Wesley BCT-6200-6SA User Manual

CURTIS INSTRUMENTS, INC.

200 Kisco Avenue

Mt. Kisco, New York 10549 USA

Tel. 914.666.2971

Fax 914.666.2188

www.curtisinstruments.com

1243

M O D E L

Generation 2

MultiMode™

MOTOR CONTROLLER

© 2011 CURTIS INSTRUMENTS, INC.

1243GEN2 Manual, p/n 37044

Rev. E: February 2011

CONTENTS

1. OVERVIEW ..............................................................................1

CONTENTS

2. INSTALLATION AND WIRING .............................................

Mounting the Controller .....................................................4

Connections: Low Current ..................................................6

Connections: High Current ................................................6

Wiring: Controller ..............................................................

Wiring: Throttle ..................................................................9

5k

Single-ended 0–5V, current source, 3-wire pot,

and electronic throttles (“Type 2”) ......................

0–5k

Wigwag 0–5V and 3-wire pot throttles .......................

Wiring: Fault Outputs ......................................................

Wiring: Spyglass Display ...................................................

Wiring: Emergency Reverse ..............................................

Wiring: Emergency Reverse Check ...................................

Wiring: Auxiliary Driver ...................................................

Contactor, Switches, and Other Hardware .........................17

3. PROGRAMMABLE PARAMETERS ......................................

Battery Parameter ...............................................................

Battery Voltage ............................................................

Acceleration Parameters ......................................................

Drive Current Limit, M1–M4 .....................................

Acceleration Rate, M1–M4 .........................................

Quick Start ..................................................................

Current Ratio ..............................................................

Braking Parameters ............................................................

Braking Current Limit, M1–M4 .................................

Deceleration Rate, M1–M4 .........................................

Throttle Deceleration Rate ..........................................

Restraint, M1–M4 .......................................................

Braking Rate, M1–M4 ................................................

Taper Rate ...................................................................

Variable Braking ..........................................................

Interlock Braking Parameters .............................................

Interlock Braking Rate ................................................

Max. Forward Regen ...................................................

Max. Reverse Regen .....................................................

Ω–0, 2-wire potentiometer throttle (“Type 1”) ........10

11

Ω, 2-wire potentiometer throttle (“Type 3”) ........13

14

14

15

16

16

16

19

21

21

21

21

21

21

22

23

23

23

23

23

24

25

25

26

26

26

26

4

7

Curtis 1243GEN2 Manual, Rev. B

iii

CONTENTS

Min. Forward Regen ...................................................27

Min. Reverse Regen .....................................................

Max. Load Volts ..........................................................

Min. Load Volts ..........................................................

Electromagnetic Brake Parameters ......................................

Aux Type .....................................................................

EM Brake PWM .........................................................

Aux Delay ....................................................................

Interlock Brake Delay ..................................................

Speed Parameters ...............................................................

Max. Forward Speed, M1–M4 ....................................

Max. Reverse Speed, M1–M4 ......................................

Creep Speed ................................................................

Load Compensation ....................................................

Throttle Parameters ............................................................

Throttle Type ..............................................................

Throttle Deadband ......................................................

Throttle Max ...............................................................

Throttle Map ...............................................................

Pot Low Fault ..............................................................

Field Parameters .................................................................

Min. Field Current Limit ............................................

Max. Field Current Limit ............................................

Field Map Start ...........................................................

Field Map ....................................................................

Field Check .................................................................

Main Contactor Parameters ...............................................

Main Contactor Interlock ............................................

Main Contactor Open Delay .......................................

Main Contactor Diagnostics ........................................

Sequencing Fault Parameters ..............................................

Anti-Tiedown ..............................................................

High Pedal Disable (HPD) ..........................................

Static Return to Off (SRO) .........................................

Sequencing Delay ........................................................

Emergency Reverse Parameters ...........................................

Emergency Reverse Current Limit ...............................

Emergency Reverse Check ...........................................

Emergency Reverse Direction Interlock .......................

Motor Protection Parameters .............................................

Warm Speed ................................................................

Motor Warm Resistance ..............................................

Motor Hot Resistance .................................................

Motor Resistance Compensation .................................

27

27

27

28

28

28

28

28

31

31

31

31

31

32

32

32

34

36

38

38

38

38

38

39

40

40

40

40

40

41

41

41

42

42

43

43

43

43

44

44

44

44

44

iv

Curtis 1243GEN2 Manual, Rev. B

Hourmeter Parameters .......................................................45

Adjust Hours High ......................................................

Adjust Hours Middle ...................................................

Adjust Hours Low .......................................................

Set Total Hours ...........................................................

Set Traction Hours ......................................................

Total Service Hours .....................................................

Traction Service Hours ................................................

Total Disable Hours ....................................................

Traction Disable Hours ...............................................

Traction Fault Speed ....................................................

Service Total ................................................................

Service Traction ...........................................................

Hourmeter Type ..........................................................

Pump Meter ................................................................

Battery Discharge Indicator (BDI) Parameters ...................

Full Voltage .................................................................

Empty Voltage .............................................................

Reset Voltage ...............................................................

Battery Adjust ..............................................................

BDI Disable ................................................................

BDI Limit Speed .........................................................

Fault Code Parameters .......................................................

Fault Code ...................................................................

BDI Lockout ...............................................................

45

45

45

45

46

46

46

46

46

47

47

47

48

48

49

49

49

49

50

50

50

51

51

52

CONTENTS

4. INSTALLATION CHECKOUT .............................................

5. VEHICLE PERFORMANCE ADJUSTMENT ......................

Major Tuning .....................................................................

Tuning the active throttle range ...................................

Tuning the controller to the motor ..............................

Setting the unloaded vehicle top speed ........................

Equalizing loaded and unloaded vehicle speed .............

Fine Tuning ........................................................................

Response to reduced throttle .......................................

Response to increased throttle .....................................

Smoothness of direction transitions .............................

Ramp climbing ............................................................

53

55

55

55

58

60

61

62

62

63

63

64

Curtis 1243GEN2 Manual, Rev. B

v

CONTENTS

6. PROGRAMMER MENUS ......................................................65

1243

1243

1243

GEN2 Parameters Menu ..............................................65

GEN2 Monitor Menu ..................................................69

GEN2 Faults/Diagnostics Menu ...................................70

7. DIAGNOSTICS AND TROUBLESHOOTING ....................

Programmer Diagnostics ....................................................

Spyglass Diagnostics ...........................................................

Status LED Diagnostics .....................................................

Fault Output LED Diagnostics ..........................................

8. CONTROLLER MAINTENANCE ........................................

Cleaning ............................................................................

Fault History ......................................................................

APPENDIX A Vehicle Design Considerations

APPENDIX B Curtis WEEE / RoHS

APPENDIX C Programming Devices

APPENDIX D Programmable Parameters Index

APPENDIX E Specifications, 1243GEN2 Controller

71

71

71

74

75

76

76

76

vi

Curtis 1243GEN2 Manual, Rev. B

FIGURES

FIG. 1: Curtis 1243GEN2 electronic motor controller ........................... 1

FIG. 2: Mounting dimensions, Curtis 1243GEN2 controller ................ 4

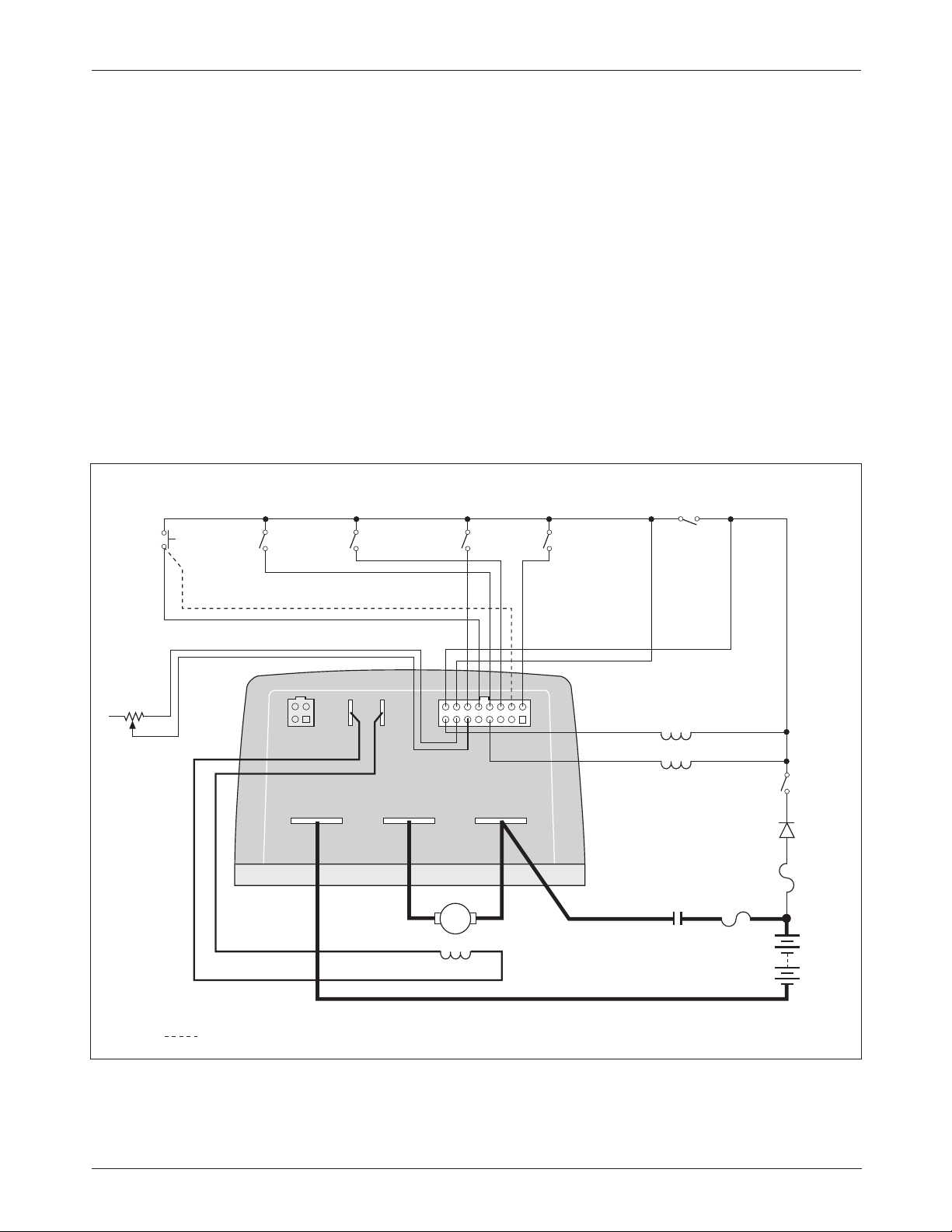

FIG. 3: Basic wiring configuration, Curtis 1243GEN2 controller ........... 7

FIG. 4: Wiring for 5kΩ–0 throttle (“Type 1”) .................................... 10

FIG. 5: Wiring for 20kΩ potentiometer used as

a wigwag-style throttle (“Type 1”) ..........................................

