Page 1

Service Manual

Patient Monitor

Service Manual

Welch Allyn

Vital Signs Monitor

Medical Division

4341 State Street Road, P.O. Box 220

Skaneateles Falls, NY 13153-0220

PN 95P360E

Copyright 1996

Page 2

Page 3

Welch Allyn Vital Signs Monitor Service Manual

SECTION 1:

General Information

Revision 4.0

Page 4

Page 5

SERVICE MANUAL

Welch Allyn

Vital Signs Monitor

Copyright 1996

Welch Allyn Co.

4341 State Street Road Service Manual pn95P360E

Skaneateles Falls, NY 13153-0220 Rev. 4, 9/98

Page 6

Page 7

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

*Note: All drawings enclosed are for reference only. Consult the system or the factory for all current drawings.

Revision History

Revision Sections Date Author Description

1.00 All 4/18/96 JDB/RJS Introduction of manual.

2.00 All 7/9/96 JDB Revision made due to

problems found in training

and changes to the repair

software.

3.00 All 5/28/97 JDB Revisions made for

support of Nellcor SpO

module.

4.00 All 10/1/98 JDB Added schematics, board

layouts and bill of

materials, miscellaneous

corrections.

2

Page 8

Page 9

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Table Of Contents

SECTION 1: General Information Sub-Section: Page:

To Service Personnel................................................ 1.1 1

Limited Warranty/Warranty Assistance ..................... 1.2 3-4

Basic System Description.......................................... 1.3 5

Basic System Operation Index .................................. 1.4 7

Basic System Operation............................................ 1.4 8-14

Block Diagram of Unit Operation............................... 1.5 16-17

Specifications ............................................................ 1.6 19-23

Serial numbering system defined.............................. 1.7 25

Firmware Identification .............................................. 1.8 27

SECTION 2: Service Set Up

Service Manual Intent & Scope ................................. 2.1 1

Test Equipment Bench Layout .................................. Fig 2.2.1 3-4

Required Tools/Equipment List ................................. 2.2.2 5

Replacement Parts List ............................................. 2.3 7-9

Maintenance/Service Support ................................... 2.4 11

SECTION 3: Problem Diagnosis

Overview ................................................................... 3.1 1

Diagnostic Process/Returned units ........................... 3.2 3-5

When and how to calibrate........................................ 3.3 7-8

Loading Unit Software............................................... 3.4 9

Welch Allyn Monitor Self Diagnostic Fault Codes ..... 3.5 11-13

“Complaint/Cause/Corrective Action” ........................ 3.6 15-19

SECTION 4: Major Component Removal/Replacement

(IN ORDER OF REMOVAL ACCESS)

Front Housing............................................................ 4.1 1-2

Main Fuse F1 on Main PCB ...................................... 4.2 3-4

Main Printed Circuit Board (PCB).............................. 4.3 5-6

DC TO DC Converter (SpO

Pressure Transducer on Main PCB........................... 4.5 9-10

Display PCB .............................................................. 4.6 11-12

Key Pad (front housing)............................................. 4.7 13-14

Temperature PCB ..................................................... 4.8 15-16

Specific Oxygen Board (Nonin) ................................. 4.9 17-19

Specific Oxygen Board (Nellcor) ............................... 4.10 21-22

Pump ......................................................................... 4.11 23-24

Pressure Switch MPL-503......................................... 4.12 25-26

Valve (Pneutronics) ................................................... 4.13 27-28

Printer/Printer PCB/keypad ....................................... 4.14 29-30

Battery ....................................................................... 4.15 31-32

units) ............................ 4.4 7-8

2

Page 10

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

SECTION 5: Test Procedures Sub-Section: Page:

Calibration test.......................................................... 5.1 1-2

Current tests............................................................. 5.2 3

Noise test.................................................................. 5.3 5

Button Test ............................................................... 5.4 7

Print quality............................................................... 5.5 9

Pneumatic test.......................................................... 5.6 11-12

Hardware Fail-safe Tests ......................................... 5.7 13

option testing................................................... 5.8 15

SpO

2

Temperature option testing....................................... 5.9 17

Check List for CBPM Service Work.......................... 5.10 19-20

SECTION 6: Drawings, Schematics, Board Layouts, Bill of Materials

SECTION 7: Repair Test Specifications

Specifications ........................................................... 7.1 1-5

CAUTION: PRIOR TO DOING REPAIR WORK, USE GROUNDING MAT AND

ANTI-ST A TIC WRIST STRAP T O MINIMIZE RISK OF DAMA GE T O SENSITIVE

ELECTRONIC COMPONENTS .

Page 11

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

1.1 To Service Personnel:

Read and understand the Welch Allyn Vital Signs Monitor Operator Manual and this Service

Manual. The information contained in both of these publications is subject to change without

notice and should not be construed as a commitment by Welch Allyn, Inc.

Welch Allyn assumes no responsibility for any errors that may appear in this manual. If the

product and/or its operation varies significantly from any description herein, please contact the

WELCH ALLYN TECHNICAL SERVICE DEPARTMENT:

1-800-450-9275

(828) 684-4895

Fax (828)687-9323

Welch Allyn, Inc.

95 Old Shoals Road

Arden, North Carolina 28704

This product has been designed to provide a high degree of safety and reliability. However, we

can not guarantee against: deterioration of components due to aging, normal wear, tampering,

and abuse.

Section 1: General Information

All service and repairs must be performed by authorized Welch Allyn personnel or agents, using

approved Welch Allyn replacement parts and approved process materials. Failure to so will

invalidate the product warranty. Please refer to the product warranty for specific coverage.

Welch Allyn, Inc.

95 Old Shoals Road

Arden, North Carolina 28704

USA

1 800 450-9275

CAUTION WHEN USING ADHESIVES:

ALWAYS WEAR SAFETY GLASSES AND PROVIDE ADEQUATE VENTILATION WHEN USING

ADHESIVES, THEIR ACCELERATORS AND RTV SEALANTS. READ, UNDERSTAND, AND COMPLY

WITH SAFETY RECOMMENDATIONS IN THE MATERIAL SAFETY DATA SHEET MSDS) FOR THESE

MATERIALS. SUPER-GLUES (CA ADHESIVES) CAN CAUSE CORNEAL DAMAGE IF ACCIDENTLY

SQUIRTED IN THE EYES, AND CAN SPONTANEOUSLY COMBUST IF SPILLAGE IS WIPED UP WITH

CLOTH OR PAPER TISSUES. READ THE WARNINGS AND CAUTIONS PRINTED ON THE BOTTLES OR

TUBES OF THESE GLUES!

1

Page 12

Page 13

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

1.2 Limited Warranty

Welch Allyn warrants the Welch Allyn Vital Signs Monitor, when new, to be free

of defects in material and workmanship and to perform in accordance with

manufacturer’s specifications for a period of two years from the date of purchase

from Welch Allyn or its authorized distributors or agents. Welch Allyn will either

repair or replace any components found to be defective or at variance from

manufacturer’s specifications within this time at no cost to the customer. It shall

be the purchaser’s responsibility to return the instrument to Welch Allyn or an

authorized distributor, agent or service representative. This warranty does not

include breakage or failure due to tampering, misuse, neglect, accidents, modification or shipping. This warranty is also void if the instrument is not used in

accordance with manufacturer’s recommendations or if repaired by other than

Welch Allyn or an authorized agent. Purchase date determines warranty requirements. No other express warranty is given.

Section 1: General Information

To receive service assistance or to ask questions regarding this warranty, please call or write:

Welch Allyn Technical Services Dept.

95 Old Shoals Road

Arden, North Carolina 28704 USA

1 (800) 450-9275 or (828) 684-4895

Fax: (828) 687-9323

Service Policy

All repairs on products under warranty must be performed or approved by a Welch Allyn

Service Center.

should be repaired by qualified electronics personnel or a Welch Allyn Service Center.

Unauthorized repairs will void the warranty

. Products out of warranty

Technical Assistance

If you have an equipment problem that you cannot resolve, call the Welch Allyn Service

Center nearest you for assistance. Technical service support is available to you by telephone on normal business days, from 8:30AM until 4:30PM Eastern Standard Time at the

phone numbers listed on the next page.

3

Page 14

Section 1: General Information

Before returning a product for repair you must obtain authorization from Welch

Allyn. An RGA (Return Goods Authorization) number will be given to you by our

service personnel. Be sure to note this number on the outside of your shipping

box. Returns without an RGA number will not be accepted for delivery.

Welch Allyn Vital Signs Monitor Service Manual

Revision

Welch Allyn Service Centers

For Service or Repair

4.0

USA Customers

Welch Allyn, Inc.

Technical Service Centers

95 Old Shoals

Arden, NC 28704-9739 USA

Phone: 828-684-4895

Fax: 828-687-9323

Welch Allyn

Technical Service Center

Zollerstrasse 2-4 Road

D-7241 7 Jungingen

GERMANY

Phone: [49]-7477-9271-73

Fax: [49]-7477-9271-93

Welch Allyn Ltd.

