WXR 3

GB Translation of the original instructions

English

Technical Data | Safety information | Menu navigation |

Care and maintenance | Warranty

DEGBESFRITPTNLSVDKFIGRCZ TRPL

35

HU

SKSLEELTLVBG

RO

HRRU

41 2

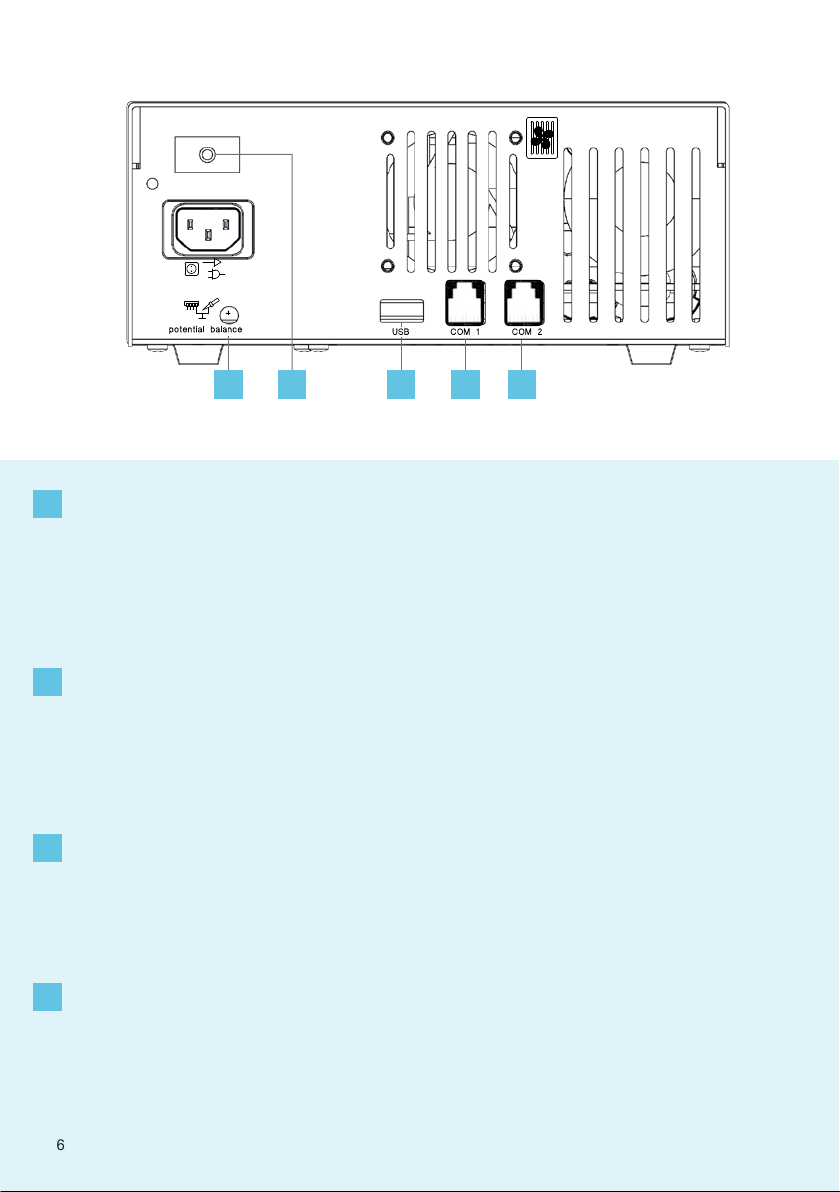

USB COM 143COM 2

DE Potentialausgleich

1

GB Equipotential bonding

ES Equipotencial

FR Compensation de potentiel

IT Compensazione di potenziale

PT Equilíbrio do potencial

NL Potentiaalvereffening

SV Potentialutjämning

DK Spændingsudligning

DE Netzsicherung

2

GB Mains fuse

ES Fusible

FR Fusible secteur

IT Protezione della rete

PT Fusível de rede

NL Netbeveiliging

SV Nätsäkring

DE USB-Schnittstelle

3

GB USB port

ES Interfaz USB

FR Interface USB

IT Interfaccia USB

PT Interface USB

NL USB-poort

SV USB-port

DE Schnittstelle

4

GB Interface

ES Interfaz

FR Interface

IT Interfaccia

PT Interface

NL Interface

SV Gränssnitt

FI Potentiaalin tasaus

GR Εξίσωση δυναμικού

TR Potansiyel dengelemesi

CZ Vyrovnání potenciálů

PL Wyrównanie potencjału

HU Feszültségkiegyenlítő hüvely

SK

Zásuvka vyrovnania potenciálov

SL Vtičnica za izenačevanje

potenciala

DK Netsikring

FI Verkkosulake

GR Ηλεκτρική ασφάλεια δικτύου

TR Şebeke sigortası

CZ Síťová pojistka

PL Bezpiecznik sieciowy

HU Hálózati biztosíték

SK Sieťová poistka

DK USB-port

FI USB-liitäntä

GR Θύρα διεπαφής USB

TR USB arabirim

CZ Rozhraní USB

PL Złącze USB

HU USB csatlakozó

SK Rozhranie USB

DK Interface

FI Liittymä

GR Θύρα διεπαφής

TR Arabirim

CZ Rozhraní

PL Interfejs

HU Interfész

SK Rozhranie

EE Potentsiaalide ühtlustuspuks

LV Potenciālu izlīdzināšanas

pieslēgvieta

LT Potencialo išlyginimo įvorė

BG Изравняване на

потенциалите

RO

Egalizare de potențial

HR Izjednačavanje potencijala

RU Выравнивание потенциалов

SL Omrežna varovalka

EE Võrgukaitse

LV Elektriskā tīkla drošinātājs

LT Tinklo saugiklis

BG Мрежов предпазител

RO Siguranţă de reţea

HR Mrežni osigurač

RU Предохранитель электросети

