UPRIGHT FREEZER

Use & Care Guide

CONGELATEUR

VERTICAL

Guide d’utilisation et d’entretien

ﻲﺳﺃﺮﻟﺍ ﺪﻤﺠﻤﻟﺍ

ﺔﻳﺎﻨﻌﻟﺍﻭ ﻡﺍﺪﺨﺘﺳﻻﺍ ﻞﻴﻟﺩ

W10443587B

Table of Contents

ﺕﺎﻳﻮﺘﺤﻤﻟﺍ ﻝﻭﺪﺟ........ 2

Table des matières

/

/

TABLE OF CONTENTS

FREEZER SAFETY ...................................................................... 3

INSTALLATION INSTRUCTIONS ...............................................4

Unpacking ................................................................................. 4

Opening Dimensions .................................................................4

Location Requirements .............................................................5

Electrical Requirements ............................................................ 5

Water Supply Requirements ..................................................... 6

Connect the Water Supply ........................................................6

Freezer Door .............................................................................7

Adjust the Door ....................................................................... 10

FREEZER USE ...........................................................................10

Ensuring Proper Air Circulation ...............................................10

Using the Control .................................................................... 10

Indicator Light ......................................................................... 11

Key Eject Lock ........................................................................11

Ice Maker ................................................................................11

TABLE DES MATIERES

SECURITE DU CONGELATEUR .............................................17

INSTRUCTIONS D’INSTALLATION ........................................18

Déballage ................................................................................ 18

Dimensions de l’ouverture .....................................................19

Emplacement d’installation ..................................................... 19

Spécifications électriques .......................................................20

Spécifications de l’alimentation en eau .................................20

Raccordement de la canalisation d’alimentation en eau ....... 21

Porte du congélateur ..............................................................22

Ajustement de la porte ............................................................ 25

UTILISATION DU CONGELATEUR .......................................... 25

Pour s’assurer d’une circulation d’air appropriée .................. 25

Utilisation de la commande ...................................................25

Témoin lumineux ..................................................................... 26

Serrure à éjection de clé ........................................................26

Machine à glaçons .................................................................26

FREEZER FEATURES ...............................................................11

Refrigerated Shelves ...............................................................11

Door Bin .................................................................................. 12

Storage Basket .......................................................................12

Storage Gate ...........................................................................12

FREEZER CARE ........................................................................12

Cleaning Your Frost-Free Freezer ........................................... 12

Base Grille ...............................................................................13

Defrosting and Cleaning Your Manual Defrost Freezer ...........13

Changing the Light Bulb .........................................................14

Power Interruptions .................................................................14

Moving Care ............................................................................14

TROUBLESHOOTING ............................................................... 14

ASSISTANCE OR SERVICE ......................................................16

CARACTERISTIQUES DU CONGELATEUR ............................27

Clayettes de réfrigération ....................................................... 27

Balconnet de porte .................................................................27

Panier d’entreposage .............................................................. 28

Barrière d’entreposage ...........................................................28

ENTRETIEN DU CONGELATEUR ...........................................28

Nettoyage du congélateur sans givre ....................................28

Grille de la base ......................................................................29

Dégivrage et nettoyage du congélateur

à dégivrage manuel ................................................................29

Remplacement de l’ampoule d’éclairage ..............................30

Pannes de courant électrique ................................................. 30

Déménagement ......................................................................30

DEPANNAGE ............................................................................. 31

ASSISTANCE OU SERVICE ......................................................33

ﺕﺎﻳﻮﺘﺤﻤﻟﺍ ﻝﻭﺪﺟ

11 .......................................................................................... ﺪﻤﺠﻤﻟﺍ ﺕﺍﺰﻴﻣ

11 .......................................................................................... ﺓﺩﺮﺒﻣ ﻑﻮﻓﺭ

12 .........................................................................................ﺏﺎﺒﻟﺍ ﻕﻭﺪﻨﺻ

12 ...........................................................................................ﻦﻳﺰﺨﺘﻟﺍ ﺔﻠﺳ

12 ......................................................................................... ﻦﻳﺰﺨﺘﻟﺍ ﺔﺑﺍﻮﺑ

12 .........................................................................................ﺪﻤﺠﻤﻟﺎﺑ ﺔﻳﺎﻨﻌﻟﺍ

12 ...................................................................ﻊﻴﻘﺼﻠﻟ ﻊﻧﺎﻤﻟﺍ ﻙﺪﻤﺠﻣ ﻒﻴﻈﻨﺗ

13 ...........................................................................................ﺓﺪﻋﺎﻘﻟﺍ ﺔﻜﺒﺷ

13 ...................................... ﺎﻳﻭﺪﻳ ﻊﻴﻘﺼﻟﺍ ﻞﻳﺰﻣ ﻙﺪﻤﺠﻣ ﻒﻴﻈﻨﺗﻭ ﻊﻴﻘﺼﻟﺍ ﺔﻟﺍﺯﺇ

14 ....................................................................................... ﺡﺎﺒﺼﻤﻟﺍ ﺮﻴﻴﻐﺗ

14 ......................................................................................ءﺎﺑﺮﻬﻜﻟﺍ ﻉﺎﻄﻘﻧﺍ

14 .....................................................................................ﻞﻘﻨﻟﺍ ءﺎﻨﺛﺃ ﺔﻳﺎﻨﻌﻟﺍ

14 .................................................................. ﺎﻬﺣﻼﺻﺇﻭ ﻝﺎﻄﻋﻷﺍ ﻑﺎﺸﻜﺘﺳﺍ

16 .................................................................................ﺔﻣﺪﺨﻟﺍ ﻭﺃ ﺓﺪﻋﺎﺴﻤﻟﺍ

2

3 ............................................................................................ ﺪﻤﺠﻤﻟﺍ ﺔﻣﻼﺳ

4 .......................................................................................ﺐﻴﻛﺮﺘﻟﺍ ﺕﺍﺩﺎﺷﺭﺇ

4 .....................................................................................ﺓﻮﺒﻌﻟﺍ ﻦﻣ ﺝﺍﺮﺧﻹﺍ

4 ...............................................................................................ﺔﺤﺘﻔﻟﺍ ﺩﺎﻌﺑﺃ

5 .........................................................................................ﻊﻗﻮﻤﻟﺍ ﺕﺎﺒﻠﻄﺘﻣ

5 .................................................................................. ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﺕﺎﺒﻠﻄﺘﻤﻟﺍ

6 ................................................................................ﻩﺎﻴﻤﻟﺍ ﺭﺪﺼﻣ ﺕﺎﺒﻠﻄﺘﻣ

6 ................................................................................. ﻩﺎﻴﻤﻟﺍ ﺭﺪﺼﻣ ﻞﻴﺻﻮﺗ

7 ...............................................................................................ﺪﻤﺠﻤﻟﺍ ﺏﺎﺑ

10 .............................................................................................ﺏﺎﺒﻟﺍ ﻂﺒﺿ

10 ....................................................................................... ﺪﻤﺠﻤﻟﺍ ﻡﺍﺪﺨﺘﺳﺍ

10 ......................................................................ءﺍﻮﻬﻟﺍ ﻥﺍﺭﻭﺩ ﺔﻣﻼﺳ ﻥﺎﻤﺿ

10 ............................................................................... ﻢﻜﺤﺘﻟﺍ ﺡﺎﺘﻔﻣ ﻡﺍﺪﺨﺘﺳﺍ

11 ......................................................................................ﻲﺋﻮﻀﻟﺍ ﺮﺷﺆﻤﻟﺍ

11 ............................................................................................. ﻞﻔﻘﻟﺍ ﺡﺎﺘﻔﻣ

11 ............................................................................................. ﺞﻠﺜﻟﺍ ﻊﻧﺎﺻ

FREEZER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of fire, electric shock, or injury when using your freezer, follow these basic precautions:

WARNING:

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

follow

■

Plug into a grounded 3 prong outlet.

■

Do not remove ground prong.

■

Do not use an adapter.

■

Do not use an extension cord.

■

Disconnect power before servicing.

■

Replace all parts and panels before operating.

■

Use nonflammable cleaner.

■

Do not use mechanical, electric or chemical means other

than those recommended by this Manufacturer to speed up

the defrost process.

■

Do not use or place electrical devices inside the appliance

compartments if they are not of the type expressly

authorized by the Manufacturer.

■

Keep flammable materials and vapors, such as gasoline,

away from freezer.

SAVE THESE INSTRUCTIONS

Proper Disposal of

Your Old Freezer or Refrigerator

WARNING

Suffocation Hazard

Remove doors or lid from your old freezer or

refrigerator.

Failure to do so can result in death or brain damage.

■

Do not store explosive substances such as aerosol cans

with a flammable propellant in this appliance.

■

Use two or more people to move and install freezer.

■

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities or lack of experience and knowledge, unless

they have been given supervision or instruction concerning

use of this appliance by a person responsible for their

safety.

■

To avoid the risk of children becoming trapped and

suffocating, do not allow them to play or hide inside the

appliance.

■

Keep key away from children.

■

Remove doors or lid from your old freezer or refrigerator.

■

Disconnect power before installing ice maker (on ice maker

kit ready models only).

