Whirlpool G-21 Service Manual

CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

G-21

USING TEST EQUIPMENT

JOB AID

Part No. 4322537A

THE VOLT-OHMMETER (VOM)

INTRODUCTION

The volt-ohmmeter, usually referred to as a ”VOM,” or ”Multimeter,”

combines two individual instruments into one. These instruments are

the:

• Ohmmeter for measuring resistance (in ohms - Ω).

• Voltmeter for measuring voltage (AC and DC).

Technicians prefer the convenience of this single meter that combines

both measuring functions. Some multimeters offer other functions, such

as AC ampere, DC millivolt, and temperature measurements.

1

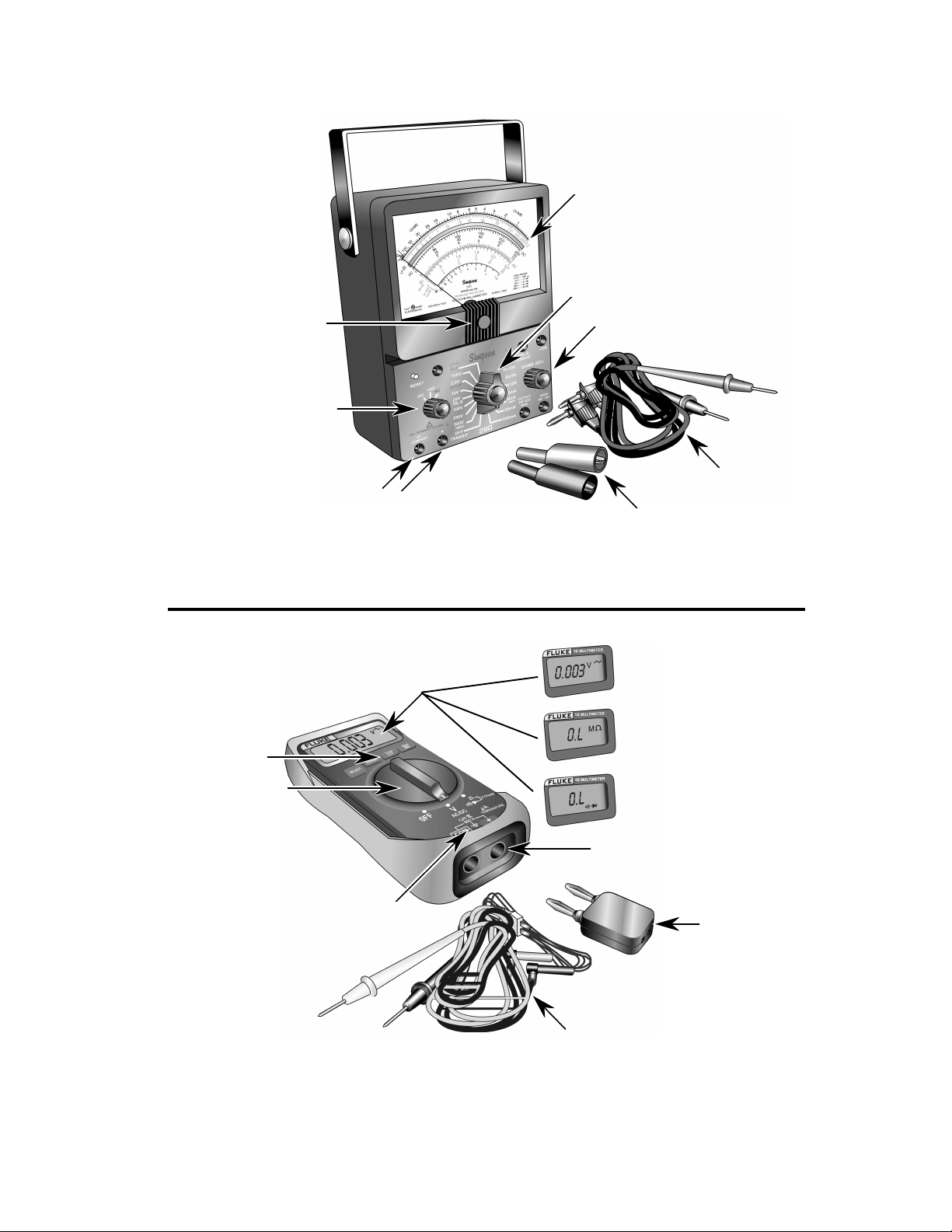

FEATURES & FUNCTIONS

Most VOMs offer the following standard features and functions:

DISPLAY — The window that shows the variable pointer, and the

printed measuring scales for the different types of readings. A digital

VOM does not use a pointer or printed scales. Instead, it displays its

measurements in actual numbers.

RANGE SELECTOR — A rotary switch that performs two functions:

1. Chooses the type of reading (AC volts, DC volts, and Ohms) to be

measured.

2. Selects the range of the highest expected reading. Some meters

use jacks instead of a selector switch, or a combination of jacks

and switches.

