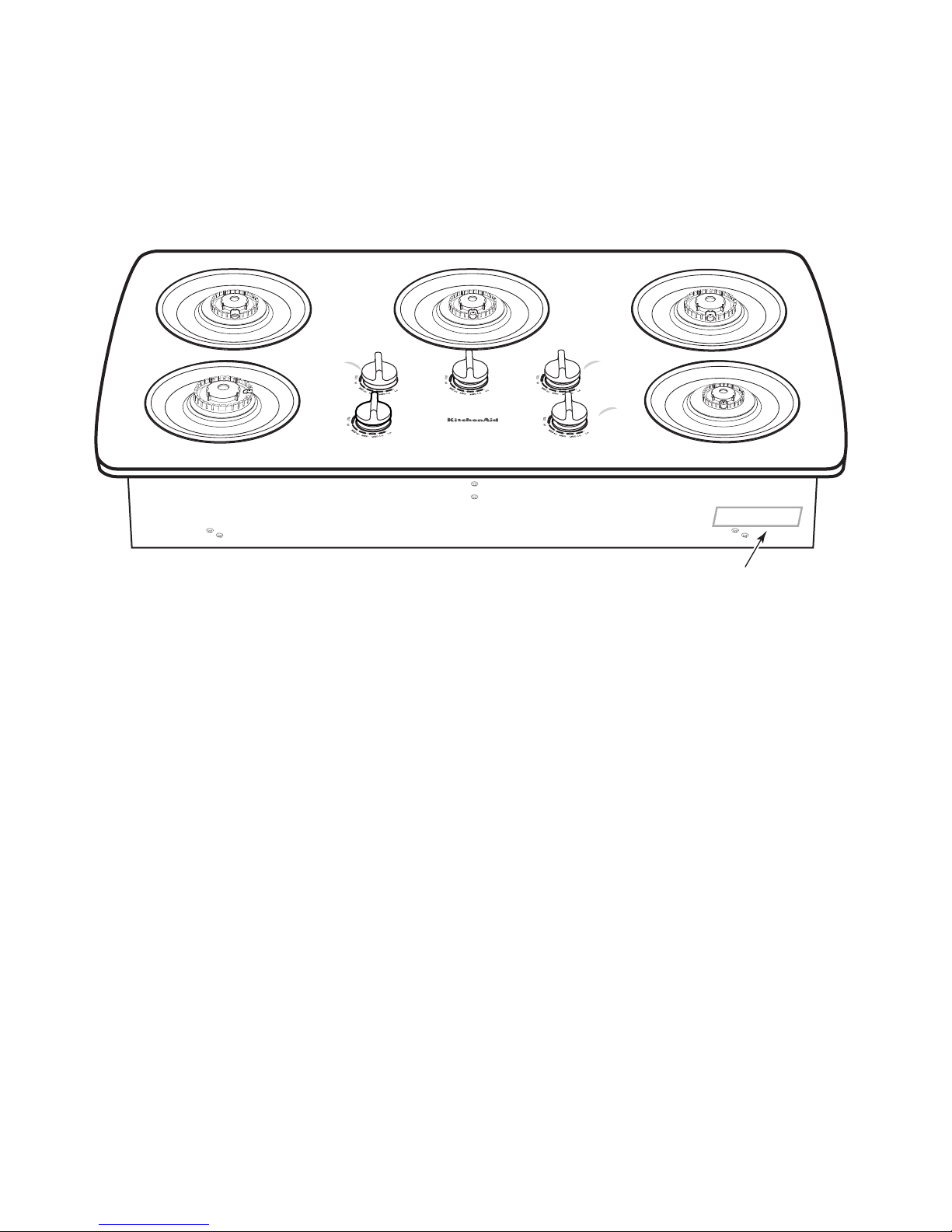

MODEL & SERIAL NUMBER LOCATION

The Model/Serial Number label is located on the underside of the cooktop burner box at the

location shown below.

Model & Serial Number

- vi -

IMPORTANT SAFETY INFORMATION

Your safety and the safety of others is very important.

Important safety messages have been provided in this Job Aid. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will be preceded by the safety alert symbol and the word

“WARNING.”

