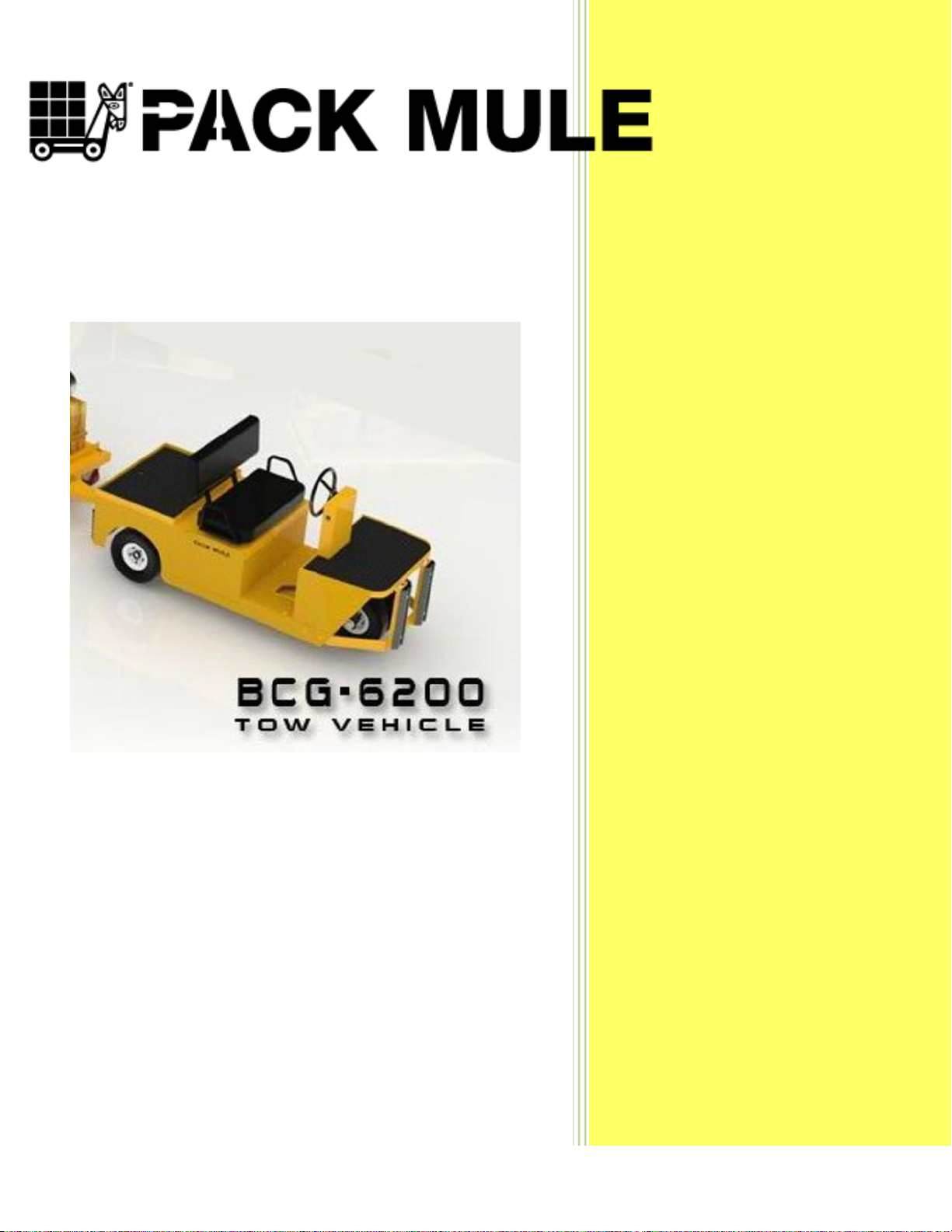

Wesley BC-6200-8SA User Manual

SEPT 2013

OWNER’S MANUAL

AND SERVICE GUIDE

INDUSTRIAL ELECTRIC VEHICLE

Owner”s Manual and Service Guide – BCG Series

BCG-SERIES

FOREWARD

NOTE

CAUTION

WARNING

A NOTE indicates a condition that should be observed.

A CAUTION indicates a condition that may result in damage to the vehicle.

A WARNING indicates a hazardous condition that could result in severe injury or death.

UPON RECEIPT OF VEHICLE/EQUIPMENT:

Please visually inspect the vehicle for any damage that may have occurred during shipping and have it noted on the

carrier’s bill immediately. Be sure to specify the nature of the damage.

This manual is a VERY IMPORTANT tool. Please keep it with the vehicle/equipment at all times. The purpose of this

manual is to provide owner, users, lessors and/or lessees with the operating instructions and precautions for the safe

and proper operation of the vehicle or equipment. It is the owner, user, lessor or lessees responsibility to ensure that

the vehicle/equipment is being used in accordance with its designed intended use.

Please read this ENTIRE manual to familiarize yourself with the safe operation of this vehicle/equipment. Pay

particular attention to anything labeled CAUTION, NOTE, OR WARNING!

Due to continuous product improvements, changes or updates may be made to this Manual, making it subject to

change without notice. For the most up to date version of the manual, please go to our website:

http://www.packmule.com/support/product-manuals/ OR call Wesley International at: 1-800-241-2869.

The Pack Mule Division of Wesley International, reserves the right to incorporate engineering and design changes to

products in this manual without any obligation to include these changes on any units/vehicles already purchased or

leased.

The Pack Mule Division and/or Wesley International accepts no liability in connection with any errors or omissions in

this Manual, and SPECIFICALLY DISCLAIMS any liability for any incidental and consequential damages arising from

the use of the information in this Manual.

The use of non OEM (Original Equipment Manufacturer) parts may void the warranty.

Overfilling the batteries may void your warranty.

The BCG tow vehicle is a Class VI Industrial Truck. Only operators trained per OSHA requirements shall operate this

vehicle.

NOTES, CAUTIONS AND WARNINGS

Throughout this guide NOTE, CAUTION, and WARNING will be used. Please observe these notes, cautions and warnings.

