Whirlpool 780164 Instruction Sheet

INSTALLATION INSTRUCTIONS

for Compactor Motor Switch Kit #780164 and

Replacement Motor Kit

wWARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all panels before operating.

Failure to do so can result in death or electrical shock.

These instructions are only applicable for repair of compactors manufactured after 1980.

1. Unplug compactor or disconnect power.

2. Remove motor from compactor.

Freestanding Models:

a. Remove the container drawer.

b. Lay the compactor on either of its sides, using a drop

cloth to protect the finish of the cabinet.

c. Remove the five (5) screws that hold the bottom pan

cover to the base and cabinet.

d. Loosen the four (4) bolts or screws that fasten the

drive mount assembly to the compactor frame.

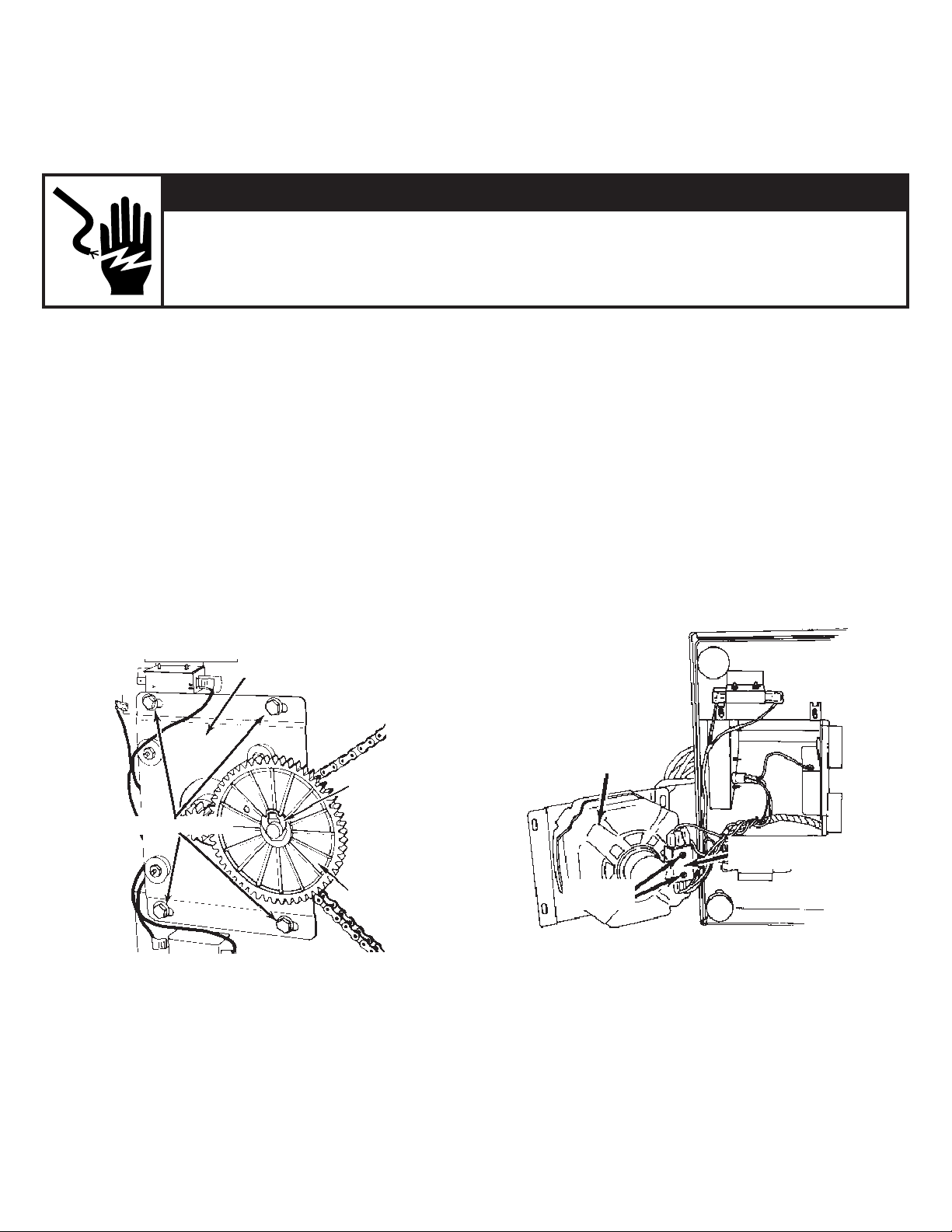

See Figure 1.

e. Remove the clip ring from the drive mount plate shaft

(Figure 1).

