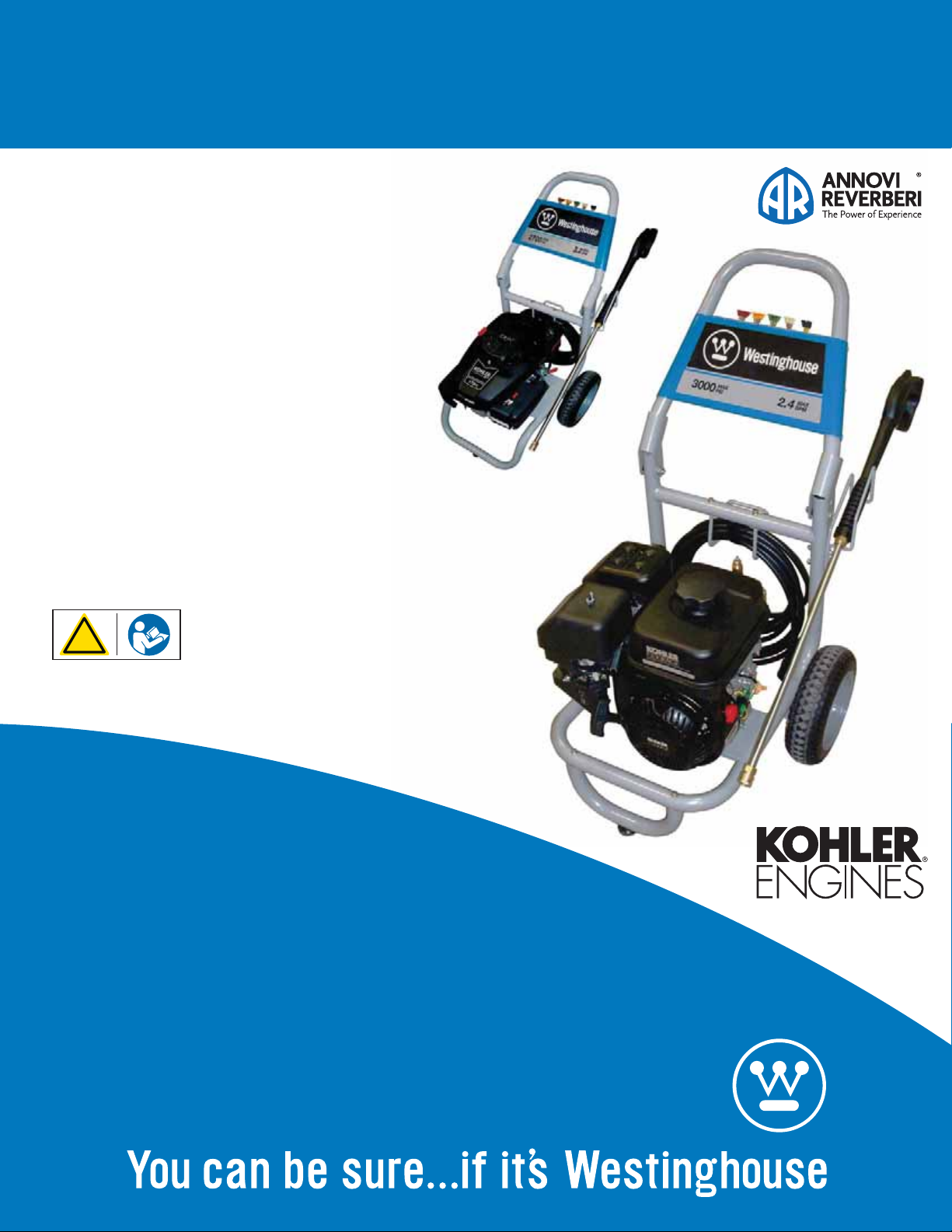

Westinghouse WP2700, WP3000 Owner's Manual

Pressure Washer

Owner’s Manual

Manual del Propietario

WP2700

WP3000

!

California

Proposition 65 Warning

The engine exhaust from this product

contains chemicals known to the state of

California to cause cancer, birth defects

or other reproductive harm.

Proposition 65 Warning

Certain components in this product and its

related accessories contain chemicals

known to the state of California to cause

cancer, birth defects or other reproductive

harm. Wash hands after handling.

California

DISCLAIMERS:

All information, illustrations and specifi cations in this manual are based on the latest information available at

the time of publishing. The illustrations used in this manual are intended as representative reference views only.

Moreover, because of our continuous product improvement policy, we may modify information, illustrations and/or

specifi cations to explain and/or exemplify a product, service or maintenance improvement. We reserve the right to

make any change at any time without notice.

ALL RIGHTS RESERVED:

No part of this publication may be reproduced or used in any form by any means – graphic, electronic or

mechanical, including photocopying, recording, taping or information storage and retrieval systems – without the

written permission of Westpro Power Systems, LLC.

2

CONGRATULATIONS ON OWNING A WESTINGHOUSE

PRESSURE WASHER

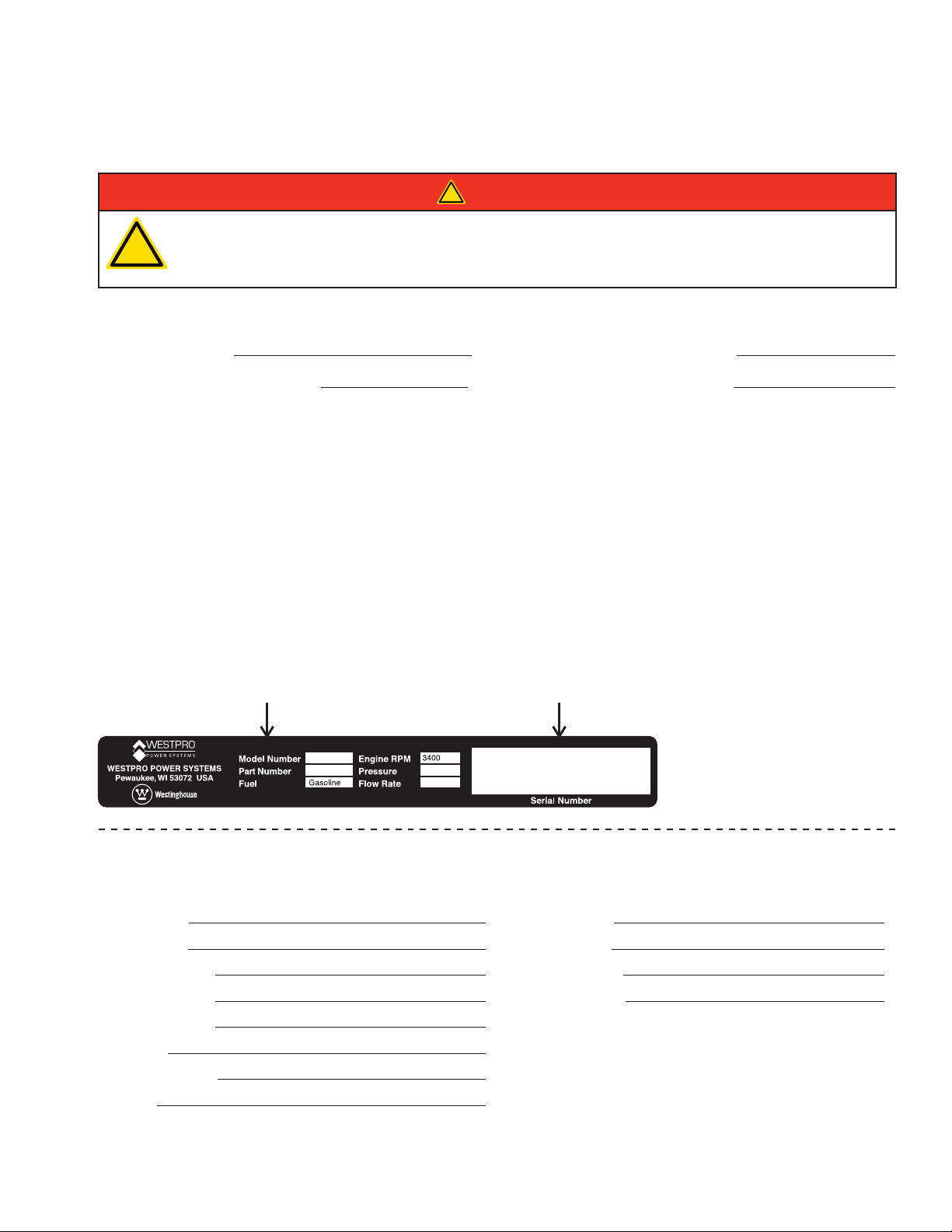

!

DANGER

This manual contains important instructions for operating this pressure washer. For your safety

!

For Your Records

Date of Purchase: Pressure Washer Model Number:

Purchased from Store/Dealer: Pressure Washer Serial Number:

Purchase Receipt: (retain your purchase receipt to ensure trouble-free warranty coverage)

Product Registration

To ensure trouble-free warranty coverage, it is important you register your Westinghouse pressure washer. You can

register your pressure washer by either:

1. Filling in the product registration form below and mailing to:

2. Registering your product online at www.westpropower.com/register.iml

To register your pressure washer you will need to locate the following information:

and the safety of others, be sure to read this manual thoroughly before operating the pressure

washer. Failure to properly follow all instructions and precautions can cause you and others to

be seriously hurt or killed.

