61833061GB.fm Page 1 Wednesday, March 29, 2006 4:39 PM

I

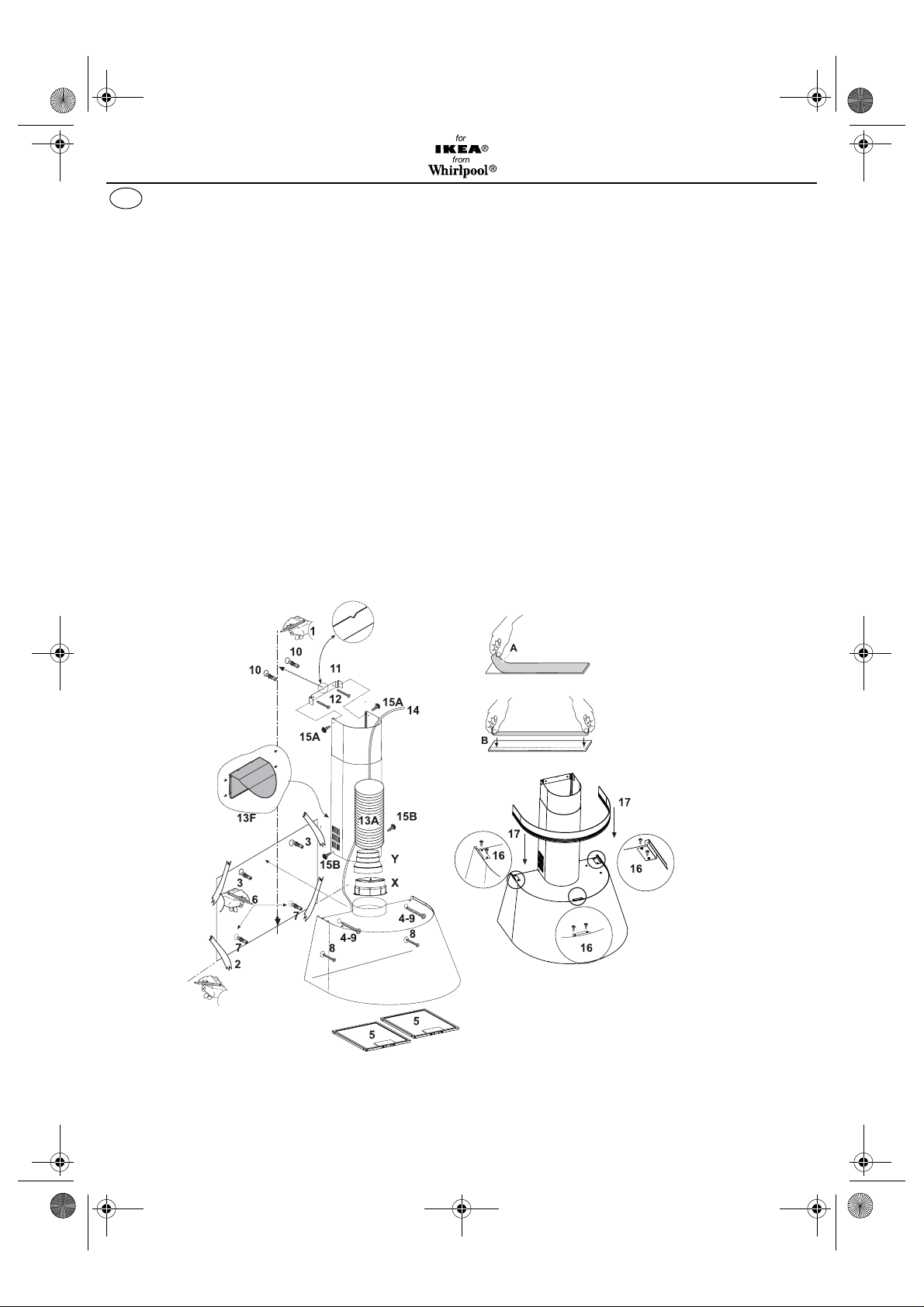

EXTRACTOR OR FILTERING HOOD INSTALLATION

The minimum distance between the support surface of the recipients on the cooking device and the lowest part of the hood

must not be less than 50 cm in case of electric cookers and 65 cm for gas or combination cookers. If the installation instructions

for the gas cooker specify a greater distance, this must be taken into account. The fume hose and hose clamps are not supplied.

