Whirlpool 761883306 User Manual

- --

/

n, /

/

-

761883306

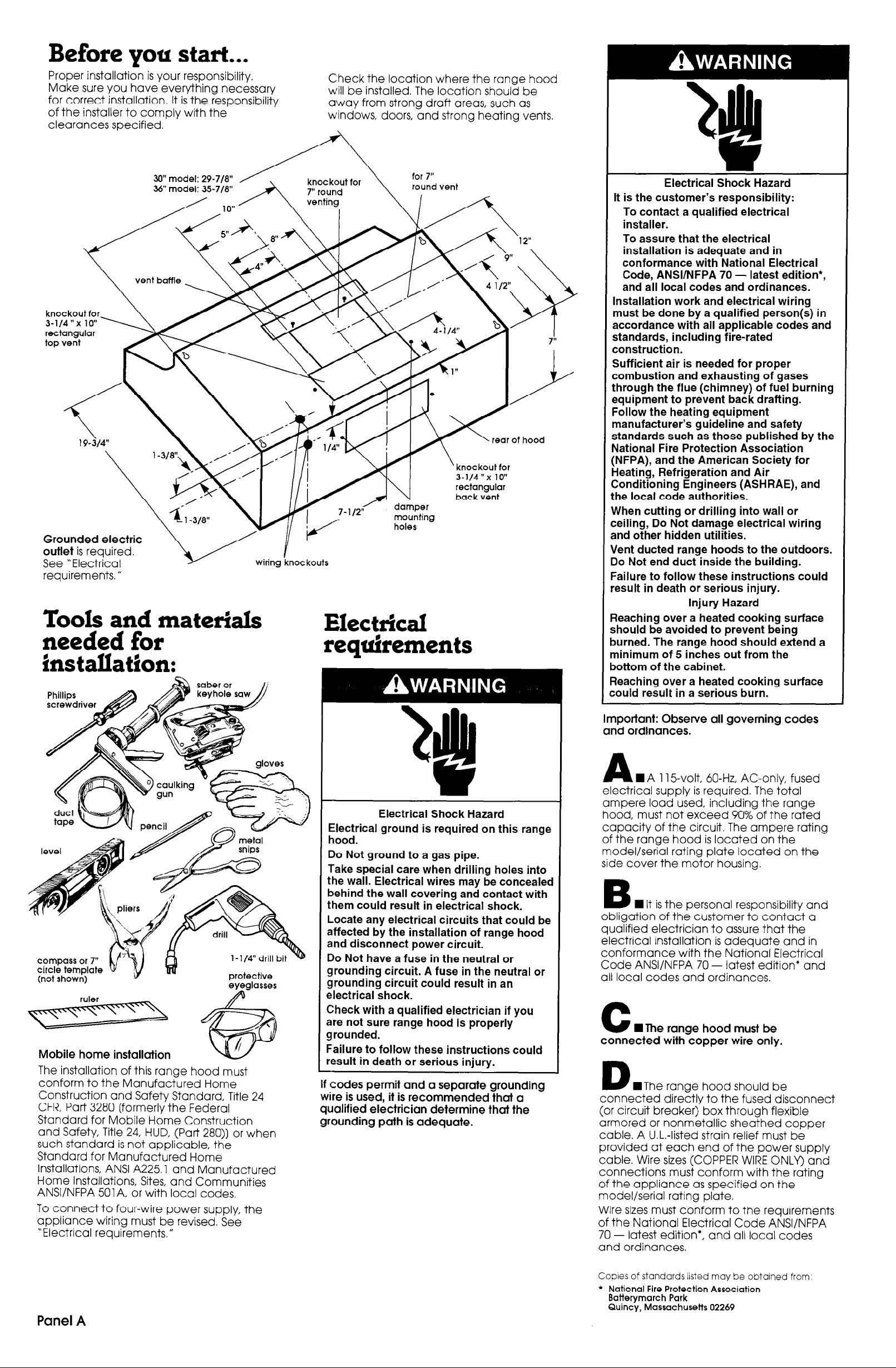

Before you start...

Proper installation is your responsibility.

Make sure you have everything necessary

for correct installation. It is the responsibility

of the installer to comply with the

clearances specified.

Check the location where the range hood

will be installed The location should be

away from strong draft areas, such as

windows, doors, and strong heating vents.