Product Registration

Westpro Power Systems, LLC

W237 N2889 Woodgate Road, Unit B

Pewaukee, WI 53072

Model Number Serial Number

WP3000

23000

3000 PSI

2.4 GPM

Product Registration Form

PERSONAL INFORMATION PRESSURE WASHER INFORMATION

First Name: Model Number:

Last Name: Serial Number:

Street Address: Date Purchased:

Street Address: Purchased From:

City, State, ZIP:

Country:

Phone Number:

E-Mail:

TABLE OF CONTENTS

CONGRATULATIONS ON OWNING A WESTINGHOUSE PRESSURE WASHER ...........................................3

For Your Records ..........................................................................................................................................3

Product Registration .....................................................................................................................................3

Product Registration Form ............................................................................................................................3

SAFETY ....................................................................................................................................................................7

SAFETY DEFINITIONS ......................................................................................................................................7

SAFETY SYMBOL DEFINITIONS ......................................................................................................................7

GENERAL SAFETY RULES ...............................................................................................................................8

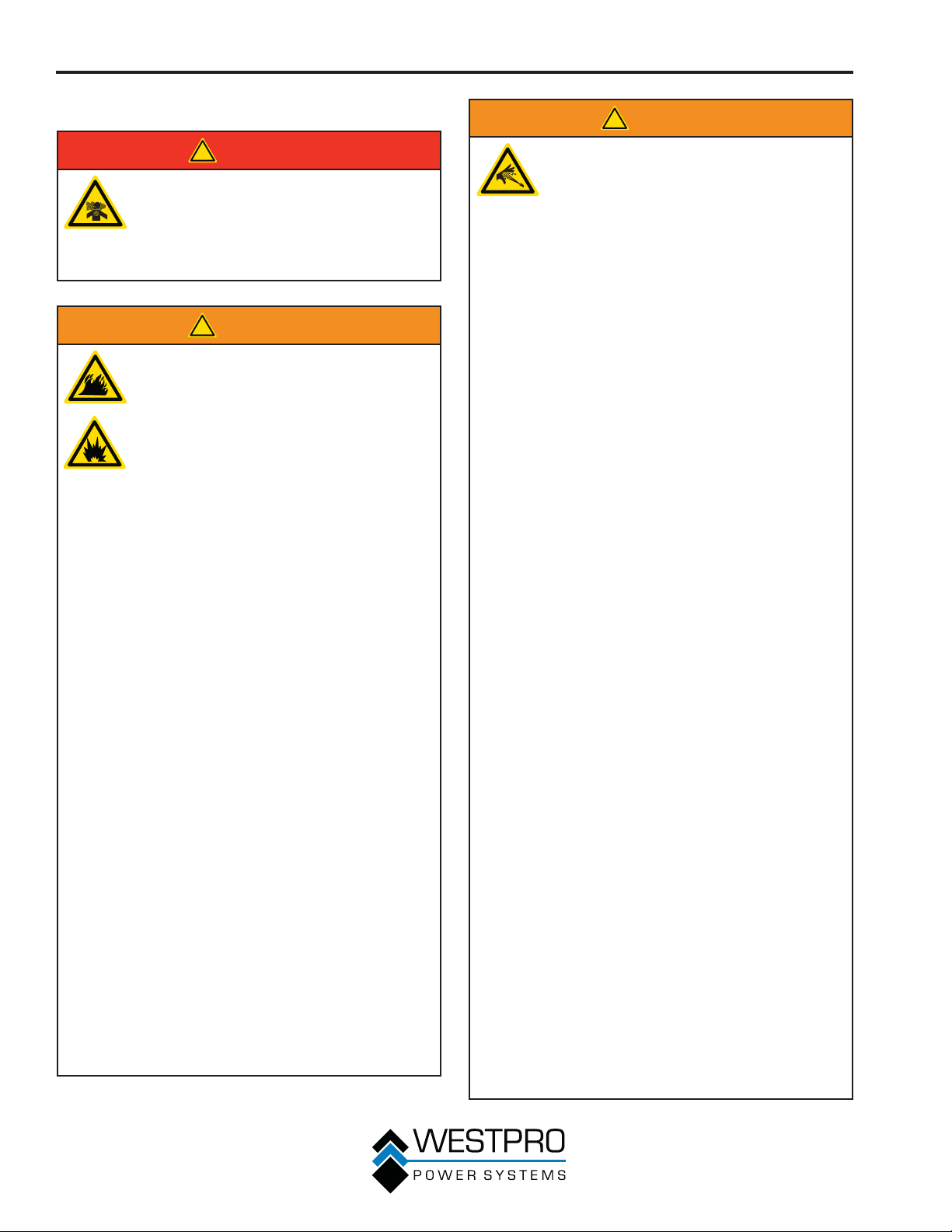

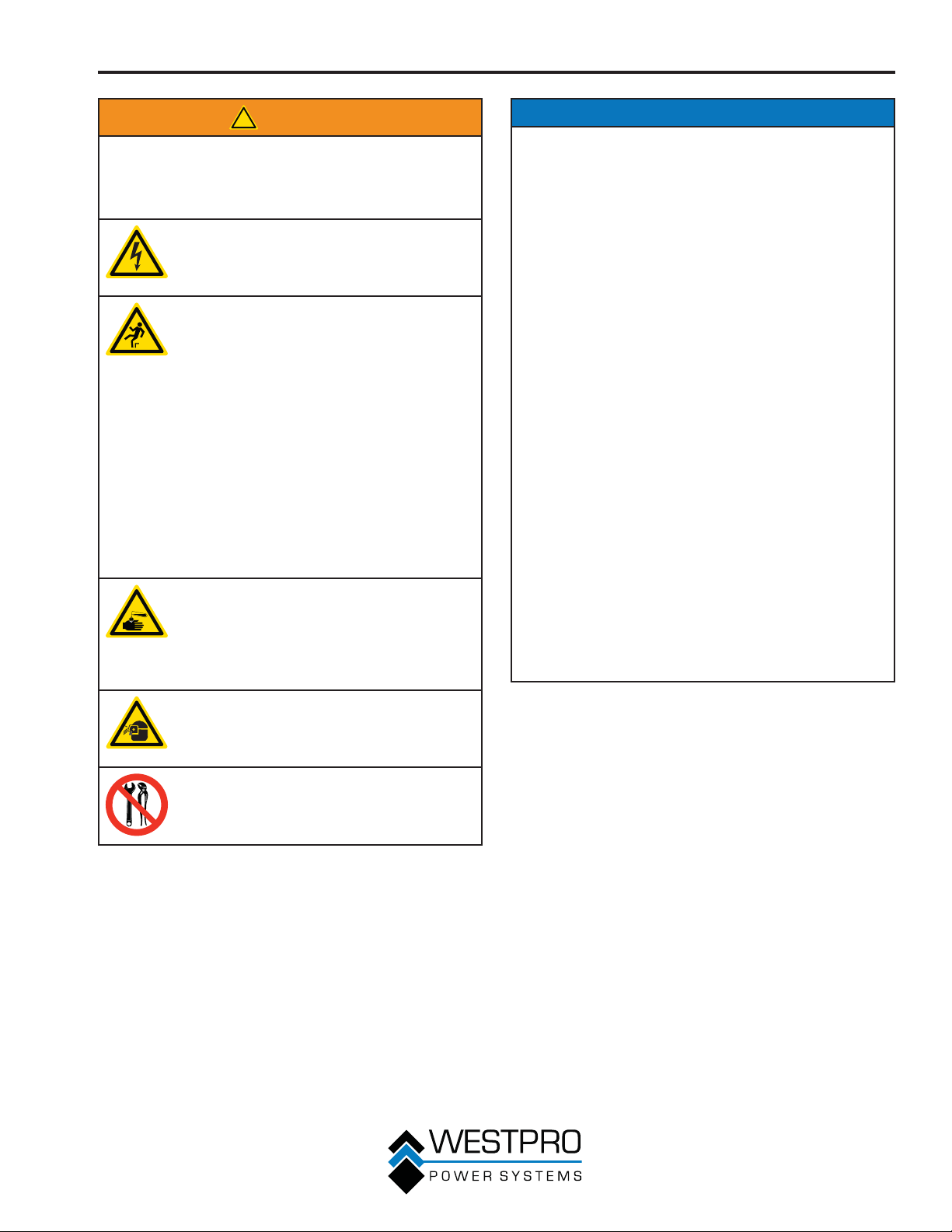

SAFETY LABELS AND DECALS .....................................................................................................................10

WP2700 ......................................................................................................................................................10

WP3000 ......................................................................................................................................................11

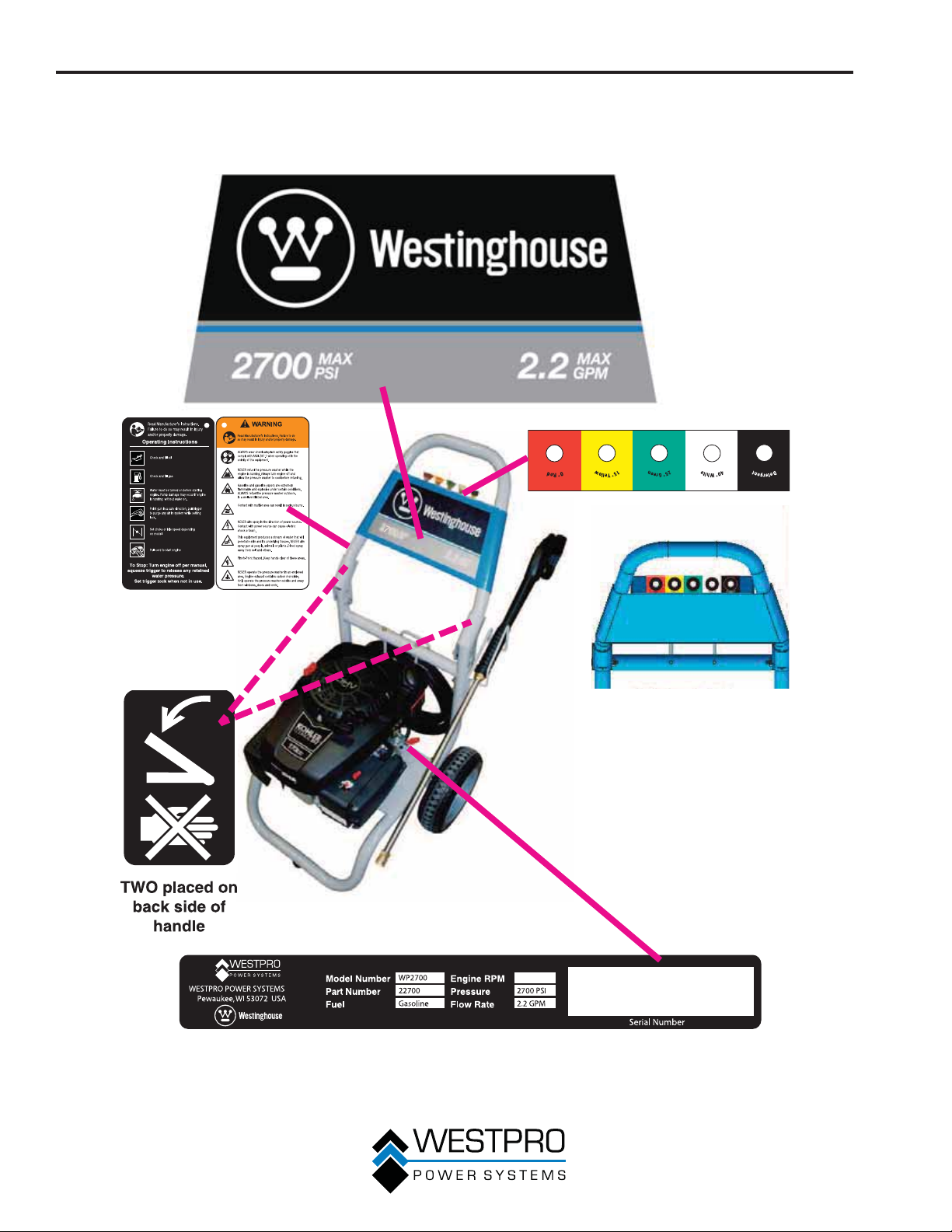

UNPACKING ...........................................................................................................................................................12

