Wesley BC-620-4CA User Manual

1234/36/38 Manual

12 3 4

M O D E L S

12 3 6

CURTIS INSTRUMENTS, INC.

200 Kisco Avenue

Mt. Kisco, New York 10549 USA

Tel. 914.666.2971

Fax 914.666.2188

www.curtisinstruments.com

&

MOTOR CONTROLLERS

© 2008 CURTIS INSTRUMENTS, INC.

DESIGN OF CURTIS PMC 1200 SERIES

CONTROLLERS PROTECTED BY U.S.

PATENT NO. 4626750.

1238

AC INDUCTION

OS 11 with VCL

1234/36/38 Manual, p/n 37022

4 August 2008

» Software version OS 11.0 «

CONTENTS

1. OVERVIEW ..............................................................................1

CONTENTS

2. INSTALLATION AND WIRING .............................................

Mounting the Controller .....................................................3

High Current Connections and Wiring Guidelines ..............6

Low Current Connections and Wiring Guidelines ...............8

Controller Wiring: Basic Configuration ............................

Switch Input Wiring ..........................................................

Throttle Wiring .................................................................13

Input/Output Specifications ...............................................

3. PROGRAMMABLE PARAMETERS .....................................

Program Menu ..................................................................

4a. MONITOR MENU ................................................................

4b. CONTROLLER INFORMATION MENU ...........................

5. INITIAL SETUP .....................................................................

6. TUNING GUIDE ...................................................................

12

13

18

23

24

64

74

75

80

3

7. VEHICLE CONTROL LANGUAGE .....................................

8. DIAGNOSTICS AND TROUBLESHOOTING ..................

MAINTENANCE .................................................................120

9.

APPENDIX A Theory of Operation

APPENDIX B Vehicle Design Considerations

APPENDIX C Programmer Operation

APPENDIX D Specifications, 1234/36/38 Controllers

84

110

Curtis 1234/36/38 Manual, OS 11 iii

FIGURES / TABLES

FIGURES

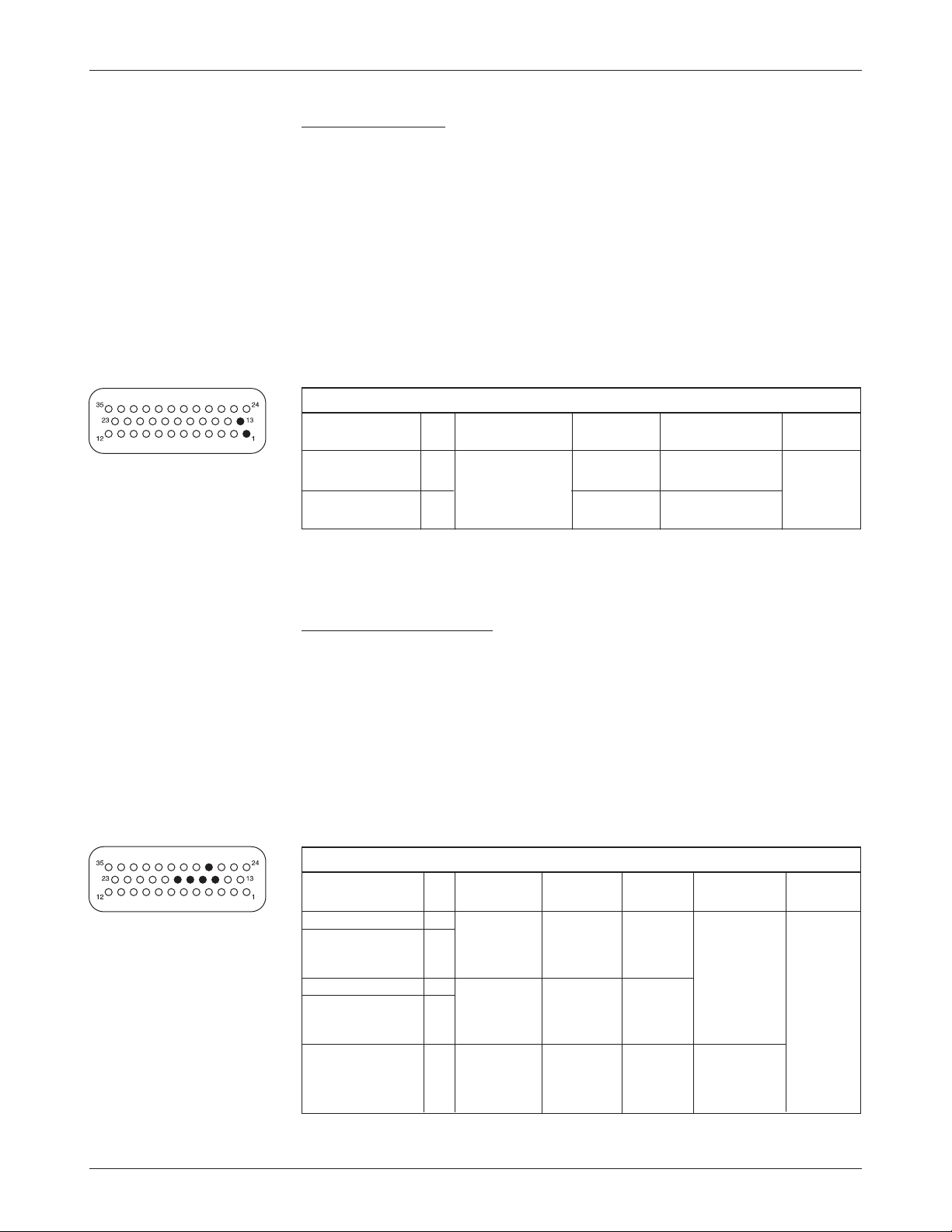

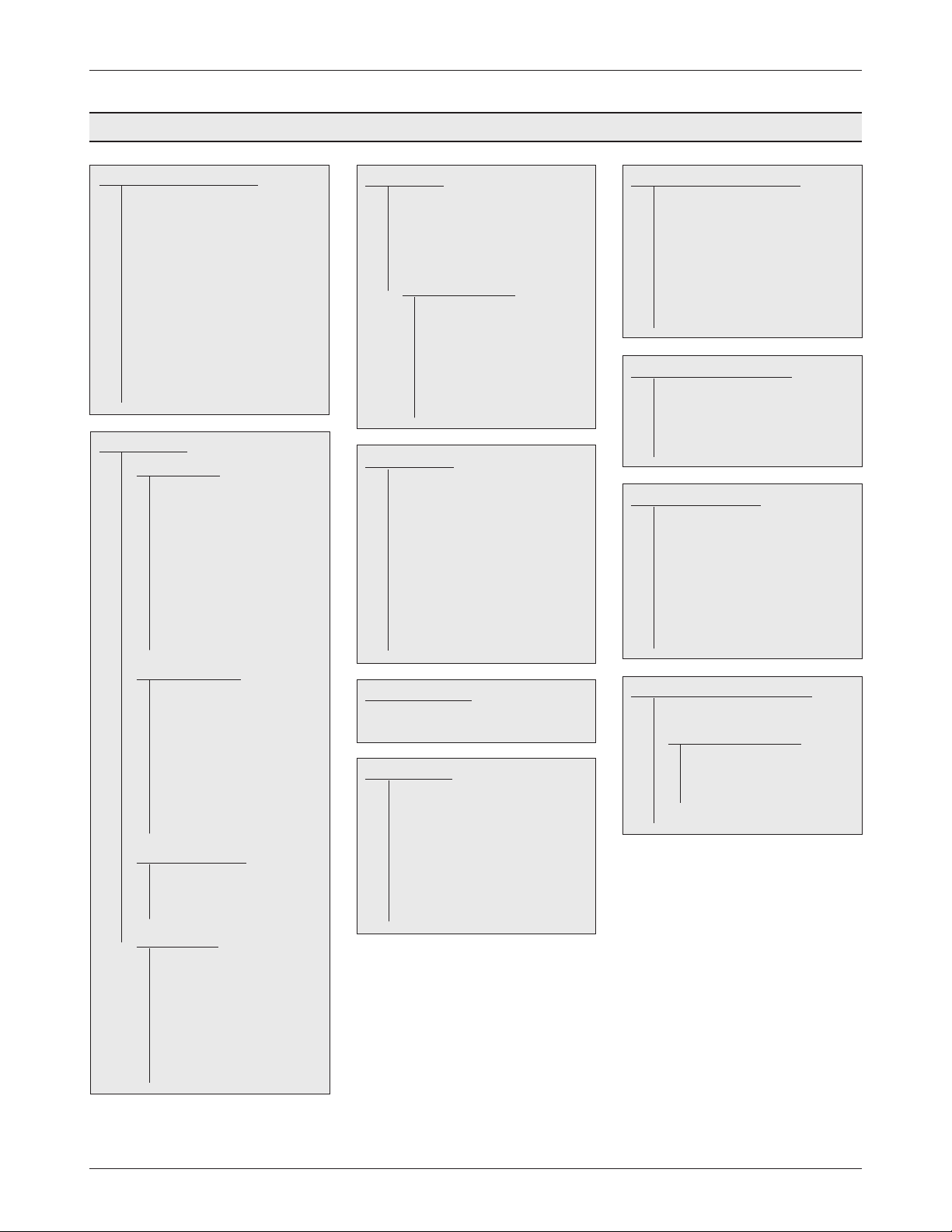

FIG. 1: Curtis 1234, 1236, and 1238 controllers ................................. 1