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and tell

you what can happen if the instructions are not followed.

WARNING: If the information in this Job Aid is not followed exactly, a fire or explosion may

result causing property damage, personal injury, or death.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

- vii -

— NOTES —

- viii -

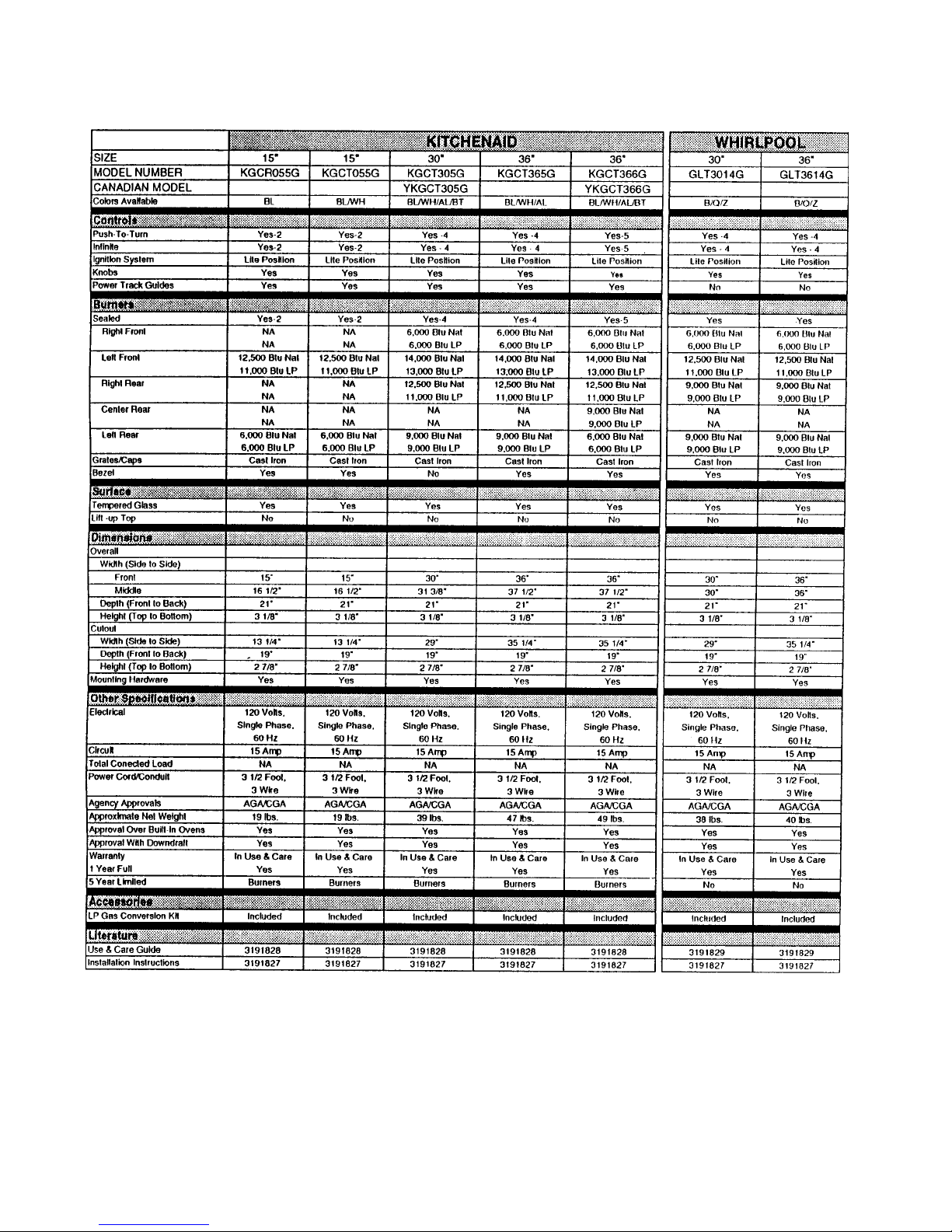

SPECIFICATIONS

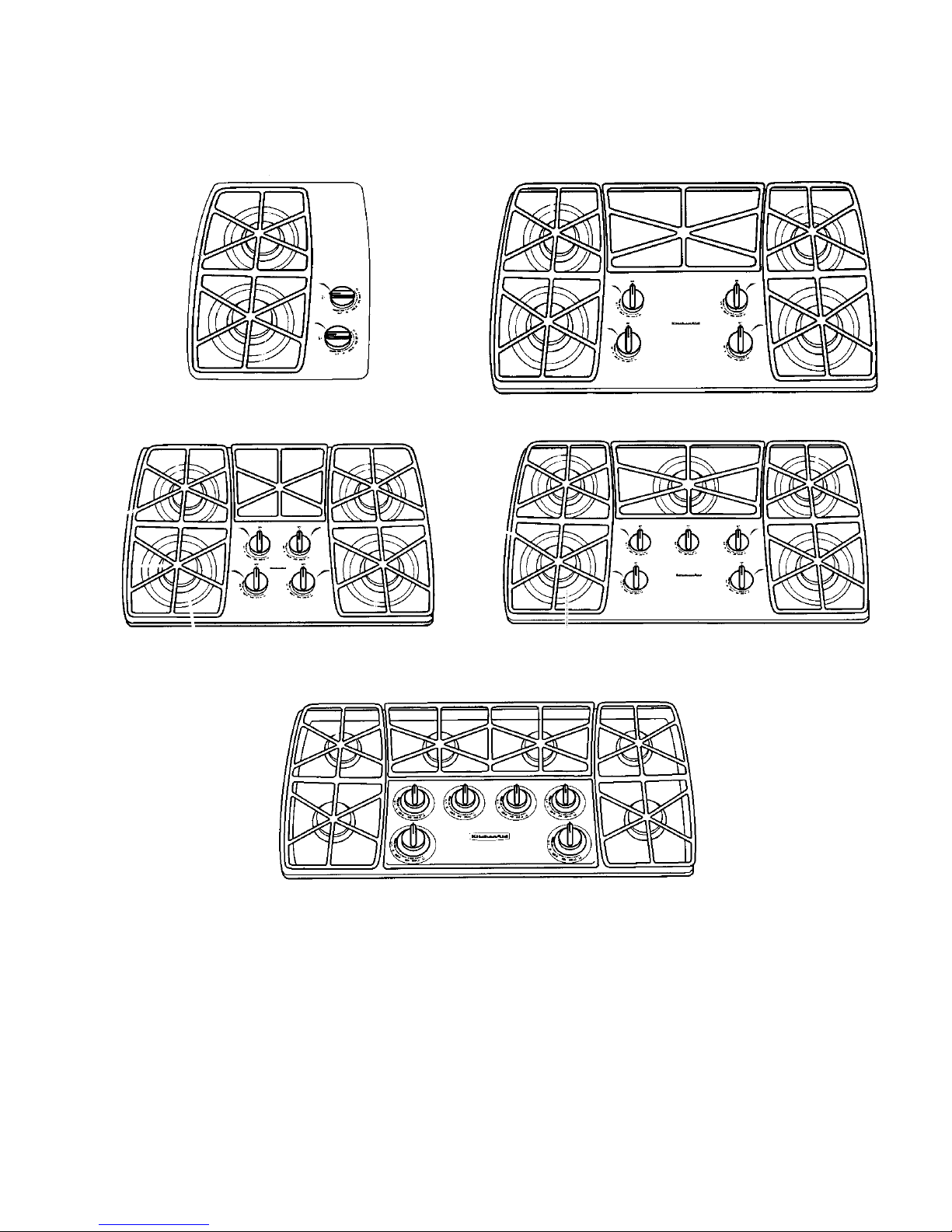

KITCHENAID MODEL GAS COOKTOPS

KGCT055 & KGCR055G

KGCS105G, KGCT305G & YKGCT305G

KGCT365G

KGCS166G, KGCT366G & YKGCT366G

KGCS127G

1-1

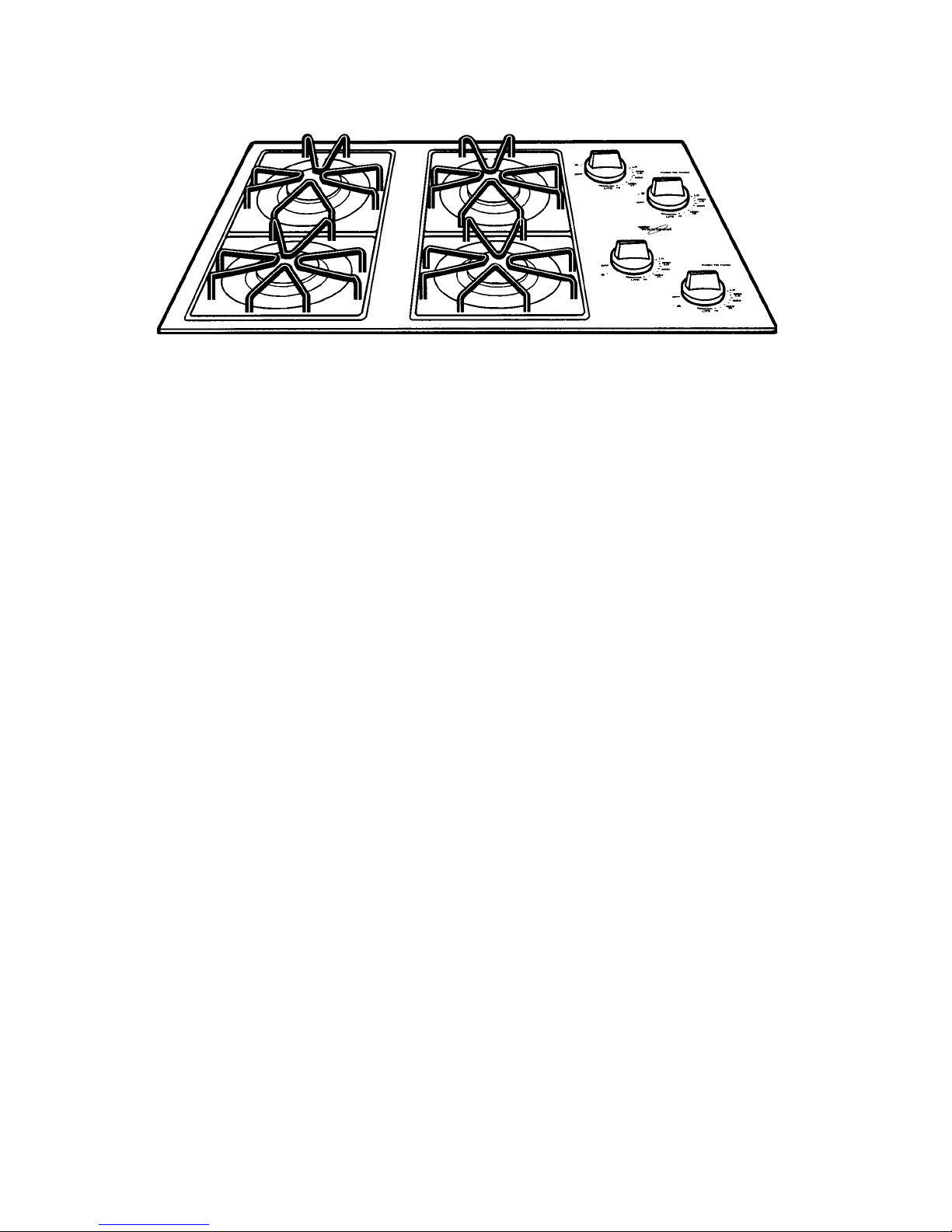

