30” EYE-LEVEL

GAS MICROWAVE RANGE

AND

30” EYE-LEVEL GAS RANGE

IMPORTANT

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE HOMEOWNER

HOMEOWNER: RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE.

ve Ovens, Compactors, Room Air Conditioners, Dehumidifiers, Automatic Washers, Clothes Dryers,

Freezers,

Refrigerator-Freezers, Ice Makers,Dishwashl

Before you begin

II

Read these instructions completely and carefully.

If followed, they will simplify the installation job.

If your range does not have a microwave upper

oven,

information.

disregard the following microwave

IMPORTANT:

Observe all governing codes and ordinances.

Failure to follow these instructions could lead

to fire or electrical shock hazard.

PRECAUTIONS TO AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

Do not attempt to operate this oven with the door open

since open-door operation can result in harmful ex-

posure to microwave energy. It is important not to

defeat or tamper with safety interlocks.

Do not place any object between the oven front face

and the door or allow soil or cleaner residue to accumulate on sealing surfaces.

Do not operate the oven if it is damaged. It is particularly

important that the oven door close properly and that

there is no damage to the:

1. Door(bent)

2. Hinges and latches(broken or loosened)

3. Door seals and sealing surfaces.

The oven should not be adjusted or repaired by anyone

except properly qualified service personnel.

The oven should be checked for microwave leakage

by qualified service personnel after a repair is made.

Do not operate the oven if the door glass is broken.

~lnstallatlon must conform with the American National Standard Natlonal Fuel Gas Code ANSI 2223.1-1980’ and local

‘Copies of the standard listed above may be obtained from:

2

AMERICAN GAS ASSOCIATION

1515 Wllson Boulevard

Arlington, Virginia 22209

codes and ordinances.