21-09 Golden

Beach Road

Singapore 199589

REPUBLIC OF SINGAPORE

Phone:

Fax: [65]-291-5780

[65]-29

Road

GmbH

Mile to 6001

l-0882

CANADA Customers

Welch Allyn Canada Limited

Technical Service Centers

160 Matheson Blvd., East

Mississauga, Ontario

Ph: 905-890-0004 or 1 800-561-8797

Fax: 905-890-0008

INTERNATIONAL Customers

Welch Allyn Australia Pty. Ltd.

Technical Service Center

Ground Floor, 18-20

Lane Cove

AUSTRALIA

Phone: [61]-29-4183-155

Fax: [61]-29-4183-650

NSW 2066

L4Z1

Orian

V4 CANADA

Road

MDI International

Technical Service Centers

7324 SW 48th Street

Miami, FL 33155 USA

Phone: 305-669-9591

Fax: 305-669-l 971

4

LATIN AMERICA Customers

Welch Allyn

\N!!

Page 15

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 1: General Information

1.3 Basic System Description

Introduction

The Welch Allyn Vital Signs Monitor is designed to non-invasively and

automatically measure systolic and diastolic pressure, pulse rate, temperature and oxygen saturation (SpO

sure, pulse, temperature and

read displays, and may be printed via an integrated thermal printer, as

desired.

The rechargeable battery and wide variety of mounting accessories make

the Clinical Monitor convenient for many locations. The operator may

choose any combination of simultaneous measurement modalities. This

flexibility, combined with features such as programmable alarms and automatic BP cycles, makes the Clinical Monitor ideal for a wide variety of patient monitoring needs.

) for adult and pediatric patients. All pres-

2

SpO2 values are displayed on large, easy-to-

Refer to the Operator Manual PART NUMBER 5200-85 (SPECIFY LANGUAGE) Section 1 for complete information on Indications For Use, Special

Features, Supplies and Accessories

5

Page 16

Page 17

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 1: General Information

1.4 Basic System Operation

INDEX

1.5.1 Blood Pressure Operating Modes

a. Max/Min Blood Pressure and Pulse Ranges

b. Blood Pressure Manual Mode

c. Blood Pressure Auto Mode

1.5.2 Temperature Operating Modes

a. Max/Min Temperature Ranges

b. Temperature Normal Mode

c. Temperature Monitor Mode

1.5.3 SpO

Operating Mode

2

a. Max/Min SpO

b. SpO

Monitor Mode

2

1.5.4 Pulse Rate Feature

Max/Min Pulse Rate Ranges

Ranges

2

7

Page 18

Section 1: General Information

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

1.4.1 Blood Pressure Operating Modes

When a blood pressure measurement cycle is initiated, the cuff will automatically be

inflated to the operator selected pressure level.

The cuff will immediately begin to deflate in a stepped fashion and will determine systolic

pressure and diastolic pressure from the pulses sensed by the cuff at various pressure

levels. This is the oscillometric method of non-invasive blood pressure monitoring.

Blood pressure measurements may be initiated manually, or automatically at time intervals determined by the user.

At the completion of a measurement cycle the systolic and diastolic pressures are displayed. If the Monitor is in Automatic Mode, the measured values are kept on display until

the next BP measurement is initiated. When not in Automatic Mode, the measured values are displayed for two minutes, after which time the display screen is blanked. The

most recent BP measurement may be recalled by pressing the REVIEW button.

When in Automatic Mode, if the unit is unable to determine the systolic or diastolic value,

the measurement will be automatically repeated once.

1.4.1.a. Max/Min Blood Pressure Ranges

The maximum and minimum ranges of blood pressure are detailed below:

Measurement Maximum Minimum

Systolic Pressure 250 mmHg 60 mmHg

Diastolic Pressure 160 mmHg 30 mmHg

8

Page 19

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 1: General Information

1.4.1.b. Blood Pressure Manual Mode

In the Manual Mode, a single blood pressure determination is made only when the

START button is pushed. The manual mode is the default mode of operation for blood

pressure determinations.

A measurement cycle may be canceled at any time by pressing the CANCEL button.

This action immediately initiates a rapid cuff deflation.

The blood pressure measurement data will appear on the display immediately following

the measurement. The display will blank after two minutes. If the display is blanked,

pressing the REVIEW button on the front panel will recall the measurement. Up to 99

prior measurements are available for review or printing.

In Blood Pressure Manual Mode, the following alarm limits may be activated; SYSTOLIC

HIGH LIMIT, SYSTOLIC LOW LIMIT, DIASTOLIC HIGH LIMIT, DIASTOLIC LOW LIMIT,

PULSE RATE HIGH LIMIT and PULSE RATE LOW LIMIT. Blood pressure determinations which activate alarms are indicated by flashing displays and a repetitive audible

tone. If an alarm limit is violated, subsequent blood pressure determinations may be

made only after the alarm condition is reset by pressing any button on the Monitor’s

display.

1.4.1.c. Blood Pressure Automatic Mode

The Automatic Blood Pressure Mode is entered by pressing the AUTO button. Pressing

the AUTO button displays a choice of 10 cycle interval times as follows: “st” (STAT mode)

3 min, 4 min, 5 min, 10 min, 15 min, 30 min, 45 min, 60 min and 90 min. These choices

represent the time interval from the beginning of one cycle to the beginning of the next

automatic cycle. STAT mode allows the monitor to take continuous blood pressure measurements for 15 minutes. In addition, the operator may choose to disable the Auto Mode

by choosing “—” (two dashes).

A measurement cycle may be canceled at any time by pressing the CANCEL button.

This action immediately initiates a rapid cuff deflation.

The blood pressure measurement data will appear on the display immediately following

the measurement and will remain displayed until the next measurement cycle is initiated.

9

Page 20

Section 1: General Information

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

1.4.1.c. Blood Pressure Automatic Mode continued

In Blood Pressure Auto Mode, the following alarm limits may be activated; SYSTOLIC

HIGH LIMIT, SYSTOLIC LOW LIMIT, DIASTOLIC HIGH LIMIT, DIASTOLIC LOW LIMIT,

PULSE RATE HIGH LIMIT and PULSE RATE LOW LIMIT. Blood pressure determinations which activate alarms are indicated by flashing displays and a repetitive audible

tone. Any alarm limit violation

sure determinations. The alarm may be reset by pressing any button on the monitor’s

display.

must be reset to continue automatically timed blood pres-

1.4.2. Temperature Operating Modes

Thermistor Thermometry measurements are made with the DIATEK/Welch Allyn

SureTemp4TM thermometer. Oral and rectal probes utilize single-use disposable probe

covers which limit cross-contamination. Oral or rectal temperatures are taken using

‘Normal’ or ‘Monitor’ operating modes. Auxiliary temperatures may be taken using the

oral probe in the monitor operating mode.

In the normal mode the thermometer’s microprocessor “predicts” body temperature in

about 4 seconds for oral temperatures and in about 15 seconds for rectal temperatures.

The monitor mode displays the patient’s actual temperature after 3 minutes and will

continue to display an updated temperature as long as the probe remains in place.

Temperature readings may be displayed in Fahrenheit or Celsius scales.

1.4.2.a. Max/Min T emperature Ranges

Readings Normal Mode Monitor Mode

Temperature Max 108.0F Max 108.0F

Max 42.2C Max 42.2C

Min 84.0F Min 84.0F

Min 28.9C Min 28.9C

10

Page 21

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 1: General Information

1.4.2.b. T emperature Normal Mode

In Normal Mode, the device will measure temperature at discrete intervals and then

calculate the rate of change according to a known algorithm. This allows the thermometer to predict the end point that the thermistor would reach if it were left in the mouth until

it reached mouth temperature. This predictive

an accurate oral temperature reading in approximately 4 seconds.

Normal mode is the default operating mode for temperature determinations.

Operator selectable patient alarm limits are not available in Temperature Normal

Mode. However, temperatures which are outside of the operating range of the

device will be noted on the temperature display.

feature allows the thermometer to arrive at

1.4.2.c. Temperature Monitor Mode

Continuous Monitor Mode operation is normally used for longer term monitoring and

when difficult situations prevent accurate temperatures from being taken in the normal

mode. The probe must be in contact with tissue for at least three (3) minutes for accurate

temperature measurement. Monitor mode temperatures may not be identical to predicted

‘Normal’ temperatures because of ambient temperature influence and other factors. The

trend in temperature is the important standard to be observed when in the ‘Monitor’ mode.

Operator selectable patient alarm limits are not available in Temperature Normal

Mode. However, temperatures which are outside of the operating range of the

device will be noted on the temperature display.

11

Page 22

Section 1: General Information

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

1.4.3 SpO Operating Mode

2

The Welch Allyn Vital Signs Monitor incorporates either the Nonin® pulse oximetry system

®

or the Nellcor

(% SpO

) by measuring the absorption of red and infrared light passed through the tis-

2

pulse oximetry system which determines arterial oxyhemoglobin saturation

sues. Changes in absorption caused by pulsation of blood in the vascular bed are used

to determine arterial saturation and pulse rate.

Oxygen saturation percent is calculated with each pulse detected, and thus the monitor

display is continually updated. The pulse signal bar graph is an indicator of the strength

and quality of the detected pulses.

When SpO

pulse rate measurement from the SpO

is measured, the patient’s pulse rate is also measured and displayed. A

2

determination overrides a pulse rate measure-

2

ment derived from a blood pressure measurement.