Owner’s Manual and Service Guide – BCG Series 2

TABLE OF CONTENTS

INTRODUCTION ................................................................................................................................................................................ 5

SAFETY INFORMATION .................................................................................................................................................................... 6

Training ........................................................................................................................................................................................... 6

Operator Qualifications ................................................................................................................................................................... 6

Safety Guidelines ............................................................................................................................................................................ 6

Loading and Unloading ................................................................................................................................................................... 7

Towing ............................................................................................................................................................................................ 7

Maintenance ................................................................................................................................................................................... 7

Ventilation ................................................................ ................................ ....................................................................................... 7

INDUSTRY STANDARDS ................................................................................................................................................................. 8

OPERATING INSTRUCTIONS .............................................................................................................................................................. 12

Initial Checklist .............................................................................................................................................................................. 12

Identification.................................................................................................................................................................................. 12

Charging ....................................................................................................................................................................................... 12

Vehicle Controls, Meters, Switches .............................................................................................................................................. 12

Driving .......................................................................................................................................................................................... 17

Towing………………………………………………………………………………………………………………………………………....17

Coasting ....................................................................................................................................................................................... 17

Loading/Unloading ........................................................................................................................................................................ 17

Parking ......................................................................................................................................................................................... 17

Startup Checklist for Industrial Trucks………………………………………………………………………………………………………18

MAINTENANCE INSTRUCTIONS ......................................................................................................................................................... 19

Maintenance Schedule ................................................................................................................................................................. 19

Routine Maintenance .................................................................................................................................................................... 20

Batteries ....................................................................................................................................................................................... 20

Battery Safety………………………………………………………………………………………………………………………………….20

Battery Care.................................................................................................................................................................................. 20

Electrolyte Levels .......................................................................................................................................................................... 21

Battery Watering System .............................................................................................................................................................. 21

Cleaning Batteries ........................................................................................................................................................................ 21

Battery Replacement .................................................................................................................................................................... 21

Lifting the Vehicle ......................................................................................................................................................................... 22

Lubrication .................................................................................................................................................................................... 22

Brakes .......................................................................................................................................................................................... 23

Tires and Wheels .......................................................................................................................................................................... 23

COMPONENTS - ELECTRICAL ............................................................................................................................................................. 24

Basic Electrical Components ........................................................................................................................................................ 25

Special Order Onboard Battery Charger ....................................................................................................................................... 26

Motor ............................................................................................................................................................................................ 28

Controller ...................................................................................................................................................................................... 28

3 Owner’s Manual and Service Guide – BCG Series

Battery Discharge Indicator (BDI) ................................................................................................................................................. 43

Speed Control Pedal ..................................................................................................................................................................... 43

Solenoid ........................................................................................................................................................................................ 43

Parts List – Electrical .................................................................................................................................................................... 44

Parts List – Available Options ..................................................................................................................................................... 455

COMPONENTS - MECHANICAL .......................................................................................................................................................... 46

Parts List – Front Wheel Steer Assembly ..................................................................................................................................... 46

Hitch Options…………………………………………………………………………………………………………………………………..47

Owner’s Manual and Service Guide – BCG Series 4

INTRODUCTION

Thank you for choosing a Pack Mule Industrial Electric Vehicle, proudly built by Wesley International in the USA. At Wesley

International, we are committed to providing you the best quality product backed by exceptional customer service. This owner’s

manual and service guide is provided to help you get the most out of your new vehicle, for many years to come.

RECORD YOUR PRODUCT INFOR MATION

Model #: Serial #:

Purchase Date:

REGISTER YOUR PRODUCT

PRODUCT REGISTRATION IS REQUIRED FOR WARRANTY COVERAGE.

Registration is easy. Simply go to http://www.packmule.com/support/warranty/ and complete the online form and click submit.

That’s it! And it will entitle you to free parts for any defective items, as outlined in our warranty document.

IF YOU NEED HELP

You will find many answers to common problems within this manual or online at www.packmule.com. If you do not find

what you need, we are always ready and willing to help. Just email us at info@wesleyintl.com or call

(800) 241-2869 or (404) 292-7441.

Wesley International

3680 Chestnut Street

Scottdale, GA 30079

Phone (404) 292-7441 • Toll Free (800) 241-2869 • Fax (404) 292-8469

info@wesleyintl.com

www.wesleyinternational.com

5 Owner’s Manual and Service Guide – BCG Series

SAFETY INFORMATION

The responsibility of safety lies with four main groups: manufacturers, owners/lessees, operators and maintenance personnel.

This manual has been designed to assist the owner-operator in operating and maintaining the vehicle in a safe manner, in

accordance with the procedures and standards to which the vehicle was designed and intended for use.

TRAINING

Vehicle owners/lessees are responsible for instructing their personnel in its safe operation. Owner/lessees must explain the

vehicle’s characteristics, features, operation of its controls, and safe driving practices. We strongly recommend that

owners/lessees first become familiar with the conditions of the place where the vehicle will be operated in order to assess its effect

on safe operation. Training should occur under the conditions of the operating environment while adhering to the safety guidelines

and include:

Safety guidelines

Operation of the vehicle under the conditions in which it will be operated

Operation of all controls

Safe driving practices

A driving and operating test

OPER ATOR QUALIFICATIONS

Operators should be selected based on their ability to safely operate the vehicle, including vision, hearing, physical and mental

capabilities. Operators must:

Demonstrate a working knowledge of all controls

Understand all safety guidelines

Be evaluated by a designated trainer who certifies the operator’s ability to properly drive and park the vehicle under the

conditions in which the vehicle will be used

Know how to properly load and unload cargo and passengers

Recognize maintenance problems

SAFETY GUIDELINES

All Pack Mule vehicles are designed for use on smooth surfaces in and around industrial plants and warehouses. Not intended for

agricultural use. While made of components that are unaffected by the rain, they are not intended for continuous outdoor use,

traversing up and down steep grades, or travelling on public roads/highways as the tires are not configured for these purposes.