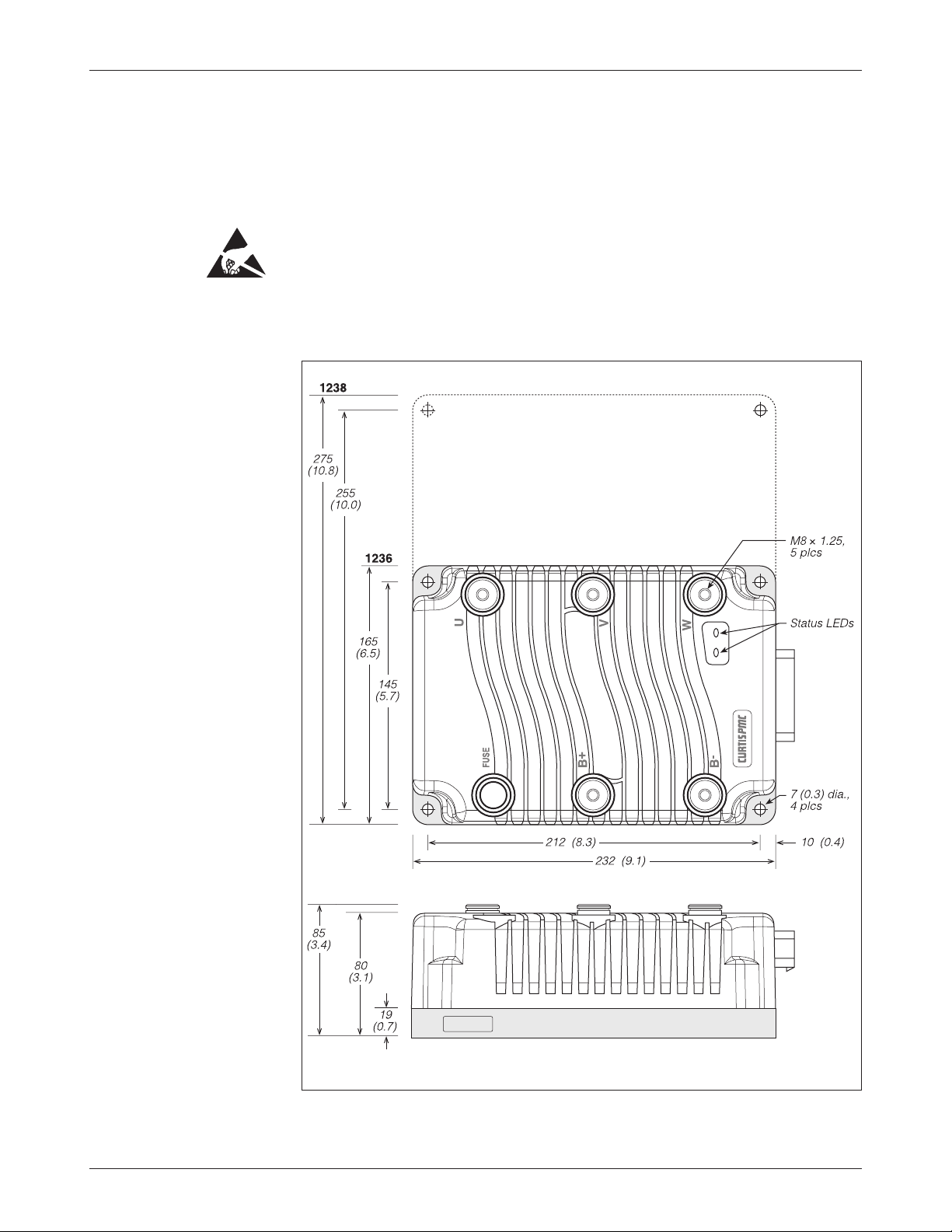

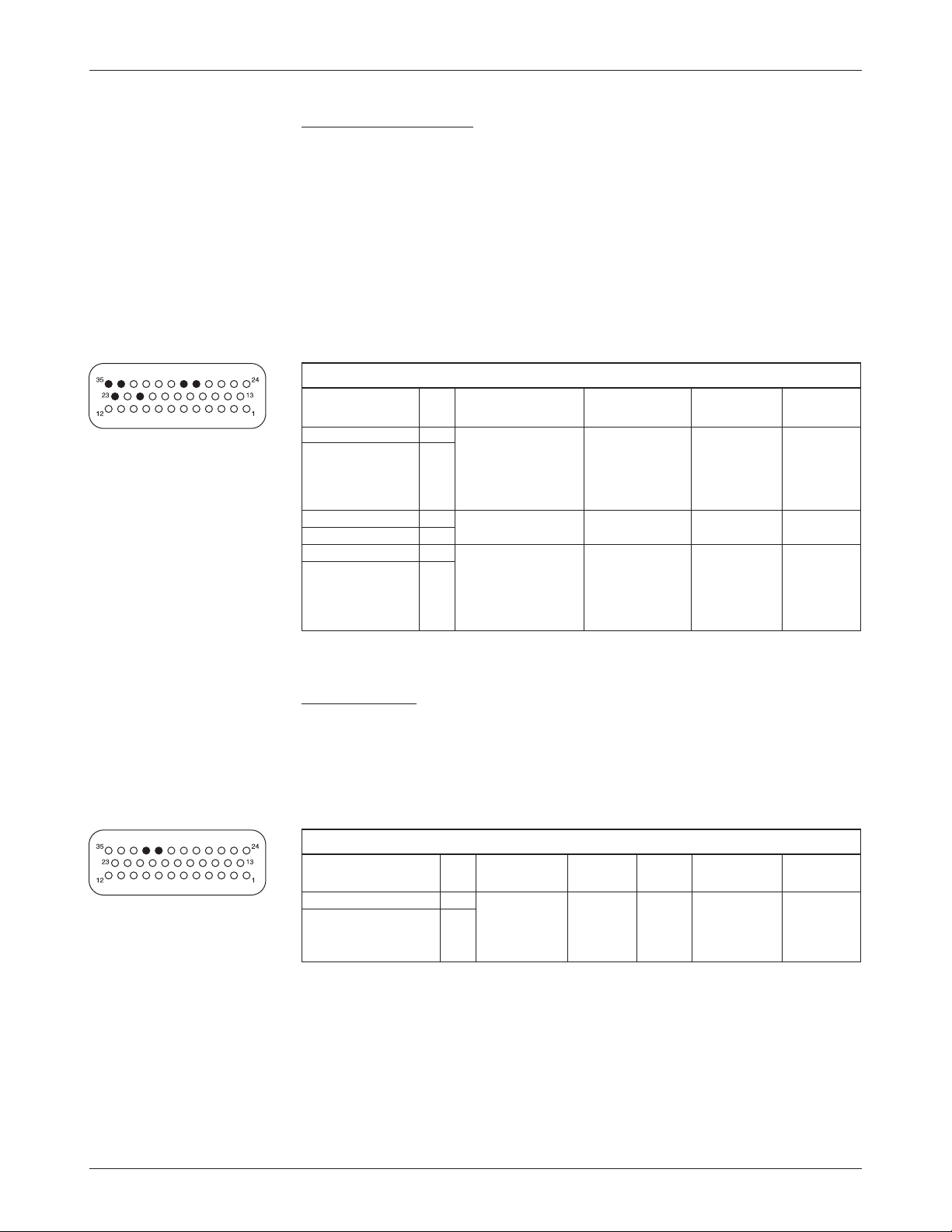

FIG. 2a: Mounting dimensions, Curtis 1234 controller ........................ 3

FIG. 2b: Mounting dimensions, Curtis 1236/38 controllers ................. 4

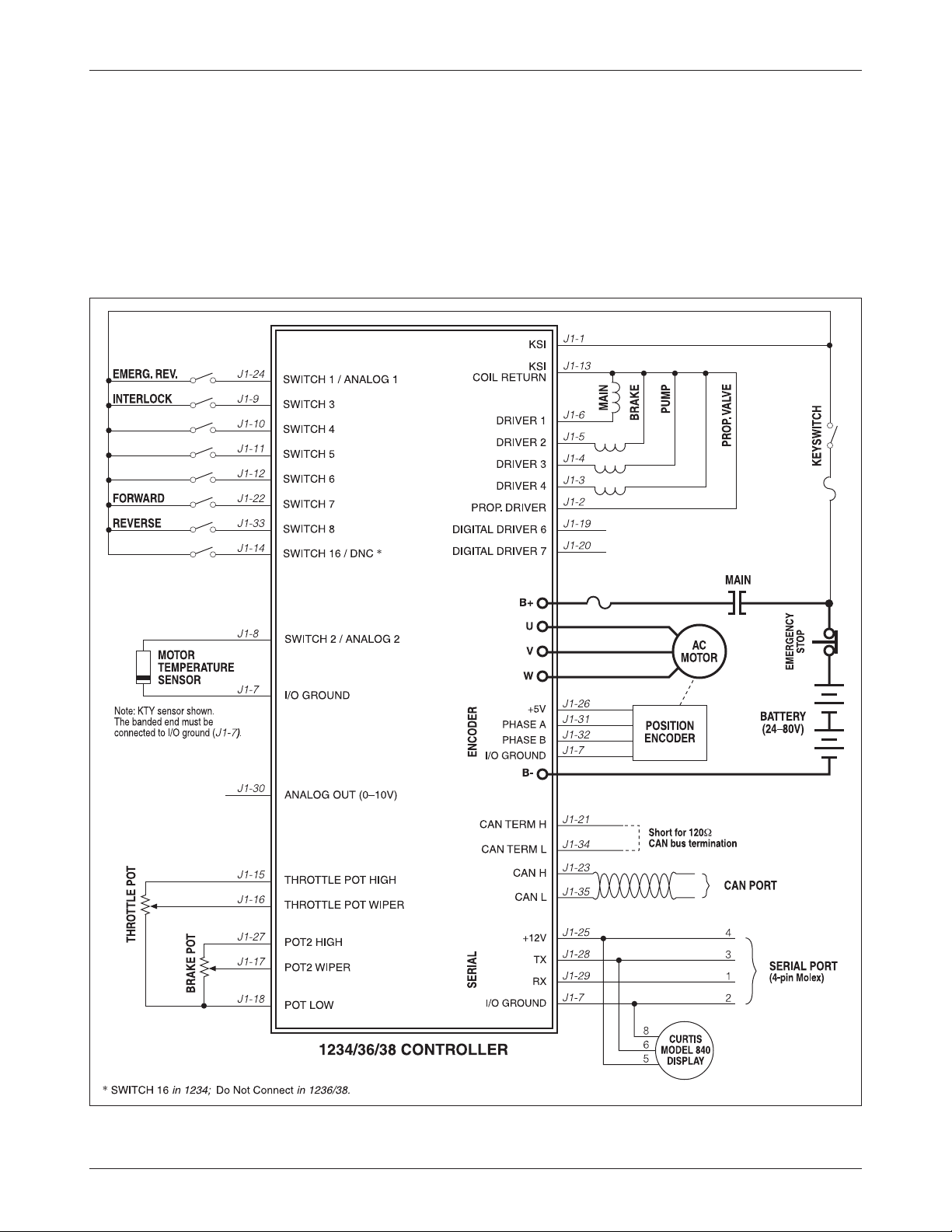

FIG. 3: Basic wiring diagram .............................................................. 12

FIG. 4: Wiring for Type 1 throttles .................................................... 14

FIG. 5: Wiring for Type 2 throttles .................................................... 15

FIG. 6: Wiring for Type 3 throttles .................................................... 16

FIG. 7: Response rate diagram ............................................................ 32

FIG. 8: Throttle mapping, torque control mode ................................ 37

FIG. 9: Effect of gear soften parameter, torque control mode ............. 37

FIG. 10: Effect of brake taper speed parameter, torque control mode ... 37

FIG. 11: Drive current limiting map .................................................... 40

FIG. 12: Regen current limiting map ................................................... 41

FIG. 13: Throttle adjustment ............................................................... 43

FIG. 14: VCL motor command diagram .............................................. 92

FIG. 15: VCL control mode processing ................................................ 96

FIG. 16: VCL proportional driver processing ....................................... 97

FIG. A-1: IFO diagram .........................................................................A-2

FIG. A-2: Power section topology ..........................................................A-3

FIG. C-1: Curtis 1311 handheld programmer ...................................... C-1

TABLES

TABLE 1: High current connections ....................................................... 6

TABLE 2: Low current connections ........................................................ 9

TABLE 3: Programmable parameter menus .......................................... 24

TABLE 4: Types of LED display ........................................................ 111

TABLE 5: Troubleshooting chart ......................................................... 112

TABLE D-1: Specifications, 1234/36/38 controllers ............................... D-1

iv

Curtis 1234/36/38 Manual, OS 11

1

1 — OVERVIEW

OVERVIEW

Curtis 1234, 1236, and 1238 AC induction motor controllers deliver smooth

power unlike any previous vehicle control system. They provide unprecedented

flexibility and power through inclusion of a field-programmable logic controller

embedded in a state-of-the-art motor controller.

The embedded logic controller runs a fully functional field-oriented AC

motor control operating system (OS) that can be user-tailored via parameter

modification; see Section 3. The OS also contains logic to execute OEMdeveloped software, called VCL, that can be used to enhance the controller

capabilities beyond the basics; see Section 7.

VCL (Vehicle Control Language) is an innovative software programming

language developed by Curtis. Many electric vehicle functions are uniquely

built into the VCL code, and additional functions can be OEM-controlled using

VCL code. VCL opens new avenues of customization, product differentiation,

and responsiveness to the market.

The CAN bus communications included in the 1234/36/38, as well as

in many other Curtis products, allow these AC induction motor controllers to

be part of an efficient distributed system. Inputs and outputs can be optimally

shared throughout the system, minimizing wiring and creating integrated

functions that often reduce the cost of the system.

Curtis 1234/36/38 controllers are the ideal solution for traction, hoist,

dual drive, and other motor drive and vehicle control needs.

Fig. 1 Curtis 1234 (left), 1236 (middle), and 1238 (right) AC induction motor controllers.

All three models have the same standard features.

Like all Curtis controllers, the 1234/36/38 offers superior operator control of

motor drive performance. Features include:

✓ High efficiency, field-oriented motor control algorithms

✓ Advanced Pulse Width Modulation technology for efficient use

of battery voltage, low motor harmonics, low torque ripple, and

minimized switching losses

✓ Extremely wide torque/speed range including full regeneration capability

✓ Smooth low speed control, including zero speed

Curtis 1234/36/38 Manual, OS 11

More Features

☞

1

1 — OVERVIEW

✓ Adaptation of control algorithm to motor temperature variation so

optimal performance is maintained under widely varying conditions

✓ Real-time battery current, motor torque, and power estimates available

✓ Power limiting maps allow performance customization for reduced motor

heating and consistent performance over varying battery state-of-charge

✓ Powerful operating system allows parallel processing of vehicle control

tasks, motor control tasks, and user configurable programmable logic

✓ A wide range of I/O can be applied wherever needed, for maximum

distributed system control

✓ Internal battery-state-of-charge, hourmeter, and maintenance timers

✓ Easily programmable through the Curtis 1311 handheld programmer

and 1314 PC Programming Station

✓ CAN bus connection allows communication with other CAN bus

enabled system components; protocol meets CANopen standards;

other 11-bit identifier field CAN protocols can be custom configured

through VCL

☞

✓ Field-programmable, with flash downloadable main operating code

✓ Thermal cutback, warning, and automatic shutdown provide protection

to motor and controller

✓ Rugged sealed housing and connectors meet IP65 environmental sealing

standards for use in harsh environments

✓ Insulated metal substrate power base provides superior heat transfer for

increased reliability

✓ Built-in Dual Drive software allows easy setup and control of typical

dual-drive vehicles, without VCL.

Note: If you have a dual-drive application, see the Dual Drive

Addendum to the 1234/36/38 manual, part number 37022-

Familiarity with your Curtis controller will help you install and operate it prop

erly. We encourage you to read this manual carefully. If you have questions,

please contact the Curtis office nearest you.

Using the 1311 handheld programmer, you can set up the controller to per

form all the basic operations. In this manual, we first show you how to wire

your system and adjust its performance characteristics without the use of VCL.

Then, in Section 7, we show you how to adjust the system using VCL, which

interacts with a second, independent software realm resident in a powerful logic

controller embedded within the 1234/36/38 controller.

DD.

-

-

2

Curtis 1234/36/38 Manual, OS 11

2

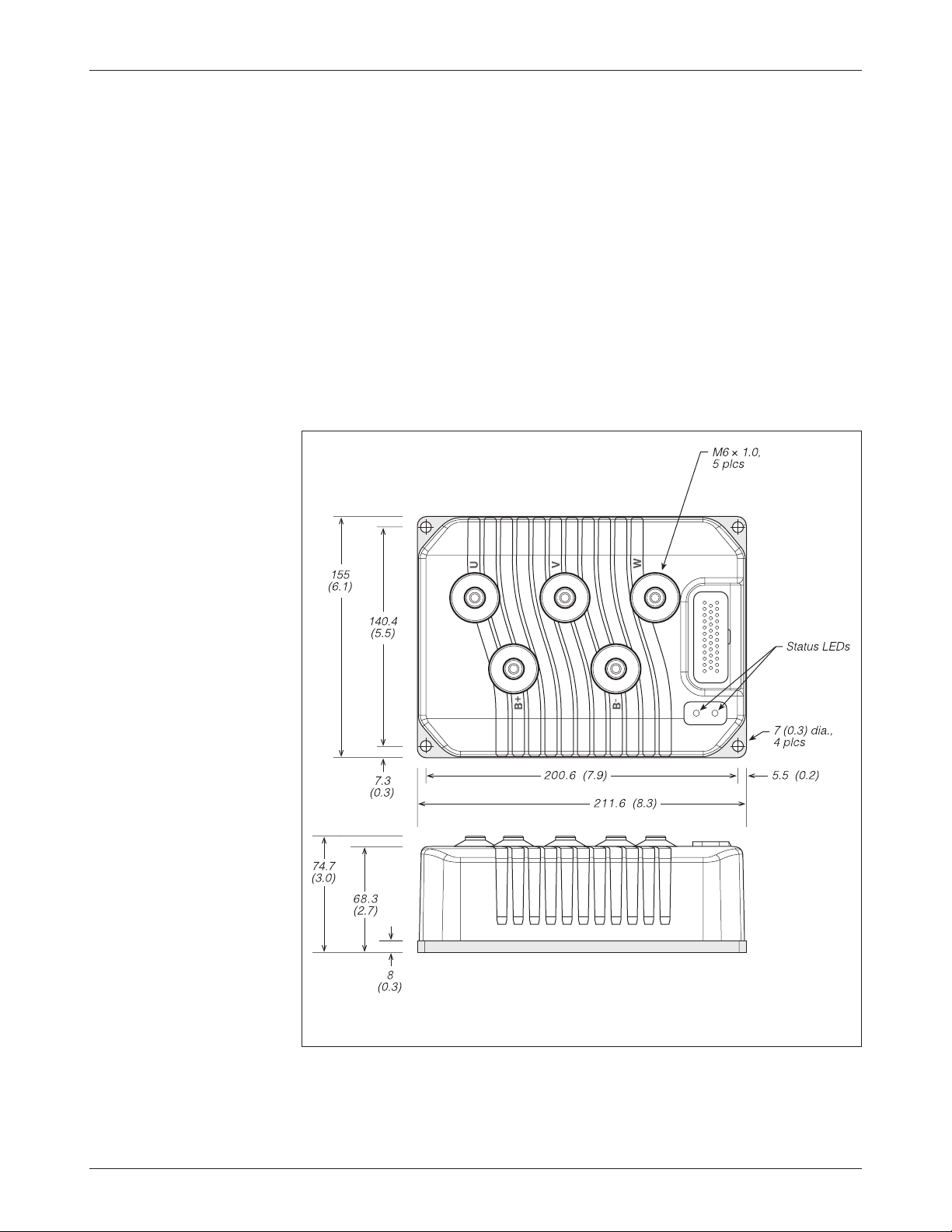

Fig. 2a Mounting

dimensions, Curtis 1234

motor controller.

2 — INSTALLATION & WIRING

INSTALLATION AND WIRING

MOUNTING THE CONTROLLER

The outline and mounting hole dimensions for the 1234 controller are shown in

Figure 2a, and for the 1236 and 1238 controllers in Figure 2b. These controllers meet the IP65 requirements for environmental protection against dust and

water. Nevertheless, in order to prevent external corrosion and leakage paths

from developing, the mounting location should be carefully chosen to keep

the controller as clean and dry as possible.

It is recommended that the controller be fastened to a clean, flat metal

surface with four 6mm (1/4") diameter bolts, using the holes provided. A thermal

joint compound can be used to improve heat conduction from the controller

Curtis 1234/36/38 Manual, OS 11

Dimensions in millimeters (and inches)

3

2 — INSTALLATION & WIRING

Fig. 2b Mounting

dimensions, Curtis 1236

and 1238 motor controllers.

heatsink to the mounting surface. Additional heatsinking or fan cooling may

be necessary to meet the desired continuous ratings.

You will need to take steps during the design and development of your

end product to ensure that its EMC performance complies with applicable

regulations; suggestions are presented in Appendix B.

The1234/36/38 controllers contain ESD-sensitive components. Use

appropriate precautions in connecting, disconnecting, and handling the controller. See installation suggestions in Appendix B for protecting the controller

from ESD damage.

4

Dimensions in millimeters (and inches)

Curtis 1234/36/38 Manual, OS 11

2 — INSTALLATION & WIRING

C AU T I O N

☞

Working on electrical systems is potentially dangerous. You should

protect yourself against uncontrolled operation, high current arcs, and

outgassing from lead acid batteries:

UNCONTROLLED OPERATION — Some conditions could cause the motor to

run out of control. Disconnect the motor or jack up the vehicle and get

the drive wheels off the ground before attempting any work on the motor

control circuitry.