UNPACKING THE PRESSURE WASHER ........................................................................................................12

COMPONENTS ................................................................................................................................................12

ASSEMBLY .............................................................................................................................................................13

ASSEMBLY .......................................................................................................................................................13

FEATURES .............................................................................................................................................................17

GENERAL PRESSURE WASHER FEATURES ................................................................................................17

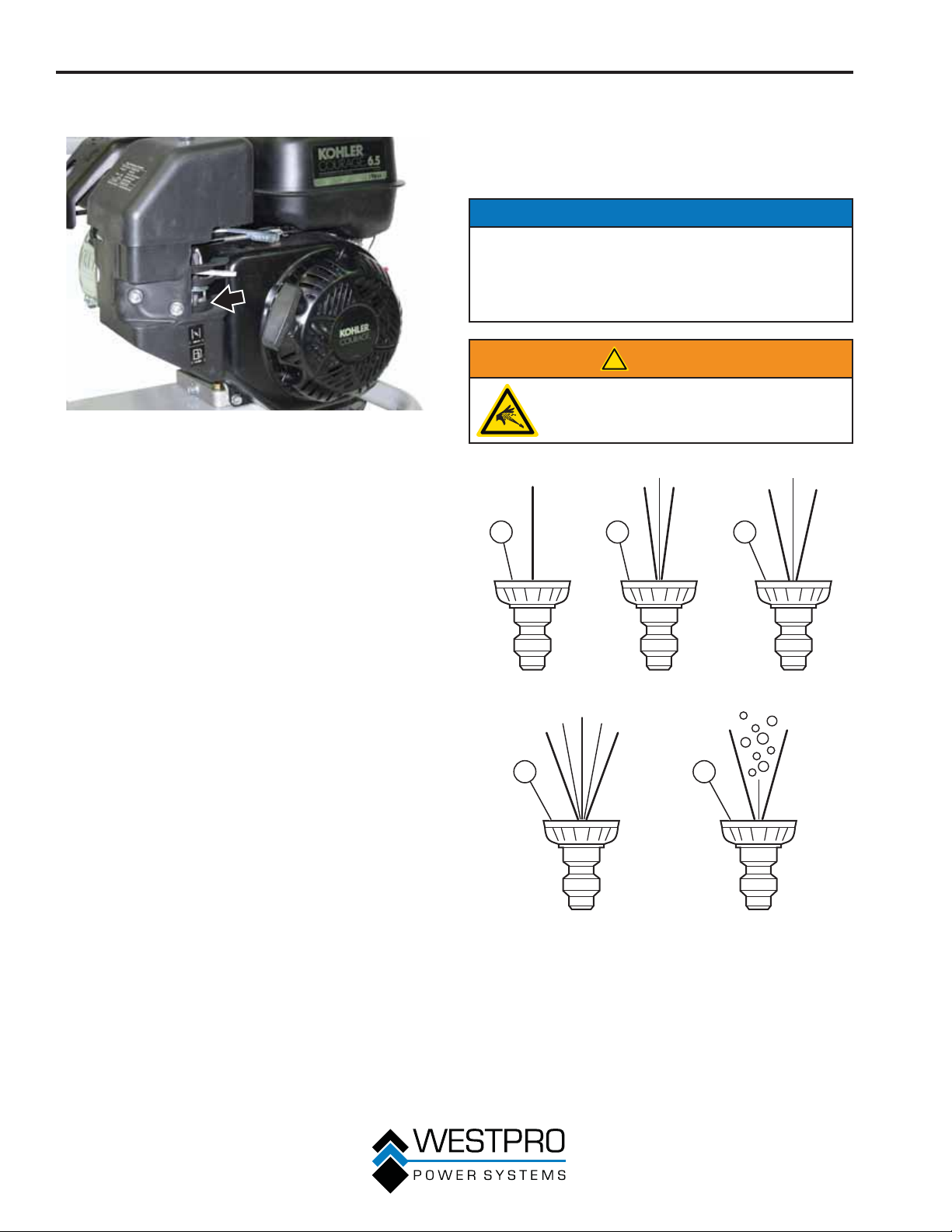

WP2700 ......................................................................................................................................................17

WP3000 ......................................................................................................................................................19

OPERATION ...........................................................................................................................................................21

BEFORE STARTING THE PRESSURE WASHER ...........................................................................................21

ADDING / CHECKING ENGINE FLUIDS AND FUEL .......................................................................................21

Checking and / or Adding Engine Oil ..........................................................................................................21

Adding Gasoline to the Fuel Tank ...............................................................................................................22

CONNECTING THE WATER SUPPLY ..............................................................................................................22

STARTING THE PRESSURE WASHER ...........................................................................................................23

STOPPING THE PRESSURE WASHER ..........................................................................................................25

Normal Operation .......................................................................................................................................25

During an Emergency .................................................................................................................................26

SELECTING NOZZLES ....................................................................................................................................26

Changing the Nozzle ..................................................................................................................................27

SPRAYING TIPS ...............................................................................................................................................27

SPRAYING SOAP .............................................................................................................................................28

RINSING ...........................................................................................................................................................28

CLEANING SOAP SIPHON HOSE ...................................................................................................................28

MAINTENANCE ......................................................................................................................................................29

MAINTENANCE ................................................................................................................................................29

Maintenance Schedule ...............................................................................................................................29

Model WP2700 ..................................................................................................................................... 30

Model WP3000 ..................................................................................................................................... 30

ENGINE OIL MAINTENANCE ..........................................................................................................................31

Engine Oil Specifi cation ..............................................................................................................................31

Checking Engine Oil ...................................................................................................................................31

Model WP2700 ..................................................................................................................................... 31

Model WP3000 ..................................................................................................................................... 31

Adding Engine Oil .......................................................................................................................................32

Changing Engine Oil ...................................................................................................................................32

Model WP2700 ..................................................................................................................................... 32

Model WP3000 ..................................................................................................................................... 33

AIR FILTER MAINTENANCE ............................................................................................................................33

Model WP2700 ...........................................................................................................................................33

Model WP3000 ...........................................................................................................................................34

SPARK PLUG MAINTENANCE ........................................................................................................................35

PRESSURE WASHER COMPONENTS ...........................................................................................................36

Water Filter Screen .....................................................................................................................................36

5

TABLE OF CONTENTS

High-Pressure Hose and Spray Gun ..........................................................................................................36

High-Pressure Hose .............................................................................................................................36

Spray Gun ............................................................................................................................................36

Soap Siphon Hose ......................................................................................................................................37

Nozzle .........................................................................................................................................................37

AFTER EACH USE ...........................................................................................................................................37

LONG-TERM STORAGE ..................................................................................................................................38

Storage Procedure for 1 – 3 Months ...........................................................................................................38

Storage Procedure for Greater Than 3 Months ..........................................................................................38

WINTER STORAGE ..........................................................................................................................................38

Remove and Install the Pump – WP2700 ...................................................................................................38

Remove and Install the Pump – WP3000 ...................................................................................................39

TROUBLESHOOTING ............................................................................................................................................40

TROUBLESHOOTING ......................................................................................................................................40

WARRANTY ............................................................................................................................................................42

WESTPRO POWER SYSTEMS “THREE YEAR” LIMITED WARRANTY .........................................................42

WESTPRO’S RESPONSIBILITY ................................................................................................................42

OWNER’S RESPONSIBILITY ....................................................................................................................42

PRODUCT WARRANTY APPLICATIONS AND PRODUCT WARRANTY PERIODS ................................42

CONSUMER APPLICATION ................................................................................................................42

COMMERCIAL APPLICATION ............................................................................................................42

EXCLUSIONS ......................................................................................................................................43

DISCLAIMER OF IMPLIED WARRANTIES ................................................................................................43

EMISSIONS CONTROL WARRANTY ....................................................................................................................44

FEDERAL AND/OR CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT ....................................44

YOUR WARRANTY RIGHTS AND OBLIGATIONS ....................................................................................44

MANUFACTURER’S WARRANTY COVERAGE: .......................................................................................44

OWNER’S WARRANTY RESPONSIBILITIES: ...........................................................................................44

DEFECTS WARRANTY REQUIREMENTS ................................................................................................44

WARRANTED PARTS: ...............................................................................................................................45

QUESTIONS: ..............................................................................................................................................46

