Whirlpool ACM 931/1 WH, ACM 931/1 IX, ACM 934/1 IX, ACM 934/1 WH, ACM 930/1 WH INSTALLATION INSTRUCTIONS

INSTRUCTIONS FOR USE

INSTALLATION INSTRUCTIONS

USE AND MAINTENANCE

BEFORE USING THE APPLIANCE

PRECAUTIONS AND GENERAL ADVICE

OVEN ACCESSORIES

CLEANING AND MAINTENANCE

TROUBLESHOOTING GUIDE

AFTER-SALES SERVICE

For best use of the oven, carefully read the operating instructions and keep them for future

consultation.

4

INSTALLATION INSTRUCTIONS

ELECTRICAL CONNECTION

This appliance must be earthed by law. Before connecting

the appliance to the electrical supply, check that the earth

system in your house is working correctly.

Check that unit voltage and power, marked on the rating plate

applied on the appliance, are correct for the supply. It is necessary

that the feeding network is protected by a powerful switch able

to disconnect completely the network with a contacts separation

of at least 3 mm. Be sure that the earth wire green/yellow is

not interrupted by the switch.

WARNING: THIS APPLIANCE MUST BE EARTHED

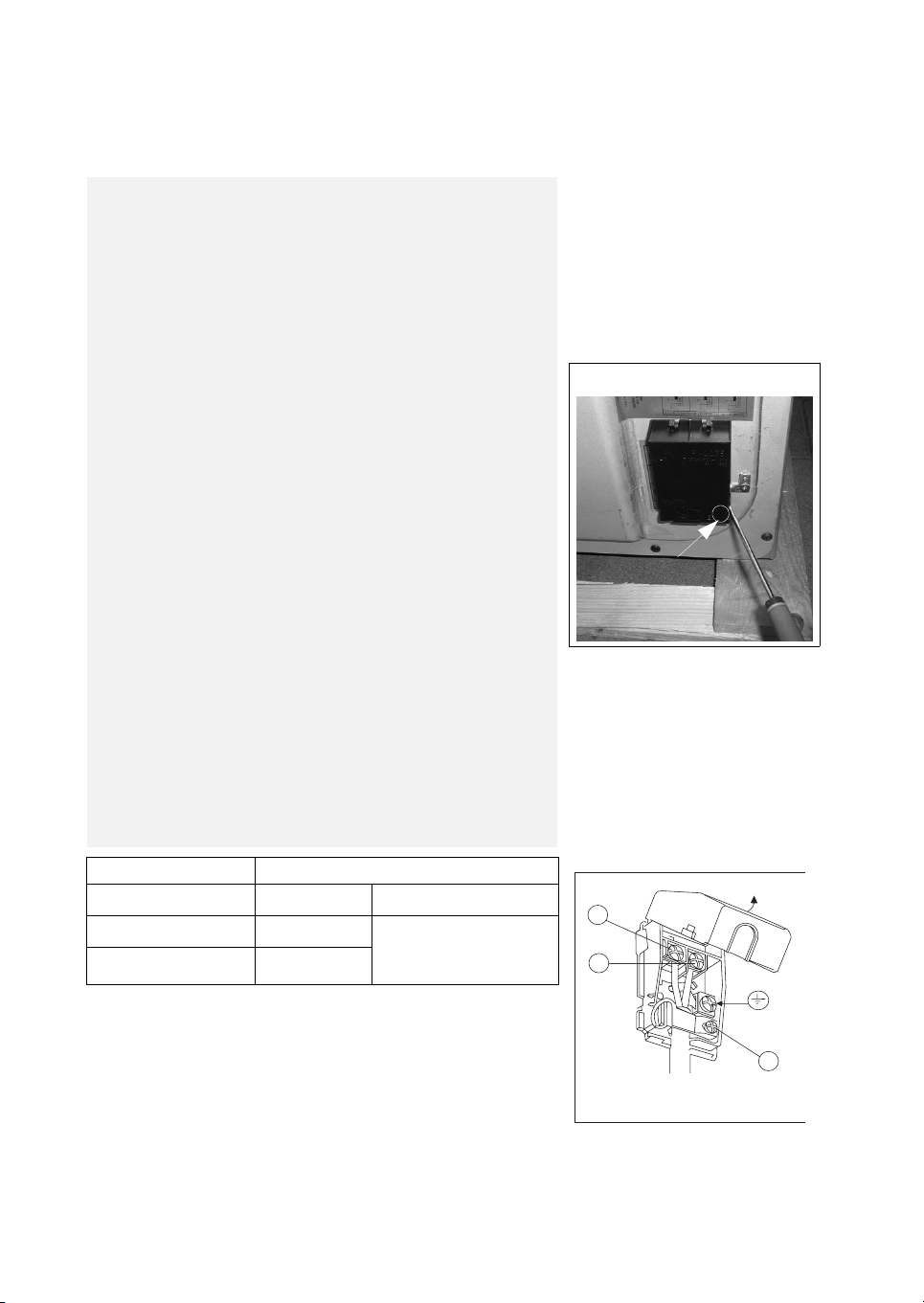

Connecting the mains cable

Open the mains terminal block cover as shown, unscrew the

cable clamp “A” and unscrew (not fully) the screws in the mains

terminal block which secure the three wires of the mains cable.