Contact a qualified technician for installation.

1. Mark a centre-line on the wall from the cooktop to the ceiling (1)

2. Taking into account the above-mentioned distances from the cooktop, mark the distance from the cooktop with a pencil and place the

template against the wall on the mark (2)

3. Using the template supplied, mark the holes, drill them and insert the rawlplugs(3), then partly screw in 2 screws in the top holes (4) and

hook the hood.

4. remove the grease filter/s (5)

5. Mark the holes for secure fixing (6)

6. Remove the hood from the bracket, drill and insert the wall plugs (7)

7. Hook the hood, tighten the two top screws (8) and insert the two safety screws in the bottom holes (9).

8. Fix the flue support to the wall as close as possible to the ceiling: drill and insert 2 plugs per wall (10), position the support (11) and fix it

with the 2 screws (12).

Extractor Version: steam and fumes are exhausted to the outside. Proceed as follows:

fit the collar with non-return valve supplied with the product (X) onto the exhaust opening of the hood, exerting light pressure. Screws are not

required to attach the collar. Then fit the adaptor for the exhaust pipe (Y) onto the collar, exerting light pressure. Fit an exhaust pipe which is

long enough to vent externally (13A). Care must be taken to ensure that the tube and adaptor fastening does not impede the electric shutter

from opening and closing. Important: If the hood is equipped with a carbon filter, this must be removed. The discharge air must not be ducted

to a flue used for removing fumes produced by appliances using gas or other fuels, but must have a separate outlet. All national regulations on

air discharge must be observed.

Filtering Version: The air is filtered by a carbon filter and recycled in the surrounding environment. In this case, fit the special deflector (13F)

to the lower flue, fixing it with 4 screws. Important: if the hood does not have a carbon filter, order one and fit it before use.

Connect the hood to the mains supply (14) and fix the telescopic flue to the flue bracket with two screws (15A). Slide the bottom section

down into its seat on the top of the hood and fix with two screws (15B).

Preparing the flange: remove the protective film (A) from the flange and apply it to the lower edge of the frame as shown in B.

Fitting the flange: fit the three brackets (16), partially undo the 6 screws (2 per bracket), bend and position the flange between the hood and

the brackets (17) so that the side with the protective strip is facing the edge of the hood. Fix the flange as close as possible to the brackets on

the edge of the hood.

5019 618 33061

The hood's top surface can support a maximum

weight of 10 Kg.

