Page 1

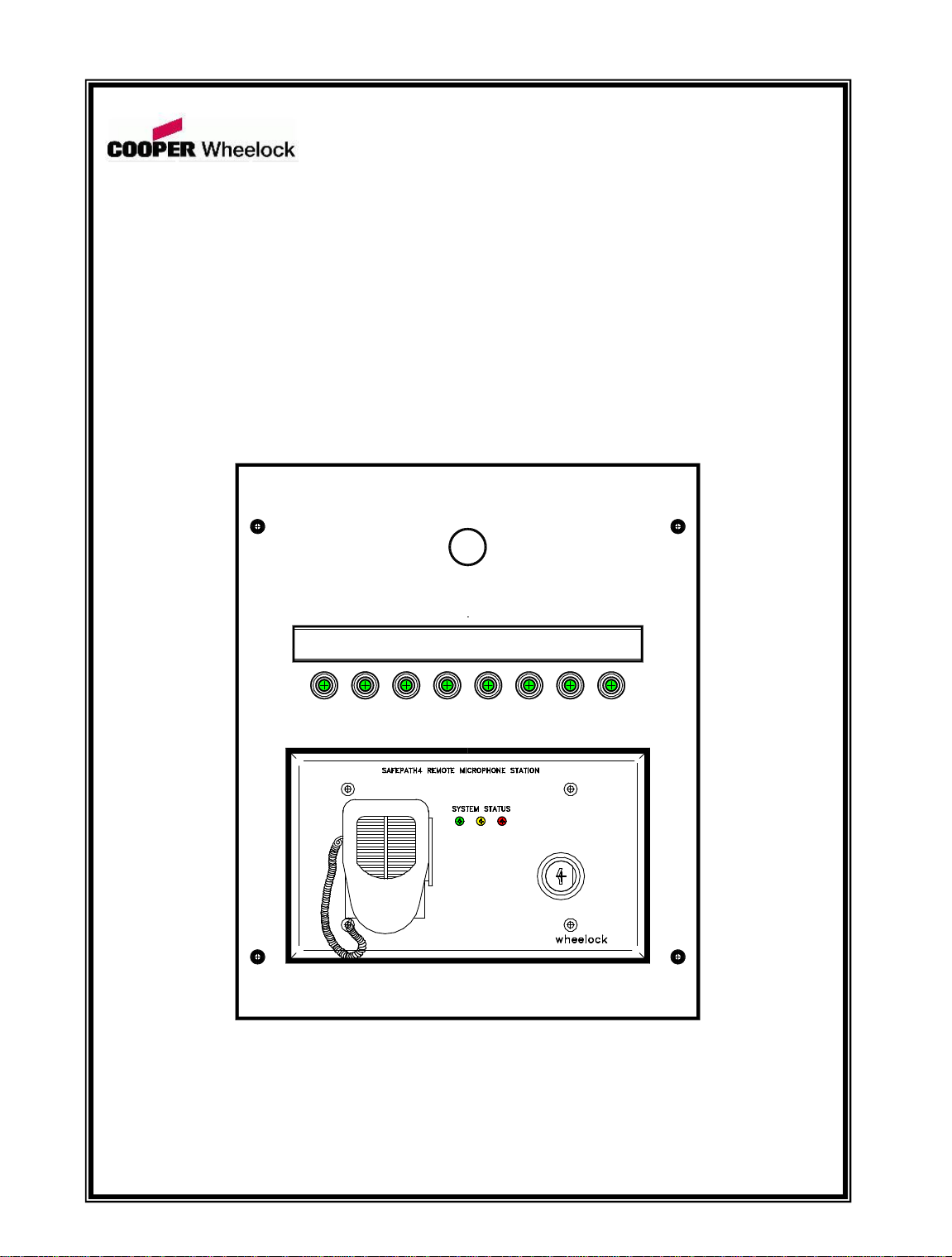

SP4-LOC

SAFEPATH4

REMOTE MICROPHONE AND LOCAL

OPERATOR CONSOLE

INSTALLATION AND OPERATION MANUAL

MASS NOTIFICATION SYSTEM

Part Number: P84767 Rev. A

Copyright 2006 Cooper Wheelock, Inc. All rights reserved.

Page 2

2

Page 3

Introduction

Thank you for using our products. Use this product according to this instruction manual.

Please keep this instruction manual for future reference.