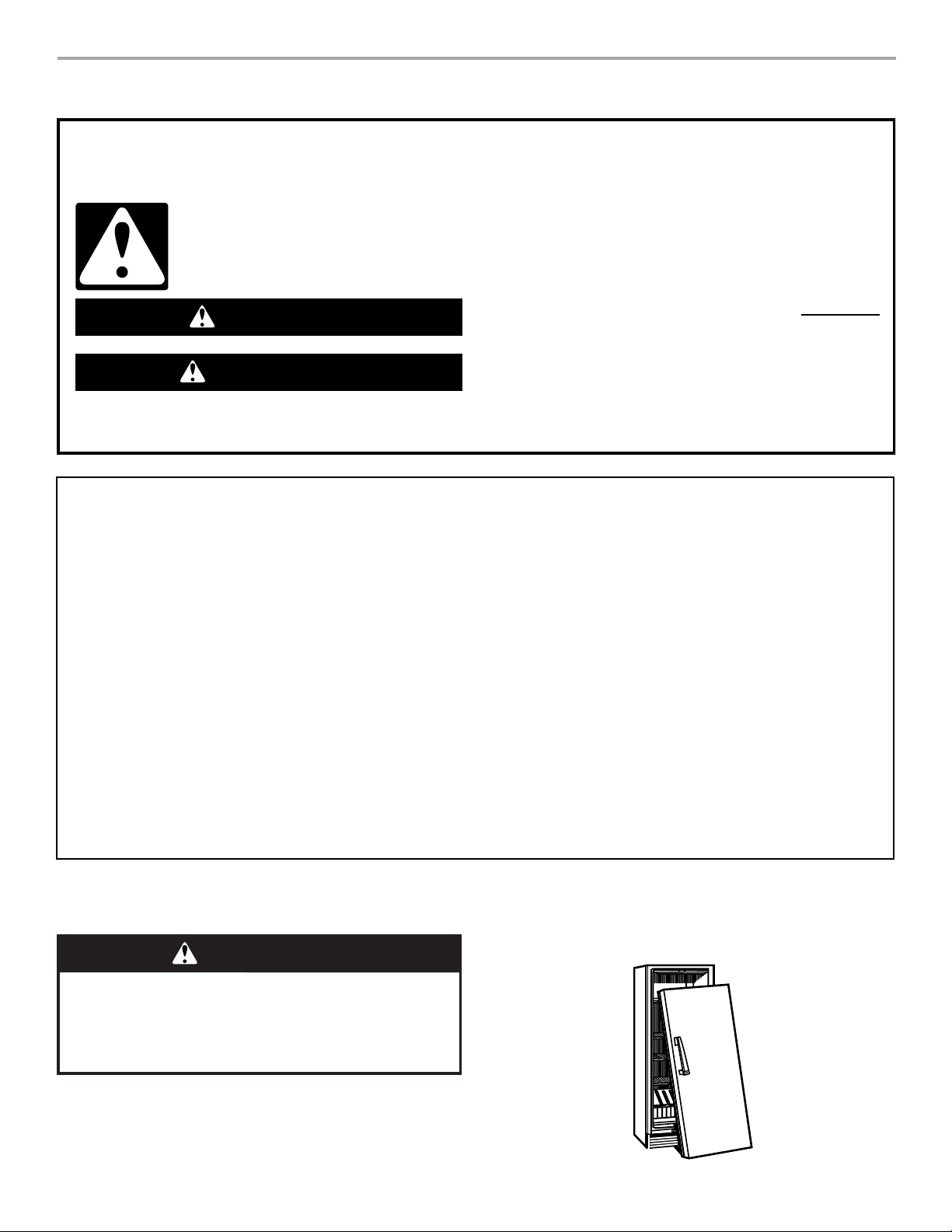

Before You Throw Away Your Old Freezer or Refrigerator:

■ Take off the doors or lid.

■ Leave the shelves in place so that children may not easily

climb inside.

IMPORTANT: Child entrapment and suffocation are not problems

of the past. Junked or abandoned freezers or refrigerators are still

dangerous ... even if they will sit for “just a few days.” If you are

getting rid of your old refrigerator or freezer, please follow these

instructions to help prevent accidents.

3

INSTALLATION INSTRUCTIONS

Unpacking

WARNING

Excessive Weight Hazard

Use two or more people to move and install freezer.

Failure to do so can result in back or other injury.

Before Using the Appliance

This appliance is intended to be used in household and similar

applications such as:

■ Staff kitchen areas in shops, offices and other working

environments

■ Farmhouses and by clients in hotels, motels and other

residential-type environments

■ Bed and breakfast type environments

Remove Packaging Materials

■ Remove tape and glue residue from surfaces before turning

on the freezer. Rub a small amount of liquid dish soap over

the adhesive with your fingers. Wipe with warm water and

dry.

■ Do not use sharp instruments, rubbing alcohol, flammable

fluids, or abrasive cleaners to remove tape or glue. These

products can damage the surface of your freezer. For more

information, see “Freezer Safety.”

Safeguarding the Environment

This product may contain Fluorinated Greenhouse Gases

covered by the Kyoto Protocol; the refrigerant gas is inside a

hermetically sealed system.

Refrigerant gas: R134A has a Global Warming Potential of

(GWP) 1300.

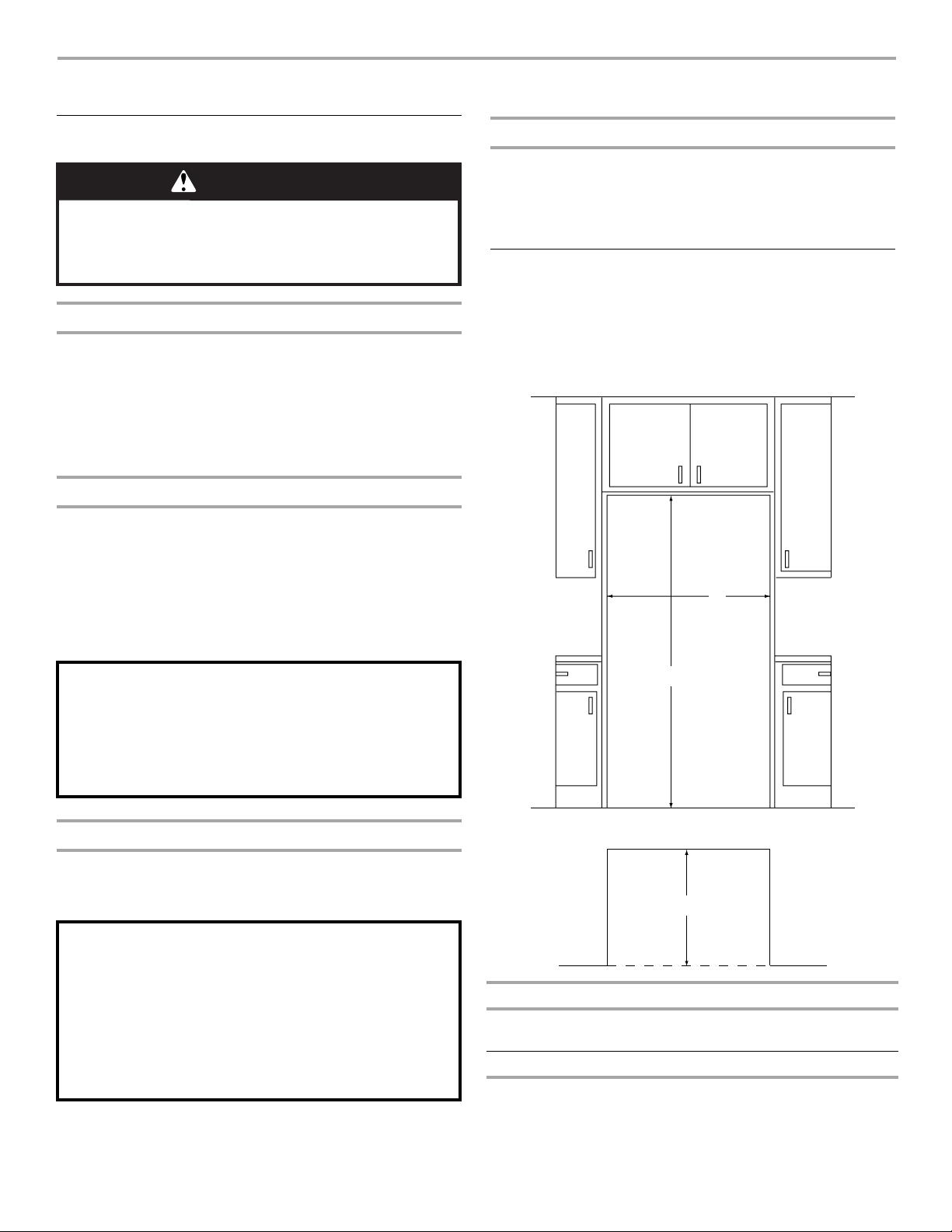

Opening Dimensions

Height dimensions are shown with the leveling legs extended to

the minimum height of ¹⁄₄" (6.35 mm) below the refrigerator.

NOTE: When the leveling legs are fully extended to 1" (25 mm)

below the refrigerator, add ³⁄₄" (19 mm) to the height dimensions.

FRONT VIEW

B

When Moving Your Freezer:

Your freezer is heavy. When moving the freezer for

cleaning or service, be sure to cover the floor with cardboard

or hardboard to avoid floor damage. Always pull the freezer

straight out when moving it. Do not wiggle or “walk” the

freezer when trying to move it, as floor damage could occur.

Clean Before Using

After you remove all of the packaging materials, clean the inside

of your freezer before using it. See the cleaning instructions in

“Freezer Care.”

Important information to know about glass shelves

and covers:

Do not clean glass shelves or covers with warm water when

they are cold. Shelves and covers may break if exposed to

sudden temperature changes or impact, such as bumping.

Tempered glass is designed to shatter into many small,

pebble-size pieces. This is normal. Glass shelves and covers

are heavy. Use both hands when removing them to avoid

dropping.