METER ZERO ADJUST — A control (usually a screw or knob) that

aligns the pointer with the zero mark on the measuring scales to in-

crease accuracy.

OHMS ZERO ADJUST — A control (usually a small knob) that aligns

the pointer with the zero mark on the Ohms scale. An internal battery

supplies a small voltage for making resistance measurements. As the

condition of the battery changes over time, the Ohms Zero Adjust con-

trol allows the user to easily zero the pointer to compensate for these

changes.

PROBE JACKS — Connection terminals for the test leads that are used

to make electrical measurements. The jacks and terminals are marked

with a (+) and a (–) symbol. They are also color-coded (usually red and

black) to ensure proper connections and polarity when making DC

measurements. If the leads are reversed when making a DC voltage

reading, the meter pointer will move in the direction opposite of the

meter scale. Some meters have a polarity reversing switch that inter-

nally reverses the (+) and (–) leads when the range switch is set to DC.

2

Display

Range Switch

Mechanical Zero Adjust

AC-DC Selector

Range Selectors

Ohms Zero Adjust

Test Leads

Probe Jacks

Alligator Clips

Figure 1

Simpson 260 Series 6XLMP Meter

Display

Voltage & Resistance

Selector

Probe Jacks

Temperature Probe Jacks

Temperature Adapter

Test Leads

Figure 2

Fluke 16 Multimeter

3

HOW THE METER MOVEMENT OPERATES

In order for the VOM to register a measurement, the meter’s pointer

must be made to move, or rotate, across the scale. For this to happen,

the base of the pointer is mounted on a pivot, and placed between the

poles of a permanent magnet. In addition, a coil of very fine wire is

wound around the base of the pointer.

As current passes through the coil, a small magnetic field is produced.

This field reacts with the field produced by the permanent magnet. The

amount of pointer movement is determined by the amount of current

passing through the coil, and the size of its magnetic field.

When current stops flowing through the coil, the pointer returns to zero.

It is very important to handle a VOM carefully, since a sudden jolt can

unseat the pointer from its pivot, and damage the movement.

4

MAKING ACCURATE MEASUREMENTS

To make your measurements as accurate as possible, use the following

steps:

1. Carefully read the operating instructions and safety information in the

VOM manual.

2. Check the meter and make sure that the pointer is set to “zero.” Use

the Mechanical Zero Adjust for the voltage scale, and the Ohm Zero

Adjust for the resistance (Ω) scale.

3. Make sure that the test leads are firmly inserted into their jacks.

Insert the black test lead into the negative (–) jack, and the red test

lead in the positive (+) jack.

4. When making a measurement, keep the metal probe tips firmly in

contact with the leads of the device being tested to insure good

metal-to-metal contact. Poor contact will cause inaccurate or fluctuat-

ing readings.

5. Do not touch the metal probes while taking a measurement. If you

touch the probes during that time, you could receive a serious electri-

cal shock. Touching the metal probes while making a resistance

measurement can cause the reading to be inaccurate because of

skin resistance.

6. Always select the range that will provide a midscale reading for the

resistance you want to measure.