WHIRLPOOL MODEL GAS COOKTOPS

SCS3004G, SCS3014G, SCS3614G,

GLT3014G, & GLT3614G

1-2

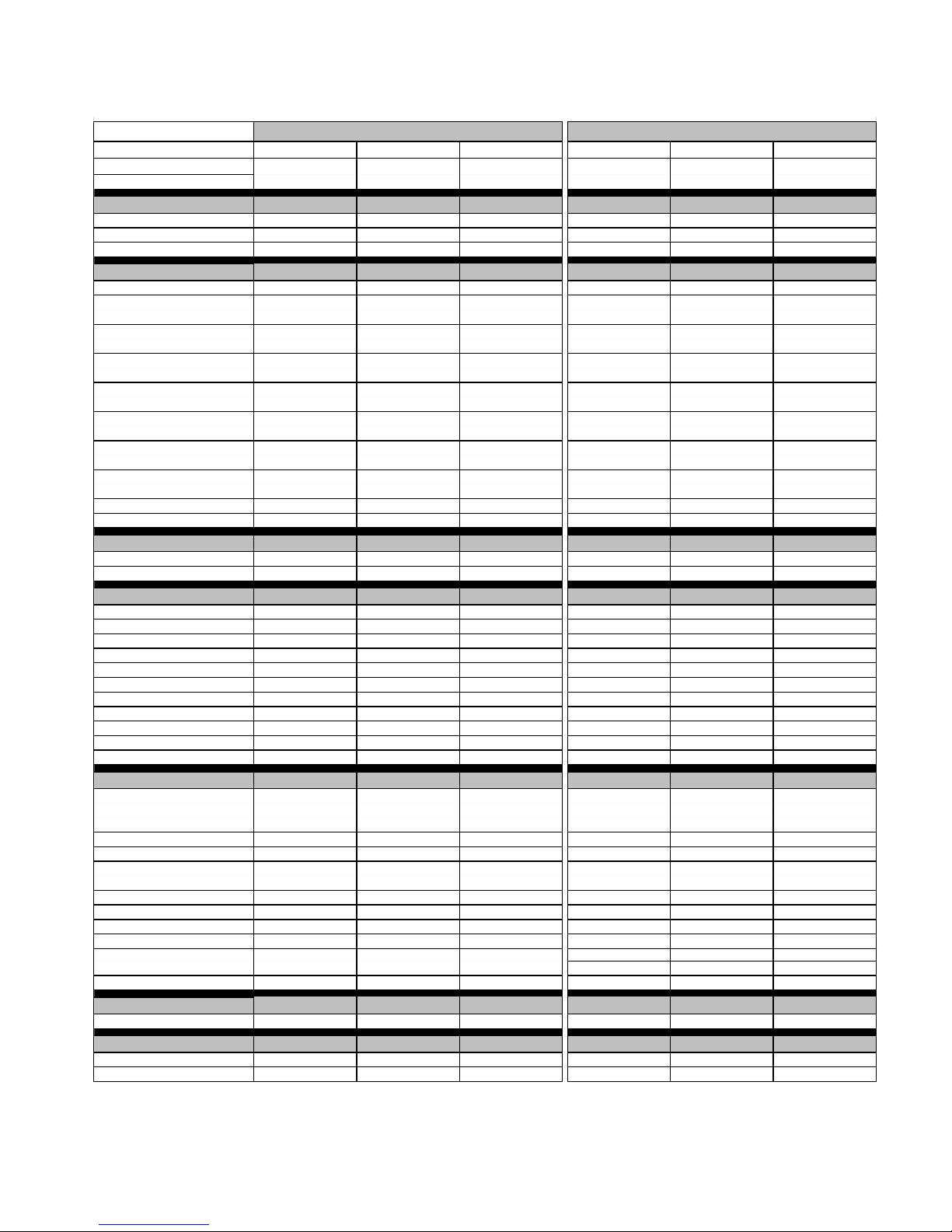

30

a

",

36", & 42" GAS PORCELAIN & METAL COOKTOPS

KITCHENAID WHIRLPOOL

SIZE 30" 36" 42" 30" 30" 36"

MODEL NUMBER KGCS105G KGCS166G KGCS127G SCS3004G SCS3014G SCS3614G

Colors Available BL/WH/AL/SS/BT BL/WH/AL/SS/BT BL/WH/AL/SS/BT W/N/S B/Q/Z/S B/Q/Z/S

Controls

Push-To-Turn Yes -4 Yes -5 Yes -6 Yes -4 Yes -4 Yes -4

Infinite Yes - 4 Yes - 5 Yes -6 Yes - 4 Yes - 4 Yes - 4

Ignition System Lite Position Lite Position Lite Position Lite Position Lite Position Lite Position