SL Vmesnik USB

EE USB-liides

LV USB pieslēgvieta

LT USB sąsaja

BG USB-интерфейс

RO Interfaţă USB

HR Sučelje USB

RU Интерфейс USB

SL Vmesnik

EE Liides

LV Saskarne

LT Sąsaja

BG Интерфейс

RO Interfaţă

HR Sučelje

RU Интерфейс

6

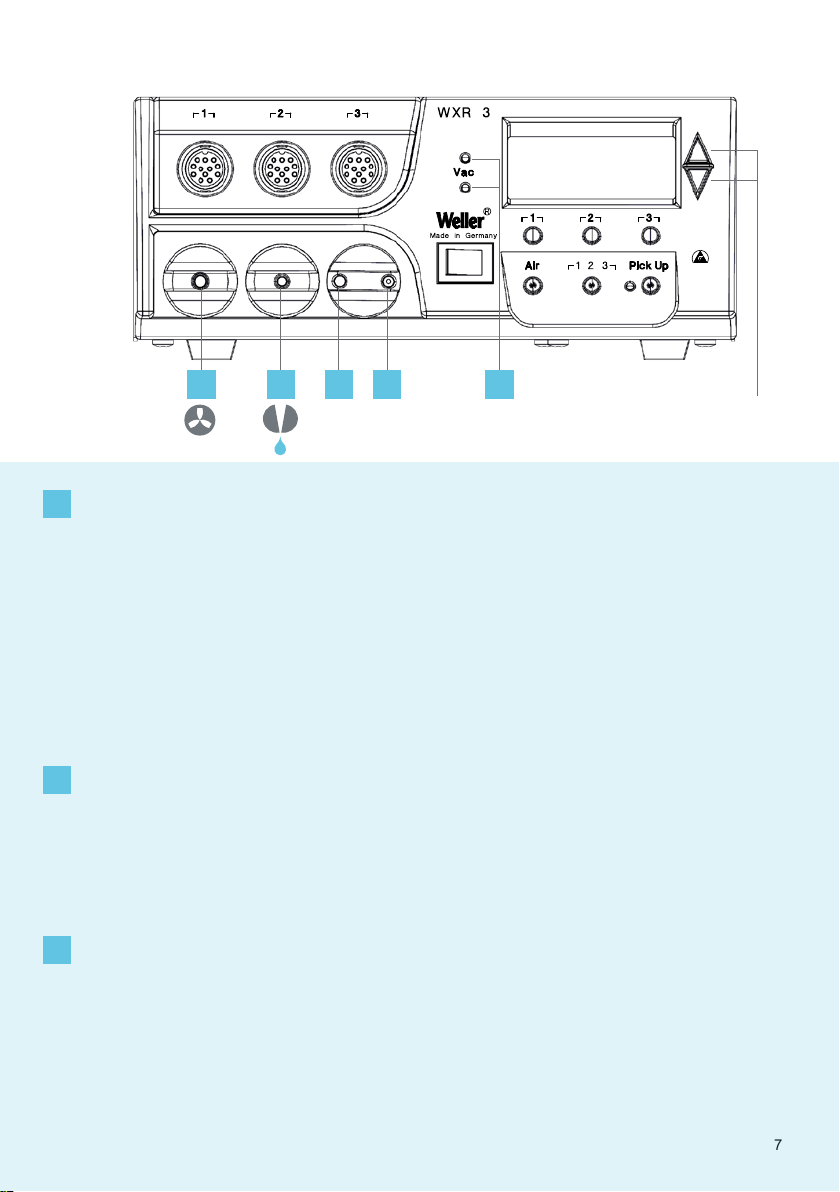

Air Vac Pick Up

¬

65 6

Pick

Up 1

¬

Pick Up

6

Pick

Up 2

7

UP /

DOWN

5

6

7

Heißluftkolben

Air connection nipple for

GB

hot air tools

Boquilla de conexión del

ES

aire para el soldador de

aire caliente

Raccord de connexion

FR

d‘air pour fers à air chaud

Nipplo di collegamento aria

IT

per saldatore ad aria calda

Niples de ligação de ar para

PT

ferros de soldar por ar quente

Luchtaansluitnippel voor

NL

heteluchtbout

Luftanslutningsnippel för

SV

hetluftspenna

DE Vakuumanschluss

GB Vacuum connection

ES Toma de vacío

FR Raccord de vide

IT Collegamento per vuoto

PT Ligação de vácuo

NL Vacuümaansluiting

SV Vakuumanslutning

DE LED Vakuum

GB Vacuum LED

ES LED Vacío

FR LED vide

IT LED Vuoto

PT LED do vácuo

NL LED vacuüm

SV Lysdiod vakuum

Luftanschlussnippel für

DE

Lufttilslutningsnippel til

DK

varmluftskolbe

Ilmaliitäntänippa ku-

FI

umailmakolville

Στόμιο σύνδεσης αέρα για

GR

έμβολο θερμού αέρα

Sıcak hava pistonu için

TR

hava bağlantı nipeli

Šroubovací přípojka vzdu-

CZ

chu pro horkovzdušný píst

Šroubovací přípojka vzdu-

PL

chu pro horkovzdušný píst

Levegőcsatlakozó a

HU

forrólevegős páka számára

Prípojka vzduchu pre

SK

teplovzdušnú rúčku

Priključni nastavek spaj-

SL

kalnika za vroči zrak

DK Vakuumtilslutning

FI Tyhjiöliitäntä

GR Σύνδεση κενού

TR Vakum bağlantısı

CZ Přípojka vakua

PL Przłącze próżni

HU Vákuumcsatlakozó

SK Prípojka vákua

SL Priključek za podtlak

DK LED vakuum

FI Tyhjiön LED

GR LED κενού

TR Vakum LED'i

CZ LED vakuum

PL Dioda LED próżni

HU Vákuum LED

SK LED-dióda: podtlak

Õhuühenduse nippel

EE

kuuma õhu kolvidele

Gaisa pieslēguma nipelis

LV

karstā gaisa lodāmuram

Karšto oro stūmoklio oro