FIG. 6: Wiring for 0–5V throttles (“Type 2”) ..................................... 11

FIG. 7: Wiring for current source throttle (“Type 2”) ........................ 12

10

FIGURES

FIG. 8: Wiring for 3-wire potentiometer throttle (“Type 2”) .............. 12

FIG. 9: Wiring for Curtis ET-XXX electronic throttle (“Type 2”) ..... 13

FIG. 10: Wiring for 0–5kΩ throttle (“Type 3”) .................................... 14

FIG. 11: Wiring for fault outputs ......................................................... 15

FIG. 12: Wiring for Curtis Spyglass display .......................................... 15

FIG. 13: Ramp restraint maps for controller with the minimum

field set at 3 amps, maximum field at 18 amps, and

braking current limit at 300 amps .........................................

FIG. 14: Electromagnetic brake parameters, in the context

of the four delay parameters ...................................................

FIG. 15: Effect of adjusting the throttle deadband parameter .............. 33

FIG. 16: Effect of adjusting the throttle max parameter ................ 34, 35

24

29

Curtis 1243GEN2 Manual, Rev. B

FIG. 17: Throttle maps for controller

with maximum speed set at 100%

and creep speed set at 0 .........................................................

FIG. 18: Throttle maps for controller

with maximum speed set at 100%

and creep speed set at 10% ...................................................

36

37

vii

TABLES

FIG. 19: Throttle maps for controller

with maximum speed set at 90%

and creep speed set at 10% ...................................................

FIG. 20: Field current relative to armature current,

with field map parameter set at 50% and 20% .....................

FIG. 21: Curtis 840 Spyglass, 3-LED and 6-LED models ................... 73

37

39

TABLES

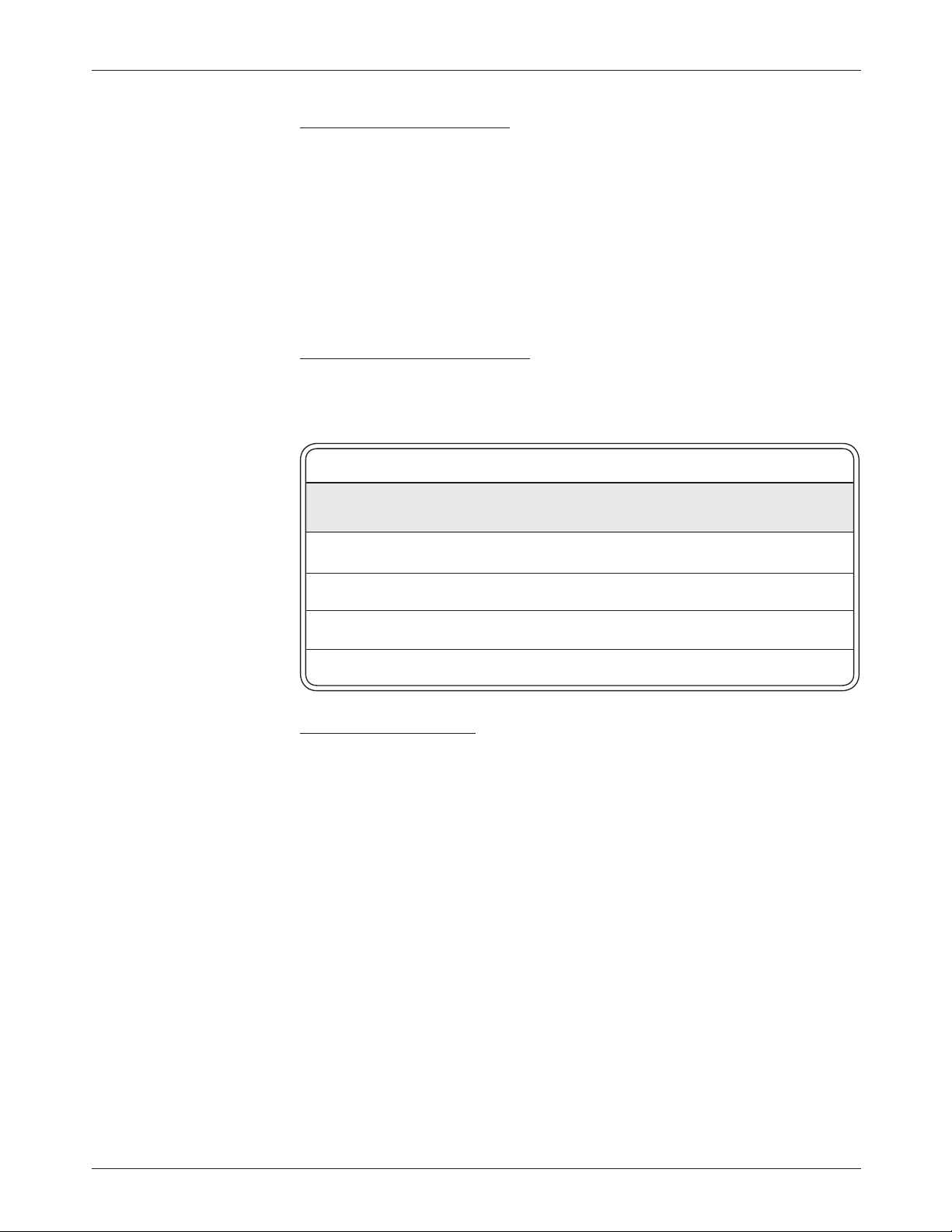

TABLE 1: Throttle wiper input (Pin 6) threshold values .......................... 9

TABLE 2: Mode selection ....................................................................... 18

TABLE 3: Configuration options: auxiliary driver .................................. 30

TABLE 4: Programmable throttle types .................................................. 32

TABLE 5: Standard battery voltages ...................................................... 49

TABLE 6: Fault categories ..................................................................... 50

TABLE 7: Troubleshooting chart ............................................................ 72

TABLE 8: Status LED fault codes .......................................................... 74

TABLE 9: Fault category codes .............................................................. 75

TABLE E-1: Specifications .....................................................................E-1

viii

Curtis 1243GEN2 Manual, Rev. B

1

Fig. 1 Curtis 1243GEN2

MultiMode™ electronic

motor controller.

1 — OVERVIEW

OVERVIEW

Curtis 1243 Generation 2 MultiMode™ controllers are separately excited motor

speed controllers designed for use in a variety of small industrial vehicles and

in material handling equipment. These programmable controllers are simple

to install, efficient, and cost effective, while offering more features than the

original 1243.

Curtis 1243GEN2 Manual, Rev. B

The 1243GEN2 MultiMode™ controller provides smooth precise control

of motor speed and torque. A full-bridge field control stage is combined with

a half-bridge armature power stage to provide solid state motor reversing and

full regenerative braking without additional relays or contactors.

The controller’s rugged IP53 housing and packaging are built to withstand

shock and vibration. State-of-the-art surface mount logic board fabrication

makes the 1243GEN2 controller even more reliable than the original 1243.

The 1243

programmer. In addition to configuration flexibility, the programmer provides

diagnostic and test capability.

GEN2 is fully programmable through the Curtis 13XX handheld

1

1 — OVERVIEW

Like all Curtis motor controllers, the 1243GEN2 offers superior operator control

of the vehicle’s motor drive speed. Features include:

✓ Interlock braking with load sensor to meet required braking distance

without unnecessary harsh braking at light loads

✓ Maintenance monitor responds to preset vehicle operating hours and

drive hours as programmed by the OEM

✓ Two hourmeters—total KSI-on hours and traction hours—and the

associated maintenance timers are built into the controller

✓ BDI calculations performed within controller

✓ Estimates motor temperature based on field resistance and cuts back

maximum speed if the motor is overheated

✓ Diagnostic checks for field open and field shorted faults

✓ Supports PWM electromagnetic brake with maximum continuous

current of 2 amps

✓ Supports Type 4 throttle

✓ Active precharge of controller capacitor bank extends life of main

contactor

✓ Compatibility with Curtis 1307/1311 handheld programmers for quick

and easy testing, diagnostics, and parameter adjustment

✓ MultiMode™ allows four user-selectable vehicle operating modes

✓ Continuous armature current control, reducing arcing and brush wear

✓ Complete diagnostics through the handheld programmer, the built-in

Status LED, and the optional 840 Spyglass display

✓ Two fault outputs provide diagnostics to remotely mounted displays

✓ Regenerative braking allows shorter stopping distances, increases battery

charge, and reduces motor heating

✓ Automatic braking when throttle is reduced provides a compression

braking feel and enhances safety

✓ Brake/Drive Interlock meets ISO stopping distance requirements

2

✓ Ramp restraint feature provides automatic electronic braking

that restricts vehicle movement while in neutral

✓ Meets EEC fault detect requirements

✓ Linear cutback of motor drive current during overtemperature

or undervoltage

Curtis 1243GEN2 Manual, Rev. B

1 — OVERVIEW

✓ Linear cutback of regenerative braking current during overvoltage

✓ High pedal disable (HPD) and static return to off (SRO) interlocks

prevent vehicle runaway at startup

✓ Internal and external watchdog circuits ensure proper software operation

✓ Fully protected inputs and short-circuit protected output drivers.

Curtis Model 840 Spyglass Display [optional]

✓ 3-wire serial interface

✓ Sequences between hourmeter, BDI, and error displays

✓ Single alphanumeric, non-backlit, 8 character, 5 mm LCD display for

hourmeter, BDI, and fault messages

✓ Display updated by dedicated unidirectional serial port

✓ Available in 52 mm round case, DIN case, and as a bare board, each

with an 8-pin Molex connector; cases feature front seal to IP65 and

rear seal to IP40; shock and vibration protection to SAE J1378

✓ Operating temperature range -10°C to 70°C; models with lower

temperature ratings available for freezer applications

Familiarity with your Curtis controller will help you install and operate it properly. We encourage you to read this manual carefully. If you have questions,

please contact the Curtis office nearest you.