HIGH CURRENT ARCS — Batteries can supply very high power, and arcing can

occur if they are short circuited. Always open the battery circuit before

working on the motor control circuit. Wear safety glasses, and use properly

insulated tools to prevent shorts.

LEAD ACID BATTERIES — Charging or discharging generates hydrogen gas,

which can build up in and around the batteries. Follow the battery man

ufacturer’s safety recommendations. Wear safety glasses

.

-

Curtis 1234/36/38 Manual, OS 11

5

2 — INSTALLATION & WIRING: High Current Connections

HIGH CURRENT CONNECTIONS

There are five high-current terminals, identified on the controller housing as

B+, B-, U, V, and W.

TERMINAL FUNCTION

B+ Positive battery to controller.

B- Negative battery to controller.

U Motor phase U.

V Motor phase V.

W Motor phase W.

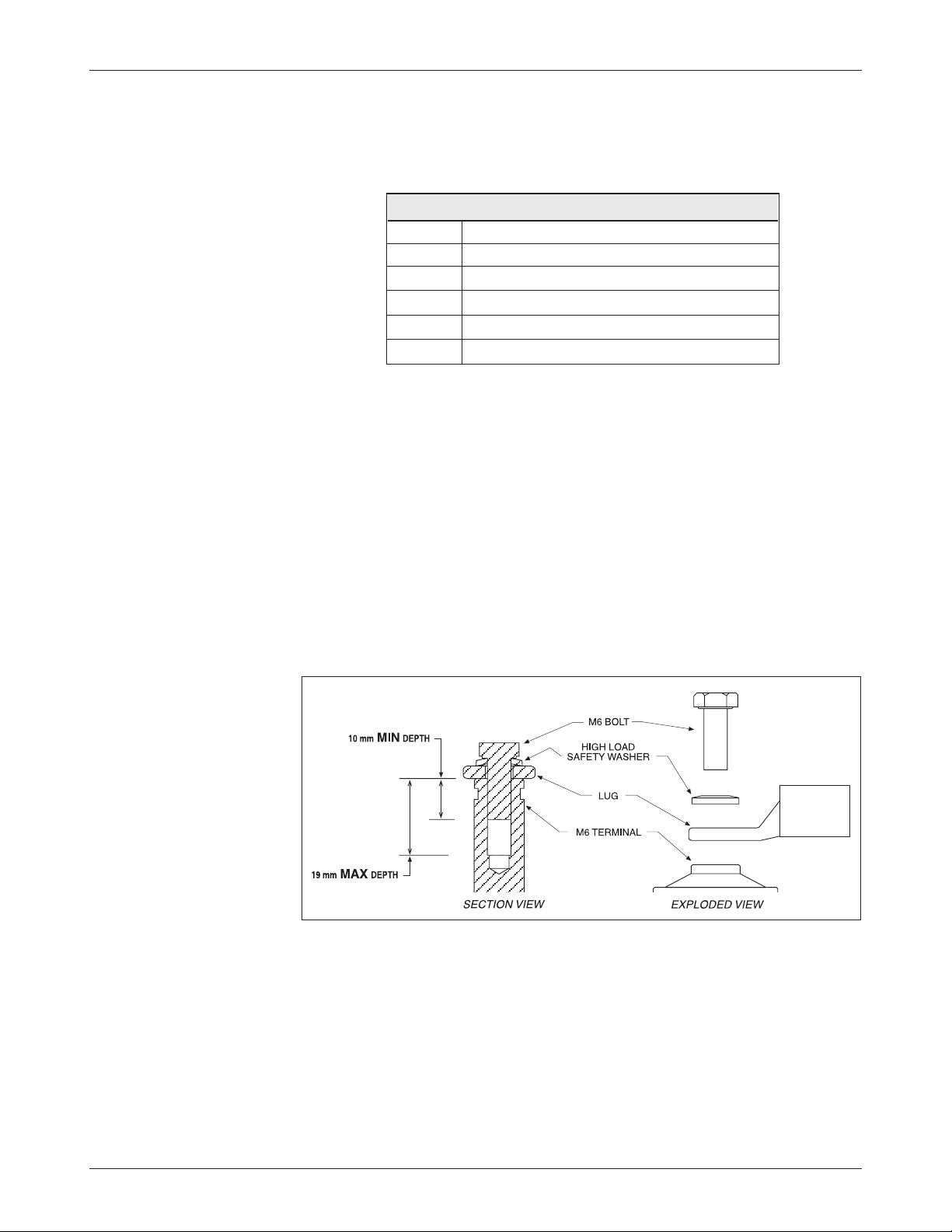

Lug assembly: 1234 models

Five aluminum M6 terminals are provided. Lugs should be installed as follows,

using M6 bolts sized to provide proper engagement (see diagram):

Table 1 High Current Connections

• Place the lug on top of the aluminum

terminal, followed by

a high-load safety washer with its convex side on top. The

washer should be a

• If two lugs are used on the same

SCHNORR 416320, or equivalent.

terminal, stack them so the

lug carrying the least current is on top.

• Tighten the assembly to 10.2 ±1.1 N·m (90 ±10 in-lbs).

6

Curtis 1234/36/38 Manual, OS 11

2 — INSTALLATION & WIRING: High Current Connections

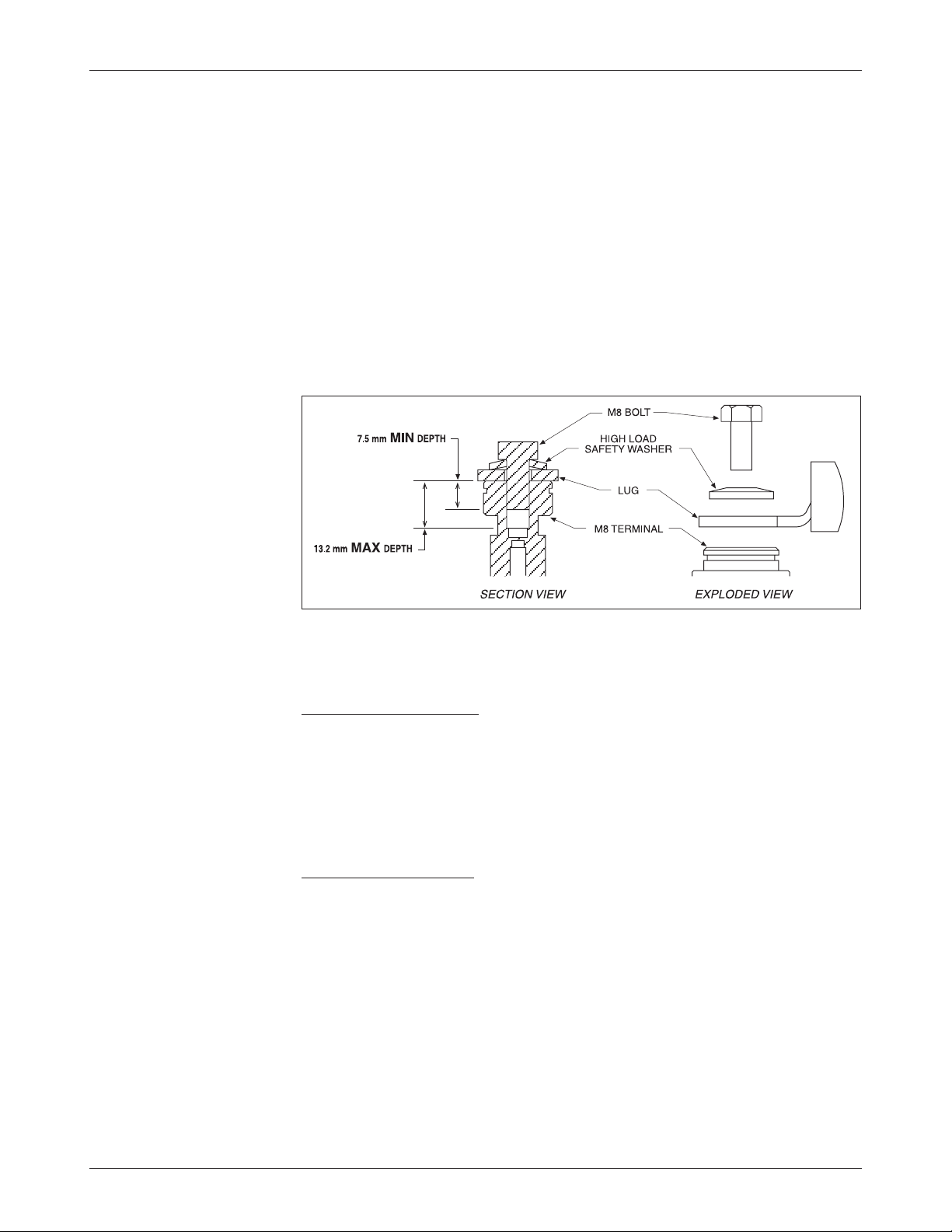

Lug assembly: 1236 and 1238 models

Five brass M8 terminals are provided. Lugs should be installed as follows, using

M8 bolts sized to provide proper engagement (see diagram):

• Place the lug on top of the brass

terminal, followed by a

high-load safety washer with its convex side on top. The

washer should be a

• If two lugs are used on the same

SCHNORR 700800, or equivalent.

terminal, stack them so the

lug carrying the least current is on top.

• Tighten the assembly to 9.6 ±0.9 N·m (85 ±8 in-lbs).

Note: The

terminals may rotate up to ±5° in the cover.

High current wiring recommendations: all models

Battery cables (B+, B-)

These two cables should be run close to each other between the controller

and the battery. Use high quality copper lugs and observe the recommended

torque ratings. For best noise immunity the cables should not run across the

center section of the controller. With multiple high current controllers, use a

star ground from the battery

Motor wiring (U, V, W)

B- terminal.

The three phase wires should be close to the same length and bundled together

as they run between the controller and the motor. The cable lengths should be

kept as short as possible. Use high quality copper lugs and observe the recom

mended torque ratings. For best noise immunity the motor cables should not

run across the center section of the controller. In applications that seek the

lowest possible emissions, a shield can be placed around the bundled motor

cables and connected to the

B- terminal at the controller. Typical installations

will readily pass the emissions standards without a shield. Low current signal

wires should not be run next to the motor cables. When necessary they should

cross the motor cables at a right angle to minimize noise coupling.