LT

jungties antgalis

Нипел за присъдиняван

BG

на въздух за поялник с

горещ въздух

Niplu de racordare pentru

RO

letconul cu aer cald

Nazuvica za priključak zra-

HR

ka za lemilo na vrući zrak

Подключение воздуха

RU

ниппель для горячей

пайки воздуха

EE Vaakumühendus

LV Vakuuma pieslēgums

LT Vakuumo jungtis

BG Съединителен елемент за

вакуум

RO Racord pentru vid

HR Vakuumski priključak

RU Вакуумное соединение

SL LED-dioda podtlaka

EE LED vaakum

LV Vakuuma LED diode

LT LED vakuumas

BG Вакуум LED

RO LED vid

HR LED vakuum

RU Светодиодный индикатор

вакуума

7

4

2 1

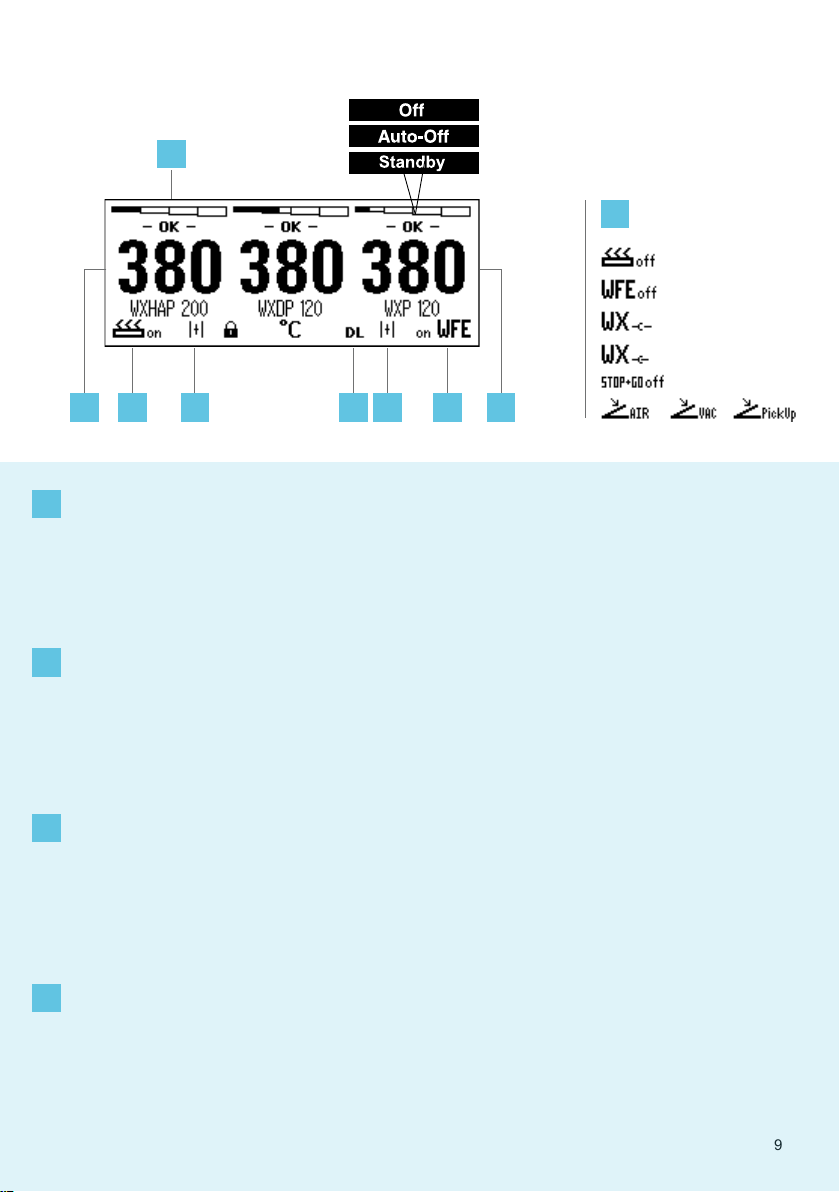

Isttemperatur / Solltemperatur

DE

1

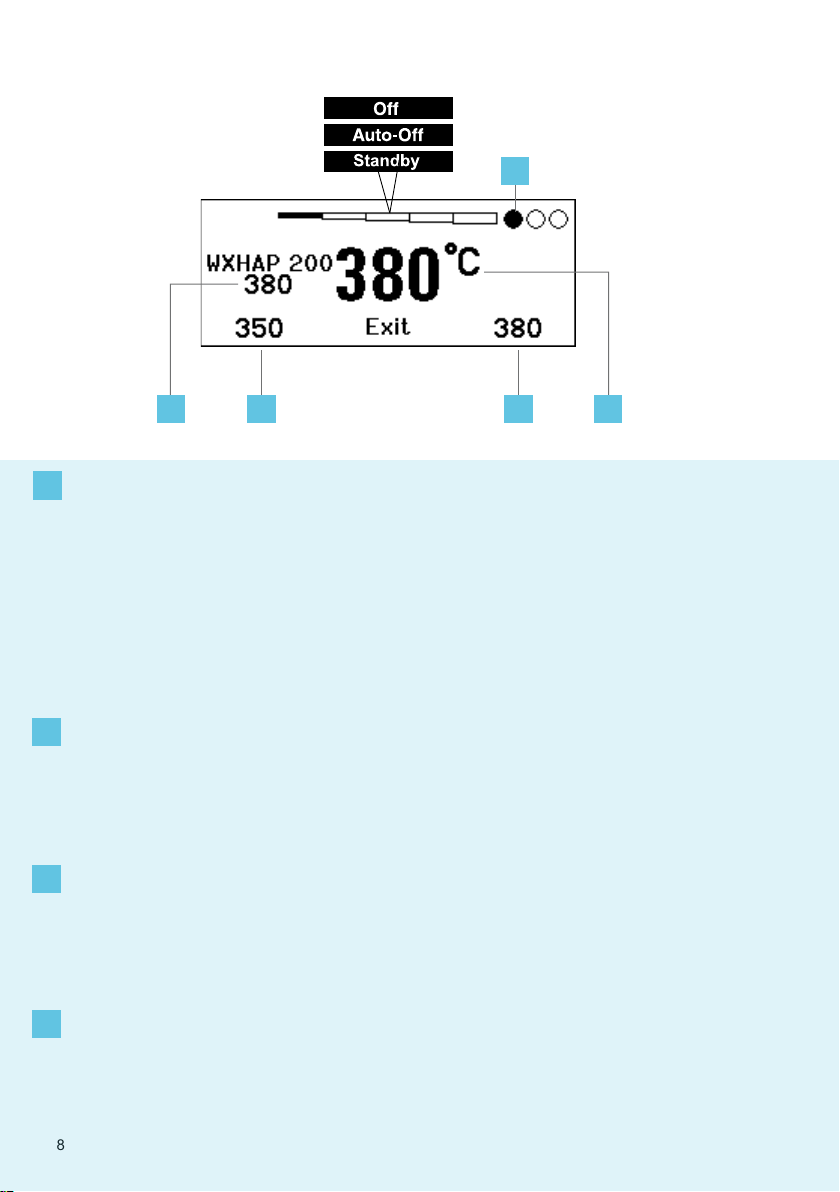

Actual temperature / nominal

GB

temperature

Temperatura real / temperatu-

ES

ra de referencia

Température réelle / tempéra-

FR

ture de consigne

Temperatura reale / tempera-

IT

tura nominale

Temperatura real / temperatu-

PT

ra nominal

Werkelijke temperatuur /

NL

gewenste temperatuur

Faktisk temperatur / börtem-

SV

peratur

DE Solltemperatur

2

GB Nominal temperature

ES Temperatura de referencia

FR Température de consigne

IT Temperatura nominale

PT Temperatura nominal

NL Gewenste temperatuur

SV Börtemperatur

DE Festtemperatur

3

GB Fixed temperature

ES Temperatura ja

FR Température xe

IT Temperatura ssa

PT Temperatura xa

NL Vaste temperatuur

SV Fast temperatur

Faktisk temperatur / nominel

DK

temperatur

Todellinen lämpötila / ohje-

FI

lämpötila

Πραγματική θερμοκρασία /

GR

ονομαστική θερμοκρασία

Fiili sıcaklık / nominal sıcaklık

TR

Skutečná teplota / nominal

CZ

sıcaklık

Temperatura rzeczywista /

PL

temperatura zadana

Mért hőmérséklet / temperatu-

HU

ra hőmérséklet

Skutočná teplota /

SK

požadovaná teplota

DK Nominel temperatur

FI Ohjelämpötila

GR Ονομαστική θερμοκρασία

TR Nominal sıcaklık

CZ Nominal sıcaklık

PL Temperatura zadana

HU Temperatura hőmérséklet

SK Požadovaná teplota

DK Fast temperatur