Curtis 1243GEN2 Manual, Rev. B

3

2 — INSTALLATION & WIRING: Controller

C

L

SEPE

X

198 (7.78)

6.4 (0.25) dia., 3 plcs

68

(2.68)

114

(4.50)

173 (6.81)

17

(0.66)

7.9

(0.31)

99

(3.88)

4.8

(0.19)

7.9

(0.31)

STAT US

Status LED

TRACTION CONTROLLER

TM

INSTALLATION AND WIRING

2

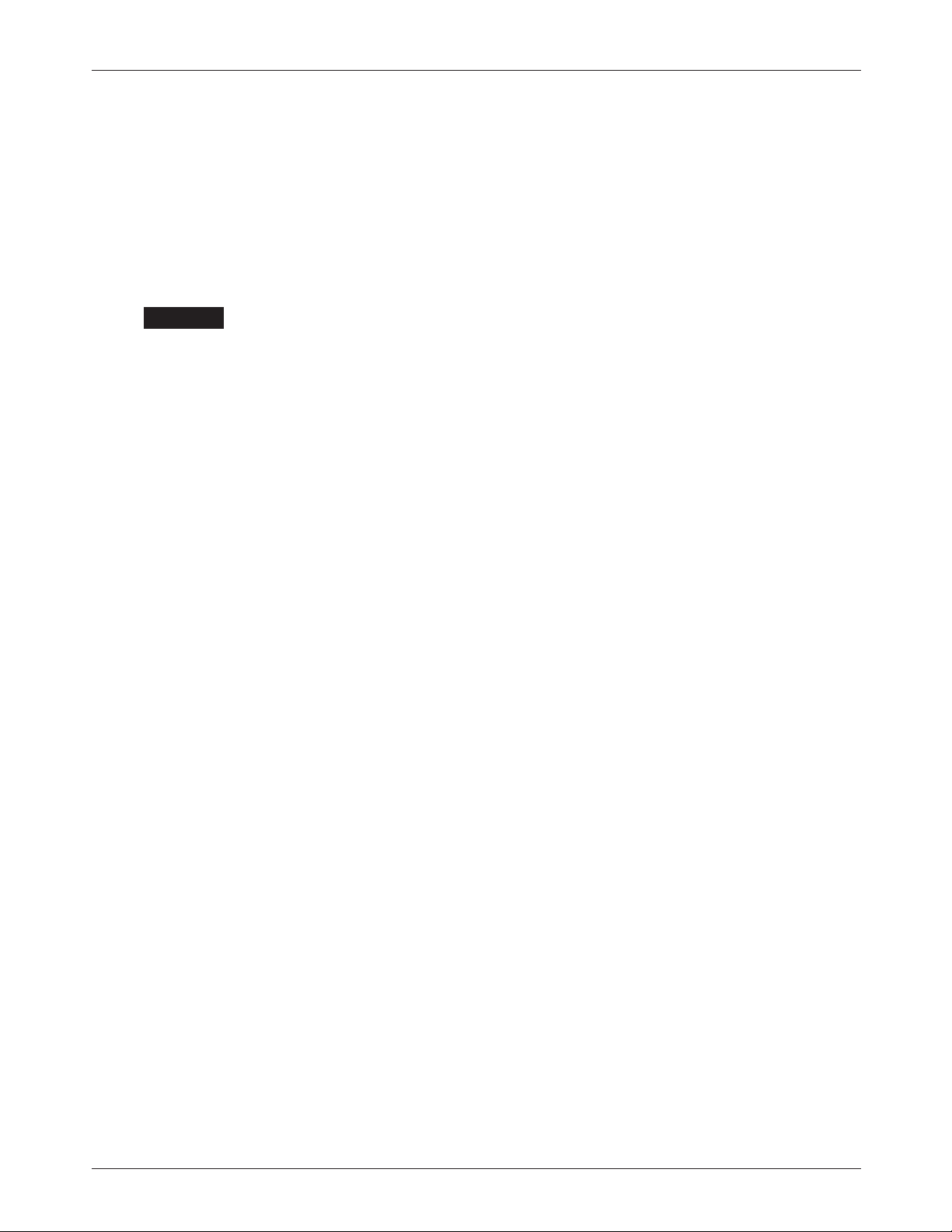

Fig. 2 Mounting

dimensions, Curtis

1243GEN2 controller.

MOUNTING THE CONTROLLER

The controller can be oriented in any position, but the location should be

carefully chosen to keep the controller as clean and dry as possible. If a

clean, dry mounting location cannot be found, a cover must be used to

shield the controller from water and contaminants.

When selecting the

mounting position, be sure to also take into consideration (1) that access is

needed at the front of the controller to plug the programmer into its connec

tor, and (2) that the built-in Status LED is visible only through the view port

in the label on top of the controller.

The outline and mounting hole dimensions for the 1243GEN2 controller are shown in Figure 2. To ensure full rated power, the controller should be

fastened to a clean, flat metal surface with three 6 mm (1/4") diameter screws,

using the holes provided.

-

Dimensions in millimeters (and inches)

4

Curtis 1243GEN2 Manual, Rev. B

2 — INSTALLATION & WIRING: Controller

The mounting surface must be at least a 300×300×3 mm (12"×12"×1/8")

aluminum plate, or its equivalent, and subjected to a minimum 3 mph airflow

to meet the specified time/current ratings. Although not usually necessary, a

thermal joint compound can be used to improve heat conduction from the

controller heatsink to the mounting surface.

You will need to take steps during the design and development of your

end product to ensure that its EMC performance complies with applicable

regulations; suggestions are presented in Appendix A.

The 1243

propriate precautions in connecting, disconnecting, and handling the controller.

See installation suggestions in Appendix A for protecting the controller from

ESD damage.

GEN2 controller contains ESD-sensitive components. Use ap-

C A U T I O N

☞

Working on electric vehicles is potentially dangerous. You should

protect yourself against runaways, high current arcs, and outgassing from

lead acid batteries:

RUNAWAYS — Some conditions could cause the vehicle to run out of

control. Disconnect the motor or jack up the vehicle and get the drive

wheels off the ground before attempting any work on the motor control

circuitry.

HIGH CURRENT ARCS — Electric vehicle batteries can supply very high

power, and arcs can occur if they are short circuited. Always open the

battery circuit before working on the motor control circuitry. Wear safety

glasses, and use properly insulated tools to prevent shorts.

LEAD ACID BATTERIES — Charging or discharging generates hydrogen

gas, which can build up in and around the batteries. Follow the battery

manufacturer’s safety recommendations. Wear safety glasses

.

Curtis 1243GEN2 Manual, Rev. B

5

2 — INSTALLATION & WIRING: Controller

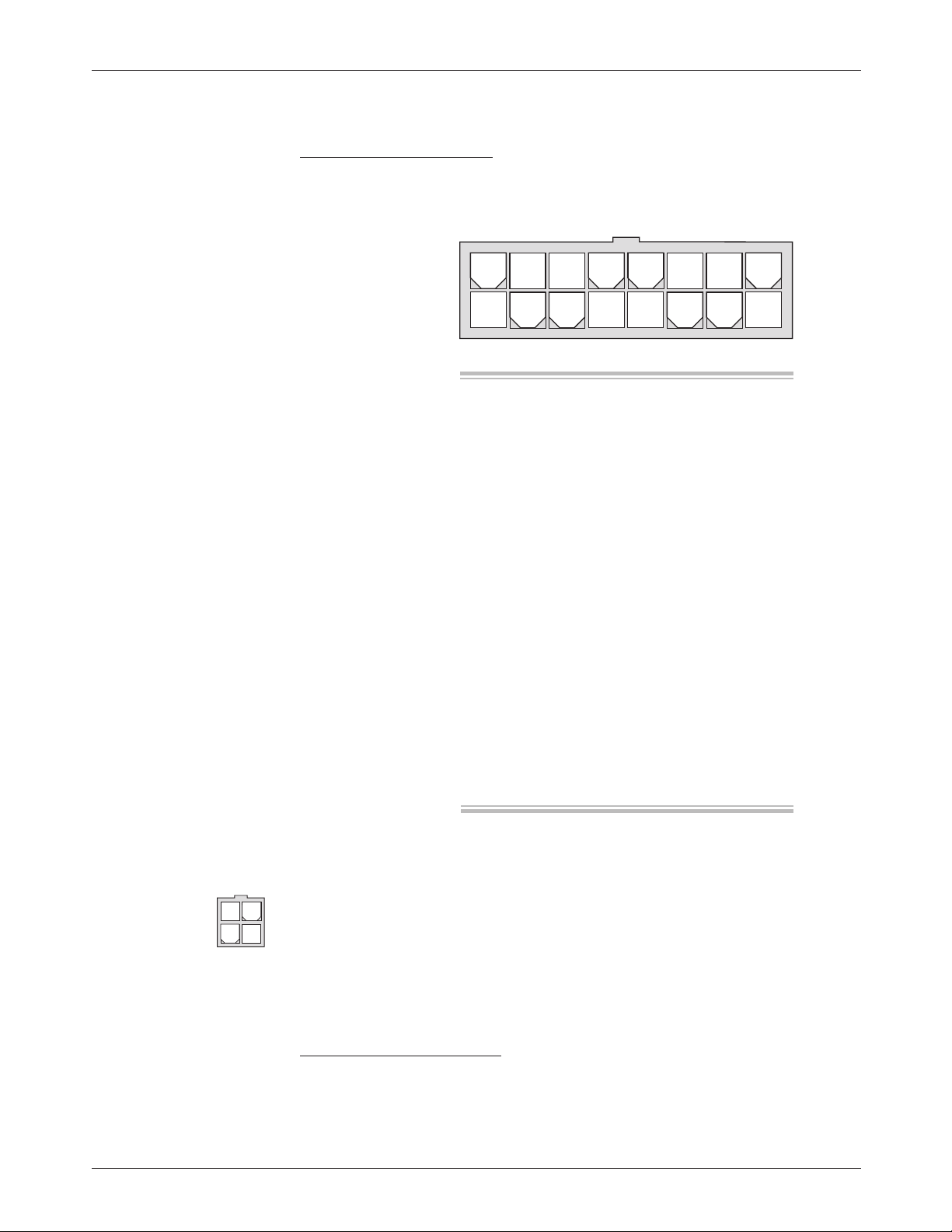

8 7 6 5 4 3 2 1

16 15 14 13 12 11 10 9

34

12

CONNECTIONS

Low Current Connections

A 16-pin Molex low current connector in the controller provides the low current logic control connections:

Pin 1 load sensor input [optional]

Pin 2 Fault 1 output / pump input

Pin 3 Fault 2 output

Pin 4 main contactor driver output

Pin 5 throttle: 3-wire pot high

Pin 6 throttle: 0–5V; pot wiper

Pin 7 throttle: pot low

Pin 8 auxiliary driver output (typically

used for an electromagnetic brake)

Pin 1 receive data (+5V)

Pin 2 ground (B-)

Pin 3 transmit data (+5V)

Pin 4 +15V supply (100mA)

Pin 9 Mode Select 2 input

Pin 10 emerg. reverse check output [optional]

Pin 11 reverse input

Pin 12 forward input

Pin 13 emergency reverse input

Pin 14 Mode Select 1 input

Pin 15 interlock input

Pin 16 keyswitch input (KSI)

The mating connector is a 16-pin Molex Mini-Fit Jr. connector p/n 39-012165 using type 5556 terminals.