A

TOP VIEW

C

Model Dimension A Dimension B Dimension C

5VEV201*/

5VEV205*

5VE250* 70³⁄₄" (179.7 cm) 42" (106.7 cm) 29³⁄₄" (75.6 cm)

*Dimensions include 3" (7.2 cm) recommended air space at the

top and sides, plus 1" (2.54 cm) recommended air space at the

back.

69" (175.3 cm) 39" (99.1 cm) 26¹⁄₂" (67.3 cm)

4

Location Requirements

Electrical Requirements

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from freezer.

Failure to do so can result in death, explosion, or fire.

IMPORTANT: Do not install the freezer near an oven, radiator, or

other heat source, nor in a location where the temperature will fall

below 40°F (5°C).

Check the strength of the floor before installing your freezer. It

should hold the weight of a freezer fully loaded with food.

Allow at least 3" (7.5 cm) of air space at the top and on both sides

of the freezer and 1" (2.5 cm) between the back of the freezer and

the wall. If the freezer is to be against a wall, leave extra space on

the hinge side so the door can open wider.

Keep the appliance ventilation openings free.

Do not damage the appliance refrigerant circuit pipes.

Install the appliance in a dry and well-ventilated place.

NOTE: Allow for a 3" (7.5 cm) clearance at the top and sides and

a ¹⁄₄" (0.64 cm) clearance between the appliances.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

A 220/240 volt, 50/60 Hz, AC only, 10-amp fused and grounded

(earthed) electrical supply is required.

Before you move your freezer into its final location, it is important

to make sure you have the proper electrical connection.

It must be possible to disconnect the appliance from the power

supply by unplugging it or by means of a mains two-pole switch

installed upstream of the socket.

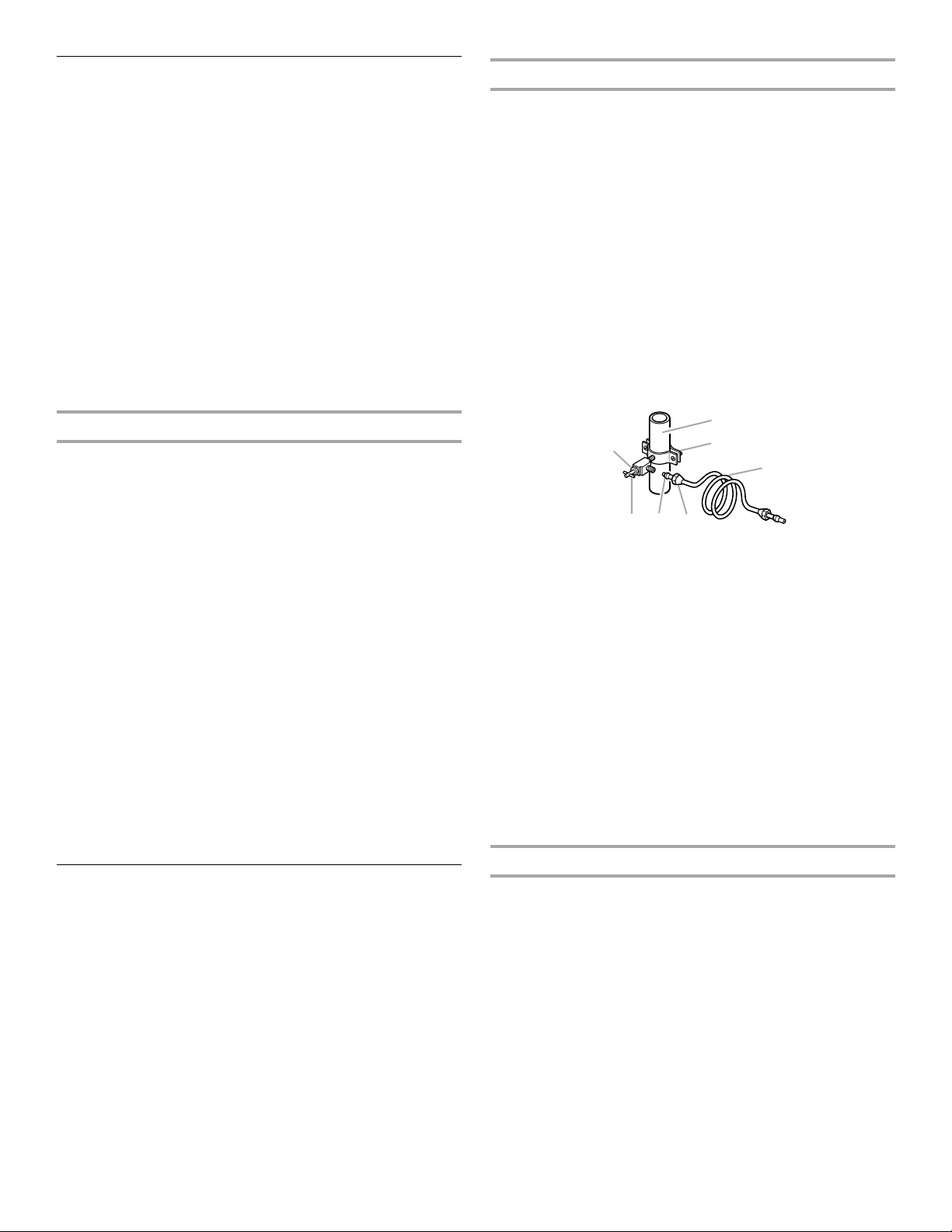

Recommended Grounding Method

It is recommended that a separate circuit serving only your

freezer be provided. Use an outlet that cannot be turned off by a

switch. Do not use an extension cord.

NOTE: Before performing any type of installation, cleaning, or

removing a light bulb, turn the Temperature Control to the OFF

position as shown and then disconnect the freezer from the

electrical source.

3" (7.5 cm)

3" (7.5 cm)

5

Water Supply Requirements

(on some models)

Read all directions before you begin.

IMPORTANT:

■ If you turn the freezer on before the water line is connected,

turn the ice maker OFF.

■ All installations must meet local plumbing code requirements.

■ Use plastic tubing and check for leaks. Install plastic tubing

only in areas where temperatures will remain above freezing.

Tools Needed: Flat-blade screwdriver, ⁷⁄₁₆" and ¹⁄₂" open-end

wrenches or two adjustable wrenches, ¹⁄₄" nut driver, drill bit and

a cordless drill.

NOTE: Your freezer dealer has a kit available with a ¹⁄₄" (6.35 mm)

saddle-type shutoff valve, a union, and plastic tubing. Before

purchasing, make sure a saddle-type valve complies with your

local plumbing codes. Do not use a piercing-type or ³⁄₁₆"

(4.76 mm) saddle valve which reduces water flow and clogs more

easily.

Water Pressure

A cold water supply with water pressure of between 30 and

120 psi (207 to 827 kPa) is required to operate the water

dispenser and ice maker. If you have questions about your water

pressure, see “Troubleshooting” or call a licensed, qualified

plumber.

Reverse Osmosis Water Supply

If a reverse osmosis water filtration system is connected to your

cold water supply, the water pressure to the system needs to be

a minimum of 40 to 60 psi (276 to 414 kPa).

If the water pressure to the reverse osmosis system is less than

40 to 60 psi (276 to 414 kPa), a booster pump can be inserted

into the small tubing that goes from the cold water line to the

reverse osmosis system.

If the water dispenser is still not dispensing water properly:

■ Check to see whether the sediment filter in the reverse

osmosis system is blocked. Replace the filter if necessary.

■ Allow the storage tank on the reverse osmosis system to refill

after heavy usage.

■ If your refrigerator has a water filter, it may further reduce the

water pressure when used in conjunction with a reverse

osmosis system. Remove the water filter.

If you have questions about your water pressure, refer to

“Troubleshooting” or call a licensed, qualified plumber.

Connect to Water Line

1. Unplug freezer or disconnect power.

2. Turn OFF main water supply. Turn ON nearest faucet long

enough to clear line of water.

3. Locate a ½" to 1¹⁄₄" (12.7 mm to 3.18 cm) vertical cold water

pipe near the freezer.

IMPORTANT:

■ Make sure it is a cold water pipe.

■ Horizontal pipe will work, but drill on the top side of the

pipe, not the bottom. This will help keep water away from

the drill and normal sediment from collecting in the valve.

4. Determine the length of plastic tubing you need. Measure

from the connection on the lower left rear of freezer to the

water pipe. Add 7 ft (2.1 m) to allow for cleaning. Use ¹⁄₄"

(6.35 mm) O.D. (outside diameter) plastic tubing. Be sure

both ends of plastic tubing are cut square.

5. Using a cordless drill, drill a ¹⁄₄" (6.35 mm) hole in the cold

water pipe you have selected.