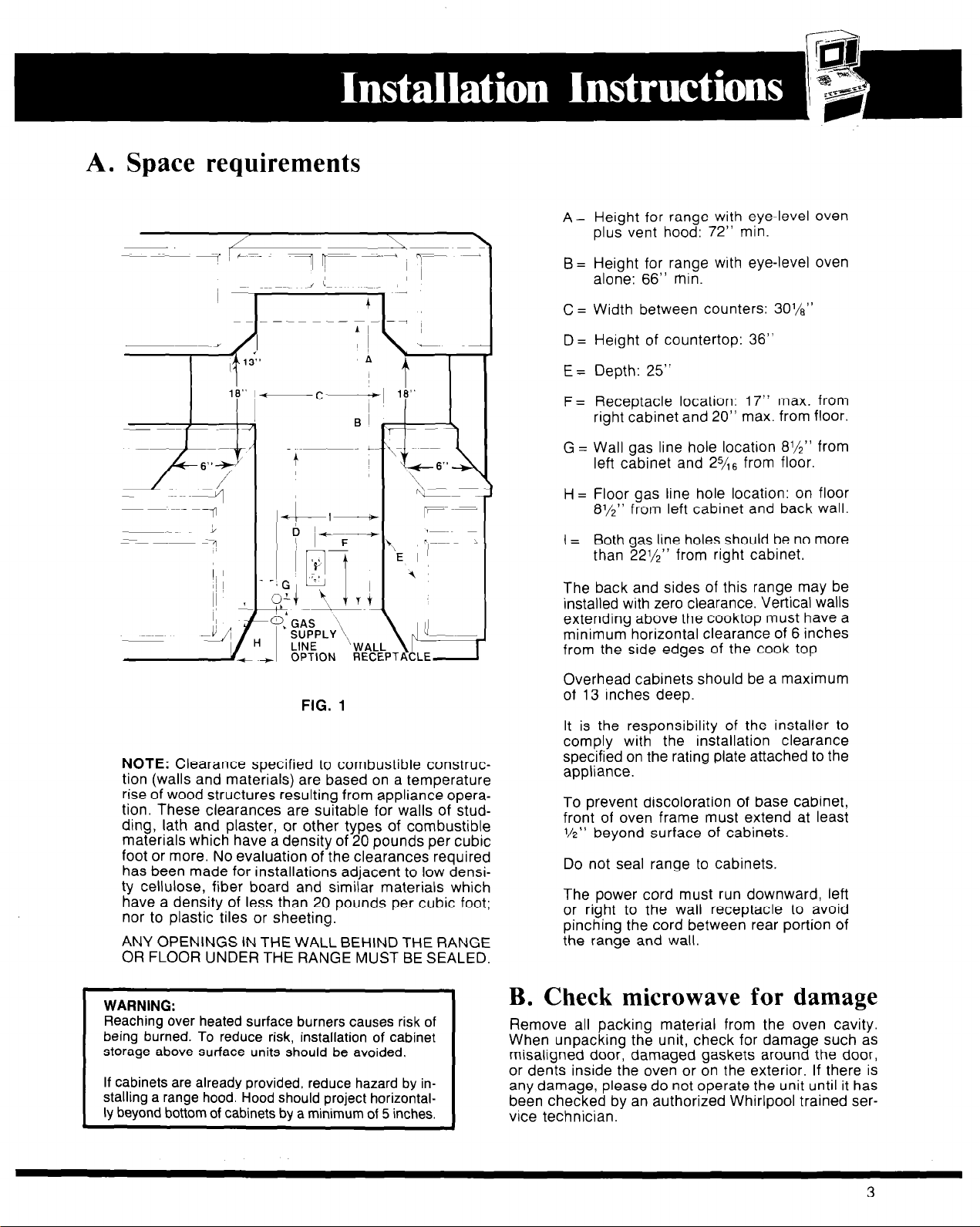

A. Space requirements

b!!“, OPTION

NOTE: Clearance specified to combustible construction (walls and materials) are based on a temperature

rise of wood structures resulting from appliance operation. These clearances are suitable for walls of studding, lath and plaster, or other types of combustible

materials which have a density of 20 pounds per cubic

foot or more. No evaluation of the clearances required

has been made for installations adjacent to low density cellulose, fiber board and similar materials which

have a density of less than 20 pounds per cubic foot;

nor to plastic tiles or sheeting.

ANY OPENINGS IN THE WALL BEHIND THE RANGE

OR FLOOR UNDER THE RANGE MUST BE SEALED.

SUPPLY 1,

LINE

FIG. 1

%%TXLE

A= Height for range with eye-level oven

plus vent hood: 72” min.

B = Height for range with eye-level oven

alone: 66” min.

C = Width between counters: 3O1/a”

D = Height of countertop: 36”

E= Depth: 25”

F = Receptacle location: 17” max. from

right cabinet and 20” max. from floor.

G = Wall gas line hole location 8’/2” from

left cabinet and

H = Floor gas line hole location: on floor

81/2’1 from left cabinet and back wall.

I = Both gas line holes should be no more

than 221,$” from right cabinet.

The back and sides of this range may be

installed with zero clearance. Vertical walls

extending above the cooktop must have a

minimum horizontal clearance of 6 inches

from the side edges of the cook top.

Overhead cabinets should be a maximum

of 13 inches deep.

It is the responsibility of the installer to

comply with the installation clearance

specified on the rating plate attached to the

appliance.

To prevent discoloration of base cabinet,

front of oven frame must extend at least

l/2"

beyond surface of cabinets.

Do not seal range to cabinets.

The power cord must run downward, left

or right to the wall receptacle to avoid

pinching the cord between rear portion of

the range and wall.

25/,6

from floor.

WARNING:

Reaching over heated surface burners causes risk of

being burned. To reduce risk, installation of cabinet

storage above surface units should be avoided.

If cabinets are already provided, reduce hazard by installing a range hood. Hood should project horizontally beyond bottom of cabinets by a minimum of 5 inches.

B. Check microwave for damage

Remove all packing material from the oven cavity.

When unpacking the unit, check for damage such as

misaligned door, damaged gaskets around the door,

or dents inside the oven or on the exterior. If there is

any damage, please do not operate the unit until it has

been checked by an authorized Whirlpool trained service technician.