A 4-pin low power connector is provided for the handheld programmer. A

complete 1311 programmer kit, including the appropriate connecting cable,

can be ordered from Curtis.

The 4-pin connector can also be used for the Spyglass display. The display

is unplugged when the programmer is used.

High Current Connections

Three tin-plated solid copper bus bars are provided for high current connections to the battery (

fastened to the bus bars by M8 bolts. The 1243

B+ and B-) and the motor armature (M-). Cables are

GEN2 case provides the capture

6

Curtis 1243GEN2 Manual, Rev. B

2 — INSTALLATION & WIRING: Controller

S1 S2

B- M- B+

INTERLOCK

5 k

Ω POT

THROTTLE

(TYPICAL)

EMERGENCY

REVERSE

emergency reverse wiring check (optional)

FORWARD

MAIN

CONTACTOR

COIL

POLARITY

PROTECTION

DIODE

REVERSE

MODE

SELECT

1

MODE

SELECT

2

ELECTRO-

MAGNETIC

BRAKE

KEY

SWITCH

POWER

FUSE

A

MAIN

CONTACT

OR

B+

B-

A2 A1

S2 S1

CONTROL

FUSE

1

9

8

16

nuts required for the M8 bolts. The maximum bolt insertion depth below

the surface of the bus bar is 1.3 cm (1/2"). Bolt shafts exceeding this length

may damage the controller. The torque applied to the bolts should not exceed

16.3 N·m (12 ft-lbs).

Two 1/4" quick connect terminals (

S1 and S2) are provided for the con-

nections to the motor field winding.

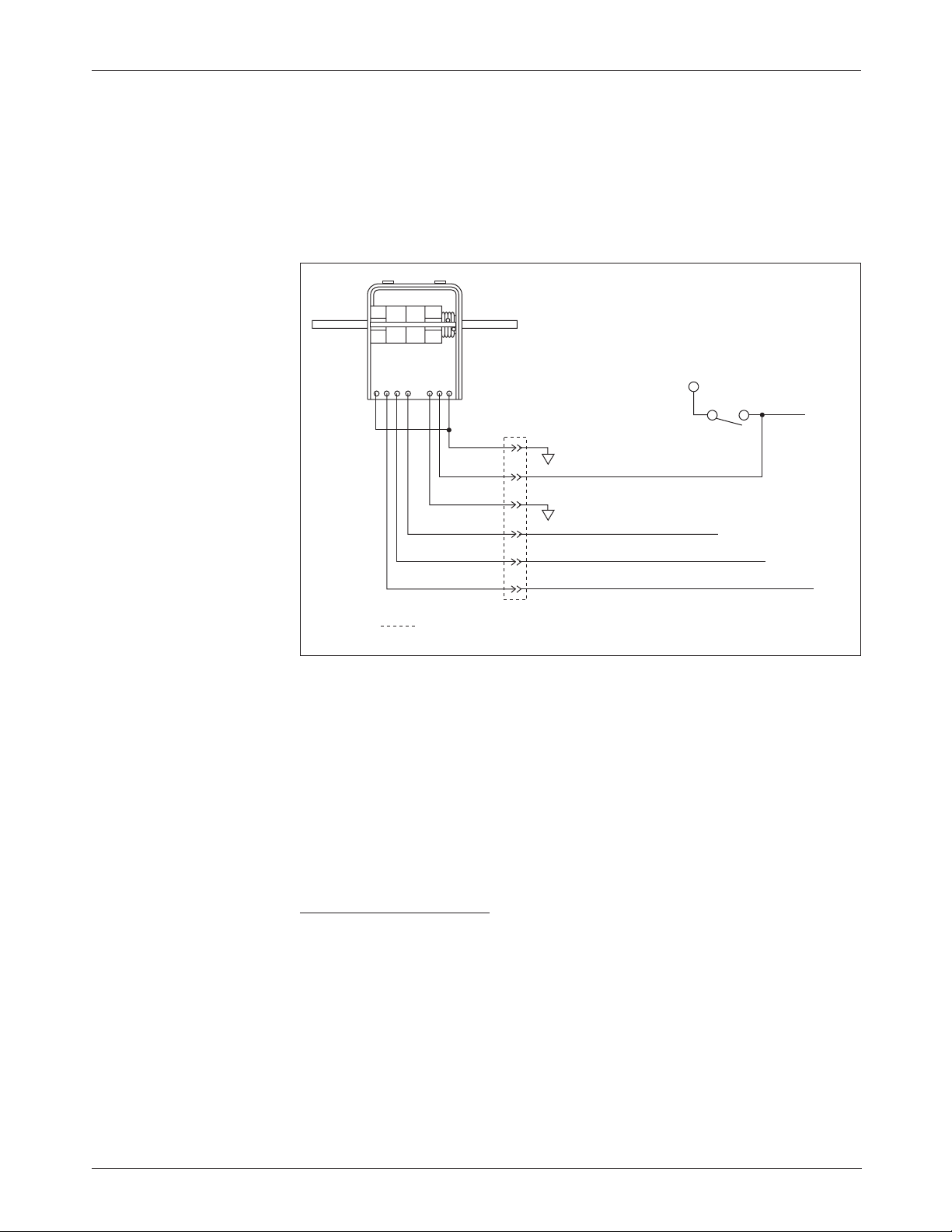

WIRING: Standard Configuration

Figure 3 shows the typical wiring configuration for most applications. For

walkie applications the interlock switch is typically activated by the tiller,

and an emergency reverse switch on the tiller handle provides the emergency

reverse signal.

For rider applications the interlock switch is typically a seat switch or

a foot switch, and there is no emergency reverse.

Fig. 3 Standard wiring configuration, Curtis 1243GEN2 controller.

Curtis 1243GEN2 Manual, Rev. B

7

2 — INSTALLATION & WIRING: Controller

Standard Power Wiring

Motor armature wiring is straightforward, with the armature’s A1 connection

going to the controller’s

to the controller’s

of vehicle travel with the forward direction selected will depend on how the

motor’s S1 and S2 connections are made to the controller’s two field terminals

(S1 and S2) and how the motor shaft is connected to the drive wheels through

C A U T I O N

☞

the vehicle’s drive train.

will affect the operation of the emergency reverse feature. The forward and

reverse switches and the

the vehicle drives away from the operator when the emergency reverse button

is pressed.

Standard Control Wiring

Wiring for the input switches and contactors is shown in Figure 3; the pins are

identified on page 6. In the standard wiring configuration, the auxiliary driver

at Pin 8 is used to drive an electromagnetic brake.

in Figure 3. The controller checks for welded or missing contactor faults and

uses the main contactor coil driver output to disconnect the battery from the

controller and motor when specific faults are present. If the main contactor

coil is not wired to Pin 4, the controller will not be able to open the main

contactor in serious fault conditions and the system will therefore not meet

EEC safety requirements.

B+ bus bar and the armature’s A2 connection going

M- bus bar.

The motor’s field connections (S1 and S2) are less obvious. The direction

CAUTION: The polarity of the S1 and S2 connections

S1 and S2 connections must be configured so that

The main contactor coil must be wired directly to the controller as shown

8

Curtis 1243GEN2 Manual, Rev. B

2 — INSTALLATION & WIRING: Throttle

WIRING: Throttle

Wiring for various throttles is described below. They are categorized as Type 1,

2, 3, and 4 throttles in the program menu of the handheld programmer. Note:

In the text, throttles are identified by their nominal range and not by their

actual active range.

Appropriate throttles for use with the 1243GEN2 controller include twowire 5k

Ω–0 throttles (“Type 1”); 0–5V throttles, current source throttles,

three-wire potentiometer throttles, and electronic throttles wired for singleended operation (all “Type 2”); two-wire 0–5k

Ω throttles (“Type 3”), and

0–5V and three-wire potentiometer throttles wired for wigwag operation (“Type

4”). The operating specifications for these throttle types are summarized in Table

1. Refer to Section 3: Programmable Parameters, for information on the effects

of the Throttle Deadband and Throttle Max parameters on the minimum and

maximum throttle thresholds.

If the throttle you are planning to use is not covered, contact the Curtis

office nearest you.

Table 1 THROTTLE WIPER INPUT THRESHOLD VALUES

MAXIMUM THROTTLE HPD THROTTLE MINIMUM

THROTTLE THROTTLE DEADBAND (25% throttle MAX THROTTLE

TYPE PARAMETER FAULT (0% speed request) active range) (100% modulation) FAULT

1 (5kΩ–0) Wiper Voltage 5.00 V 3.80 V 2.70 V 0.20 V 0.06 V

2 (0–5V) Wiper Voltage 0.06 V 0.20 V 1.50 V 5.00 V 5.80 V

3 (0–5kΩ) Wiper Voltage 0.06 V 0.20 V 1.30 V 3.80 V 5.00 V

4 (0–5V) Wiper Voltage 0.50 V 2.50 V (fwd) * 3.10 V (fwd) 4.40 V (fwd) 4.50 V

2.50 V (rev)

Wiper Resistance 7.50 kΩ 5.50 kΩ 3.85 kΩ 0 kΩ —

Wiper Resistance — — — — —

Wiper Resistance — 0 kΩ 1.65 kΩ 5.50 kΩ 7.50 kΩ

* 1.90 V (rev) 0.60 V (rev)

Wiper Resistance — — — — —

Notes: The Throttle Deadband and Throttle Max thresholds are valid for nominal 5kΩ

potentiometers or 5V sources with the default Throttle Deadband and Throttle

Max parameter settings of 0% and 100% respectively. These threshold values

will change with variations in the Throttle Deadband and Throttle Max parameter

settings.