30” model: 29-7/8”

knockout for

\‘l-318”

Grounded electric

outlet is required.

See “Electrical

requirements. ”

/

wiring knockouts

Tools and materials

needed for

installation:

mounting

holes

Electrical requirements

Electrical Shock Hazard

It is the customer’s responsibility:

To contact a qualified electrical

installer.

To assure that the electrical

installation is adequate and in

conformance with National Electrical

Code, ANSVNFPA 70 - latest edition*,

and all local codes and ordinances.

Installation work and electrical wiring

must be done by a qualified person(s) in

accordance with all applicable codes and

standards, including fire-rated

construction.

Sufficient air is needed for proper

combustion and exhausting of gases

through the flue (chimney) of fuel burning

equipment to prevent back drafting.

Follow the heating equipment

manufacturer’s guideline and safety

standards such as those published by the

National Fire Protection Association

:NFPA), and the American Society for

Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and

:he local code authorities.

When cutting or drilling into wall or

:eiling, Do Not damage electrical wiring

and other hidden utilities.

ilent ducted range hoods to the outdoors.

IO Not end duct inside the building.

-ailure to follow these instructions could

,esult in death or serious injury.

Injury Hazard

?eaching over a heated cooking surface

should be avoided to prevent being

turned. The range hood should extend a

ninimum of 5 inches out from the

Bottom of the cabinet.

qeaching over a heated cooking surface

:ould result in a serious burn.

I -3 \ A

compass or 7”

circle template w

(not shown)

Mobile home installation

The installation of this range hood must

conform to the Manufactured Home

Construction and Safety Standard, Title 24

CFR, Part 3280 [formerly the Federal

Standard for Mobile Home Construction

and Safety, Title 24, HUD, (Part 280)) or when

such standard is not applicable, the

Standard for Manufactured Home

Installations, ANSI A225 1 and Manufactured

Home Installations, Sites, and Communities

ANSVNFPA 501 A, or with local codes,

To connect to four-wire power supply, the

appliance wiring must be revised. See

“Electrical requirements.”

v flu

l-1/4” drill bit

protective

eyeglasses

Electrical Shock Hazard

Electrical ground is required on this range

hood.

Do Not ground to a gas pipe.

Take special care when drilling holes into

the wall. Electrical wires may be concealed

behind the wall covering and contact with

them could result in electrical shock.

Locate any electrical circuits that could be

affected by the installation of range hood

and disconnect power circuit.

v

Do Not have a fuse in the neutral or

grounding circuit. A fuse in the neutral or

grounding circuit could result in an

electrical shock.

Check with a qualified electrician if you

are not sure range hood is properly

grounded.

Failure to follow these instructions could

result in death or serious injury.

If codes permit and a separate grounding

wire is used, it is recommended that a

qualified electrician determine that the

grounding path is adequate.

Important: Observe all governing codes

and ordinances.

A

WA 115volt, 60-Hz, AC-only, fused

electrical supply is required. The total

ampere load used, including the range

hood, must not exceed 90% of the rated

capacity of the circuit. The ampere rating

of the range hood is located on the

model/serial rating plate located on the

side cover the motor housing.

n

B

obligation of the customer to contact a

qualified electrician to assure that the

electrical installation is adequate and in

conformance with the National Electrical

Code ANSVNFPA 70 - latest edition* and

all local codes and ordinances.

C

connected with copper wire only.

D

connected directly to the fused disconnect

(or circuit breaker) box through flexible

armored or nonmetallic sheathed copper

cable. A U.L.-listed strain relief must be

provided at each end of the power supply

cable. Wire sizes (COPPER WIRE ONLY) and

connections must conform with the rating

of the appliance as specified on the

model/serial rating plate.

Wire sizes must conform to the requirements

of the National Electrical Code ANSI/NFPA

70 - latest edition*, and all local codes

and ordinances.

It is the personal responsibility and

W The range hood must be

WThe range hood should be

Panel A

Copies of standards listed may be obtained from:

l

National Fire Protection Association

Batterymarch Park

Quincy, Massachuseits 02269

Venting requirements

Horizontal Wall Venting

Now start...

With range hood in kitchen.

’ f

f

I

Aib

Fire Hazard

Venting system must terminate to the

outside.

Do Not vent exhaust air into spaces

within walls or ceilings or into attics,

crawl spaces or garages.

Use metal duct only.

Do Not use four-inch laundry-type wall

caps.