In SpO2 monitoring mode operator selectable alarm limits for low SpO2 % may be acti-

vated. A condition which violates the SpO

low limit alarm is indicated by a flashing

2

display and repetitive audible tone. Should a patient alarm condition for ≤ or pulse rate

occur, the Monitor will indicate an alarm condition (flashing & beeping) while continuing to

monitor and display the patient’s current SpO

%. The alarm will automatically reset when

2

the patient’s condition returns to within the preset alarm parameters.

Should a patient alarm condition for SpO

or pulse rate occur, the operator may invoke

2

“Silence Mode” by pressing the SILENCE button. This will silence the audible tone

(display will continue to flash), while the practitioner attends to the patient and the monitor. Silence mode resets automatically after 30 seconds, or when the patient’s condition

returns to within the preset alarm parameters.

Removal of the SpO

sensor from the patient will initiate an alarm. To reset the sensor

2

alarm, press any button on the monitor’s display.

SpO

is generally measured via pulses detected using a finger sensor. However, for

2

certain situations SpO

may be measured at alternate sites including the earlobe, fore-

2

head and toes. Special sensors must be employed in these situations.

12

Page 23

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 1: General Information

1.4.3.a. Max/Min SpO

Ranges

2

The SpO2 sensor is designed to detect oxygen saturation as follows.

Maximum Minimum

SpO

2

1.4.3.b. SpO

Monitor Mode

2

99% 40%

The SpO2 monitor performs most accurately with the finger clip sensor, which may be

used on all fingers except the thumb. The finger clip sensor is recommended for spot

checks or short term (<30 minutes) continuous monitoring.

The device determines arterial oxyhemoglobin saturation (SpO

%) by measuring the

2

absorption of red and infrared light passed through the tissue. Oxygen saturation and

pulse rate are displayed on the LED digital display. On each detected pulse, the pulse

signal bar graph flashes. The intensity of this signal is a simple visual indicator of waveform signal strength, and can identify situations where the pulsatile nature of the tissue

may not be adequate for an accurate SpO

reading. The update interval of the bar graph

2

should correspond to the patient’s pulse rate. This is an indication of the quality of the

SpO2 signal.

1.4.4 Pulse Rate Feature

The Welch Allyn Vital Signs Monitor is capable of determining pulse rate as an adjunct to

the blood pressure measurement and the SpO

The pulse rate, in beats per minute, will be determined primarily from the SpO

methodology. In the case where SpO

is not available, or is disabled, the pulse rate display

2

will be driven from data collected as part of the blood pressure measurement method.

There are two operator selectable alarm limits for the pulse rate. They are PULSE RATE

HIGH LIMIT and PULSE RATE LOW LIMIT. Pulse rates which activate alarm limits are

indicated by a flashing display and a repetitive audible tone.

Should a pulse rate alarm occur when the pulse rate measurement is derived from the

blood pressure measurement, no subsequent blood pressure or pulse rate measurements

may be made until the alarm is reset. The alarm may be reset by pressing any button on

the monitor’s display.

measurement.

2

measurement

2

13

Page 24

Section 1: General Information

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Should a pulse rate alarm occur when the pulse rate measurement is derived from the

SpO

measurement, the monitor will indicate an alarm condition (flashing & beeping)

2

while continuing to monitor and display the patient’s current SpO

% and pulse rate. The

2

alarm will automatically reset when the patient’s condition returns to within the preset

alarm parameters.

Should a patient alarm condition for pulse rate occur during SpO

monitoring, the opera-

2

tor may invoke “Silence Mode” by pressing the SILENCE button. This will silence the

audible tone (display will continue to flash), while the practitioner attends to the patient

and Monitor. Silence mode resets automatically after 30 seconds, or when the patient’s

condition returns to within the preset alarm parameters.

1.4.4.a. Max/Min Pulse Rate Ranges

The maximum and minimum pulse rate ranges are as follows:

Maximum Minimum

Pulse Rate 200 bpm 40 bpm

14

Page 25

Page 26

Section 1: General Information

Welch Allyn Vital Signs Monitor Service Manual

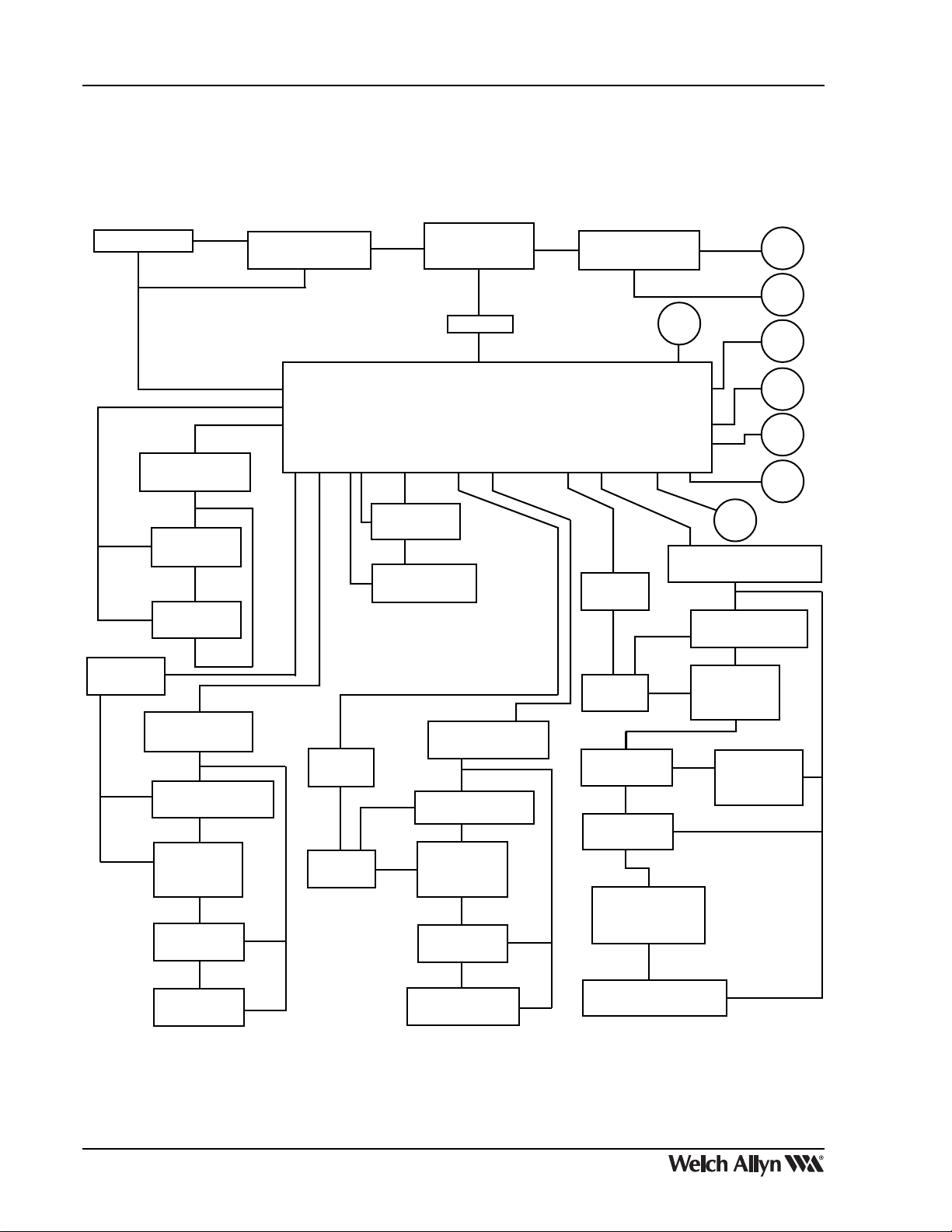

Figure 1.5 Block Diagram of Unit Operation

Revision 4.0

Off

➤

Yes

Yes

Reset

Display?

➤

Yes

➤

Yes

➤

➤

Start Taking

Reading

Is Cancel

Pressed?

No

➤➤➤

Is Reading

Finished?

No

➤

Display Last

Reading

Any button than

review select?

➤➤

No

Is 10 sec.

since last

action?

➤

No

Is Review

Pressed?

Yes

➤

Display

Next RDG?

➤

Is Power Button

➤

➤

➤

No

➤

Pressed?

No

Power

Start

Review

➤

➤

Display

Record

Setting

Reset

➤

Yes

➤

Silence

➤

➤

➤

No

Is Alarm

Activated?

➤

Yes

Silence Alarm

for 30 Seconds

Yes

➤

Yes

➤

Is Start

Button Pressed?

No

➤➤

Post

Ready State

Auto

➤

Display Current

Timer Setting

Any button than

auto select?

Is 10 sec.

since last

action?

Is Auto

Pressed?

Display

Next Setting?

➤

No

No

➤➤➤➤

Yes

➤

No

Yes

➤

Is Cancel

➤

Button Pressed?

No

Select

➤

Reset

Display

➤

Record

Setting

➤

Is Adjust

Pressed?

No

➤

Is Select

Pressed?

Yes

➤

Record Setting

for Displayed

Alarm

➤

Display Next Alarm

@ Current Setting

Yes

➤

➤

F2

➤

Feed

Print

Mode

➤

➤

Display Current

Setting of 1st Alarm

Any button than

Yes

➤

Yes

Yes

➤

No

➤

➤

➤

M2

➤

adjust select?