-

Curtis 1234/36/38 Manual, OS 11

7

2 — INSTALLATION & WIRING: Low Current Connections

LOW CURRENT CONNECTIONS

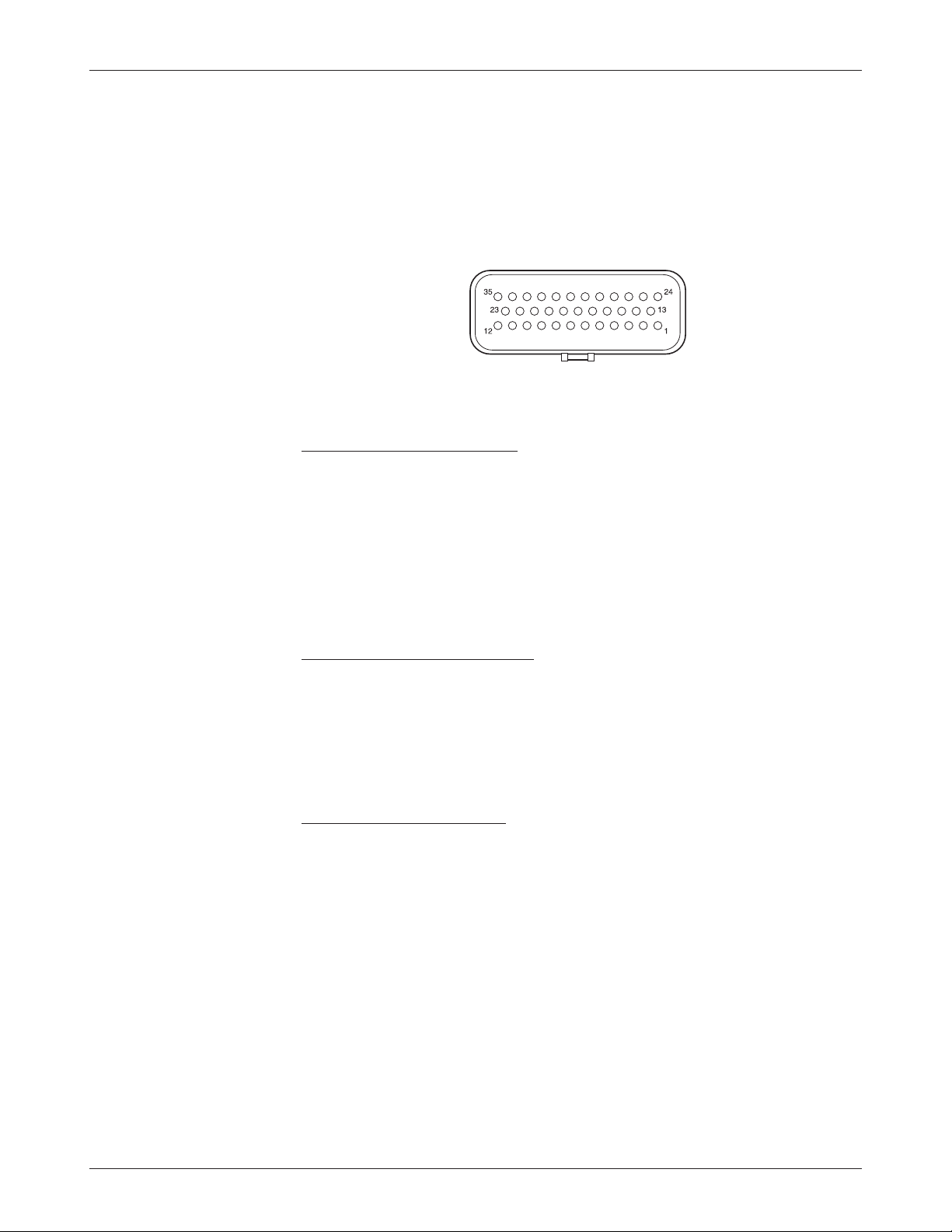

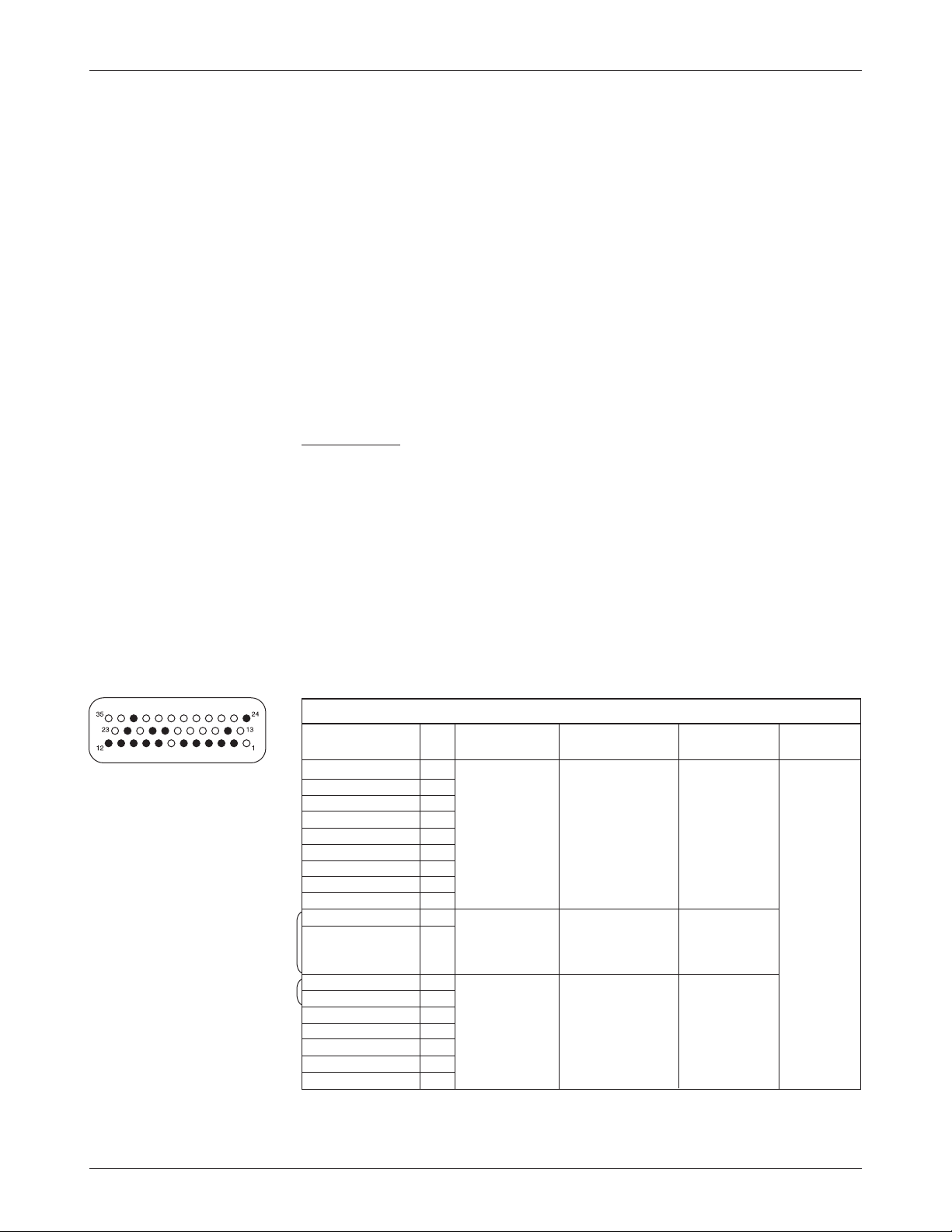

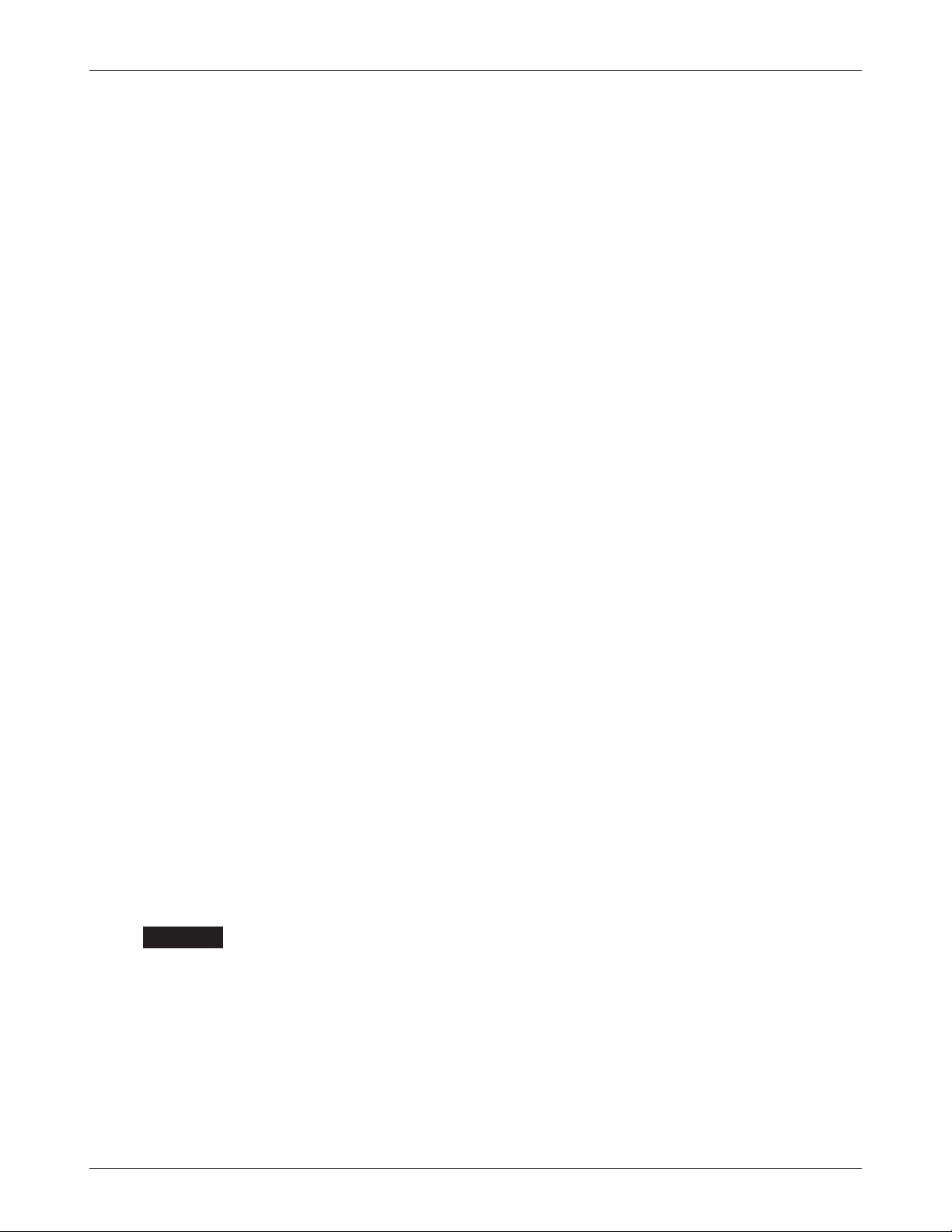

All low power connections are made through a single 35-pin AMPSEAL con

nector. The mating plug housing is AMP p/n 776164-1 and the contact pins

are AMP p/n 770520-3. The connector will accept 20 to 16 AWG wire with

a 1.7 to 2.7mm diameter thin-wall insulation.

The 35 individual pins are characterized in Table 2.

J1

Low current wiring recommendations

Motor encoder (Pins 31, 32)

All four encoder wires should be bundled together as they run between the

motor and controller logic connector. These can often be run with the rest of

the low current wiring harness. The encoder cables should not be run near

the motor cables. In applications where this is necessary, shielded cable should

be used with the ground shield connected to the I/O ground (pin 7) at only

the controller side. In extreme applications, common mode filters (e.g. ferrite

beads) could be used.

-

CAN bus (Pins 21, 23, 34, 35)

It is recommended that the CAN wires be run as a twisted pair. However,

many successful applications at 125 kBaud are run without twisting, simply

using two lines bundled in with the rest of the low current wiring. CAN wiring

should be kept away from the high current cables and cross it at right angles

when necessary.

All other low current wiring

The remaining low current wiring should be run according to standard practices.

Running low current wiring next to the high current wiring should always be

avoided.

8

Curtis 1234/36/38 Manual, OS 11

2 — INSTALLATION & WIRING: Low Current Connections

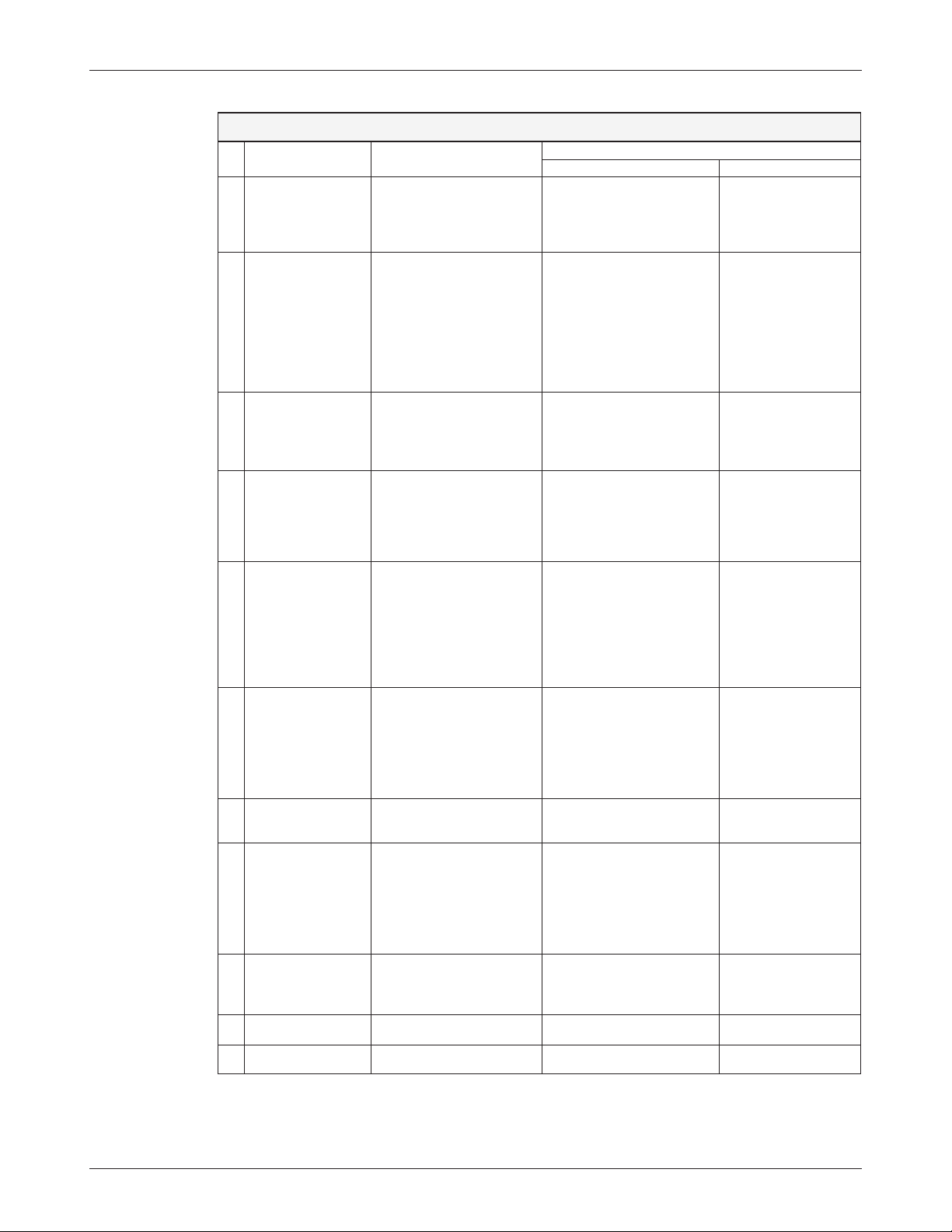

Table 2 Low Current Connections

PIN NAME DESCRIPTION

1 KSI Keyswitch input. Setup_BDI Keyswitch_Voltage

Provides logic power for

the controller and power

for the coil drivers.

2 Prop. Driver Proportional driver. Automate_PWM Sw_13

This is a coil driver with Put_PWM PWM5

current control capability PD_Current

typically used for a PD_Output

proportional valve on a PD_Throttle

hydraulic manifold. VCL_PD_Throttle

Can also be used as a

digital input.

3 Driver 4 Generic driver #4; can Automate_PWM Sw_12

also be used as a digital Put_PWM PWM4

input. Has low frequency PWM4_Output

PWM capabilities.

4 Driver 3 Generic driver #3; can Automate_PWM Sw_11

also be used as a digital Put_PWM PWM3

input. Has low frequency PWM3_Output

PWM capabilities. Typically

used for pump contactor.

FUNCTIONS REFERENCES

RELATED VCL

*

5 Driver 2 Generic driver #2; can Automate_PWM Sw_10

also be used as a digital Put_PWM PWM2

input. Has low frequency PWM2_Output

PWM capabilities and a

slightly higher current

rating.Typically used for

electromagnetic brake.

6 Driver 1 Generic driver #1; can Automate_PWM Sw_9

also be used as a digital Put_PWM PWM1

input. Has low frequency Set_Interlock PWM1_Output

PWM capabilities. Clear_Interlock Interlock_State

Typically used for main Main_State

contactor.

7 I/O Ground Input and output ground

reference.

8 Switch 2 Can be used as generic Sw_2

Analog 2 switch input #2 or as Analog2_Input

generic analog input #2.

Typically used as the

motor temperature

analog input.

9 Switch 3 Generic switch input #3. Sw_3

Typically used as the

interlock switch.

10 Switch 4 Generic switch input #4. Sw_4

11 Switch 5 Generic switch input #5. Sw_5

Curtis 1234/36/38 Manual, OS 11

* The related VCL columns are vital when writing VCL code (see Section 7).

VCL “functions” are used to access the various I/Os; VCL “references” are

predefined names for specific pins.

9

2 — INSTALLATION & WIRING: Low Current Connections

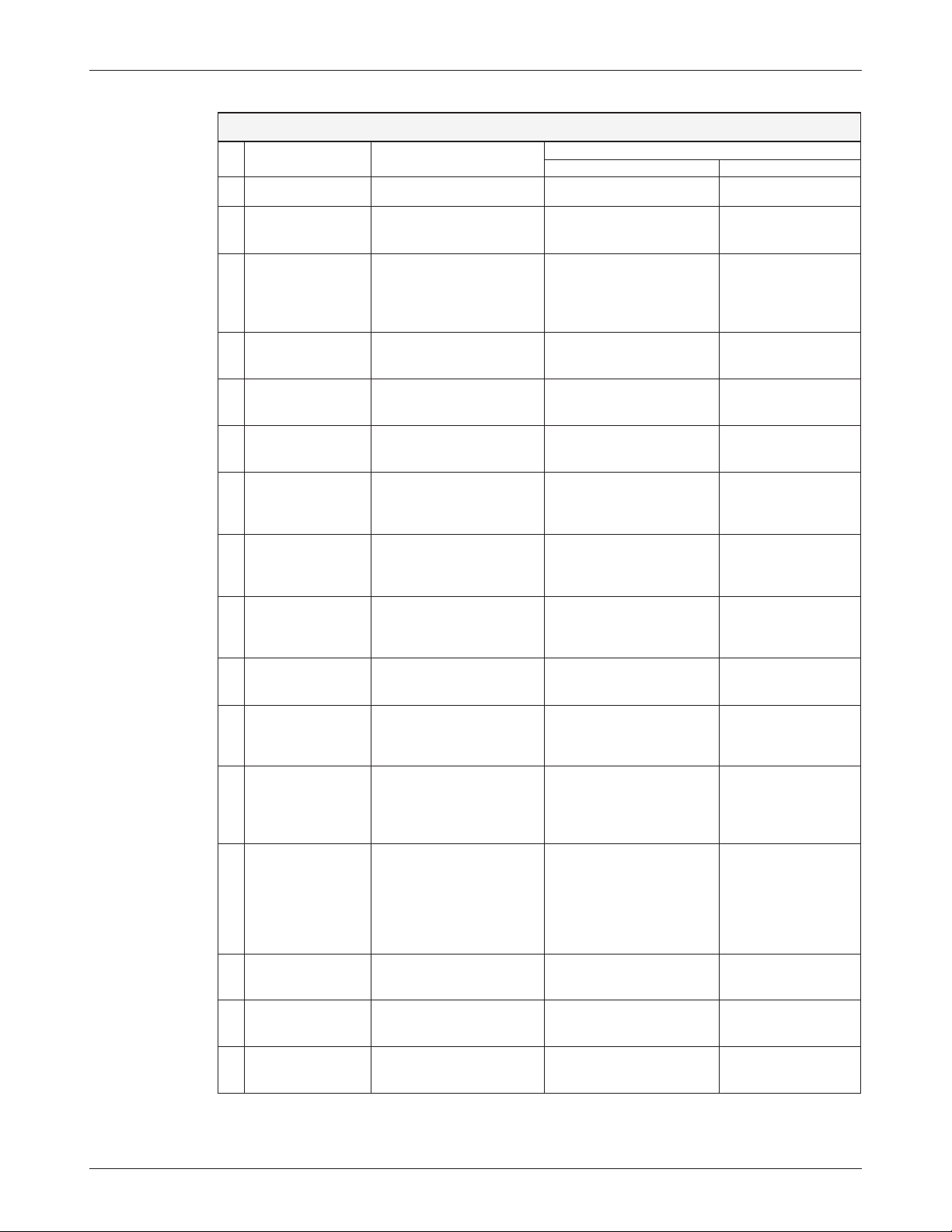

Table 2 Low Current Connections, cont’d

RELATED VCL

PIN NAME DESCRIPTION

12 Switch 6 Generic switch input #6. Sw_6

13 Coil Return This is the coil return pin

for all the contactor coils.