Fit the cable and refit the cable clamp “A” (fig. 1 ).

IMPORTANT

The wires in the mains lead are coloured in accordance with the

following code:

GREEN & YELLOW ............................................ EARTH

BLUE.................................................................... NEUTRAL

BROWN............................................................... LIVE

The supply cable must not come into contact with any

component the temperature of which exceeds the ambient

temperature by 50°C.

Easy access to the plug or the switch is ensured once the

appliance is installed.

Ensured that there is sufficient cable allowed for any subsequent

removal of the unit.

In order to avoid hazard, any electrical work performed on this

equipment or its associated wiring should only be done by persons

authorised by the manifacture or similary qualified persons.

Terminal block cover

A

Appliance type Single-phase alimentation 230 V~

All gas

All gas + elett. grill

All gas + hotplates

3 x 0,75 mm

3 x 1,5 mm

3 x 1,5 mm

2

2

2

Ty p e o f c ab le

Rubber H05 RR-F

or

Rubber H05 VV-F

L

N

A

Fig. 1

5

This appliance is in Class 1.

The appliance must be used with the gas specified on the appliance data plate located on the

back cover (see details given on the product).

Installation and maintenance of the appliance must be carried out by a qualified technician in

compliance with the conditions established in the applicable regulation documents and the

ethical codes.