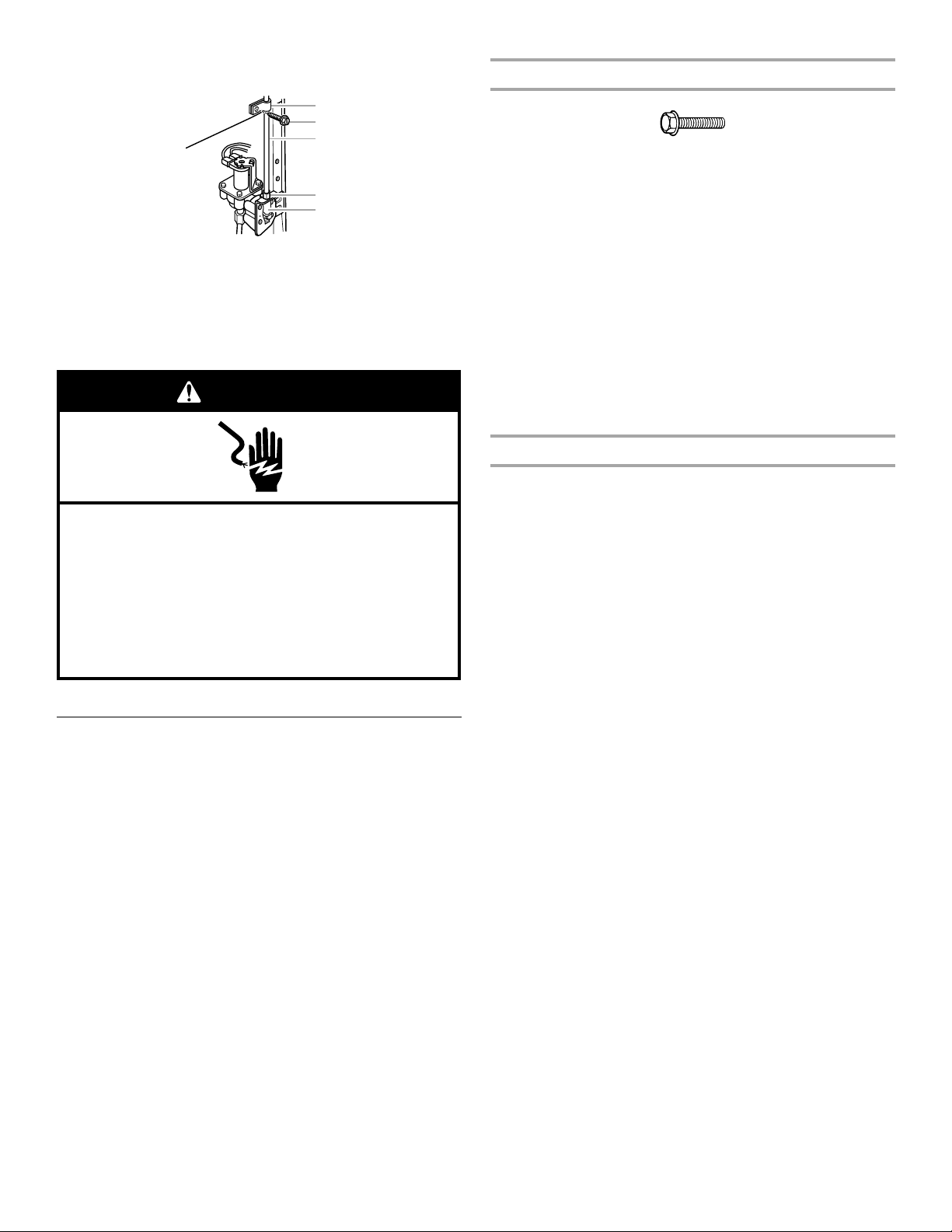

A

G

B

C

DEF

A. Cold water pipe

B. Pipe clamp

C. Copper tubing

D. Compression nut

E. Compression sleeve

F. Sh u tof f v al v e

G. Packing nut

6. Fasten the shutoff valve to the cold water pipe with the pipe

clamp. Be sure the outlet end is solidly in the ¹⁄₄" (6.35 mm)

drilled hole in the water pipe and that the washer is under the

pipe clamp. Tighten the packing nut. Tighten the pipe clamp

screws slowly and evenly so washer makes a watertight seal.

Do not overtighten or you may crush the plastic tubing.

7. Slip the compression sleeve and compression nut on the

plastic tubing as shown. Insert the end of the tubing into the

outlet end squarely as far as it will go. Screw compression nut

onto outlet end with adjustable wrench. Do not overtighten.

8. Place the free end of the tubing in a container or sink, and

turn ON the main water supply. Flush the tubing until water is

clear. Turn OFF the shutoff valve on the water pipe. Coil the

plastic tubing.

Connect to Freezer

Connect the Water Supply

(on some models)

NOTES:

■ All appliances equipped with an automatic ice maker and

water dispenser must be connected to a water supply that

only delivers drinking water (with mains water pressure of

between 0.21 and 0.83 Mpa (2.1 and 8.3 bar). Automatic ice

makers and/or water dispensers not directly connected to the

water supply must be filled with drinking water only.

■ For the water connection, use the pipe supplied with the new

appliance. Do not reuse that of the previous appliance.

6

1. Attach the plastic tube to the valve inlet using a compression

nut and sleeve as shown. Tighten the compression nut. Do

not overtighten.

2. Use the tube clamp on the back of the freezer to fasten the

tubing to the freezer as shown. This will help avoid damage to

the tubing when the freezer is pushed back against the wall.

3. Turn shutoff valve ON.

4. Check for leaks. Tighten any connections (including

C

connections at the valve) or nuts that leak.

A

B

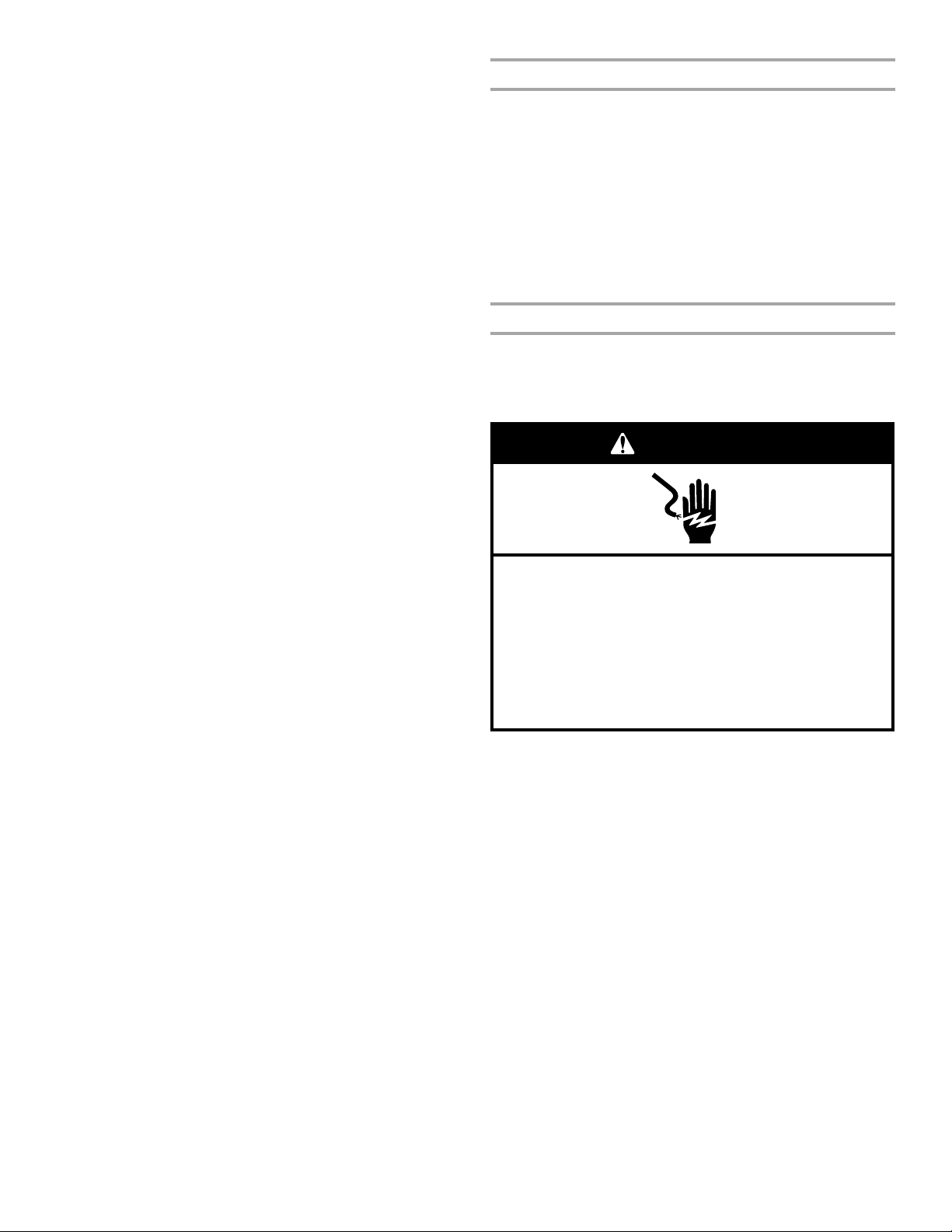

Remove Door and Hinges

⁵⁄₁₆

" hex-head hinge screw

D

E

A. Tube clamp

B. Tube clamp screw

C. Plastic tubing

5. The ice maker is equipped with a built-in water strainer. If

your water conditions require a second water strainer, install

it in the ¹⁄₄" (6.35 mm) water line at either tube connection.

Obtain a water strainer from your nearest appliance dealer.

D. Compression nut

E. Valve inlet

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

6. Plug into a grounded 3 prong outlet.

Freezer Door

Tools Needed: ⁵⁄₁₆" hex-head socket wrench, ⁵⁄₈" hex-head

socket wrench, ¹⁄₄" hex-head socket wrench, ¹⁄₂" hex-head socket

wrench, ³⁄₈" hex-head socket wrench, #2 Phillips screwdriver, flatblade screwdriver, ⁵⁄₁₆" open-end wrench, flat 2" putty knife.

IMPORTANT:

■ All graphics referenced in the following instructions are

included later in this section after “Final Steps.” The graphics

shown are for a right-hand swing door (hinges factory

installed on the right).

