Wesley shipboard User Manual

NSN 3920 Truck, Hand Lift, Pallet.

Manual-Hydraulic, Shipboard, HS Safety

Rating, 42-27-60XTSB

PALLET MULE

SHIPBOARD PALLET TRUCK

42-27-60XTSB

PARTS / SERVICE MANUAL

REVISED – FEBRUARY 2003

WESLEY INTERNATIONAL

3680 Chestnut Street Scottdale, GA 30079

800-241-2869 404-292-7441 404-292-8469 Fax

WWW.PALLETMULE.COM

1

INTRODUCTION

The factory-installed oil in the Shipboard Pallet Mule is automatic transmission fluid, type dextron 2.

The hydraulic system holds approximately one pint of fluid and operates on approximately ½ pint of

fluid.

The oil level and filler plug is located on the left-hand side on the pump assembly approximately 2

inches down from the top of the pump.

To properly fill the reservoir, lower forks, remove level-filler plug, squirt fluid from squirt-type oil can

into hole until oil trickles out the bottom edge of the hole. This is the maximum amount of fluid necessary to operate properly.

The wiper seals around the top of the pump piston and lift ram are fully functional wiper rings and do

not need to be replaced unless they are damaged, as both the pump piston and lift ram can be removed

directly from and reinstalled through the wiper seals without their having to be removed.

USE OF LOCTITE WHEN NECESSARY TO INSTALL:

(A) Preparation on the B1-15.5 pump piston seal involving installation in its oversize casting bore.

1. The seal and its respective casting bore must be clean and free of debris and oil.

2. To clean: Spray the casting bore surface, and the outer perimeter of the pump seal with Locquic

Primer-Cleaner grade T, and then wipe with a clean rag.

3. Next: Spray the casting bore surface, and outer perimeter of the pump seal again with Locquic

Primer-Cleaner grade T, this time allowing to dry for approximately 5 minutes.

4. Loctite Locquic Primer-Cleaner grade T causes the Loctite retaining compound to harden faster

and insures best results. MIL Spec. 22473

(B) Application of the Loctite Retaining Compound to the B1-15.5 pump seal and its respective over-

size casting bore. MIL Spec. R46082

1. Apply a coating of retaining co mpound to the inside perimeter of the casting bore. Also apply a

coating of retaining compound to the outside perimeter seal.

2. Insert seal in casting bore: allow 1 hour for proper hardening.

3. It is of great importance that the clearances between the mating parts be completely filled in order to obtain a leak-proof seal. Make certain not to remove require material while wiping any

excess, specifically where the pump piston is involved. Loctite is a material that hardens from a

liquid state into a solid state when confined between mating parts without the presence of air.

The pump piston, lift ram and release plunger cylinders are all burnished to a #10 finish. In conjunction

with this fine finish, the Pallet Mule uses simplified packing, consisting of polyurethane O-rings and Ucups. This packing is made of the same tough, resilient material that the wheels are coated with. The

combination of polyurethane working against this fine finish means years of trouble free hydraulic operation.

2

SAFETY AND

OPERATIONAL CONSIDERATIONS

• Read Manual before operating hand pallet jack.

• Always make sure hand pallet truck is operated by trained personnel.

• Keep hands, feet and loose clothing clear of area beneath hand pallet truck.

• Always make certain that your view is unobstructed in the direction that you are

moving.

• Do balance the load evenly on the forks.

• Do Not exceed the maximum lifting capacity as shown on the id plate.

• Do Not ride or carry personnel on hand pallet truck.

• Do Not lift loads or objects with the fork tips.

• Do Not use hand pallet truck on grades.

How to Operate

• To raise the load, pump handle until load reaches desired height

• Hold the release lever up – The truck will lower load.

• Hold brake handle up to move. Releasing brake handle will immediately apply

brakes.

Take Hand Pallet Truck out of service immediately if:

• Hydraulic pump is leaking

• Any fasteners are loose or missing

• Any part of the hand pallet truck is bent or damaged.

• Brake does not automatically hold hand pallet truck in a locked position.