5

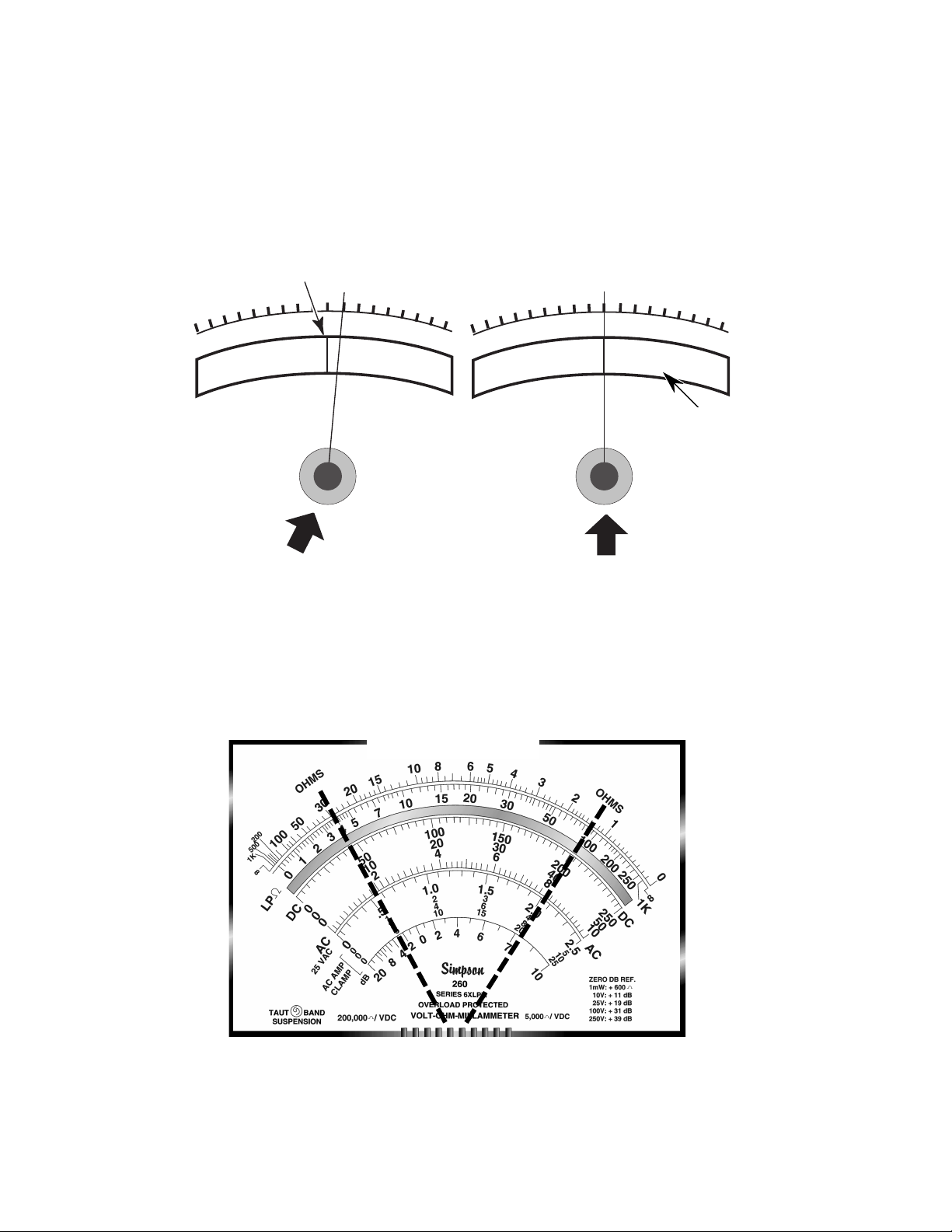

7. Look straight at the meter pointer and scale. If you view them at an

angle, you can get an inaccurate reading. Some meters have a

mirrored scale to help prevent reading errors. With this type of scale,

you know that you are viewing straight if the pointer hides its reflec-

tion in the mirror (see Figure 3).

Pointer Reflection

No Pointer Reflection

Mirror

Figure 3

Incorrect Eye Position

Correct Eye Position

8. Select the appropriate voltage or resistance range so that the read-

ings are in the center portion of the scale. This will give a more accu-

rate reading (see Figure 4).

Midrange Viewing

Figure 4

6

RESISTANCE

MEASURING RESISTANCE (Ω)

When a resistance measurement is made, the test probes connect the

meter in series with the component, or load. To prevent damage to the

meter during a resistance measurement, the circuit or component is

always disconnected from the power source.

A very small current is needed to obtain a resistance measurement, and

is provided by a battery inside the VOM.

Note that the resistance, or ohm’s scale (Ω) of the meter, is the reverse

of the volts scales (see Figure 5). That is, the zero on each scale is at

the opposite ends of the meter.

Zero

Ohms

Zero

Volts

Less Current Flow

More Resistance

When the maximum amount of current is flowing through the circuit, the

pointer will rotate all the way to the zero end of the ohms scale.

When very little current is flowing, the pointer will remain at, or near, the

infinity (∞), or maximum resistance, end of the ohms scale. The Range

switch has various resistance values built into the meter, which allows

for the proper measurement of resistance.

Before making a resistance reading, any changes in the battery condi-

tion must be compensated for to assure accuracy. In order to do this:

1. Touch the test lead probe tips together to obtain the maximum cur-

rent flow from the battery.

Figure 5

More Current Flow

Less Resistance

2. Zero the resistance scale pointer with the Ohms Zero Adjustment

knob.

