Whirlpool AGB 681/WP, AGB 688/WP, AGB 789/WP, AGB 675/WP, AGB 674/WP INSTRUCTION FOR USE

...Page 1

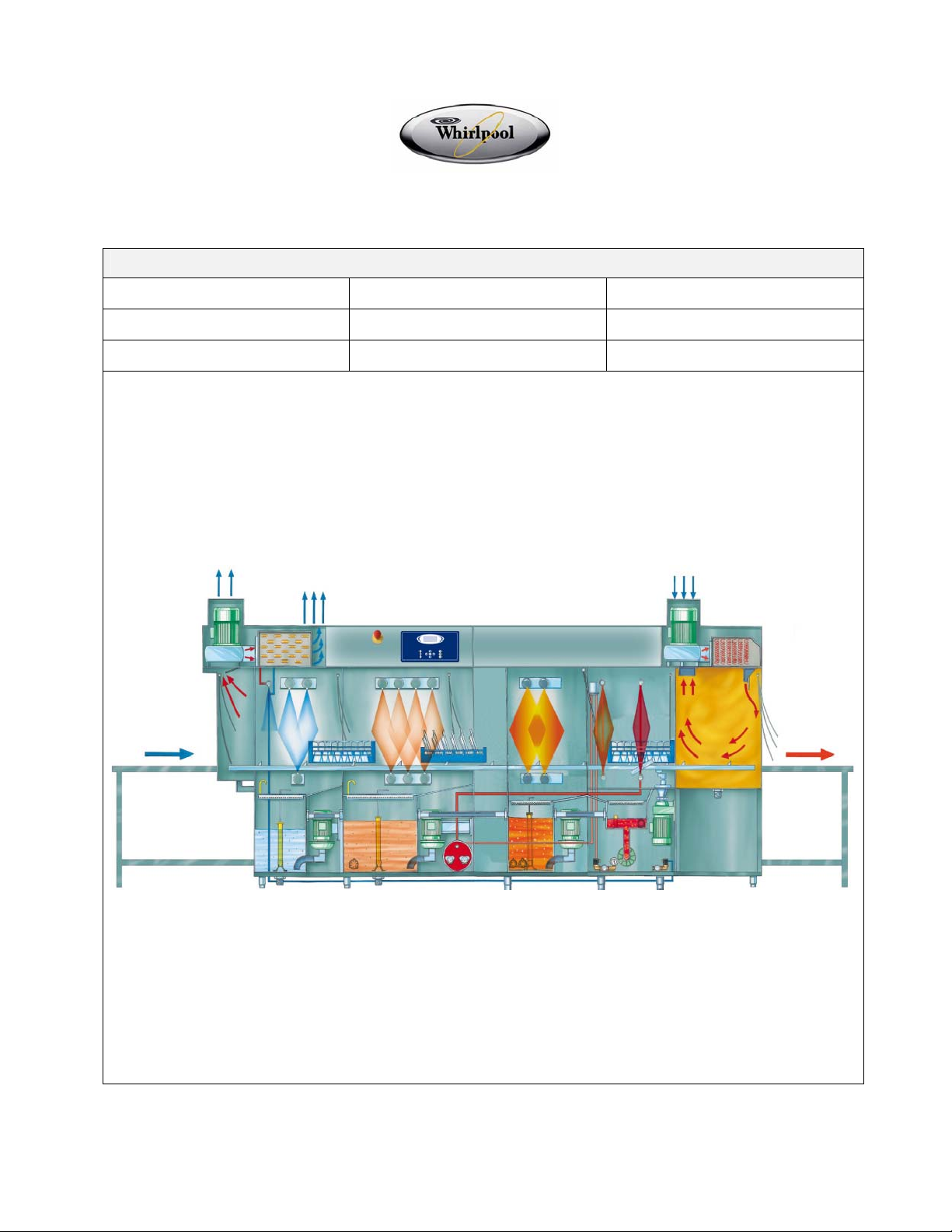

PROFESSIONAL DISHWASHERS

AGB 674-780 AGB 675-676 AGB 681-682

AGB 693-694 AGB 685-686 AGB 687-789

AGB 790-791

MODELS

Page 2

1 Usage and safety warnings

2 Installation and positioning

3 Technical characteristics

4 Installer instructions

5 First startup

6 User instructions

7 Maintenance and cleaning (user)

8 Problems and anomalies (user)

Thank you for having chosen this product.