■ If you only want to remove and replace the door, see the

“Remove Door and Hinges” and “Replace Door and Hinges.”

■ Before you begin, turn the control OFF, and remove food and

adjustable door or utility bins from door.

1. Unplug freezer or disconnect power.

2. Open freezer door and remove base grille from the bottom

front of the freezer. See Base Grille Graphic 1A.

3. Close the freezer door and keep it closed until you are ready

to lift it free from the cabinet.

NOTE: Provide additional support for the door while the

hinges are being moved. Do not depend on the door magnets

to hold the door in place while you are working.

4. Remove the parts for the top hinge as shown in Top Hinge

Graphic 1B.

5. Lift the freezer door free from the lower hinge and cabinet and

set aside.

6. Remove 2 hex-head hinge screws and bottom hinge

assembly. See Bottom Hinge Graphic 1C.

Reverse Door (optional on some models)

IMPORTANT: If you want to reverse your door so that it opens in

the opposite direction, continue with “Reverse Door (optional on

some models)” instructions. If you are not reversing the door, see

“Replace Door and Hinges.”

Cabinet

1. Remove the cabinet hinge hole plugs from the cabinet top

and move them to the opposite side hinge holes as shown in

Graphic 2.

2. Remove the door stop screws from the Bottom Hinge

bracket. See Bottom Hinge Graphic 1C.

3. Remove the Hinge Pin Nut and Hinge Pin from the hinge

bracket.

4. Rotate the hinge bracket for installation on the opposite side

of the cabinet. See Graphic 3.

5. Reinstall the Hinge Pin Nut and Hinge Pin to the hinge

bracket. Hinge Pin must point “up” when hinge bracket is

installed to the cabinet.

6. Invert the door stop so that the countersunk holes line up

with the screw holes in the hinge assembly. See Graphic 3.

7. Reinstall the door stop screws. See Graphic 3.

8. Reinstall the hinge bracket to the cabinet with the 2 hex-head

hinge screws.

Door

1. Remove the 3 hinge leaf screws that fasten a hinge leaf to

both the top and bottom of the door. See Graphic 5.

2. Remove the hinge leaf from the top of the door and from the

bottom of the door, and transfer them to the opposite side.

3. Fasten the hinge leaf to the door using the hinge leaf screws

removed in Step 1.

7

Handle

Move the door handle from one side of the door to the other.

Style 1

1. Grasping the lower part of the handle firmly, slide it up and

pull the handle straight out from the door. See Graphic 1-1.

2. Using a ¹⁄₄" hex-head socket wrench, remove the grommets

from the door.

3. Reinstall the grommets on the opposite side of the door.

4. Position the handle so that the large holes in the mounting

clips are down and align the holes with the grommets.

5. Rotate the handle so that the mounting clips are flat against

the door and slide the handle down to engage.

Style 2

1. Loosen setscrews located on side of handle at each end. See

Graphic 1-2.

2. Remove handle from grommets.

3. Using a ¹⁄₄" hex-head socket wrench, remove the grommets

from the door.

4. Position the grommets on the opposite side of the door and

reinstall.

5. Position the handle over grommets on the opposite side of

the freezer door.

6. Ensure grommets are fitted into handle holes.

7. Tighten the upper and lower setscrews with hex key

provided. Do not overtighten setscrews.

Style 3

1. Slide the handle up and off the clips. See Graphic 1-3.

2. Using a flat-blade screwdriver, remove the screws from the

clips and remove the clips from the door.

3. Position the clips on the opposite side of the freezer door and

reinstall the screws.

4. Position handle over the clips.

5. Apply even pressure and push down to lock into place.

Replace Door and Hinges

NOTE: Graphic may be reversed if door swing is reversed.

1. Replace the parts for the bottom hinge as shown and tighten

screws. See Bottom Hinge Graphic 1C. Replace the freezer

door.

NOTE: Provide additional support for the door while the

hinges are being moved. Do not depend on the door magnets

to hold the door in place while you are working.

2. Assemble the parts of the top hinge as shown in the Top

Hinge Graphic 1B. Do not tighten the screws completely.

3. Line up the door so that the bottom aligns evenly with the

cabinet. Tighten all screws.

Final Steps

1. Check all holes to make sure that hole plugs and screws are

in place. Reinstall top hinge cover. See Top Hinge

Graphic 1B.

2. Replace the base grille. See Base Grille Graphic 1A.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

3. Plug into a grounded 3 prong outlet.

4. Reset the control. See “Using the Control.”

5. Return all removable door parts to door and food to freezer.

8

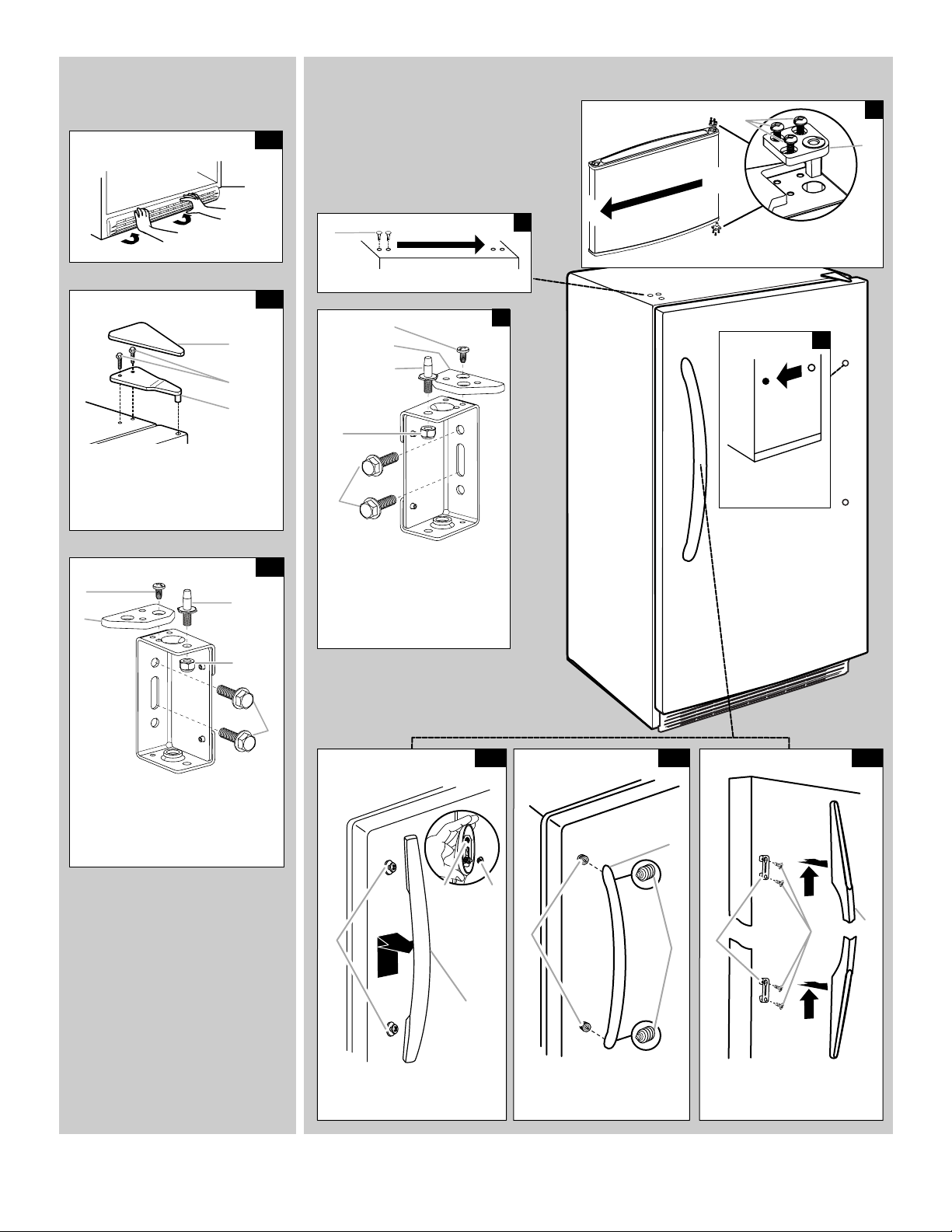

Door Removal &

Replacement

Base Grille

1A

Door Swing Reversal (optional)

A

5

B

Top Hinge

A. Top Hinge Cover

3

/8" or

5

/8"

Hex-Head Hinge

B.

Screws (depending on model)

C. Top Hinge

Bottom Hinge

A

B

A

2

A. Hinge Leaf Screws

B. Hinge Leaf

A. Cabinet Hinge Hole Plugs

1B

A

A

B

C

D

E

1C

A. Door Stop Screws

B

C

B. Door Stop

C

D

C. Hinge Pin

D. Hinge Pin Nut

5

E.

/8"

Hex-Head Hinge Screws

3

6

Door Handle

Seal Screw

A. Door Stop Screws

B. Door Stop

C. Hinge Pin

D. Hinge Pin Nut

5

/8"

Hex-Head Hinge Screws

E.

E

Style 1

A

A. Grommet

B. Clip

C. Handle

1-1

B A

C

Style 2

A

A. Grommet

B. Handle

C. Setscrews

1-2

Style 3

B

A

C

A. Clips

B. Handle Screws

C. Handle

1-3

B

C

9

Adjust the Door

1. Adjust the front legs enough to lift the cabinet up off of the

floor.

NOTE: If your model is equipped with rollers, the front legs

should be lowered enough to lift the rollers off of the floor to

ensure the freezer does not roll forward when the door is

opened.

