Western Digital Purple PR1000M, WD40PURX, WD30PURX, WD30PURZ, WD20PURZ Technical Reference Manual

...Page 1

WD Purple™ PR1334M

Surveillance Hard Drives

Technical Reference Manual

WD40PURX

WD40PURZ

WD40EVRX

WD CONFIDENTIAL

Page 2

© 2017 Western Digital Corporation or its subsidiaries

All Rights Reserved

Information furnished by WD is believed to be accurate and reliable. No license is granted by

implication or otherwise under any patent or patent rights of WD. WD reserves the right to change

specifications at any time without notice.

Western Digital, WD, and the WD logo are registered trademarks in the U.S. and other countries;

and WD Purple, IntelliSeek, NoTouch, Data Lifeguard, CacheFlow, and FIT Lab are trademarks of

Western Digital Technologies, Inc. Other marks may be mentioned herein that belong to other

companies.

Western Digital

3355 Michelson Drive, Suite 100

Irvine, California 92612

2679-800084-A04

Document Control Number Definition:

2679-800xxx- Axx-Px NRD

Doc Control No. Doc Revision Level Non-Released Document

Axx = Released Version

Px = Review Cycle

WD CONFIDENTIAL

Page 3

WD Purple PR1334M

WD Purple PR1334M

Technical Reference Manual

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) iii

Page 4

WD Purple™ PR1334M

iv RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 5

WD Purple™ PR1334M Table of Contents

TABLE OF CONTENTS

1. DESCRIPTION AND FEATURES ............................................................................................. 1

1.1 General Description ...........................................................................................................................1

1.2 Product Features ................................................................................................................................1

2. SPECIFICATIONS................................................................................................................4

2.1 Performance Specifications.............................................................................................................. 4

2.2 Physical Specifications...................................................................................................................... 4

2.2.1 Physical Dimensions ................................................................................................................. 4

2.3 Mechanical Specifications................................................................................................................. 5

2.4 Electrical Specifications.................................................................................................................... 6

2.4.1 Current Requirements and Power Dissipation....................................................................... 6

2.4.2 Input Voltage Requirements ................................................................................................... 6

2.4.3 Ripple......................................................................................................................................... 6

2.4.4 Power Connectors and Cables ...............................................................................................6

2.5 Environmental Specifications ............................................................................................................7

2.5.1 Shock and Vibration ..................................................................................................................7

2.5.2 Temperature and Humidity .....................................................................................................8

2.5.3 Thermocouple Location ..........................................................................................................9

2.5.4 Cooling .................................................................................................................................10

2.5.5 Atmospheric Pressure ............................................................................................................ 10

2.5.6 Acoustics................................................................................................................................. 10

2.5.7 RoHS (Restriction of Hazardous Substances) ...................................................................... 10

2.6 Reliability Specifications and Characteristics................................................................................ 11

2.7 Device Plug Connector Pin Definitions...........................................................................................11

2.8 Agency Approvals ............................................................................................................................ 11

2.9 Full Model Number Specification ....................................................................................................12

3. PRODUCT FEATURES ....................................................................................................... 13

3.1 SATA 6 Gb/s .....................................................................................................................................14

3.2 AllFrame 4K Technology ..................................................................................................................14

3.3 IntelliSeek..........................................................................................................................................14

3.4 Dynamic Fly Height Control ............................................................................................................14

3.5 Perpendicular Magnetic Recording (PMR) .....................................................................................15

3.6 NoTouch Ramp Load Technology ..................................................................................................15

3.7 Dual Stage Actuator Technology....................................................................................................15

3.8 Advanced Format (AF) .....................................................................................................................15

3.9 Native Command Queuing (NCQ) ..................................................................................................16

3.10Pre-emptive Wear Leveling (PWL).................................................................................................16

3.11S.M.A.R.T. Command Transport (SCT)............................................................................................16

3.11.1 Write Same.............................................................................................................................16

3.11.2 Temperature Reporting ........................................................................................................17

3.12World Wide Name (WWN) ............................................................................................................. 17

3.13Reliability Features Set.....................................................................................................................17

3.13.1 Data Lifeguard™ ....................................................................................................................17

3.13.2 Thermal Management ........................................................................................................18

3.13.3 Internal Environmental Protection System .........................................................................19

3.13.4 Recoverable Errors ................................................................................................................19

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) v

Page 6

Table of Contents WD Purple™ PR1334M

3.13.5 Unrecoverable Errors.............................................................................................................19

3.13.6 Self Test ..................................................................................................................................19

3.13.7 ATA Error Logging .................................................................................................................19

3.13.8 Defect Management ........................................................................................................... 20

3.14Automatic Defect Retirement ........................................................................................................ 20

3.14.1 Error Recovery Process ........................................................................................................ 20

3.15Hot Plug Support..............................................................................................................................21

3.16Active LED Status .............................................................................................................................21

3.17Fluid Dynamic Bearings (FDB) .........................................................................................................21

3.18Staggered Spinup and Activity Indication (SATA Power Pin 11) .................................................21

3.18.1 Staggered Spinup................................................................................................................. 22

3.18.2 Activity Indication ................................................................................................................ 22

3.19CacheFlow™.................................................................................................................................... 22

3.19.1 Write Cache .......................................................................................................................... 22

3.19.2 Read Cache ............................................................................................................................23

3.2048-bit Logical Block Addressing (LBA) ..........................................................................................23

3.21Power Management .........................................................................................................................23

3.22Self-Monitoring, Analysis, and Reporting Technology (S.M.A.R.T.) .............................................23

3.23Security Mode.................................................................................................................................. 24

3.23.1 Master and User Passwords................................................................................................. 24

3.23.2 Security Levels...................................................................................................................... 24

4. ATA COMMAND SET .......................................................................................................25

4.1 Host Interface Commands.............................................................................................................. 25

4.1.1 ATA-8 Commands................................................................................................................... 25

4.1.2 SATA Commands.................................................................................................................27

4.1.3 Obsolete Commands ..............................................................................................................27

4.1.4 SCT Commands .......................................................................................................................27

4.2 S.M.A.R.T. (B0h) ................................................................................................................................27

4.2.1 Read Attribute Values Sub-Command.................................................................................. 28

4.2.2 Supported Attributes.............................................................................................................29

4.2.3 Read Log Sector...................................................................................................................30

4.3 Identify Device (ECh) .......................................................................................................................31

4.4 Set Features (EFh) ........................................................................................................................... 38

5. INSTALLATION AND SETUP PROCEDURES........................................................................... 39

5.1 Unpacking .........................................................................................................................................39

5.1.1 Handling Precautions ..............................................................................................................39

5.1.2 Inspection of Shipping Container ..........................................................................................39

5.1.3 Removal From Shipping Container ........................................................................................39

5.1.4 Removal From Static Shielding Bag.....................................................................................40

5.1.5 Moving Precautions ................................................................................................................ 40

5.2 Mounting ..........................................................................................................................................40

5.2.1 Mounting Restrictions ............................................................................................................ 40

5.2.2 Orientation .............................................................................................................................. 40

5.2.3 Screw Size Limitations ........................................................................................................... 40

5.2.4 Grounding ............................................................................................................................... 40

5.3 Hard Drive Installation......................................................................................................................41

5.3.1 Jumper Settings .......................................................................................................................41

5.3.2 Attach the Power Supply Cable............................................................................................43

5.3.3 Attach SATA Interface Cable..................................................................................................43

vi RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 7

WD Purple™ PR1334M Table of Contents

5.4 Serial ATA Latching Connector .......................................................................................................43

6. MAINTENANCE ................................................................................................................44

ECHNICAL SUPPORT ......................................................................................................45

7. T

7.1 WD Online Services......................................................................................................................... 45

8. GLOSSARY ......................................................................................................................46

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) vii

Page 8

Table of Contents WD Purple™ PR1334M

viii RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 9

WD Purple™ PR1334M List of Figures

LIST OF FIGURES

Figure 1 Mounting Dimensions ..................................................................................................................... 5

Figure 2 Drive Base Casting Thermocouple Location ................................................................................ 9

Figure 3 Forced Airflow Direction .............................................................................................................. 10

Figure 12 Jumper Settings........................................................................................................................... 42

Figure 13 Connector Locations ...................................................................................................................43

Figure 14 SATA Interface Cable...................................................................................................................43

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) ix

Page 10

List of Figures WD Purple™ PR1334M

x RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 11

WD Purple™ PR1334M List of Tables

LIST OF TABLES

Table 1 Shock and Vibration..........................................................................................................................7

Table 4 Full Model Number Description .....................................................................................................12

Table 5 ATA-8 Command Opcodes ........................................................................................................... 25

Table 6 SATA Command Opcodes..............................................................................................................27

Table 7 Obsolete Command Opcodes .......................................................................................................27

Table 8 SCT Action Codes...........................................................................................................................27

Table 9 Definitions for the 512 Bytes. ........................................................................................................ 28

Table 10 Log Address Definition ................................................................................................................ 30

Table 11 Identify Device Command ............................................................................................................31

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) xi

Page 12

List of Tables WD Purple™ PR1334M

xii RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 13

WD Purple PR1334M Description and Features

1.0 DESCRIPTION AND FEATURES

1.1 General Description

WD Purple Surveillance Storage is built for 24/7 always-on surveillance in highdefinition security systems that utilize higher hard drive bay counts and up to 64

cameras. Exclusive AllFrame 4K™ technology works with ATA streaming to reduce

error pixilation and video interruptions that occur when desktop hard drives are

incorrectly used as storage in security systems.