14 Switch 16 / DNC In the 1234, this is Sw_16

generic switch input #16.

In the 1236 and 1238,

Do Not Connect.

15 Throttle Pot High Pot high connection for

a 3-wire throttle pot.

16 Throttle Pot Wiper Pot wiper connection for Setup_Pot Throttle_Pot

the throttle pot. Setup_Pot_Faults Throttle_Pot_Output

17 Pot2 Wiper Pot wiper connection for Setup_Pot Brake_Pot

the brake pot. Setup_Pot_Faults Brake_Pot_Output

18 Pot Low Common pot low Pot_Low_Output

connection for the throttle

and brake pots.

FUNCTIONS REFERENCES

Yes, this

remains

Brake_Pot

in VCL.

19 Digital Out 6 An open collector digital Set_DigOut Sw_14

output. Can also be used Clear_DigOut DigOut6

as a digital input. Dig6_Output

20 Digital Out 7 An open collector digital Set_DigOut Sw_15

output. Can also be used Clear_DigOut DigOut7

as a digital input. Dig7_Output

21 CAN Term H High connection for the

CAN termination jumper.

22 Switch 7 Generic switch input #7. Sw_7

Typically used as the

Forward switch.

23 CANH CAN bus high. Setup_CAN

Setup_Mailbox

Send_Mailbox

etc.

24 Switch 1 Can be used as generic Sw_1

Analog 1 switch input #1 or as Analog1_Input

generic analog input #1.

Typically used for

emergency reverse switch

(if applicable).

25 +12V Out Unregulated low power Ext_Supply_Current

+12V output.

10

26 +5V Out Regulated low power 5_Volts_Output

+5V output. Ext_Supply_Current

27 Pot2 High Pot high connection for

a 3-wire brake pot.

Curtis 1234/36/38 Manual, OS 11

2 — INSTALLATION & WIRING: Low Current Connections

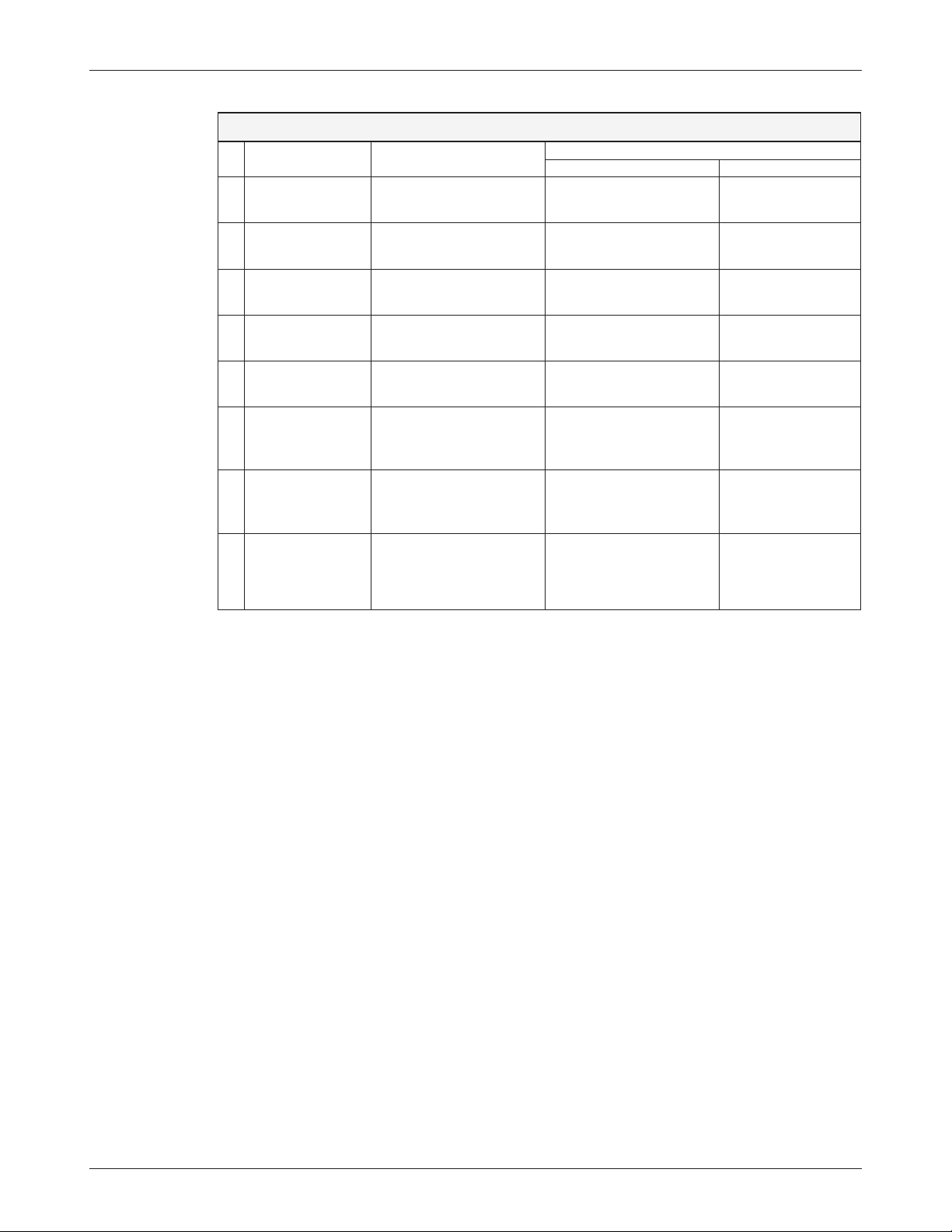

Table 2 Low Current Connections, cont’d

RELATED VCL

PIN NAME DESCRIPTION

28 Serial TX Serial transmit line for Setup_Serial

display or flash update.

29 Serial RX Serial receive line for Setup_Serial

flash update.

30 Analog Output Low power, low frequency Automate_PWM PWM6

0–10V analog output. Put_PWM Analog_Output

31 Encoder A Quadrature encoder Motor_RPM

input phase A. MotorspeedA

32 Encoder B Quadrature encoder Motor_RPM

input phase B. MotorspeedB

33 Switch 8 Generic switch input #8. Sw_8

Typically used as the

Reverse switch.

34 CAN Term L Low connection for the

CAN bus termination

jumper.

FUNCTIONS REFERENCES

35 CANL CAN bus low. Setup_CAN

Setup_Mailbox

Send_Mailbox

etc.

Curtis 1234/36/38 Manual, OS 11

11

2 — INSTALLATION & WIRING: Standard Wiring Diagram

CONTROLLER WIRING: BASIC CONFIGURATION

A basic wiring diagram is shown in Figure 3. Throttle and brake are shown in

the diagram as 3-wire potentiometers; other types of throttle and brake inputs

are easily accommodated, and are discussed in the following throttle wiring

section.

The main contactor coil must be wired directly to the controller as shown

in Figure 3 to meet EEC safety requirements. The controller can be programmed

Fig. 3 Basic wiring diagram, Curtis 1234/36/38 motor controller.

12

Curtis 1234/36/38 Manual, OS 11

2 — INSTALLATION & WIRING: Throttle Wiring

to check for welded or missing contactor faults and uses the main contactor

coil driver output to remove power from the controller and motor in the event

of various other faults. If the main contactor coil is not wired to Pin 6 of

the 35-pin connector as shown, the controller will not be able to open the

main contactor in serious fault conditions and the system will therefore

not meet EEC safety requirements.

Note that the basic wiring diagram is designed for generic applications

and may not fully meet the requirements of your system. These controllers have

very flexible I/O and wiring configurations; you may wish to contact your local

Curtis representative to discuss your particular application.

SWITCH INPUT WIRING

The following inputs are dedicated to specific functions when the parameter

settings are as shown:

Switch 1: Emergency Reverse input if the EMR Enable = On

and EMR Type = 0 (see page 59).

Switch 3: Interlock input if Interlock Type = 0 (see page 48).

Switch 5: Lift input (depends on VCL program).

Switch 6: Lower input (depends on VCL program).

Switch 7: Forward input if Throttle Type = 1–3 (see page 42).

Switch 8: Reverse input if Throttle Type = 1–3 (see page 42).

THROTTLE WIRING

In this manual, the term throttle is used in two senses: as another name for the

drive throttle, and as a generic term covering both the drive throttle and the

brake throttle. Wiring is the same, whether the throttle in question is used for

braking or for acceleration.

Various throttles can be used with the 1234/36/38 controller. They

are characterized as one of five types in the programming menu of the 1311

programmer.

Type 1: 2-wire 5kΩ–0 potentiometers

Type 2: single-ended 0–5V throttles, current source throttles,

3-wire potentiometers, and electronic throttles

Curtis 1234/36/38 Manual, OS 11

Type 3: 2-wire 0–5k

Type 4: wigwag 0–5V throttles and 3-wire potentiometers

Type 5: VCL input (VCL_Throttle or VCL_Brake)

Ω potentiometers

The two throttle inputs (drive throttle and brake throttle) are programmed

independently.

13

2 — INSTALLATION & WIRING: Throttle Wiring

For potentiometers, the controller provides complete throttle fault

protection that meets all applicable EEC regulations. For voltage throttles, the

controller protects against out-of-range wiper values, but does not detect wiring

faults; it is therefore the responsibility of the OEM to provide full throttle fault

protection in vehicles using voltage throttles.

Throttle types 1–3 use the forward and reverse inputs (switches 7 and 8) in

addition to the throttle pot input to define the throttle command (see Figure 13).

Throttle types 4 and 5 do not use the forward and reverse inputs.

Wiring for the most common throttles is described in the following text

and shown in the accompanying illustrations. If a throttle you are planning to

use is not covered, contact the Curtis office nearest you.