Follow these guidelines to safely drive the vehicle:

Read, understand and observe all labels affixed to the vehicle

Do not start the vehicle without checking the brakes first

Do not mount or dismount the vehicle when the key is in the ON position

Do not drive the vehicle if the accelerator requires excessive pressure

Do not park or operate the vehicle near flammable objects or in a flammable or hazardous environment

Use only necessary power

Keep both hands on the steering wheel while operating the vehicle

Accelerate and decelerate slowly and in a controlled manner

Always reduce speed to compensate for poor terrain or conditions

Always maintain adequate distance between vehicles, people, and obstacles

Do not use the vehicle to push objects

Do not allow the tires to lose contact with the ground

Proceed around low overhangs with caution. Be sure there is enough clearance for the operator’s head and the highest

point of the vehicle or any attached accessories.

Never abruptly change direction

Always drive directly up an incline; never across

Never exceed the designated passenger, load or towing capacity

On grades, it is possible for vehicles to coast at greater than normal speeds encountered on a flat surface. To prevent loss of

vehicle control and possible serious injury, speeds should be limited to no more than maximum speed on level ground.

.

Owner’s Manual and Service Guide – BCG Series 6

WARNING

WARNING

SAFETY INFORMATION

Good common sense and prudent driving practices do more to prevent accidents and injuries than all of the warnings and

instructions combined. Wesley International strongly suggests that the owner-operator read this entire manual paying particular

attention to the CAUTIONS and WARNINGS contained therein

Loading and Unloading

Follow these guidelines when loading and unloading cargo from the vehicle or trailers:

Turn the vehicle off while loading

Do not exceed the maximum passenger or cargo load capacity

Carefully and evenly position all loads

Secure cargo so that nothing can easily fall off of the vehicle or trailer

Be extremely careful carrying loads that extend beyond the vehicle’s deck

TOWING

Follow these guidelines when towing:

Turn the vehicle off when connecting equipment that will be towed

Always use a properly installed hitch that matches the trailer tongue (Optional hitches available from Wesley International)

Do not exceed the maximum towing capacity

Do not exceed 5 mph when towing

Take extreme care when towing down an incline. Do not tow trailers down an incline with a grade of more than 15%.

MAINTENANCE

Always maintain your vehicle in accordance with the service schedule within this manual and keep complete records of the

maintenance history of the vehicle. Ensure the maintenance personnel performing any service or repair work on the vehicle are

trained and qualified to do so. Be sure to disable the vehicle before performing any maintenance including removing the key from

the key switch and removal of a battery cable.

Always insulate any tools used within the battery area in order to prevent sparks or battery

explosion caused by shorting the battery terminals or associated wiring.

Be sure to check the polarity of each battery terminal and be sure to rewire the batteries correctly. Never install a wire instead of a

proper fuse, even for a temporary fix. It may cause extensive damage and possible fire. Do not use a screwdriver or other metal

object to remove fuses. Doing so may cause an electrical short and damage the system. Do not modify or tamper with any part of

the operating or speed control systems. All inspections and adjustments must be made by a qualified technician.

Always support the vehicle using wheel chocks and safety stands. Never get under a vehicle that is supported by a jack. Lift the

vehicle in accordance with the instructions in this manual.

Always test drive the vehicle after any repairs or maintenance in a safe area free of any other vehicles or pedestrians.

VENTILATIO N

Hydrogen gas is generated in the charging cycle of batteries and is explosive in concentrations

as low as 4%. Because hydrogen gas is lighter than air, it will collect in the ceilings of buildings

and therefore, proper ventilation is required. Five air exchanges per hour is considered the

minimum ventilation required.

Always use a dedicated circuit for each battery charger. Do not permit other appliances to be plugged into the receptacle when the

charger is in operation.

7 Owner’s Manual and Service Guide – BCG Series

INDUSTRY STANDARDS

The following text is provided as recommended by Part II,

“For the User”, of ANSI/ITSDF B56.8-2011, Safety Standard

for Personnel and Burden Carriers. The manufacturer

strongly endorses the contents of this specification.

6 GENERAL SAFETY PRACTICES

6.1 Introduction

6.1.1 Like other machines, carriers can cause injury if

improperly used or maintained. Part II contains broad safety

practices applicable to carrier operation. Before operation,

the user shall establish such additional specific safety

practices as may reasonably be required for safe operation.

6.1.2 Premise review — The user shall periodically

review their premises, and as conditions warrant, identify

areas where carriers should not be operated and to identify

possible hazards such as the following examples:

(a) Steep Grade — In areas where steep grades exist,

carrier operation should be restricted to the designated

vehicle’s pathways where possible, and shall be identified

with a suitable warning giving the following information:

“Warning, steep grade.”

(b) Wet Areas — Wet areas could cause a carrier to lose

traction and could affect steering, stability and braking.

(c) Sharp Turns, Blind Spots, Bridge Approaches —

Sharp turns, blind spots, bridge approaches, and other

potentially hazardous areas shall be identified with a suitable

warning to the operator of the nature of the hazard and

stating the proper precautions to be taken to avoid the

hazard.

(d) Loose Terrain — Loose terrain could cause a carrier

to lose traction and could affect steering, stability, and

braking.

6.2 Operation

Experience has shown that carriers, which comply with the

provisions, stated in paragraphs 9.4, 9.5, and 9.6 are stable

when properly operated and when operated in accordance

with specific safety rules and practices established to meet

actual operating terrain and conditions. However, improper

operation, faulty maintenance, or poor housekeeping may

contribute to a condition of instability and defeat the purpose

of the standard. Some of the conditions which may affect

stability are failure of the user to follow safety practices; also,

ground and floor conditions, grade, speed, loading, the

operation of the carrier with improper loads, battery weight,

dynamic and static forces, and the judgment exercised by

the carrier operator.

(a) The user shall train carrier operators to adhere

strictly to the operating instructions stated in this Standard.

(b) The user shall survey specific operating conditions

and environment, and establish and train carrier operators to

comply with additional, specific safety practices.

6.3 Nameplates, Markings, Capacity, and Modifications

6.3.1 The user shall maintain in a legible condition all

nameplates, warnings, and instructions, which are supplied

by the manufacturer.