We recommend that all of the instructions contained in the manual be read carefully in order to fully

understand the most suitable conditions for proper use of the dishwasher.

TECHNICAL INSTRUCTIONS:

Are intended for qualified personnel who shall perform installation, activation, testing

and eventual assistance interventions.

USER INSTRUCTIONS:

Indicate suggestions for use, description of commands and proper dishwasher cleaning

and maintenance.

2

Page 3

1 USAGE AND SAFETY WARNINGS

THIS MANUAL CONSTITUTES AND INTEGRAL PART OF THE DISHWASHER; IT MUST ALWAYS BE

PRESERVED INTACT, TOGETHER WITH THE MACHINE.

POSITIONING, CO NNECTIONS, ACTIV ATION AND TROUBLES HOOTING, AND SUBS TITUTION OF THE

POWER CABLE MUST BE PERFORMED BY QUALIFIED PERSONNEL.

THE DISHWASHER IS INTENDED EXCLUSIVELY FOR PROFESSIONAL USE AND MUST BE USED BY AUTHORIZED

PERSONNEL. IT IS DESIGNED TO WASH DISHES (PLATES, CUPS, BOWLS, TRAYS, SILVERWARE) AND SIMILAR

ITEMS USED IN GASTRONOMIC SECTORS AS WELL AS IN THE PUBLIC CATERING BRANCH, AND IN CONFORMITY

TO THE INTERNATIONAL ELECTRICAL AND MECHANICAL SAFETY (CEI-EN-IEC 60335-2-58/61770) AND

ELECTROMAGNETIC COMPATIBILITY (CEI-IEC-EN 55014-1/-2, 61000-3;4, 50366) NORMS.

THE MANUFACTUIRER DECLINES ANY RESPONSIBILITY FOR DAMAGE TO PERSONS OR THINGS CAUSED BY

FAILURE TO OBSERVE THE INSTRUCTIONS PRESENT IN THE MANUAL, INCORRECT USE, TAMPERING, EVEN

WITH A SINGLE PART OF THE MACHINE, AND THE USE OF NON-ORIGINAL SPARE PARTS.

THE GROUNDING CONNECTION, IN CONFORMITY TO THE METHODS PRESCRIBED BY THE

ELECTRICAL SYSTEM’S SAFETY NORMS, IS OBLIGATORY.

THIS MACHINE IS MARKED IN CONFORMITY TO THE EUROPEAN DIRECTIVE 2002/96/EC, WASTE ELECTRICAL

AND ELECTRONIC EQUIPMENT (WEE).

ENSURING THAT THIS PRODUCT BE DISPOSED OF IN A PROPER MANNER CONTRIBUTES TO THE PREVENTION OF

POTENTIAL NEGATIVE HEALTH AND ENVIRONMENTAL CONSEQUENCES.

THE

PRODUCT MAY NOT BE TREATED AS DOMESTIC WASTE, BUT RATHER MUST BE TAKEN TO A COLLECTION

FACILITY WHICH IS SUITABLE FOR THE RECYCLING OF ELECTRIC AND ELECTRONIC EQUIPMENT.

DISCARD THIS PRODUCT IN CONFORMITY TO THE LOCAL NORMS REGARDING WASTE DISPOSAL.

FOR MORE INFORMATION REGARDING THE TREATMENT, SALVAGE AND RECYCLING OF THIS PRODUCT,

CONTACT YOUR COMPETENT LOCAL OFFICES, YOUR LOCAL WASTE COLLECTION SERVICE PROVIDER OR THE

POINT OF SALE IN WHICH THE PRODUCT WAS PURCHASED.

SYMBOL UPON THE PRODUCT, OR UPON ITS ACCOMPANYING DOCUMENTATION, INDICATES THAT THIS

DO NOT INSERT SOLVENTS SUCH AS ALCOHOL OR TURPENTINE INTO THE MACHINE, AS THEY

COULD CAUSE AN EXPLOSION. DO NOT INSERT DISHES WITH ASH, WAX OR VARNISH RESIDUES

INTO THE MACHINE.

NEVER USE THE DISHWASHER OR ITS PARTS AS A STEPLADDER OR SUPPORT FOR PERSONS,

THINGS OR ANIMALS.