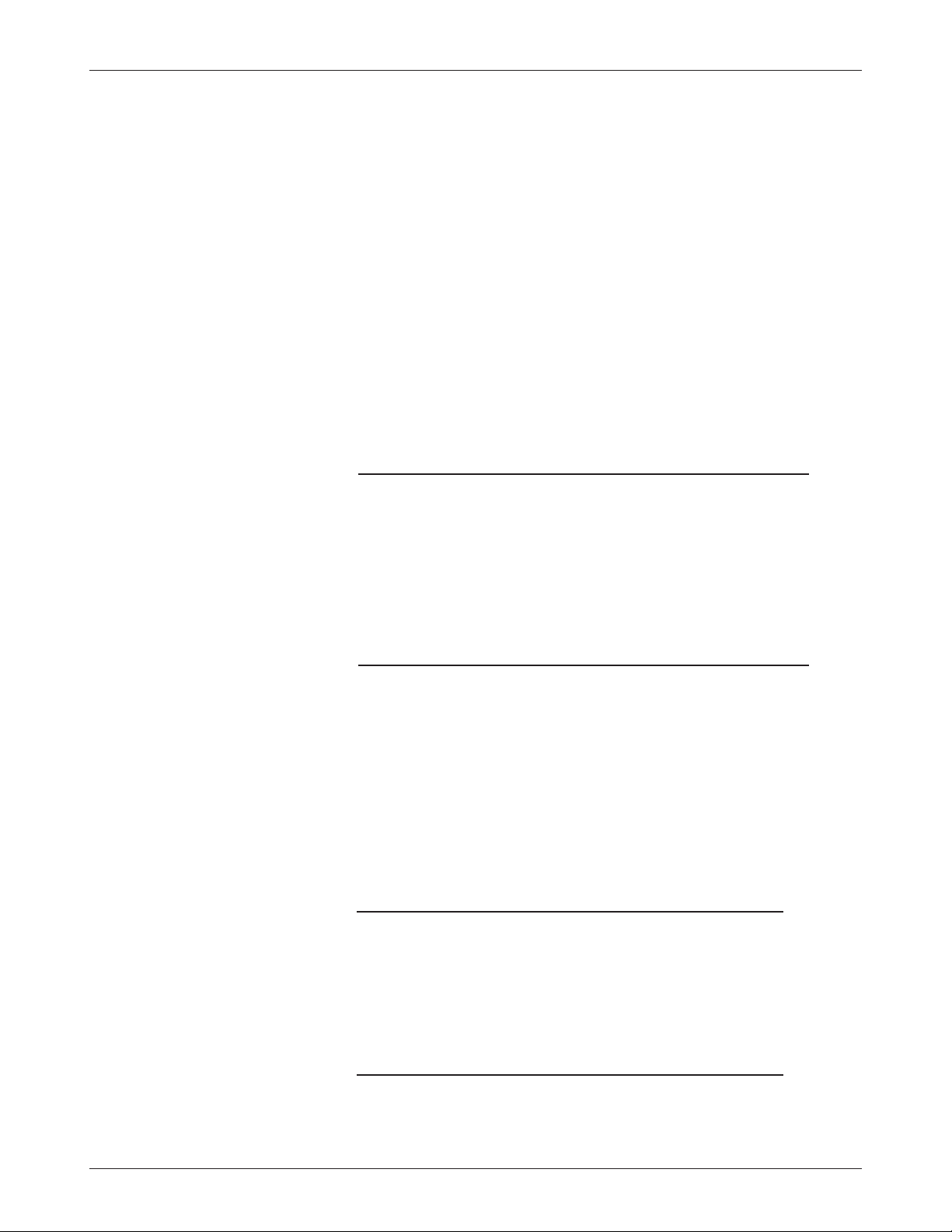

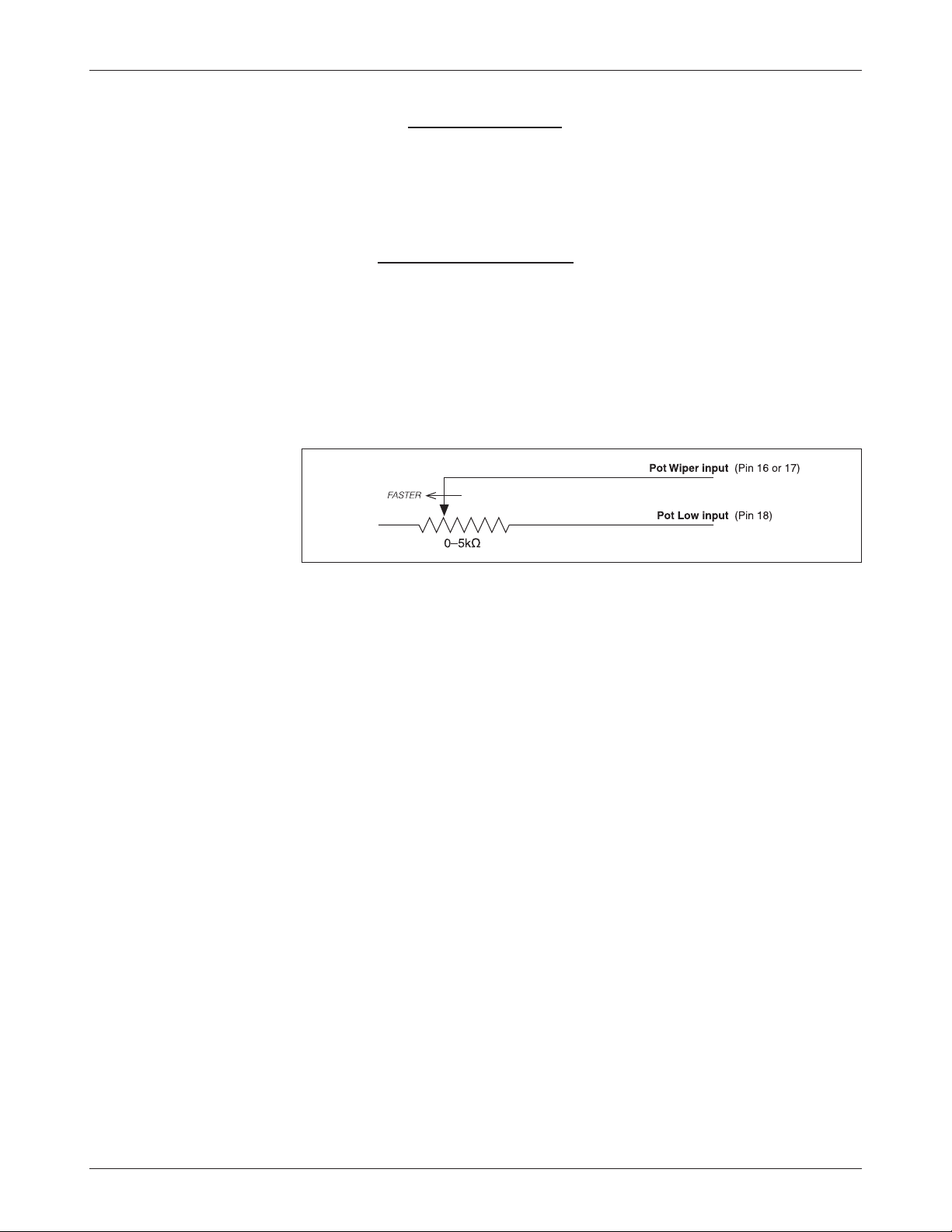

Throttle Type 1

For these 2-wire resistive potentiometers, shown in Figure 4, full throttle request

corresponds to 0

Fig. 4 Wiring for Type 1

throttles.

Ω measured between the pot wiper pin and the Pot Low pin.

Broken wire protection is provided by the controller sensing the current flow

from the pot wiper input (pin 16 or 17) through the potentiometer and into

Pot Low (pin 18). If the Pot Low input current falls below 0.65 mA, a throttle

fault is generated and the throttle request is zeroed. Note: Pot Low (pin 18)

must not be tied to ground (B-).

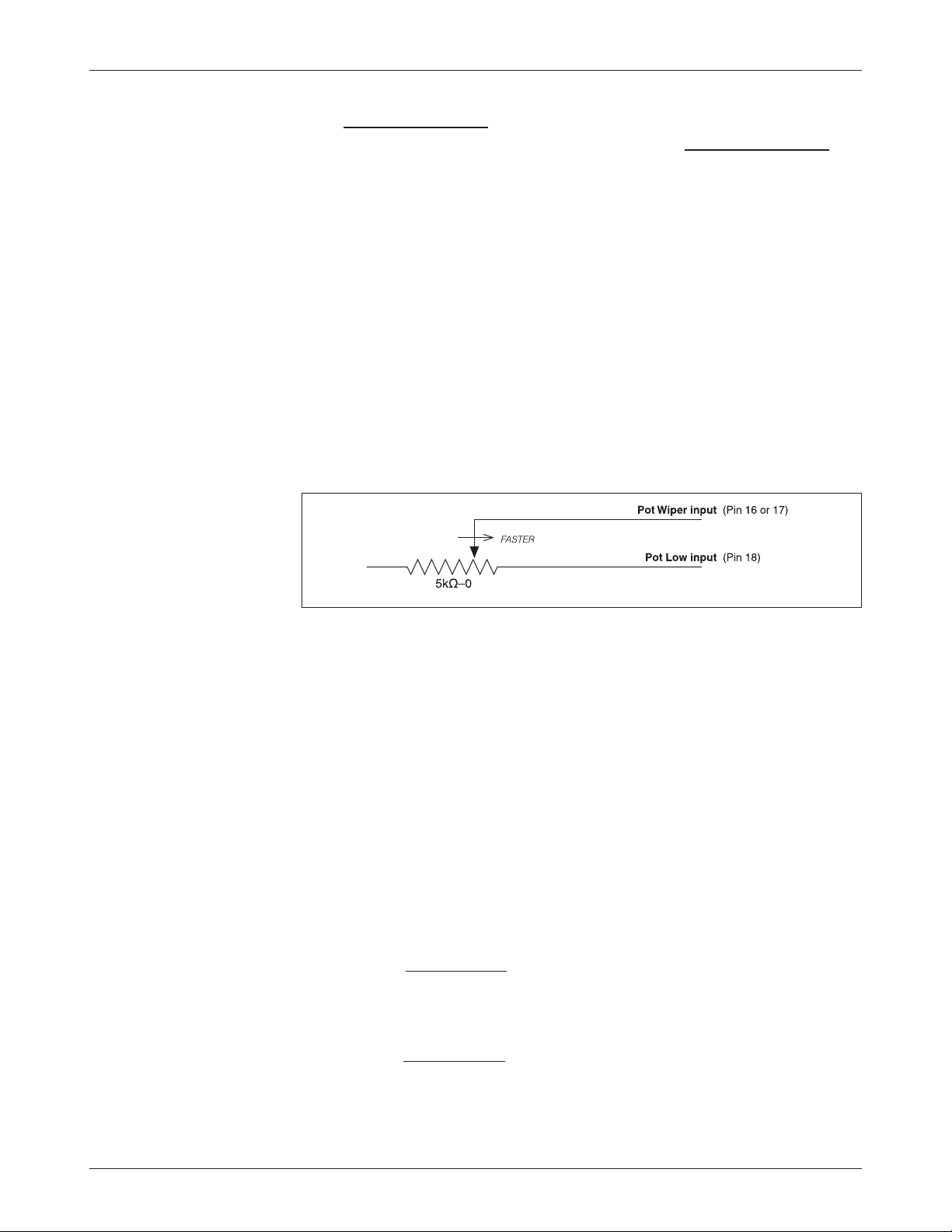

Throttle Type 2

With these throttles, the controller looks for a voltage signal at the wiper input.

Zero throttle request corresponds to 0 V and full throttle request to 5 V. A variety

of devices can be used with this throttle input type, including voltage sources,

current sources, 3-wire pots, and electronic throttles. The wiring for each is

slightly different, as shown in Figure 5, and they have varying levels of throttle

fault protection.

When a voltage source is used as a throttle, it is the responsibility of the

OEM to provide appropriate throttle fault detection. For ground-referenced

0–5V throttles, the controller will detect open breaks in the wiper input but

cannot provide full throttle fault protection.

To use a current source as a throttle, a resistor must be added to the circuit

to convert the current source value to a voltage; the resistor should be sized to

provide a 0–5V signal variation over the full current range. It is the responsibil

ity of the OEM to provide appropriate throttle fault detection.

-

14

Curtis 1234/36/38 Manual, OS 11

2 — INSTALLATION & WIRING: Throttle Wiring

+

+

-

Fig. 5 Wiring for Type 2

throttles.

Voltage Source

Current Source

3-wire Potentiometer

Curtis ET-XXX Electronic Throttle

Curtis 1234/36/38 Manual, OS 11

15

2 — INSTALLATION & WIRING: Throttle Wiring

When a 3-wire potentiometer is used, the controller provides full fault

protection in accordance with EEC requirements. The pot is used in its voltage

divider mode, with the controller providing the voltage source and return. Pot

High provides a current limited 5V source to the pot, and Pot Low provides

the return path. This is the throttle shown in the basic wiring diagram (Figure 3)

for the drive throttle and for the brake throttle.

The ET-XXX electronic throttle is typically used only as a drive throttle.

The ET-XXX contains no built-in fault detection, and the controller will detect

only open wiper faults. It is the responsibility of the OEM to provide any ad

ditional throttle fault detection necessary.

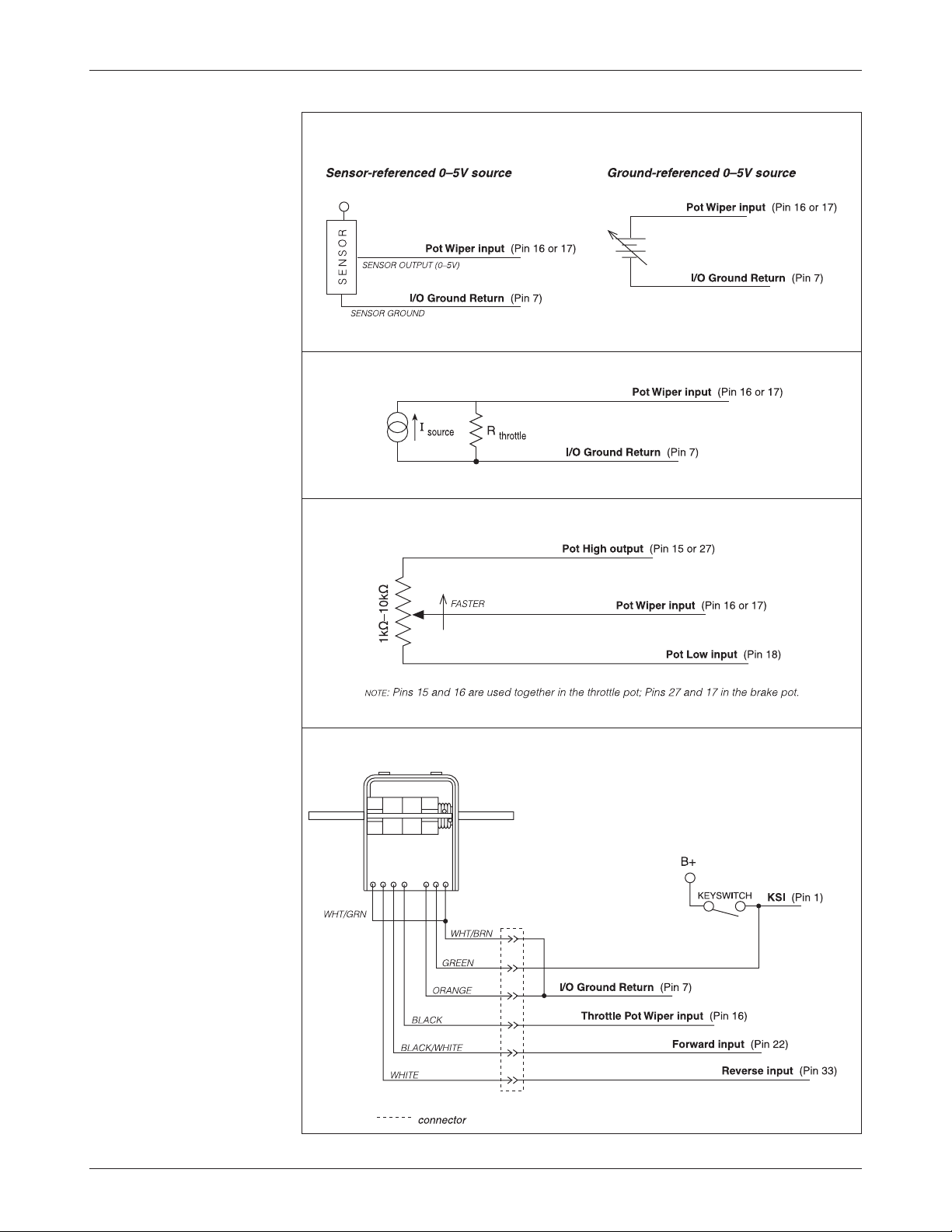

Throttle Type 3

For these 2-wire resistive potentiometers, shown in Figure 6, full throttle request

corresponds to 5 k

Fig. 6 Wiring for Type 3

throttles.

-

Ω measured between the pot wiper pin and the Pot Low pin.

Broken wire protection is provided by the controller sensing the current flow

from the wiper input (pin 16 or 17) through the potentiometer and into Pot

Low (pin 18). If the Pot Low input current falls below 0.65 mA, a throttle

fault is generated and the throttle request is zeroed. Note: Pot Low (pin 18)

must not be tied to ground (B-).

Throttle Type 4

Type 4 throttles operate in wigwag style. No signals to the controller’s forward

and reverse inputs are required; the direction is determined by the wiper input

value. Only 0–5V voltage sources and 3-wire potentiometers can be used as

Type 4 throttles. The controller interface for Type 4 throttles is the same as for

Type 2 throttles; see Figure 5. The neutral point will be with the wiper at 2.5

V, measured between pot wiper input (pin 16) and I/O ground return (pin 7).

The controller will provide increasing forward speed as the wiper input value is

increased, and increasing reverse speed as the wiper input value is decreased.

When a 3-wire pot is used, the controller provides full fault protection.

When a voltage throttle is used, the controller will detect open breaks in the

wiper input but cannot provide full throttle fault protection.

16

Curtis 1234/36/38 Manual, OS 11

2 — INSTALLATION & WIRING: Throttle Wiring

Throttle Type 5

Throttle Type 5 provides a different way of sending the throttle command to

the controller. This throttle type uses VCL to define the throttle signal that

will be “input” into the throttle signal chain (see Figure 14). This throttle

type can be used for either the drive throttle or the brake throttle by using

the VCL variables VCL_Throttle and VCL_Brake. How the VCL program is

written will determine where the throttle signal originates from, making this

a very flexible throttle input method. VCL can be written to use the throttle

pot inputs, switch inputs, or CAN communication messages as the source of

the throttle signals. If you have questions regarding this throttle type, contact

the Curtis office nearest you.

Setting the Throttle Type to Type 5 also allows the throttle and brake

pot inputs to be redefined by a VCL program for uses other than throttle or

brake input. The variable names that VCL can use to interface with these two

inputs are Throttle_Pot_Output (see page 93) and Brake_Pot_Output (see

page 95).