➤

No

Is 10 sec.

since last

action?

No

Display

Next

Setting?

D

C

F1

P1

P2➤

M1

➤

➤

➤

➤

16

Page 27

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 1: General Information

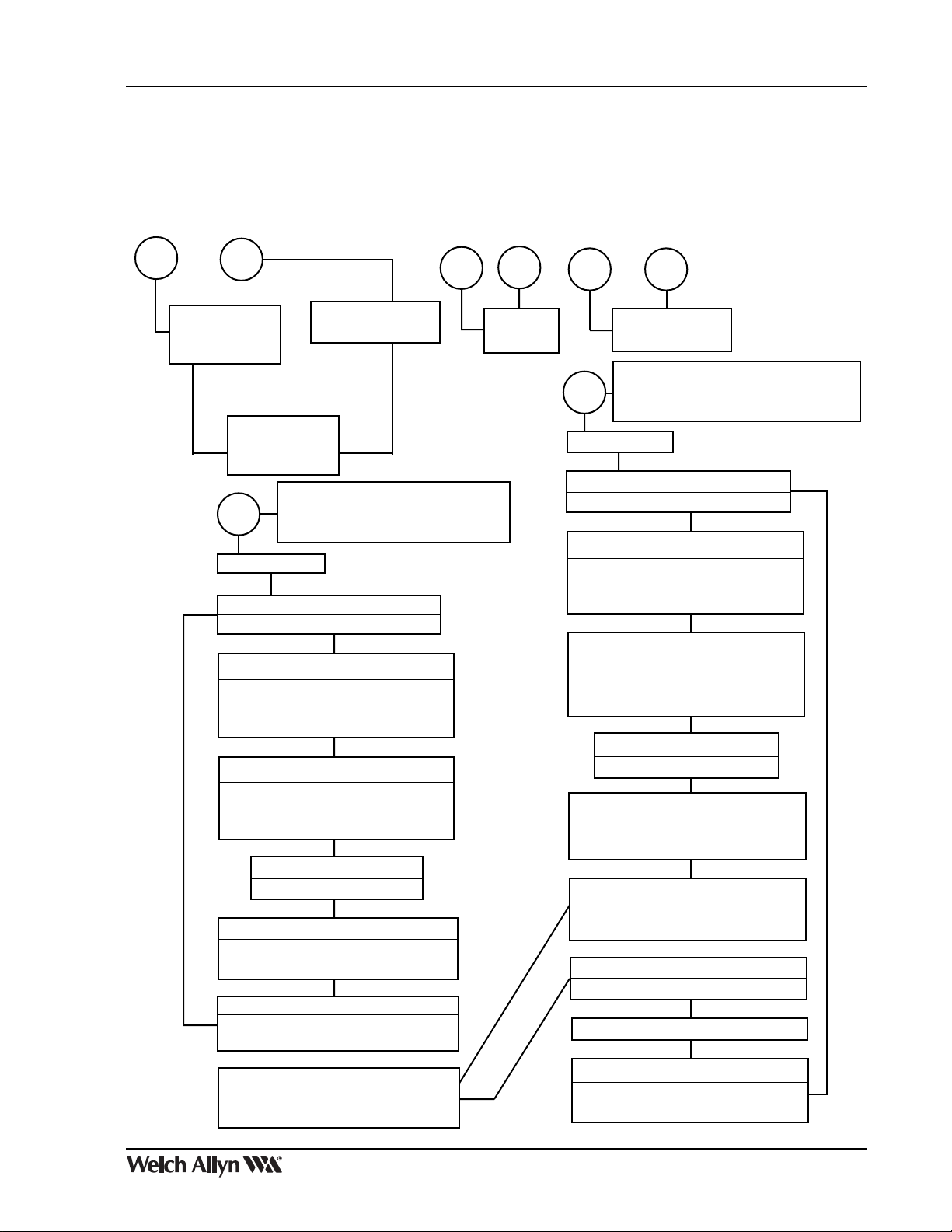

Figure 1.5 Block Diagram of Unit Operation

M2

➤

BP module

active, SpO

module inactive

➤

M1

Both BP and SpO

2

SpO2 module

active, BP

module inactive

C

➤

Post

➤

➤

Show Versions

Print produces version report

Start closes valve

Cancel opens valve

Auto runs pump while pressed

module active

Review advances to next box

Power returns to “O” at any time

Cancel resets changes

Calibration

➤

➤

➤

P1

➤

Print

Report

F2

➤

D

➤

Post

Print produces version report

Auto runs pump while pressed

Auto runs pump while pressed

F1

➤

Advance Paper

One line

Review advances to next box

Power returns to “O” at any time

Cancel resets changes

➤

Show Versions

➤

Calibration

Start closes valve

Cancel opens valve

➤

Battery Voltage

Start closes valve

Cancel opens valve

➤

➤

P2

2

Battery Voltage

Start closes valve

Cancel opens valve

Auto runs pump while pressed

Temp Module Setup

Adjust changes setup

Set Date

Adjust changes flashing display

Select makes next display flash

➤➤➤➤➤

Set Time

Adjust changes flashing display

Select makes next display flash

SpO2 perfusion signal - systolic

display, display perfusion status

➤

Temp Module Setup

Adjust changes setup

Adjust changes flashing display

Select makes next display flash

Adjust changes flashing display

Select makes next display flash

A/D Channel Noise

Select changes A/D channels

➤

RS232/Service Port Test

Start begins cycling

Cancel halts cycling

➤ ➤

Set Date

Set Time

➤➤

Life Test

17

Page 28

Page 29

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 1: General Information

1.6 Specifications

Index:

1.6.1 Performance Specifications

1.6.2 Technical Specifications

a. Mechanical Specifications

b. Electrical Specifications

c. Environmental Specifications

1.6.3 Printer Specifications

1.6.1 Performance Specifications

The performance specifications of the Clinical Vital Signs Monitor are as follows:

CUFF PRESSURE RANGE

0 mmHg - 300 mmHg

INITIAL CUFF INFLATION

120 mmHg, 140 mmHg, 160 mmHg, 200 mmHg, 240 mmHg or 280 mmHg depending on

pressure preset level.

SYSTOLIC DETERMINATION

Maximum: 250 mmHg

Minimum: 60 mmHg

DIASTOLIC DETERMINATION

Maximum: 160 mmHg

Minimum: 30 mmHg

BLOOD PRESSURE ACCURACY

Blood pressure accuracy meets or exceeds SP10-1992 AAMI standards for non-invasive

blood pressure accuracy (AAMI standard: ± 5 mmHg mean error; 8 mmHg standard

deviation). Blood pressure accuracy is validated for pressure measurement using the

upper arm only.

BLOOD PRESSURE DETERMINATION TIME

20 seconds to 45 seconds typical, 140 seconds maximum.

19

Page 30

Section 1: General Information

Welch Allyn Vital Signs Monitor Service Manual

PULSE RATE DETERMINATION

Maximum: 200 bpm

Minimum: 40 bpm

PULSE RATE ACCURACY

SpO

Module Heart Rate ±3.0%

2

Blood Pressure Algorithm Heart Rate ±5.0%

OVERPRESSURE CUTOFF

295 mmHg to 330 mmHg

TEMPERATURE DETERMINATION

Normal Mode Maximum 108.0F (42.2C)

Minimum 84.0F (28.9C)

Monitor Mode Maximum 108.0F (42.2C)

Minimum 84.0F (28.9C)

Revision 4.0

TEMPERATURE ACCURACY

Temperature accuracy meets ASTM E112-86: “Standard Specification for Electronic

Thermometer for Intermittent Determination of Patient Temperature.”

TEMPERATURE DETERMINATION TIME

Normal Mode: ORAL: 4 seconds typical, 15 seconds maximum

Monitor Mode: ORAL: 3 minutes.

OXYGEN SATURATION RANGE (SpO2%)

40-99% oxygen saturation

SpO2 ACCURACY

±3% in the range of 70-99% oxygen saturation (1 Standard Deviation)

BATTERY CHARGING

To at least 90% capacity in 12 hours. Unit will operate and charge battery simultaneously

when connected to power source.

20

Page 31

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

1.6.2 Technical Specifications:

1.6.2.a Mechanical Specifications

Dimensions

Height 6.5 inches (16.5cm)

Length 8.6 inches (21.8cm)

Depth 5.0 inches (12.7cm)

Weight

Approximately 6 pounds (2.8Kg)

Color

Oral Temperature Probe - Blue

Rectal Temperature Probe - Red

Section 1: General Information

Mounting

Self-supporting on rubber feet

IV Pole Mountable

Custom Mobile Stand

Wall Mountable

Attaches to Bed Rail

Portability

-May be hand carried when held by the recessed handle.

-When attached to an IV pole, or mounted on its custom mobile stand, the monitor

and accessories can be wheeled from patient to patient.

-When attached to the bed rail may be transported with the patient within the

hospital environment.

Operator Instructions/Alarm Interpretation

Comprehensive Operator Manual available. Quick reference operator instructions and

alarm interpretation are located on side panel labels.