The SP4 –LOC Remote Microphone and Local Operator Console is designed to be used

with the Facility Communications System using the SafePath4 SP40/2 and the SP40S

panels. It contains the SafePath4 SPRM Remote Microphone Module and eight black

Push On /Push Off buttons which provide a contact closure to activate the SP40/2 or the

SP40S digital messages in the Push On position. These buttons change color from black

in the OFF position to green in the ON position. A message name plate holder is located

above the pushbuttons. An optional red mushroom type, cutoff pushbutton is available for

HVAC emergency shutoff.

The Remote Microphone (SPRM) incorporates a Push-To-Talk (PTT) microphone and

system status LED indicators. The SPRM provides a microphone override for any tone

generation, digital voice module prerecorded message, background music, or telephone

paging. It is equipped with a keyed lock that, when activated allows the use of the

module. The key can not be removable in the ON position. The SPRM is fully supervised

from the SP40/2 or SP40S panel and contains front panel LED’s for remote indications of

System Normal, System Trouble and Alarm conditions. Voice frequency response shall

be 275 Hz - -6.5 kHz +/- 2.4 dB. Power requirements shall be 24VDC and will be

supplied by the SP40/2 or SP40S. Input current for standby mode shall be 26mA and

38mA in the alarm mode. Shielded 6-wire cable shall be used. Approvals for the system

shall include; UL Standard 864, UL Standard 1711, FCC Part 15, and CSFM. The panel

shall be OSHA 1910.165 and ADA compliant

The SP4-LOC is available in two models. The flush mount model has a 1/2 inch skirt

around the door section, while the surface mount model door section is flush with the

back box. Both models use the same white 4 inch deep backbox with three 1/2 inch/ 3/4

inch double knockouts, one each in the back center, and top and bottom of the backbox.

The flush mount door section has exterior dimensions of 15-1/2 inches wide and 16-1/4

inches high. The surface mount model has dimensions of 14-1/2 inches wide, 15-1/2

inches high and 4 inches deep. Both models have a pull slam latch to open the continuous

hinged door. Both models are available in white.

The SP4-LOC can be installed up to 2,000 feet from the SP40/2 or SP40S panel using 1418 AWG wiring. Shielded wire is only required for the 1Vrms output from the SPRM.

3

Page 4

Notation Conventions

This manual uses the following notation conventions:

INDICATES A POTENTIALLY HAZARDOUS SITUATION THAT, IF NOT

AVOIDED, COULD RESULT IN SERIOUS PERSONAL INJURY OR DEATH

TO YOU AND OR OTHERS.

Indicates a potentially hazardous situation that, if not avoided, could result in minor or

moderate injury. It may also be used to alert against unsafe practices.

Safety

De-energize all electrical circuits and equipment associated with installing the SP4-LOC.

If the HVAC Pushbutton option is being added, the circuit can contain high voltage that

can cause serious injury or death to the installer.

Additional copies of this manual may be obtained from www.cooperwheelock.com in the

Technical Support section, or from:

Cooper Wheelock, Inc.