The HPD thresholds are 25% of the active throttle range and therefore depen

dent on the programmed Throttle Deadband and Throttle Max settings (which

define the active range).

The wiper voltage is measured with respect to B-.

The wiper resistance is measured from pot low to pot wiper. The potentiometer

must be disconnected from the controller when making this measurement.

-

* With a 0% Throttle Deadband setting, there is no neutral point

on a Type 4 throttle. A Throttle Deadband setting of at least 8%

is recommended for Type 4 throttles.

Curtis 1243GEN2 Manual, Rev. B

9

2 — INSTALLATION & WIRING: Throttle

20 kΩ

FASTERFASTER

Pot Wiper input (Pin 6)

Pot Low input (Pin 7)

5kΩ–0

Pot Low input (Pin 7)

Pot Wiper input (Pin 6)

FASTER

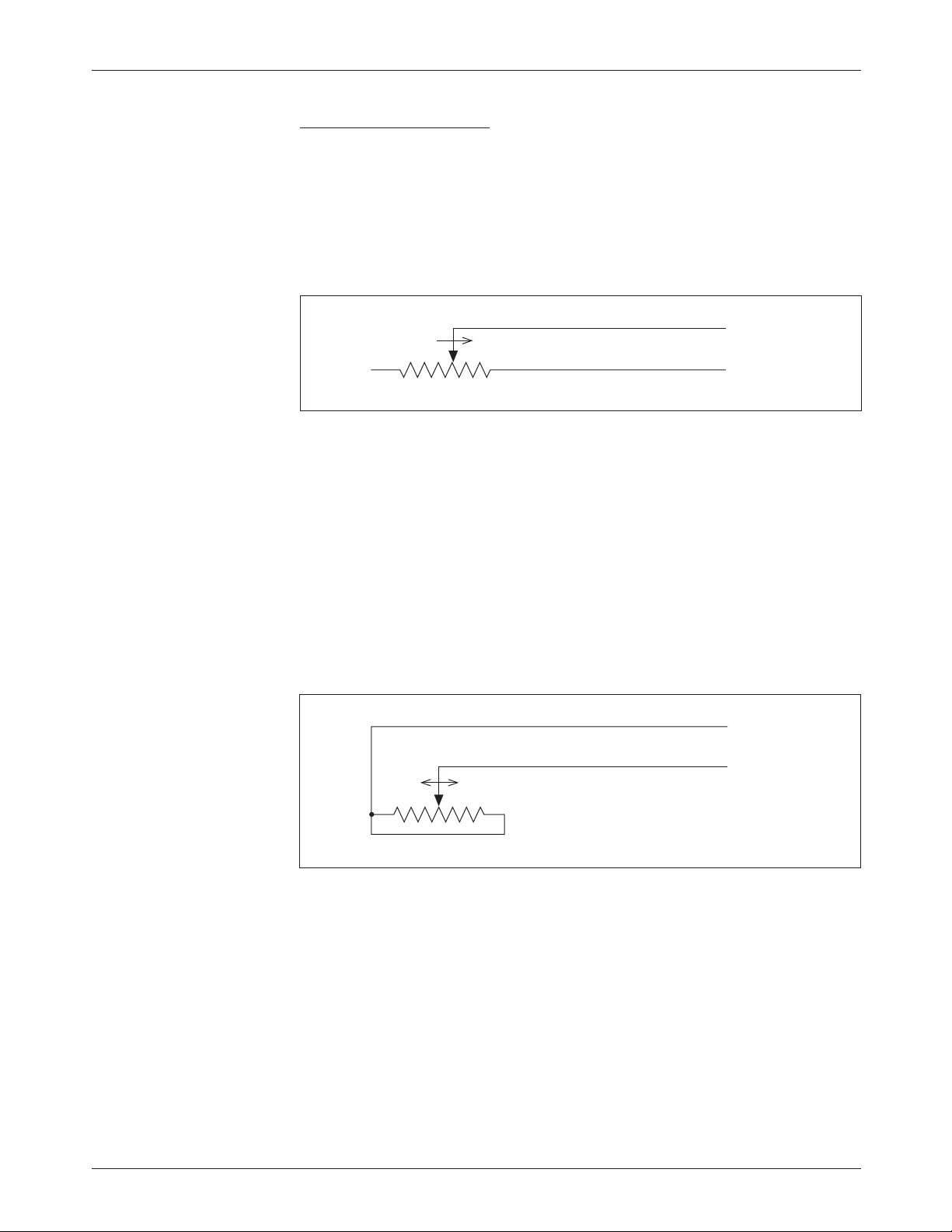

5kΩ–0 Throttle (“Type 1”)

The 5kΩ–0 throttle (called a “Type 1” throttle in the programming menu of the

13XX programmer) is a 2-wire resistive throttle that connects between the Pot

Wiper and Pot Low pins (Pins 6 and 7), as shown in Figure 4. It doesn’t matter

which wire goes on which pin. For Type 1 throttles, zero speed corresponds to

5 kΩ measured between the two pins and full speed corresponds to 0 Ω. (Note:

This wiring is also shown in the standard wiring diagram, Figure 3.)

Fig. 4 Wiring for 5k

Ω

throttle (“Type 1”).

Fig. 5 Wiring for 20k

potentiometer used as a

wigwag-style throttle

(“Type 1”).

Ω

–0

In addition to accommodating the basic 5kΩ–0 throttle, the Type

1 throttle is the easiest with which to implement a wigwag-style throttle.

Using a 20k

can be set such that the controller has 5 k

Ω potentiometer wired as shown in Figure 5, the pot wiper

Ω between Pins 6 and 7 when

the throttle is in the neutral position. The throttle mechanism can then be

designed such that rotating it either forward or back decreases the resistance

between Pins 6 and 7, which increases the controller output. The throttle

mechanism must provide signals to the controller’s forward and reverse

inputs independent of the throttle pot resistance. The controller will not

sense direction from the pot resistance.

10

Broken wire protection is provided by the controller sensing the current

flow from the wiper input through the potentiometer and into the Pot Low pin.

If the Pot Low input current falls below 0.65 mA or its voltage below 0.06 V,

a throttle fault is generated and the controller is disabled. Note: The Pot Low

pin (Pin 7) must not be tied to ground (B-).

Curtis 1243GEN2 Manual, Rev. B

2 — INSTALLATION & WIRING: Throttle

+

-

B-

+

SENSOR GROUND

SENSOR OUTPUT (0–5V)

S E N S O R

Pot Low input (Pin 7)

0–5V input (Pin 6)

0–5V input (Pin 6)

Pot Low Fault setting = OFF

☞

0–5V, Current Source, 3-Wire Potentiometer,

and Electronic Throttles (“Type 2”)

With these throttles (“Type 2” in the programming menu) the controller looks

for a voltage signal at the wiper input (Pin 6). Zero speed will correspond to

0 V and full speed to 5 V (measurements made relative to B-). A voltage source,

current source, 3-wire potentiometer, or electronic throttle can be used with

this throttle type. The wiring for each is slightly different and each has varying

levels of throttle fault detection associated with it.

0–5V Throttle

Two ways of wiring the 0–5V throttle are shown in Figure 6. The active range

for this throttle is from 0.2 V (at 0% Throttle Deadband) to 5.0 V (at 100%

Throttle Max), measured relative to B-.

Fig. 6 Wiring for

0–5V throttles (“Type 2”).

Sensor-referenced 0–5V source Ground-referenced 0–5V source

Sensor-referenced 0–5V throttles must provide a Pot Low current greater

than 0.65 mA to prevent shutdown due to pot faults. It is recommended that

the maximum Pot Low current be limited to 55 mA to prevent damage to the

Pot Low circuitry.

Ground-referenced 0–5V throttles require setting the Pot Low Fault pa

rameter (see Section 3, page 38) to Off; otherwise the controller will register

a throttle fault and will shut down. For ground-referenced 0–5V throttles, the

controller will detect open breaks in the wiper input but cannot provide full

throttle fault protection. Also, the controller recognizes the voltage between

the wiper input and B- as the applied throttle voltage and not the voltage from

the voltage source relative to the Pot Low input.

For either throttle input, if the 0–5V throttle input (Pin 6) exceeds 5.5 V

relative to B-, the controller will register a fault and shut down.

-

Curtis 1243GEN2 Manual, Rev. B

11

2 — INSTALLATION & WIRING: Throttle

1kΩ–10kΩ

Pot Wiper input (Pin 6)

Pot Low input (Pin 7)

Pot High output (Pin 5)

FASTER

R

throttle

B-B-

0–5V input (Pin 6)