3. Zero the meter each time the range switch is changed.

7

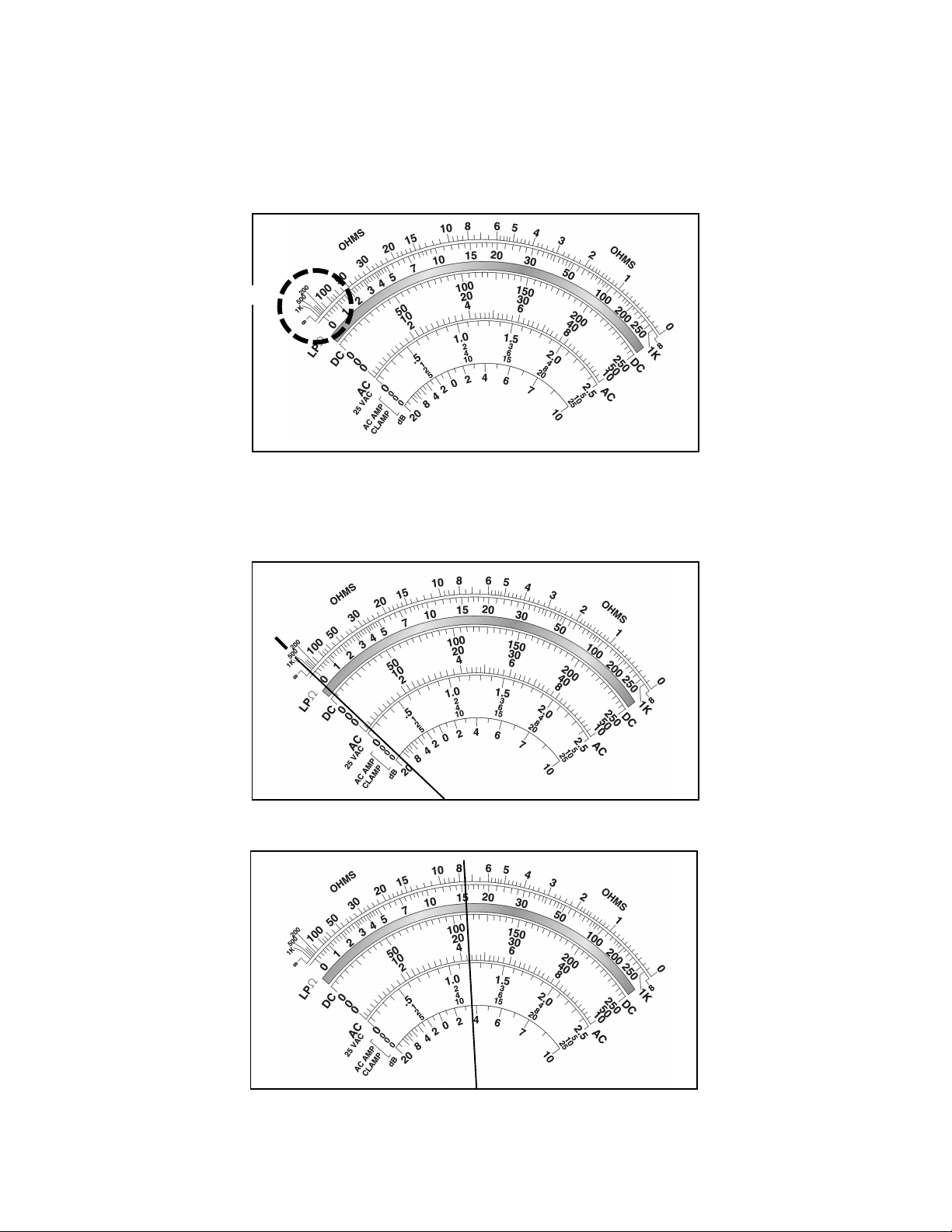

CHOOSING THE CORRECT RESISTANCE RANGE

Four resistance ranges are available on the meter, as shown in Figure

6. Each of these ranges show the user how much to multiply the meter

indication by. The four range scales are read as follows:

a) R x 1 = Reading on Scale x 1.

b) R x 100 = Reading on Scale x 100.

c) R x 1 K = Reading on Scale x 1,000.

d) R x 10K = Reading on Scale x 10,000.

The easiest way to remember how much to add to the meter reading, is

to add zeros to it. For example, if the meter indicates 5, and the Range

switch is set to R x 100, then adding two zeros to the 5, would equal

500. If the meter indicates 37 and the Range switch is set to R x 10K,

then adding four zeros (10,000) would make the reading 370,000.

Figure 6

8

Unlike voltage scales, the scale used for resistance measurements is

not divided into equally-spaced increments. As resistance becomes

higher, the numbers on the scale are grouped closer together, making

an accurate reading difficult (see Figure 7).

Difficult Viewing

Figure 7

When making resistance measurements, it is important to try to get a

lower, or “midscale” reading, whenever possible (see Figure 8).