Burners

Sealed Yes-4 Yes-5 Yes-6 Yes - 4 Yes Yes

Right Front 6,000 Btu Nat 6,000 Btu Nat 6,000 Btu Nat 6,000 Btu Nat 6,000 Btu Nat 6,000 Btu Nat

Left Front 14,000 Btu Nat 14,000 Btu Nat 14,000 Btu Nat 9,000 Btu Nat 12,500 Btu Nat 12,500 Btu Nat

Right Rear 12,500 Btu Nat 12,500 Btu Nat 12,500 Btu Nat 9,000 Btu Nat 9,000 Btu Nat 9,000 Btu Nat

Center Right Rear NA NA 9,000 Btu Nat NA NA NA

Center Rear NA 9,000 Btu nat NA NA NA NA

Center Left Rear N A NA 6,000 Btu nat NA NA NA

Left Rear 9,000 Btu nat 6,000 Btu nat 9,000 Btu nat 9,000 Btu nat 9,000 Btu nat 9,000 Btu Nat

Grates Cast Iron Cast Iron Cast Iron Square-Stamped Square-Cast Iron Square-Cast Iron

Bezel No No No No Yes Yes

Surface

Porcelain/Metal Yes Yes Yes Yes Yes Yes

Lift -up Top No No No No No No

Dimensions

Overall

Width (Side to Side)

Front 30" 36" 42" 30 " 3 0" 3 6"

Middle 31 3/8" 37 1/2" 43 1/2" 31 3/8" 31 3/8" 37 1/2"

Depth (Front to Back) 21 " 21 " 21" 2 1" 2 1" 2 1"

Height (Top to Bottom) 3 3/8" 3 3/8" 3 3/8" 3 3/8" 3 3/8" 3 3/8"

Cutout

Width (Side to Side) 29 " 35 1/4" 40 1/2" 29" 2 9" 35 1/4"

Depth (Front to Back) 19 " 19 " 19" 1 9" 1 9" 1 9"

Height (Top to Bottom) 2 7/8" 2 7/8" 2 7/8" 2 7/8" 2 7/8" 2 7/8"

Mounting Hardware Yes Yes Yes Yes Yes Yes

Other Specifications

Electrical 120 Volts, 120 Volts, 120 Volts, 120 Volts, 120 Volts, 120 Volts,

Circuit 15 Amp 15 Amp 15 Amp 15 Amp 15 Amp 15 Amp

Total Conected Load NA NA NA NA NA NA

Power Cord/Conduit 3 1/2 Foot, 3 1/2 Foot, 3 1/2 Foot, 3 1/2 Foot, 3 1/2 Foot, 3 1/2 Foot,

Agency Approvals AGA/CGA AGA/CGA AGA/CGA AGA AGA/CGA AGA

Approximate Net Weight 38 lbs. 42 lbs. 45 lbs. 35 lbs. 35 lbs. 39 lbs.

Approval Over Built-in Ovens Yes Yes Yes Yes Yes Yes

Approval With Downdraft Yes Yes Yes Yes Yes Yes

Warranty In Use & Care In Use & Care In Use & Care In Use & Care In Use & Care In Use & Care

1 Year Full Yes Yes Yes Yes Yes Yes

5 Year Limited Burners Burners Burners No No No

Accessories

LP Gas Conversion Kit Included Included Included Included Included Included

Literature

Use & Care Guide 3191828 3191828 3191828 3191829 3191829 3191829

Installation Instructions 3191827 3191827 3191827 3191827 3191827 3191827

6,000 Btu LP 6,000 Btu LP 6,000 Btu LP 6,000 Btu LP 6,000 Btu LP 6,000 Btu LP

13,000 Btu LP 13,000 Btu LP 13,000 Btu LP 9,000btu LP 11,000 Btu LP 11,000 Btu LP