61833061GB.fm Page 2 Wednesday, March 29, 2006 4:39 PM

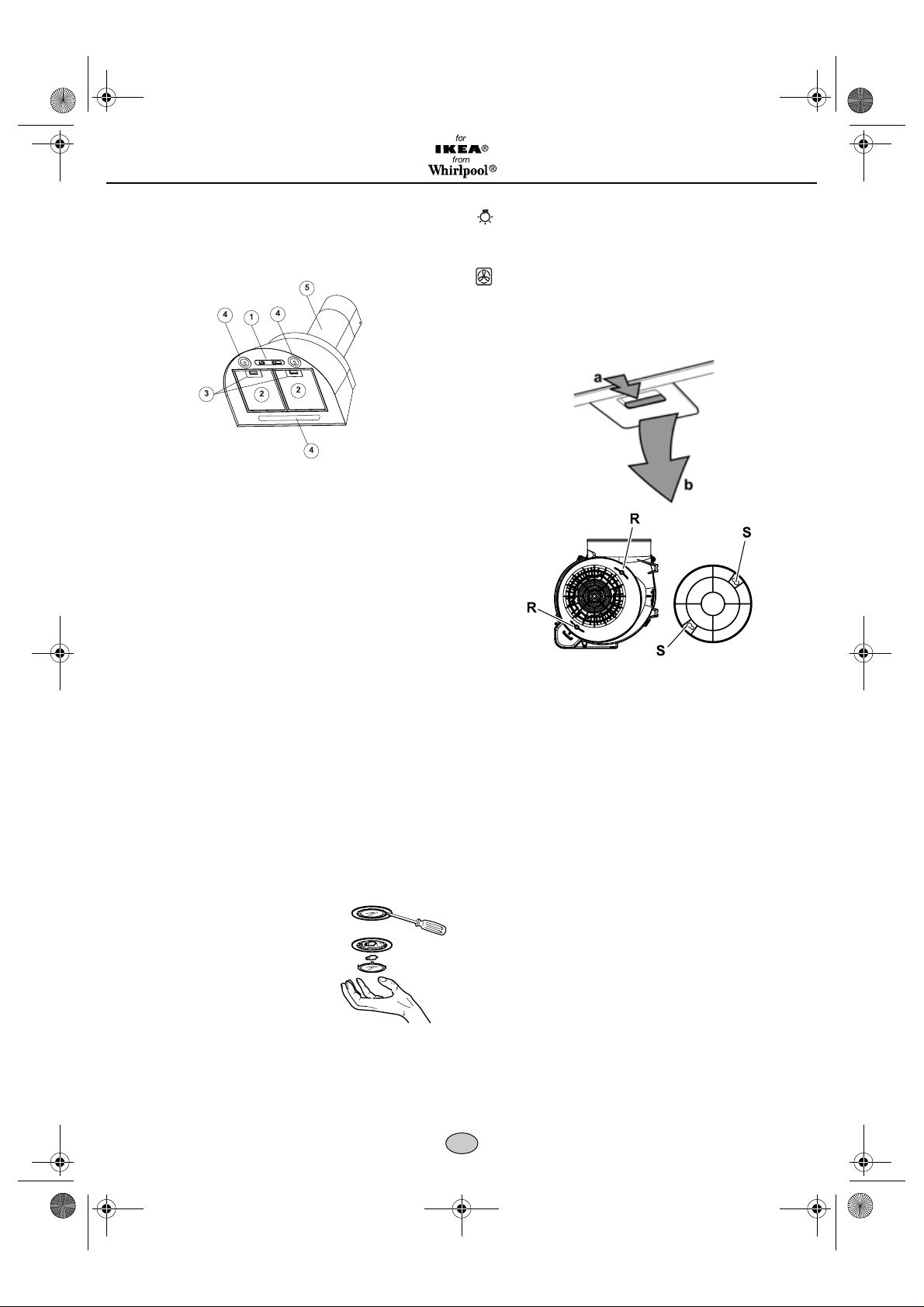

1. Control panel

2. Grease filters

3. Grease filter handles

4. Light above cooker (depending on model)

5. Telescopic flue

To clean the grease filter

Clean the grease filter once a month.

1. Disconnect the electrical power supply.

2. Remove the grease filters - Fig. 1:

a - push the handles backwards

b - and then downwards.

3. After cleaning the grease filter refit in reverse order,

making sure the entire extraction surface is covered.

Fitting or replacing the carbon filter:

Change the carbon filter every six months.

1. Disconnect the electrical power supply.

2. Remove the grease filters (Fig. 1 - a, b).

3. Fit the filters over the motor: make sure the pins R on the

manifold match the slots S, then turn clockwise until

locked.

4. Carry out in the reverse order to remove.

5. Refit the grease filters.

Replacing bulbs

1. Disconnect the electrical power supply.

2. Remove the grease filters (Fig. 1 - a, b).

3. Remove the burnt-out bulb.

Replace using 40W max E14 bulbs only.

4. Refit the grease filters.

Halogen lamps:

Use a small screwdriver or other

suitable tool to prise off the cover . Refit

the cover.

5. Use only max 40 W E14 bulbs or max 20 W halogen

bulbs (depending on the

model), taking care not to

touch them with your hands.

CONTROL PANEL

Light switch.

The switch has two positions

(lights OFF - lights ON).

To switch on the lights: move the switch to the right.

Extraction speed selection switch.

The extraction speed switch has different settings,

depending on the amount of steam and fumes.

To increase the extraction speed: move the switch to the

right.

Fig.1

Fig.2

Cleaning the hood

Warning! Failure to remove oil/grease (at least

once a month) could lead to fire.

Use a soft cloth with a neutral detergent. Never use abrasive

substances or alcohol.

Before using the hood

Please read these instructions carefully and keep them for

future reference, in order to ensure best use of your hood.

Packaging materials (plastic bags, polystyrene, etc.) can be

dangerous for children and should be kept well out of their

reach.

Make sure the hood has not been damaged during transport.

Installation and electrical connections must be carried out by

a qualified technician in compliance with the current local

regulations.

5019 618 33061

GB

Loading...

Loading...