Pot Low Fault setting = OFF

☞

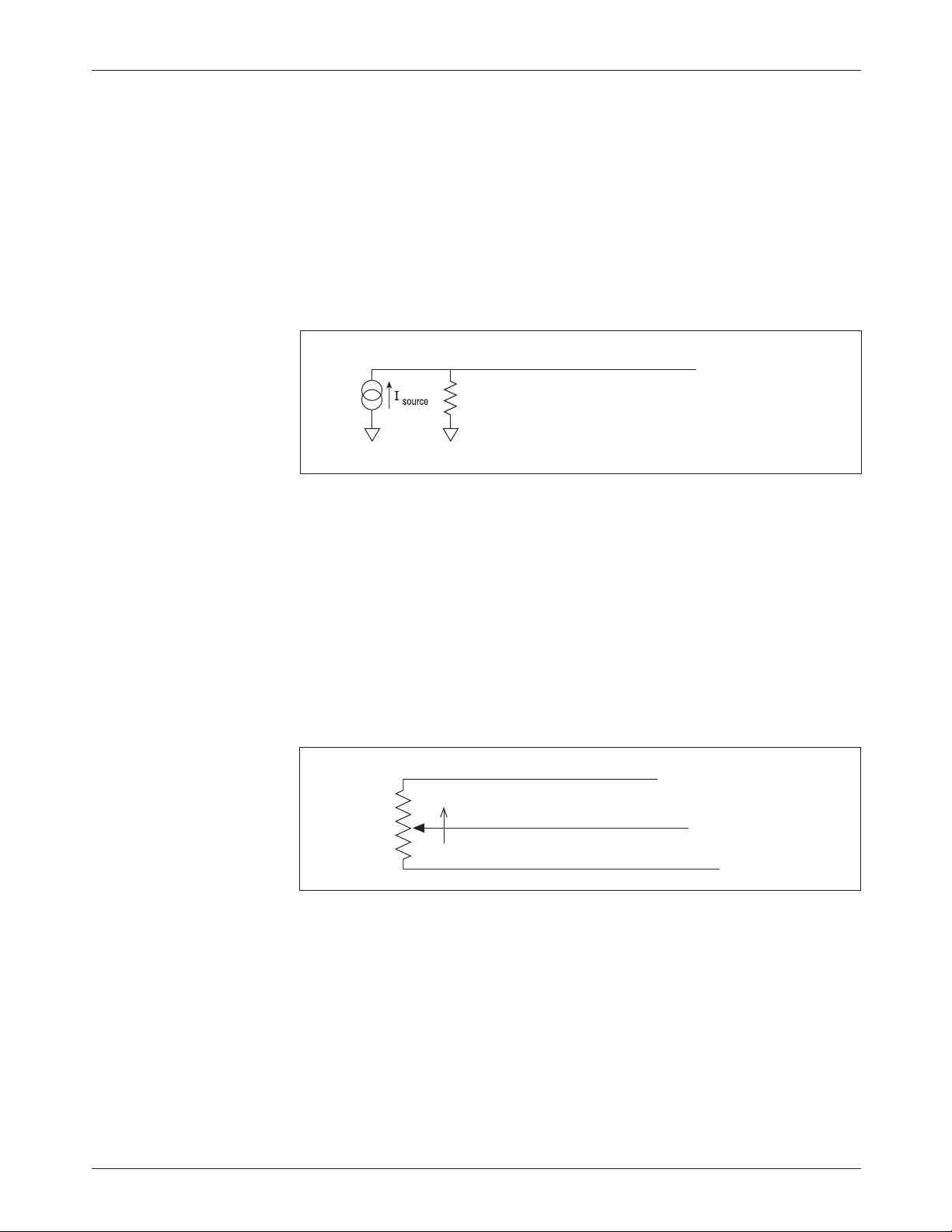

Current Sources As Throttles

A current source can also be used as a throttle input, wired as shown in Figure 7.

A resistor, R

age. The resistor should be sized to provide a 0–5V signal variation over the

full current range.

otherwise the controller will register a throttle fault and will shut down. It is

the responsibility of the vehicle manufacturer to provide appropriate throttle

fault detection in applications using a current source as a throttle.

Fig. 7 Wiring for current

source throttle (“Type 2”).

, must be used to convert the current source value to a volt-

throttle

The Pot Low Fault parameter (see Section 3, page 38) must be set to Off;

Fig. 8 Wiring for 3-wire

potentiometer throttle

(“Type 2”).

3-Wire Potentiometer (1kΩ–10k1Ω) Throttle

A 3-wire pot with a total resistance value anywhere between 1 k

Ω and 10 kΩ can

be used, wired as shown in Figure 8. The pot is used in its voltage divider mode,

with the voltage source and return being provided by the 1243

GEN2 controller.

Pot High (Pin 5) provides a current limited 5V source to the pot, and Pot Low

(Pin 7) provides the return path. If a 3-wire pot is used and the Pot Low Fault

parameter (see Section 3, page 38) is set to On, the controller will provide full

throttle fault protection in accordance with EEC requirements. Note: the Pot

Low pin (Pin 7) must not be tied to ground (B-).

12

Curtis 1243GEN2 Manual, Rev. B

Fig. 9 Wiring for Curtis

GREEN

ORANGE

BLACK

BLACK/WHITE

WHITE

WHT/BRN

B+

KEYSWITCH

connector

WHT/GRN

Reverse input (Pin 11)

KSI (Pin 16)

0–5V input (Pin 6)

Forward input (Pin 12)

Pot Low Fault setting = OFF

☞

B-

B-

ET-XXX electronic throttle

(“Type 2”).

2 — INSTALLATION & WIRING: Throttle

Curtis ET-XXX Electronic Throttle

The Curtis ET-XXX provides a 0–5V throttle and forward/reverse inputs for

the 1243

GEN2 controller. Wiring for the ET-XXX is shown in Figure 9. When

an electronic throttle is used, the Pot Low Fault parameter (see Section 3, page

38) must be set to Off; otherwise the controller will register a throttle fault

and will shut down.

Curtis 1243GEN2 Manual, Rev. B

There is no fault detection built into the ET-XXX, and the controller will

detect only open wiper faults. It is the responsibility of the vehicle manufacturer

to provide any additional throttle fault detection necessary.

The ET-XXX can be integrated into a control head to provide wigwagstyle throttle control. Alternatively, a complete control head assembly is avail

able from Curtis. This control head assembly—the CH series—combines the

ET-XXX throttle with a variety of standard control head switch functions for

use in walkie and lift truck applications.

0–5kΩ Throttle (“Type 3”)

The 0–5kΩ throttle (“Type 3” in the programming menu) is a 2-wire resistive

throttle that connects between the Pot Wiper and Pot Low pins (Pins 6 and

7) as shown in Figure 10. Zero speed corresponds to 0

the two pins and full speed corresponds to 5 k

Ω measured between

Ω. This throttle type is not ap-

propriate for use in wigwag-style applications.

Broken wire protection is provided by the controller sensing the current

flow from the wiper input through the potentiometer and into the Pot Low pin.

If the Pot Low input current falls below 0.65 mA or its voltage below 0.06 V,

13

-

2 — INSTALLATION & WIRING: Throttle

0–5kΩ

Pot Low input (Pin 7)

Pot Wiper input (Pin 6)

FASTER

Fig. 10 Wiring for

0–5kΩ throttle

(“Type 3”).

a throttle fault is generated and the controller is disabled. Note: The Pot Low

pin (Pin 7) must not be tied to ground (B-).

Wigwag-Style 0–5V Voltage Source and 3-Wire Pot Throttle (“Type 4”)

These throttles (“Type 4” in the programming menu) operate in true wigwag

style. No signals to the controller’s forward and reverse inputs are required; the

action is determined by the wiper input value. The interface to the controller

for Type 4 devices is similar to that for Type 2 devices. The neutral point will

be with the wiper at 2.5 V, measured between Pin 6 and B-.

value (Pin 6) is increased, with maximum forward speed reached at 4.5 V.

The controller will provide increasing reverse speed as the wiper input value is

decreased, with maximum reverse speed reached at 0.5 V. The minimum and

maximum wiper voltage must not exceed the 0.5V and 4.5V fault limits.

3, page 36) is set to On, the controller provides full fault protection for Type 4

traction throttles. Any potentiometer value between 1 kΩ and 10 kΩ is supported. When a voltage throttle is used, it is the responsibility of the OEM to

provide appropriate throttle fault detection.

neutral switch should be wired to the forward switch input (Pin 12). The con

troller will behave as though no throttle is requested when the neutral switch

is high, and will use the throttle value when the neutral switch is low.