273 Branchport Ave.

Long Branch, N.J. 07740

Tel: (732) 222- 6880

Fax: (732) 222- 2588

E-mail: info@cooperwheelock.com

4

Page 5

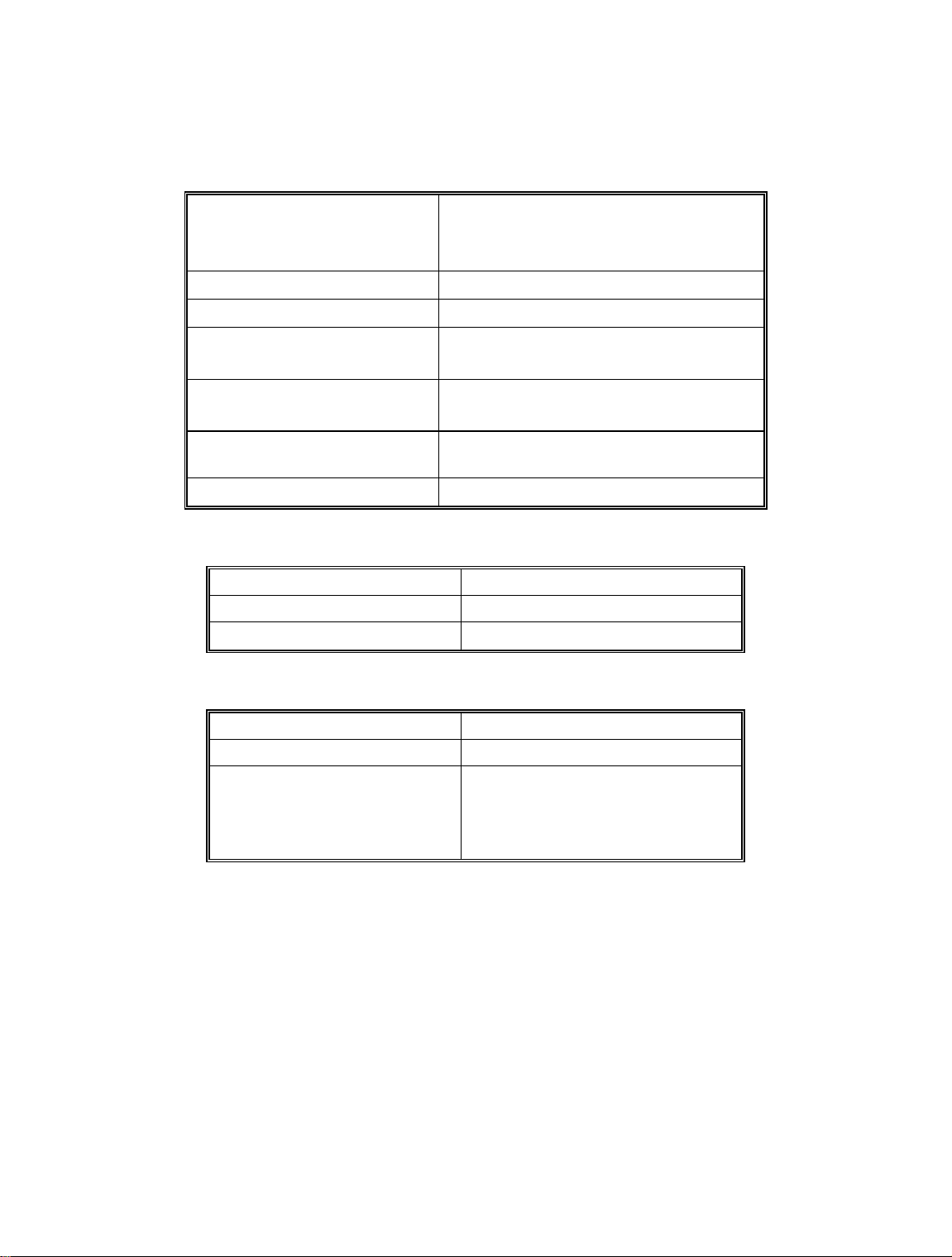

Technical Specifications

Dimensions (H x W x D)

See Figure 1.

Backbox: 15 1/4 x 14 1/2 x 4 in.

Surface Front: 15 1/4 x 14 1/2 x 1/8 in.

Flush Front: 16 1/4 x 15 1/2 x 1/8 in.

Weight

8 lb.

Finish

White

Mounting

Indoor surface mount

Indoor flush mount

Wiring

Entry

Top, bottom and back knockouts (1/2”

and 3/4”) (3 total)

Door Lock

Pull slam latch with 1/8” security tamper

indicator installation holes

PC Boards

SPRM

Operating Temperature

0 to 49 °C (32 to 120 °F)

Storage Temperature

-20 to 70 °C (-4 to 158 °F)

Humidity, Non-condensing

85±5% at 30±2 °C (86 4 °F)

Pushbutton switch rating

30 VDC at ½ Amp (15 Watts)

HVAC mushroom pushbutton

230VAC at 3 Amps.

SPRM from the SP40S

Maximum distance from SP40S

is 2,000 feet using 14–18 AWG

shielded wire.

6 wire

Input Voltage 24VDC at .038 Amps

1Vrms audio output to SP40S.

Contact closure to SP40S.

Mechanical

Environmental

Electrical

5

Page 6

MASS NOTIFICATION

SYSTEM

15.50"

14.50"

16.25"

15.25"

BACKBOX OUTLINE

TRIM RING 1/2"

PANEL DOOR

Figure 1. Outside Dimensions for the SP4-LOC Front

Mounting

COMPLY WITH ALL OF THE LATEST APPLICABLE CODES, REGULATIONS, LAWS,

STANDARDS, AND GUIDELINES.