Curtis 1234/36/38 Manual, OS 11

17

2 — INSTALLATION & WIRING: I/O Signal Specifications

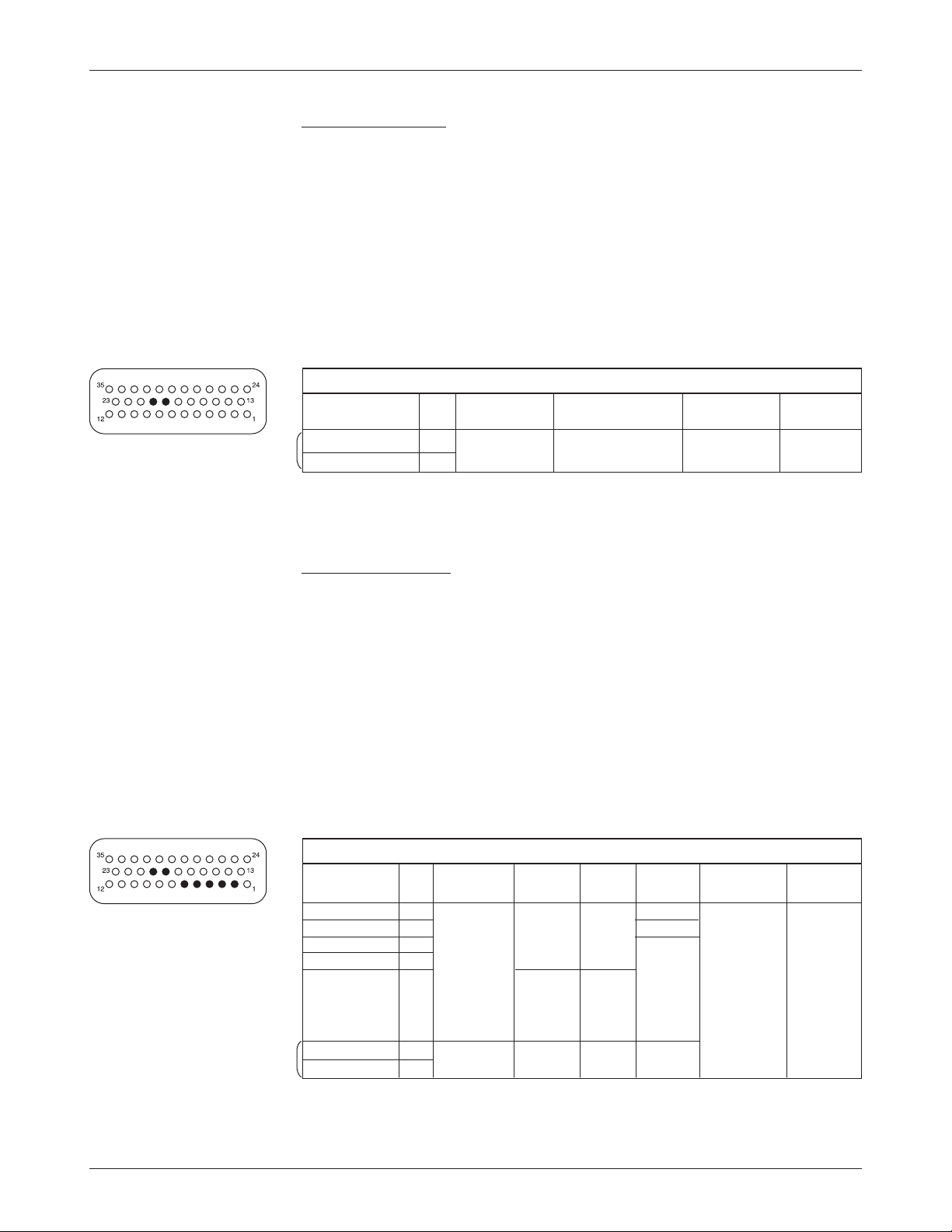

INPUT/OUTPUT SIGNAL SPECIFICATIONS

The input/output signals wired to the 35-pin connector can be grouped by

type as follows; their electrical characteristics are discussed below.

Digital inputs

These control lines can be used as digital (on/off) inputs. Normal “on” connection

is direct to B+; “off” is direct to B-. Input will pull low (off) if no connection

is made. All digital inputs are protected against shorts to B+ or B-.

Nine of these lines (Switches 1–8, 16) are designed to pull current to keep

switch contacts clean and prevent leakage paths from causing false signals.

The remaining lines are digital inputs associated with driver outputs; note

that they have much higher input impedances. The two digital output lines can

also be read as inputs, and are therefore included in this group.

The lines at pins 24 and 8 can also be used as analog inputs, and are

included in that group as well.

— digital inputs

— low power outputs

— high power outputs

— analog inputs

— analog output

— power supply outputs

— KSI and coil return inputs

— throttle and brake inputs

— communications port inputs/outputs

— encoder inputs.

1234 only (DNC in 1236/38) →

1236/38 →

1234 →

DIGITAL INPUT SPECIFICATIONS

LOGIC

SIGNAL NAME PIN THRESHOLDS

Switch 1 24 Rising edge= 24-36V models: -10 V to ± 8 kV (air

Switch 2 8 4.4 V max

Switch 3 9 Falling edge= 36-48V models:

Switch 4 10 1.5 V min about 11.0 k

Switch 5 11 48-80V models:

Switch 6 12 about 26.0 k

Switch 7 22

Switch 8 33

Switch 16 14

Digital Out 6 19 Rising edge= Below 5.5 V= - 5 V to

Digital Out 7 20 29.5 V max 134 k

Falling edge= Above 5.5 V=

10.1 V min 124 k

Digital Out 6 19 Rising edge= Below 10 V= - 0.5 V to

Digital Out 7 20 4.4 V max 300 k

Driver 1 6 Falling edge= Above 10 V=

Driver 2 5 1.5 V min 150 k

Driver 3 4

Driver 4 3

Prop Driver 2

“MaxV” in this and the following tables is the controller’s maximum voltage: 30 V for 24V models;

*

45 V for 24–36V models; 60 V for 36–48V models; and 105 V for 48–80V models.

INPUT VOLTAGE ESD

IMPEDANCE RANGE

about 7.1 kΩ (MaxV + 10 V) discharge)

Ω

Ω

Ω (MaxV + 10 V)

Ω

Ω (MaxV + 10 V)

Ω

*

TOLERANCE

18

Curtis 1234/36/38 Manual, OS 11

1236/38 * →

2 — INSTALLATION & WIRING: I/O Signal Specifications

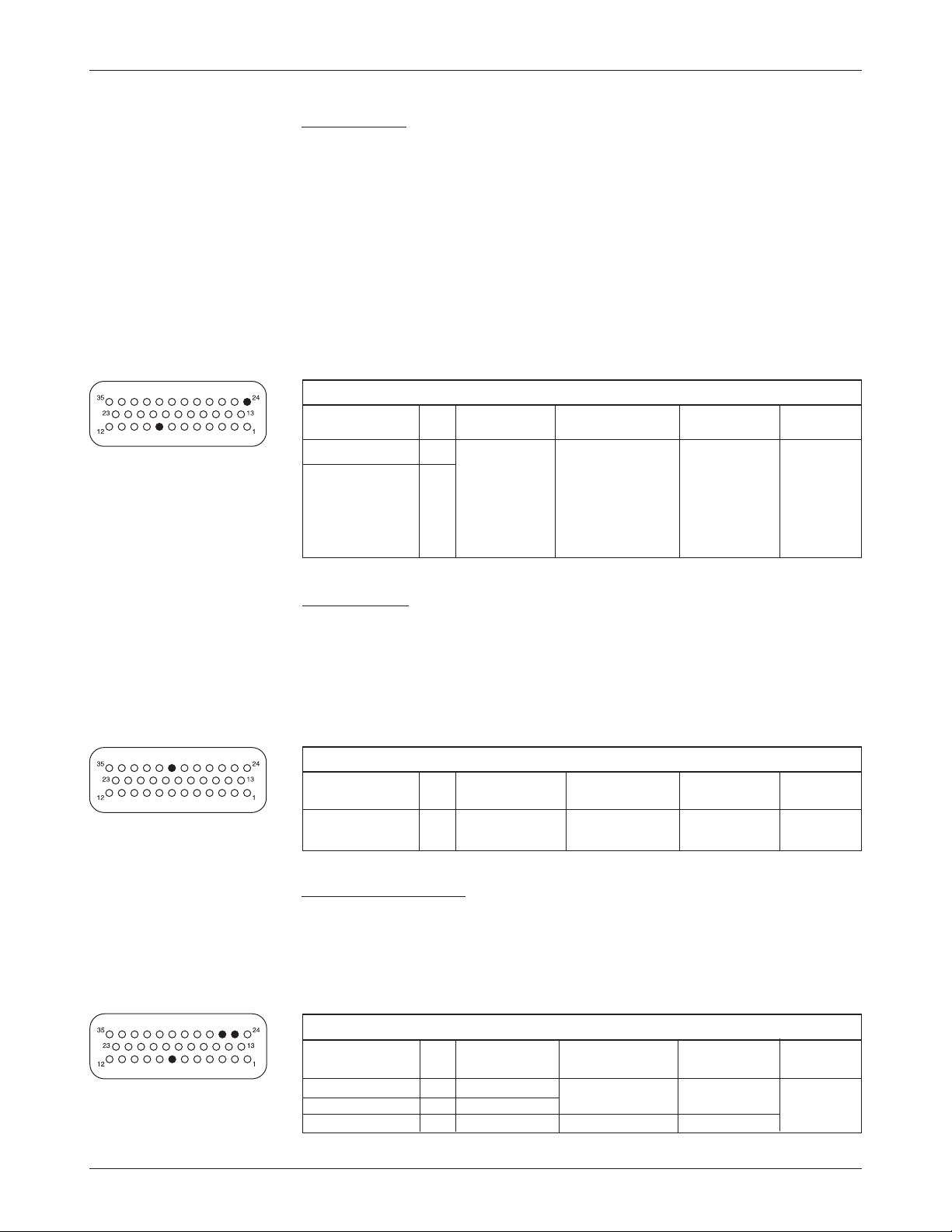

Low power outputs

Two control lines on the 1236/38 are available as low power digital outputs.

These are open collector drivers that can only sink current, not source it, and

are intended to drive LEDs or other low current loads connected to the +5V

or +12V external power supplies; see power supply output group specs. Fault

protection will turn off these outputs if output voltage exceeds about 15 V

when the output is On (low output). Both outputs are protected against shorts

to B+ or B-.

These lines can also be used as digital inputs, and are included in that

group as well.

LOW POWER OUTPUT SPECIFICATIONS

ALLOWED

SIGNAL NAME PIN VOLTAGE

Digital Out 6 19 0 to 15 V On: 1 kΩ to B- - 5 V to ± 8 kV (air

Digital Out 7 20 Off: 134 k

* The digital outputs for the 1234 are below, with the high power outputs.

OUTPUT PROTECTED ESD

IMPEDANCE VOLTAGE TOLERANCE

Ω (MaxV + 10 V) discharge)

1234 * →

High power outputs

Seven control lines on the 1234 and five on the 1236/38 can be used as high

power output drivers. One of these, the proportional driver, can be operated in

a current control mode for driving a proportional valve or similar load. Each

output can be independently turned on continuously (low level) or pulse width

modulated to set the average output voltage. These outputs are intended to

drive inductive loads such as contactors and electromagnetic brakes but could

also be used to drive resistive loads if peak current ratings are not exceeded. All

these outputs are protected against shorts to B+ or B-.

These lines can also be used as digital inputs, and are included in that

group as well.

HIGH POWER OUTPUT SPECIFICATIONS

SIGNAL NAME PIN PWM

Driver 1 6 0 to 100% n/a 200 Hz 2 A max - 0.5 V to ± 8 kV (air

Driver 2 5 duty cycle 3 A max keyswitch discharge)

Driver 3 4 2 A max voltage

Driver 4 3

Prop Driver 2 0 to 2 A 18 kHz

in 607

nominal

steps

Digital Out 6 19 on/off n/a n/a 1 A max

Digital Out 7 20

PV FREQ- OUTPUT PROTECTED ESD

CURRENT UENCY CURRENT VOLTAGE TOLERANCE

Curtis 1234/36/38 Manual, OS 11

* On the 1234, the combined current supplied

by all seven output drivers should not exceed 10 A.

19

2 — INSTALLATION & WIRING: I/O Signal Specifications

Analog inputs

Two control lines can be used as analog inputs. Both inputs are protected

against shorts to B+ or B-.

Typically Analog 2 is used as the input for the motor temperature sensor.

This input provides a constant current appropriate for a thermistor sensor. Some

standard predefined motor temperature sensors are supported in software (see

Sensor Type parameter, page 50). Note: The industry standard KTY tempera

ture sensors are silicon temperature sensors with a polarity band; the polarity

band of a KTY sensor must be the end connected to I/O Ground (pin 7).

These lines can also be used as digital inputs, and are included in that

group as well.

OPERATING

SIGNAL NAME PIN VOLTAGE

Analog 1 24 0 to 10 V in 24-36V models: - 10 V to ± 8 kV (air

Analog 2 8 1024 steps

36-48V models:

48-80V models:

ANALOG INPUT SPECIFICATIONS

INPUT PROTECTED ESD

IMPEDANCE VOLTAGE TOLERANCE

about 7.1 kΩ (MaxV + 10 V) discharge)

about 11.0 kΩ

about 26.0 kΩ

-

Analog output

A single line is available as a low power analog output and is intended to drive

instrumentation such as a battery discharge indicator. This output is generated

from a filtered PWM signal and has about 1% ripple. The 2% settling time

is <25ms for a 0–5V step and <30 ms for a 0–10V step. This output line is

protected against shorts to B+ or B-.

ANALOG OUTPUT SPECIFICATIONS

OUTPUT

SIGNAL NAME PIN VOLTAGE

Analog Out 30 0 to 10 V Source: 100 Ω - 1 V to ± 8 kV (air

Sink: 66 k

OUTPUT PROTECTED ESD

IMPEDANCE VOLTAGE TOLERANCE

Ω (MaxV + 10 V) discharge)

Power supply outputs

Two lines provide auxiliary output power for low power circuits such as electronic throttles, LED indicators, displays, position encoder, and remote I/O

boards. I/O Ground (at pin 7) is the return line for these low power devices.

Both power supply outputs are protected against shorts to B+ or B-.

POWER SUPPLY OUTPUT SPECIFICATIONS

OUTPUT

SIGNAL NAME PIN VOLTAGE

+12V Out 25 11.5 to 14.5 V 200 mA max - 1 V to ± 8 kV (air

+5V Out 26 5 V ±5% (combined total) (MaxV + 10 V) discharge)

I/O Ground 7 n/a 500 mA max not protected

OUTPUT PROTECTED ESD

CURRENT VOLTAGE TOLERANCE

20

Curtis 1234/36/38 Manual, OS 11

2 — INSTALLATION & WIRING: I/O Signal Specifications

KSI and coil return

KSI input provides power for all low power control circuits, power capacitor

precharge (before main contactor turn on), power supply outputs, and high

power output drivers. Battery voltage is sensed on the input for the VCL bat

tery discharge function.

Coil Return should be wired to the positive battery side of the contactors

being driven so that switching noise associated with PWM operation of the

contactors is localized to the contactor wiring only.

It is important to maintain the division between KSI and coil return

in order to ensure reverse polarity protection (vehicle wiring correct, battery

terminals reversed).

KSI AND COIL RETURN INPUT SPECIFICATIONS

OPERATING

SIGNAL NAME PIN VOLTAGE

KSI 1 Between under- 1.0 A max * ± (MaxV + 10 V) ± 8 kV (air

and overvoltage discharge)

Coil Return 13

(MaxV + 10 V)

cutbacks

INPUT PROTECTED ESD

CURRENT VOLTAGE TOLERANCE

12 A max

(KSI - 0.3 V) to

**

* Additionally must carry the current supplied to the driver loads by the coil return (pin 13).

** On the 1234, the combined current supplied by all seven output drivers should not exceed 10 A.

-

Throttle and brake inputs

The two pot inputs are independently programmable to allow use of a voltage

throttle or a 2-wire or 3-wire resistance throttle. Voltage throttles require only

the Pot Wiper input (with I/O Ground for the return line). Resistance throttles

require Pot Wiper and Pot Low (2-wire) or Pot High, Pot Wiper, and Pot Low

(3-wire). All throttle I/O is protected against shorts to B+ or B-.

Alternatively, these two inputs can be used for analog signals other than

the throttle and brake pot inputs. Configuring the inputs for use with other

signals requires VCL programming; see Section 7.