3

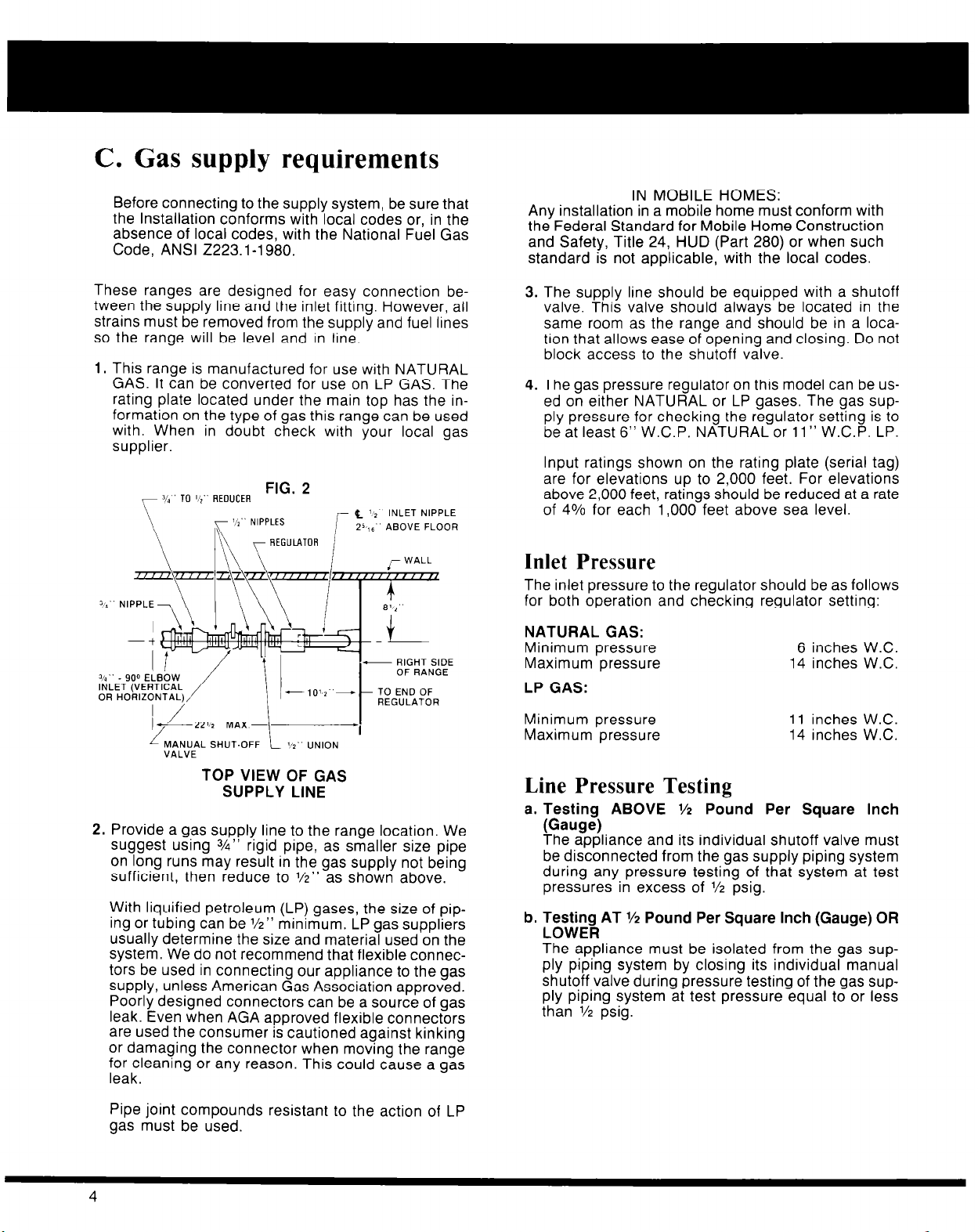

C. Gas supply requirements

Before connecting to the supply system, be sure that

the Installation conforms with local codes or, in the

absence of local codes, with the National Fuel Gas

Code, ANSI 2223.1-l 980.