6.3.2 Except as provided in 6.3.4, no modifications or

alterations to a carrier, which may affect the capacity,

stability, or safe operation of the carrier, shall be made

without the prior written approval of the original carrier

manufacturer or a successor thereof. When the carrier

manufacturer or its successor approves a modification or

alteration, appropriate changes shall be made to capacity

plates, decals, tags, and operation and maintenance

manuals.

6.3.3 As required under paragraphs 6.3.1 or 6.3.2, the

manufacturer shall be contacted to secure new nameplates,

warnings, or instructions, which shall then be affixed in their

proper place on the carrier.

6.3.4 In the event that the carrier manufacturer is no

longer in business and there is no successor in interest to

the business, the user may arrange for a modification or

alteration to a carrier, provided however, the controlling party

shall:

(1) Arrange for the modification or alteration to be

designed, tested, and implemented by an engineer(s) expert

in carrier(s) and their safety;

(2) Maintain a permanent record of the design, test(s),

and implementation of the modification or alteration;

(3) Make appropriate changes to the capacity plate(s),

decals, tags, and operation and maintenance manuals;

(4) Affix a permanent and readily visible label on the

carrier stating the manner in which the carrier has been

modified or altered together with the date of the modification

or alteration, and the name of the organization that

accomplished the tasks.

6.4 Changing and Charging Storage Batteries for

Electric Personnel and Burden Carriers

6.4.1 The user shall require battery changing and

charging facilities and procedures to be in accordance with

ANSI/NFPA 505 or as required by local ordinance.

6.4.2 The user shall periodically inspect facilities and

review procedures to be certain that ANSI/NFPA 505 or as

required by local ordinance, are strictly complied with, and

shall familiarize carrier operators with it.

Owner’s Manual and Service Guide – BCG Series 8

INDUSTRY STANDARDS

6.4.3 Maintenance and storage areas for carriers shall be

properly ventilated to avoid fire hazards in accordance with

applicable fire codes and ordinances.

Ventilation for internal combustion engine powered carriers

shall be provided to remove flammable vapors (gases),

fumes and other flammable materials. Consult applicable fire

codes for specific levels of ventilation.

Ventilation for electric powered carriers shall be provided to

remove the accumulation of flammable hydrogen gas

emitted during the battery charging process.

The amount of hydrogen gas emitted depends upon a

number of factors such as the condition of the batteries, the

output rate of the battery charger and the amount of time the

batteries are on charge. Because of the highly volatile nature

of hydrogen gas and its propensity to accumulate in pockets,

a minimum number of air changes per hour is required

during charging.

Consult applicable fire and safety codes for the specific

ventilation levels required as well as the use of explosion

proof electrical apparatus. SAE J1718 can be followed to

check for hydrogen gas levels.

6.5 Hazardous Locations

6.5.1 The user shall determine the hazard classification

of the particular atmosphere or location in which the carrier

is to be use in the accordance with ANSI/NFPA 505.

6.5.2 The user shall permit in hazardous areas only those

carriers approved and of the type required by ANSI/NFPA

505.

6.6 Lighting for Operating Area

The user, in accordance with his responsibility to survey the

environment and operating conditions, shall determine if the

carrier requires lights and, if so, shall equip the carrier with

appropriate lights.

6.7 Control of Noxious Gases and Fumes

When equipment powered by internal combustion engines is

used in enclosed areas, the atmosphere shall be maintained

within limits specified in the American Conference of

Governmental Industrial Hygienists publication, “Threshold

Limit Values for Chemical Substances and Physical Agents

in the Workroom Environment.” This may be accomplished

by ventilation provided by the user, or the installation, use,

and proper maintenance of emission control equipment

recommended or provided by the manufacturer of the

equipment.

6.8 Warning Device(s)

6.8.1 The user shall make periodic inspections of the

carrier to be certain that the sound-producing and/or visual

device(s) if so equipped are maintained in good operating

condition.

6.8.2 The user shall determine if operating conditions

require the carrier to be equipped with additional sound

producing or visual devices or both and be responsible for

providing and maintaining such devices, in accordance with

the manufacturer’s recommendations.

6.9 Safety Interlocks

The user shall make periodic inspections of the carrier to be

certain that the safety interlock system, if so equipped, is

operating properly.

7 OPERATING SAFETY RULES AND PRACTICES

7.1 Personnel and Burden Carrier Operator

Qualifications

Only persons who are trained in the proper operation of the

carrier shall be authorized to operate the carrier. Operators

shall be qualified as to visual, auditory, physical, and mental

ability to safely operate the equipment according to Section

7, all other applicable parts of this Standard and the

operators’ manual.

7.2 Personnel and Burden Carrier Operators’ Training

7.2.1 The user shall conduct an operators’ training

program.

7.2.2 Successful completion of the operators’ training

program by the operator shall be required before operation

of the carrier. The program shall be presented in its entirely

to all-new operators and not condensed for those claiming

previous experience.

7.2.3 The user shall include as a minimum in the

operators’ training program the following:

(a) Instructional material provided by the manufacturer

including the operators’ manual;

(b) Emphasis on safety of passengers, material loads,

carrier operator, and other person(s);

(c) General safety rules contained within this Standard

and the additional specific rules determined by the user in

accordance with this Standard, and why they were

formulated;

(d) Introduction of equipment, control locations and

functions, and explanation of how they work when used

properly and when used improperly; and surface conditions,

grade, and other conditions of the environment which could

affect carrier operation;

(e) Operator competency evaluations.

9 Owner’s Manual and Service Guide – BCG Series

INDUSTRY STANDARDS

7.3 Personnel and Burden Carrier Operator

Responsibility

7.3.1 General Operator Responsibility

7.3.1.1 Read and follow operators’ manual.

7.3.1.2 Do not operate carrier under the influence of drugs

and alcohol.

7.3.1.3 Safeguard the pedestrians at all times. Do not drive

carrier in a manner that would endanger other persons.

7.3.1.4 Riding on the carrier by persons other than the

operator is authorized only on personnel seat(s) provided by

the manufacturer. All parts of each person’s body shall

remain within the plan view outline of the carrier.