THROTTLE INPUT SPECIFICATIONS

OPERATING

SIGNAL NAME PIN VOLTAGE

Throttle Pot High 15 0 V (shorted n/a 7 mA - 50 V to ± 8 kV (air

Pot2 High 27 to Pot Low) nominal (MaxV + 10 V) discharge)

5 V (open (source)

circuit)

Throttle Pot Wiper 16 0 to 6.25 V 290 kΩ 0.76 mA

Pot2 Wiper 17 (voltage nominal

and 3-wire) (source,

2-wire)

Pot Low 18 0 to 10 V 20 Ω nom. Faults if -1 V to

above (MaxV + 10 V)

11 mA

(sink)

INPUT S/SINK PROTECTED ESD

IMPEDANCE CURRENT VOLTAGE TOLERANCE

Curtis 1234/36/38 Manual, OS 11

21

2 — INSTALLATION & WIRING: I/O Signal Specifications

Communications ports

Separate CAN and serial ports provide complete communications and programming capability for all user available controller information.

The Curtis 1311 handheld programmer plugs into a connector wired to

pins 28 and 29, along with ground (pin 7) and the +12V power supply (pin

25); see wiring diagram, Figure 3. The Curtis Model 840 display can plug into

the same 4-pin connector.

Wiring the CAN Term H and CAN Term L pins together provides a local

CAN termination of 120

Term H and CAN Term L should never be connected to any external wiring.

SUPPORTED

SIGNAL NAME PIN PROTOCOL/DEVICES

CANH 23 CANopen, up to 500 kbps Continuous= ± 8 kV (air

CANL 35 NODES 2.0, - 36 V to discharge)

other 11-bit (MaxV + 10 V)

identifier field Transient=

CAN protocols ± 200 V

CAN Term H 21

CAN Term L 34

Serial TX 28

Serial RX 29 1311 Handheld 9.6 to 56 kbps discharge)

1314 PC Program-

ming Station

Ω, 0.5 W; keep the length of these wires short. CAN

COMMUNICATIONS PORT SPECIFICATIONS

DATA RATE VOLTAGE TOLERANCE

Curtis 840 Display, as required, -0.3 to 12 V ± 8 kV (air

Programmer,

PROTECTED ESD

(no connection ± 8 kV (air

to external wiring)

discharge)

Encoder inputs

Two control lines are internally configured to read a quadrature type position

encoder. The encoder is typically powered from the 5V supply (pin 26) or 12V

supply (pin 25), but can be powered from any external supply (from 5 V up

to B+) as long as the logic threshold requirements are met.

ENCODER INPUT SPECIFICATIONS

LOGIC

SIGNAL NAME PIN THRESHOLDS

Encoder A 31 Rising edge= 720 Ω 10 kHz - 5 V to ± 8 kV (air

Encoder B 32 2.8 V max (internal (MaxV + 10 V) discharge)

Falling edge= pull-up

2.2 V min to +4V)

INPUT MAX PROTECTED ESD

IMPEDANCE FREQ. VOLTAGE TOLERANCE

22

Curtis 1234/36/38 Manual, OS 11

3

3 — PROGRAMMABLE PARAMETERS

PROGRAMMABLE PARAMETERS

These controllers have a number of parameters that can be programmed using

a Curtis 1311 handheld programmer or 1314 Programming Station. The pro

grammable parameters allow the vehicle’s performance to be customized to fit the

needs of specific applications. For programmer operation, see Appendix C.

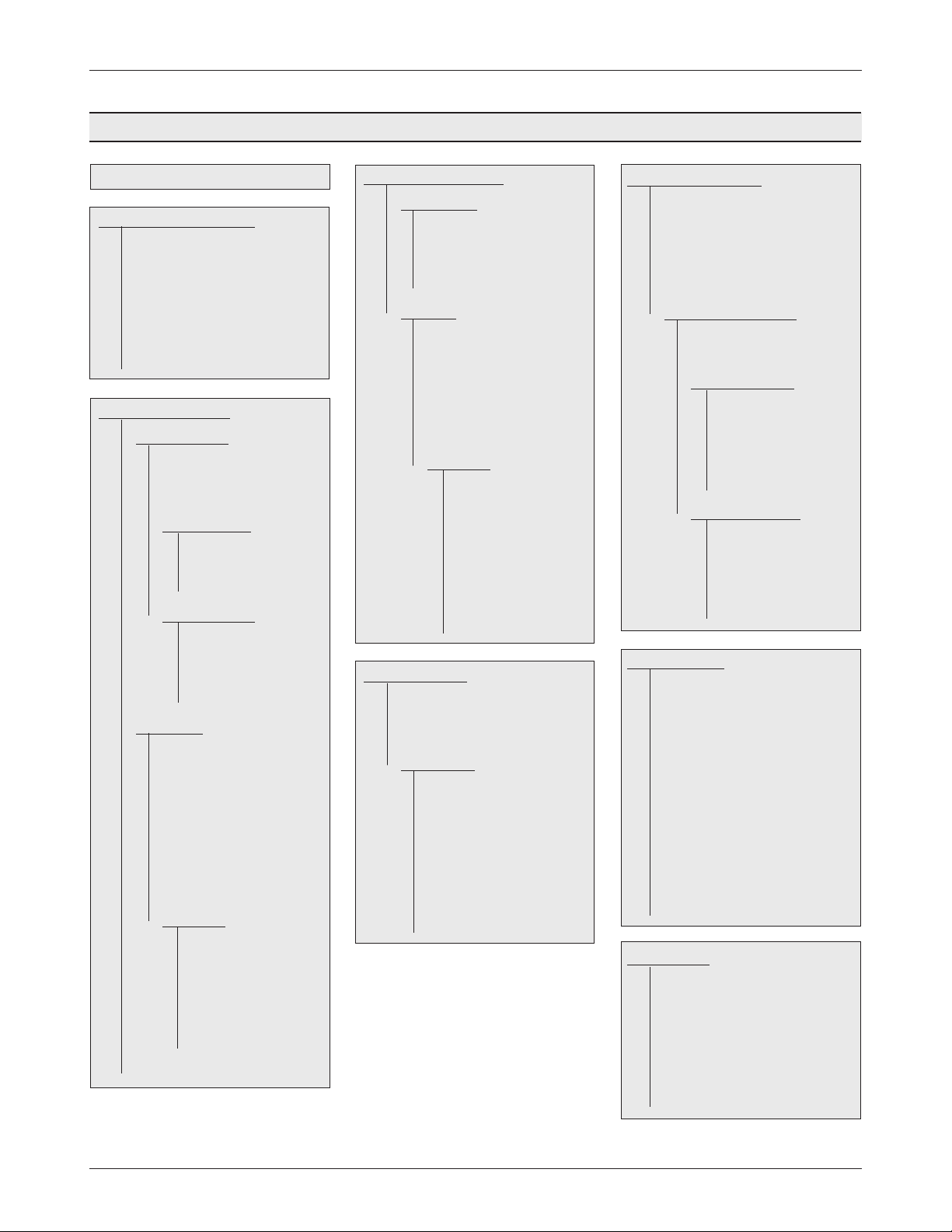

PROGRAMMING MENUS

The programmable parameters are grouped into nested hierarchical menus, as

shown in Table 3.

Motor response tuning

Motor response characteristics can be tuned through speed control or through

torque control, depending on the application. Use the Control Mode Select

parameter (page 27) to select which tuning mode you will use:

• Speed Mode Express

-

C AU T I O N

☞

• Speed Mode

• Torque Mode.

Speed Mode Express is a simplified version of Speed Mode with a reduced set

of parameters that is adequate for most speed-controlled applications.

Use Speed Mode or Speed Mode Express for applications where throttle

input corresponds to motor speed output.

Use Torque Mode for applications where throttle input corresponds to

motor torque output.

Note: You can tune using torque control or speed control, but not both.

For example, if you adjust a torque control parameter while Speed Mode or

Speed Mode Express has been selected as your tuning mode, the programmer

will show the new setting but it will have no effect.

We strongly urge you to read Section 5, Initial Setup, before adjusting any of

the parameters.

Even if you opt to leave most of the parameters at their default settings,

is imperative that you perform the procedures outlined in Section 5, which

set up the basic system characteristics for your application

.

it

Curtis 1234/36/38 Manual, OS 11

23

3 — PROGRAMMABLE PARAMETERS

Table 3 Programmable Parameter Menus: 1311 Programmer

CONTROL MODE SELECT ........... p. 27

0 - SPEED MODE EXPRESS

—Max Speed

—Kp

—Ki

—Accel Rate

—Decel Rate

—Brake Rate

—Pump Enable

1 - SPEED MODE MENU

—Speed Controller

—Max Speed

—Kp

—Ki

—Vel Feedforward

....... p. 28

............... p. 29

......... p. 29

—Kvff

—Build Rate

—Release Rate

—Acc Feedforward ........ p. 30

—Kaff

—Kbff

—Build Rate

—Release Rate

—Response ..................... p. 31

—Full Accel Rate HS

—Full Accel Rate LS

—Low Accel Rate

—Neutral Decel Rate HS

—Neutral Decel Rate LS

—Full Brake Rate HS

—Full Brake Rate LS

—Low Brake Rate

—Fine Tuning

—Partial Decel Rate

—HS (High Speed)

—LS (Low Speed)

—Reversal Soften

—Max Speed Accel

—Max Speed Decel

—Pump Enable ................. p. 33

............... p. 32

2 - TORQUE MODE MENU

—Speed Limiter ................... p. 34

—Max Speed

—Kp

—Ki

—Kd

—Response ....................... p. 35

—Accel Rate

—Accel Release Rate

—Brake Rate

—Brake Release Rate

—Neutral Braking

—Neutral Taper Speed

—Creep Torque

—Brake Full Creep Cancel

—Creep Build Rate

—Creep Release Rate

—Gear Soften

—Brake Taper Speed

—Reversal Soften

—Max Speed Decel

RESTRAINT MENU ..................... p. 38

—Restraint Forward

—Restraint Back

—Soft Stop Speed

—Position Hold

—Position Hold Enable

—Kp

—Kp Deadband (Motor Deg)

—Kd

—Set Speed Settling Time

—Set Speed Threshold

—Entry Rate

—Exit Rollback Reduction

—Fine Tuning ............... p. 36

................... p. 38

CURRENT LIMITS MENU ............. p. 39

—Drive Current Limit

—Regen Current Limit

—Brake Current Limit

—EMR Current Limit

—Interlock Brake Current Limit

—Power Limiting Map

.... p. 40

—PL Nominal Speed

—Delta Speed

—Drive Limiting Map ..... p. 40

—Nominal

—Plus Delta

—Plus 2xDelta

—Plus 4xDelta

—Plus 8xDelta

—Regen Limiting Map

—Nominal

—Plus Delta

—Plus 2xDelta

—Plus 4xDelta

—Plus 8xDelta

THROTTLE MENU

—Throttle Type

—Forward Deadband

—Forward Map

—Forward Max

—Forward Offset

—Reverse Deadband

—Reverse Map

—Reverse Max

—Reverse Offset

—HPD/SRO Type

—Sequencing Delay

—VCL Throttle Enable

BRAKE MENU

—Brake Pedal Enable

—Brake Type

—Brake Deadband

—Brake Map

—Brake Max

—Brake Offset

—VCL Brake Enable

.......................... p. 45

.... p. 44

....................... p. 42

24

Curtis 1234/36/38 Manual, OS 11

3 — PROGRAMMABLE PARAMETERS

Table 3 Programmable Parameter Menus: 1311 Programmer, cont’d

EM BRAKE CONTROL MENU ........ p. 46

—Brake Type

—Pull In Voltage

—Holding Voltage

—Battery Voltage Comp

—Set EM Brake On Fault

—Set Speed Threshold

—Release Delay

—Set Speed Settling Time

—Torque Preload Delay

—Torque Preload Enable

—Torque Preload Cancel Delay

DRIVERS MENU

—Main Contactor

—Main Enable

—Pull In Voltage

—Holding Voltage

—Battery Voltage Comp

—Interlock Type

—Open Delay

—Checks Enable

—Main DNC Threshold

—Precharge Enable

—Proportional Driver

—PD Enable

—Hyd Lower Enable

—PD Max Current

—PD Min Current

—PD Dither %

—PD Dither Period

—PD Kp

—PD Ki

Hydraulic Contactor .......... p. 51

—

—Contactor Enable

—Pull In Voltage

—Holding Voltage

—Fault Checking

—Driver1 Checks Enable

—Driver2 Checks Enable

—Driver3 Checks Enable

—Driver4 Checks Enable

—PD Checks Enable

—External Supply Max

—External Supply Min

................ p. 48

........... p. 50

................. p. 52

MOTOR MENU ............................ p. 53

—Typical Max Speed

—Swap Encoder Direction

—Swap Two Phases

—Encoder Steps

—Temperature Control

.......... p. 54

—Sensor Enable

—Sensor Type

—Sensor Offset

—Temperature Hot

—Temperature Max

—MotorTemp LOS Max Speed

BATTERY MENU

—Nominal Voltage

—Undervoltage Cutback Range

—User Overvoltage

—User Undervoltage

—Reset Volts Per Cell

—Full Volts Per Cell

—Empty Volts Per Cell

—Discharge Time

—BDI Reset Percent

DUAL DRIVE MENU

VEHICLE MENU .......................... p. 58

—Metric Units

—Speed to RPM

—Capture Speed 1

—Capture Speed 2

—Capture Distance 1

—Capture Distance 2

—Capture Distance 3

......................... p. 55

........ see Sec. 4 of

of the Dual Drive

addendum, p/n 37022-DD.

EMERGENCY REVERSE MENU ..... p. 59

—EMR Enable

—EMR Type

—EMR Dir Interlock

—EMR Time Limit

—EMR Speed

—EMR Accel Rate

—EMR Decel Rate

INTERLOCK BRAKING MENU

—Enable

—Decel Rate HS

—Decel Rate LS

—Interlock Brake Timeout

CAN INTERFACE MENU

—CANopen Interlock

—CAN Node ID

—Baud Rate

—Heartbeat Rate

—PDO Timeout Period

—Emergency Message Rate

—Suppress CANopen Init

MOTOR CONTROL TUNING MENU

—Motor Characterization Tests

—Field Weakening Control

—FW Base Speed

—Field Weakening

—Weakening Rate

—Motor Type ..................... p. 62

....... p. 60

............... p. 61

. p. 62

.... p. 62

Curtis 1234/36/38 Manual, OS 11

25

3 — PROGRAMMABLE PARAMETERS

Individual parameters are presented as follows in the menu charts:

Parameter name Allowable range Description of the parameter’s

as it appears in the in the function and, where applicable,

programmer display programmer’s units suggestions for setting it

⇓ ⇓ ⇓

Max Speed 100–8000 rpm Defines the maximum allowed motor rpm at full throttle.

Max_Speed_SpdM 100–8000

⇑ ⇑

Parameter name Allowable range

in VCL in VCL units

Note: All bit variables have two VCL parameter names. The first is the name

of the bit, and the second is the name of the byte containing the bit. The bit

position within the byte is indicated in brackets after the byte name.

Examples:

BIT NAME: Metric_Units

BYTE NAME: OptionBits3 [Bit 5]

BIT NAME: EMR_Dir_Interlock

BYTE NAME: EMR_Dir_Interlock_Bit0 [Bit 0]

In the second example, “_Bit0” is part of the byte name, and does not indicate

the bit position; this byte, like all bytes, has 8 available bits.

Within the menu charts, each pair of bit variable names is shown as a

grouped set, with the bit name appearing first and then the byte name:

Metric Units On/Off

Metric_Units On/Off

OptionBits3 [Bit 5]

26

Curtis 1234/36/38 Manual, OS 11

Loading...

Loading...