The controller will provide increasing forward speed as its wiper input

When a 3-wire pot is used and the Pot Low Fault parameter (see Section

Note: If your Type 4 throttle has an internal neutral switch, this internal

-

14

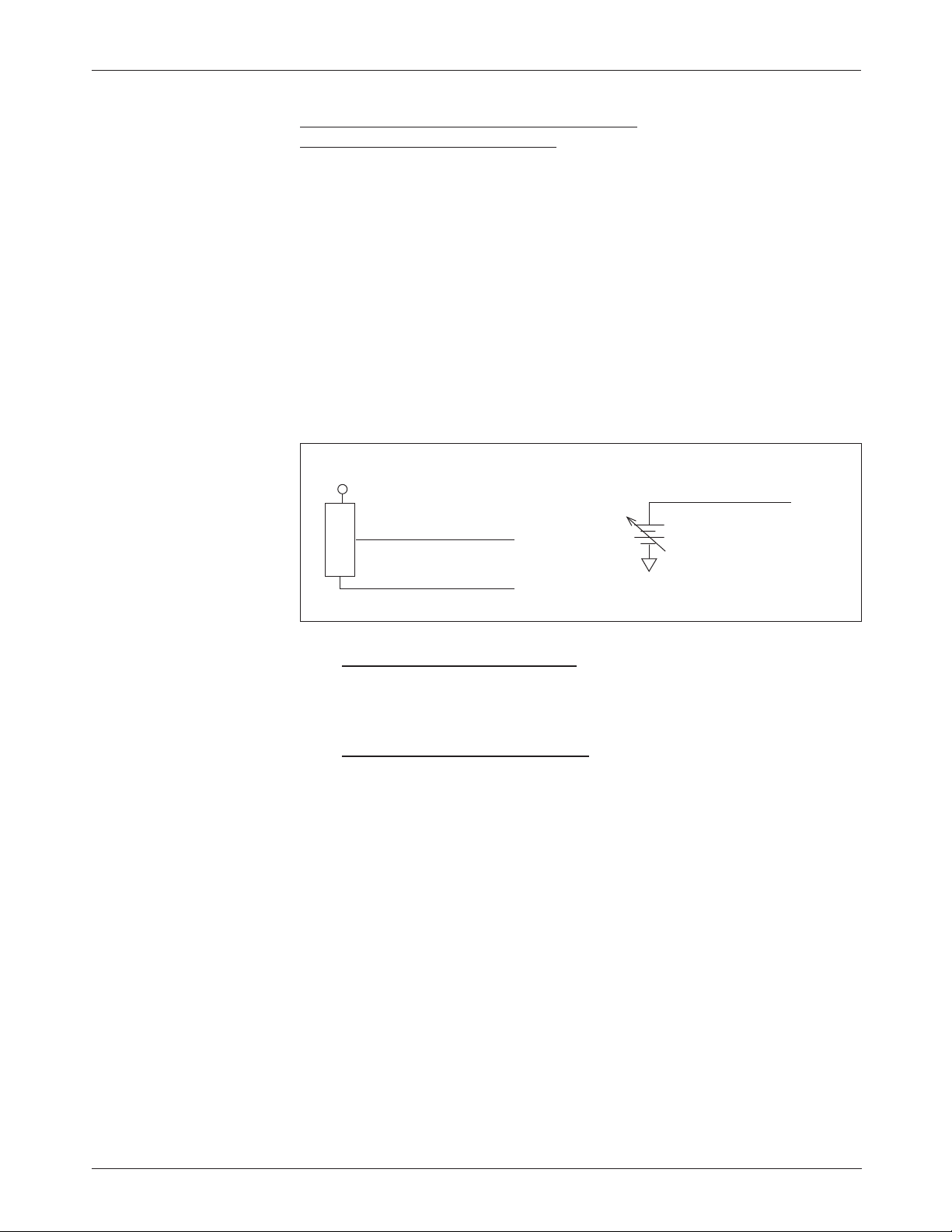

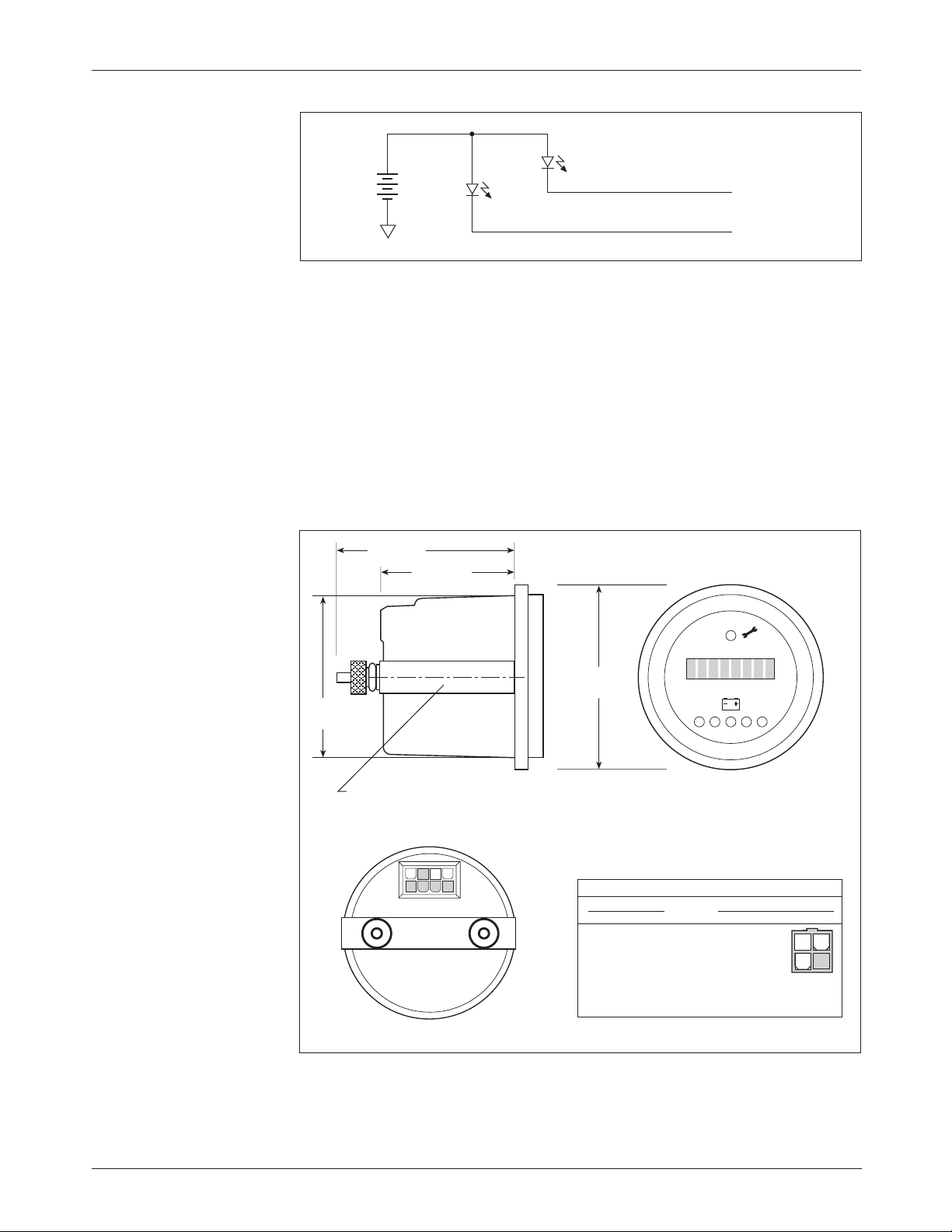

WIRING: Fault Outputs

The 1243

GEN2 has two fault signal outputs (Pins 2 and 3), which can be used

to provide diagnostic information to a display panel. These current-sinking

outputs can drive LEDs or other loads requiring less than 10 mA. Since these

outputs are intended to drive LEDs, each contains a dropping resistor; as a

result, these outputs will not pull down to B-. Wiring is shown in Figure 11.

The Fault 1 and Fault 2 outputs can be programmed to display fault

information in either of two formats: Fault Code format or Fault Category

format (see Section 3, page 51).

Alternatively, Pin 2 can be used to provide a pump input signal (see pump

meter parameter, Section 3, page 48); Pin 3 can be used to interface an external

auxiliary enable circuit (see BDI lockout parameter, Section 3, page 52).

Curtis 1243GEN2 Manual, Rev. B

Fig. 11 Wiring for fault

B-

+

-

Fault 1 output (Pin 2)

Fault 2 output (Pin 3)

SPYGLASS 1243·GEN·2 CONTROLLER

PIN # FUNCTION PIN #

1–4 N.C. –

5 +12V, +15V 4

6 receive data 3

7 N.C. –

8 ground (B+) 2

58

(2.25)

44 (1.75)

8

58 (2.25)

52

(2.0)

“U” clamp for

up to 6 (0.25)

panel thickness

5

4 1

WIRING GUIDE

34

12

0 1

outputs, when used to drive

LEDs. Alternatively, Pin 2

can be used for a pump meter input, and Pin 3 can be

used to interface an external

enable circuit.

2 — INSTALLATION & WIRING: Spyglass Display

WIRING: Spyglass Display

The Curtis 840 Spyglass features an 8-character LCD display that sequences

between hourmeter, BDI %, and fault messages. Depending on the model,

either three or six indicator LEDs are also located on the face of the gauge.

See Section 7 (Diagnostics and Troubleshooting) for more information on the

Spyglass displays.

The mating 8-pin connector is Molex 39-01-2085, with 39-00-0039

(18–24 AWG) pins.

Fig. 12 Wiring guide and

mounting dimensions for

Curtis Spyglass (6-LED

model shown; dimensions

and wiring are identical for

the 3-LED model).

Curtis 1243GEN2 Manual, Rev. B

Dimensions in millimeters (and inches)

15

2 — INSTALLATION & WIRING: Emerg. Reverse and Aux Driver

WIRING: Emergency Reverse

To implement the emergency reverse feature, Pin 13 (the emergency reverse

input) must be connected to battery voltage as shown in the standard wiring

diagram, Figure 3.

The controller provides maximum braking torque as soon as the emer

gency reverse switch is closed. The vehicle will then be automatically driven in

the reverse direction at the programmed emergency reverse current limit until

the emergency reverse switch is released.

C A U T I O N

☞

CAUTION: The polarity of the S1 and S2 connections will affect the op-

eration of the emergency reverse feature. The forward and reverse switches and

the S1 and S2 connections must be configured so that the vehicle drives away

from the operator when the emergency reverse button is pressed.

WIRING: Emergency Reverse Check

An optional wire connected directly to the emergency reverse switch provides

for broken wire detection when that feature is programmed On (see Section

3, page 43). The emergency reverse check output wire periodically pulses the

emergency reverse circuit to check for continuity in the wiring. If there is no con

tinuity, the controller output is inhibited until the wiring fault is corrected.

The emergency reverse check wire is connected to Pin 10 as shown by the

dotted line in the standard wiring diagram, Figure 3. If the option is selected

and the check wire is not connected, the vehicle will not operate. If the op

tion is not selected and the check wire is connected, no harm will occur—but

continuity will not be checked.

-

-

-

16

WIRING: Auxiliary Driver

The 1243

designed to energize an electromagnetic brake coil, as shown in the standard

wiring diagram (Figure 3). The output is rated at 2 amps and is overcurrent

protected. A coil suppression diode is provided internally to protect the driver

from inductive spikes generated at turn-off. The recommended wiring is shown

in the standard wiring diagram, Figure 3. The contactor coil or driver load should

not be connected directly to B+, which would cause the controller to be always

biased On via a path through the coil suppression diode to the KSI input.

can be used to drive a pump contactor or hydraulic steering assist in applications not requiring an EM brake.

programmable parameters related to this driver are described in the electromagnetic brake parameter group; see page 28.

GEN2 provides an auxiliary driver at Pin 8. This low side driver is

Although it is typically used to drive an EM brake, the auxiliary driver

Note: Because the auxiliary driver is typically used for an EM brake, the

Curtis 1243GEN2 Manual, Rev. B

2 — INSTALLATION & WIRING: Main Contactor & Switches, etc.

CONTACTOR, SWITCHES, and OTHER HARDWARE

Main Contactor

A main contactor should be used with any 1243GEN2 controller; otherwise the

controller’s fault detects will not be able to fully protect the controller and mo

tor drive system from damage in a fault condition. The main contactor allows

the controller and motor to be disconnected from the battery. This provides

a significant safety feature in that the battery power can be removed from the

drive system if a controller or wiring fault results in full battery power being

applied to the motor. If the Contactor Diagnostics parameter (see Section 3,

page 40) is On, the controller will conduct a missing contactor check and a

welded contactor check each time the main contactor is requested to close and

will not proceed with the request if a fault is found.

A single-pole, single-throw (SPST) contactor with silver-alloy contacts,

such as an Albright SW80 or SW180—available from Curtis—is recommended

for use as the main contactor. The contactor coils should be specified with a

continuous rating at the nominal battery pack voltage.

The main contactor coil driver output (Pin 4) is rated at 2 amps, is overcurrent protected, and is checked for open coil faults. A built-in coil suppres

sion diode is connected between the main contactor coil driver output and the

keyswitch input. This protects the main contactor coil driver from failure due

to inductive voltage kickback spikes when the contactor is turned off.

-

-

Keyswitch and Interlock Switch

The vehicle should have a master on/off switch to turn the system off when not

in use. The keyswitch input provides logic power for the controller.

The interlock switch—which is typically implemented as a tiller switch,

deadman footswitch, or seatswitch—provides a safety interlock for the system.

The keyswitch and interlock switch provide current to drive the main

contactor coil and all other output driver loads as well as the controller’s internal

logic circuitry and must be rated to carry these currents.