7.3.1.5 When a carrier is to be left unattended, stop the

carrier, apply the parking brake, stop the engine or turn off

power, turn off the control or ignition circuit, and remove the

key if provided. Additionally, for electric carriers, the forward

and reverse directional controls, should be neutralized if a

means is provided. Block the wheels if the carrier is on an

incline.

7.3.1.6 A carrier is considered unattended when the

operator is 7.6m (25 ft) or more from the carrier which

remains in his view, or whenever the operator leaves the

carrier and it is not within his view. When the operator is

dismounted and within 7.6m (25 ft) of the carrier still in his

view, he still must have controls neutralized, and the parking

brake(s) set to prevent movement.

7.3.1.7 Maintain a safe distance from potential hazards,

such as edges of ramps and platforms.

7.3.1.8 Use only approved carriers in hazardous locations,

as defined in the appropriate safety standards.

7.3.1.9 Report all accidents to the user.

7.3.1.10 Do not add to, or modify, the carrier.

7.3.1.11 Carriers shall not be parked or left unattended

such that they block or obstruct fire aisles, access to

stairways, or fire equipment.

7.3.1.12 Only operate carrier while within operator’s

station.

7.3.2 Traveling

7.3.2.1 Observe all traffic regulations, including authorized

speed limits. Under normal traffic conditions keep to the

right. Maintain a safe distance, based on speed of travel,

from a carrier or vehicle ahead; and keep the carrier under

control at all times.

7.3.2.2 Yield the right of way to pedestrians, ambulances,

fire trucks, or other carriers/vehicles in emergency situations.

7.3.2.3 Do not pass another carrier or vehicle traveling in

the same direction at intersections, blind spots, or at other

dangerous locations.

7.3.2.4 Keep a clear view of the path of travel, observe

other traffic and personnel, and maintain a safe clearance.

7.3.2.5 Slow down or stop, as conditions dictate, and

activate the sound-producing warning device at cross aisles

and when visibility is obstructed at other locations.

7.3.2.6 Ascend or descend grades slowly.

7.3.2.7 Avoid turning, if possible, and use extreme caution

on grades, ramps, or inclines; normally travel straight up and

down.

7.3.2.8 Under all travel conditions the carrier shall be

operated at a speed that will permit it to be brought to a stop

in a safe manner.

7.3.2.9 Make starts, stops, turns, or direction reversals in a

smooth manner so as not to shift the load, endanger

passengers, or lose control of the carrier.

7.3.2.10 Do not operate carrier in a dangerous manner.

7.3.2.11 Slow down when approaching, or on, wet or

slippery surfaces.

7.3.2.12 Do not drive carrier onto any elevator unless

specifically authorized to do so. Approach elevators slowly,

and then enter squarely after the elevator car is properly

leveled. Once on the elevator, neutralize the controls, shut

off power, and set parking brakes. It is advisable that all

other personnel leave the elevator before a carrier is allowed

to enter or exit.

7.3.2.13 Avoid running over loose objects, potholes, and

bumps.

7.3.2.14 Reduce carrier speed to negotiate turns.

7.3.2.15 Avoid any action verbal or physical by an operator

or passenger, which could cause the operator to be

distracted.

7.3.3 Loading

7.3.3.1 Refer to operators’ manual for loading instruction.

7.3.3.2 Handle only stable and safely arranged loads.

When handling off-center loads, which cannot be centered,

operate with extra caution.

7.3.3.3 Handle only loads within the capacity of each cargo

area of the carrier as specified by the manufacturer.

7.3.3.4 Avoid material loads exceeding the physical

dimensions of the carrier or as specified by the carrier

manufacturer.

Owner’s Manual and Service Guide – BCG Series 10

INDUSTRY STANDARDS

7.3.4 Operator Care of Personnel and Burden

Carriers

7.3.4.1 Read and follow operators’ manual.

7.3.4.2 At the beginning of each shift during which the

carrier will be used, the operator shall check the carrier

condition and inspect the tires, warning devices, lights,

battery(s), speed and directional controllers, brakes, safety

interlocks, and steering mechanism. If the carrier is found to

be in need of repair or is in any way unsafe, the matter shall

be reported immediately to the user and the carrier shall not

be operated until restored to safe operating condition.

7.3.4.3 If during operation the carrier becomes unsafe in

any way, the matter shall be reported immediately to the

user, and the carrier shall not be operated until it has been

restored to safe operating condition.

7.3.4.4 Do not make repairs or adjustments unless

specifically trained and authorized to do so.

7.3.4.5 Before refueling, the engine shall be stopped and

allowed to cool. The operator and passengers shall leave

the carrier before refueling.

7.3.4.6 Spillage of hazardous materials shall be contained

immediately and addressed via appropriate hazardous

materials regulations.

7.3.4.7 Do not operate a carrier with a leak in the fuel

system or battery(s). Battery(s) shall be charged and

serviced per manufacturer’s instructions.

7.3.4.8 Do not use open flames for checking electrolyte

level in storage battery(s) or liquid level in fuel tanks.

8 MAINTENANCE PRACTICES

8.1 Introduction

Carriers may become hazardous if maintenance is

neglected. Maintenance facilities, trained personnel, and

procedures shall be provided. Such facilities may be on or

off the premises.

8.2 Maintenance Procedures

Maintenance and inspection of all carriers shall be

performed in conformance with the following practices and

should follow the manufacturer’s recommendations.

(a) A scheduled preventive maintenance, lubrication,

and inspection system shall be followed.

(b) Only trained and authorized personnel shall be

permitted to maintain, repair, adjust, and inspect carriers.

(c) Before undertaking maintenance or repair, follow the

manufacturer’s recommendations for immobilizing the

carrier.

(d) Chock wheels and support carrier, before working

underneath it.

(e) Before disconnecting any part of the engine fuel

system, be sure the shutoff valve, if so equipped, is closed

and follow carrier manufacturer’s recommended practice.

(f) Operation to check performance of the carrier shall be

conducted in an authorized area where suitable conditions

exist, free of vehicular and pedestrian traffic.

(g) Before returning carrier to service, follow the

manufacturer’s instructions and recommended procedures.