3

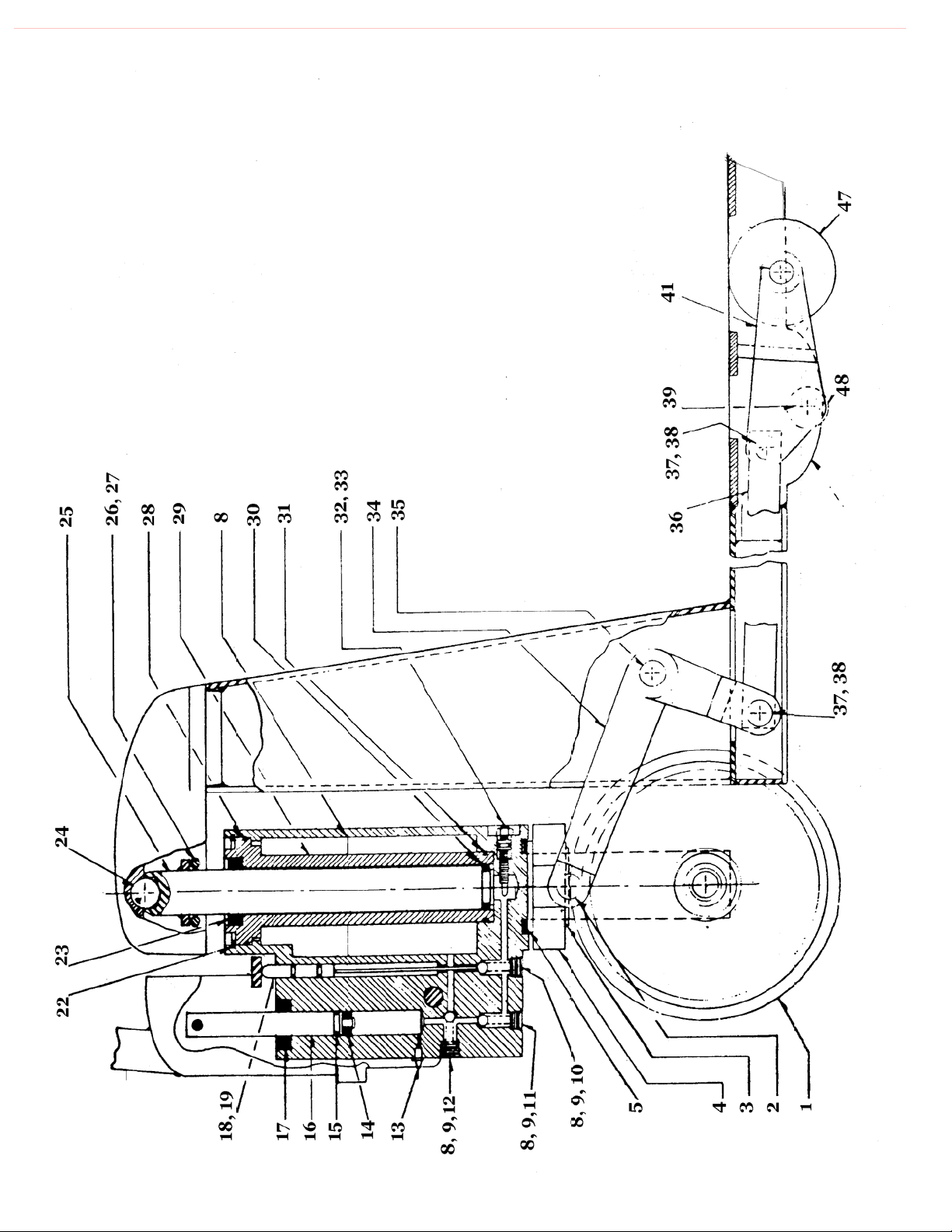

Drawing 1

(Parts List on Following Page)