750 Ω On R x 1 Scale

750 Ω On R x 100 Scale

Figure 8

9

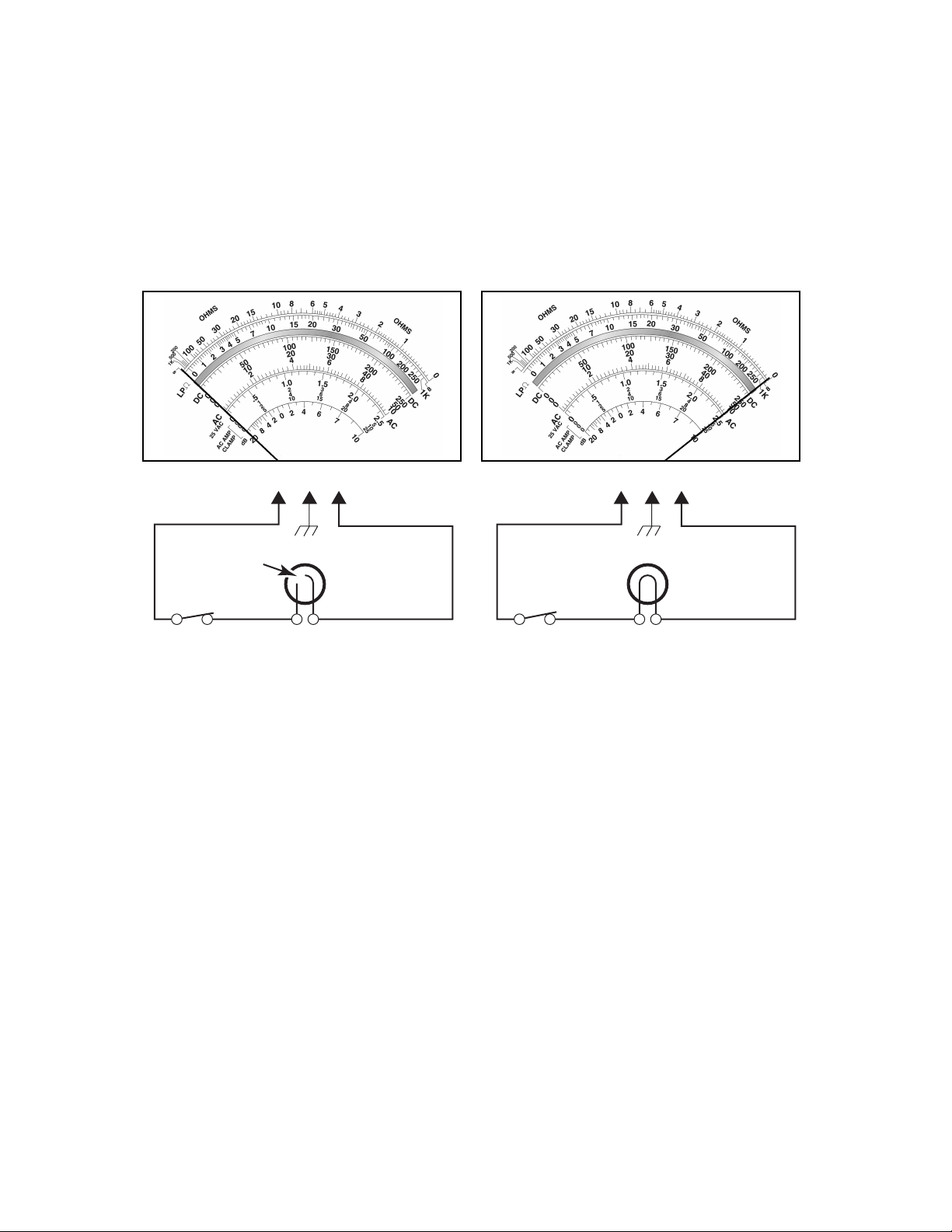

MEASURING CONTINUITY

The ohmmeter can also be used to check continuity in a circuit. Continu-

ity is a “continuous,” or “closed” circuit. An open circuit means that the

continuous circuit has been broken at some point. In this case, the

meter would indicate “infinite” resistance.

Figure 9 shows an open and a closed circuit.

AB

AB

Open

Infinite Resistance

Open Circuit

Figure 9

0 Ω Resistance

Closed Circuit

BASIC RULES FOR MEASURING RESISTANCE

When making a resistance measurement, remember several basic

rules:

a) Always disconnect the circuit, or component being checked, from

the voltage source before connecting the meter probes.

b) Isolate the component being checked by disconnecting one side

of the component from the circuit. This assures that meter current

will flow only through the component being checked.

c) Use the Range switch, and select the resistance range you will be

measuring.

d) Zero the meter with the Zero Ohms Adjust knob.