(h) Avoid fire hazards and have fire protection equipment

present in the work area. Do not use an open flame to check

level or leakage of fuel, battery electrolyte, or coolant.

(i) Properly ventilate the work area in accordance with

applicable regulations or local ordinance.

(j) Handle fuel cylinders with care. Physical damage,

such as dents, scrapes, or gouges, may dangerously

weaken the tank and make it unsafe for use.

(k) Brakes, steering mechanisms, speed and directional

control mechanisms, warning devices, lights, governors,

guards, and safety devices shall be inspected regularly and

maintained in accordance with manufacturer’s

recommendations.

(l) Carriers or devices designed and approved for

hazardous area operation shall be inspected to ensure that

maintenance preserves the original approved safe operating

features.

(m) Fuel systems shall be checked for leaks and

condition of parts. If a leak is found, action shall be taken to

prevent the use of the carrier until the cause of the leak has

been repaired.

(n) The carrier manufacturer’s capacity, operation, and

maintenance instruction plated, tags, or decals shall be

maintained in legible condition.

(o) Batteries, motors, speed and directional controllers,

limit-switches ,protective-devices ,electrical

conductors/insulators, and connections shall be inspected

and maintained per carrier manufacturer’s recommendation.

(p) Carriers shall be kept clean to minimize hazards and

facilitate detection of components needing service

(q) Modifications and additions which affect capacity and

safe carrier operation shall not be performed without

manufacturer’s prior written authorization; where authorized

modifications have been made, the user shall ensure that

capacity, operation, warning, and maintenance instruction

plates, tags, or safety labels are changed accordingly.

(r) Care shall be taken to ensure that all replacement

parts are interchangeable with the original parts and of a

quality at least equal to that provided in the original

equipment.

(s) Disconnect batteries, negative connection(s) first.

When reconnecting, connect positive connection first.

(t) Hydraulic systems, if so equipped, shall be checked

for leaks, for condition of parts. Keep body and hands away

from pin-holes or nozzles that eject fluids under high

pressure. Use paper or cardboard, not hands, to check for

leaks.

11 Owner’s Manual and Service Guide – BCG Series

OPERATING INSTRUCTIONS

On/Off Switch

FIGURE 1

Key Switch

INITIAL CHECK LIST

Use the following checklist to inspect and prep your vehicle

prior to initial use.

□ Check for evidence of leaking fluids, i.e. battery acid, or

gear oil.

□ Check condition of tires and tire air pressure. Maximum

90 psi Cold; 60 psi recommended. (Pneumatic tires

only).

□ Check to ensure wheel lug nuts are tight.

□ Check that all battery connections are tight/corrosion

free

□ Check for smooth operation of controls, switches, and

brakes.

□ Charge batteries.

IDEN TIFICATION

The product model number, serial number, and year of

manufacture is located on a

silver label ( Figure 1), either on

the front of the vehicle near the

switches, on the underside of

the plate where the seat is

mounted, or inside the motor

compartment attached to a side

panel.

Whenever you correspond with

Wesley International regarding

your vehicle, be sure to include

this information.

CHAR GIN G BATTERIES

The BCG Series electric vehicles come standard with an

Industrial battery. Industrial batteries are charged with rapid

chargers that normally are hard wired into the plant electrical

system. No onboard charger is provided. However, we will

accept special orders that include an onboard charger.

When charging, follow these steps to charge the battery:

1) Position the vehicle within reach of the external

charger cord.

2) Slide seat to the rear most position and tilt forward to

open battery compartment.

3) Check all battery cells for proper acid level. Fluid

should be above plates

4) Unplug the battery from the vehicle and plug it into

the externally mounted charger using the cord from the

external charger.

CAUTION: Onboard chargers require extension cords that

are 3-wire cord no longer than 30m (100’) at 10AWG or 7.5m

(25’) at 16 AWG per UL guidelines. Only connect ONE

onboard charger to a single 15A circuit or the circuit may

become overloaded.

VEHICLE CO NTR OLS, METERS, SWITCHES

The controls, meters and switches consist of:

Key Switch, Perma-Key Switch, or On/Off Switch

FWD/REV Directional Selector Switch

Battery Discharge Indicator (BDI)

Headlight / Tail Light Switch (Optional)

Parking Brake

Speed Control Pedal

Brake Pedal

Horn Button

Seat Presence Sensor Switch

Foot Presence Switch (Optional)

Key Switch: For vehicles equipped with a key switch (Figure

2), the vehicle only operates when the key is in the switch. It

has two positions – run and off.

FIGURE 2

Perma-Key Switch (Optional): An optional Perma-Key

switch is available to replace the standard key switch. It

works the same way, but eliminates the need for a separate

key that may get lost. It has three positions – run, off, and

charge only.

On/Off Rocker Switch (Optional): An optional 2 position

on/off Rocker switch is available to replace the standard key

switch. (Figure 3).

Owner’s Manual and Service Guide – BCG Series 12

.

FIGURE 3

WARNING

OPERATING INSTRUCTIONS

FIGURE 4

To prevent unexpected vehicle movement or

unauthorized use, always turn the key switch to the OFF

position and remove key when the vehicle is not in use

Programmable Security Switch (Optional): SAFE-T-

LOCK™ is a programmable code switch,( Figure 4), which

prevents unauthorized use of the vehicle. It is offered as an

option, part number EVE901. The SAFE-T-LOCK

switch is installed in lieu of

the standard switch to

control access and

operation of the vehicle

within the customer’s

premises. It can be preinstalled at time of order, or

purchased separately to

upgrade existing vehicles.

The STL1000 switch allows

plant and facility managers

to input up to 99 different users/drivers to track vehicle

usage. If an accident occurs, or the vehicle is damaged, the

manager can easily identify the last operator. The switch

also features an internal clock that records "on" hours and

notifies the operator when the 250-hour mark is reached.

Each user can select a four- to eight-digit personal access

code and a separate supervisor user menu programs the

unit. The switch will provide the last user ID code when

prompted by the supervisor. In operation, only users with

active ID codes can operate the vehicle, virtually eliminating

all unauthorized use, the company said.