6

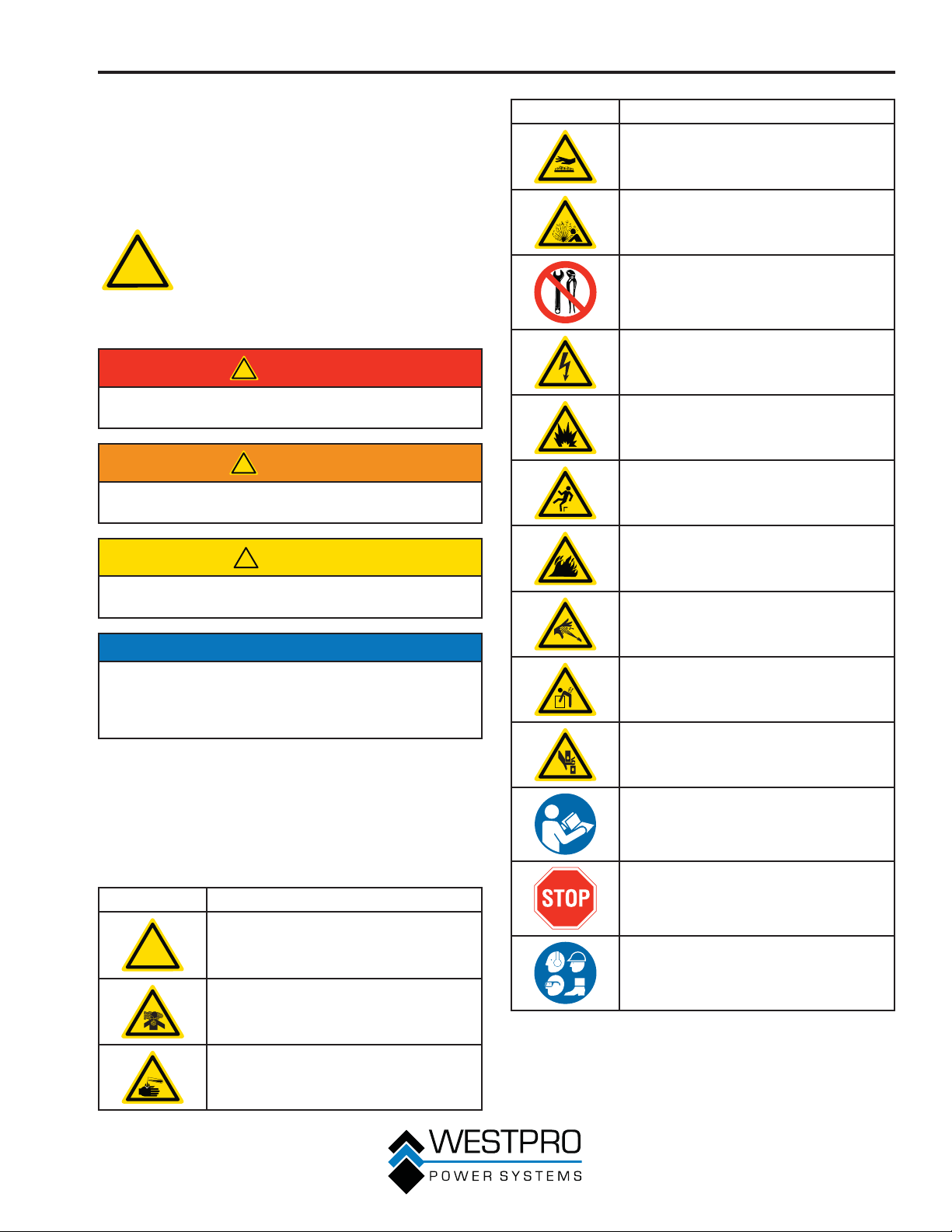

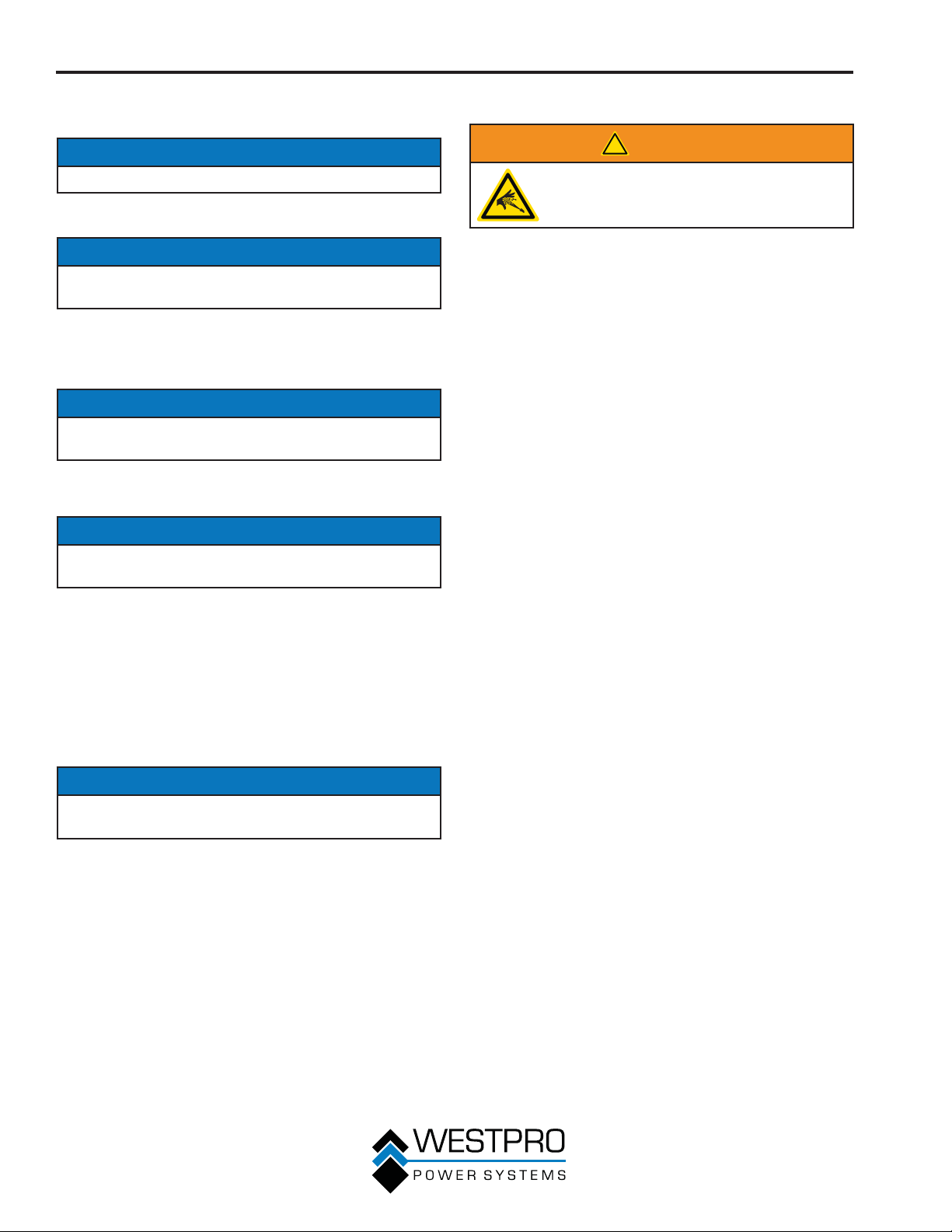

SAFETY

SAFETY DEFINITIONS

The words DANGER, WARNING, CAUTION and

NOTICE are used throughout this manual to highlight

important information. Be certain that the meanings of

these alerts are known to all who work on or near the

equipment.

This safety alert symbol appears

with most safety statements. It

!

Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

Indicates a situation which can cause damage to

the pressure washer, personal property and/or the

environment, or cause the equipment to operate

improperly.

means attention, become alert, your

safety is involved! Please read and

abide by the message that follows

the safety alert symbol.

!

DANGER

!

WARNING

!

CAUTION

NOTICE

Symbol Description

Burn Hazard

Burst/Pressure Hazard

Don’t leave tools in the area

Electrical Shock Hazard

Explosion Hazard

Fall Hazard

Fire Hazard

High-Pressure Hazard

Lifting Hazard

OTE: N Indicates a procedure, practice or condition that

should be followed in order for the pressure

washer to function in the manner intended.

Pinch-Point Hazard

Read Manufacturer’s Instructions

SAFETY SYMBOL

DEFINITIONS

Symbol Description

!

7

Safety Alert Symbol

Asphyxiation Hazard

Burn Hazard (Chemical)

Read Safety Messages Before

Proceeding

Wear Personal Protective Equipment

(PPE)

SAFETY

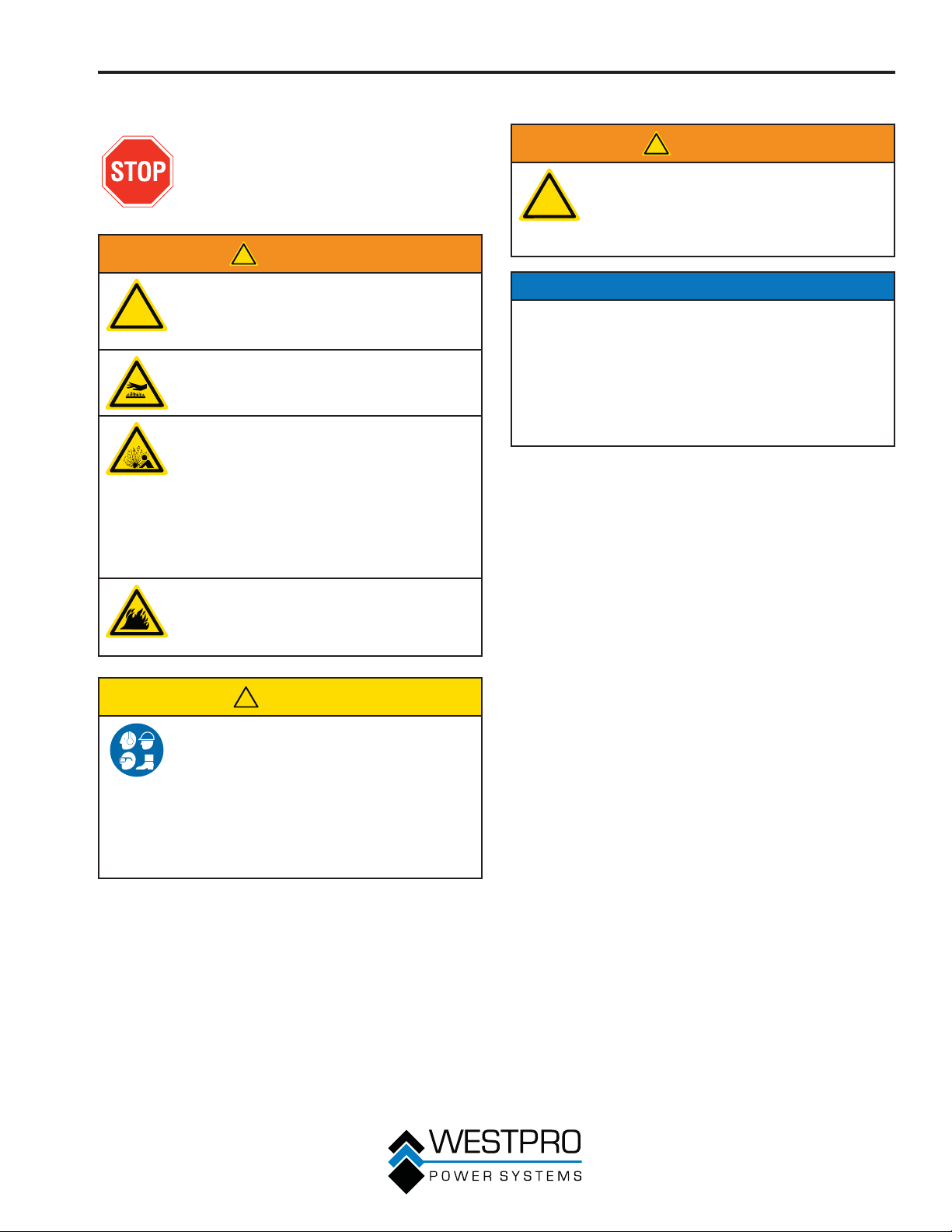

GENERAL SAFETY RULES

!

DANGER

NEVER operate the pressure washer

in an enclosed area. Engine exhaust

contains carbon monoxide. Only

operate the pressure washer outside

and away from windows, doors and

vents.