1.2 Product Features

• Serial ATA (SATA) — Serial ATA (SATA) is the industry standard bus interface for

hard drives. It is designed to replace Parallel ATA, and has many advantages

including increased transfer rate, improved signal integrity, enhanced data protection, and hot plug support.

• AllFrame 4K™ — All WD Purple™ drives are equipped with AllFrame 4K™ tech-

nology, which improves ATA streaming to help reduce frame loss, improve overall

video playback, and increase the number of hard drive bays supported within a

NVR. Help make your surveillance solution future-ready knowing that WD Purple™

drives are ready for ultra high definition cameras.

• Premium Protection -- Designed with tarnish-resistant components, this WD Pur-

ple drive offers premium protection in harsh environments where surveillance systems may be installed.

• IntelliSeek™ — Calculates optimum seek speeds to lower power consumption,

noise, and vibration.

• Dynamic Fly Height Control — Designed to compensate for head/media separa-

tion changes due to temperature and altitude. This feature adds video quality

margins across temperature and altitude changes.

• Perpendicular Magnetic Recording (PMR) — With PMR technology the magneti-

zation of each data bit is aligned vertically to the spinning disk, rather than longitudinally as has been the case in hard drive technology for decades. This enables

more data on a given disk than is possible with conventional longitudinal recording, and provides a platform for future expansion of hard drive densities.

• NoTouch™ Ramp Load Technology — The recording head never touches the disk

media ensuring significantly less wear to the recording head and media as well as

better drive protection in transit.

• Dual Stage Actuator Technology — A head positioning system with dual-stage

actuators that improves positioning accuracy over the data track(s). The primary

stage provides course displacement; the secondary stage uses piezo electric

motion to fine tune the head positioning to a higher degree of precision.

• Advanced Format (AF) — Technology adopted by WD and other drive manufac-

turers as one of multiple ways to continue growing hard drive capacities. AF is a

more efficient media format that enables increased areal densities.

• Native Command Queuing (NCQ ) — Performance of a random I/O workload can

be improved through intelligent re-ordering of the I/O requests so they read/

write to and from the nearest available sectors and minimize the need for additional disk revolutions or head actuator movement. This improvement can be

achieved though Native Command Queuing (NCQ ), which is supported by these

hard drives.

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 1

Page 14

Description and Features WD Purple PR1334M

• Pre-emptive Wear Leveling (PWL) —This WD feature provides a solution for pro-

tecting the recording media against mechanical wear. In cases where the drive is

so busy with incoming commands that it is forced to stay in a same cylinder position for a long time, the PWL control engine initiates forced seeks so that disk

lubricant maintains an even distribution and does not become depleted. This feature ensures reliability for applications that perform a high incidence of read/

write operations at the same physical location on the disk.

• S.M.A.R.T. Command Transport (SCT) — The SCT Command Transport feature set

provides a method for a host to send commands and data to a device and for a

device to send data and status to a host using log pages.

• World Wide Name (WWN) — The World Wide Name (WWN) defined in ATA/

ATAPI-7 is a modification of the IEEE extended unique identifier 64 bit standard

(EUI-64) and is comprised of three major components: naming authority, organizationally unique identifier (OUI) and serial number. WD's OUI is 0014EEh.

• Reliability Features Set-Data Lifeguard™ — Representing WD's ongoing commit-

ment to data protection, Data Lifeguard includes features that enhance the drives

ability to prevent data loss. Data Lifeguard data protection utilities include thermal management, an environmental protection system, and embedded error

detection and repair features that automatically detect, isolate, and repair problem areas that may develop over the extended use of the hard drive. With these

enhanced data reliability features, the drive can perform more accurate monitoring, error repair, and deliver exceptional data security.

• Hot Plug Support — SATA supports hot plugging (also known as “hot swapping”),

the ability to swap out a failed hard drive without having to power down the system or reboot. This capability contributes to both data availability and serviceability without any associated downtime, making it a critical feature for extending

SATA into enterprise applications.

• Active LED Status — The drive supports external LED requirements. It provides an

activity LED output which is ON during command execution and OFF otherwise.

• Fluid Dynamic Bearings (FDB) — Bearing design that incorporates a layer of high-

viscosity lubricant instead of ball bearings in the hard drive spindle motor. As an

alternative to conventional ball bearing technology, FDB designs provide

increased non-operational shock resistance, speed control, and improved acoustics.

• Staggered Spin-Up — SATA 3 Gb/s feature that allows the system to control

whether the drive will spin up immediately or wait until the interface is fully ready

(available for specific OEM configurations).

• CacheFlow™ —WD’s unique, multi-generation caching algorithm evaluates the

way data is read from and written to the drive and adapts “on-the-fly” to the optimum read and write caching methods. CacheFlow minimizes disk seek operations

and overheads due to rotational latency. CacheFlow supports sequential and random write cache. With write cache and other CacheFlow features, the user can

cache both read and write data. The cache can hold multiple writes and collectively write them to the hard disk.

• 48-bit Logical Block Addressing (LBA) — WD SATA drives support both 48-bit

and 28-bit LBA and CHS-based addressing. LBA is included in advanced BIOS and

operating system device drivers and ensures high capacity disk integration.

2 RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 15

WD Purple PR1334M Description and Features

• Power Management — The drive supports the ATA and SATA power management

command set, allowing the host to reduce the power consumption of the drive

by issuing a variety of power management commands.

• Self-Monitoring, Analysis, and Reporting Technology (S.M.A.R.T.) — S.M.A.R.T.

enables a drives internal status to be monitored through diagnostic commands at

the host level and during offline activities. S.M.A.R.T. devices employ data analysis

algorithms that are used to predict the likelihood of some near-term degradation

or fault conditions. When used with a S.M.A.R.T. application, the drive can alert

the host system of a negative reliability status condition. The host system can

then warn the user of the impending risk of data loss and recommend an appropriate action.

• ATA Security — The drive supports the ATA Security Mode Feature set. The ATA

Security Mode feature set allows the user to create a device lock password that

prevents unauthorized hard disk access even if the drive is removed from the host

computer. The correct password must be supplied to the hard drive in order to

access user data. Both the User and Master Password features are supported,

along with the High and Maximum security modes. The Master Password Revision

code is also supported. This feature varies by drive configuration and may not be

available on all configurations.