11, 000 Btu LP 11, 000 Btu LP 11, 000 Btu LP 9,000btu LP 9,000btu LP 9,000btu LP

NA NA 9,000 Btu LP NA NA NA

NA 9,000 Btu LP NA NA NA NA

NA NA 6,000 Btu LP NA NA NA

9,000 Btu LP 6,000 Btu LP 9,000 Btu LP 9,000btu LP 9,000btu LP 9,000btu LP

Single Phase, Single Phase, Single Phase, Single Phase, Single Phase, Single Phase,

60 Hz 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz

3 Wire 3 Wire 3 Wire 3 Wire 3 Wire 3 Wire

1-3

15

",

30", & 36" GAS GLASS COOKTOPS

1-4

INSTALLATION HIGHLIGHTS

GAS SUPPLY REQUIREMENTS

2. Input ratings shown on the model/serial

WARNING

Explosion Hazard

Use a new AGA approved gas supply

line.

Install a shutoff valve.

Securely tighten all gas connections.

If connected to LP gas, have a qualified

person make sure gas pressure does

not exceed 14" water column.

Examples of a qualified person includes licensed heating personnel, authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Observe all governing codes and ordinances.

Important: The cooktop must be connected

to a regulated gas supply.

1. This installation must conform with local

codes and ordinances. In the absence of

local codes, installations must conform

with American National Standard, National

Fuel Gas Code ANSI Z223.1— latest edition*** or CANI — B149.1 or 2**.

**Canadian Standard Association

178 Rexdale Boulevard

Etobicoke, Ontario M9W 1R3

rating plate are for elevations up to 2,000

feet (610 m). For elevations above 2,000

feet (610 m), ratings are reduced at a rate

of 4% for each 1,000 feet (305 m) above

sea level.

3. The cooktop is equipped for use with

NATURAL gas. It is design-certified by the

American Gas Association for NATURAL

and L.P. gases with the appropriate conversion. The model/serial rating plate, located on the underside of the burner box,

has information on the type of gas that can

be used. If this information does not agree

with the type of gas available, check with

the local gas supplier. See Page 2-6 for

L.P. gas conversion instructions.

4. Provide a gas supply line of 3/4" rigid pipe

to the cooktop location. A smaller size pipe

on long runs may result in insufficient gas

supply. Pipe-joint compounds, suitable for

use with L.P. gas, must be used. With L.P

gas, piping or tubing size can be a minimum of 1/2". L.P. gas suppliers usually

determine the size and materials used on

the system.

5. If local codes permit, a new A.G.A. designcertified, 4-5 foot (1.2-1.5 m) long, 1/2" or

3/4" I.D., flexible metal appliance connector is recommended for connecting this

cooktop to the gas supply line. Do not kink

or damage the flexible connector when

moving the cooktop. The pressure regulator has 3/8" female pipe threads. You will

need to determine the fittings required,

depending on the size of your gas supply

line, flexible metal connector and shutoff

valve.