Forward, Reverse, Mode Select, and Emergency Reverse Switches

These input switches can be any type of single-pole, single-throw (SPST) switch

capable of switching the battery voltage at 10 mA. Typically the emergency

reverse switch is a momentary switch, active only while it is being pressed.

Reverse Polarity Protection Diode

For reverse polarity protection, a diode should be added in series between the

battery and KSI. This diode will prohibit main contactor operation and cur

rent flow if the battery pack is accidentally wired with the B+ and B- terminals

exchanged. It should be sized appropriately for the maximum contactor coil

and fault diode currents required from the control circuit. The reverse polarity

protection diode should be wired as shown in the standard wiring diagram,

Figure 3 (page 7).

-

Curtis 1243GEN2 Manual, Rev. B

17

2 — INSTALLATION & WIRING: Switches, etc.

Circuitry Protection Devices

To protect the control circuitry from accidental shorts, a low current fuse

(appropriate for the maximum current draw) should be connected in series

between the battery and KSI. Additionally, a high current fuse should be wired

in series with the main contactor to protect the motor, controller, and batteries from accidental shorts in the power system. The appropriate fuse for each

application should be selected with the help of a reputable fuse manufacturer

or dealer. The standard wiring diagram, Figure 3, shows the recommended

location for each fuse.

Mode Select Switch Operation

The two mode select switches (Mode Select 1 and Mode Select 2) together define

the four operating modes. The switch combinations are shown in Table 2.

MODE MODE

OPERATING MODE SELECT SELECT

MultiMode™ 1 OPEN OPEN

Table 2 MODE SELECTION

SWITCH 1 SWITCH 2

MultiMode™ 2 CLOSED OPEN

MultiMode™ 3 OPEN CLOSED

MultiMode™ 4 CLOSED CLOSED

Load Sensor [optional]

The 1243GEN2 provides a load sensor input at Pin 1. The controller can be

programmed to vary the strength of regen braking depending on the load

sensor input. The load sensor, if one is used, should be sized to handle your

application’s maximum expected load without exceeding 5 V.

18

Curtis 1243GEN2 Manual, Rev. B

3 — PROGRAMMABLE PARAMETERS

PROGRAMMABLE PARAMETERS

3

The 1243GEN2 controller has a number of parameters that can be programmed

using a Curtis programming device. These programmable parameters allow

the vehicle’s performance characteristics to be customized to fit the needs of

individual vehicles or vehicle applications.

The OEM can specify the default value for each parameter and can also

designate whether a parameter will have User or OEM access rights. Accordingly,

programmers are available in User and OEM versions. The User programmer

can adjust only those parameters with User access rights, whereas the OEM

programmer can adjust all the parameters. For information about Curtis pro

gramming devices, see Appendix C.

The MultiMode™ feature of the 1243

four distinct modes. These modes can be programmed to provide four different

sets of operating characteristics, which can be useful for operating in different

conditions, such as slow precise indoor maneuvering in Mode 1; faster, long

distance, outdoor travel in Mode 4; and application-specific special conditions

in Modes 2 and 3. Eight parameters can be configured independently in each

of the four modes:

— acceleration rate (M1–M4)

— braking current limit (M1–M4)

— braking rate (M1–M4)

— deceleration rate (M1–M4)

— drive current limit (M1–M4)

— maximum forward speed (M1–M4)

— maximum reverse speed (M1–M4)

— restraint (M1–M4).

GEN2 controller allows operation in

-

Curtis 1243GEN2 Manual, Rev. B

To better describe their interrelationships, the individual parameters are

grouped into categories as follows:

Battery Parameters

Acceleration Parameters

Braking Parameters

Interlock Braking Parameters

Electromagnetic Brake Parameters

Speed Parameters

Throttle Parameters

Field Parameters

Contactor Parameters

Sequencing Fault Parameters

Emergency Reverse Parameters

Motor Protection Parameters

Hourmeter Parameters

BDI Parameters

Fault Code Parameters

19

3 — PROGRAMMABLE PARAMETERS

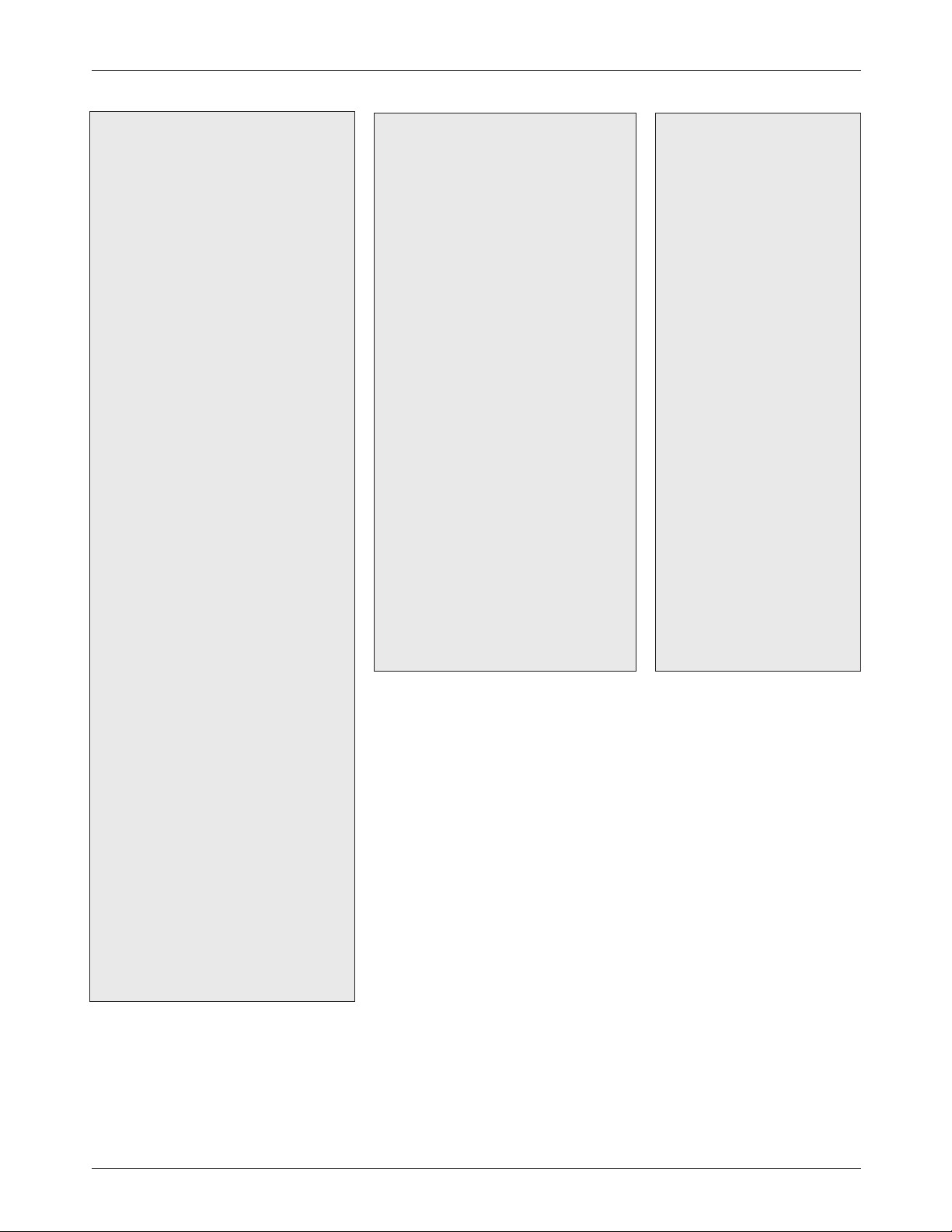

Battery Parameter ..................... p.21

Battery Voltage

Acceleration Parameters ........... p.21

Drive Current Limit, M1–M4

Acceleration Rate, M1–M4

Quick Start

Current Ratio

Braking Parameters ................... p.23

Braking Current Limit, M1–M4

Deceleration Rate, M1–M4

Throttle Deceleration Rate

Restraint, M1–M4

Braking Rate, M1–M4

Taper Rate

Variable Braking

Interlock Braking

Parameters .................................. p.26

Interlock Braking Rate

Max. Forward Regen

Max. Reverse Regen

Min. Forward Regen

Min. Reverse Regen

Max. Load Volts

Min. Load Volts

Electromagnetic Brake

Parameters .................................. p.28

Auxiliary Driver Type

Electromagnetic Brake PWM

Auxiliary Driver Delay

Interlock Brake Delay

Field Parameters ........................ p.38

Min. Field Current Limit

Max. Field Current Limit

Field Map Start

Field Map

Field Check

Main Contactor Parameters .... p.40

Main Contactor Interlock

Main Contactor Open Delay

Main Contactor Diagnostics

Sequencing Fault Parameters .. p.41

Anti-Tiedown

High Pedal Disable (HPD)

Static Return to Off (SRO)

Sequencing Delay

Emergency Reverse

Parameters .................................. p.43

Emerg. Reverse Current Limit

Emerg. Reverse Check

Emerg. Reverse Direction Interlock

Motor Protection Parameters .. p.44

Warm Speed

Motor Warm Resistance

Motor Hot Resistance

Motor Resistance Compensation

Hourmeter

Parameters ................... p. 45

Adjust Hours High

Adjust Hours Middle

Adjust Hours Low

Set Total Hours

Set Traction Hours

Total Service Hours

Traction Service Hours

Total Disable Hours

Traction Disable Hours

Traction Fault Speed

Service Total

Service Traction

Hourmeter Type

Pump Meter

BDI Parameters ...........p.49

Full Voltage

Empty Voltage

Reset Voltage

Battery Adjust

BDI Disable

BDI Limit Speed

Fault Code

Parameters ....................p.51

Fault Code

BDI Lockout

Speed Parameters ....................... p.31

Max. Forward Speed, M1–M4

Max. Reverse Speed, M1–M4

Creep Speed

Load Compensation

Throttle Parameters .................. p.32

Throttle Type

Throttle Deadband

Throttle Max

Throttle Map

Pot Low Fault

20

☞

Individual parameters are described in the following text

in the order they are listed on this page. They are listed by

the abbreviated names that are displayed by the program

ming device. Not all of these parameters are displayed on

all controllers; the list for any given controller depends on

its specifications.

The programmer displays the parameters in a different

order. For a list of the individual parameters in the order

in which they are displayed, see Section 6: Programmer

Menus.

Curtis 1243GEN2 Manual, Rev. B

-

Loading...

Loading...