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 3

Page 16

Specifications WD Purple PR1334M

2.0 SPECIFICATIONS

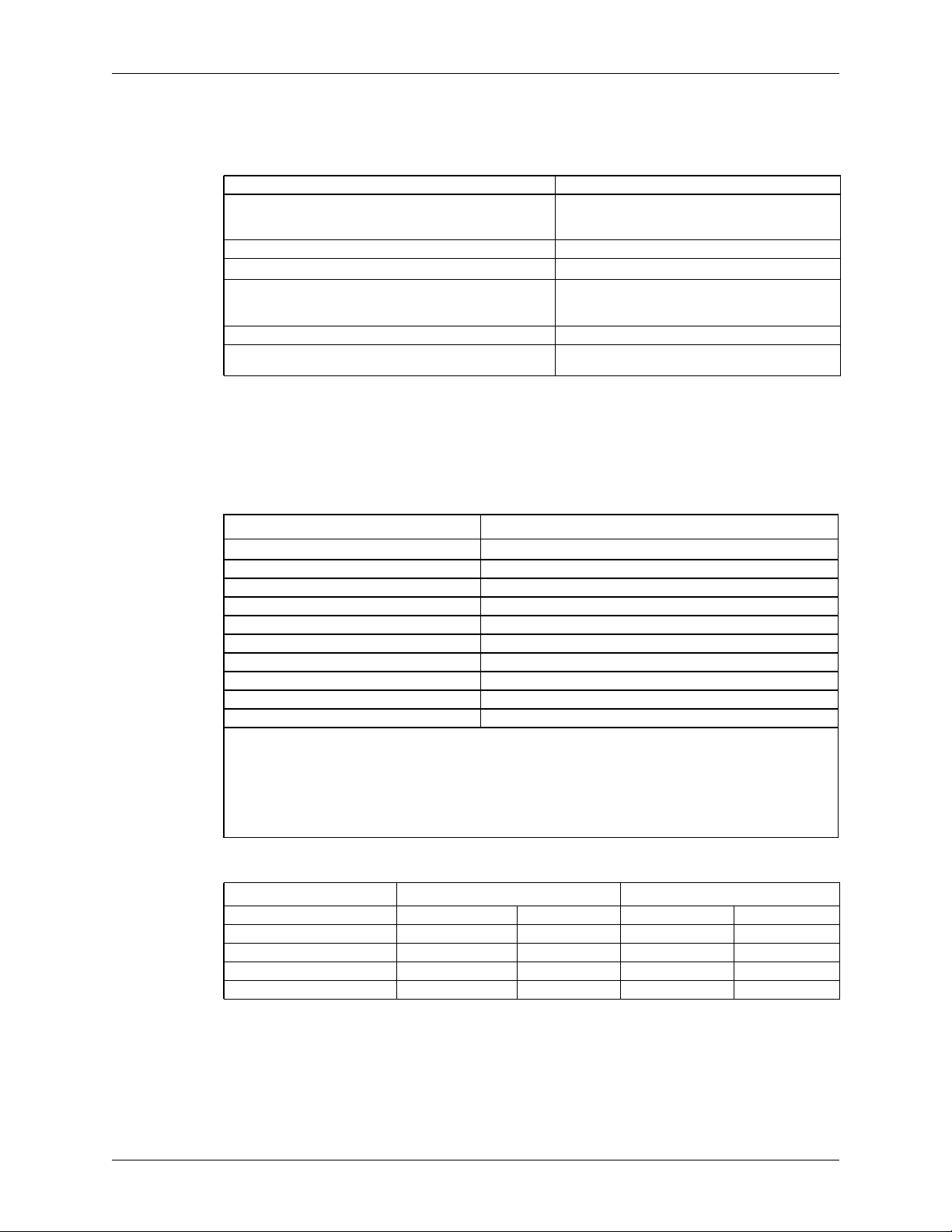

2.1 Performance Specifications

Performance Class 5400 RPM Class

Data Transfer Rate

- Buffer to Host

- Host to/from Disk

Buffer Size 64 MB

Error Rate - Unrecoverable <1 in 10

Spindle Start Time

- From Power-on to Drive Ready

- From Power-on to Rotational Speed

Spindle Stop Time <15s average

Load/Unload Cycles (controlled unload at ambient

condition)

1

As used for buffer or cache, one megabyte (MB) = 1,048,576 bytes. As used for transfer rate or interface,

megabyte per second (MB/s) = one million bytes per second, and gigabit per second (Gb/s) = one billion bits

per second. Effective maximum SATA 6 Gb/s transfer rate calculated according to the Serial ATA specification

published by the SATA-IO organization as of the date of this document. Visit www.sata-io.org for details.

2.2 Physical Specifications

Specifications represented are of a typical production drive and may be subject to

change or variation without notice.

Physical Specifications

Capacity

Interface SATA 6 Gb/s

Number of Disks 3

Data Surfaces 6

Number of Heads 6

Physical bytes per sector 4096

Host bytes per sector 512

User Sectors per Drive 7,814,037,168

Servo Type Embedded

Recording Method LDPC Target

2

1

Specifications represented are of a typical production drive and may be subject to change or variation without

notice.

2

As used for storage capacity, one megabyte (MB) = one million bytes, one gigabyte (GB) = one billion bytes,

and one terabyte (TB) = one trillion bytes. Total accessible capacity varies depending on operating

environment. As used for buffer or cache, one megabyte (MB) = 1,048,576 bytes. As used for transfer rate or

interface, megabyte per second (MB/s) = one million bytes per second, and gigabit per second (Gb/s) = one

billion bits per second. Effective maximum SATA 3 Gb/s transfer rate calculated according to the Serial ATA

specification published by the SATA-IO organization as of the date of this document. Visit www.sata-io.org for

details.

1

1

6 Gb/s maximum

175 MB/s sustained (typical)

14

bits read

14.5s average

9s average

300,000

WD40PURX/WD40PURZ/WD40EVRX

4 TB

2.2.1 Physical Dimensions

English Metric

Dimension Tolerance Dimension Tolerance

Height 1.028 inches MAX 26.1 mm MAX

Length 5.787 inches MAX 147.0 mm MAX

Width 4.00 inches ±0.01 inch 101.6 mm ±0.25 mm

Weight 1.40 pounds ±10% 0.635 kg ±10%

4 RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 17

WD Purple PR1334M Specifications

2.3 Mechanical Specifications

Figure 2-1 shows the mounting dimensions and locations of the screw holes for the

drive.

Figure 1. Mounting Dimensions

127(681/(6627+(5:,6(63(&,),('

',0(16,216$5(,10,//,0(7(56

',0(16,216,1%5$&.(76$5(,1,1&+(6

>@

;

<

0$;

0$;

;

;

=

&

&211(&725

/

>@

>@;<

>@;<

>@

;81&%7+5($'

)$67(1(53(1(75$7,21

>@0$;

<

=

=

<

=

0$;

0$;

<

&

2)'5,9(

/

;

;

;

;

;

;81&%7+5($'

)$67(1(53(1(75$7,21

>@0$;

;

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 5

Page 18

Specifications WD Purple PR1334M

2.4 Electrical Specifications

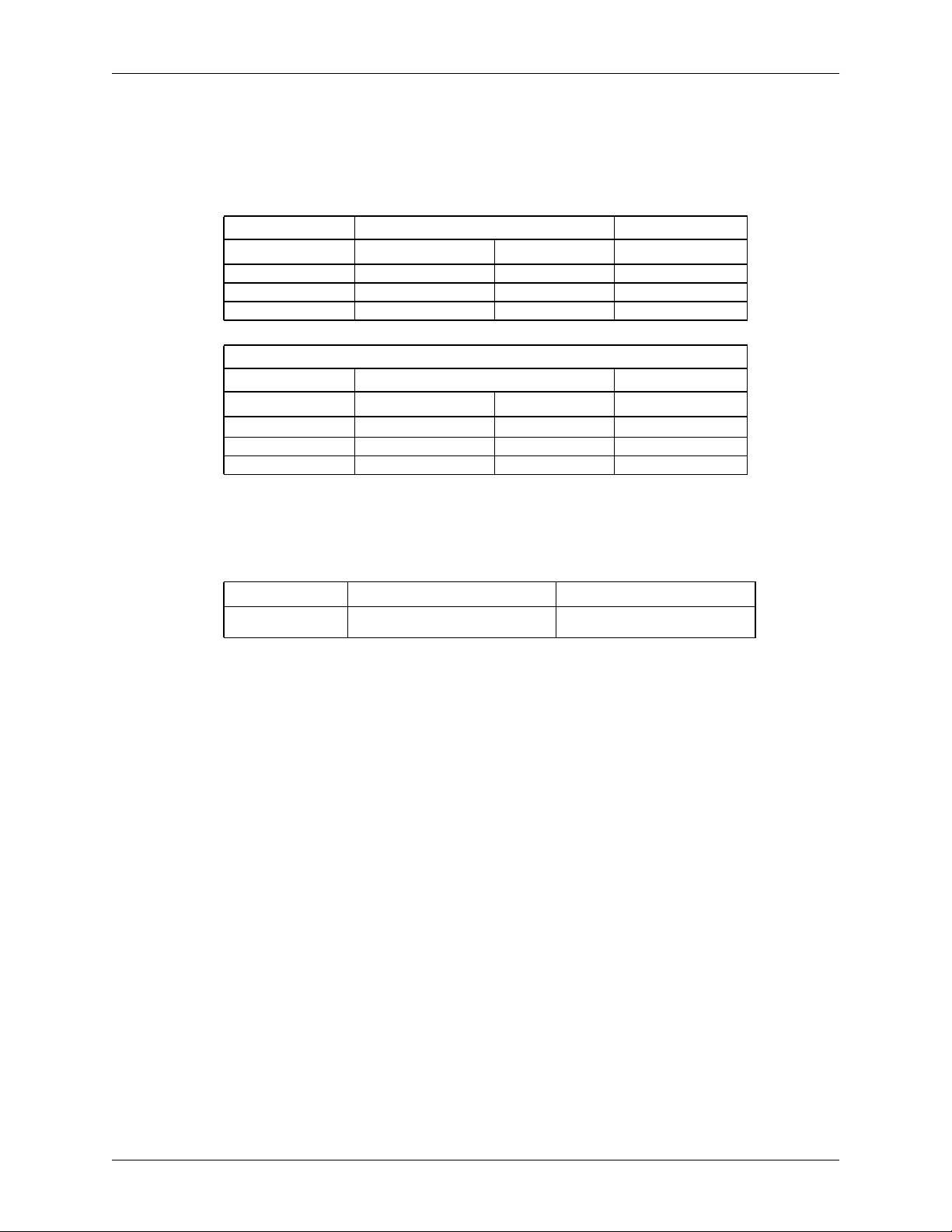

2.4.1 Current Requirements and Power Dissipation

All values are typical (25°C, 5.0V, and 12V input). 3.3V Serial ATA power not utilized in

this product.