These ranges are designed for easy connection between the supply line and the inlet fitting. However, all

strains must be removed from the supply and fuel lines

so the range will be level and in line.

1. This range is manufactured for use with NATURAL

GAS. It can be converted for use on LP GAS. The

rating plate located under the main top has the information on the type of gas this range can be used

with. When in doubt check with your local gas

supplier.

3/a” TO ‘2“ REOUCER

m

FIG. 2

‘12” NIPPLES

r REGULATOR

INLET NIPPLE

L ‘12

Z5,s” ABOVE FLOOR

81/Z”

-L

- RIGHT SIDE

214” - 900 ELBOW

INLET (VERTICAL

MANUAL SHUT-OFF

VALVE

-,iJ12.‘-

TOP VIEW OF GAS

SUPPLY LINE

2. Provide a gas supply line to the range location. We

suggest using a/4” rigid pipe, as smaller size pipe

on long runs may result in the gas supply not being

sufficient, then reduce to

l/2”

as shown above.

With liquified petroleum (LP) gases, the size of piping or tubing can be

l/2”

minimum. LP gas suppliers

usually determine the size and material used on the

system. We do not recommend that flexible connectors be used in connecting our appliance to the gas

supply, unless American Gas Association approved.

Poorly designed connectors can be a source of gas

leak. Even when AGA approved flexible connectors

are used the consumer is cautioned against kinking

or damaging the connector when moving the range

for cleaning or any reason. This could cause a gas

leak.

OF RANGE

TO END OF

REGULATOR

IN MOBILE HOMES:

Any installation in a mobile home must conform with

the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD (Part 280) or when such

standard is not applicable, with the local codes.

3. The supply line should be equipped with a shutoff

valve. This valve should always be located in the

same room as the range and should be in a location that allows ease of opening and closing. Do not

block access to the shutoff valve.

4. The gas pressure regulator on this model can be used on either NATURAL or LP gases. The gas supply pressure for checking the regulator setting is to

be at least 6” W.C.P. NATURAL or 11” W.C.P. LP.

Input ratings shown on the rating plate (serial tag)

are for elevations up to 2,000 feet. For elevations

above 2,000 feet, ratings should be reduced at a rate

of

4%

for each 1,000 feet above sea level.

Inlet Pressure

The inlet pressure to the regulator should be as follows

for both operation and checking regulator setting:

NATURAL GAS:

Minimum pressure

Maximum pressure

6 inches W.C.

14 inches W.C.

LP GAS:

Minimum pressure

Maximum pressure

11 inches W.C.

14 inches W.C.

Line Pressure Testing

a. Testing ABOVE l/z Pound Per Square Inch

Gauge)

The appliance and its individual shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of

b. Testing AT 1/2 Pound Per Square Inch (Gauge) OR

LOWER

The appliance must be isolated from the gas sup-

ply piping system by closing its individual manual

shutoff valve during pressure testing of the gas sup-

ply piping system at test pressure equal to or less

than

l/2

psig.

l/2

psig.

Pipe joint compounds resistant to the action of LP

gas must be used.

4

D. Electrical requirements -

Conventional Eyelevel

Check the polarity of the receptacle before plugging in. See “Alternate Grounding Method.”

A 120 Volt, 60 Hz, AC only, 15 Ampere fused electrical

supply is required (time delay fuse or circuit breaker

is recommended). It is recommended that a separate

circuit serving only this appliance be provided. DO NOT

use an extension cord.

The wiring diagram is located on the storage drawer.

1. Recommended grounding method

For your personal safety, electrical ground is re-

quired on this appliance.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE POWER SUPPLY CORD GROUND

PRONG.