FI Kiinteä lämpötila

GR Σταθερή θερμοκρασία

TR Sabit sıcaklık

CZ Stanovená teplota

PL Temperatura stała

HU Rögzített hőmérséklet

SK Pevná teplota

33

Dejanska temperatura /

SL

želena temperatura

Tegelik väärtus / sihttempe-

EE

ratuur

Faktiskā temperatūra / vēlamā

LV

temperatūra

Esama temperatūra / nustaty-

LT

toji temperatūra

Действителна температура /

BG

Зададена температура

Temperatura efectivă / Tem-

RO

peratura nominală

Stvarna temperatura / Zadana

HR

temperatura

Фактическая температура /

RU

Заданная температура

SL Želena temperatura

EE Sihttemperatuur

LV Vēlamā temperatūra

LT Nustatytoji temperatūra

BG Зададена температура

RO Temperatura nominală

HR Zadana temperatura

RU Заданная температура

SL Stalna temperatura

EE Püsitemperatuur

LV Noteiktā temperatūra

LT Fiksuotoji temperatūra

BG Непроменлива температура

RO Temperatura xă

HR Fiksna temperatura

RU Фиксированная температура

DE Aktiver Kanal

4

GB Active channel

ES Canal activo

FR Canal actif

IT Canale attivo

PT Canal ativo

NL Actief kanaal

SV Aktiv kanal

8

DK Aktiv kanal

FI Aktivoitu kanava

GR Ενεργό κανάλι

TR Aktif kanal

CZ Aktivní kanál

PL Aktywny kanał

HU Aktív csatorna

SK Aktívny kanál

SL Aktivni kanal

EE Aktiivne kanal

LV Aktīvais kanāls

LT Aktyvus kanalas

BG Активен канал

RO Canal activ

HR Aktivni kanal

RU Aктивный канал

8

1 5

5 7 66

COM 1 COM 2

5

1

DE Schnittstelle COM 1 / COM 2

5

GB Interface COM 1 / COM 2

ES Interfaz COM 1 / COM 2

FR Interface COM 1 / COM 2

IT Interfaccia COM 1 / COM 2

PT Interface COM 1 / COM 2

NL Interface COM 1 / COM 2

SV Gränssnitt COM 1 / COM 2

WFV 60A

6

DE Zustandsanzeige

GB Status indication

ES Indicación del estado

FR Indication d'état

IT Indicatore di stato

PT Indicação de status

NL Statusweergave

SV Statusvisning

DATA LOGGER (DL) aktiv

DE

7

8

DATA LOGGER (DL) active

GB

DATA LOGGER (DL) activo

ES

DATA LOGGER (DL) actif

FR

DATA LOGGER (DL) attivo

IT

REGISTO DE DADOS (DL)