Operating Mode Mean Current Power, Average

12 VDC 5 VDC

Spinup (max) 1.75 A – 24.5 W

Read/Write 235 mA 335 mA 4.5 W

Seek 260 mA 300 mA 4.6 W

POWER MANAGEMENT COMMANDS

Operating Mode Mean Current Power, Average

12 VDC 5 VDC

Idle

Standby 7 mA 70 mA 0.4 W

Sleep 7 mA 70 mA 0.4 W

230 mA 260 mA 4.1 W

2.4.2 Input Voltage Requirements

The input voltage requirements are +5.0V ± 5% and +12.0V ± 10%.

2.4.3 Ripple

+12 VDC +5 VDC

Maximum

Frequency

200 mV (peak-to-peak)

0-30 MHz

100 mV (peak-to-peak)

0-30 MHz

2.4.4 Power Connectors and Cables

SATA Connectors

For information on SATA data connectors, refer to the Serial ATA 1.0 specification

available for download at www.serialata.org.

At the time of this printing, there are no published standards for SATA power/mating

connectors or power/data cable wire gauges.

Cabling Requirements for SATA

The SATA cable consists of four conductors in two differential pairs. The cable may

also include drain wires to be terminated to the ground pins in the SATA cable

receptacle connectors. See the SATA 1.0 specification for cable specifications. The

cable's maximum length is one meter.

6 RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 19

WD Purple PR1334M Specifications

2.5 Environmental Specifications

2.5.1 Shock and Vibration

Table 1. Shock and Vibration

Shock

Operating 30G, 2 ms (read/write)

65G, 2 ms (read)

Non-operating (2 ms) 250G

Note: Half-sine wave, measured without shock isolation and without non-recoverable errors.

Vibration

Operating Linear: 20-300 Hz, 0.75G (0 to peak)

Random: 0.004 g2 /Hz (10-300 Hz)

Non-operating Linear: 20-500 Hz, 4.0G (0 to peak)

2

Random: 0.05 g

Sweep Rate 0.5 octave/minute minimum

Rotational Vibration

12.5 rad/sec

Frequency (Hz) 20 200 300 900 1400 1500

(Rad/sec2)2/Hz

Drive Generated Vibration

Operating 0.2 gm-mm average with the drive in an unconstrained condition

Rotational Shock Non-Operating

Amplitude 20K rad/sec

Duration 2 ms

2

based on the following PSD profile maintaining < 20% degradation:

0.035 0.035 0.2 0.2 0.002 0.002

/Hz (10-300 Hz)

2

Operating Vibration

Drives are tested by applying a random excitation in each linear axis, one axis at a

time. The drive incurs no physical damage and no hard errors while subjected to

continuous vibration not exceeding the level listed in Table 1. Operating performance

may degrade during periods of exposure to continuous vibration.

Non-Operating Vibration

Note: This specification applies to handling and transportation of unmounted drives.

Drives are tested by applying a random excitation in each linear axis, one axis at a

time. The drive incurs no physical damage when subjected to continuous vibration

not exceeding the level listed in Table 1.

Packaged Shock and Vibration

The shipping packaging is designed to meet the National/International Safe Transit

Association (N/ISTA) standards for packaged products. The drive incurs no physical

damage when subjected to the N/ISTA standards.

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 7

Page 20

Specifications WD Purple PR1334M

2.5.2 Temperature and Humidity

The system environment must allow sufficient air flow to limit maximum surface

temperatures as defined. AFR can be affected by workload and operating

temperature. See Section 2.6 on page 11 for further details.

Operation

Min-Max Base Casting Temperature

Humidity 5-95% RH non-condensing

Thermal Gradient 20C/hour (maximum)

Humidity Gradient 20%/hour (maximum)

Temperature -40°C to 70°C (-40°F to 158°F)

Humidity 5-95% RH non-condensing

Thermal Gradient 30C/hour (maximum)

Humidity Gradient 20%/hour (maximum)

1

Operating at elevated base casting temperatures will result in a higher AFR.

See Section 2.6 on page 11 for further details.

1

Non-Operation

0C to 65C (32F to 149F)

37.7C (maximum wet bulb)

35C (maximum wet bulb)

8 RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 21

WD Purple PR1334M Specifications

2.5.3 Thermocouple Location

Component Location

Drive base casting #1, Figure 2

The system environment must allow sufficient air flow to limit maximum base casting temperatures as defined

in Figure 2 below.

Figure 2. Drive Base Casting Thermocouple Location

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 9

Page 22

Specifications WD Purple PR1334M

2.5.4 Cooling

If forced air cooling is required, the drive must be positioned to receive airflow from

one or more fans as indicated in Figure 3.

Figure 3. Forced Airflow Direction

$%29('5,9(

%(/2:'5,9(

2.5.5 Atmospheric Pressure

Altitude

Operating -1,000 feet to 10,000 feet (-305M to 3,050M)

Non-operating -1,000 feet to 40,000 feet (-305M to 12,200M)

2.5.6 Acoustics

TYPICAL SOUND POWER LEVEL

Measured per ECMA-74/ISO 7779

Idle Mode (average dBA, no audible pure tones) 23

Seek Mode (average dBA) 24

2.5.7 RoHS (Restriction of Hazardous Substances)

WD complies with the Restriction of Hazardous Substances (RoHS) Directive 2011/

65/EU of the European Parliament, which is effective in the EU beginning July 8, 2011.

RoHS aims to protect human health and the environment by restricting the use of

certain hazardous substances in new equipment, and consists of restrictions on lead,

mercury, cadmium, and other substances.

10 RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 23

WD Purple PR1334M Specifications

2.6 Reliability Specifications and Characteristics

The average Annualized Failure Rate (AFR) calculations assumes operation at

nominal voltages, a base casting temperature of 40°C, and the workload

usage of a typical surveillance environment. Workload is defined as the

number of bytes transferred by the user to/from the drive. If the system(s)

that the drive is installed in are not capable of meeting the characteristics

listed below, please use a WD drive that matches your system(s)' capability.

Operating drives outside any of the reliability characteristics listed below will

result in a higher AFR.