LEANING OR SITTING UPON THE DISHWASHER’S OPEN DOOR COULD CAUSE IT TO TIP AND POSE A

DANGER TO PEOPLE IN THE VICINITY.

IN ORDER TO AVOID TRIPPING UPON IT, DO NOT LEAVE THE DISHWASHER DOOR OPEN.

DO NOT DRINK THE RESIDUAL WATER WHICH MAY BE PRESENT WITHIN THE DISHES OR THE

DISHWASHER ITSELF AFTER A WASH CYCLE.

THE MACHINE IS NOT SUITABLE TO BE USED BY MINORS, AND BY PEOPLE WITH REDUCED

PHYSICAL, SENSORIAL OR MENTAL CAPABILITIES, WHO LACK THE NECESSARY EXPERIENCE AND

KNOWLEDGE FOR ITS PROPER OPERATION. US E OF THE MACHINE IS PE RMIT T ED T O TH ES E P E OPLE

EXCLUSIVELY UNDER THE SUPERVISION OF A PERSON IN CHARGE OF THEIR SAFETY.

3

Page 4

2 INSTALLATION AND POSITIONING

INSTALLATION AND POSITIONING

Bring the dishwasher to its installation location, remove its packaging and verify the integrity of the

apparatus and of its components. If damaged, written notification must be sent to the transporter.

The packaging elements (plastic bags, polystyrene foam, nails, etc) must not be left within reach of children

and domestic animals as they are a potential source of danger.

All of the materials used for packaging are compatible with the environment. They may be safely preserved,

or may be disposed of at an appropriate waste disposal facility.

The components in plastic material subject to eventual disposal through recycling are marked in the

following manner:

PE polyethylene: external wrapping, instructions bag, protection bags.

PP polypropylene: straps.

PS polystyrene foam: protective corners, packaging cover.

The wood and cardboard components can be disposed of by respecting the norms in vigor.

When disposing of the product, do not abandon it in the environment; its disposal must respect the norms in

vigor. All of the metallic parts are in stainless steel and are detachable.

The plastic parts are marked with the symbol of the rela tive material.

POSITIONING:

Warning:

installed, must answer to the norms in vigor.

The manufacturer declines any responsibility for direct damages to persons of things deriving from lack of

respect for the said norms.

Prior to installation, verify that objects and materials which could be damaged by aqueous vapor or by

spray from washing solutions are not in the vicinity, or are adequately protected.

Position the dishwasher in the desired position and remove the protective wrapping.

Level the dishwasher (with the help of a level) on its four feet, regulating them in such a way so as to

guarantee stability; any alternate solution must be approved by the manufacturer.

the internal system and the locations in which communal apparatus are to be

4

Page 5

3 TECHNICAL CHARACTERISTICS

Power supply V 400V/3 400V/3 400V/3 400V/3 400V/3 400V/3 400V/3

Frequency Hz

Max. power consumed kW

Boiler element power kW

1st Wash Tank element

power

2nd Wash Tank element

power

1st Rinse Tank element

power

Pre wash pump power kW

Wash pump power kW

Water supply pressure kPa

Water supply temperature °C

Water supply hardness °dF 7 – 12 7 – 12 7 – 12 7 – 12 7 – 12 7 – 12 7 – 12

Water consumption per

rinse

Pre wash water

temperature

Wash water temperature °C 55-60 55-60 55-60 55-60 55-60 55-60 55-60

Rinse water temperature °C 80-85 80-85 80-85 80-85 80-85 80-85 80-85

Pre washTank capacity l

WashTank capacity l

1st rinse tank capacity l

Theoretical production

with water supply at 50°C

Net weight kg

Power cable type ◄HAR► H07RN-F H07RN-F H07RN-F H07RN-F H07RN-F H07RN-F H07RN-F

Ambient temperature max °C 40 40 40 40 40 40 40

kW

kW

kW

l/h

°C

baskets/h

AGB 674-

780

50 50 50 50 50 50 50

23,5 24,2 24,2 31,25 28,95 36,05

14 14 14 20 14 20

8 8 8 8 8 8

- - - - - -

- - - - 4,5 4,5

- - - 1,1 - 1,1

1,35 2 2 2 2 2

200-400 200-400 200-400 200-400 200-400 200-400 200-400

55 55 55 55 55 55 55

285 285 285 380 285 380

40-45 40-45 40-45 40-45 40-45 40-45

- - - 55 - 55

100 100 100 100 100 100

- - - - 20 20

76 95 76/115 112/169 90/135 137/206 172/259

200 210 230 295 265 325

AGB 675-

676

AGB 681-

682

AGB 693-

694

AGB 685-

686

AGB 687-

789

AGB 790-

791

53,55

20

8

14

6

1,1

2

380

40-45

55

100

20

405

5

Page 6

4 INSTALLER INSTRUCTIONS

The installation must be made by a qualified person, carefully observing all the manufacturer's