2. Place a leveling tool on top of the freezer first side to side,

then front to back. Turn leg counterclockwise to raise a

corner. Turn leg clockwise to lower a corner.

3. Repeat Step 2 until freezer is level.

4. After freezer is fully loaded with food, recheck with level as in

Step 2.

FREEZER USE

Ensuring Proper Air Circulation

In order to ensure proper temperature, you need to permit proper

airflow in the freezer. As shown in the illustration, cool air enters

through the freezer wall and moves down. The air then

recirculates through the vent near the bottom.

NOTE: When the freezer is first started, the compressor will run

constantly until the freezer is cooled. It may take up to 6 or

8 hours (or longer), depending on room temperature and the

number of times the freezer door is opened. After the freezer is

cooled, the compressor will turn on and off as needed to keep

the freezer at the proper temperature.

The outside of your freezer may feel warm. This is normal. The

freezer’s design and main function is to remove heat from

packages and air space inside the freezer. The heat is transferred

to the room air, making the outside of the freezer feel warm.

Adjusting Control

■ Turn control to a higher number for colder temperatures.

■ Turn control to a lower number for less cold temperatures.

NOTE: The small snowflake icon represents the number 1 or

the least cold setting. The large snowflake icon represents 6

or the coldest setting.

Fast Freeze (on some models)

This setting causes the freezer to run continuously, driving the

freezer temperature to the coldest possible temperature. To

activate, adjust the control knob to the igloo icon, which

represents the fast freeze setting. Use this feature just before

adding large amounts of unfrozen foods. For best food quality, do

not exceed 3 lbs (1,350 g) per cubic foot (28.32 L). Return to your

normal setting after 24 to 48 hours.

Do not block any of these vents with food packages. If the vents

are blocked, airflow will be restricted, and temperature and

moisture problems may occur.

IMPORTANT: To avoid odor transfer and drying out of food, wrap

or cover foods tightly.

Using the Control

Turn the freezer temperature control to 4. This setting is designed

to maintain the temperature at or near 0°F (-17.8°C) under normal

operating conditions.

Allow the freezer to cool 6 to 8 hours before filling with frozen

food. Let the freezer cool overnight before adding large amounts

of unfrozen food. Do not add more than 2 to 3 lbs (907 to 1,350 g)

of unfrozen food per cubic foot (28.32 L) of freezer space.

10

Temperature Alarm (on some models)

The temperature monitor alarm is located to the left of the

temperature control and sounds an audible alarm if the

temperature reaches 10°F (-12°C) or more above normal for the

selected setting.

The alarm is controlled by a three-position switch.

| The proper setting for normal freezer use. The alarm

is on, and the amber light will be illuminated.

0 Keeps the alarm from sounding when the freezer is

warm, such as during start-up or defrosting.

✔ Tests the alarm regardless of temperature.

Indicator Light

(on some models)

The indicator light assures you that your freezer is running. If the

indicator light is not glowing, immediately check for:

■ Power interruption.

■ An unplugged power cord.

■ An open circuit breaker or blown fuse.

■ A burned out indicator light.

Key Eject Lock

(on some models)

To lock or unlock the freezer, you must hold the key in the lock

while turning. The lock is spring loaded, so the key cannot be left

in the lock.

Ice Production Rate

The ice maker should produce approximately 7 to 9 batches of

ice in a 24-hour period. If ice is not being made fast enough, turn

the Temperature Control toward a higher (colder) number in half

number steps. (For example, if the control is at 3, move it to

between 3 and 4.) Wait 24 hours and, if necessary, gradually turn

the Temperature Control to the highest setting, waiting 24 hours

between each increase.

Remember

■ Allow 24 hours to produce the first batch of ice. Discard the

first three batches of ice produced.

■ The quality of your ice will be only as good as the quality of

the water supplied to your ice maker. Avoid connecting the

ice maker to a softened water supply. Water softener

chemicals (such as salt) can damage parts of the ice maker

and lead to poor quality ice. If a softened water supply cannot

be avoided, make sure the water softener is operating

properly and is well maintained.

■ Do not store anything on top of the ice maker or in the ice

storage bin.

FREEZER FEATURES

This manual covers several different models. The freezer you

have purchased may have some or all of the items listed. The

locations of the features may not match those of your model.

If the key is lost, contact your dealer for a replacement. Always

give the model and serial number of your freezer when requesting

a replacement key.

NOTE: Keep the key out of the reach of children. Do not keep the

key close to the freezer/refrigerator.

Ice Maker

(on some models)

To Turn the Ice Maker On/Off

NOTE: Do not force the wire shutoff arm up or down.

■ To turn the ice maker on, simply lower the wire shutoff arm.

NOTE: Your ice maker has an automatic shutoff. As ice is

made, the ice cubes fill the ice storage bin and the ice cubes

will raise the wire shutoff arm to the OFF (arm up) position.

■ To manually turn the ice maker off, lift the wire shutoff arm to

the OFF (arm up) position and listen for the click to make sure

the ice maker will not continue to operate.

Refrigerated Shelves

(on some models)

Your freezer is equipped with refrigerated interior shelves.

Packages in direct contact with the shelves will have the best

refrigeration. Fresh, unfrozen food packages should be stored

directly on the shelves and not on top of already frozen food

packages.

When placing the food packages in your freezer, please

remember:

■ The cabinet shelves have the best freezing capability. The

door shelves and the bottom of the cabinet have a slightly

less cold temperature. Therefore, packages sensitive to

temperature (meat, poultry, etc.) should not be placed on the

door shelves or the freezer bottom.

■ Leave some space between the food packages so that cold

air can pass over and around them.

11

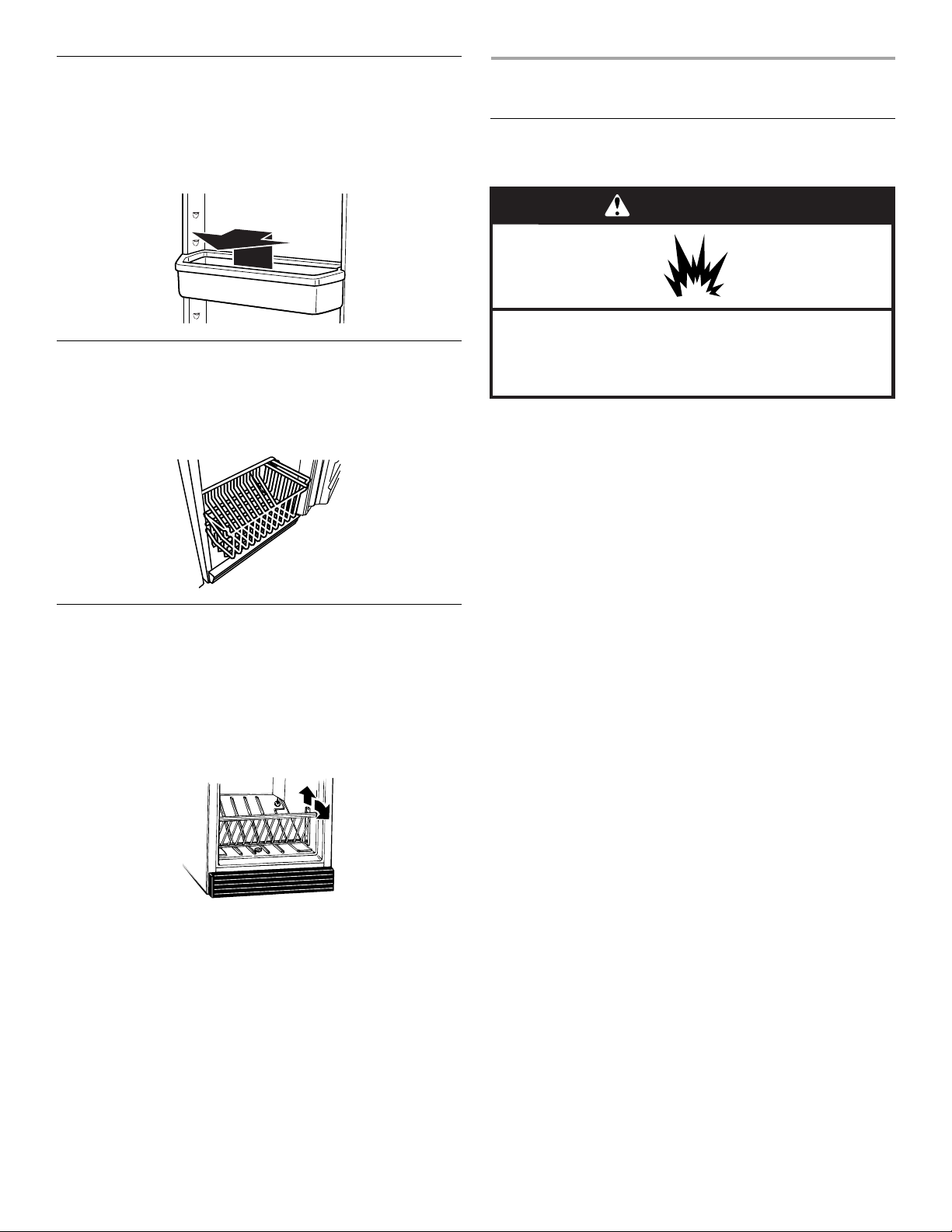

Door Bin

To Remove and Replace the Bin:

1. Remove the bin by tipping the front of the bin forward and

sliding out.

2. Replace the bin by sliding it in above the desired support

tilting it back into place.

Storage Basket

(on some models)

The slide out basket provides separate storage space for items

that are difficult to store on freezer shelves. To remove the

basket, pull out and lift up.