Do Not use plastic ductwork.

Flexible metal duct is Not recommended.

If it is used, calculate each foot of flexible

metal duct as two feet of straight duct.

Flexible metal elbows count twice as

much as standard elbows.

Do Not use to exhaust hazardous or

explosive materials and vapors.

Failure to follow these instructions could

result in a fire.

3-l/&x 10”

throuah the wall

7” min. diameter

round ductwork

elbow

3-1/4”x 10” to round

ductwork transition

Figure 3

*I...

. -.-m..---l

: :‘I-’

I I*\

I I

‘.{ a.

:.--

l t

-:,,--’

A

.:

J

I cap

wall cap

l \

Slide cardboard or hardboard under range

before moving range across floor to

prevent damaging floor covering.

Cover countertop, cooktop or set-in range

with a thick, protective covering to prevent

damaging countertop.

1 Put on safety glasses and gloves.

I

n

2

range from cabinet opening to provide

easier access to upper cabinet and rear

wall. Put a thick, protective covering over

cooktop, set-in range or countertop to

protect from damage or dirt

3

(roof or wall venting or non-venting) you

need to use. This range hood is shipped for

non-vented installation.

If non-venting (recirculating) installation is

desired, follow instructions on Panel D.

Disconnect and move freestanding

H Determine which venting method

Vented installation

vent baffle

Ductwork needed for insfallofion is not

included. Wall or roof caps used must have

backdrafl damper.

Determine which outside venting method

needs to be used NOTE: If a non-vented

(recirculating) installation is desired, follow

instructions on Panel D.

The length of the ductwork and number of

elbows should be kept to a minimum to

provide efficient performance. The size of

the ductwork should be uniform. Do Not

install two elbows together. Use duct tape

to seal all joints in the ductwork system.

Ductwork can terminate either through the

roof or wall. Use caulking to seal exterior

wall or roof opening around exhaust hood.

For the most efficient and quiet operation, it

is recommended that the range be vented

vertically through the roof through 7” round

ductwork.

Figures l-4 show common venting methods

and what types of materials are needed.

Vertical Roof Venting

7” round

through t

roof

roof cap

Figure 4

Recommended ductwork length

Use 3-l /4” x 10” or 7” ductwork with a

m’aximum length of 26 feet for ductwork

system. For best performance, use no more

Wan three 90” elbows. To calculate the

length of system you need, add the

equivalent feet for each ductwork piece

used in the system. See the following

examples.

3- l/4” x 10” ductwork system

3 - 114” x 10”

elbow

H- 6 ft.

0 3 -7

u

Maximum 1 - 90” elbow IenLth

* ft’

8 feet straight

1 - wall cap

Length of

3- l/4” x 10” system

wall cap

= = 26 5ft feet

= 8ft.

= Oft.

= 13 ft.

Recommended standard fittings

.‘Q:,

F

W Remove screws from vent baffle on

4

top of range hood. Remove vent baffle.

top of range hood so that the word

“Vented” is facing up. Fasten vent baffle

with screws.

in

damper locatec?as far from hood

as possible

Figure 1

Vertical Roof Venting

3-114” x 10”

through the roof

ro/f cap

3-114” x 10”

damper

3-114” x 10” 90”

elbow = 5 ft.

3-114” x 10” flat 3-l/4” x 10” wail

elbow = 12 ft.

cap=oft.

7” ductwork system

/

3-1/4”x 10”

to 7”

transition

Maximum length

1 - transition

2 - 90” elbows

8 feet straight

1 - wall cap

Length of 7” system = 22.5 ft

= 26 feel

= 4,5 ft

=lO ft.

= 8 ft.

= 0 ft.

Recommended standard fittings

knockouts

n

6

opening (top or rear) to be used.

For rectangular venting, remove only the

3-l/4” x 10” rectangular opening knockout.

For round ductwork venting through roof,

remove both opening knockouts.

Remove knockout from the wiring

terminal

box

Panel B

Figure 2

3-114” x IO” to 3-114” x 10” to 7” 7” to 3-114” x 10”

7” = 4.5 ft. 90” elbow = 5 ft. 90” elbow = 9 ft.

90” elbow = 7” to 3-114”

5 ft.

xlO”=lft.

;“,“;lbow = I’;wtizll cap

. .

n

Remove terminal box cover

range hood

from

Loading...

Loading...