indications. After having unpacked the dishwasher, inspect it to see if it has been damaged during

shipment. If there is any suspect evidence, consult a service representative. All the packing materials

(bags - Styrofoam - nails - etc.) must not be left where they can cause harm to persons, especially

children. When installing, made certain the unit is perfectly level - adjusting the feet as required as this wi ll

ensure correct operation.

When locating the machine, allow plenty of free space around it to permit easy access and operation by

maintenance personnel. Remove the rear panel to permit making the water connections. Mount any shelves,

benches or roller units that are to be mounted to the machine inlets and outlets, and then make the end-travel

micro switch electrical connections at the terminals located inside the machine. The machine must be fitted

with detergent and brightening dosing equipment, which will be furnished and installed by the firm that supplies

the cleaning products. The electrical terminal strip for making connections to the dosing units is located inside

the electrical box.

The terminals (B) and (D) on the terminal strip are for the dosing connections: (B) for the brightener and (D) for

the detergent. Do not pour detergent directly into the tubs; this will cause dark marks to appear on their

surfaces. Only use antifoaming detergent. The brightening equipment (B) operates on 24V, and the detergent

equipment (D) operates on the mains voltage. The machine equipped with a IPX1 degree of protection and

should therefore not be washed using direct jets of water.

4.1 WATER CONNECTIONS:

The machine has a filter whose inlet, install a maintenance and safety valve in an easily accessible position

upstream. The water temperature should be between 50°and 55°C; the pressure should be between 200/400

kPa and the water hardness should be between 7° and 12° French.

Hold down the button located next to the thermostat and fill the boiler with water. When the boiler is

completely full, water will issue from the rinsing nozzles. Now set the thermostat to 90°C.

Be careful here, because if you let it get to high you could burn out the electrical.

With machines that have a steam-condenser and heat energy-recovery capability, cold water must be feeding at

a temperature of between 10° and 15°C.

4.2 DRAIN WATER:

Install a floor-level discharging siphon connected to the discharge drain. If no siphon is provided, install one soas

to avoid fumes. Make sure that the discharge tube can resist a temperature of 70°C and no kinks in it.

4.3 STEAM FEEDING:

Connect to the machine fittings as shown in the installation drawing. Install quick-closing and shit-off valves to

make the equipment independent from the main line. The steam should be supplied , saturated and dry, at

pressures ranging between a minimum of 0.5 bar (50Kpa-110.8°C) and a maximum of 0.8 bar (80Kpa-110.8°C)

4.4 STEAM DRAIN:

The condensed steam discharge line to the recovery system has to have an adequate slope to provide positive

evacuation. Install a recycling pump if required. This is only for steam heated machine. A maintenance quick

closing valve should be installed in parallel with the condensate discharge, so as to be able to deviate the

condensate to the sewer.

Caution: make sure that the supply and drain tubes are not bent, restricted or crushed after

installation.

4.5 Electrical connection

The dishwasher’s electrical connection, and that of eventual supplementary apparatus, is to be

entrusted to authorized and qualified personnel, with respect to the norms in vigor; the technical

regulations for the connections are also to be observed. The total power installed is given upon the

apparatus’ technical data label.Other apparatus must not be protected together with the dishwasher.

The user must provide for the installation, according to the norms in vigor, of a main electrical power

switch and of a differential switch compatible with the machine’s characteristics.

These switches must be installed near the dishwasher, be easily accessible after installation and

guarantee complete disconnection from the electrical supply in category III over voltage conditions.

6

Page 7

Caution!!!