1. Remove the FRONT DOOR ASSEMBLY from the backbox by removing the eight (8)

nuts holding the assembly in place.

2. Remove the INNER DOOR ASSEMBLY (Figure 2) and terminal block from the

backbox.

6

Page 7

MASS NOTIFICATION SYSTEM

SAFEPATH4 REMOTE

MICROPHONE (SPRM)

EIGHT (8) PUSH ON/PUSH OFF

BUTTON SWITCHES (WHEN THE

GREEN PUSH SWITCH IS PUSHED

TO THE ON POSITION, THE COLOR

CHANGES TO BLACK.)

MESSAGE NAMEPLATE

HOLDER

MOUNTING HOLE FOR

OPTIONAL HVAC

EMERGENCY CUTOFF

PUSHBUTTON

#8-32 TRUSS HEAD SCREWS FOR

MOUNTING THE INNER DOOR

Figure 2. Inner Door Assembly

2. Mount the backbox assembly. See Figure 3 for mounting holes. Insure that the

orientation label inside the backbox is pointing “UP” and that the studs for mounting

the terminal block are on the left side.

NOTE: All mounting holes are laser cut as knockouts. Punch out the holes required for

either flush or surface mounting.

7

Page 8

14.50"

15.25"

9.25"

11.00"

SURFACE

MOUNT

HOLES (4)

FLUSH

MOUNT

HOLES (8)

1/4"x1/2"

DOUBLE KNOCKOUT (3)

TOP, BOTTOM, AND BACK

1/2"/3/4"

TERMINAL BLOCK

MOUNTING STUDS

#8-32

Figure 3. Mounting Holes for Mounting the Backbox, Flush and Surface

3. Connect conduit fittings to the desired cable knockouts, and run the appropriate

pushbutton and SPRM wiring into the backbox.

If the optional HVAC pushbutton is installed, run the HVAC wiring through a separate

conduit away from the push button and remote microphone wiring. This will prevent

electrical interference and false troubles from appearing on the SP40S.

NOTE: If the SP4-LOC is being flush mounted and finish work on the location has to be

completed, stop here and complete the work before connecting and mounting the

inner and outer doors.

8

Page 9

Installing and Wiring the Inner Door

MASS NOTIFICATION SYSTEM

_

_

+

_

+

+

TB7

IN1

IN2

IN3

IN4

_

+

_

+

_

+

IN5

IN6

SP40/2

SP4-3MEM

_

_

+_+

+

TB1

24V

S1 S2 S3 S4 S5 S6 S7 S8

SP4-LOC HARNESS WIRING

S1

S2

S8

S7

S6

S5

S4

S3

4. Place the terminal block with the wire harness pointing down, onto the terminal block

studs.

5. Connect the wire tie around the harness and to the bottom terminal block stud.

6. Using the washers and nuts, fasten the terminal block to the backbox..

7. If applicable, mount and wire the optional HVAC Emergency Shutoff pushbutton.

8. Connect the pushbutton wiring to the terminal block as shown in Figure 4 (SP40/2) and

Figure 5 (SP40S).

Figure 4. Wiring Diagram SP4-LOC to SP40/2

NOTE: The SP40/2 requires a 9 to 31VDC input in order to initiate a digital message.

9

Page 10

MASS NOTIFICATION SYSTEM

S1 S2 S3 S4 S5 S6 S7 S8

SP4-LOC HARNESS WIRING

S1

S2

S8

S7

S6

S5

S4

S3

_

_

+

_

+

+

TB7

_

+

IN1

IN2

IN3

IN4

_

_

+

_

+

+

TB8

_

+

IN5

IN6

IN7

IN8

SP40S

Figure 5. Wiring Diagram SP4-LOC to SP40S

NOTE: The SP40S inputs can be supervised by placing a 10K Ohm resistor across each

pair of input terminals on the SP4-LOC terminal block and by switching ON the

DIP switches on switch block SW7 positions 1 through 8.

9. Connect the SPRM to the SP40. Figure 6 shows the proper wiring connections for the

SPRM to the SP40/2. Figure 7 shows the proper wiring connections for the SPRM to

the SP40S.