10

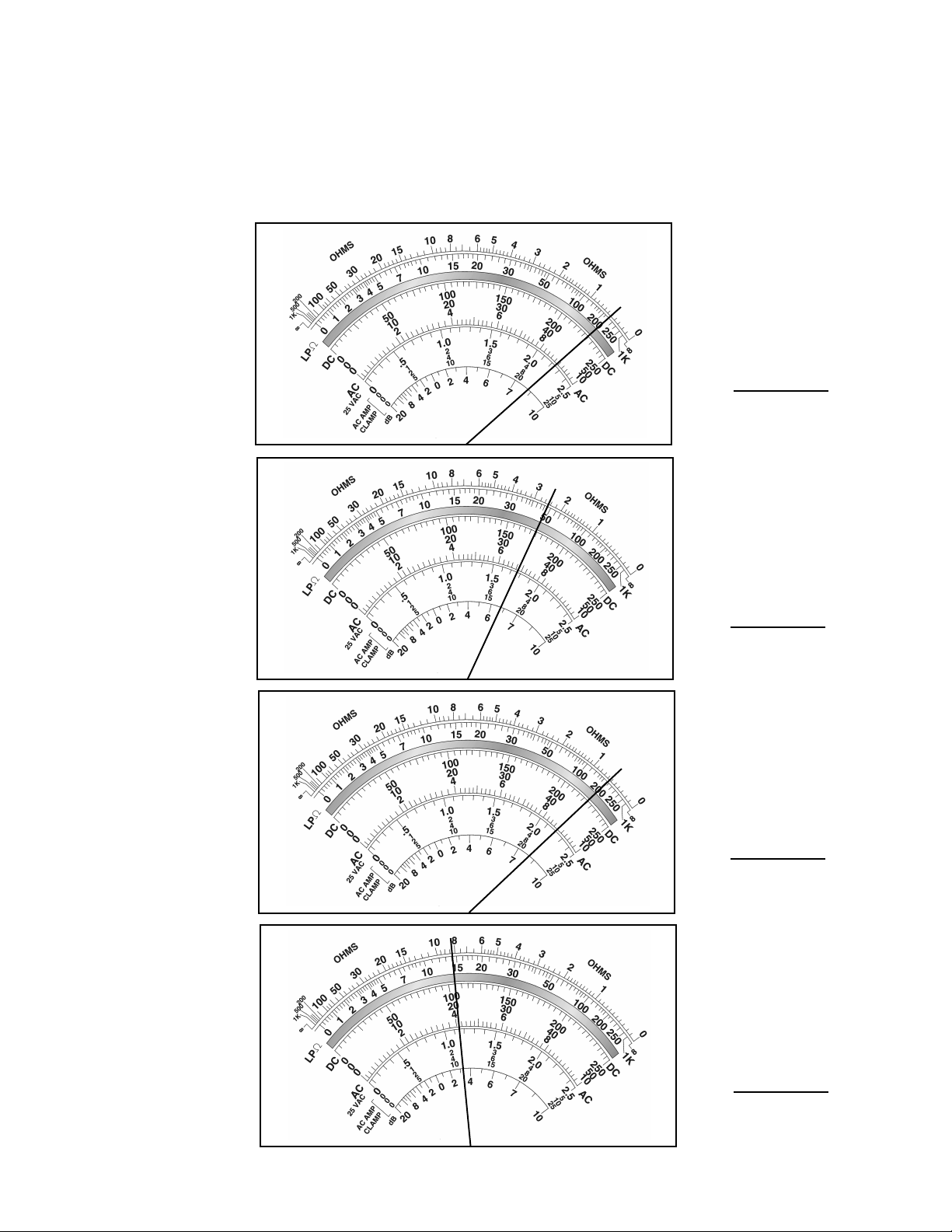

PRACTICE EXERCISE 1

READING THE RESISTANCE SCALE

Write the correct resistance reading in the space provided by each

illustration. The resistance ranges are shown.

1.

2.

R x 10K

R x 1K

3.

4.