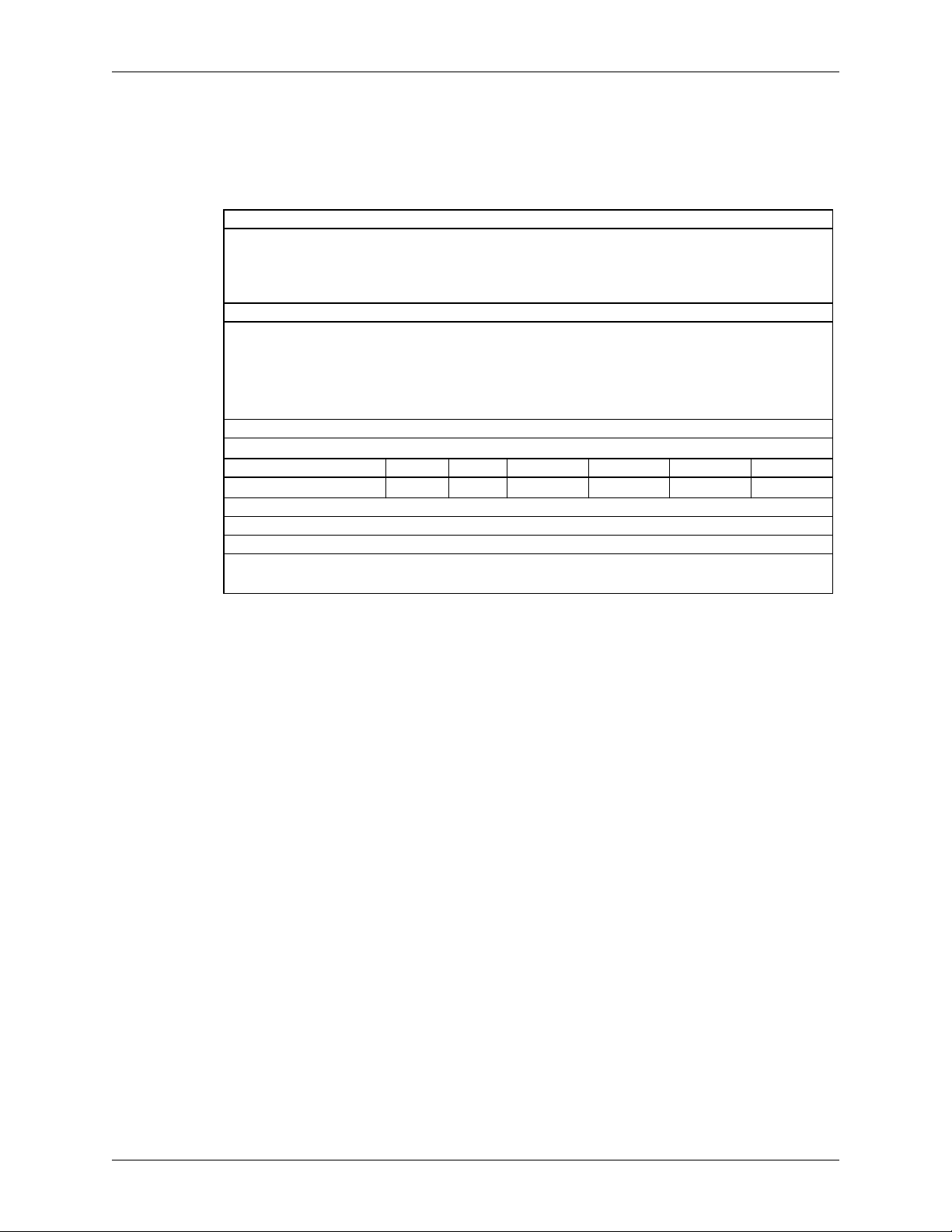

Reliability Specification

Average AFR over the Limited Warranty Period 0.88%

Reliability Characteristics

Base Casting Temperature 40 C

Annual Power on Hours (POH) <=8760

Annualized Workload Rate

1

Annualized Workload Rate = TB transferred x (8760/recorded power-on hours)

1

<=180 TB/Year

2.7 Device Plug Connector Pin Definitions

For information on SATA data connectors, including the pin definitions of the SATA

connectors and

the corresponding signal names and signal functions, refer to the latest SATA

specification available for

download at www.serialata.org.

2.8 Agency Approvals

PR1334M Regulatory Number (R/N): 800055

These drives meet the standards of the following regulatory agencies:

• Underwriters Laboratories: Bi-National UL Standard CAN/CSA-C22.2 No. 60950/

UL 60950-1. Standard for Safety of Information Technology Equipment, including

Electrical Business Equipment (File E101559).

• TUV NORD CERT GmbH: IEC 60950-1 per EN 60950-1, Standard for Safety of Infor-

mation Technology Equipment, including Electrical Business Equipment. IEC

60065. Standard of Safety for Audio, Video, and Similar Electronic Apparatus.

• CE Compliance for Europe: Complies with EN 55022: 2010 RF/ Conducted Emis-

sions and EN 55024: 2010 Immunity requirements. Including EU Directive 2011/

65/EU RoHS II requirements.

• RCM Compliance for Australia and New Zealand: Verified to comply with AS/NZS

CISPR 22 for RF Emissions as required by the Australian Communications Authority.

• Korean KC Mark: Registered as a Class-B product with the South Korean Ministry

of Information and Communication.

• Taiwan BSMI EMI Certification: Certified as a Class-B product with the Bureau of

Standards Metrology and Inspection (BSMI).

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 11

Page 24

Specifications WD Purple PR1334M

2.9 Full Model Number Specification

Table 4 below provides a summary specification of the model number suffix for this

product platform.

Table 4. Full Model Number Description

Model Number Format ID Product Brand Description

WD40PURX-xxNZ6Y0 NZ6 WD Purple PR1334M-4TB Surveillance 64 MB SATA 6 Gb/s AF

WD40PURX-xxN96Y0 N96 WD Purple PR1334M-4TB Surveillance 64 MB SATA 6 Gb/s AF

WD40PURZ-xxTTDY0 TTD WD Purple PR1334M-4TB Surveillance 64 MB SATA 6 Gb/s AF

WD40EVRX-xxB9FY0 B9F WD Purple PR1334M-4TB Surveillance 64 MB SATA 6 Gb/s AF

12 RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 25

WD Purple PR1334M Product Features

3.0 PRODUCT FEATURES

n SATA 6 Gb/s

n AllFrame 4k™ Technology

n IntelliSeek™

n Dynamic Fly Height Control

n Perpendicular Magnetic Recording (PMR)

n NoTouch™

n Dual Stage Actuator Technology

n Advanced Format

n Native Command Queuing (NCQ )

n Pre-Emptive Wear Leveling (PWL)

n S.M.A.R.T. Command Transport (SCT)

n World Wide Name (WWN)

n Reliability Features Set—Data Lifeguard™

n Hot Plug Support

n Active LED Status

n Fluid Dynamic Bearings (FDB)

n Staggered Spin-Up and Activity Indication (SATA Power Pin 11)

n CacheFlow™

n 48-bit Logical Block Addressing (LBA)

n Power Management

n Self-Monitoring, Analysis, and Reporting Technology (S.M.A.R.T.)

n Security Mode

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 13

Page 26

Product Features WD Purple PR1334M

3.1 SATA 6 Gb/s

SATA 6 Gb/s is the next generation interface for SATA hard drives. It adds to the

functionality of the SATA 1.5 Gb/s interface with the following features:

n Native Command Queuing (NCQ ) — server feature for performance in random I/

O transaction environments. It aggregates many small random data transfers and

allows the disk to reorder the commands in a sequential order for faster access.

n Improved Power Management— provides improved power management

features including Host Initiated SATA Power Management (HIPM) and Device

Initiated SATA Power Management (DIPM).

n Staggered Spin-up — allows the system to control whether the drive will spin up

immediately or wait until the interface is fully ready before spinning up.

n Asynchronous Signal Recovery (ASR) — robustness feature that improves signal

recovery.

n Enclosure Services — defines external enclosure management and support

features.

n Backplane Interconnect — defines how to lay out signal line traces in a

backplane.

n Auto-activate DMA — provides increased command efficiency through

automated activation of the DMA controller.

n Device Configuration Overlay (DCO) — allows hiding of supported features via a

SATA feature mask.

3.2 AllFrame 4K Technology

All WD Purple™ drives are equipped with AllFrame 4K™ technology, which improves

ATA streaming to help reduce frame loss, improve overall video playback, and

increase the number of hard drive bays supported within a NVR. Help make your

surveillance solution future-ready knowing that WD Purple™ drives are ready for ultra

high definition cameras.

3.3 IntelliSeek

WD’s unique IntelliSeek technology proactively calculates an optimum seek speed to

eliminate hasty movement of the actuator that produces noise and requires power,

which is common in other drives. With IntelliSeek, the actuator’s movement is

controlled so the head reaches the next target sector just in time to read the next

piece of information, rather than rapidly accelerating and waiting for the drive

rotation to catch up. This smooth motion reduces power usage by more than 60

percent compared with standard drives, as well as quiets seek operation and lowers

vibration.

3.4 Dynamic Fly Height Control

This feature is designed to compensate for head/media separation changes due to

temperature and altitude. It adds video quality margins across temperature and

altitude changes.

14 RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 27

WD Purple PR1334M Product Features

3.5 Perpendicular Magnetic Recording (PMR)

In perpendicular magnetic recording (PMR), the magnetization of each data bit is

aligned vertically to the spinning disk, rather than longitudinally as has been the case

in hard drive technology for decades. In longitudinal recording, as the bits become

smaller and closer together, they experience an increasing demagnetizing field, much

like two bar magnets that are placed end-to-end repel one another. A property of the

media called coercivity must be increased to counteract the demagnetization to keep

the bits stable under thermal fluctuations; otherwise data corruption may occur over

time. Higher media coercivity has pushed the recording head write field to the limit of

known materials.

In perpendicular recording, the adjacent bits attract instead of repel (as with bar

magnets placed side by side,) creating more thermally stable bits. In addition, the

media contains a magnetically soft underlayer (SUL) beneath the recording layer. This

SUL allows a larger effective write field, thus higher coercivity media, enabling further

increases in density. Lastly, because of the vertical orientation of the bits, the PMR

recording layer tends to be thicker than that used for longitudinal recording,

providing increased signal for the read heads. All of these benefits enable WD

engineers to reliably pack more data on a given disk than is possible with

conventional longitudinal recording.

3.6 NoTouch Ramp Load Technology

Parks the recording heads off the disk surface during spin up, spin down and when

the drive is off. This ensures the recording head never touches the disk surface

resulting in improved long term reliability due to less head wear, and improved nonoperational shock tolerance.