SIDE VIEW

4

SIDE VIEW PARTS

1 DM-09 2 Steer Wheel Assembly 25 B1-26 10M SS 1 Lift Ram 10M, Stainless Steel

Item Part # Qty Description Item Part # Qty Description

3 B1-08B 1 Load Arm Snap Ring 27 B1-34B 2 Nut

2 B1-03C SS 2 Load Arm Pivot, Stainless Steel 26 B1.34 2 Stripper Bolt

5 AA-30 CR 1 Thrust Bearing 29 B1-01C 10M 1 Center Cylinder 10M

4 B1-03 Spec 1 Load Arm 28 B1-29 1 Center Cylinder O-ring, Top

9 B1-16 3 Ball 31 B1-06 1 Center Cylinder O-ring, Bottom

8 B1-20 4 Plug 30 B1-32 10M 1 Lift Ram U-cup, 10M

11 B1-33 1 High Pressure Spring 33 B1-38B 1 Restrictor O-ring

10 B1-35 1 Low Valve Ball Spring 32 B1-38 1 Restrictor

12 B1-31 1 Low Pressure Spring 34 B3-01 L7 Spec 1 Left Bell Crank

13 B1-11 1 Bleeder Valve 34 B3-01 R7 Spec 1 Right Bell Crank

15 B1-36.5 1 Air Seal 36 B6-01 Spec 2 Push Rod

14 B1-18.5 1 Pump Piston U-Cup 35 B3-02 1 Bell Crank Axle

16 B1.17.5 SS 1 Pump Piston, Stainless Steel 37 B6-02 4 Push Rod Axle

17 B1-15.5 1 Pump Piston Seal 39 B4-02 Spec 2 Load Wheel Fork Axle

19 B1-14 2 Release Plunger O-ring 42 B4-04 SS Spec 2 Load Wheel Axle, Stainless Steel

18 B1-13 SS 1 Release Plunger, Stainless Steel 41 B4-01T GF 2 Load Wheel Fork, w/ Grease Fit

23 B1-27 10M 1 Lift Ram Seal 47 A3X4POSB 4 Load Wheel

22 B1-28 1 Cylinder Snap Ring 43 B4-07 OSB 8 Load Wheel Bearing

24 B1-25 1 Load Pivot Ball 49 Roll Pin

5

73

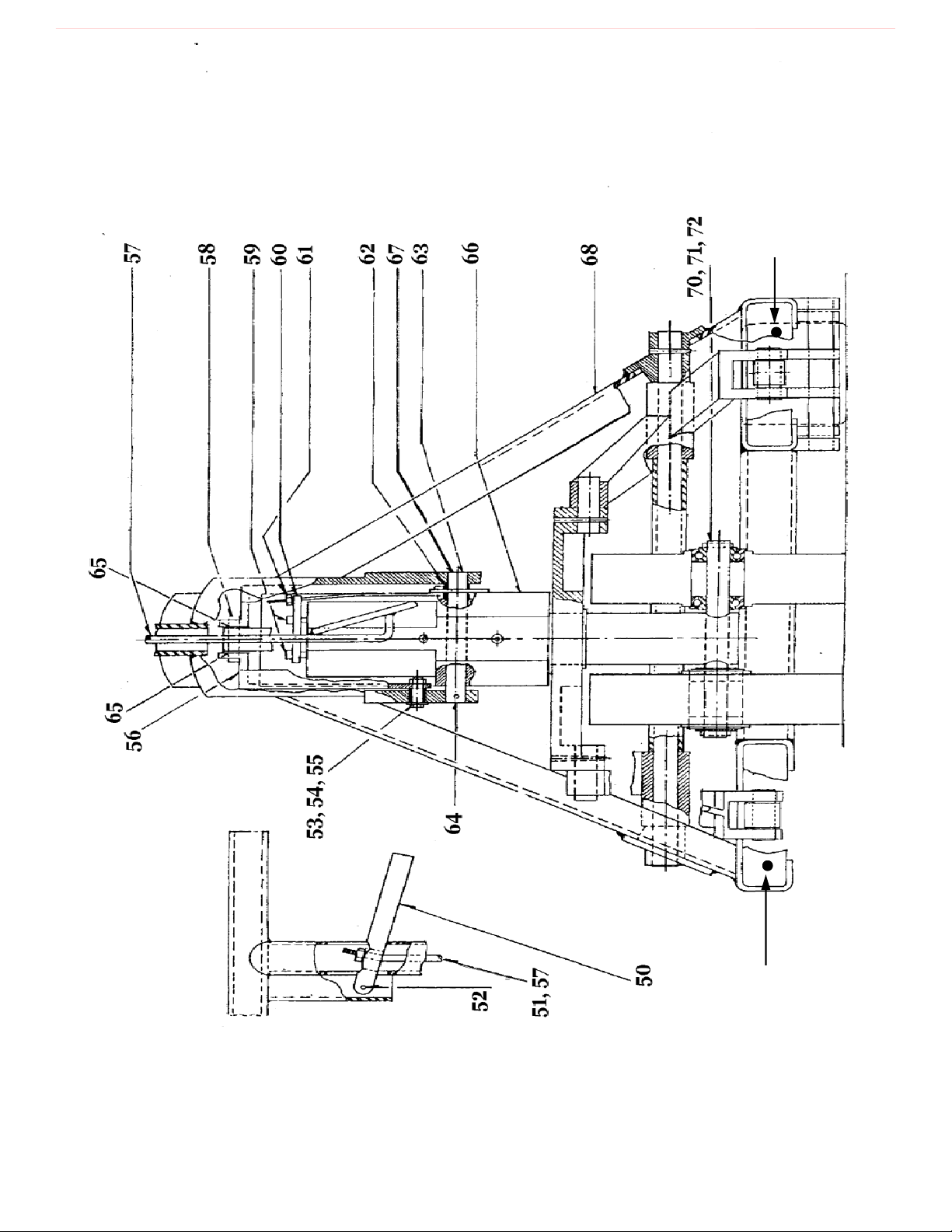

Drawing 2

(Parts List on Following Page)

Rear Pump View

73

6

Loading...

Loading...