!

WARNING

Gasoline and gasoline vapors are

extremely fl ammable and explosive

under certain conditions.

• ALWAYS refuel the pressure washer

outdoors, in a well-ventilated area.

• NEVER remove the fuel cap with the

engine running.

• NEVER refuel the pressure washer

while the engine is running. Always

turn engine off and allow the

pressure washer to cool before

refueling.

• Only fi ll fuel tank with gasoline.

• Keep sparks, open fl ames or other

form of ignition (such as match,

cigarette, static electric source) away

when refueling.

• NEVER overfi ll the fuel tank. Leave

room for fuel to expand. Overfi lling

the fuel tank can result in a sudden

overfl ow of gasoline and result in

spilled gasoline coming in contact

with HOT surfaces. Spilled fuel

can ignite. If fuel is spilled on the

pressure washer, wipe up any

spills immediately. Dispose of rag

properly. Allow area of spilled fuel

to dry before operating the pressure

washer.

• Wear eye protection while refueling.

• NEVER use gasoline as a cleaning

agent.

• Store any containers containing

gasoline in a well-ventilated area,

away from any combustibles or

source of ignition.

• Check for fuel leaks after refueling.

Never operate the engine if a fuel leak

is discovered.

!

WARNING

This equipment produces a stream

of water with enough high pressure

to penetrate skin and its underlying

tissues, which could result in

amputation or other serious injury.

Spray gun traps high-pressure water,

even when engine is stopped and

water is disconnected. Leaks caused

by loose fi ttings or worn or damaged

hoses can result in injection injuries.

DO NOT TREAT FLUID INJECTION

AS A SIMPLE CUT! See a physician

immediately!

• NEVER aim spray gun at people,

animals or plants. Direct spray away

from self and others.

• NEVER place hands in front of nozzle.

• ALWAYS point spray gun in safe

direction while spraying and when

relieving retained high pressure after

stopping engine.

• DO NOT allow CHILDREN to operate

pressure washer.

• NEVER leave spray gun unattended

while machine is running.

• NEVER secure spray gun in open

position.

• DO NOT twist nozzle while spraying.

• NEVER repair a high-pressure hose.

ALWAYS replace it.

• NEVER repair leaking connections

with sealant of any kind. ALWAYS use

factory-recommended repair parts.

• NEVER hold onto the hose or fi ttings

during operation.

• DO NOT allow high-pressure hose to

contact muffl er or other extremely

hot surfaces.

• ALWAYS be certain spray gun,

nozzles and hoses are correctly

attached and in working order.

• NEVER use spray gun if trigger lock

is not in working order.

• ALWAYS use spray gun, hoses and

connections rated for pressure

higher than your pressure washer’s

psi.

• NEVER attach or remove spray gun,

nozzles or hoses while system is

pressurized.

8

SAFETY

!

WARNING

• NEVER modify spray equipment.

• ALWAYS wear protective clothing to

protect eyes and skin from contact

with sprayed materials.

NEVER aim spray in the direction of

power source. Contact with power

source can cause electric shock or

burn.

Unexpected kickback while spraying

can cause you to fall.

• Use of pressure washer can create

slippery surfaces and puddles. The

operating area of this equipment

should have adequate drainage to

reduce the possibility of a fall due to

slippery surfaces.

• Be extremely careful if necessary

to use the pressure washer from

a ladder, scaffolding or any other

similar location.

• Use both hands to fi rmly gasp the

spray gun while in use to avoid injury

from high-pressure kickback.

NEVER use acids, toxic or corrosive

chemicals, poisons, insecticides, or

any kind of fl ammable solvent with

this equipment. Only use detergents,

cleaners and degreasers recommended

for use in this pressure washer.

ALWAYS wear chemical splash safety

goggles that comply with ANSI Z87.1

when operating or in the vicinity of this

equipment.

ALWAYS remove any tools or other

service equipment used during

maintenance from the pressure washer

before operating.

NOTICE

NEVER operate pressure washer with damaged or

missing parts.

NEVER modify any feature or component of pressure

washer.

NEVER spray at glass when using the high-pressure

nozzle (red). High-pressure spray may damage fragile

items including glass.

DO NOT exceed rated pressure when operating

pressure washer.

NEVER move pressure washer by pulling on any

hoses. Always use handle to move pressure washer.

Check components for ice forming on components

when operating in cold weather.

Remove the protective shipping caps from the pump’s

water inlet and outlet.

Be sure the water supply is connected and turned

on before starting the engine. Damage to the pump

could occur and will void the warranty.

Water supply must deliver a minimum of 3.8 gal

(14.3 L) per minute and at least 30 psi (2 bar). Do

not siphon standing water for the water supply. Water

temperature must not exceed 100°F (37.7°C).

DO NOT install a one-way valve, vacuum breaker or

check valve at the pump’s water inlet. Installing one of

these devices at the pump’s water inlet could cause

damage to the pump and will void the warranty. Allow

at least 10 feet (3 m) of unrestricted hose length

between the pump’s water inlet and a one-way valve,

vacuum breaker or check valve.

9

SAFETY

SAFETY LABELS AND DECALS

WP2700

10

3400

Figure 1

WP3000

SAFETY

TWO placed on

back side of

handle

3400

Figure 2

11

UNPACKING

UNPACKING THE PRESSURE

WASHER

!

CAUTION

Always have assistance when lifting

the pressure washer. The pressure

washer is heavy; lifting it could cause

bodily harm.

Avoid cutting on or near staples to

prevent personal injury.

!

Tthe following tools are required:

x Box cutter or similar device

x 10 mm wrench

1. Carefully cut the packing tape on top of the carton.

2. Fold back top fl aps to reveal the owner’s manual.

Remove owner’s manual and save it for reference.

3. Carefully cut two sides of the carton to remove the

pressure washer.

COMPONENTS

Verify the contents against the list below. If any

parts are missing, please locate an authorized

Westinghouse dealer at www.westpropower.com or call

1-855-WHHELP1 (1-855-944-3571).

1

2

3

1

8

Figure 4 – Hardware

1 - Hose Bracket

Nuts M6 (2)

2 - Wheel Axle Pin

16 mm x 105 mm

(2)

3 - Spray Gun

Bracket

4 - Spray Gun

Bracket Nuts M6

(2)

5 - Spare Parts:

High-Pressure

Hose O-Rings (2)

Inlet Screens (2)

2

4

7

9

10

6 - Wheel Axle Lock

7 - Wheel Axle

8 - Hose Bracket

9 - Front Support –

10 - Front Support

6

Pin (2)

Washer (2)

WP3000 only

Nuts M6 (2) –

WP3000 only

3

5

5

Figure 3 – Unpacking

1 - Spray Wand (1)

2 - High-Pressure

Hose (1)

3 - Wheels (2)

OTE: N A 0.6-liter bottle of SAE 10W30 oil is also

included. Soap reservoir is not included.

12

4

4 - Soap Hose (1)

5 - Spray Gun (1)

ASSEMBLY

ASSEMBLY

Before assembling the pressure

washer, review Safety on page 7

and the following safety messages.

!

CAUTION

Never lift the pressure washer without

assistance. The pressure washer is

heavy and lifting without assistance

could result in personal injury.

Never use the handles as a lifting point

!

Assembling the pressure washer will require tipping

the unit. Make sure all engine oil and fuel are drained

from the unit prior to assembling.

Once assembled, the wheels are not intended for

on-road use. The wheels are designed for use on this

pressure washer only.

Never tip the pressure washer after it has been fully

assembled and fi lled with oil and fuel.

to support the entire weight of the

pressure washer. Only use the handles

to move the pressure washer by lifting

the handles and using the wheels to

move the pressure washer.

Use caution when collapsing the

handles. Hands and fi ngers could get

caught and pinched.

NOTICE

2. Push the lock pin in and raise the handle (see

Figure 5).

Figure 5 – Raising Handle

3. Be sure the handle is locked in position with the pin

protruding through handle hinge (see Figure 6).

1. Place pressure washer on a fl at surface.

Figure 6 – Raising Handle

13

ASSEMBLY

4. Slide the wheel axle washer onto the wheel axle pin

(see Figure 7).

1

2

Figure 7 – Installing Wheel Axle Washer

1 - Wheel Axle

Washer

5. Install the pin into the wheel assembly.

6. Locate the wheel axle mounting holes (see Figure

8). Install the pin through the axle mounting holes.

2 - Wheel Axle Pin

7. Secure the wheel axle pin in position with the wheel

axle lock pin (see Figure 9).

Figure 9 – Installing Wheel Axle Lock Pin

8. WP3000 only – Install the front support using

the two front support nuts (M6). Tighten the nuts

securely (see Figure 10).

Figure 8 – Wheel Axle Mounting Holes

2

1

Figure 10 – Installing Front Support

1 - Front Support 2 - Front Support

Nuts (M6)

14

ASSEMBLY

9. Install the spray gun bracket using the two spray

gun bracket nuts (M6). Tighten the nuts securely

(see Figure 11).

4

2

1

3

Figure 11 – Installing Spray Gun Bracket and Hose

Bracket

1 - Spray Gun

Bracket

2 - Spray Gun

Bracket Nuts

(M6)

10. Install the hose bracket using the two hose bracket

nuts (M6). Tighten the nuts securely (see Figure

11).

11. Connect the wand to the spray gun and turn the

fi tting counterclockwise to tighten (see Figure 12).

Do not overtighten. The fi tting only needs to be

hand-tight.

3 - Hose Bracket

4 - Hose Bracket

Nuts (M6)

12. Inspect the O-rings on both sides of the highpressure hose. Moisten the O-rings with water (see

Figure 13).

Figure 13 – High-Pressure Hose O-Rings

13. Connect the high-pressure hose to the pump and

tighten the hose fi tting (see Figure 14 and Figure

15). Do not overtighten. The fi tting only needs to be

hand-tight.