‐ Connect the apparatus to the usage equalizer. The

‐ The protection conductor (PE) is yellow-green in color, the neutral conductor (N) is blue and the phase

The dishwasher is free of electrical current only when the main switch is off.

clamp for the connection is located at the lower

back of the machine.

conductors (L1, L2, L3) are black

5 FIRST STARTUP ( Installer )

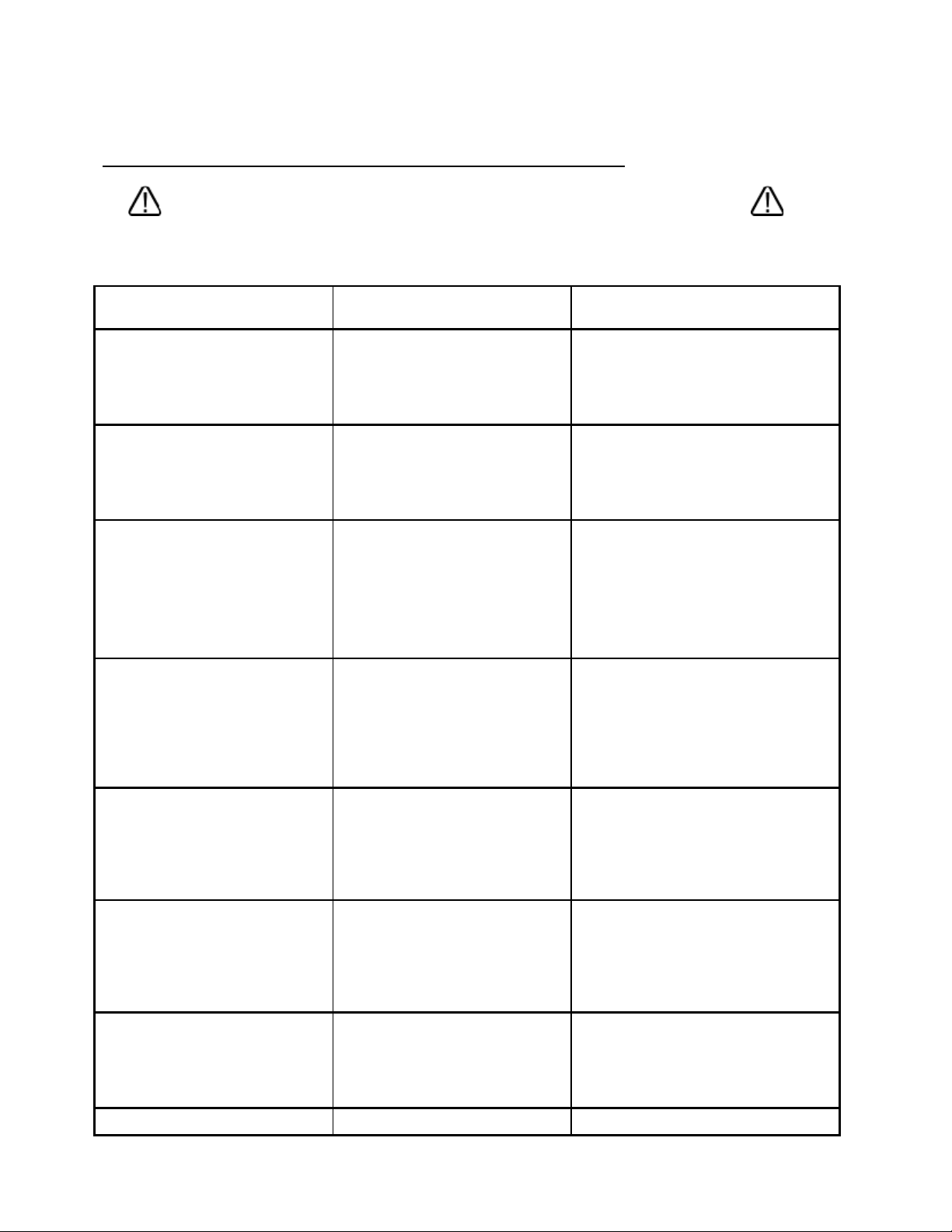

Before starting up the machine, make sure:

The inlet

water valves

are open

The brightener and

detergent containers are

full and their respective

dosing units are

working properly

The wall switch

is turned on

- The overflow tubes are located

correctly.

- The filters are well located.

- Curtains are correctly placed.

- The doors are closed.

5.1 FIRST START UP ( BOILER AND TANK EMPTY )

Visualization What to do and what happens

CAUTION

.