PT

activo

DATA LOGGER (DL) actief

NL

DATA LOGGER (DL) aktiv

SV

DATA LOGGER (DL) aktiv

DK

2 CH 1, 2, 3

Indikator Schaltausgang

DE

Switching output indicator

GB

Indicador salida de conexión

ES

Indicateur sortie de commutation

FR

Indicatore uscita di commuta-

IT

zione

Indicador da saída de comu-

PT

tação

Indicator schakeluitgang

NL

DK Interface COM 1 / COM 2

FI Liittymä COM 1 / COM 2

GR Θύρα διεπαφής COM 1/ COM 2

TR Arabirim COM 1 / COM 2

CZ Rozhraní COM 1 / COM 2

PL Interfejs COM 1 / COM 2

HU Interfész COM 1 / COM 2

SK Rozhranie COM 1 / COM 2

DK Statusindikator

FI Tilanneilmaisin

GR Ενδειξη προόδου

TR Durum göstergesidir

CZ Zobrazení stavu

PL Wyświetlacz stanu

HU Állapot kijelző

SK Zobrazenie stavu

DATA LOGGER (DL) aktivoitu

FI

DATA LOGGER (DL) ενεργό

GR

VERİ GÜNLÜKLEYİCİ (DL) aktif

TR

DATA LOGGER (DL) aktivní

CZ

DATA LOGGER (DL) aktywny

PL

DATA LOGGER (DL - adatnap-

HU

lózás) aktív

DATA LOGGER (DL) aktívny

SK

DATA LOGGER (DL) je aktiviran

SL

DATA LOGGER (DL) on aktiivne

EE

Indikator kopplingsutgång

SV

Indikator koblingsudgang

DK

Kytkentälähdön ilmaisin

FI

Δείκτης επαφής εξόδου

GR

Devre çıkışı göstergesi

TR

Indikátor spínacího výstupu

CZ

Wskaźnik wyjścia

PL

przełączającego

Kapcsolókimenet indikátor

HU

Indikátor spínacieho výstupu

SK

SL Vmesnik COM 1 / COM 2

EE Liides COM 1 / COM 2

LV Saskarne COM 1 / COM 2

LT Sąsaja COM 1 / COM 2

BG Интерфейс COM 1 / COM 2

RO Interfaţă COM 1 / COM 2

HR Sučelje COM 1 / COM 2

RU Интерфейс COM 1 / COM 2

SL Prikaz stanja

EE Olekuekraan

LV Stāvokļa displejs

LT Būklės indikatorius

BG Индикация на състоянието

RO Aşajul de stare

HR Prikaz stanja

RU Индикация состояния

DATU REĢISTRĒTĀJS (DR) ir

LV

ieslēgts

Aktyvintas duomenų registravi-

LT

mo įtaisas DATA LOGGER (DL)

DATA LOGGER (DL) активна

BG

DATA LOGGER (DL) activ

RO

DATA LOGGER (DL) aktiviran

HR

РЕГИСТРАТОР ДАННЫХ

RU

(РД) активирован

Indikator izhoda

SL

Lülitusväljundi indikaator

EE

Slēguma izejas indikators

LV

LT Indikatoriaus jungimo išvadas

BG Включване индикатор изход

RO Indicator ieşire de comutare

HR Indikator prekidača za izlaz

Индикатор коммутируемого

RU

выхода

9

For your safety

Thank you for the condence you have shown in

buying this device.

The device has been manufactured in accordance

with the most rigorous quality standards which ensure that it operates perfectly.

Read these instructions and the

accompanying safety information

carefully before starting up the device

and starting work with the device.

Keep these instructions in a place that is accessible to all users.

Safety information

For safety reasons, children

and youths under the age of 16,

as well as persons who are not

familiar with these operating inst-

ructions, may not use the device.

Children should be supervised in

order to ensure that they do not

play with the tool.

Warning! Electrical shock

Connecting the control unit incorrectly poses a risk of injury due to electric shock and

can damage the device.

Carefully read the attached safety information, the safety information accompanying these

operating instructions as well as the operating instructions for your control unit before putting

the control unit into operation and observe the safety precautions specied therein.

Only connect WELLER WX tools.

Never use the USB port as a power supply for third-party devices.

If the device is faulty, active electrical conductors may be bare or the PE conductor

may not be functional.

Repairs must always be referred to a Weller-trained specialist.

If the electrical tool‘s power supply cord is damaged, this must be replaced with a specially

prefabricated power supply cord available through the customer service organisation.

These instructions contain important information

which will help you to start up, operate and service

the device safely and correctly as well as to eliminate

simple faults and malfunctions yourselves.

The device has been manufactured in accordance

with state-of-the-art technology and acknowledged regulations concerning safety.

There is nevertheless the risk of personal injury and

damage to property if you fail to observe the safety

information set out in the accompanying booklet and

the warnings given in these instructions.

This device is not intended

for use by persons (including

children) with limited physical,

sensory or mental aptitude, or

by persons who lack knowledge

or experience in handling the

device.

EN

Warning! Risk of burns

Risk of burns from the soldering tool while the control unit is operating. Tools may

still be hot long after they have been switched off.

Always place the soldering tool in the safety rest while not in use.

Only connect the vacuum and hot air at the designated points.

Do not direct hot air soldering tools at people or inammable objects.

35

For your safety

Warning! Fire and explosion hazard!

Hot tools represent a re hazard

EN

Specied Conditions Of Use

Always place the soldering tool in the safety rest while not in use.

Do not direct hot air soldering tools at people or inammable objects.

Keep explosive and ammable objects well away from the device.

Do not cover the device.

Supply unit for WELLER WX soldering tools.

Use the repair station only for the purpose indica-

ted in the operating instructions of soldering and

desoldering under the conditions specied herein.

Flammable gases and liquids may not

be extracted.

The device may only be used with

correctly tted and suitable lter

cartridges.

Replace lter cartridges when full.

Only use the device indoors. Protect against mois-

ture and direct sunlight.

Intended use of the soldering station/ desoldering

station also includes the requirement that you

adhere to these instructions,

observe all other accompanying documents,

comply with national accident prevention

guidelines applicable at the place of use.