10

Page 11

REMOTE MICROPHONE

SP40/2 PANEL

AUDIO OUT

AUX IN

CC/NAC

+

-

+

-

TB6

24VDC

RM AUDIO

STATUS (CC)

-

+

-

+

654321

+

-

+

-

+

+

+

-

-

IN

BAT

24V

Figure 6. Wiring Diagram SPRM to SP40/2

REMOTE MICROPHONE

SP40S PANEL

24V OUT

AUX

CC/NAC

+

-

+

-

TB6

24VDC

RM AUDIO

STATUS (CC)

-

+

-

+

654321

+

-

+

-

This wiring is power limited.

Figure 7. Wiring Diagram SPRM to SP40S

This wiring is power limited.

10. Mount the INNER DOOR to the backbox using the four #8-32 truss head screws and

plastic washers.

11. Mount the FRONT DOOR to the backbox using the eight washers and #8-32 nuts in

the locations shown in Figure 11.

NOTE: Figure 8 shows a diagram of a surface mount FRONT DOOR with a dotted line

indicating the trim ring for a flush mount door.

11

Page 12

MASS NOTIFICATION

SYSTEM

1/8" SECURITY

WIRE HOLES

SLAM LATCH

#8-32 X 3/4" STUDS (8)

ON BACK OF FRONT RING

1/2" TRIM RING ON FLUSH

MOUNT MODEL FRONT RING

Figure 8. Front Door Layout

_

_

+

_

+

+

TB6

AUX

IN

AUX

CC/NAC

AUX IN

NAC

CC

W5

W4

SW4

100V

70V

25V

1V

AUDIO OUT

AUXILIARY INPUT SELECTION

JUMPER J4. SELECT 1V POSITION

CC/NAC SWITCH SW4

PLACE IN CC POSITION

AUXILIARY INPUT SUPERVISION

JUMPER W5. REMOVE FOR

SUPERVISION.

Operating Instructions:

SP40/2 Panel

Figure 9. Switch locations on the SP40/2 for SPRM Operation

12

Page 13

Figure 9 shows the locations of the switches and LED’s on the SP40/2 that are required

_

_

+

_

+

+

TB6

AUX

CC/NAC

24V OUT

CC/NAC

SW6

100V

70V

25V

1V

J4

AUX

IN

AUX

SUP

JP4

SP40S

CC/NAC SWITCH SW6

PLACE IN CC POSITION

AUXILIARY INPUT SELECTION

JUMPER J4. SELECT 1V POSITION

AUXILIARY INPUT SUPERVISION

JUMPER JP4. REMOVE FOR

SUPERVISION.

for SPRM operation.

1. Set the NAC/CC switch (SW4) on the SP40/2 PC board to the CC position.

2. Set the AUX IN jumper J2 to the 1V position.

3. Remove AUX SUP jumper (W5).

4. Install a UL Listed 10K Ohm End of Line Resistor (EOLR) on the AUX IN of

SP40/2.

SP40S Panel

Figure 10. Switch and Jumper locations on the SP40S for SPRM Operation

See Figure 10 for switch and jumper locations.

1. Set the NAC/CC Switch (SW6) on the SP40S PC board to the CC position.

2. Set the AUX IN jumper J4 to the 1V position.

3. Remove AUX SUP jumper (JP4)

Testing

1. Energize the SP40/2 or SP40S Panel. Install the backup batteries.

2. Test each pushbutton circuit to insure the SP4-LOC is operational.

3. Insert key and turned to the ON position for the controls to function. (The key is

removable only in the OFF position.)

13

Page 14

HVAC

SHUTOF F

1

2

1

2

3

5

4

3

MASS NOTIFICATION SYSTEM

4

INNER PANEL

BACK BOX

FRONT DOOR ASSEMBLY

5

6

6

7

7

(SURFACE AND FLUSH)

8

SYSTEM

MASS NOTIFICATION

8

PARTS LEGEND:

ELECTRICAL CONDUIT AND FIELD WIRES.

(1/2" AND 3/4" KNOCKOUTS PROVIDED ON

TOP, BOTTOM AND BACK FACE.)

SP4-LOC BACKBOX

ORIENTATION LABEL

#8-32 TRUSS HEAD (4) INNER PANEL

MOUNTING SCREW

TERMINAL STRIP AND WIRING HARNESS

1/4" DIAMETER HOLE (6) TO ACCEPT #8-32

STUDS FROM FRONT DOOR PANEL. #8-32

SEMS NUT (6) PROVIDED.