-

In order to turn the machine on rotate the main switch

to the right on to position start. Main switch

will illuminate green.

Wait for push button

tank is full.

Fill up boiler keeping pressed the push button S5. Keep

it pressed until water will come out from rinse arms

indicating boiler is full.

Settle tank thermostat T3 at 55°C and boiler

thermostat T10 at 85°C.

The manufacturer declines any responsibility for

damages to elements deriving from not following the

said operations.

Make sure that all motors turn in the right direction;

generally this can be taken for granted if the arrow on

the drive assembly turn in the right direction. Motor

gear must turn clock wise.

to turn on green indicating

7

Page 8

6 USER INSTRUCTIONS

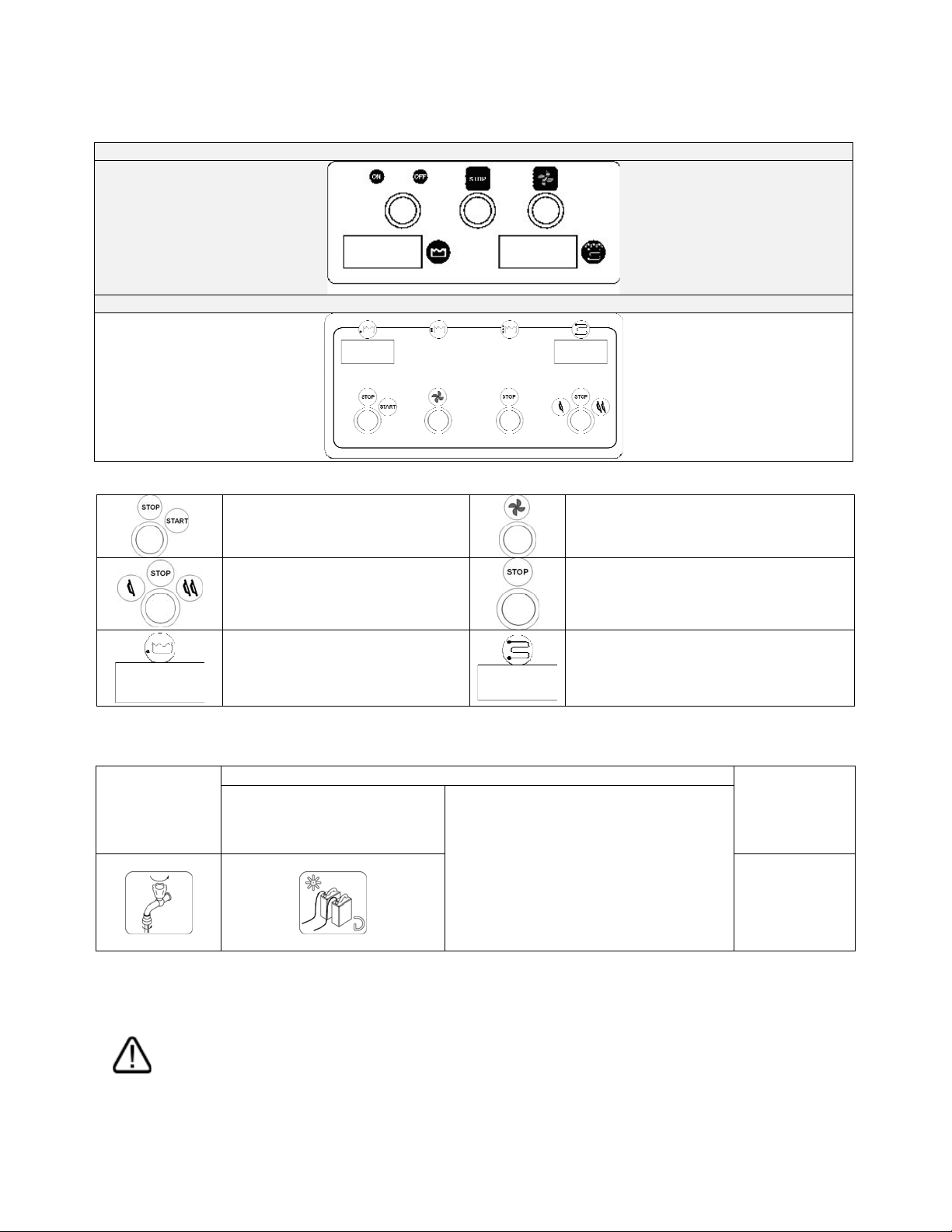

AGB 674-780

AGB 675-676-681-682-693-694-685-686-687-789-790-791

on/off selector

Speed selector

Wash Tanks thermometres

Cycle push button

Stop push button

Rinse thermometre

6.1 Before washing

Before starting up the machine, make sure:

The inlet water

valves are open

Use only detergents and rinse-aids for industrial dishwashers.