21

Page 32

Section 1: General Information

Welch Allyn Vital Signs Monitor Service Manual

1.6.2.b Electrical Specifications

Power Requirements

Patient-Rated isolation transformer is connected to AC mains:

Revision 4.0

North American Version

International Versions:

Battery

6 v, 4 Ahr / 20 hr Sealed Rechargeable Lead Gel Cell

A fully charged battery will support 200 “typical” blood pressure determinations taken at 3

minute intervals (10 hours). Battery is 90-100% charged after 12 hours of charging. The

battery automatically charges when the monitor is powered through the AC power transformer. The battery will charge faster when the instrument is not in operation.

120VAC, 60 Hz.

220-240VAC, 50-60Hz.

1.6.2.c Environmental Specifications

Operating Temperature

+10C to +40C

+50F to +104F

*Exception: Thermometry module will not operate below 60-F (16-C).

Storage Temperature

-20C to +50C

-4F to +122F

Relative Humidity

15 to 90% (non-condensing)

Operating Altitude

-170 m to + 4877 m

-557 ft. to +16,000 ft.

22

Page 33

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

1.6.3 Printer T echnical Specifications

Type

Thermal printer, dot matrix

Print speed

46 cps

Paper feed

friction type

Voltage

5 v

Average power when printing

880 mA

Section 1: General Information

Paper width

57 - 58 mm

23

Page 34

Page 35

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 1: General Information

1.7 Serial Numbering System Defined

The serial plate for the 52000 Series (Welch Allyn Vital Signs Monitor) is located on the bottom

of the unit. The serial number consists of seven digits.

95 00569

or

1999 0569

The two or four digits on the left The four or five digits on the right

are the year of manufacture. are the sequence of build

starting with 00001 annually.

(The example unit was the 569th unit built in 1995 or 1999).

25

Page 36

Page 37

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 1: General Information

1.8 Firmware Identification

To confirm these levels, place the unit into the “Configuration” mode. Hold down the

Start

button while the unit is being powered up.

Release the button when the main firmware version appears in the

Systolic/Diastolic window. The SpO2 option and Temperature option (if installed) will

appear in the Temperature and SpO

Verify the firmware levels by reviewing the Repair Test Specifications document.

displays.

2

27

Page 38

Page 39

Welch Allyn Vital Signs Monitor Service Manual

SECTION 2:

Service Set Up

Revision 4.0

Page 40

Page 41

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 2: Service Set Up

2.1 Intent of Manual and Product Scope

This manual provides technical service and recalibration information to technicians

authorized to repair and recalibrate Welch Allyn, Inc. products. When used in

conjunction with the required test equipment and tools, technicians will be able to

diagnose, repair, recalibrate, and test the Clinical Vital Signs Monitor. The manual

includes: Calibration Software and Recalibration instructions, fault/cause analysis,

step by step disassembly and reassembly procedures, repair, adjustment, and retest procedures.

1

Page 42

Page 43

Welch Allyn Vital Signs Monitor Service Manual

500 cc

100 cc

250 cc

SETRA

METER

Computer

Minimum Requirements:

386 IBM Compatible

20 MHz or Better

Windows 3.1 or Better

NETECH

METER

T o SPO2

To RS232

NELLCOR/

W elch Allyn

Vital Signs

Block Diagram f or W elch Allyn Vital Signs

Monitor Set-up

Revision 4.0

2.2.1 Test Equipment Bench Layout:

Figure 2.2.1 depicts recommended layout of test equipment and special tools for

service and recalibration of the Welch Al

lyn

Vital Signs Monitor.

Section 2: Service Set Up

BENCH layout for recalibrating and testing Welch Allyn Vital Signs Monitor

FIGURE 2.2.1

3

Page 44

Section 2: Service Set Up

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Service Notes:

The following commercially available equipment is required for service and calibration of

the Welch Allyn Vital Signs Monitor – not available from Welch Allyn.

– IBM compatible 386 20 MHz computer or better. The computer must have Windows

3.1 or higher, DOS 5.1 or higher, a serial port.

– 2 Digital Multi-Meters. These meters must have 4 1/2 digit displays for accuracy.

– Power Supply. 0-20 Vdc adjustable with 0-3A output.

– Oscilloscope. 60 MHz minimum.

4

Page 45

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 2: Service Set Up

2.2.2 Welch Allyn Vital Signs Service Tools

OPTION II: Partial Service Set

OPTION I: Complete Service Set

DESCRIPTION TOOL # LEAD TIME COMPANY

100cc Test Volume T112819 3 Weeks Welch Allyn ⓦⓦ

250cc Test Volume T112818 3 Weeks Welch Allyn ⓦⓦ

500cc Test Volume T112854 3 Weeks Welch Allyn ⓦⓦ

Digital Timer 8456T12 3 Days McMaster-Carr ⓦⓦ

NeTech Meter* 200-2000IN 3 Days NeTech

– OR –

Setra Meter* (0-10 PSIG) 2270-01 6-8 Weeks Setra Systems

Pliers T112458 3 Weeks Biltmore Tool ⓦ

Bulb And Valve 5088-01 3 Weeks Welch Allyn ⓦⓦ

Keypad Engaging Tool T112067 3 Weeks Welch Allyn ⓦ

ESD Kit T112469 Stock Cameron & Barkley ⓦ

WIRE Cutters T112486 Stock Welch Allyn ⓦ

Tweezers T112511 Stock Welch Allyn ⓦ

Electronic Swabs 318M2 Stock Welch Allyn ⓦ

Pneumatic Tubing (Cut) 97P24 Stock Welch Allyn ⓦⓦ

“Y” Fitting 9586TPK4 2 Weeks Festo ⓦⓦ

“T” Fitting (3) 9585TPK4 2 Weeks Festo ⓦⓦ

Test Cable 130S28 3 Weeks Welch Allyn ⓦⓦ

Pneumatic Clamps (3) 21730-001 Stock VWR Scientific ⓦⓦ

Torque Screwdriver T112917 Stock Tool And Gauge ⓦ

Torque Screwdriver T112918 Stock Tool And Gauge ⓦ

Custom Repair Software 130S29E Stock Welch Allyn ⓦⓦ

#4 Phillips Bit T112919 Stock Biltmore Tool ⓦ

#6 Phillips Bit T112933 Stock Biltmore Tool ⓦ

T8 Torx Bit T112464A 3 Weeks Welch Allyn ⓦ

7/16" Wrench T112990 Stock McMaster Carr ⓦ

Cable Tie Tool T112845 Stock Newerk ⓦ

Nonin Patient Simulator 8000S Stock Nonin ⓦⓦ

Nonin Phantom Fingers 9440 Stock Nonin ⓦ

Nonin Cable 8500-I Stock Nonin ⓦⓦ

Diatek 9600 Calibrator 01800-110 Stock Diatek ⓦ

Diatek Cal. Key 06137-000 3 Weeks Diatek ⓦⓦ

LG. Adult Cuff/Bag 5200-02 Stock Welch Allyn ⓦⓦ

Pneumatic Tubing (Coiled) 5200-07 Stock Welch Allyn ⓦⓦ

Service Manual 5200-86E Stock Welch Allyn ⓦⓦ

Nellcor Patient Simulator SRC2 Stock Nellcor ⓦⓦ

Nellcor Test Cable EC-8 Stock Nellcor ⓦⓦ

££

* Choose one of these meters for calibration. DO NOT ORDER BOTH METERS.

Allowing the bio-medical department to use a water bath to check temperature

(measuring against a temperature standard) That standard must be accurate to with +/- 1F.

See Section 1.1 for ordering tools.

5

Page 46

Page 47

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 2: Service Set Up

2.3 Replacement Parts – Welch Allyn

In addition to individual parts listed below, S

PARE PARTS KITS have been made up for

your convenience. This assures that you will have all the mounting materials and other

small items needed for a repair. The foam pads mounted on the battery are one such

example. Kits will not be broken down. FOR AUTHORIZED REPAIR SITES ONLY.

Welch Allyn Replacement Parts:

PART#: DESCRIPTION:

130S1-E English Front Housing Kit

130S1-S Spanish Front Housing Kit

130S1-F French Front Housing Kit

130S1-G German Front Housing Kit

130S1-I Italian Front Housing Kit

130S2 Front Housing Switch Array

130S3* Main PCB Assembly

Includes: hardware

130S4* Display PCB Assembly

Includes: hardware

130S5* Valve

130S6 Pneumatic Connector

Includes: connector, washer, nut, and grommet

130S7* Pump Assembly

Includes: pump, cable tie mount, 2 cable ties, foam pads, instructions, specifications

130S8E English Rear Housing Kit

130S8F French Rear Housing Kit

130S8G German Rear Housing Kit

130S8I Italian Rear Housing Kit

130S8S Spanish Rear Housing Kit

130S9 Power Jack

130S10 Back Panel

Includes: panel and hardware

130S11 Tubing Assembly

Includes: all tubing, “T” fitting, instructions

130S12 Pressure Switch

Includes: switch and hardware

130S13 Bumpers (2 ea.)