This appliance is equipped with a power supply cord

having a 3-prong grounding plug. To minimize possible shock hazard, the cord must be pluged into a

mating 3-prong grounding type wall receptacle, grounded in accordance with the National Electrical Code, ANSllNFPA NO. 70-l 981 l *

dinances. If a mating wall receptacle is not available,

it is the personal responsibility and obligation of the

customer to have a properly grounded 3-prong wall

receptacle installed by a qualified electrician.

XPRONG

GROUNDING TYPE

WALL RECEPTACLE

and local codes and or-

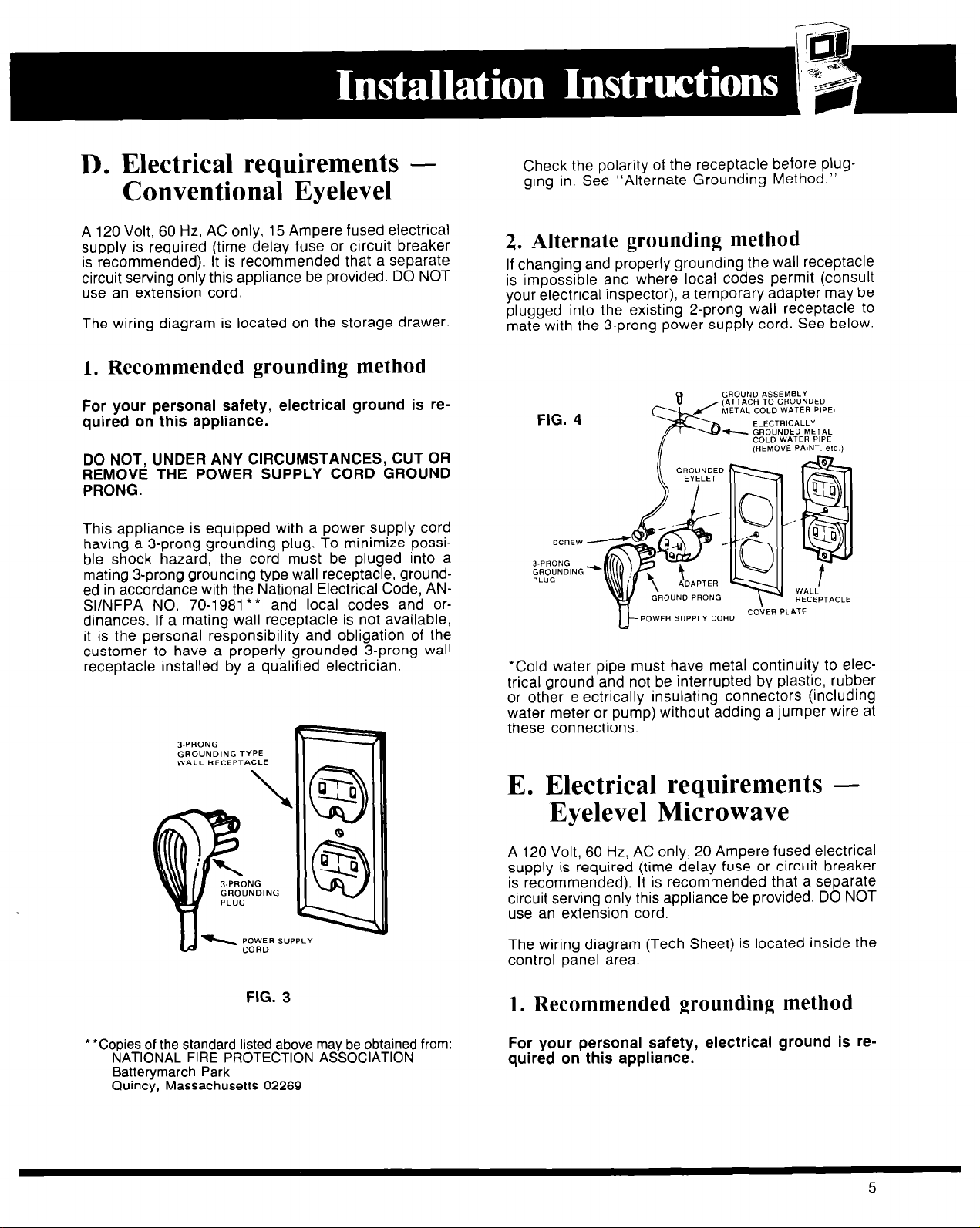

2. Alternate grounding method

If changing and properly grounding the wall receptacle

is impossible and where local codes permit (consult

your electrical inspector), a temporary adapter may be

plugged into the existing 2-prong wall receptacle to

mate with the 3-prong power supply cord. See below.