The switch operates in a voltage range from 9 to 120 volts

DC and is enclosed in an IP65 rated housing. Two internal

LEDs indicate operational status - red indicates an error or

lock mode and green indicates key press or touch is active.

The unit also provides user feedback with key beep and

error tones.

Step-by-Step Programming Instructions:

1 – Log onto the Supervisor Mode. Press 0 0 1 2 3 4

ENTER. Red and Green LED flashes along with an up tone

beep indicate you are in the Supervisor Mode and ready to

enter a Supervisor Mode menu.

Note: As you enter each Supervisor Mode menu, the number

of Red LED flashes will correspond to the menu number. For

example, one Red LED flash for menu 1, two Red LED

flashes for menu 2, etc.

Before changing the Supervisor PIN, you are first going to

add User locations. For this example you will check on and

add User location 01 as well as more User locations as

required. To do this you must go into the Add / Delete User

Menu.

2 – Go into Add / Delete User Menu. Press 2 ENTER. There

will be a beep along with two Red LED flashes indicating you

are in Menu 2. Press 0 1 ENTER. If there is a Red flash and

a low beep, it indicates that user location 01 has already

been assigned. To remove location 01, press ENTER again.

This will delete the location from use.

Add location 01. Press 0 1 ENTER. You should now get a

Green flash along with an up tone beep indicating the

location is ready to be added or assigned to a user. Press

ENTER. You will get a Green LED flash along with a beep.

The user location has been added.

At this point you can, in the same way, check on and add

more user locations.

Before leaving Menu 2, check to make sure that location 01

and any others have been added. Press 0 1 ENTER. There

should be a Red LED flash along with a low tone beep

indicating the location has been assigned to the user. Check

any other locations you’ve added the same way. A Red flash

along with a low tone beep means the location has been

assigned. A Green flash along with an up tone beep means

the location is not assigned.

3 – Go out of Menu 2. Press CE. The switch will indicate you

are back in Supervisor Mode. Press CE again to go out of

Supervisor Mode. (CE can be pressed several times to make

sure you are completely clear and ready to enter the next

mode.)

4 – Log onto the User Mode. Press 0 1 1 2 3 4 ENTER. The

switch will close and the Green LED will flash at a slow rate.

5 – Change User PIN. First decide on a new PIN. In this

example

e use 5 4 3 2 1. Press 1, ENTER. (This puts you in the

Change User PIN Menu.) Note that the switch will open

when you go into this menu.

Note: The User has 1 minute after logging on the User Mode

to use menu 1 before the menu function is locked out until

the next User log on.

Press 5 4 3 2 1 ENTER, again press 5 4 3 2 1 ENTER. The

switch will indicate that the new PIN has been accepted.

6 – Use the new PIN to close the switch. Press 0 1 5 4 3 2 1

ENTER. The switch will close. Press ENTER to open the

switch and go out of User Mode. (Since this is an example,

you may want to set the PIN for User location 01 back to the

1 2 3 4 default.)

7 – Log back onto the Supervisor Mode to change the

Supervisor PIN. Press 0 0 1 2 3 4 ENTER. Press 1 ENTER

to go into the Change Supervisor PIN Menu. The red LED

will flash once. Now just you did in the User Mode, put the

new PIN in twice and enter each time. Example: Press 5 4 3

2 1 ENTER, again 5 4 3 2 1 ENTER. The switch will give an

indication that the PIN was changed.

13 Owner’s Manual and Service Guide – BCG Series

WARNING

NOTE

OPERATING INSTRUCTIONS

Directional Switch

8 – Go out of Menu 1. Press CE. Press CE again to Log Off

the Supervisor Mode.

9 – Check out the new Supervisor PIN. Press 0 0 5 4 3 2 1

ENTER. You should be in Supervisor Mode. You can now go

to any menu by pressing the menu number and ENTER.

Remember: This is an example. You should change your

Supervisor PIN to one known only to you.

10 – Determine Last user. While in Supervisor Mode press 3

ENTER. This places you in the Last User Menu as indicated

by three red LED flashes. Press ENTER again. The LED

flashes will indicate the last user. The Green LED is for the

10’s digit. The Red LED is for the 1’s digit. Example 1: A

single Red LED flash indicates User 01 last operated the

vehicle. Example 2: Two Green flashes and three Red

flashes would indicate User 23 last operated the vehicle.

Press CE to leave the menu.

11 – Enable or Disable Maintenance Alarm. Press 4 ENTER.

There will be four red LED flashes. Press ENTER again. If

the Green LED flashes, the alarm is enabled. Press ENTER

again and the Red LED will flash showing the alarm to be

disabled. Press ENTER again and the Green LED will flash

showing the alarm to be again enabled.

12 – Listen to the maintenance alarm. While in Menu 4 press

1 ENTER. The maintenance alarm will sound. Press CE to

leave the menu. Press CE again to Log Off the Supervisor

Mode.

Note: If the switch is left unattended in Supervisor mode, it

will automatically exit the mode after approximately one

minute.

13 – If you are unable to get into the Supervisor mode after

trying either the default PIN or a newly assigned PIN, go

back to Step 1 and reset the switch.

If all else fails or if you have questions about programming or

installing the SAFE-T-LOCK, call Tech Support at 1-800241-2869.