1

2

1 2

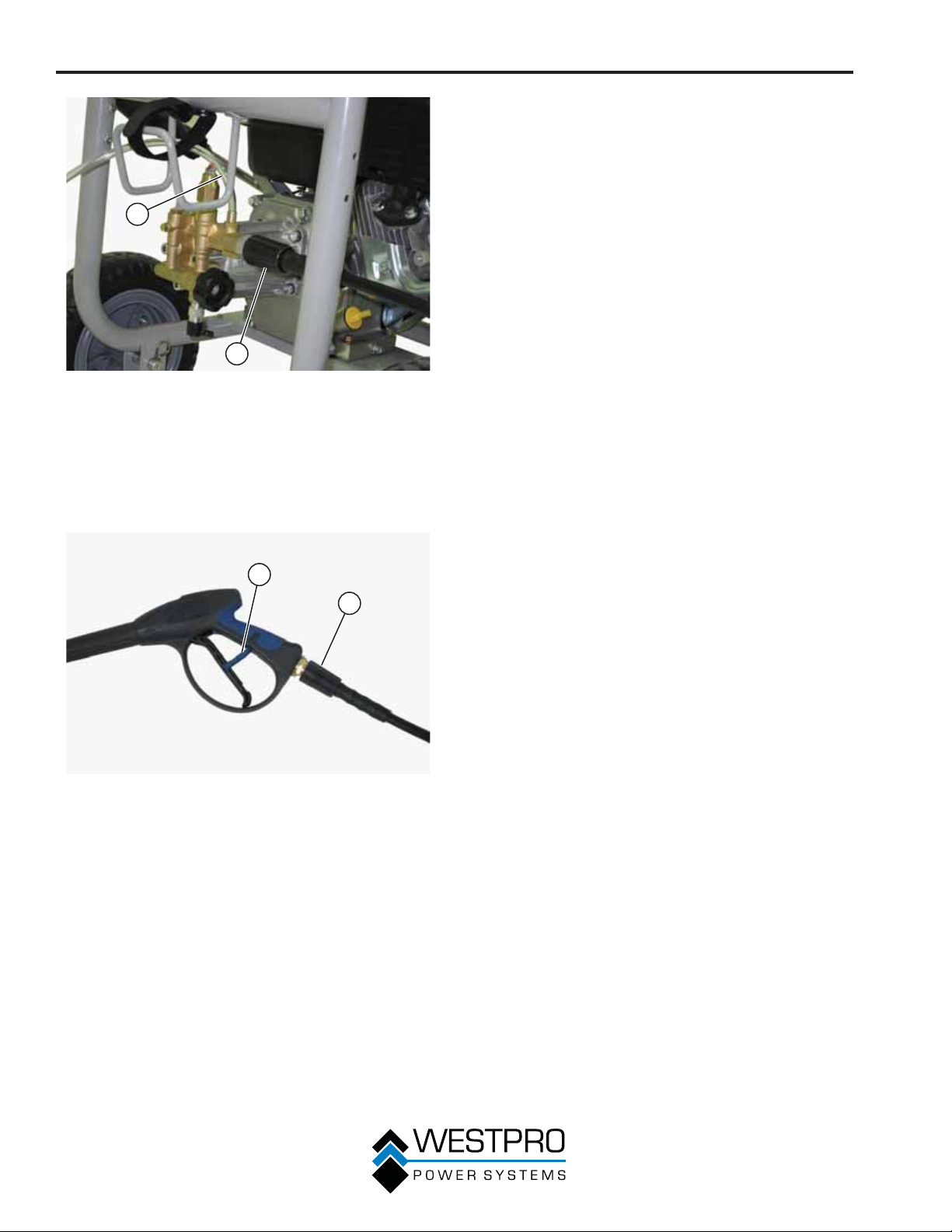

Figure 14 – Installing High-Pressure Hose – WP2700

1 - Soap Hose 2 - Hose Fitting

Figure 12 – Connecting Spray Wand

1 - Fitting 2 - Spray Wand

15

ASSEMBLY

1

2

Figure 15 – Installing High-Pressure Hose – WP3000

1 - Soap Hose 2 - Hose Fitting

14. Connect the soap hose to the barbed fi tting if you

are going to be using soap (see Figure 14 and

Figure 15).

15. Flip the trigger lock up to lock the trigger in the OFF

position (see Figure 16).

1

2

Figure 16 – Trigger Lock in OFF Position

1 - Trigger Lock 2 - Hose Fitting

16. Install the high-pressure hose to the spray gun

and tighten the hose fi tting (see Figure 16). Do not

overtighten. The fi tting only needs to be hand-tight.

16

GENERAL PRESSURE WASHER FEATURES

WP2700

2

1

FEATURES

3

8

1 - ON/OFF Switch

2 - Starter Handle

3 - Spray Gun Bracket

4 - Hose Bracket

4

5

7

Figure 17

5 - Water Inlet Fitting

6 - High-Pressure Outlet Fitting

7 - Choke Lever

8 - Air Cleaner

6

17

FEATURES

WP2700

1

2

3

7

4

5

6

1 - Spray Gun

2 - Nozzle Storage

3 - Fuel Cap

4 - Engine Oil Fill Plug/Dipstick

18

Figure 18

5 - Spark Plug

6 - Oil Drain Plug

7 - High-Pressure Hose

WP3000

FEATURES

3

2

1

1 - ON/OFF Switch

2 - Fuel Cap

3 - Spray Gun Bracket

4 - Hose Bracket

4

5

7

6

Figure 19

5 - High-Pressure Hose

6 - Engine Oil Fill Plug/Dipstick

7 - Oil Drain Plug

19

FEATURES

WP3000

2

1

3

4

9

8

1 - Spark Plug

2 - Nozzle Storage

3 - Air Cleaner

4 - Throttle Lever

5 - Starter Handle

5

6

7

Figure 20

6 - Fuel Shutoff Lever

7 - Choke Lever

8 - Water Inlet Fitting

9 - High-Pressure Outlet Fitting

20

OPERATION

BEFORE STARTING THE

PRESSURE WASHER

Before starting the pressure washer,

review Safety on page 7.

Location Selection – Before starting the pressure

washer, avoid exhaust and location hazards by verifying

the following:

x You have selected a location to operate the pressure

washer that is outdoors and well ventilated.

x You have selected a location with adequate drainage

but still level enough to prevent the pressure washer

from tipping over.

x You have selected a location that is at least 5 feet

(1.5 m) away from any building, other equipment or

combustible material.

x If the pressure washer is located close to a building,

make sure it is not located near any windows, doors

and/or vents.

!

WARNING

Always operate the pressure washer on

a surface that will prevent the pressure

washer from tipping over. Placing the

pressure washer on a surface that may

allow the pressure washer to tip over,

could cause fuel and oil to spill. Spilled

fuel can ignite if it comes in contact

with an ignition source such as a very

hot surface.

NOTICE

Operating the pressure washer on a surface with

loose material such as sand or grass clippings can

cause debris to be ingested by the pressure washer

that could:

• Block cooling vents

• Block air intake system

Check the following items before starting the engine:

1. Verify the pressure washer is properly assembled.

2. Check that recommended engine oil has been

added to proper level in the engine crankcase.

3. Add recommended fuel to fuel tank.

4. Check for properly tightened hose connections.

5. Check to make sure there are no kinks, cuts or

damage to high-pressure hose.

6. Provide a proper water supply at an adequate fl ow.

ADDING / CHECKING ENGINE

FLUIDS AND FUEL

Before adding/checking engine

fl uids and fuel, review Safety on

page 7.

!

DANGER

Filling the fuel tank with gasoline

while the pressure washer is running

can cause gasoline to leak and come

in contact with hot surfaces that can

ignite the gasoline.

Before starting the pressure washer, always check the

level of:

x Engine oil

x Gasoline in the fuel tank

Once the pressure washer is started and the engine

gets warm, it is not safe to add gasoline to the fuel tank

or engine oil to the engine while the engine is running

or the engine and muffl er are hot.

Checking and / or Adding Engine Oil

!

WARNING

Internal pressure can build in the

engine crankcase while the engine

is running. Removing the oil fi ll plug/

dipstick while the engine is hot can

cause extremely hot oil to spray out

of the crankcase and can severely

burn skin. Allow engine oil to cool for

several minutes before removing the oil

fi ll plug/dipstick.

The unit as shipped does not contain oil in the

engine. You must add engine oil before starting

the pressure washer for the fi rst time. Use the

entire supplied 0.6-liter container of engine

oil. See Checking Engine Oil on page 31 and

Adding Engine Oil on page 32 for instructions

on checking engine oil level and the procedure for

adding engine oil.

NOTICE

The pressure washer does not contain engine oil

as shipped. Attempting to start the engine without

adding engine oil can permanently damage internal

engine components.

21

OPERATION

Adding Gasoline to the Fuel Tank

!

WARNING

Never refuel the pressure washer while

the engine is running.

Always turn the engine off and allow

the pressure washer to cool before

refueling.

Required Gasoline – Only use gasoline that meets the

following requirements:

x Unleaded gasoline only

x Gasoline with maximum 10% ethanol added

x Gasoline with an 87 octane rating or higher

Filling the Fuel Tank – Follow the steps below to fi ll the

fuel tank:

1. Shut off the pressure washer.

2. Allow the pressure washer to cool down so all

surface areas of the muffl er and engine are cool to

the touch.

3. Move the

4. Clean area around the fuel cap.

5. Remove the fuel cap by rotating counterclockwise.

6. Slowly add gasoline into the fuel tank. Be very

careful not to overfi ll the tank. The gasoline level

should NOT be higher than the bottom of the fi ller

neck.

pressure washer to a fl at surface.

CONNECTING THE WATER

SUPPLY

NOTICE

Do not start the engine without the water supply

connected and turned on. Running the pump without

water will damage the pump.

Water supply must deliver a minimum of 3.8 gal

(14.3 L) per minute and at least 30 psi (2 bar). Do

not siphon standing water for the water supply. Water

temperature must not exceed 100°F (37.7°C).

1. Run water through your garden hose to clear out

any debris that may have been in the hose.

2. Inspect the water inlet screen to make sure it is in

place and free of debris (see Figure 21 and Figure

22). Do not operate the pressure washer with a

missing or damaged inlet screen.

2

NOTICE

Take care when installing the fuel cap. Threads can

be damaged if cap is incorrectly installed.

7. Install the fuel cap by rotating clockwise until it hits

the stop, indicating the cap is completely installed.

!

CAUTION

Avoid prolonged skin contact with

!

gasoline. Avoid prolonged breathing of

gasoline vapors.