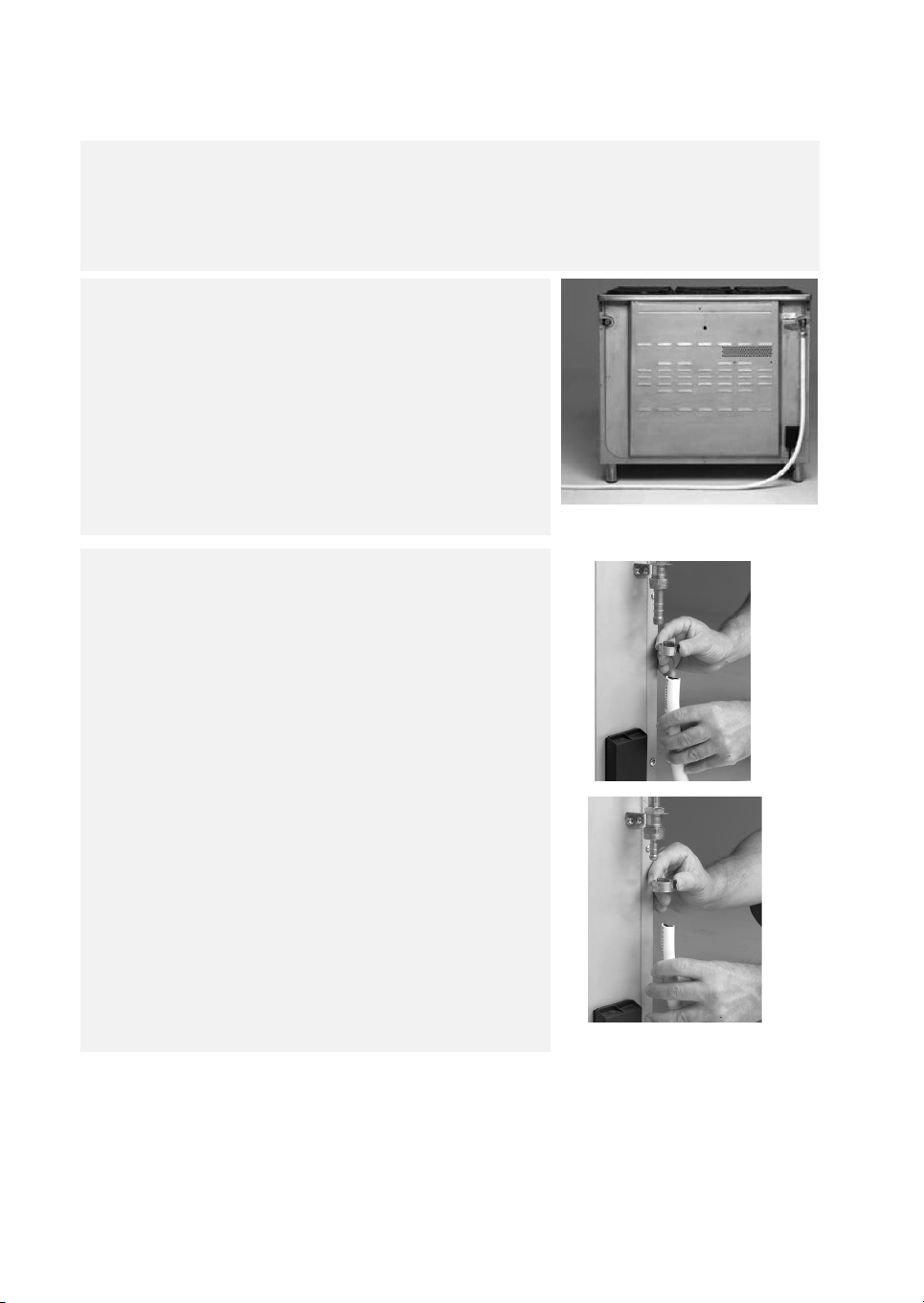

Gas connection

The gas supply system must comply with current local

regulations.

Important: the rubber hose must be installed in such a way

as not to be in contact with hot parts of the rear of the

appliance or kitchen. It must pass through an area free of

any hindrances and in a place where it can be inspected

along its entire length (Fig. 2).

When the appliance is connected to the gas supply, use

soapy water to check for gas leaks.

The rubber hose must be connected as shown in Fig. 3 and

4, in compliance with local applicable regulations

Natural gas

Use outlet connector GN for natural gas or a propane-air

mixture.

The rubber hose must be connected to the outlet connector and

secured using hose clamp A (Fig. 3).

Butane/Propane gas

Use outlet connector B/P for Butane/Propane gas.

The rubber hose must be connected to the outlet connector and

secured using hose clamp A (Fig. 4).

The maximum length of the rubber hose is 2 m. It must be a

standard hose and must be replaced within the date printed on it.

Important: Close the gas supply tap before carrying out any

maintenance operation.

Connection details: see the specific regulations for your country.

A

Fig. 2

Fig. 3

A

Fig. 4

6

Gas adjustments

Use pressure regulators that are suitable for the gas

pressure values indicated in the Product Description Sheet

supplied separately.

If the appliance is arranged for a type of gas different from that

available, it is necessary to change the injectors, adjust the

minimum flame, change the outlet connector.

Carry out the following operations to change the hob injectors:

remove the grills; remove the burners, the burner caps

(see Fig. 5); change the injector and replace it with one suitable

for the new type of gas (see table in separate Product Sheet).

Replace the gas calibration label with the new label included in the

injector bag.

Refit everything in reverse order, making sure to correctly fit the

burner cap on the burner.

Minimum for hob taps

To adjust the minimum flame, proceed as follows:

• Light the burner and turn the knob to minimum ; remove

the tap knob (Fig. 6). Insert a small screwdriver next to the tap

pin (Fig. 7).

Attention: in taps with security valve, the minimum adjusting

screws is placed outside the rod tap (fig. 7A).

Turn the adjustment screw anticlockwise to increase the flame,

or clockwise to decrease it. Adjustment is correct when the flame

is approx. 3 - 4 mm.

The adjustment screw must be completely screwed down for

butane/propane gas.

Make sure the flame does not go out when switching suddenly

from high to low flame and vice versa.

Refit the knob.