The manufacturer will not be liable for unautho-

rised modications to the device.

User groups

Due to differing degrees of risk and potential hazards, several work steps may only be performed by

trained experts.

Work step User groups

Default soldering parameters Specialist personnel with technical training

Replacing electrical replacement parts Electricians

Default maintenance intervals Safety expert

Operation

Filter change

Operation

Filter change

Replacing electrical replacement parts

Non-specialists

Technical trainees under the guidance and supervision

of a trained expert

36

For your safety

Starting up the device

Caution!

Please adhere to the operating instructions of

the connected devices.

Put the tool into operation as described in the

chapter „Placing into operation“.

Check to see if the mains voltage matches the ratings on the nameplate.

Soldering and desoldering

Carry out soldering work as directed in the operating instructions of your connected soldering tool.

Handling the soldering tips

Coat the selective and tinnable soldering tip with

solder when heating it up for the rst time. This

removes oxide coatings which have formed

during storage and impurities from the soldering

tip.

Make sure that the soldering tip is well coated

with solder during breaks between soldering work

and prior to storage of the device.

Do not use aggressive uxing agents.

Always make sure that the soldering tips are

tted properly.

Select as low a working temperature as possible.

Select the largest possible soldering tip shape for

the application.

Rule of thumb: the soldering tip should be roughly

as large as the soldering pad.

Coat the soldering tip well with solder to ensure

Make sure the machine is switched off before

plugging in.

After switching on the device, the microprocessor

carries out a self- test and reads out the values of

the parameters stored in the tool.

The set-point temperature and xed temperatures

are stored in the tool. The actual temperature

value increases to the set-point temperature (=

soldering tool is heated up).

that there is efcient heat transfer between the

soldering tip and the soldering area.

Prior to extended breaks between soldering work,

switch off the soldering system or use the Weller

function to reduce the temperature when the

soldering equipment is not in use.

Coat the tip with solder prior to storage if you do

not intend to use the soldering iron for an

extended period of time.

Apply solder directly to the soldering area, not to

the soldering tip.

Change the soldering tips using the designated

tool.

Do not apply mechanical force to the soldering

tip.

Notice

The control units have been adapted to hold a

medium-sized soldering tip. Discrepancies may

occur if the tip is changed or a different shaped

tip is used.

EN

Overload cut-out

To avoid overloading the station, power output is

automatically reduced in the event of an overload.

37

For your safety

Equipotential bonding

EN

a

b

c

d

Carrying out a rmware update

Notice

The station must not be switched off while the

rmware update is running.

Care and maintenance

Warning!

Before doing any work on the machine, pull the plug out of the socket.

Warning!

Use original replacement parts only.

Warning! Risk of burns

Only replace solder tips when cold

Replace and clean suction nozzles

only when hot and using the suitable

tool

Only replace hot air nozzles using

the suitable tool

Only clean or replace solder

collection tubes when cold

Four variants are possible by connecting the 3.5 mm jack socket

differently:

a Hard-grounded supplied without plug.

b Equipotential

bonding

c Floating with plug

d Soft-grounded with plug and soldered resistor. Ground-

Switch off station 1.

2. Insert the memory stick into the USB port.

Switch on station 3.

The rmware update is performed automatically.

If you have a more already installed more recent

rmware on your station, this will not be changed.

Clean the operator panel, if dirty, using a suitable

cleaning cloth.

Filter change

To ensure that the ltration system functions properly, the lter must be replaced as follows

with plug, equaliser at centre contact.

ed through selected resistor.

at least once a year or

when indicated or

as per maintenance schedule

Contaminated lters must be treated as special

waste.

Dispose of replaced equipment parts, lters

or old devices in accordance with the rules

and regulations applicable in your country.

Wear suitable protective gear.

38

Parameter menu

Standby Temp. Menu access Tool parameters

The soldering tools have a usage detection device

(sensor) in the handle which automatically initiates

cooling to Standby temperature when the solde-

ring tool is not in use.

Standby time (temperature deactivation) Menu access Tool parameters

When the soldering tool is not in use, the tem-

perature is reduced to Standby temperature on

expiration of the set Standby time. The display

reads „Standby“.

Press control key to exit Standby mode. The

sensor integrated tool detects the change in state

and deactivates Standby mode as soon as the tool

is moved.

Option Description

OFF standby time is deactivated (factory

setting)

1-999 min standby time, individually adjustable

--- The tool is not supported

AUTO OFF time (automatic switch-off time) Menu access Tool parameters

When the soldering tool is not in use, the soldering

tool heater is switched off when the AUTO OFF

time expires.

Temperature deactivation is performed indepen-

dently of the set standby function. The actual

temperature is indicated and serves as a residual

heat display. The display reads „AUTO OFF“.

Option Description

OFF AUTO OFF function is deactivated

(factory setting)

1-999 min AUTO-OFF time, can be set indivi-

dually.

Sensitivity Menu access Tool parameters

Option Description

low Non-sensitive – Reacts to heavy (long) movement

normal standard (factory setting)

high Sensitive - Reacts to light (short) movement

--- The tool is not supported

EN

Max. hot air duration WXHAP Menu access Tool parameters

The on-time of the hot air ow of the WXHAP can

be limited in increments of 1 to between 0 and 300

sec. The factory default is 0 s („OFF“), i.e. air ows

only as long as the button on the hot air tool or the

optional footswitch is pressed.

Option Description

OFF No duration dened

(factory setting)

1-300 s Individually adjustable

Offset (Temperature-Offset) Menu access Tool parameters

The actual soldering-tip temperature can be

adapted by entering a temperature offset around ±

40 °C (± 72 °F).

39

Parameter menu

Perform. Mode Menu access Tool parameters

The function determines the heating characteris-

EN

tics of the soldering tool to achieve the set tool

temperature.