Do not use detergents intended for hand washing.

It is recommended to use products which were designed especially for this dishwasher.

During the loading of the tanks, be careful not to switch products as this could provoke dishwasher

malfunction and damage.

Do not mix different detergents together as this could damage the metering unit.

Detergents for industrial dishwashers can cause serious irritations. Take care to respect the instructions

provided by the detergent manufacturer on the packaging.

Rinse aid and detergent

containers are full and their

respective dosing units are

working properly

The wall switch

is turned on

- The overflow tubes are located

correctly.

- The filters are well located.

- Curtains are correctly placed.

- The doors are closed.

8

Page 9

6.2 Loading the dishes

Plates

The rack can hold 12 bowls or 18

plates. Remove solid residues from

the plates (bones, peels, cores, etc.);

let plates, with dried residues of

cheese, egg, etc., soak in cold water

before washing.

Glasses

Position the glasses upside down .

Silverware

Use the appropriate basket. It is preferable to arrange large amounts of silverware with the handles facing

down, taking care to avoid injury from fork prongs and knife blades.

6.3 First daily use

Visualization What to do and what happens

Azionare l’interruttore a muro.

Open the door, insert the overflow pipe, verify filters

are well located and close the door.

Rotate main selector

will illuminate green. Wait for push button

turn on green indicating tank is full. Wait until the

wash tank temperature reaches 55/60°C and rinse

temperature reaches 80/85°C; at this point the

machine is ready for use.

Select the desired program by turning

long cycle or speed cycle.

on to Start, main switch

to

:

Push switch

conveyor bar and wash pumps will start, rinse will start

automatically when baskets will pass the rinse area.

to start the washing process:

9

Page 10

Remove from the dishes all food leftovers and grease

then place the items to be washed in the baskets. If the

tableware has been waiting a long time to be washed,

it will first to be soaked.

Introduce basket into the machine.

Caution: when the machine is functioning do not open

doors quickly

When the baskets are not removed, they continue

onward until they contact the end-travel micro switch

which automatically stops the bar movement and turns

off the rinse water. When the micro switch interrupts

the conveying bar movement, turn off the machine

before removing the cause of the stoppage.

To turn off the machine, whenever required or when the

6.4 Total drainage at the end of the day

When finished using the machine, after having performed the final drainage, turn the machine off by

pressing the on/off button, deactivate the wall switch and turn off the water interception faucet.

Do not leave the machine on, inactive and unutilized for long period s of time.

work has been completed, press button

the control panel.

THE "RED BUTTON" MUST ONLY BE PRESSED

TO TURN PFF THE MACHINE IN CASE OF AN EMERGENCY

Turn the machine off by rotating the selector

on to

turn off the water interception faucet. Open the door

and remove the overflow pipe for draining tanks.

. Deactivate the general wall switch and

located on

10

Page 11

7 MAINTENANCE AND CLEANING

Although special, programmed maintenance is not required, we recommend having the dishwasher checked by a

specialized technician twice a year.

Note: intentional damage or that derived from carelessness, negligence, lack of respect for the regulations,

instructions and norms or erred connections are not to be considered the responsibility of the manufacturer.

7.1 Daily cleaning

The dishwasher has an IPX1 protection rating, but the use of direct streams of water for its cleaning is

forbidden.

CLEANING OF THE FILTER DURING THE DAY

In case of particularly heavy usage it is recommended to perform a cleaning of the filter every 30-40 wash cycles

in order to maintain the machine in operative condition; Use “partia l tank draini ng” in order t o perform th ese

cleanings.

Open the door and remove the "overflow" tube to drain the tube. When the tube

is empty, clean it thoroughly.