130S14 Battery Access Plate

Includes: plate and hardware

130S15 Wire Harness

Includes: 14 pin MTA connector, 3 pin MTA connector, faston receptacles for the

power supply, power jack, battery, and valve lead wires all assembled

130S16 Temperature Plug

130S17 Printer Assembly

Includes: thermal printer, double faced adhesive foam all assembled

130S18* Printer Housing

Includes: housing, switch array, PCB, hardware, flex strip

130S19 RS232 Cable

Includes: DB9 connector, hardware, 4 pin MTA, lead wires all assembled

Includes: front housing with loose labels. Four different types of

labels for the four different configurations i.e.:

BP w/Printer Only,

BP w/Printer + Temp,

BP w/Printer + SpO2,

BP w/Printer + Temp +

SpO

2

7

Page 48

Section 2: Service Set Up

PART#: DESCRIPTION:

130S20* SpO2 PCB (Nonin)

Includes: PCB with cable attached, DB9 connector and cable (not attached),

and hardware with instructions

130S21 SpO2 Sensor Interconnect (Nonin)

Includes: lead wires and 4 pin MTA connector

130S22* Temperature PCB Assembly

Includes: PCB, hardware, lead wire and connectors

130S23 Temperature Connector

Includes: connector, lead wires and hardware

130S24 Temperature Probe Housing

Includes: housing and hardware

130S26 Main PCB Fuse

130S27 Printer Paper Cover

130S28 Cable, DB9 Female to DB9 Female 42" long

130S29 Software, Repair

130S34 Kit, Repair, Nellcor SpO2 PCB with connector

130S35 Kit, Repair, SpO2 Cable (Nellcor)

130S36 Kit, Repair, SpO2 Cable to Main (Nellcor)

130S37 Upgrade, Software, Version 3.11

41P100** Check Valve

117S144** DC to DC Converter

114S588** Pressure Sensor

66S530** “Printer, Flat Cable”

5200-01 Cuff Assy, Adult with 1 tube bag

5200-02 Cuff Assy, Lg Adult with 1 tube bag

5200-03 Cuff Assy, Child Print with 1 tube bag

5200-04 Bag, Adult with cut tube

5200-05 Bag, Lg Adult with cut tube

5200-06 Bag, Child with cut tube

5082-59 Cuff, Adult Black

5082-61 Cuff, Lg Adult Black

5082-63 Cuff, Child Print

5200-07 Pressure Hose with new Luer fitting

5200-08 Calibration T connector

5200-20 Probe, Oral 9 Ft, Diatek

5200-22 Probe, Rectal 9 Ft, Diatek

5200-40 Sensor, SSpO2 Finger Clip (3 meter cord) (Nonin)

5200-41 Sensor, SpO2 Ear Clip (Nonin)

5200-42 Sensor, SpO2 Flex (Nonin)

5200-44 Sensor, SSpO2 Reflectance (Nonin)

5200-45 Holder, SpO2 Reflectance Sensor (Nonin)

5200-46 Sensor, SpO2 Adult Finger Flexi-form (Nonin)

5200-47 Sensor, SpO2 Ped Finger Flexi-form (Nonin)

5200-50 Tape, SpO2 Sensor Attachment (Nonin)

5200-51 Tape Strips, Hydrogel for SpO2 (Nonin)

5200-52 Cable, SpO2 Extension 3 Ft (Nonin)

5200-53 Kit, SpO2 Finger Phantom Calibration (Nonin)

5200-54 Sensor, SpO2 Finger Clip (1 meter cord) (Nonin)

5200-12 Tubing, straight 8 ft. with fitting

5200-56 Pediatric Finger Clip Sensor (Nonin) 9 ft. cable

5200-55 Extension Cord 10 ft. for SpO2 sensor (Nonin)

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

8

Page 49

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

PART#: DESCRIPTION:

5200-60 Mobile Stand Kit

5200-61 Mobile Stand Kit, Modified

5200-62 Wall Mount Kit

5200-63 Wall Mount Kit, Modified

5200-64 IV Pole Kit

5200-65 IV Pole Kit, Modified

5200-66 Bed Rail Kit

5200-67 Bed Rail Kit, Modified

5200-68 Cuff Clip

5200-69 Accessory Pack

7052-25 Printer Paper (5 rolls)

5200-101 Transformer, USA 120V, 60 Hz

5200-102 Transformer, Europe 220V, 50 Hz

5200-103 Transformer, UK 230V, 50 Hz

5200-103 Transformer, Australia 230V, 50 Hz

5200-110 Power Cord, USA/Japan

5200-111 Power Cord, Europe

5200-112 Power Cord, UK

5200-113 Power Cord, Australia

5200-114 Power Cord, Switzerland

5200-115 Power Cord, South America

5200-84 Battery, 6 Volt Lead Acid

D-25 OXISENSOR II adult digit oxygen transducer (Nellcor)

D-25L OXISENSOR II adult digit oxygen transducer with long cable (Nellcor)

D-20 OXISENSOR II pediatric oxygen transducer (Nellcor)

R-15 OXISENSOR adult nasal oxygen transducer (Nellcor)

I-20 OXISENSOR II infant digit oxygen transducer (Nellcor)

EC-8 Extension Cable – 8 foot (Nellcor)

OXICLIQ-A Adult oxygen transducer for use only with OXICLIQ sensor cable OC-3 (Nellcor)

OXICLIQ-P Pediatric oxygen transducer for use only with OXICLIQ SENSOR CABLE MODEL OC-3 (Nellcor)

OXI-A/N OXIBAND adult/neonatal oxygen transducer (Nellcor)

OXI-P/I OXIBAND pediatric/infant oxygen transducer (Nellcor)

RS-10 Reflectance oxygen transducer (Nellcor)

D-YS DURA-Y oxygen transducer (Nellcor)

SRC-2 Portable oximetry tester (Nellcor)

DS100A DURASENSOR adult oxygen transducer (Nellcor)

OC-3 Cable, OXICLIQ Sensors (Nellcor)

D-YSE Ear Clip (use with DURA-Y sensor) (Nellcor)

D-YSPD Pedicheck Pediatric Spot-Check (use with DURA-Y Sensor) (Nellcor)

ASP-3 Sensor Assortment Pack (Nellcor)

05031-101 Diatek Probe Covers

5200-25 Temperature Cal. Key

01800-210 Model 9600 Temperature Cal. Kit 110V.

5200-85E Operations Manual

5200-86E Service Manual

Section 2: Service Set Up

* - Indicates that these parts can be traded in. If the part is under warranty, with a trade in you get full

credit. If the parts is out of warranty, you will get a 40% discount from the price.”

** - Only regional service centers may purchase these parts.

See section 1.1 for ordering parts.

9

Page 50

Page 51

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 2: Service Set Up

2.4 Welch Allyn Vital Signs Monitor

Maintenance and Service Support

Owner Maintenance: Non-Technical customers can perform normal maintenance per the

instructions provided in the Operator Manual, Section V. End users will be able to perform basic

operations such as replacement of: hoses, cuffs, probes, printer paper and batteries. On this

level the unit will not be opened. However, opening of the WELCH ALLYN VITAL SIGNS MONITOR by untrained individuals may damage the unit and void the warranty.

Technical Service/Repair/Re-calibration: Properly trained and equipped bio-

medical departments and service centers will be able to utilize the content of this Service Manual.

Technical skills in electronics and PC skills are required. These departments and centers must

have service manual and re-calibration software, repair tools and test equipment as listed in this

manual. They must also have minimum recommended quantities of repair parts and sub-assemblies. See the listings of repair parts and kits in this manual.

11

Page 52

Page 53

Welch Allyn Vital Signs Monitor Service Manual

SECTION 3:

Problem Diagnosis

Revision 4.0

Page 54

Page 55

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 3: Problem Diagnosis

3.1 Overview

The Welch Allyn Vital Signs Monitor can be diagnosed and repaired to board level without

the necessity of electrical schematics.

Repair/Replace decisions will be made on the basis of information obtained from Calibration Software, Test Software, Printed Troubleshooting tables as seen in this section and

in the Error Code Chart.

With a few exceptions, individual circuit board components will not be on the repair bill of

materials, and therefore can not be ordered.

1

Page 56

Page 57

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 3: Problem Diagnosis

3.2 Diagnostic Procedure for

Returned Units

NOTES:

A. The word “unit” in this text refers to the WELCH ALLYN VITAL SIGNS MONITOR.

B. Menu|Choice represents menu commands. Rather than use the phrase “choose the

exit command from the File menu.”

1. Remove the battery from the unit. Connect the unit to the power supply. Set the power

supply to 6.5 Vdc +/- 0.5 Vdc.

2. With a digital multi-meter, check the voltage of the battery. If the voltage of the battery

is less than 6.0 Vdc, the battery needs to be charged. Up on completion of this proce-

dure, place the battery back into the unit and plug in the charger. Let the battery

charge for 8 hours. Next allow the unit to sit for 1 day and recheck the battery voltage.

If the voltage is below 6.0 Vdc, change the battery. (Reference section 4.15)

3. Power up the unit. If the unit does not power up:

A. Insure the power supply is on and has the correct requirements as called out

in 1. (see above).