Drive mount

assembly

f. Slide the motor mount plate forward and lift the driven

gear and sprocket from the drive mount plate shaft.

g. Remove the four (4) bolts or screws that fasten the

drive mount assembly.

h. The motor and drive mount plate can now be removed

so the switch can be replaced (Figure 2).

IMPORTANT: Do not let motor fall and damage switch

arms during removal.

Mounting bolts (4)

© Whirlpool Corporation 2001

(All Rights Reserved)

Figure 1

Clip ring

Driven gear

Drive

motor

Centrifugal

switch

Mounting

screws

Figure 2

(continued)

Instruction Sheet 675397 Rev. D 2/01

1

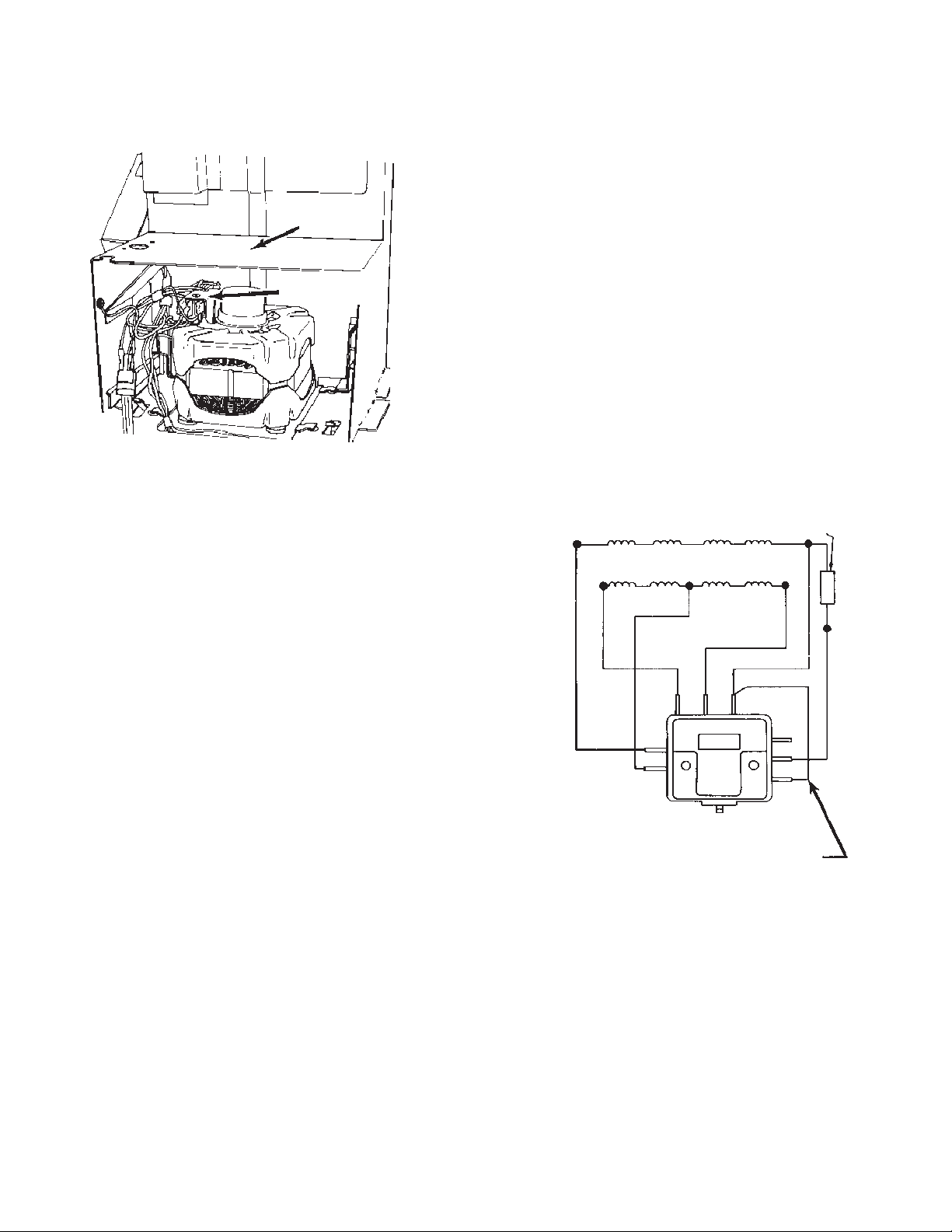

Undercounter Models:

NOTE: When servicing the switch or motor on undercounter

models, the motor backplate and motor cover can be

removed, as shown in Figure 3.

Motor

cover

Centrifugal

switch

Figure 3

3. Remove failed switch (if replacing motor, go

directly to step 5).

a. Disconnect motor and wiring harness leads from

switch terminals.

b. With motor removed, remove the two (2) switch

mounting screws.

4. Install new switch.

a. Mount the new motor switch to the end shield of the

motor with the two screws.

b. Connect motor leads to the new switch.

• Connect yellow lead to terminal “Y“

• Connect brown lead to terminal “4”

• Connect gray lead to terminal “3”

• Connect red lead to terminal “R”

• Connect blue lead to terminal “1”

• Connect white lead to terminal “W”

IMPORTANT: Jumper wire must be connected to

terminals “1” and “2”

c. Connect wire harness leads to the new switch.

• Connect yellow lead to terminal “Y

• Connect gray lead to terminal “3”

• Connect brown lead to terminal “4”

• Connect red lead to terminal “R”

• Connect blue lead to terminal “2”

• Connect white lead to terminal “W”

• Connect orange/black lead (if present) to

terminal “O/BK”

Protector

Red

Blue

Yellow

Gray

Start 1

Brown

Run

Start 2

Jumper

wire

3

Y

Switch

4

W

1R

O/

BK

2

NOTE: Leave jumper wire intact

White

(continued)