3.7 Dual Stage Actuator Technology

A head positioning system with dual-stage actuators that improves positioning

accuracy over the data track(s). The primary stage provides course displacement; the

secondary stage uses piezo electric motion to fine tune the head positioning to a

higher degree of precision.

3.8 Advanced Format (AF)

Advanced Format (AF) technology is adopted by WD and other drive manufacturers

as one of multiple ways to continue growing hard drive capacities. AF is a more

efficient media format that enables increased areal densities.

In AF, each physical sector is composed of eight 512 byte logical sectors, totaling

4096 bytes. WD is shipping AF drives as 512 Byte Emulated Devices until full

operating system support for the AF host interface is available. 512 Byte Emulated

Device drives are backward compatible with 512 byte sector accesses.

WD AF hard drives may require you to run the WD Align software utility after you

install your operating system or partition and format the drive as a secondary drive.

WD Align software aligns partitions on the AF drive to ensure it provides full

performance for certain configurations. Go to www.wdc.com/advformat for important

configuration and installation guidelines.

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 15

Page 28

Product Features WD Purple PR1334M

3.9 Native Command Queuing (NCQ )

These drives support Native Command Queuing. NCQ is a true Enterprise feature for

environments such as database, Web servers, and e-mail servers.

Performance of a random I/O workload can be improved through intelligent reordering of the I/O requests so they read/write to and from the nearest available

sectors and minimize the need for additional disk revolutions or head actuator

movement. This improvement is achieved though Native Command Queuing (NCQ ).

NCQ allows the drive to re-order read commands, thereby increasing random read

IOPs. Additional NCQ features that can prove beneficial include a Write Cache

disabled IOP increase and a queuing implementation built upon an existing, highly

automated cache architecture. Queued reads in NCQ leverage the same re-ordering

schemes used for write caching. The firmware design maintains the “order” of

overlapping/colliding queued commands. NCQ is designed to excel in multithreaded environments with high random I/O loads.

3.10 Pre-emptive Wear Leveling (PWL)

This WD feature provides a solution for protecting the recording media against

mechanical wear. In cases where the drive is so busy with incoming commands that it

is forced to stay in a same cylinder position for a long time, the PWL control engine

initiates forced seeks so that disk lubricant maintains an even distribution and does

not become depleted. This feature ensures reliability for applications that perform a

high incidence of read/write operations at the same physical location on the disk.

3.11 S.M.A.R.T. Command Transport (SCT)

The SCT Command Transport feature set provides a method for a host to send

commands and data to a device and for a device to send data and status to a host

using log pages. Standard ATA commands may be interspersed with SCT commands,

but SCT commands cannot be nested. SCT commands that do not require a

subsequent data transfer operation are not interspersed with any ATA commands or

each other.

The SCT Command Transport feature set provides a method for a host to send

commands and data to a device and for a device to send data and status to a host

using log pages. This capability is used to pass commands through a driver interface

or a bridge where new or unknown commands may be filtered and not passed to the

drive. SCT is also used for issuing commands that require more than 8 parameter

bytes. ATA8-ACS provides detailed information on the usage and capabilities of SCT.

The SCT feature set includes the following commands:

n Write Same

n Temperature Reporting

3.11.1 Write Same

The Write Same command allows the host to erase the media, or write a pattern

repeatedly across the media, with a minimum of data transfer from the host. The host

can clear the entire media to zeros or a specific pattern by sending this command

with the pattern as a parameter—no data transfer is necessary. Write Same can write

the entire media, or just a portion of the media. The host can monitor the progress of

16 RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 29

WD Purple PR1334M Product Features

the Write Same by issuing SCT Status requests. This frees the host system to do other

tasks while the media is being cleared.

3.11.2 Temperature Reporting

The SCT Temperature Reporting (SCT TR) feature allows a host system to access

temperature information in the drive. The S.M.A.R.T. temperature value is reported

within ±3°C of the base casting temperature. This information can been used to

control fans or adjust the usage of various system components to keep the drive

within its normal operating temperature. Applications include Enterprise, Laptop,

Desktop and Consumer Electronics. SCT TR reports the maximum and minimum

sustained operating limits, warning level limits, and drive damage limits. In addition to

reporting the limits, SCT TR returns the current drive temperature (a temperature

history which the host can use to predict heating or cooling trends) and the maximum

temperature achieved during the lifetime of the drive as well as the highest

temperature achieved since the power was applied to the drive. Detailed information

on this capability can be found in ATA8-ACS.

3.12 World Wide Name (WWN)

It has become a critical requirement that hard drives be uniquely identified by

computer systems. This allows a drive to maintain its identity as it is transported from

system to system or placed on a network. IEEE has defined a format for serial numbers

that is widely recognized in the computing industry by adding World Wide Name

(WWN) to ATA/ATAPI-7 in 2002.

The World Wide Name (WWN) defined in ATA/ATAPI-7 is a modification of the IEEE

Extended Unique Identifier 64 bit standard (EUI-64) and is comprised of three major

components: naming authority, organizationally unique identifier (OUI) and serial

number. WD's OUI is 0014EEh.

3.13 Reliability Features Set

3.13.1 Data Lifeguard™

Representing WD's ongoing commitment to data protection, Data Lifeguard includes

features that enhance the drives ability to prevent data loss. Data Lifeguard data

protection utilities include thermal management, an environmental protection

system, and embedded error detection and repair features that automatically detect,

isolate, and repair problem areas that may develop over the extended use of the hard

drive. With these enhanced data reliability features, the drive can perform more

accurate monitoring, error repair, and deliver exceptional data security.

All WD drives are defect-free and low-level formatted at the factory. After prolonged

use, any drive, including a WD drive, may develop defects. If you continue receiving

data errors in any given file, use the Data Lifeguard Diagnostics utility to recover,

relocate and rewrite the user data to the nearest spare sector and maintain a

secondary defect list.

CAUTION: As with all format utilities, some options in the Data Lifeguard Diagnostics

utility will overwrite user data.

Download the latest versions of the Data Lifeguard Diagnostic and Data Lifeguard

Tools programs at support.wdc.com.

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 17

Page 30

Product Features WD Purple PR1334M

3.13.2 Thermal Management

The drive is designed with Thermal Management features for high reliability.

n State-of-the-art mechanical design—Mechanical design is optimized to reduce

the drives temperature. State-of-the-art thermal dissipation and windage design

is employed.

n Closed loop servo management—Thermal management monitors the drive

temperature and can control servo operations to maintain a stable operating

temperature under high temperature conditions. This is a closed loop servo and

thermal control system.

n S.M.A.R.T. HDA Temperature Attribute—The S.M.A.R.T. HDA Temperature

Attribute is supported. The S.M.A.R.T. temperature value is reported within ±3°C

of the base casting temperature.

n Ducted airflow—Provides protection to the Read/Write element from heated air.

18 RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 31

WD Purple PR1334M Product Features

3.13.3 Internal Environmental Protection System

This dual filter system protects the inside environment of the drive from

contamination. System features include:

n Dual Filtration System to ensure fast clean-up times

n Directed airflow to maximize mechanical cooling

n Increase casting surface area to maximize cooling

n Ducted air flow to protect Read Rite elements from heated air

n Breather filter located at low pressure area

n Enhanced heat dissipation

3.13.4 Recoverable Errors

A sector marked for repair is written back to the same location. The sector is then

read several times to be sure that it was written correctly and that there is no media

damage at its location (sector test). If the sector does not easily and consistently read

correctly, the sector is then relocated with original data.

3.13.5 Unrecoverable Errors

If an unrecoverable error is found during the offline scan, the sector is marked. Future

reads from this location will continue to perform full error recovery. However, the

next write to this location will perform a sector test to be sure the media is not

damaged, and the sector relocated if the sector test fails.

3.13.6 Self Test

Self Test is a quick way to determine the operation status of a drive. The following

Self Tests are supported:

n Quick Test: Completes in less than two minutes.

n Extended Test: Tests all the critical subsystems of the drive.

n Conveyance Test: Quickly identifies issues caused by handling damage.

n Selective Test: Scans host-defined sections of the drive.

The test may be run to completion or be performed as a background task as the drive

processes other commands from the host. The host may then poll the drive for

runtime status and test results. Since the test is embedded in the drives firmware, it is

always available, requires no installation and can be faster and more effective than a

software-based drive test.

3.13.7 ATA Error Logging

ATA Error Logging provides an industry standard means to record error events and

supporting information that is then accessible by the host. The event record includes

the exact command that caused the failure, the response of the drive, the time of the

event and information about the four commands immediately prior to the errant

command. Error Logging can reliably and quickly determine whether a system

problem is the result of a hard drive failure or other component malfunction. Error

Logging retains total error count for the life of the drive and complete records for the

last five errors.