1

Figure 21 – Water Connection – WP2700

1 - Water Inlet

Screen

2 - Water Inlet

Fitting

22

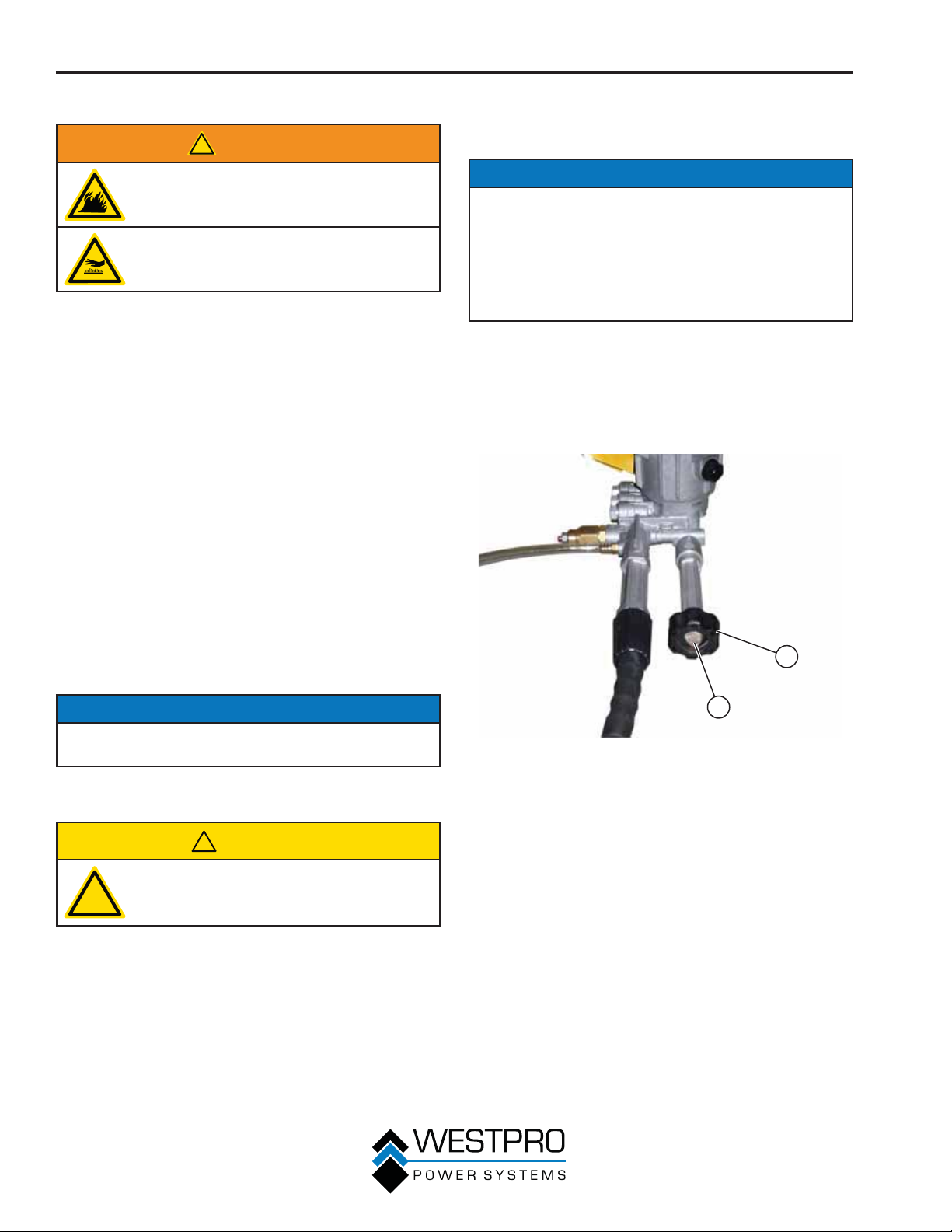

2

1

Figure 22 – Water Connection – WP3000

1 - Water Inlet

Screen

2 - Water Inlet

Fitting

NOTICE

Make sure water inlet screen is in place before

attaching hose.

3. Use the shortest hose possible to complete the

job at hand. Using a longer hose may affect

performace. Connect a garden hose that is not

longer than 50 feet (15.2 m) to the water inlet fi tting

(see Figure 21 and Figure 22).

4. Tighten the fi tting onto the hose.

5. Turn the water on and inspect for leaks.

6. Squeeze the trigger on the gun and allow any air to

bleed out of the hoses and the pump before starting

the engine.

7. Connect the soap hose to the soap bottle if using

soap.

OPERATION

STARTING THE PRESSURE

WASHER

Before starting the pressure washer,

review Safety on page 7.

OTE: N Pressure washer may walk or move when used

on hard surfaces. Be sure the unit is secure

during operation.

Before attempting to start the pressure washer, verify

the following:

x The engine is fi lled with engine oil (see Checking

Engine Oil on page 31).

x The pressure washer is situated in a proper location

(see Location Selection on page 21).

!

DANGER

Never operate the pressure washer

in an enclosed area. Engine exhaust

contains carbon monoxide that can kill

in minutes. Only operate the pressure

washer outside and away from

windows, doors and vents.

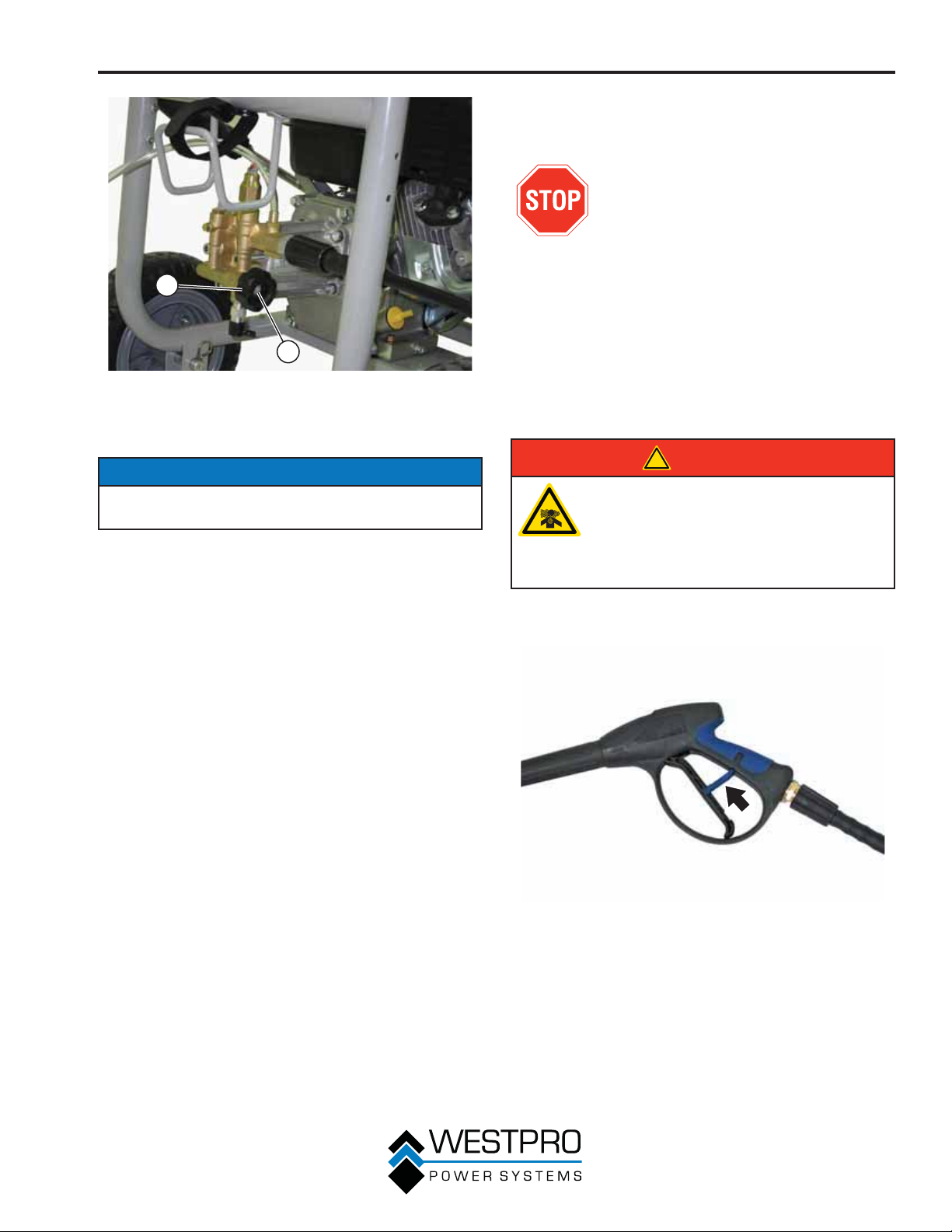

1. Flip the trigger lock lever up and lock the trigger in

the OFF position (see Figure 23).

Figure 23 – Trigger Lock Lever

2. Make sure the water supply is turned on.

23

OPERATION

OTE: N The pump is equipped a with a thermo valve

(see Figure 24 and Figure 25). If the pump

is run for an extended period of time without

water fl owing through it, it could overheat. If

the pump gets to a certain temperature, the

thermo valve will open and discharge warm

water out the valve to allow cold water in to

cool the pump.

3. Point the thermo valve away from the work area

you are washing to avoid being sprayed with warm

water.

Figure 24 – Pump Thermo Valve – WP2700

4. WP2700 – Move the engine ON/OFF switch to the

ON (I) position (see Figure 26). Move the choke

lever to the choke position.

3

1

2

Figure 26 – Engine ON/OFF Switch – WP2700

1 - Engine ON/OFF

Switch

2 - Choke Lever

5. WP3000 – Move the engine ON/OFF switch to the

ON position (I) (see Figure 27).

3 - Starter Handle

Figure 25 – Pump Thermo Valve – WP3000

24

Figure 27 – Engine ON/OFF Switch – WP3000

OPERATION

6. WP3000 – Move the throttle lever to the full throttle

position (see Figure 28). Move the choke lever to

the choke position. Open the fuel shutoff valve.

1

2

3

4

Figure 28 – Throttle Lever, Choke Lever, Fuel Shutoff

Valve

1 - Throttle Lever

2 - Choke Lever

7. Firmly grasp and pull the starter handle slowly until

you feel increased resistance. At this point, apply a

rapid pull on the starter handle.

OTE: N If the engine starts briefl y and then shuts off,

squeeze the trigger on the spray gun to relieve

the pressure before trying to start the engine

again.

8. Once the engine starts, move the choke lever to the

open position. Allow the engine to warm up slightly

before beginning washing.

3 - Fuel Shutoff

Valve

4 - Starter Handle

STOPPING THE PRESSURE

WASHER

Normal Operation

During normal operation, use the following steps to stop

your pressure washer:

1. Lock the spray gun trigger lock in the OFF position.

2. Move the engine ON/OFF switch to the OFF (O)

position (see Figure 29 and Figure 30).

Figure 29 – Engine ON/OFF Switch OFF Position –

WP2700

OTE: N WP3000 – Always operate the engine at full

throttle position when washing.

Figure 30 – Engine ON/OFF Switch OFF Position –

WP3000

25

OPERATION

3. WP3000 – Close the fuel shutoff valve (see Figure

31).