675397-D

2

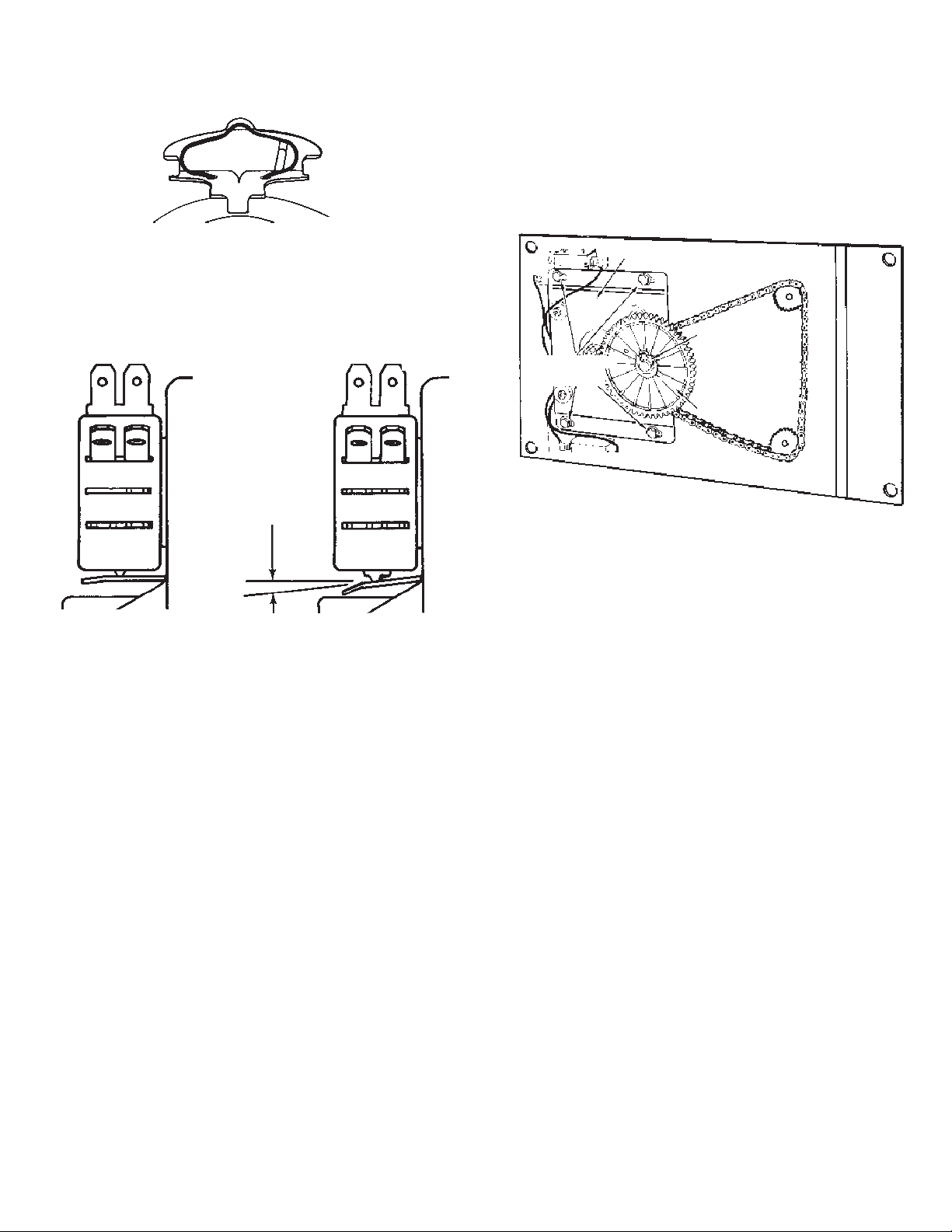

d. The actuating lever should remain seated evenly in the

motor end shield notches and the spring clip should

remain fixed in place in the notch provided in the end

shield. (See Figure 4.)

Figure 4

e. Check actuating lever positions as shown in Figures 5

and 6. With motor stopped, the lever should be in

position shown in Figure 5. With motor running, the

lever should be in position shown in Figure 6.

7. Reassemble compactor.

a. Reassemble compactor in reverse order.

b. Adjust chain tension as evenly as possible and still

allow room to rotate big gear 180°. Allow approximately

1

⁄4" deflection between any two (2) of the three (3)

sprockets. (See Figure 7.)

NOTE: When reassembling the driven gear to the driven

mount shaft, make sure the parts are placed on the drive

mount shaft in correct sequence.

Drive motor assembly

Clip ring

Mounting

nuts (4)

Driven gear

.010 minimum.

Figure 5. Motor idle Figure 6. Motor running

5. Remove old motor.

IMPORTANT: Do not let motor fall and damage switch

arms during removal.

6. Install new motor.

Refer to step 4, c for instructions on how to connect the

compactor’s wire harness to the motor switch.

Figure 7

(continued)