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 19

Page 32

Product Features WD Purple PR1334M

3.13.8 Defect Management

Every WD drive undergoes factory-level intelligent burn in, which thoroughly tests for

and maps out defective sectors on the media before the drive leaves the

manufacturing facility. Following the factory tests, a primary defect list is created. The

list contains the cylinder, head, and sector numbers for all defects.

Defects managed at the factory are sector slipped. Grown defects that can occur in

the field are mapped out by relocation to spare sectors on the inner cylinders of the

drive.

3.14 Automatic Defect Retirement

The automatic defect retirement feature automatically maps out defective sectors

while reading or writing. If a defective sector appears, the drive finds a spare sector.

The following item is specific to automatic defect retirement on writes (write autorelocation):

n Data is always written to disk (using automatic defect retirement if required) and

no error is reported.

The following item is specific to automatic defect retirement on reads (read autorelocation):

n When host retries are enabled, the drive will internally flag any unrecoverable

errors (DAMNF or ECC). This flagging allows subsequent write commands to this

location to relocate the sector only if the sector test fails.

3.14.1 Error Recovery Process

The drive has four means of error recovery:

n ECC On-the-Fly

n Preamp Thermal Asperity (TA) Compensation

n Read/Write Retry Procedure

n Extended Read Retry Procedure

ECC On-the-Fly – If an ECC error occurs, the drive attempts to correct it on-the-fly

without retries. Data can be corrected in this manner without performance penalty.

The details of the correction algorithm appear in the next section.

Preamp Thermal Asperity Compensation – A Thermal Asperity (TA) is a baseline shift in

the readback signal due to heating of the magnetoresistive stripe on the head as a

result of physical contact with the disk or a particle. The preamp circuit has the ability

to detect and compensate for thermal asperities. When an error cannot be corrected

by ECC On-the-Fly, another retry is performed, where the preamp with its thermal

asperity detection feature determines if the error is due to a thermal asperity. Once

the preamp determines that the error is due to thermal asperity, preamp

compensation is enabled. If preamp compensation alone is not enough to recover,

then the channel performs a series of TA-specific recoveries.

Read/Write Retry Procedure – This retry procedure is used by all disk controller error

types. If the procedure succeeds in reading or writing the sector being tried, then

recovery is complete and the controller continues with the command. Each retry

operation also checks for servo errors. The procedure ends when error recovery is

achieved or when all possible retries have been attempted.

Extended Read Retry Procedure – This retry procedure tries combinations of

positive/negative track offsets and data DAC manipulations to recover the data. This

20 RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 33

WD Purple PR1334M Product Features

retry procedure applies only to read data recovery. The Read/Write Retry procedure

performs the actual retry operation.

When an extended retry operation is successful, the controller continues with the

command. The controller clears any changes in track offset or data DAC settings

before the command continues.

3.15 Hot Plug Support

SATA supports hot plugging (also known as “hot swapping”), the ability to swap out a

failed hard drive without having to power down the system or reboot. This capability

contributes to both data availability and serviceability without any associated

downtime, making it a critical feature for extending SATA into enterprise applications.

These WD hard drives support SATA 2.5 hot plugging only in systems where a SATA

hard drive storage backplane is used.

The Serial ATA revision 2.5 specification requires staggered pins for both the hard

drive and drive receptacles. Staggered pins mate the power signals in the

appropriate sequences required for powering up the hot plugged device. These pins

are also specified to handle in excess of the maximum allowed inrush current that

occurs during drive insertion. SATA-compliant devices thus need no further

modification to be hot pluggable and provide the necessary building blocks for a

robust hot plug solution, which typically includes:

n Device detection even with power downed receptacles (typical of server

applications).

n Pre-charging resistors to passively limit inrush current during drive insertion.

n Hot plug controllers to actively limit inrush current during drive insertion.

3.16 Active LED Status

The drive supports external LED requirements. It provides an activity LED output

which is ON during command execution and OFF otherwise.

The drive strength of this open Drain Drive Active signal is that it can sink 12mA to

0.4V Max. It is 5V tolerant, meaning that the external LED may be driven from +5V or

+3.3V so long as the Host system provides a series resistor to limit the LED current to

the lower of 12mA or the rated operating current of the LED. As an example with +5V

and a 2 volt forward drop across a 10mA LED, a 300 Ohm 5% 1/16W resistor would

be suitable. In the case of a 3.3V supply for the same LED, the resistor would be 130

Ohm 5% 1/16W.

The pin corresponding to P11 shall be used for Active LED (see “Device Plug

Connector Pin Definitions” on page 11).

3.17 Fluid Dynamic Bearings (FDB)

Bearing design that incorporates a layer of high-viscosity lubricant instead of ball

bearings in the hard drive spindle motor. As an alternative to conventional ball

bearing technology, FDB designs provide increased non-operational shock resistance,

speed control, and improved acoustics.

3.18 Staggered Spinup and Activity Indication (SATA Power Pin 11)

Note: This feature is available for specific OEM configurations.

SATA device power connector pin 11 is defined as a means by the host to DISABLE

staggered spinup and it may also be used by the device to provide the host with an

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 21

Page 34

Product Features WD Purple PR1334M

activity indication. According to the SATA spec, “Staggered Spin-up Disable and

Activity Signal shall not be enabled at the same time.”

3.18.1 Staggered Spinup

When multiple disks are installed in an enclosure, it is desirable to provide a simple

mechanism by which a subsystem controller can sequence hard drive initialization to

minimize the current load presented during power up. Staggered spinup provides

this mechanism by preventing the hard drives from spinning up until after successful

PHY initialization (i.e., after PHY enters DP7:DR_Ready state).

Staggered spinup is only applicable during initial power-up. If a drive is spun down

using ATA commands—as a result of having been placed in Standby or Sleep power

modes, for example—the drive shall spin up following the rules that govern spinup

from low power modes described in ATA/ATAPI-6 or later.

3.18.2 Activity Indication

The host controller through SATA power pin 11 may access storage device status and

activity. The signal provided by the device for activity indication is a low-voltage lowcurrent signal. It is not suitable for directly driving an LED. A buffer circuit external to

the device must be employed to drive the LED. The activity signal is based on an

open-collector or open-drain active low driver. The device shall tolerate the activity

signal being shorted to ground.

3.19 CacheFlow™

CacheFlow is WD’s unique, multi-generation disk caching system. It incorporates read

cache with write cache.

WD designed CacheFlow to obtain maximum performance with today’s most popular

operating systems and applications. CacheFlow increases performance over prior

caching algorithms by increasing the number of times that requested data is in the

cache. This reduces the number of host commands that require actual media access

thereby improving overall drive performance.

Typical applications perform a variety of access patterns, such as random, sequential,

and repetitive. CacheFlow is designed to dynamically adapt to the changes in access

patterns that occur during the course of application execution.

Random mode is the default operational mode for CacheFlow. Once CacheFlow

detects a sequential access pattern, it leaves random mode. CacheFlow also

performs predictive read operations to increase the probability that data requested in

future commands already exists in the cache.

CacheFlow partitions the buffer into multiple segments to allow for the fact that

applications may access multiple non-contiguous areas on the disk. CacheFlow tracks

the amount of valid data in each segment and controls the deallocation of segments

to maximize drive performance.

3.19.1 Write Cache

CacheFlow is designed to improve both single and multi-sector write performance by

reducing delays caused by seek time and rotational latency.

The write cache adaptively detects random and sequential access patterns during

application execution.

22 RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 35

WD Purple PR1334M Product Features

If a defective sector is found during a write cache operation, that sector is

automatically relocated before the write occurs.

3.19.2 Read Cache

CacheFlow implements a multiple segment read cache. Cache segments are assigned

to read commands as they are received from the host.

Each read segment consists of pre and post read sectors in addition to the hostrequested sectors. This maximizes the amount of cache data in the drives buffer,

thereby increasing the likelihood of cache hits and improving overall performance.

3.20 48-bit Logical Block Addressing (LBA)

The 48-bit Address feature set allows devices with capacities up to approximately 281

tera sectors or approximately 144 peta bytes. In addition, the number of sectors that

may be transferred by a single command are increased by increasing the allowable

sector count to 16 bits.

48-bit Address

Bits (47:40) Bits (39:32) Bits (31:24) Bits (23:16) Bits (15:8) Bits (7:0)

LBA High (exp) LBA Mid (exp) LBA Low (exp) LBA High LBA Mid LBA Low

16-bit Sector Count

Bits (15:8) Bits (7:0)

Sector Count

(exp)

Sector Count

3.21 Power Management

This drive supports the ATA power management commands that lower the average

power consumption of the hard drives. For example, to take advantage of the lower

power consumption modes of the drive, an energy efficient host system could

implement a power management scheme that issues a Standby Immediate command

when a host resident disk inactivity timer expires. The Standby Immediate command

causes the drive to spin down and enter a low-power mode. Subsequent disk access

commands would cause the drive to spin up and execute the new command. To

avoid excessive wear on the drive due to the starting and stopping of the HDA, set

the host’s disk inactivity timer to no shorter than ten minutes.