Figure 31 – Closing Fuel Shutoff Valve – WP3000

4. Turn the water supply off.

5. Unlock the spray gun trigger and squeeze the

trigger to release any pressure in the hoses and

pump.

6. Disconnect the garden hose from the water inlet.

SELECTING NOZZLES

The quick-connect feature allows changing between

nozzles while the pressure washer is running once the

spray gun trigger is locked in the safe position.

NOTICE

Only use the nozzles that were supplied with the

pressure washers. Using any other nozzles can

affect performance and may void the warranty. For

replacement nozzles go to www.westpropower.com

or call (855) 944-3571.

!

WARNING

Always apply the trigger lock to change

a nozzle if the engine is running.

1 2 3

During an Emergency

If there is an emergency and the pressure washer must

be stopped quickly, push the engine control switch to

the OFF (O) position immediately.

4 5

Figure 32 – Nozzle Spray Pattern

1 - Red High

Pressure 0°

2 - Yellow High

to Medium

Pressure 15°

3 - Green Medium

Pressure 25°

4 - White Low

Pressure 40°

5 - Black Soap

26

OPERATION

Table 1: Nozzles

Nozzle Use

1. High Pressure

Nozzle (Red) –

higher pressure

and smallest spray

pattern

NOTICE: The red

nozzle can damage

surfaces if it is held

too close for an

extended time

2. High to Medium

Pressure Nozzle

(Yellow) – high to

medium pressure

with smallest angle

spray pattern

3. Medium Pressure

Nozzle (Green) –

medium pressure and

medium spray pattern

4. Low Pressure Nozzle

(White) – lower

pressure and widest

spray pattern

5. Soap Nozzle (Black)

NOTICE: Only use

pressure washer–

safe soap.

Use to clean hard,

embedded dirt

and grime. Use on

concrete, brick,

driveways and patios.

Use to clean paint,

stain, mildew, oil, and

compacted dirt and

grime. Use on wood

decks, home siding,

driveways and patios.

Use to clean paint,

stain, mildew, oil, and

compacted dirt and

grime. Use on wood

decks, home siding,

driveways and patios.

Use to clean general

loose dirt and grime.

For use on most

surfaces including

cars, wood decks,

patios, outdoor

furniture, home

siding, and lawn and

garden equipment.

Use to apply soap

to cleaning surfaces

in order to provide a

thorough cleaning.

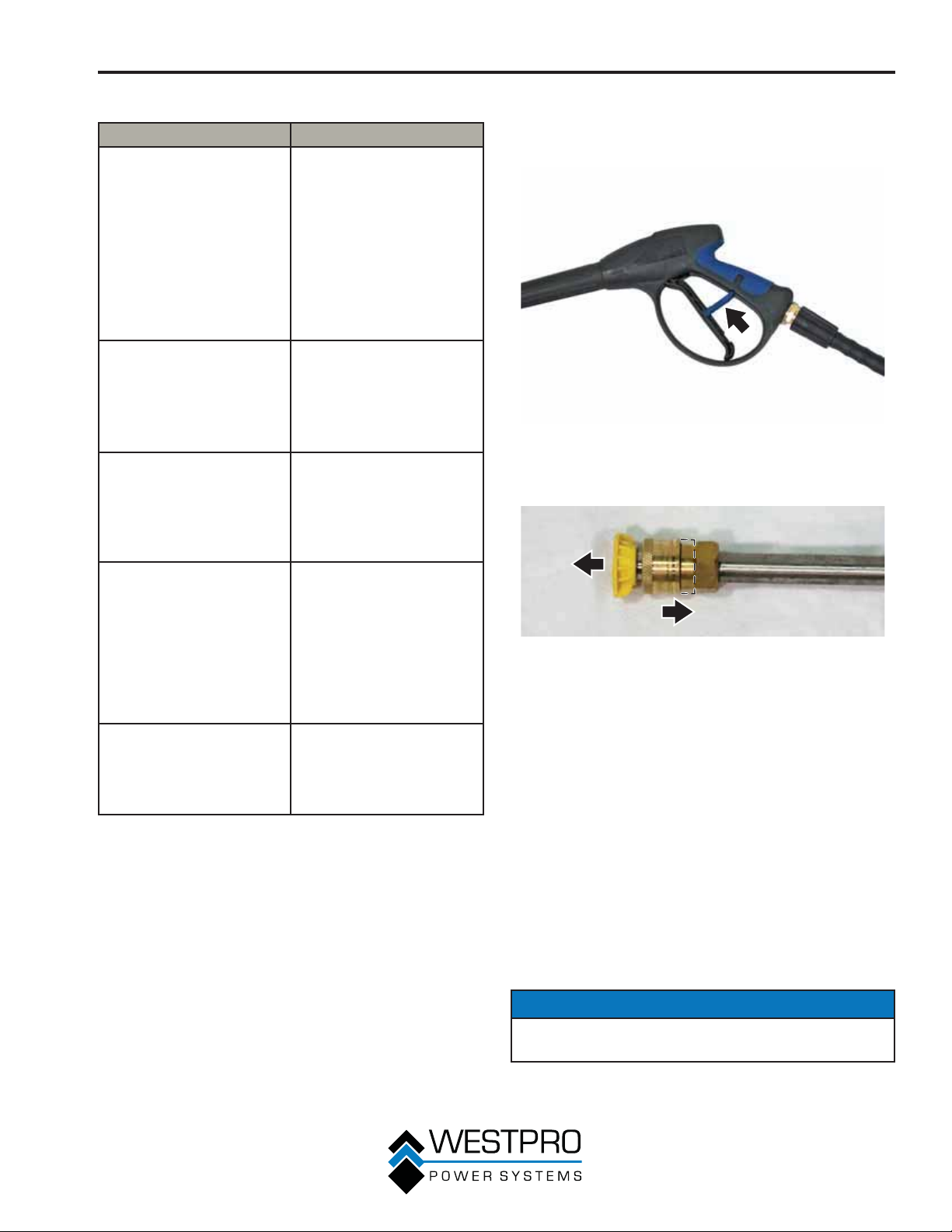

Changing the Nozzle

1. Push up the trigger lock to lock it in the OFF

position (see Figure 33).

Figure 33 – Trigger Lock Locked

2. Pull the quick coupler toward the spray gun (see

Figure 34).

Figure 34 – Installing a Nozzle

3. Push the nozzle into the coupler and push the

coupler away from the spray gun (see Figure 34).

The nozzle will lock into place. Tug on the nozzle to

verify it is locked in place.

SPRAYING TIPS

For most cleaning, keep nozzle 8 – 24 in. (20 – 61 cm)

away from cleaning surface.

x Damage may occur to the cleaning surface if you

spray too close, especially with high-pressure

nozzles.

x When you begin spraying, start farther away and

move closer to avoid damage to the surface.

x When cleaning tires, allow at least 6 in. (15 cm)

between a tire and the nozzle.

NOTICE

Do not get any closer than 6 in. (15 cm). Spraying

closer than 6 in. (15 cm) may damage tire.

To relieve system pressure, shut off engine, turn off water

supply and pull gun trigger until water stops fl owing.

27

OPERATION

SPRAYING SOAP

NOTICE

Only use pressure washer–safe soap.

1. Install the soap nozzle (black).

NOTICE

Only use the soap nozzle to apply soap. Using other

nozzles will not apply soap.

2. Prepare soap solution following manufacturer’s

instructions.

3. Place soap siphon hose into

NOTICE

Do not route soap siphon hose where it can contact

the muffl er while the engine is running.

4. Make sure the garden hose and high-pressure hose

are connected.

NOTICE

All hoses must be connected before starting the

engine.

5. Turn on the water supply.

6. Start the engine and squeeze the trigger.

7. Use long, even overlapping stroke to apply

8. Allow 3 – 5 minutes for the soap to soak in before

washing and rinsing. Do not allow the

dry on the surface before rinsing. Reapply

necessary to maintain a wet surface for the soap to

soak in.

soap container.

soap.

soap to

soap if

RINSING

!

WARNING

Always apply the trigger lock to change

a nozzle if the engine is running.

1. Select the desired nozzle and change nozzle. See

Selecting Nozzles on page 26.

2. Squeeze the trigger and carefully start to spray,

keeping nozzle a safe distance from the cleaning

surface.

3. Starting from the top of the surface, spray a small

area then check surface for damage. If no damage,

continue rinsing by using overlapping strokes

working down the surface. Keep checking surface

for damage while rinsing.

CLEANING SOAP SIPHON

HOSE

If used, clean the soap siphon hose before stopping the

engine.

1. If necessary, install the soap nozzle (black).

2. Use clean water to fl ush the soap siphon hose.

Submerge the soap siphon hose in the clean water.

3. Flush the soap siphon hose for 1 – 2 minutes while

the engine is running.

4. Once clean, stop the engine.

5. Point spray gun in a safe direction. Squeeze the

trigger to release pressure within the system.

NOTICE

Clean the soap siphon hose once done. See

Cleaning Soap Siphon Hose on page 28.

28

MAINTENANCE

MAINTENANCE

Before performing maintenance on

the pressure washer, review Safety

on page 7 and the following

safety messages.

!

WARNING

Avoid accidentally starting the

!

pressure washer during maintenance

by removing the spark plug boot from

the spark plug.

Allow hot components to cool to

the touch prior to performing any

maintenance procedure.

Internal pressure can build in the

engine crankcase while the engine

is running. Removing the oil fi ll plug/

dipstick while the engine is hot can

cause extremely hot oil to spray out

of the crankcase and can severely

burn skin. Allow engine oil to cool for

several minutes before removing the oil

fi ll plug/dipstick.

Always perform maintenance in a wellventilated area. Gasoline fuel and fuel

vapors are extremely fl ammable and

can ignite under certain conditions.

Maintenance Schedule

!

WARNING

Failure to perform periodic

!

maintenance or not following

maintenance procedures can cause the

pressure washer to malfunction and

could result in death or serious injury.

NOTICE

Periodic maintenance intervals vary depending on

pressure washer operating conditions. Operating the

pressure washer under severe conditions, such as

sustained high-load, high-temperature, or unusually

wet or dusty environments, will require more frequent

periodic maintenance. The intervals listed in the

maintenance schedule should be treated only as a

general guideline.

Following the maintenance schedule is important to

keep the pressure washer in good operating condition.

The following is a summary of maintenance items by

periodic maintenance intervals.

!

CAUTION

Avoid skin contact with engine oil or

gasoline. Prolonged skin contact with

engine oil or gasoline can be harmful.

Frequent and prolonged contact with

engine oil may cause skin cancer.

Take protective measures and wear

protective clothing and equipment.

Wash all exposed skin with soap and

water.

29

Loading...

Loading...