GROUND ASSEMBLY

(ATTACH TOGROUNDED

FIG. 4

3.PRONG

GAOUNDING

PLUG

OUND PRONG

POWER SUPPLY CORD

*Cold water pipe must have metal continuity to electrical ground and not be interrupted by plastic, rubber

or other electrically insulating connectors (including

water meter or pump) without adding a jumper wire at

these connections.

METAL COLD WATER PIPE)

ELECTRICALLY

- GROUNDED METAL

NG

NDING

\ POWER SUPPLY

CORD

FIG. 3

**Copies of the standard listed above may be obtained from:

NATIONAL FIRE PROTECTION ASSOCIATION

Batterymarch Park

Quincy, Massachusetts 02269

E. Electrical requirements -

Eyelevel Mi&owave

A 120 Volt, 60 Hz, AC only, 20 Ampere fused electrical

supply is required (time delay fuse or circuit breaker

is recommended). It is recommended that a separate

circuit serving only this appliance be provided. DO NOT

use an extension cord.

The wiring diagram (Tech Sheet) is located inside the

control panel area.

1. Recommended grounding method

For your personal safety, electrical ground is required on this appliance.

5

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE POWER SUPPLY CORD GROUND

PRONG.

This appliance is equipped with a power supply cord

having a 3-prong grounding plug. (See Figure 5.) To

minimize possible shock hazard, the cord must be pluged into a mating 3-prong grounding type wall receptacle, grounded in accordance with the National Electrical Code, ANSUNFPA NO. 70-1981 l * and local

codes and ordinances. If a mating wall receptacle is

not available, it is the personal responsibility and obligatton of the customer to have a properly grounded

3-prong wall receptacle installed by a qualified

electrician.