R x 1

R x 100

11

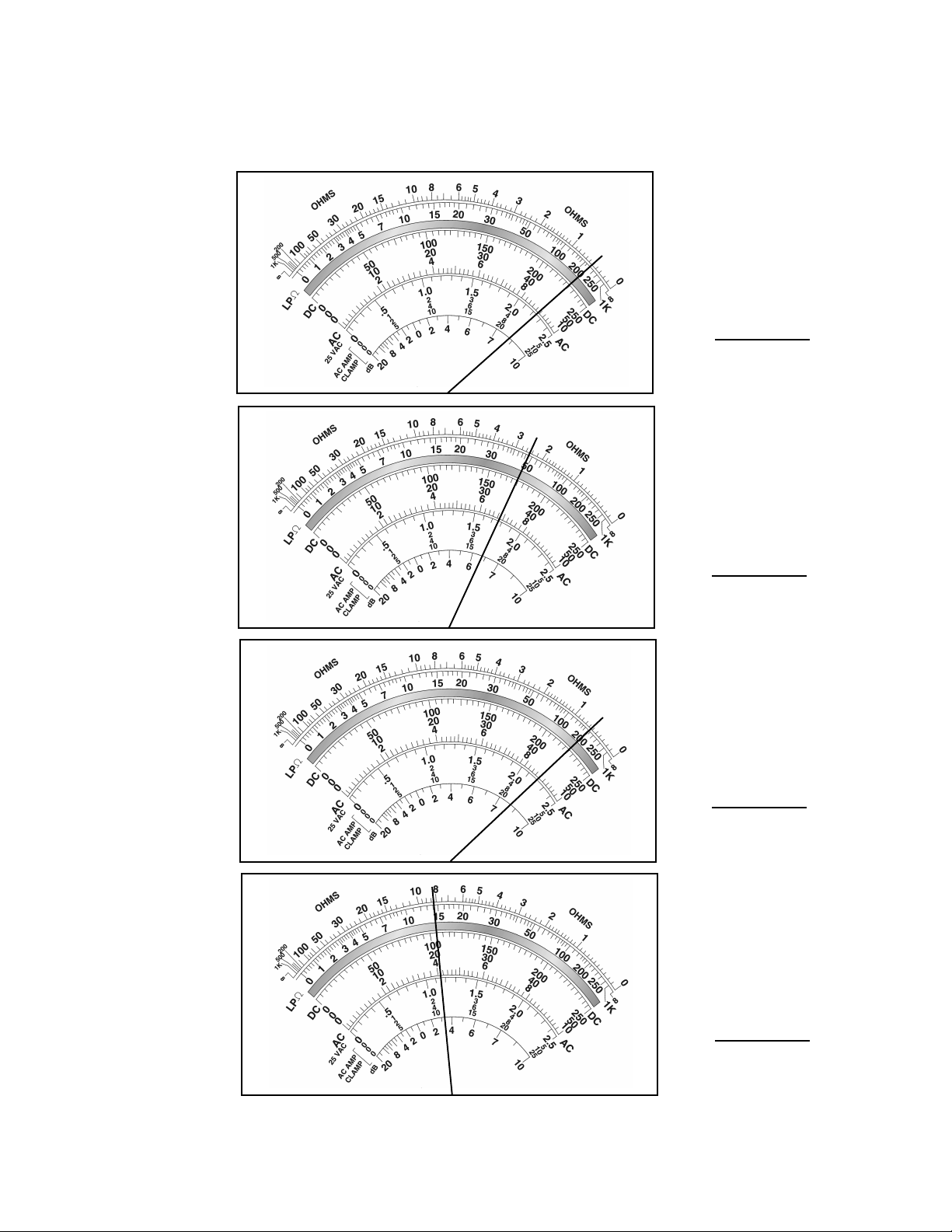

PRACTICE EXERCISE 1 ANSWERS

READING THE RESISTANCE SCALE

1.

2.

R x 10K

5000 Ω

R x 1K

3.

4.

2500 Ω

R x 1

.6 Ω

R x 100

12

820 Ω

VOLTAGE

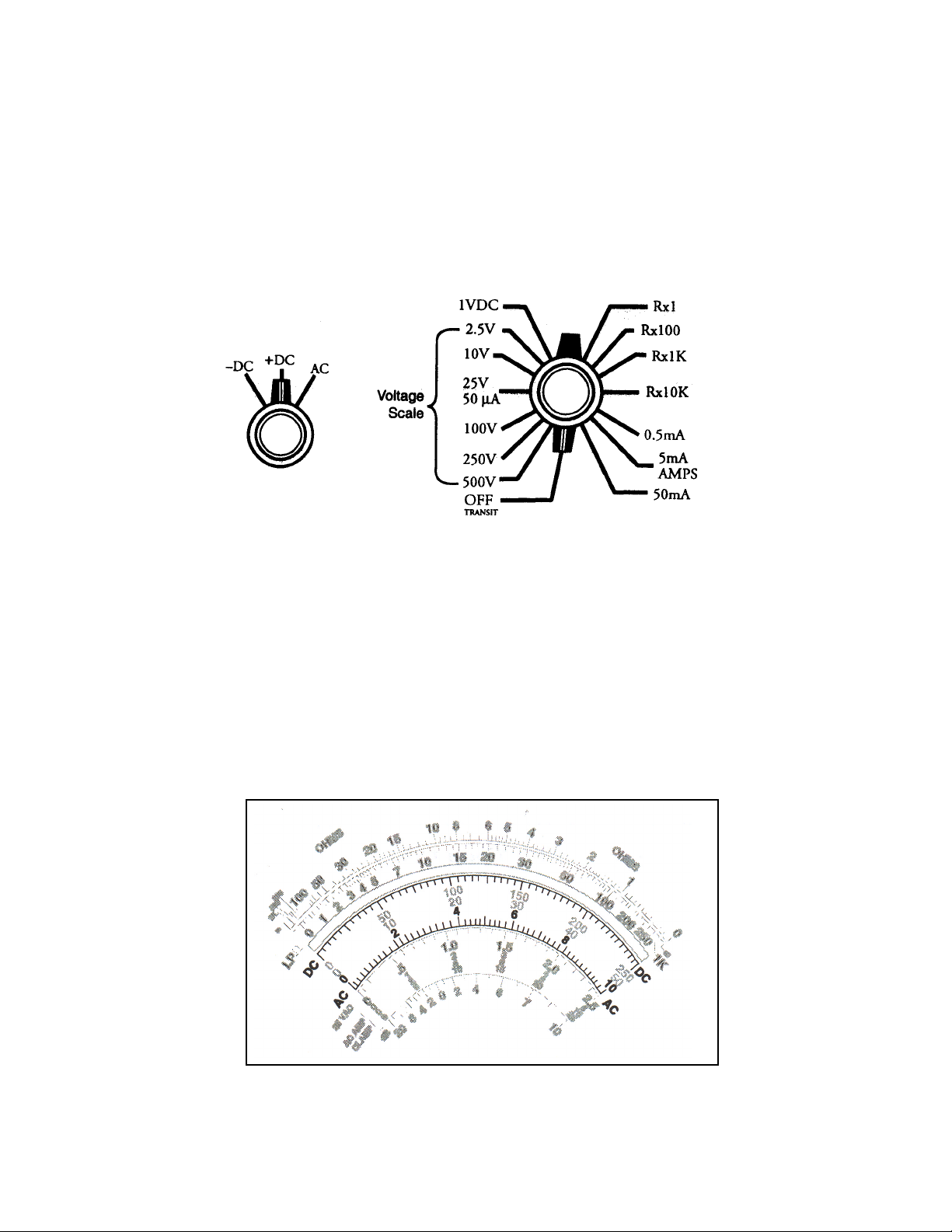

THE RANGE SWITCH

The Range switch has various settings for DC volts and for AC volts.