B. The power supply is connected to the unit.

C. Check that the fuse is not blown. (Reference section 4.2)

D. Change the main PCB. (Reference section 4.3)

E. Change the display PCB. (Reference section 4.6)

If the unit does power up:

4. To check the display PCB, observe the unit during power up. All of the LEDs should

be lit for 1-2 seconds before the unit gets to its normal mode. If the unit has any LEDs

out change the display PCB. (Reference section 4.6)

5 Run a couple of blood pressure cycles to ensure proper inflation/deflation and readings.

6. If the unit is not inflating/deflating properly:

A. Open up the unit by removing the 6 housing screws.

B. Check the unit for pinched tubing if the unit is deflating too slowly. With the

housing opened, re-run the blood pressure cycle to see if the deflating problem

has been fixed. Re-route tubing.

C. If there are no pinched tubes, change the valve.

(Reference section 4.13)

3

Page 58

Section 3: Problem Diagnosis

D. If this still does not clear up the problem of deflation too slow, change the pres-

sure switch. (Reference section 4.12)

E. Power down the unit. Place unit into detailed test mode by holding down the

“start” and “cancel” buttons as power is re-applied. Press the review button until

“cal” appears in the systolic window. Press the “start” button to close the valve.

Pump up the unit using the bulb and valve inflate the unit to 250 mmHg. Confirm the unit meets the specification for leak called out in the Repair Test Specification document. If the unit is leaking:

F. Pinch off the tubing leading to the pump. If this stops the leak, change the

pump. (Reference section 4.11)

G. Pinch off the tubing leading to the valve. If this stops the leak, change the valve.

(Reference section 4.13)

H. Pinch off the tubing leading to the transducer. If this stops the leak, change the

transducer. (Reference section 4.5)

I. Pinch off the tubing leading to the pressure switch. If this stops the leak,

change the pressure switch. (Reference section 4.12)

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

7. If the unit is inflating/deflating properly however there is no reading given, change out

the main PCB. (Reference section 4.3)

8. FOR THE PRINTER OPTION: Load the printer with paper if there is no paper. Press

the form feed button to see if that will advance the paper. Next, press the print button

to see if the unit will print. If these functions do not work, first change the printer PCB

and re-test. If the problem is still evident, change out the printer itself. (Reference

section 4.13)

9. FOR THE SpO

OPTION: Connect the patient simulator to the unit SpO2 connection

2

by the Nonin or Nellcor cable (depending upon which is installed). Confirm readings

equal to the specifications called out in Section 7. If there is no reading, change out

the SpO

SpO

connector and PCB. (Reference section 4.9 or 4.10 depending on which

2

Module is installed)

2

10.FOR THE TEMPERATURE OPTION: Plug in the Diatek 9600 calibrator and set it for

96.4 F/ 35.8 C or use a water bath between 84 F (28.8 C) and 106 F (41.1 C). Remove the temperature probe and view the temperature window on the display. Make

sure the temperature is in the “monitor mode.” This will be displayed at the bottom of

the window. If the unit is not in monitor mode, wait approximately 40-60 seconds and

the unit will automatically transfer into the monitor mode. Place the probe into the

small hoe on top of the 9600 calibrator or into bath. If there is no reading place the

probe back into its housing, remove and retry. If there is still no reading, change the

probe and retry the test. If there is still no reading place the probe back into the housing, unplug the probe and plug in the cal-key, remove the probe and Confirm reading

meets specifications called out in Section 7. If there is no reading at this point, change

the temperature connector and PCB. (Reference section 4.8)

4

Page 59

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 3: Problem Diagnosis

11.FOR THE RS232 OPTION: Connect the RS232 cable from the PC to the unit. Select

Unit|Information

screen, check the connection to the unit and the PC. Select

in the repair software. If a communication error appears on the PC

Tools|Options

to insure

that the communication port that the cable is connected to is selected. Re-try the test.

If the error is still present change out the main PCB.

5

Page 60

Page 61

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 3: Problem Diagnosis

3.3 Calibration Procedure

3.3.1 VOLTAGE CALIBRATION

1. Connect the unit to the test station by hooking up the pneumatic tubing, cable from the

PC, and removing the battery and connecting the power supply.

2. Place the unit into the “detailed test mode” by holding down the start and cancel buttons while powering up the unit. Allow the software versions to be displayed then

press the review button until the unit displays “BAT” in the systolic window.

3. Go to the repair software and choose

between 5.6 Vdc and 5.9 Vdc.

4. View the digital multi-meter (DMM) that is connected to the power supply reading the

voltage. Move the cursor to the “Calibrated Voltage” box and type in the voltage that

you observe on the DMM. In the software, click on “Update.”

5. The software will then prompt you to enter in a “Calibration Signature.” Move the

cursor to the box and enter the three initials of your name. Then click “OK.”

6. At this point you should see the voltage on the display of the WELCH ALLYN VITAL

SIGNS MONITOR change to match that of the DMM.

7. Adjust the power supply to 6.5 Vdc ± .05 Vdc.

Calibrate|Voltage

. Adjust the power supply to

7

Page 62

Section 3: Problem Diagnosis

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

3.3.2 PRESSURE CALIBRATION

1. Connect the unit to the test station by hooking up the pneumatic tubing, cable from the

PC, and removing the battery and connecting the power supply.

2. Place the unit into the “detailed test mode” by holding down the start and cancel buttons while powering up the unit. Allow the software versions to be displayed then

press the review button until the unit displays “CAL” in the systolic window. Make sure

that clamps are on the 100cc and 250cc volumes.

3. Go to the repair software and choose

4. Press the “Calibrate” button to begin the calibration procedure.

5. The software will first check to make sure that the units internal temperature is below

32°C. If it is not the user will be warned that they can not perform a calibration at this

time.

6. If the temperature is within the 32°C limit the software will tell the unit to perform an

auto-zero. If this is unsuccessful the user will be prompted to perform a zero potentiometer calibration. This is an automatic calibration. The user just needs to answer

YES or NO. A no will cancel the calibration procedure.

7. Once a successful autozero has been completed the “Gain Calibration at 200 mmHg”

box will be activated. This box consists of a slider control and a pressure display. To

perform the span calibration pump the unit up to 200 mmHg +/- 5 mmHg using the

bulb. Wait 15 seconds to allow the pressure to stabilize. Adjust the slide control until

the reading on the PC matches as close as possible to the reading on the pressure

standard. Once the difference has been minimized, Press “record” and proceed.

8. Once the gain calibration is complete the pressure calibration points can be calibrated.

There are three points that require calibration, 95, 195 and 285 mmHg. First set the

pressure to the desired value within +/- 5 mmHg of that value. Wait 15 seconds to

allow the pressure to stabilize. Adjust the slide control until the reading on the PC

matches as close as possible to the reading on the pressure standard. Press “record”

after each setting. YOU MUST DO THIS FOR ALL THREE VALUES. Once this is

completed press the “update” button.

Calibrate|Manometer

.

9. The software will then prompt you to enter in a “Calibration Signature.” Move the

cursor to the box and type the three initials of your name. Then click “OK.”

10.Press Close to exit the calibration dialog box.

8

Page 63

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 3: Problem Diagnosis

3.4 Loading Unit Software

*WARNING: DO NOT REMOVE POWER OR TURN OFF UNIT DURING THE SOFTWARE

LOADING OPERATION. The unit will be in an unrecoverable state if this happens.

1. Plug the wall transformer into the Welch Allyn Vital Signs Monitor.

2. Connect the unit to the RS232 cable of the test station.

3. Start the Repair Software by clicking on its icon. Go into Unit/Update Software.

4. Press the “Select File” button in the software.

5. Choose the correct unit software (cbpXXX.mot) file per instructions from the manufacturer. (Where “XXX” is the number of the software version to be loaded)

6. Once the software file is selected, press the “OK” button. This will return you to the

Repair Software. The Repair Software will then ensure that the cbpXXX.mot file you

are about to load into the unit is “Valid.” If so, press the “Load” button in the software.

The unit will take about 10 minutes to load the software. (If the software file you have

chosen is “Not Valid,” repeat steps 4 and 5, choose the correct version and then

proceed. If problems persist, please contact your nearest Regional Service Center.)

NOTE: If the computer or the software malfunctions during the software loading operation, re-boot the computer, re-start windows and start the Repair Software. The Repair

Software will start in the “Recovery Mode.” The software will prompt you to continue/

resume the software loading process.

9

Page 64

Page 65

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 3: Problem Diagnosis

3.5 Welch Allyn Vital Signs Monitor

Self Diagnostic Fault Codes

The following is a list of all possible error codes and their meanings.