Remove and clean the filters. With the steam condensate machines, remove and

clean the filter. In order to avoid burns and skin irritation, do not put naked

hands in hot cleaning water with detergent. If you happen to do so, rinse your

hands

off immediately under lots of running water. When you have completed these

operations, put all the components back in their original locations and leave the

door open in order to avoid unpleasant odours forming. Do not use corrosive

substances,

such as calcium hypochlorite (chlorox,etc.), acids (such as hypochloric acid) or

steel wool or steel brushes to clean the inside and outside parts of the machine.

In order to keep the machine in good running order, any hard-water deposits

(calcium and magnesium carbonates, etc.) should be periodically

removed by qualified professionals.

In order to avoid drops or vapors damaging the steel surfaces, do not even use the above-indicated products for

the cleaning of the flooring beneath or around the dishwasher.

7.2 Periodic checks

Disassemble the wash and rinse arms (lower and up per).

Clean the holes and the nozzles under a stream of clean water. Do not use utensils which could cause damage.

Carefully reassemble the wash/rinse arms.

Clean the outside of the machine with neutral soap and a damp cloth. Rinse and dry with care.

7.3 Prolonged disuse

If the use of the dishwasher is not foreseen for a relatively long period of time, it is necessary to drain the

detergent and rinse-aid dispenser in order to avoid crystallization and pump damage: Remove the suction

tubes from the detergent and rinse-aid containers and emerge them in a container filled with clean water.

Perform a few wash cycles and drain the machine completely.

11

Page 12

Finally, turn off the main switch and close the water supply faucet. The detergent and rinse-aid suction tubes

will be placed back in the containers when the machine is ready to be put back in use, taking care so as not to

invert the tubes

Do not leave the device on, inactive and unutilized for long periods of time.

PROBLEM

The voltage

indicator light does

not turn on

At start-up water

is not loaded

Wash and conveying

phases not

operating

8 PROBLEMS AND ANOMALIES (USER)

POSSIBLE CAUSE

Burned out bulb

Blown magneto thermals

Burned out low-voltage

transformer

Power loss in the mains

Water valve is closed

Dirty air trap

Defective pressure switch

Burned electrovalve coil

Broken or defective membrane

Interrupted end-travel

microswitch

Door microswitch interrupted

Coil remote switch interrupted

Defective button

Motor thermals blown

POSSIBLE REMEDY

Replace

Reset

Replace

Check power loss in the mains

Open de valve

Clean trap

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Reset

Feed water temperature

Rinse water in tub

does not heat

up or not

enough

Tub does not

stop filling

Insufficient

washing

Insufficient

rinsing

Spots and shadows on Water containing calcium and Inspect and request intervention by

Burned electrical resistance

Thermostat out of calibration

Remote switch interrupted

Electrical resistance coated with

deposits

Boiler coated with deposits

Burned electrovalve coil

Membrane broken or defective

Dirty air trap

Pressure switch broken or out of

calibration

Dtached pressure-switch tube

Plugged nozzles

Water temperature too low

Insufficient detergent

Detergent not suitable

Bad detergent dosing

Pump not functioning

Nozzles plugged

Dirty electrovalve

Inlet water pressure unsuitable

Boiler contains deposits Missing

wash/rinse divisory curtain

Check

Replace

Replace

Replace

Clean

Clean

Replace

Replace

Clean

Replace

Reattach

Clean

Check temperature

Ask detergent

technicians to intervene

Replace

Clean

Clean

Check water circuit

Clean Position

12

Page 13

glassed and silverware magnesium

Hardness values not within

7°/10°F Water contains other

minerals (Fe,etc.)

a specialized technician

Insufficient

drying

Insufficient

steam condensate

Insufficient

Washing,rinsing

and drying

Wash/rinse temperature too low

Defective motor, resistances,

etc.

Air intake holes obstructed

Brightener doser inoperative

Brightener container empty

Air expulsion holes obstructed

Plugged filter battery

Cold water inlet closed

Dirty or interrupted electrovalve

Defective motor or electrical

components

FOR STEAM DISHWASHERS

Steam shutter closed

Condensate discharger

obstructed

Steam electrovalve inoperative

Condensate recycling

Deposits on boiler coils and tubs

Insufficient steam pressure and

flow

Steam heating battery

plugged or defective drying

Check

Check and replace

Check

Adjust or replace

Fill

Check

Clean

Open

Clean or replace

Check or replace

Open

Clean

Replace

Check

Clean

Check

Replace

13

Loading...

Loading...