Both types of voltage have ranges with six settings: 2.5, 10, 25, 100,

250, and 500 volts (see Figure 10). The AC - DC Selector switch selects

the type of voltage being measured (–DC, +DC, AC).

Figure 10

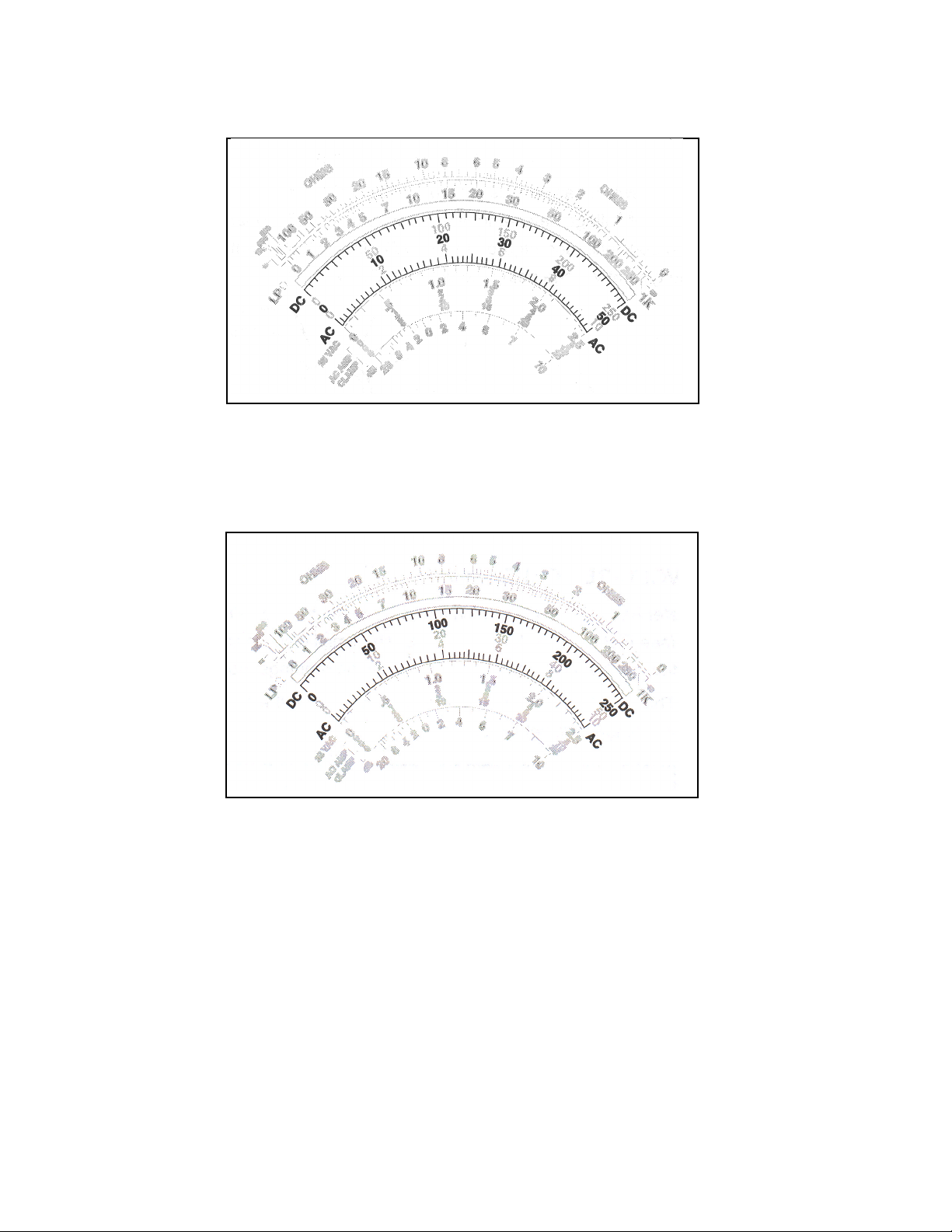

THE VOLTAGE SCALE

The meter has three scales which are divided into the following incre-

ments (see Figures 11 A, B, & C). NOTE: The small division lines be-

tween the numbers on the scales help make the readings more exact:

a) The 0 - 10 scale is used to read voltages when the 10 or 100 volt

ranges are selected.

Figure 11A

13

b) The 0 - 50 scale is used with the 500 volt range.

Figure 11B

c) The 0 - 250 scale is used with the 2.5, 25, or 250 volt ranges.

Figure 11C

14

Loading...

Loading...