The drive also supports the SATA power management feature that lowers the average

power consumption of the SATA interface.

3.22 Self-Monitoring, Analysis, and Reporting Technology (S.M.A.R.T.)

S.M.A.R.T. helps you monitor a drives internal status through diagnostic commands at

the host level.

The drive monitors Read Error Rate, Start/Stop Count, Re-allocated Sector Count,

Seek Error Rate, Power-on Hours Count, Spin-up Retry Count, Drive Calibration Retry

Count, Drive Power Cycle Count, Offline Scan Uncorrectable Sector Count, CRC Error

Rate, Multi-zone Error Rate, Spin-up Time, Relocation Event Count, and Current

Pending Sector Count. The hard drive updates and stores these attributes in the

reserved area of the disk. The drive also stores a set of attribute thresholds that

correspond to the calculated attribute values. Each attribute threshold indicates the

point at which its corresponding attribute value achieves a negative reliability status.

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 23

Page 36

Product Features WD Purple PR1334M

3.23 Security Mode

The Security Mode feature set allows the user to create a device lock password that

prevents unauthorized hard drive access even if the drive is removed from the

computer. This feature varies by drive configuration and may not be available on all

configurations.

3.23.1 Master and User Passwords

The manufacturer/dealer can set a master password using the Security Set Password

command, without enabling the device lock function. The user password should be

given or changed by a system user.

Master Password Identifier is supported and set to a default value of 00FE. If a Master

Password is set via a Security Set Password Command, a valid Master Password

Revision code value of 0001h – FFFEh must be used. A Master Password Identifier of

0000h is ignored.

When the master password is set, the drive does not enable the device lock function.

When the user password is set, the drive enables the device lock function, and the

drive is locked after the next power on reset or hard reset.

3.23.2 Security Levels

High - If High level security is set and the user password is forgotten, the master

password can be used to unlock the drive and access the data.

Maximum - If Maximum level security is set and the user password is forgotten, data

access is impossible. Only the master password with a Security Erase Unit command

can unlock the drive when the device lock function is enabled and the user password

has been forgotten. When the Security Erase Unit command is used to unlock the

drive, all user data is erased.

24 RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 37

WD Purple PR1334M ATA Command Set

4.0 ATA COMMAND SET

4.1 Host Interface Commands

4.1.1 ATA-8 Commands

Table 5 lists the hexadecimal codes specific to each ATA-8 command supported by

these hard drives. Refer to the D1699 ATA8-ACS specification for full details on each

command.

Table 5. ATA-8 Command Opcodes

COMMAND HEX OPCODE

CHECK POWER MODE E5

DEVICE CONFIGURATION OVERLAY B1

DOWNLOAD MICROCODE 92

EXECUTE DEVICE DIAGNOSTIC 90

FLUSH CACHE E7

FLUSH CACHE EXT EA

IDENTIFY DEVICE EC

IDLE E3

IDLE IMMEDIATE E1

NOP 00

READ BUFFER E4

READ DMA C8

READ DMA EXT 25

READ FPDMA QUEUED 60

READ LOG EXT 2F

READ LOG DMA EXT 47

READ MULTIPLE C4

READ MULTIPLE EXT 29

READ NATIVE MAX ADDRESS F8

READ NATIVE MAX ADDRESS EXT 27

READ SECTOR(S) 20

READ SECTORS(S) EXT 24

READ VERIFY SECTOR(S) EXT 42

READ VERIFY SECTORS(S) 40

S.M.A.R.T. B0

SECURITY DISABLE PASSWORD F6

SECURITY ERASE PREPARE F3

SECURITY ERASE UNIT F4

SECURITY FREEZE LOCK F5

SECURITY SET PASSWORD F1

SECURITY UNLOCK F2

SET FEATURES EF

SET MAX F9

SET MAX ADDRESS EXT 37

SET MULTIPLE C6

SLEEP E6

STANDBY E2

STANDBY IMMEDIATE E0

WRITE BUFFER E8

WRITE DMA CA

WRITE DMA EXT 35

WRITE FPDMA QUEUED 61

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 25

Page 38

ATA Command Set WD Purple PR1334M

COMMAND HEX OPCODE

WRITE LOG EXT 3F

WRITE LOG DMA EXT 57

WRITE MULTIPLE C5

WRITE MULTIPLE EXT 39

WRITE SECTOR(S) 30

WRITE SECTOR(S) EXT 34

WRITE UNCORRECTABLE EXT 45

26 RELEASED 5/3/17 (WD CONFIDENTIAL) 2679-800084-A04

Page 39

WD Purple PR1334M ATA Command Set

4.1.2 SATA Commands

Table 6 lists the hexadecimal codes specific to each SATA command supported by

these hard drives. Refer to the SATA specification for full details on each command.

Table 6. SATA Command Opcodes

COMMAND HEX OPCODE

READ FPDMA QUEUED 60

WRITE FPDMA QUEUED 61

4.1.3 Obsolete Commands

Table 7 lists the hexadecimal codes specific to each obsolete command supported by

these hard drives.

Table 7. Obsolete Command Opcodes

COMMAND HEX OPCODE

INITIALIZE DEVICE PARAMETERS 91

READ LONG 22

RECALIBRATE 10

SEEK 70

WRITE LONG 32

4.1.4 SCT Commands

SCT commands provide capabilities not covered in ATA/ATAPI-7 for commands that

do not fit the ATA command delivery model. Some SCT commands report completion

when the command begins execution. Execution progress for these commands may

be checked by requesting SCT status. For instance, the host can track the progress of

a Write Same command by issuing a status request once per minute. See ATA8-ACS

for a full description of SCT.

Table 8. SCT Action Codes

ACTION CODE DESCRIPTION

0000h RESERVED

0001h Long Sector Access

0002h Write Same

0004h Features Control

0005h SCT Data Tables

0006h Vendor specific

0007h SCT BIST

C000h FFFFh Vendor specific

4.2 S.M.A.R.T. (B0h)

The S.M.A.R.T. command provides access to attribute values, S.M.A.R.T. status, and

other S.M.A.R.T. information. These commands can be used for logging and reporting

purposes, and for accommodating special user needs.

Prior to writing the S.M.A.R.T. command to the Command Register, the host must

write key values into the LBA Mid and LBA High Registers (4Fh, C2h) or the command

will be aborted and an error will be reported.

The S.M.A.R.T. command has several sub-commands that are selectable via the

Features Register when the host issues the S.M.A.R.T. command. To select a subcommand, the host must write the appropriate sub-command code to the Features

2679-800084-A04 RELEASED 5/3/17 (WD CONFIDENTIAL) 27

Page 40

ATA Command Set WD Purple PR1334M

Register before issuing the S.M.A.R.T. command. The sub-commands and their

respective codes are listed below. For more detailed information on executing

S.M.A.R.T. commands, see the ATA-7 specification.

4.2.1 Read Attribute Values Sub-Command

This command returns a sector of data with the drives S.M.A.R.T. data structure.

Table 9. Definitions for the 512 Bytes.

BYTE VALUE DESCRIPTION

0 - 1 0001h S.M.A.R.T. Data Structure Revision

2 -361 XX S.M.A.R.T. Attribute Data

135 - 361 XX S.M.A.R.T. Attribute Data

362 XX Offline data collection status

0Xh OL disabled

8Xh OL enabled

X0h scan not run

X2h scan complete

X4h scan suspended

363 XX Self-Test execution status byte.

364 - 365 XX

366 XX

367 07Bh

368 - 369 0003h

370 01h

371 XX

372 XX

373 XX

374 XX

375 - 510 XX

511 XX

X5h scan aborted

00h The previous self-test routine completed without error or no

01h The self-test routine was aborted by the host

02h The self-test routine was interrupted by the host with a hard

03h A fatal error or unknown test error occurred while the device

04h The previous self-test completed having a test element that

05h The previous self-test completed having a test element that

06h The previous self-test completed having a test element that

07h The previous self-test completed having a test element that

08h The previous self-test completed having a test element that

09-0Eh Reserved

0Fh Self-test routine in progress

Total time in seconds to complete offline data collection activity

Reserved

Offline data collection capability. Bits are as follows:

S.M.A.R.T. Capability. Bits are as follows:

Error logging capability. Bits are as follows:

Reserved

Short self-test routine completion time in minutes