Option Description

standard adapted (medium) heating (factory

setting)

min. slow heating

max. rapid heating

Button lock WXHAP Menu access Tool parameters

This function can be used to adjust the factory

button presets of the WXAHP tool.

Option Description

OFF –

ON The WXHAP is switched on the rst

time the button is pressed and switched

off the next time the button is pressed.

Process window Menu access Tool parameters

The temperature range set in the process window

determines the signal response of the oating

switching output.

Notice

On tools with an LED ring light (e.g. WXDP 120),

the process window denes the illumination

characteristics of the LED ring light.

If the LED is continuously illuminated, this means

that the preselected temperature has been

reached or that the temperature is within the

predetermined process window.

A ashing LED indicates that the system is

heated or that the temperature is outside the

process window.

Language Menu access Station parameters

CHN

中文

DEN Dansk

ENG English

ESP Español

FIN Suomi

FRA Français

GER Deutsch

HUN Magyar

ITA Italiano

POR Português

RUS Pусский

SWE Svenska

TUR Türkçe

JPN

日本語

POL Polski

KOR

CZE Český

한국말

Temperature version °C/°F (temperature units) Menu access Station parameters

Option Description

° C Celsius

° F Fahrenheit

40

Parameter menu

Password (lock function) Menu access Station parameters

After switching the lock function on, only the xed

temperature keys can be operated on the solde-

ring station. All other settings are disabled until the

repair station is unlocked again.

Notice

If you want only one temperature value to be

selectable, the control keys xed temperature

keys) must be set to the same temperature value.

Locking the soldering station

Set the desired three-digit locking code (between

001 and 999) using the UP / DOWN buttons.

Conrm the code with the Enter key.

The lock is active (the display shows a lock

symbol).

Unlocking the soldering station

1. Call up the parameter menu. If the lock function

is active, the password menu item opens

automatically. Three stars (***) are shown on

the display.

2. Set the three-digit locking code using the UP /

DOWN buttons.

3. Conrm the code with the Enter key.

Forgotten code?

Please contact our Customer

Service: technical-service@

weller-tools.com

Single-channel display Menu access Station parameters

To obtain more straightforward readings, the

display mode from can switched from 3-channel

display to 1-channel display.

If single-channel display is selected, the device

does not reset automatically to 3-channel display

after setting the temperature of a tool channel.

The display mode can be reset using ┌ 2 ┐.

Option Description

OFF Automatic reset to 3-channel display

(factory setting)

ON No automatic reset to 3-channel

display

Vacuum pre-feed Menu access Station parameters

In order to prevent the pump from starting pre-

maturely or to ensure a dened soldering-joint

preheating time, it is possible to set an ON delay.

Option Description

0 sec OFF: vacuum pre-feed function is

OFF (factory setting)

1-10 sec ON: vacuum pre-feed time, indivi-

dually

EN

Vacuum run-on Menu access Station parameters

To prevent the desoldering iron from becoming

clogged, it is possible to set a vacuum run-on time.

Option Description

0 sec OFF: vacuum run-on function is OFF

(factory setting)

1-10 sec ON: vacuum run-on time, individually

adjustable

41

Parameter menu

Pressure gauge threshold Menu access Station parameters

This function can be used to dene the mainte-

EN

nance interval of the desoldering tool. This is done

by setting the value in mbar at which the electric

pressure gauge issues a warning signal when the

intake system is contaminated (LED of the vacuum

pump switches from green to red). The set value is

dependent on the suction nozzles used.

Adjustable -400 mbar to -800 mbar

factory setting -600 mbar

1. The system (tips and lter) must be free.

2. Select the menu item „Pressure gauge

threshold“ in the menu.

3. Set the „Pressure gauge threshold“ pressure

value with the UP or DOWN button. The status

LED switches back and forth between red and

green. Use the UP button to increase vacuum

by 50 to 80 mbar, then pinch the vacuum tube

and check whether the LED switches from

green to red.

4. Adopting the set change.

Interface COM 1 / 2 Menu access Station parameters

Option Description

RS232 Serial communication with PC or other compatible Weller devices (factory setting).

Air The COM 1 port is congured as a foot switch input for activating the air ow.

Vac The COM 1 port is congured as a foot switch input for activating the vacuum.

PickUp The COM 1 port is congured as a foot switch input for activating the PickUp vacuum.

Stop&Go The COM 1 port is used to drive an optional optotransmitter so that a KHE-P control

unit can be activated via an optical bre.

The output is activated when a tool is used. In addition, the oating switched output is

closed. The output is off in the Standby, Auto Off or Off positions, or if no tool is inserted.

Floating switching output 1 Menu access Station parameters

Floating switching output 1 is located at the COM 1 port.

Option Description

OFF (factory setting)

ZeroSmog The oating switching output is closed when a tool is in use. Selected Zero Smog

extraction systems can be connected using an optional adaptor (WX HUB). The rear

RS 232 port remains functional.

Switching output is open in the Standby, Auto Off or Off positions, or if no tool is inser-

ted.

42

Notice

If the COM 1 port is also congured for „Stop&Go“ use, the „Filter full“

message is evaluated by the WX HUB and, where applicable, a

message appears on the display .

Parameter menu

Floating switching output 2 Menu access Station parameters

Floating switching output 2 is located at the COM 2 port.

Option Description

OFF (factory setting)

CH 1 Tool channel 1 controls the switching output

CH 1+2 Tool channel 1 + 2 controls the switching output

CH 1+2+3 Tool channel 1 + 2 + 3 controls the switching output

Notice

If the robot is at working temperature, the display will show – ok –.