Storage Gate

(on some models)

To Lower and Raise the Storage Gate:

1. Lift the top of the gate up slightly, out of the supports. Pull the

gate forward and down.

2. Return the gate to the upright position. Lift the top of the gate

slightly to clear the supports. Lower the gate into the

supports.

FREEZER CARE

Cleaning Your Frost-Free Freezer

(on some models)

WARNING

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

Frost-free means that you will not have to defrost your freezer.

Frost is removed by air moving and collecting any moisture and

depositing it on the cooling coil. The cooling coil periodically

warms up enough to melt the frost, and it then flows down to the

drain pan (located behind the base grille) where it is evaporated.

Complete cleaning should be done at least once a year.

1. Unplug freezer or disconnect power.

2. Remove all frozen food. Wrap frozen food in several layers of

newspaper and cover with a blanket. Food will stay frozen for

several hours. You may also store frozen food in a cooler,

additional refrigerator-freezer, or in a cool area.

3. Wash the inside walls with a solution of mild detergent in

warm water or 2 tbs (26 mg) baking soda to 1 qt (0.95 L)

warm water.

■ Do not use abrasive or harsh cleaners such as window

sprays, scouring cleansers, flammable fluids, cleaning

waxes, concentrated detergents, bleaches or cleansers

containing petroleum products on plastic parts, interior

and door liners or gaskets. Do not use paper towels,

scouring pads, or other harsh cleaning tools. These can

scratch or damage materials.

4. Rinse well and wipe dry with a clean soft cloth.

5. Use the appropriate cleaning method for your exterior finish.

Painted metal: Wash exteriors with a clean sponge or soft

cloth and a mild detergent in warm water. Do not use abrasive

or harsh cleaners, or cleaners designed for stainless steel.

Dry thoroughly with a soft cloth.

Stainless steel finish: Wash with a clean sponge or soft

cloth and a mild detergent in warm water. Do not use abrasive

or harsh cleaners. Dry thoroughly with a soft cloth.

■ To keep your stainless steel refrigerator looking like new

and to remove minor scuffs or marks, it is suggested that

you use the manufacturer’s approved Stainless Steel

Cleaner and Polish.

IMPORTANT: This cleaner is for stainless steel parts only!

■ Do not allow the Stainless Steel Cleaner and Polish to

come into contact with any plastic parts such as the trim

pieces, dispenser covers or door gaskets. If unintentional

contact does occur, clean plastic part with a sponge and

mild detergent in warm water. Dry thoroughly with a soft

cloth.

6. Replace all frozen food.

7. Plug in freezer or reconnect power.

8. See “Using the Control.”

12

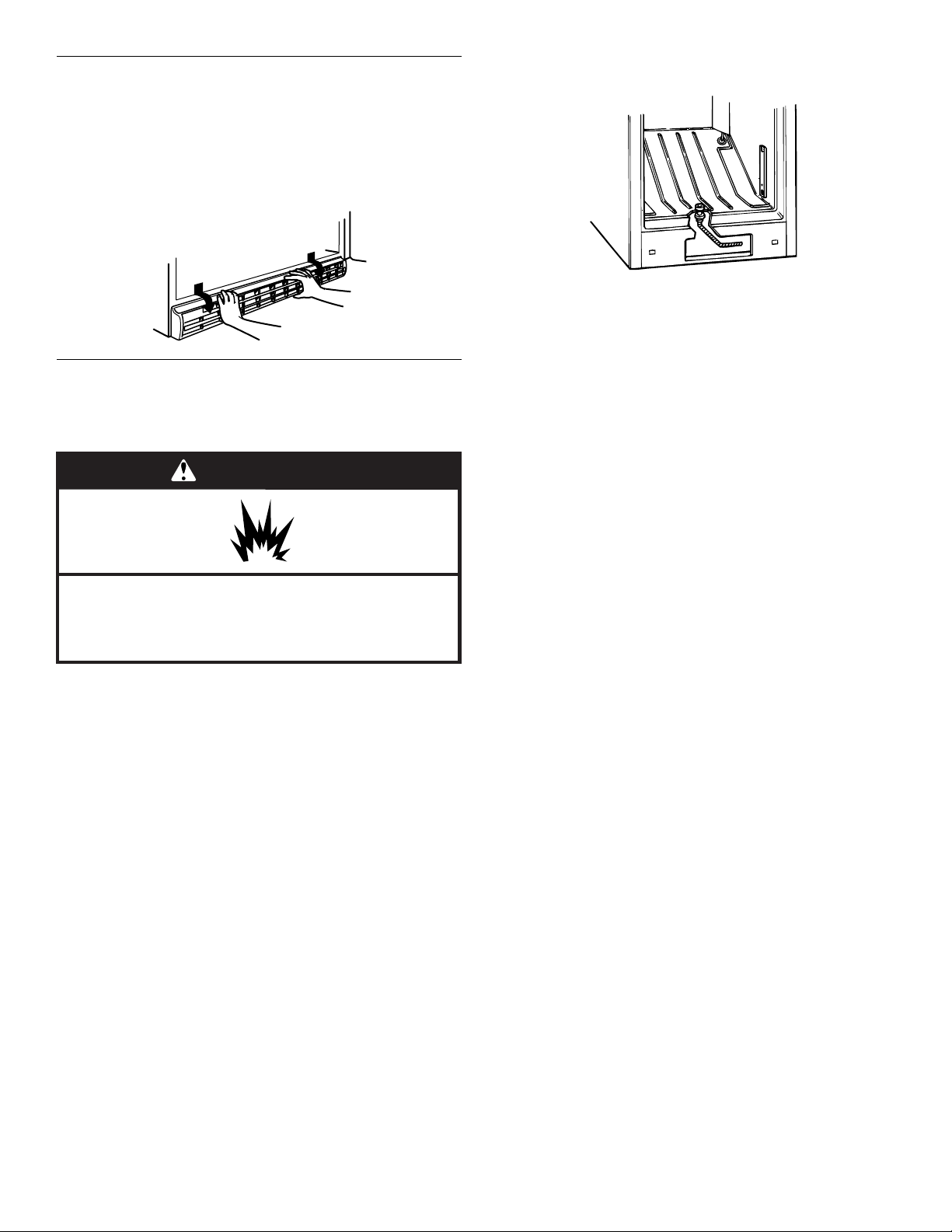

Base Grille

To Remove and Replace the Base Grille:

1. Open the freezer door and remove the base grille by pulling

down and out from the top.

2. Replace the base grille by putting the clips in the openings in

the refrigerator panel. Push in until the base grille snaps into

place.

Defrosting and Cleaning Your

Manual Defrost Freezer

(on some models)

WARNING

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

Defrost and clean your freezer when frost has built up to about

¹⁄₄" (6 mm) thickness. Complete defrosting and cleaning should

be done at least once a year. In high humidity areas, a freezer

may need more frequent defrosting and cleaning.

Do not use abrasive cleaners on your freezer. Do not use cleaning

waxes, concentrated detergents, bleaches, or cleaners

containing petroleum on plastic parts. Damage can occur.

NOTE: The drain cap must be removed before defrosting the

freezer and replaced securely afterward.

1. Unplug freezer or disconnect power.

2. Remove all frozen food. Wrap frozen food in several layers of

newspaper and cover with a blanket. Food will stay frozen for

several hours. You may also store frozen food in a cooler, an

additional refrigerator or freezer, or a cool area.

3. Remove base grille. See “Base Grille.”

4. Style 1–Models With a Drain System

Reach under the unit and pull the drain hose out through the

opening. The drain hose carries defrost water out of the

freezer, and through the area behind the base grille. Place a

large shallow pan under the drain hose. Remove the drain

cap inside freezer.

NOTE: Check the drain pan frequently to avoid water

overflow. Have a second pan handy for easier emptying.

Style 2–Models Without a Drain System

Remove water from the freezer bottom using a sponge or

baster and empty the water into a large pan.

5. Place pans of hot water in freezer with door open to speed

melting. Directing air from an electric fan into freezer will also

help. Do not place fan or any electrical device in freezer.

6. Use a plastic scraper to remove frost.

NOTE: Do not use an ice pick, knife, or other sharp-pointed

tool to defrost freezer. Damage can occur.

7. Wipe water from walls with a towel or sponge.

8. Wash the inside walls with a solution of mild detergent in

warm water or 2 tbs (26 mg) baking soda to 1 qt (0.95 L)

warm water. Do not use abrasive or harsh cleaners.

9. Rinse well and wipe dry with a clean soft cloth.

10. Use the appropriate cleaning method for your exterior finish.

Painted metal: Wash exteriors with a clean sponge or soft

cloth and a mild detergent in warm water. Do not use abrasive

or harsh cleaners, or cleaners designed for stainless steel.

Dry thoroughly with a soft cloth.

Stainless steel finish: Wash with a clean sponge or soft

cloth and a mild detergent in warm water. Do not use abrasive

or harsh cleaners, or cleaners designed for stainless steel.

Dry thoroughly with a soft cloth.

■ To keep your Stainless Steel refrigerator looking like new

and to remove minor scuffs or marks, it is suggested that

you use the manufacturer’s approved Stainless Steel

Cleaner and Polish.

IMPORTANT: This cleaner is for Stainless Steel parts only!

■ Do not allow the Stainless Steel Cleaner and Polish to

come into contact with any plastic parts such as the trim

pieces, dispenser covers or door gaskets. If unintentional

contact does occur, clean plastic part with a sponge and

mild detergent in warm water. Dry thoroughly with a soft

cloth. To order the cleaner, see “Accessories.”