OPTIONAL "HVAC SHUTOFF" LABEL AND

MUSHROOM HEAD PUSHBUTTON SWITCH

1/8" HOLES (2) FOR SECURITY TAMPER

INDICATOR

Figure 11. Exploded View of the Sp4-LOC

14

Page 15

Warranty

Limited Warranty

Cooper Wheelock, Inc. products must be used within their published specifications and

must be PROPERLY specified, applied, installed, operated, maintained, and

operationally tested in accordance with these instructions at the time of installation and at

least twice a year or more often in accordance with local, state and federal codes,

regulations and laws. Specification, application, installation, operation, maintenance, and

testing must be performed by qualified personnel for proper operation in accordance with

all of the latest National Fire Protection Association (NFPA), Underwriters' Laboratories

(UL), Underwriters’ Laboratories of Canada (ULC), National Electrical Code (NEC),

Occupational Safety and Health Administration (OSHA), local, state, county, province,

district, federal and other applicable building and fire standards, guidelines, regulations,

laws and codes including, but not limited to, all appendices and amendments and the

requirements of the local authority having jurisdiction (AHJ). Cooper Wheelock, Inc.

products when properly specified, applied, installed, operated, maintained, and

operationally tested as provided above are warranted against mechanical and electrical

defects for a period of three years from date of manufacture (as determined by date code).

Correction of defects by Cooper Wheelock, Inc providing repairs or a replacement shall

be at Cooper Wheelock, Inc.'s sole discretion and shall constitute fulfillment of all

warranty obligations.

The foregoing limited warranty shall immediately terminate in the event any part not

furnished by Cooper Wheelock, Inc. is installed in the product. The foregoing limited

warranty specifically excludes any software required for the operation of or included in a

product. COOPER WHEELOCK, INC. MAKES NO REPRESENTATION OR

WARRANTY OF ANY OTHER KIND, EXPRESS, IMPLIED OR STATUTORY

WHETHER AS TO MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE OR ANY OTHER MATTER.

Users are solely responsible for determining whether a product is suitable for the user's

purposes, or whether it will achieve the user's intended results. There is no warranty

against damage resulting from misapplication, improper specification, abuse, accident, or

other operating conditions beyond Cooper Wheelock, Inc.'s control.

Some Cooper Wheelock, Inc. products contain software. With respect to those products,

Cooper Wheelock, Inc. does not warranty that the operation of the software will be

uninterrupted or error-free or that the software will meet any other standard of

performance, or that the functions or performance of the software will meet the user's

requirements. Cooper Wheelock, Inc. shall not be liable for any delays, breakdowns,

interruptions, loss, destruction, alteration, or other problems in the use of a product

arising out of or caused by the software.

The liability of Cooper Wheelock, Inc. arising out of the supplying of a product, or its

use, whether based on warranty, negligence, or otherwise, shall not in any case exceed

the cost of correcting defects as stated in the limited warranty and upon expiration of the

warranty period all such liability shall terminate. Cooper Wheelock, Inc. is not liable for

labor costs incurred in removal, reinstallation, or for damage of any type whatsoever,

including but not limited to, loss of profit or incidental or consequential damages. The

15

Page 16

foregoing shall constitute the sole remedy of the purchaser and the exclusive liability of

Cooper Wheelock, Inc.

In no case will Cooper Wheelock, Inc.'s liability exceed the purchase price paid for a

product.

Limitation of Liability

Cooper Wheelock, Inc.'s liability on any claim of any kind, including negligence, breach

of warranty, or otherwise, for any loss or damage resulting from, arising out of, or

connected with any contract, or from the manufacture, sale, delivery, resale, repair or use

of any product shall be limited to the price applicable to the product or part thereof which

gives rise to the claim. Cooper Wheelock, Inc.'s liability on any claim of any kind shall

cease immediately upon the installation in the product of any part not furnished by

Cooper Wheelock, Inc. In no event shall Cooper Wheelock, Inc. be liable for any claim

of any kind unless it is proven that our product was a direct cause of such claim.

FURTHER, IN NO EVENT, INCLUDING IN THE CASE OF A CLAIM OF

NEGLIGENCE, SHALL COOPER WHEELOCK, INC. BE LIABLE FOR

INCIDENTAL, INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES. Some

states do not allow the exclusion or limitation of incidental or consequential damages, so

the preceding limitation may not apply to all purchasers.

16

Loading...

Loading...