20 AMPERE

GROUNDING TYPE

WALL RECEPTACLE

3-PRONG

GROUNDING

PLUG

\ POWER SUPPLY

-

CORD

FIG. 5

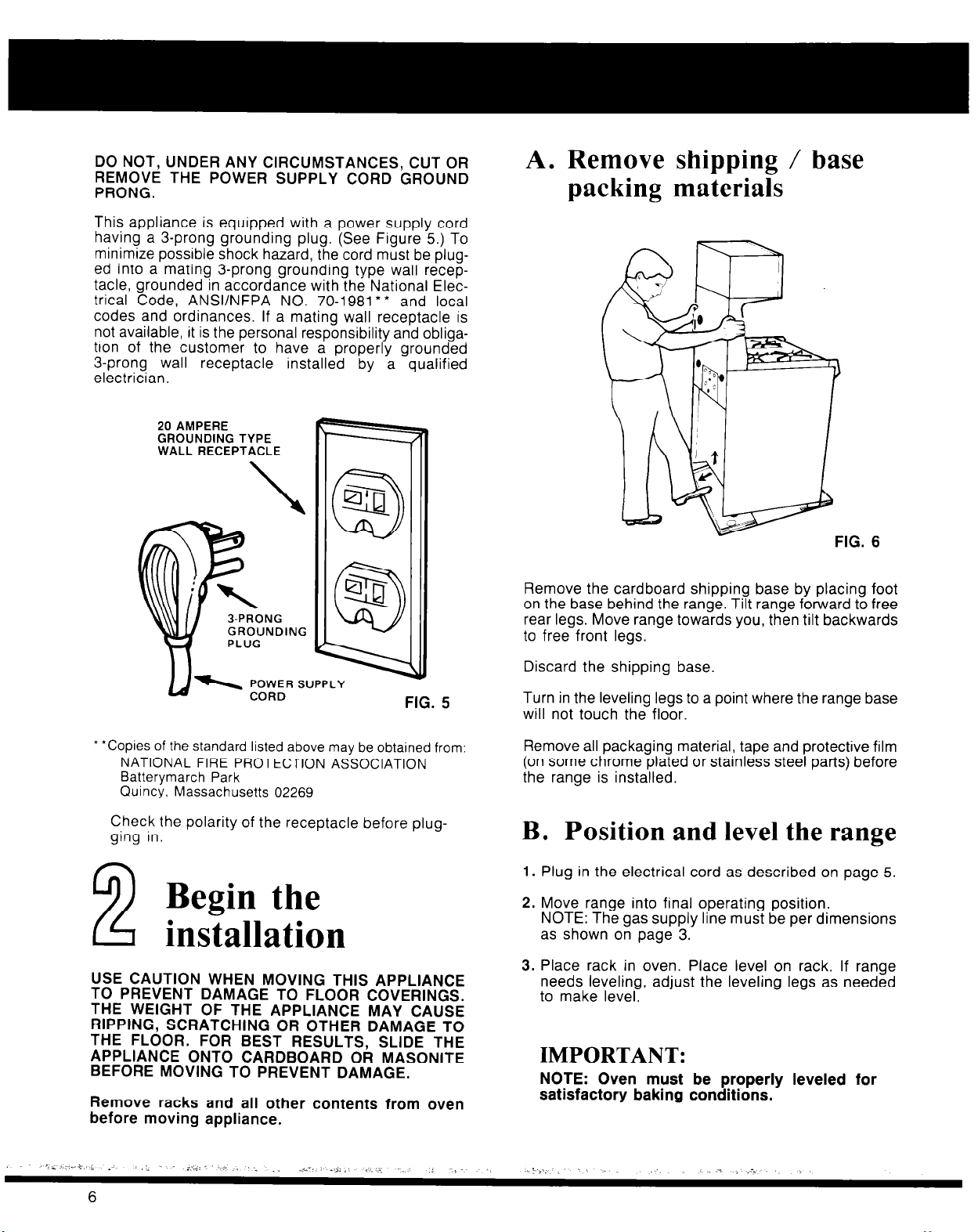

A. Remove shipping / base

packing materials

Remove the cardboard shipping base by placing foot

on the base behind the range. Tilt range forward to free

rear legs. Move range towards you, then tilt backwards

to free front legs.

Discard the shipping base.

Turn in the leveling legs to a point where the range base

will not touch the floor.

l

‘Copies of the standard listed above may be obtained from:

NATIONAL FIRE PROTECTION ASSOCIATION

Batterymarch Park

Quincy, Massachusetts 02269

Check the polarity of the receptacle before plugging in.

9

Begin the

IL7 installation

USE CAUTION WHEN MOVING THIS APPLIANCE

TO PREVENT DAMAGE TO FLOOR COVERINGS.

THE WEIGHT OF THE APPLIANCE MAY CAUSE

RIPPING, SCRATCHING OR OTHER DAMAGE TO

THE FLOOR. FOR BEST RESULTS, SLIDE THE

APPLIANCE ONTO CARDBOARD OR MASONITE

BEFORE MOVING TO PREVENT DAMAGE.

Remove racks and all other contents from oven

before moving appliance.

6

Remove all packaging material, tape and protective film

(on some chrome plated or stainless steel parts) before

the range is installed.

B. Position and level the range

1. Plug in the electrical cord as described on page 5.

2. Move range into final operating position.

NOTE: The gas supply line must be per dimensions

as shown on page 3.

3. Place rack in oven. Place level on rack. If range

needs leveling, adjust the leveling legs as needed

to make level.

IMPORTANT:

NOTE: Oven must be properly leveled for

satisfactory baking conditions.

Loading...

Loading...