Fig. 5

Fig. 6

Fig. 7

Fig. 7A

7

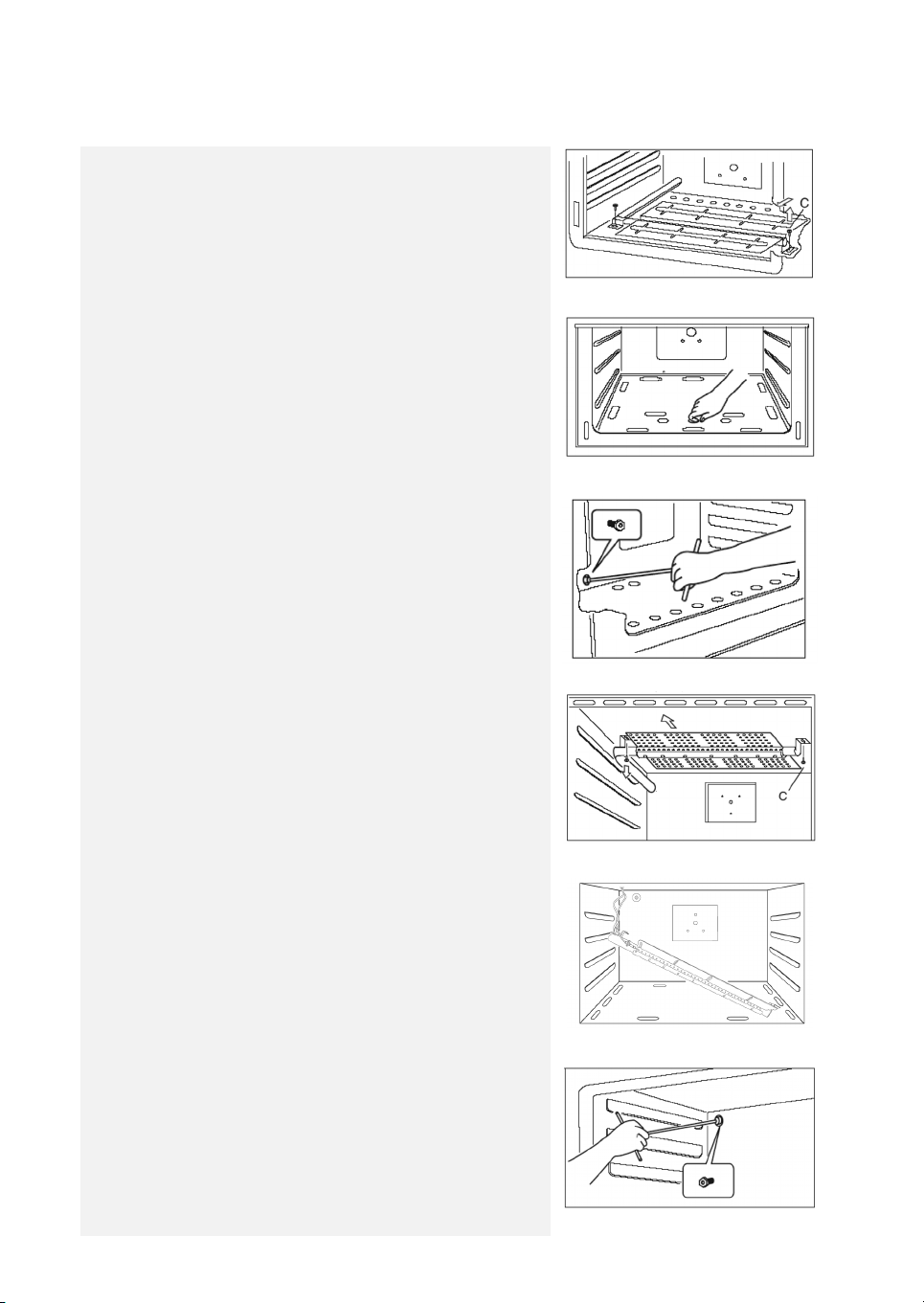

To change the oven injector, it is necessary to act as follows: open

the oven door, remove the lower side of the oven (see Fig. 8),

unscrew the screw C and disassemble the oven burner (see Fig. 9).

Change the injector (see Fig. 10) and replace it with another one

suitable for the new gas type (see table in separate Product Sheet).

Re - assemble everything in the opposite direction, paying

attention to place the burner in the right way on its rear slot.

To change the grill injector, it is necessary to act as follows:

open the oven door, unscrew the screw C (see Fig. 11) and

disassemble the grill burner (see Fig. 11A).

Change the injector (see Fig. 12) and replace it with another one

suitable for the new gas type (see table in separate Product

Sheet).

Fig. 8

Fig. 9

Fig. 10

Re-assemble everything in the opposite direction, paying

attention to place the burner in the right way on its rear slot.

8

Fig. 11

Fig. 11A

Fig. 12

REGULATION OF AIR ADJUSTER (oven burner)

To do this,

unscrew the screw (A) in order to rotate the metal ring at the

end of the burner (Fig. 13).

In this way entrance of the air increases or decreases, obtaining a

correct flame.

Be sure that the flame does not lift or light back or present a

yellow coloration.

REGULATION OF AIR ADJUSTER (grill burner)

To do this,

unscrew the screw (A) in order to slip it forwards or backwards

(Fig. 14).

In this way entrance of the air increases or decreases obtaining a

correct flame.

Be sure that the flame does not lift or light back or present a

yellow coloration.

WARNING

On completion of all the burner gas type conversion operations,

re-do all the seals on the air supply controls.

Fig. 13

To raise the

cooking hob

end to push in

ahead

Fig. 14

Fig. 15

9

Loading...

Loading...