3

675397-D

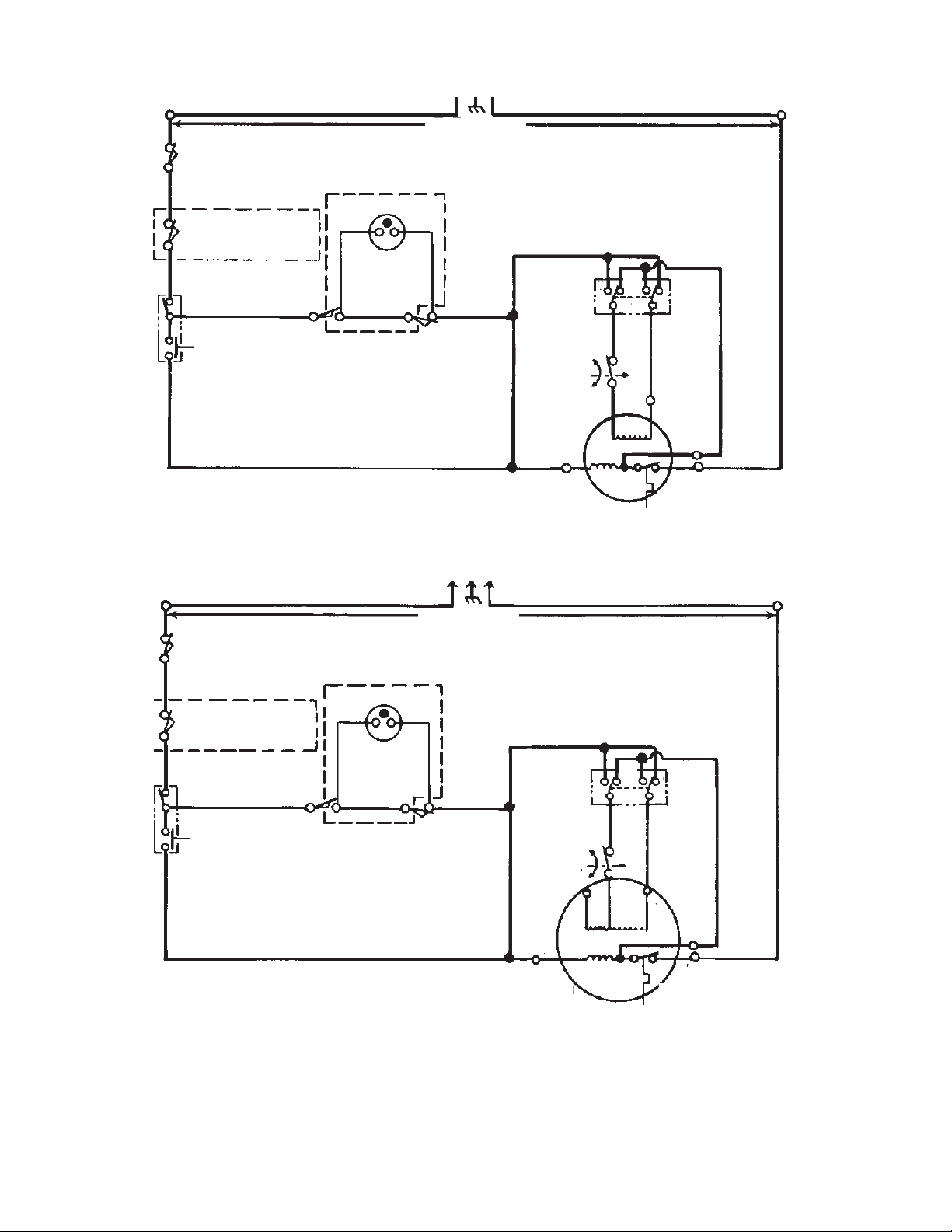

Diagram #1

One Start Winding with Two Reversing Switches

L1

BK

Drawer safety switch

Key lock

safety switch

Run switch

V

Start switch

Y

V

Restart light

BR Y

Top limit

switch

BR

Original motor

Line voltage

Drawer tilt

switch

N

W

Y

Directional

Y

switch

Y

BU

Y

GY

BU

Y

R

GY

Motor

Y

centrifugal

switch

BK

R

R

Start

Run

YY

Y

BU BU

WW

Drive motor

Motor protector

NOTE: Unit may or may not have features indicated by dotted lines. Wiring will be the same in either case.

Replacement motor

L1

BK

Drawer safety switch

Key lock

safety switch

Run switch

V

Start switch

Y

V

Top limit

switch

Restart light

BR

BR

Y

BR

Drawer tilt

switch

Line voltage

Y

#2

Y

#3

#4

GY

Y

BU

BU

Y

R

R

R

Y

Directional

Y

switch

Motor

centrifugal

Y

switch

N

W

675397-D

Remove jumper wire from

terminals 1 and 2 and discard.

Circuit showing unit at normal end of cycle.

Y

4

Y

Y

Drive motor

Run

Start

#1

BU

W

W

Motor protector

(continued)

Loading...

Loading...