11. For models with a drain system, you should replace the drain

hose, drain cap and base grille.

12. Replace all frozen food.

13. Plug in freezer or reconnect power.

14. See “Using the Control.”

13

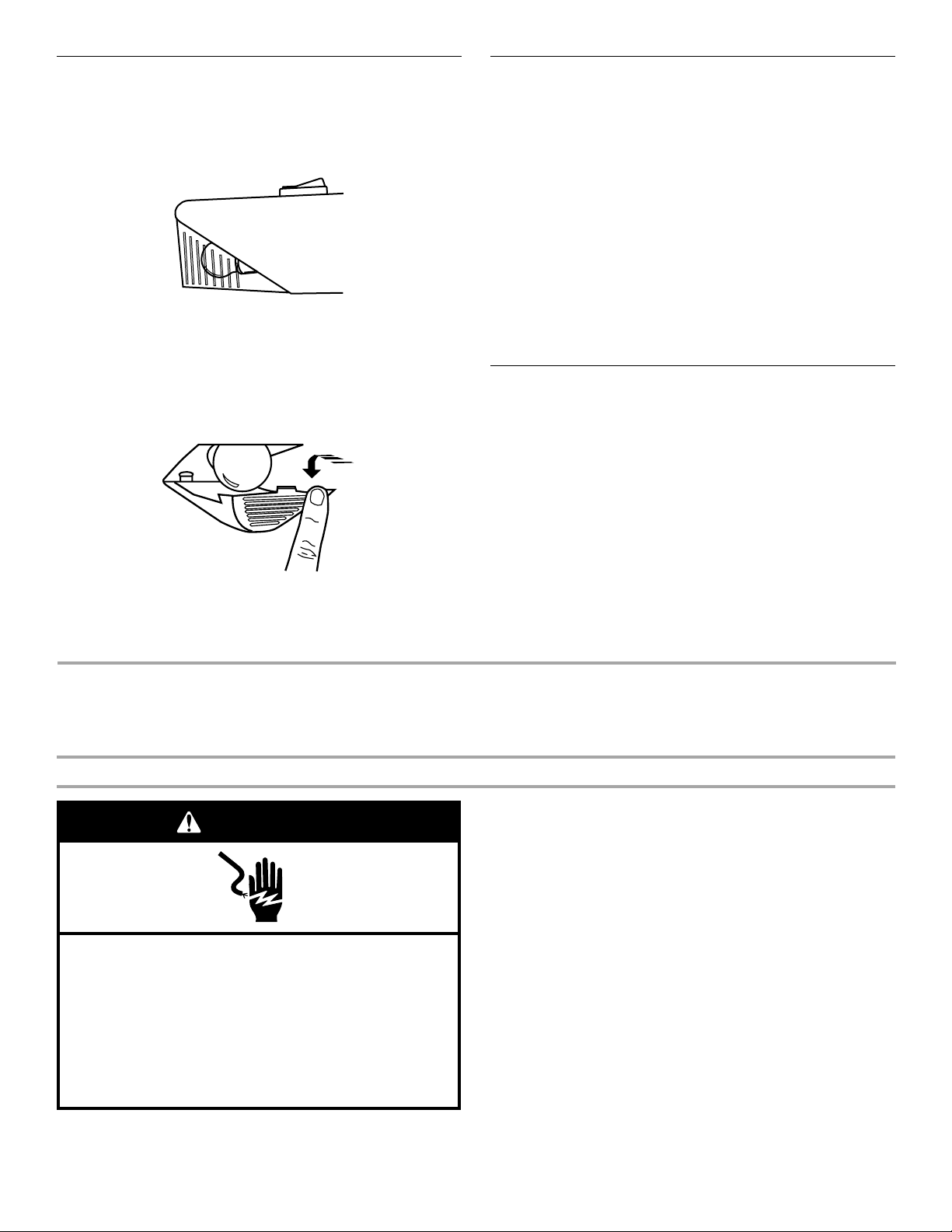

Changing the Light Bulb

NOTE: Not all appliance bulbs will fit your freezer. Be sure to

replace the bulb with one of the same size, shape, and wattage.

Style 1

1. Unplug freezer or disconnect power.

2. Replace the light bulb with an appliance bulb of the same

wattage.

3. Plug in freezer or reconnect power.

Style 2

1. Unplug freezer or disconnect power.

2. Remove the light shield. From the front of the light shield,

push backward and down.

3. Replace the light bulb with an appliance bulb of the same

wattage.

4. Replace the light shield.

5. Plug in freezer or reconnect power.

Power Interruptions

If the power will be out for 24 hours or less, keep the door closed

to help food stay cold and frozen.

If the power will be out for more than 24 hours, do one of the

following:

■ Remove all frozen food and store it in a frozen food locker.

■ If a food locker is not available, consume or can perishable

food at once.

After the power is restored, unplug the freezer for 30 minutes, to

allow the refrigeration system to equalize. During this time keep

the door closed whenever possible.

REMEMBER: A full freezer stays cold longer than a partially filled

one. A freezer full of meat stays cold longer than a freezer full of

baked goods. If you see that food contains ice crystals, it may be

refrozen, although the quality and flavor may be affected. If the

condition of the food is poor, dispose of it.

Moving Care

When you are moving your freezer to a new home, follow these

steps to prepare it for the move.

1. Remove all frozen food.

2. Unplug the freezer.

3. Take out all removable parts, wrap them well, and tape them

together so they don’t shift and rattle during the move.

4. Clean the freezer thoroughly.

5. Tape the freezer shut and tape the electrical cord to the

cabinet.

When you get to your new home, refer to the “Installation

Instructions” and “Freezer Use” sections for information on

installation and setting the controls.

TROUBLESHOOTING

Try the solutions suggested here first to avoid the cost of an unnecessary service call...

Your freezer will not operate

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

■ Is the power supply cord unplugged? Plug into a grounded

3 prong outlet.

■ Has a household fuse blown or circuit breaker tripped?

Replace the fuse or reset the circuit breaker.

■ Is the Temperature Control turned to the OFF position?

See “Using the Control.”

■ Is the freezer defrosting (on some models)? Recheck to

see whether the freezer is operating in 30 minutes. Your

freezer will regularly run an automatic defrost cycle.

14

The lights do not work

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

■ Is the power supply cord unplugged? Plug into a grounded

3 prong outlet.

■ Is a light bulb loose in the socket or burned out? See

“Changing the Light Bulb.”

There is water in the defrost drain pan (on some models)

■ Is the freezer defrosting? The water will evaporate. It is

normal for water to drip into the defrost pan.

■ Is it more humid than normal? When it is humid, expect that

the water in the defrost pan will take longer to evaporate.

■ Is there enough air circulation space around the freezer?

See “Location Requirements.”

NOTE: If the problem is not due to any of the above,

remember that your new freezer will run longer than your old

one due to its high-efficiency motor.

The ice maker is not producing ice or not enough ice

(on some models)

■ Has the ice maker just been installed? Wait 72 hours for full

ice production to begin. Once your freezer is cooled, the ice

maker should produce 70-120 cubes every 24 hours.

■ Is the freezer temperature cold enough to produce ice?

Wait 24 hours after hookup for ice production. See “Using the

Control.”

■ Is the wire shutoff arm in the OFF (arm up) position?

Lower the wire shutoff arm to the ON (arm down) position.

See “Ice Maker.”

■ Is the water line shutoff valve to the freezer turned on?

Turn on the water valve. See “Connect the Water Supply.”

■ Does the ice maker mold have water in it or has no ice

been produced? Be sure your freezer has been connected to

a water supply and the supply shutoff valve is turned on. See

“Connect the Water Supply.”

■ Is an ice cube jammed in the ejector arm? Remove the ice

from the ejector arm with a plastic utensil. See “Ice Maker.”

■ Has a large amount of ice just been removed? Allow

24 hours for ice maker to produce more ice.

■ Is the control set correctly? If too little ice is produced, see

“Using the Control.”

NOTE: If not due to any of the above, there may be a problem

with the water line. Call for service.

The motor seems to run too much

■ Is there excessive frost or a package keeping the door

from closing? Defrost and clean the freezer, or move the

package so the door closes properly.

■ Is the room temperature hotter than normal? The motor

will run longer under warm conditions. At normal room

temperatures, your motor will run about 40% to 80% of the

time. Under warmer conditions, it will run even more.

■ Has a large amount of food just been added to the

freezer? Adding a large amount of food warms the freezer.

The motor normally will run longer to cool the freezer back

down.

■ Is the door opened often? The motor will run longer when

this occurs. Conserve energy by getting all items out at one

time, keeping food organized, and closing the door as soon

as possible.

■ Is the control set correctly for the surrounding

conditions? See “Using the Control.”

■ Is the door completely closed? Push the door firmly shut. If

it will not shut all the way, see “The door will not close

completely or is difficult to open” later in this section.

■ Are the condenser coils dirty (on some models)? This

blocks air transfer and makes the motor work harder. Clean

the condenser coils. See “Freezer Care.”

■ Is the door gasket sealed all the way around? Contact a

qualified person or a technician.

Off-taste, odor or gray color in the ice (on some models)

■ Are the plumbing connections new, causing discolored or

off-flavored ice? Discard the first few batches of ice.

■ Have the ice cubes been stored too long? Throw old ice

away and make a new supply.

WARNING

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

■ Do the freezer and ice bin need to be cleaned? See

“Freezer Care.”

■ Does the water contain minerals (such as sulfur)? A filter

may need to be installed to remove the minerals.

15

Loading...

Loading...