Flexible Gas Supply Line

***American Gas Association

1515 Wilson Boulevard

Arlington, Virginia 22209

2-1

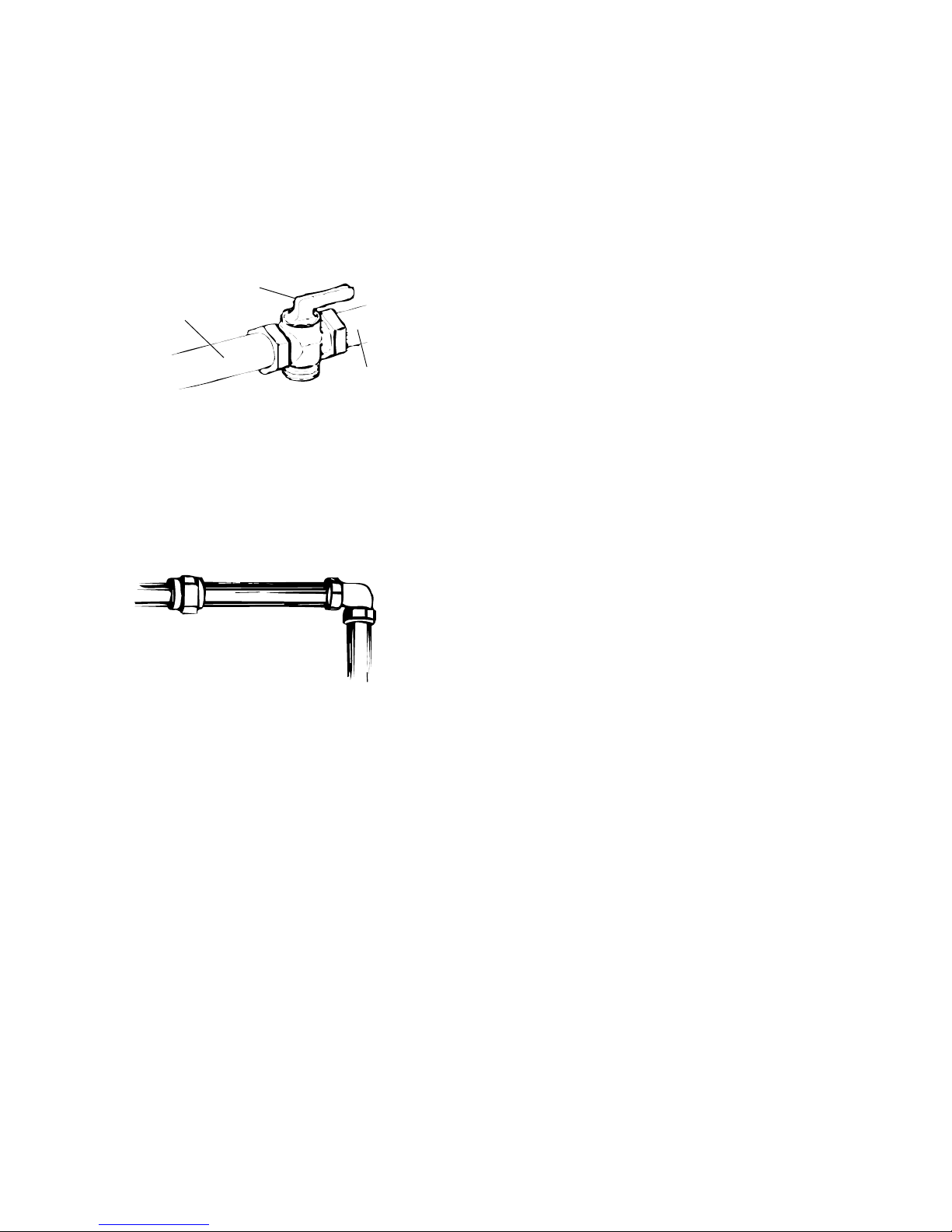

6. The supply line shall be equipped with an

approved shutoff valve. This valve should

be located in the same room as the cooktop

and should be in a location that allows

ease of opening and closing. Do not block

access to the shutoff valve. The valve is

for turning on or shutting off gas to the

appliance.

Shutoff Valve

(open)

To Cooktop

Gas Supply

Line

8. The regulator must be checked at a minimum 1-inch (2.5 cm) water column above

the set pressure. The inlet pressure to the

regulator should be as follows for operation and checking the regulator setting:

NATURAL GAS

Set pressure: 4 inches (10.2 cm).

Supply pressure: 7-14 inches (17.8 cm to 35.5

cm) maximum.

L.P. GAS

Minimum pressure: 10 inches (25.4 cm).

Supply pressure: 14 inches (35.5 cm).

7. If rigid pipe is used as a gas supply line, a

combination of pipe fittings must be used

to obtain an in-line connection to the

cooktop. All strains must be removed from

the supply and fuel lines so cooktop will be

level and in line.

Rigid Pipe

9. Line Pressure Testing:

Testing Above 1/2 psi (3.5 kPa)

(14 inches (35.6 cm)) W.C. (gauge)

The cooktop and its individual shutoff valve

must be disconnected from the gas supply

piping system during any pressure testing

of that system at test pressures greater

than 1/2 psig (3.5kPa).

Testing Below 1/2 psi (3.5 kPa) (14

inches (35.6 cm)) W.C. (gauge), Or

Lower

The cooktop must be isolated from the gas

supply piping system by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping

system at test pressures equal to or less

than 1/2 psig (3 5 kPa).

2-2

Loading...

Loading...