Whirlpool 759105-U User Manual

IMPORIANr

Instai/er: Leave Instaiiat/oo Instructions

Homeowner. Keep insto,lotion instructions

Save !n.staliat,on lnstructions~for loco)

With the homeow.oer

lor future reference

electrical inspectors use.

InstallaHon Instructions

Part No. 759105-U

Ice Maker

WhirWoI

Before you start...

Proper insîallotion is your responsibility.

Make sure you have everything

necessary for correct installation, It

is the customer's responsibility to

contact a qualified installer to as

sure that the plumbing and electri

cal installations are adequate and

meet all local codes and ordinan

ces,

Proper electrical supply, water

supply lines, and floor drain or

sump pump must be available or

must be installed, as specified,

within the shaded area, (See

"Electrical", "Water", and "Drain re

quirements"' sections.) Plumbing

and wiring should not cross in front

of fhe ice maker motor. Wiring

should not pass through the drain

area.

Important: Observe all govern

ing codes and ordinances.

Electrical ground is required (See

"Electrical requirements".)

Do Not close in the front of the ice

maker. The ice maker cannot work

properly if the airflow to the front

of the ice maker is blocked.

Compliance with National Sanita

tion Foundation standards requires

that this type of product be

sealed to the floor at the bottom

rail in order to prevent contamina

tion from spills or vermin. Therefore,

we recommend that when install

ing this product you seal it to the

floor in accordance with those

standards. A silicone-type sealer is

recommended.

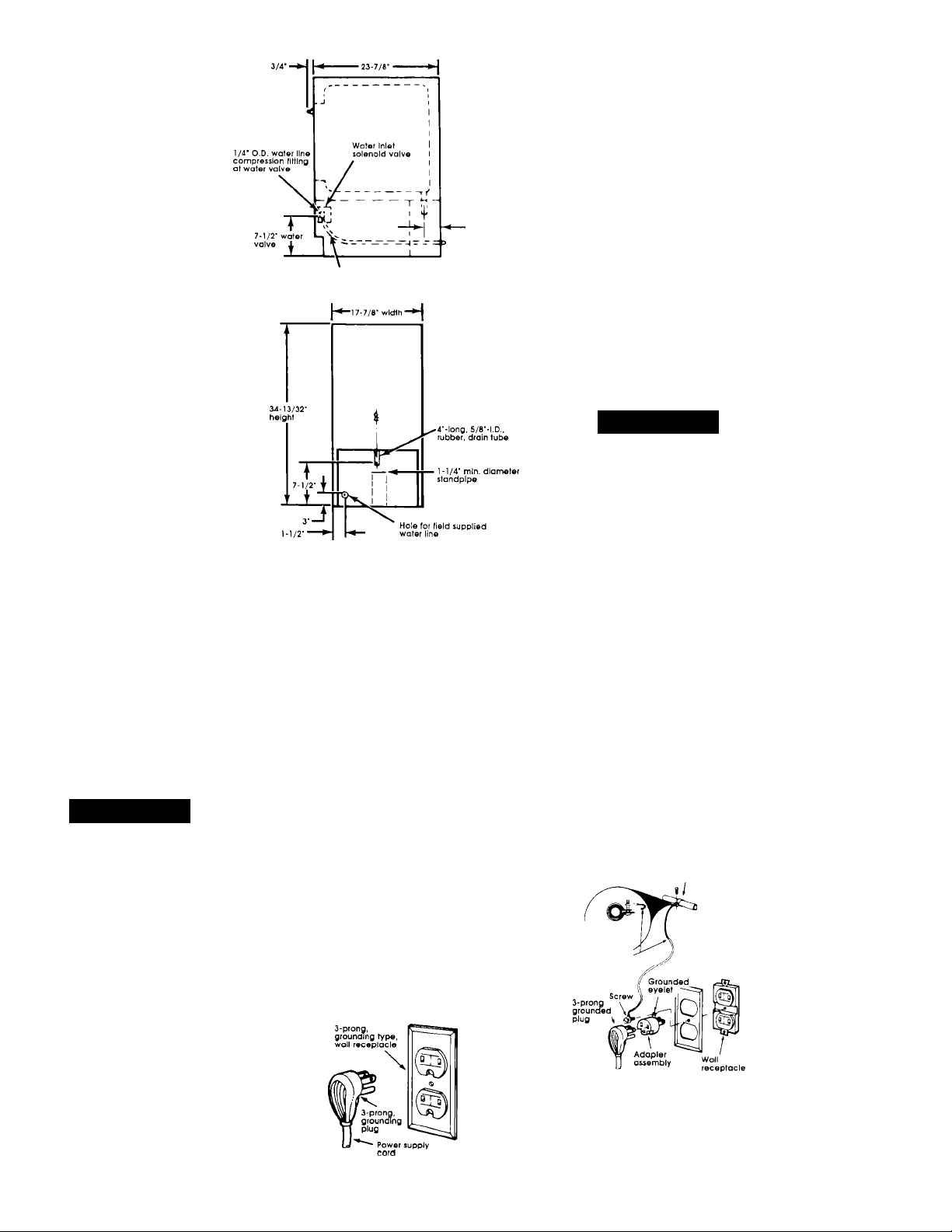

Right side view

Bend field supplied water line

to connect lo water valve fitting

Figure 1

Check the location where the ice maker

will be installed. The location must

provide;