Technical Data

Repair station WXR 3

Dimensions L x W x H 273 x 235 x 102 mm

(10,75 x 9,25 x 4,02 inch)

Weight ca. 6,7 kg

Mains supply voltage 230 V, 50 Hz T0053500699

120 V, 60 Hz WXR 3

100 V 50/60 Hz T0053500199

Power consumption 420 W (600 W)

Safety class I, antistatic housing

Fuse Overcurrent release 230 V; 2,0 A

Temperature range Celsius: 100 - 450°C (550°C)

Temperature accuracy ± 9 °C (± 17 °F) Tool dependent (WXHAP ±30 °C / ±80 °F)

Temperature stability ± 2 °C (± 4 °F)

Equipotential bonding Via 3.5 mm pawl socket on back of unit

Display 240 x 88 dots / Backlighting

USB port The control unit comes with a front-side USB port for installing rmware

Pump (Intermittent mode

(30/30) s)

Additional vacuum pump Max. vacuum0,5 bar

III, Soldering tool

120 V; 4,0 A

Fahrenheit: 200 - 850°F (999°F)

Controllable temperature range is tool-dependent

updates, conguration and monitoring.

Max. vacuum 0,7 bar

Max. delivery rate 18 l/min

Max. hot air 15 l/min

Max. delivery rate 1,7 l/min

EN

43

Error messages and error clearance

Message/symptom Possible cause Remedial measures

EN

Display: „- - -

No display function (display

OFF)

No vacuum at desoldering tool

Insufcient vacuum at desolde-

ring tool

Hot air tool has no air

Tool has not been detected

Tool defective

No mains supply voltage Turn on mains power switch

Vacuum not connected

Desoldering nozzle clogged

Pump faulty

Filter cartridge on desoldering

tool full

Main lter full

Air hose not connected

Main lter full

Check connection of tool to

device

Check connected tool

Check mains supply voltage

Check device fuse

Connect vacuum hose to

vacuum connection

Service desoldering nozzle

using cleaning tool

Change lter cartridge on

desoldering tool full

Change the main lter element

on the soldering station

Connect or check air hose

Change main lter cartridge on

soldering station

Symbols

Caution!

Soldering

Read the operating instructions!

44

Before performing work of any kind

on the unit, always disconnect the

power plug from the socket.

ESD-compatible design and ESDcompatible workstation

Equipotential bonding

CE mark of conformity

Fuse

Safety transformer

Desoldering

Hot air

Disposal

Do not dispose of electric tools together

with household waste material! In

observance of European Directive

2012/19/EU on waste electrical and

electronic equipment and its implementation in accordance with national law,

electric tools that have reached the end

of their life must be collected separately

and returned to an environmentally

compatible recycling facility.

Dispose of replaced equipment parts,

lters or old devices in accordance with

the rules and regulations applicable in

your country.

Original declaration of conformity

Repair station WXR 3

Tool WXHAP 200, WXDP 120, WXDV 120, WXP 65, WXP 120,

We hereby declare that the products described herein comply with the following guidelines:

2011/65/EU (RoHS), 2004/108/EG, 2006/42/EG

Applied harmonised standards:

DIN EN 55014-1: 2012-05 DIN EN 60335-1: 2012-10

DIN EN 55014-2: 2009-06 DIN EN 60335-2-45: 2012-08

DIN EN 61000-3-2: 2010-03 / 2011-06 DIN EN 62233: 2008-11 / 2009-04

DIN EN 61000-3-3: 2014-03 DIN EN 50581:2013-02

Besigheim, 2014-07-18

T. Fischer S. Hofmann

Technical director Managing director

Authorised to compile technical documentation.

Weller Tools GmbH

Carl-Benz-Straße 2, 74354 Besigheim, Germany

WXP 200, WXMP, WXMT, WXSB 200, WXHP 120

Warranty

Claims by the buyer for physical defects are timebarred after a period of one year from delivery to

the buyer. This does not apply to claims by the

buyer for indemnication in accordance with §§

478, 479 BGB (German Federal Law Gazette).

We shall only be liable for claims arising from a

warranty furnished by us if the quality or durability

warranty has been furnished by use in writing and

using the term „Warranty“.

The warranty shall be void if damage is due to improper use and if the device has been tampered with by

unauthorised persons.

Subject to technical alterations and amendments.

For more information please visit www.weller-tools.

com.

EN

45

T0055735700 / 06.2014

GERMANY

Weller Tools GmbH

Carl-Benz-Straße 2

74354 Besigheim

Tel: +49 (0)7143 580-0

Fax: +49 (0)7143 580-108

GREAT BRITAIN

Apex Tool Group (UK Operations) Ltd

4th Floor Pennine House

Washington, Tyne & Wear

NE37 1LY

Tel: +44 (0) 191 419 7700

Fax: +44 (0) 191 417 9421

FRANCE

Apex Tool Group S.N.C.

25 Avenue Maurice Chevalier B.P. 46

77832 Ozoir-la-Ferrière Cedex

Tel: +33 (0) 1.64.43.22.00

Fax: +33 (0) 1.64.43.21.62

ITALY

Apex Tool S.r.l.

Viale Europa 80

20090 Cusago (MI)

Tel: +39 (02)9033101

Fax: +39 (02)90394231

SWEDEN

Apex Tool Group AB

William Gibsons väg 1A

43376 Jonsered

Tel: +46 (0) 31 725 64 39

Fax: +46 (0) 31 725 64 38

CHINA

Apex Tool Group

A-8 building

No. 38 Dongsheng Road

Heqing Industrial Park, Pudong

Shanghai 201201

Tel: +86 (21)60880288

Fax: +86 (21)60880289

USA

Apex Tool Group, LLC

14600 York Rd. Suite A

Sparks, MD 21152

Tel: +1 (800)688-8949

Fax: +1 (800)234-0472

CANADA

Apex Tools – Canada

5925 McLaughlin Rd.

Mississauga, Ontario L5R 1B8

Tel. +1 (905) 501-4785

Fax. +1 (905) 387-2640

AUSTRALIA

Ap ex To ols

P.O. Box 366

519 Nurigong Street

Albury, N.S.W. 2640

Australia

Tel: +61 (2)6058-0300

Fax: +61 (2)6021-7403

www.weller-tools.com

© 2014, Apex Tool Group, LLC.

Weller® is a registered Trademark and registered Design of Apex Tool Group, LLC.

Loading...

Loading...