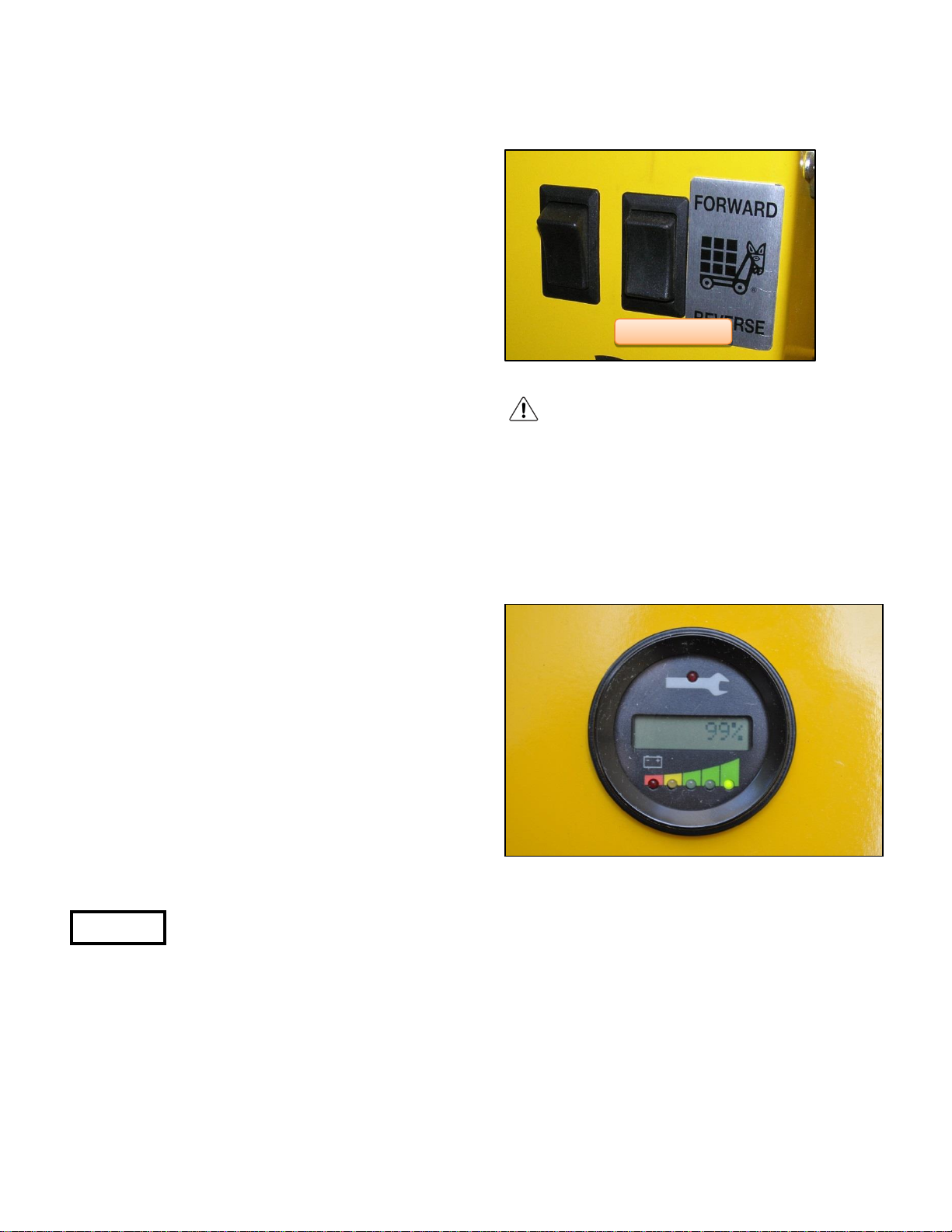

Directional Switch: The directional rocker or toggle switch

is used to place the vehicle in one of three operating modes

– forward, reverse, or neutral. (Figure 5) shows a rocker

directional switch.

The directional switch MUST be in

NEUTRAL (center) position BEFORE

selecting vehicle “ON” or a “Static Return

to Off” (SRO) error code will be generated by the motor

controller. The vehicle is temporarily immobilized as a

standard safety feature. (If your vehicle is equipped with the

Optional Foot Presence Switch and the unit is already turned

on and in neutral position, the foot presence switch MUST

be engaged before the directional switch is placed in forward

or reverse mode, or the same error code will be displayed

and the vehicle temporarily immobilized.) If this error code is

displayed, return the directional switch back to neutral,

ensure the foot presence switch is engaged, and then switch

the directional Switch to the desired forward or reverse

position and the vehicle will operate.

FIGURE 5

To prevent unexpected vehicle

movement, always place the

directional switch in the

NEUTRAL position when

leaving the vehicle.

Battery Discharge Indicator (BDI): The battery discharge

indicator, (Figure 6), communicates directly with the onboard

controller and provides information on various system

parameters, such as battery state-of-charge, operating hours

(on some models), or maintenance status including error

codes.

FIGURE 6

When powering on the vehicle, the BDI first indicates the

hours (Note: The controller is programmed to indicated

traction hours, which is the time that the motor is engaged

and the vehicle is moving. The controller can be

programmed to display “key-on” hours which records time

that the key switch is in the on position, regardless of

whether it is moving or not). It then cycles through to the

state of battery charge, measured in percent charge

remaining. If there are any faults recorded by the controller,

the BDI will display an error code and the LED by the tool

wrench symbol will illuminate.

Owner’s Manual and Service Guide – BCG Series 14

OPERATING INSTRUCTIONS

Headlight/Taillight Switch

Headlight / Tail-Light and Switch (Optional): Some

vehicles may include the headlight and/or tail-light (Figure 7)

option. In which case, there will also be a rocker switch to

turn the lights on or off. (Figure 8).

Brake Pedal: The brake pedal, Figure 10, is located to the

left of the accelerator pedal and is the smaller of the two.

Applying pressure on the brake pedal will slow the vehicle

down in addition to the motor braking. If driving down an

incline, the brake pedal should be used to control the speed.

FIGURE 7

FIGURE 8

SPEED CONTROL PEDAL:

The speed control pedal, (Figure 9) is located to the right of

the brake pedal. It controls the speed of the vehicle and is

operated with the right foot like the accelerator of an

automobile. Depressing the pedal starts the motor.

Releasing the pedal stops the motor. Reverse speed is half

of forward speed.

FIGURE 10

The brake pedal has a brake lock feature which can lock the

brake pedal into the down position (Figure 11), thus acting

as a parking brake. Simply push the brake pedal all the way

down while pushing at the bottom edge of the brake pedal.

This will engage the black pedal lock to latch onto the body

frame, retaining the brake pedal in the engaged position.

To release, simply push the top edge of the brake pedal and

the brake pedal will disengage and be free to move to its

disengaged position (Figure 12).

FIGURE 11 FIGURE 12

FIGURE 9

15 Owner’s Manual and Service Guide – BCG Series

Loading...

Loading...