• Easy access to water, electricity and

drainage lines,

• Protection from wind, weather,

dripping or spraying water, and other

harmful elements,

• Protection from cold temperatures to

prevent the water inlet valve and

drain from freezing,

• Good ventilation and unobstructed

airflow to the front of the ice maker.

• Room to fully open the ice maker

door.

• Room to move the cabinet forward for

servicing, it necessary.

The unit may be enclosed around the

sides, top and rear of ice maker.

Protection from weather: Do Not store or

operate the ice maker below 55‘^F or

above 1 IChF. For best results, operate

the ice maker at temperatures between

70°F to 90^F,

Drain system requires either a gravity,

floor-drain system or a drain pump (see

"Dram requirements'") to lift the water to

an existing drain, A 1-1/4" min, diameter

standpipe or 5/8" I.D, minimum drain

tube to an open drain is required.

^WARNING

Electrical Shock Hazard

Do Not let electrical wiring and

components contact the drain

hose or any plumbing materials.

Failure to follow these instructions

could result in fire, electrical

shock or other personal injury.

Read and follow the "Electrical

requiremehts", "Water requirements"

and "Drain requirements" sections

before installing the ice maker.

Shipboard installatior^s:

Ice makers installed in ships require a

water deflector (available from your

local authorized parts distributor).

The deflector keeps the water that

flows over the evaporator from

spilling into the storage bin area.

Install deflector according to the

instructions provided with the

deflector kit.

Electrical

requirements

AWARNING

Electrical Shock Hazard

• Electrical ground is required on

this appliance.

• Check with a qualified

electrician if you are in doubt as

to whether the appliance Is

properly grounded. Do Not

modify or remove the power

supply cord plug. If it will not fit

the outlet, have a proper outlet

Installed by a qualified

electrician.

• Improper connection of the

equipment-grounding

conductor can result in a risk of

electrical shock.

• Do Not use an extension cord

with this appliance.

• Do Not have a fuse in the neutral

or grounding circuit.

• Do Not connect to electrical

supply until appliance is

permanently grounded.

Failure to follow these instructions

could result in a fire, electrical

shock, or other personal injury.

A 120-volt, 60-Hz, AC only, 15-

ampere, fused, electrical supply is

required. Time-delay fuse or circuit

breaker is recommended, it is

Panel A

recommended that a separate

circuit serving only this appliance

be provided.

It the personal responsiPility and

obligation of the customer to

contact a qualified electrician to

assure that fhe electrical installation

is adequate and in conformance

with the National Electrical Code

ANSI/NFPA 70 latest edition, and all

local codes and ordinances.

Recommended grounding

method

For your personal safety, this

appliance must be grounded. This

appliance is equipped with a power

supply cord having q 3-prong,

grounding plug. To minimize possible

shock hazard, the cord must be

plugged into a mating, 3-prong,

grounding-type wall receptacle,

grounded in accordance with the

National Electrical Code ANSI/NFPA

70-latest edition, and local codes

and ordinances. (See Figure 2.)

If a mating wall receptacle is not

available, it is the personal

responsibility and obligation of the

customer to have a properly

grounded, 3-prong, wall receptacle

installed by a qualified electrician.

Figure 2

Temporary grounding method

If changing and properly grounding

the wall receptacle is impossible and

where local codes permit (consult

your electrical inspector), a

temporary adapter may be plugged

into the existing, 2-prong, wall

receptacle to mate with the

3-prong, power supply cord,

THIS, HOWEVER, IS NOT

RECOMMENDED.

If this is done, you must connect a

separate, copper, grounding wire

(No, 18 minimum) to a grounded,

cold water pipe’ by means of a

clamp and then to the external

grounding connector screw.

connect to a gas supply pipe or hot

water pipe.

(See Figure 3.)

Ground clamp

must be tight

on pipe

Ground wire

(# IBmInimum)

Power supply cord

Do Not

Ground assembly

(attach to grounded

cold water pipe)

\

Electrically

grounded cold

water pipe (remove

paint, etc.)

Figure 3

■ Grounded, cold water pipe must have

metal conrinuity to electrical ground and not

be interrupted by plastic, rubber, or other

electrical insulating connectors such as hoses,

fittings, washers or gaskets (including water

meter or pump). Any electrical insuiatinQ

connector should be jumped as shown with a

length of No, 4, copper wire securely

clamped to bare metal at both ends.

Loading...

Loading...