MAIN BOARD ERROR CODES

ERROR CODE DESCRIPTION

CO1 User abort

CO2 Auto-zero failure

CO3 Inflation too fast

CO4 Inflation too long

CO5 Excessive noise

CO6 Outside measuring range

“ “ BP not available

E10 Over pressure

E11 Fail-safe violation

E12 Ambient temp. limit

E13 Battery failure

E20 A/D failure

E30 ROM failure

E31 RAM failure

E32 Factory EPROM checksum fail

E33 User EPROM checksum failure

E34 A/D converter failure

E35 SpO

E36 Temperature PCB failure

E37 Printer failure

E38 Real time clock failure

PCB failure

2

SpO

BOARD ERROR CODES (Both Nonin and Nellcor)

2

ERROR CODE DESCRIPTION

“—“ Sensor error

E7 SpO

“ “ SpO

PCB bad

2

off

2

11

Page 66

Section 3: Problem Diagnosis

Welch Allyn Vital Signs Monitor Service Manual

TEMPERATURE BOARD ERROR CODES

ERROR CODE DESCRIPTION

E0.0 Stack RAM error

E0.1 Internal RAM test failure

E0.2 Internal ROM checksum failure

E0.3 Instrument error

E0.4 EEPROM checksum error

E0.5 RAM checksum error

E0.6 EEPROM busy too long

E0.7 EEPROM address write error

E1.0 External interrupt 0

E1.2 Transmitter interrupt

E1.3 Timer Y interrupt

E1.4 Timer 2 interrupt

E1.5 External counter interrupt

E1.6 Timer 1 interrupt

E1.7 Serial I/O

E1.8 Software break

E2.0 Low cal. resistor pulse width error

E2.1 High Cal. resistor pulse width error

E2.2 PTB resistor pulse width error

E2.3 Probe pulse width error

E2.4 Could not determine cause

E3.0 Low battery error

E3.1 PTB test error

E3.2 Outside operating temp. range

E4.0 Floating point overflow

E4.1 Log of zero undefined

E5.0 Q warmer transistor error

E5.1 C warmer transistor error

E5.2 Warmer protection circuit failure

Revision 4.0

E5.3 Probe warmer not warming

E5.4 Probe missing, thermistor failure

E5.5 Warmer circuit failure

E5.6 Warmer overheated

E5.7 Warmer watch-dog time out

E6.1 Serial overrun error

E6.2 Serial framing error

12

Page 67

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

TEMPERATURE BOARD ERROR CODES (CONT’D)

ERROR CODE DESCRIPTION

E6.3 No data time out error

E6.4 Transmit buffer overflow

E9.1 Undefined software state

C20 Probe missing or broken

C21 Probe Characterization aborted

P Probe position

PC Probe characterization

“ “ Temperature off

Section 3: Problem Diagnosis

13

Page 68

Page 69

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 3: Problem Diagnosis

3.6 Complaint/ Cause/ Corrective Action

COMPLAINT CAUSE CORRECTIVE ACTION

Does Not Power Up Battery Voltage LOW .......... Check Voltage Level

Battery Voltage Less

Than 5.4 Volts..................... Charge Battery

Fuse F1 Blown .................... Replace Fuse After Cause

Of Short Identified

Battery Connector ............... Verify Connection And Replace

Required

Charge Light not on when

Charger Plugged in ............. Change Main PCB.U28 is blown.

Constant Alarm Overpressure ...................... Check For Pinched/Blocked Hose

Hardware Fails.................... Verify Performance Of The

Following Parts:

A) Pressure Switch

B) Transducer

C) Valve

D) Main PCB

Air Leak Pneumatic Connector ......... Check Seals

Pump................................... Verify Proper Operation

Valve................................... Verify Proper Operation

Check Valve Drivers

Unit Tubing.......................... Verify Connectors And

Integrity Of Hoses

Cuff ..................................... Verify Air Seal Of Coiled Hose

And Cuff Connectors

Verify Air Seal From Pneumatic

Connector Of Welch Allyn Vital Signs Monitor

To Coiled Hose.

Overpressure Switch........... Verify Connections And

Integrity Of Hose.

Verify Switch Operation.

SpO2 Failure SPO2 Board And Harness.. Replace Probe And Retest.

Verify All Connections To The

SpO2 Board

Replace

SpO2 Board.

15

Page 70

Section 3: Problem Diagnosis

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

COMPLAINT CAUSE CORRECTIVE ACTION

Temp Failure Probe .................................. Replace Probe And Retest

Diatek Board & Harness ..... Verify All Connections To The

Temperature Board.

Opto-Reflector..................... Verify Probe Is Seen Only When

Removed From Holster.

Connector PCB................... Verify That The Temp Probe

Connector Is Properly Seated

In The Connector On The Unit.

Verify That The Connector From Diatek

Board Is Connected To The Connector

On The PCB.

Temp. Error Code ............... See Page 19

Printer Failure Flex Cable (Main PCB

To Printer PCB)................... Verify That The Flex Cable

From The Main PCB Is Fully Seated

In The Board Cable Connectors.

Flex Cable (Printer

To Printer PCB)................... Verify That The Flex Cable From The

Printer To The Printer PCB Is Fully Seated

In The Board Cable Connector.

Paper Jam........................... Check Condition Of Paper Roll

In The Printer Housing.

Printer Home Position ......... Verify That The Printer Head Fully

Actuates The Printer Home Switch.

BP Readings High See pages 17 & 18 for ways to check to

ensure the monitor is accurate.

16

Page 71

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 3: Problem Diagnosis

CHECKLIST FOR COMPARING AUTOMATED BP MONITORING TO MANUAL METHODS

• Blood pressure can vary between the left and right arm by as much as 20 mmHg

on some patients. When comparing the Welch Allyn measurement to a manual

reading on an opposite arm it is important to repeat the comparison after switching

arms and then compare the average of both readings. This will help to eliminate

the difference between the two arms.

• A person's blood pressure is continuously changing in reaction to their environment and physical state. Posture changes, conversation and other influences can

easily cause a person's blood pressure to change dramatically. When comparing

the Welch Allyn measurement to a subsequent manual reading on the same arm it

is important to enure that the person's blood pressure has stabilized. To determine

this, it is best to take a manual reading before and after the Welch Allyn reading. A

stable subject should not have a change in systolic or diastolic of more than 5

mmHg.

• It is very important that both of the subject's arm remain in the same relative location throughout the test. One inch of elevation change will result in 1.8 mmHg

change in the systolic and diastolic pressures.

• When taking the manual auscultatory reading it is very important to maintain a 3

mmHg/sec deflation rate. This deflation has been prescribed by the American

Heart Association. Deflating the cuff too rapidly will result in an inaccurate blood

pressure reading.

• Hearing acuity vary from individual to individual an can cause different blood pressure measurements on the same subject. This effect is compounded when a

subject has very weak Korotkoff sounds. When taking auscultatory readings for

comparison to the Welch Allyn, it is best to use a teaching stethoscope with two

sets of binaurals and two persons trained in taking blood pressures. The two observers should write down their readings and not reveal the readings to each other,

which may introduce bias. The two observers should agree within 5 mmHg for both

systolic and diastolic, and the average of their readings used for the comparison.

Inability of the two observers to agree within 5 mmHg denotes a subject which

cannot be repeatedly measured by auscultation and should not be used for comparison.

• Proper cuff sizing is important. Using a cuff that is too small or too large will result

in inaccurate blood pressure readings.

• Some situations can introduce a psychological bias in the auscultatory readings.

For instance, a drug testing clinic wishing for subjects with systolic pressure below

an acceptance threshold may result in biased low systolic readings, in some instances.

17

Page 72

Section 3: Problem Diagnosis

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

CHECKLIST FOR COMPARING BP MEASUREMENTS MADE WITH THE WELCH ALLYN TO OTHER AUTOMATED

MONITORS

• The Welch Allyn monitor has been validated according to the AAMI protocol using

auscultatory readings. Many other manufacturer's monitors have been validated to

the AAMI protocol

intra-arterial

blood pressure readings. Intra-arterial blood pressure readings do not necessarily agree with auscultatory readings. In fact, it is

common for the diastolic pressure determined intra-arterially to be 7-10 mmHg

lower than an auscultatory reading.

• Blood pressure can vary between the left and right arm by as much as 20 mmHg

on some patients. When comparing the Welch Allyn measurement to a manual

reading on an opposite arm it is important to repeat the comparison after switching

arms and then compare the average of both readings. This will help to eliminate

the difference between the two arms.

• A person's blood pressure is continuously changing in reaction to their environment and physical state. Posture changes, conversation and other influences can

easily cause a person's blood pressure to change dramatically. When comparing

the Welch Allyn measurement to a subsequent manual reading on the same arm it

is important to enure that the person's blood pressure has stabilized. To determine

this, it is best to take a manual reading before and after the Welch Allyn reading. A

stable subject should not have a change in systolic or diastolic of more than 5

mmHg.

• It is very important that both of the subject's arm remain in the same relative location throughout the test. One inch of elevation change will result in 1.8 mmHg

change in the systolic and diastolic pressures.

• Proper cuff sizing is important. Using a cuff that is too small or too large will result

in inaccurate blood pressure readings.

18

Page 73

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

Section 3: Problem Diagnosis

TEMPERATURE ERROR CODE CORRECTION

1. Turn the unit off.

2. Hold down the “Start” button as you turn the unit back on. Continue to hold down

the “Start” button until the alarm signals dissipate.

3. Make sure that you see either a “2.4” or a “24” in the temperature window.

4. Press the “Review” button and you should see “CAL” in the systolic window.

5. Press the “Review” button again and you should see “BAT” in the systolic window.

6. Press the “Review” button again and make sure that three dashes (---) appear in

the temperature window.

7. Once this has been confirmed, press the “Review” button until you see “2.4” or

“24” in the temperature window. Make sure the probe is in the housing.

8. Turn the unit off, then turn the unit on allowing it to boot up into its normal mode.

9. Allow the “PC” to disappear from the temperature window.

10. Remove the probe from the housing. You should see a “1888” then “ORL” appear. If not, contact your local service department.

19

Page 74

Page 75

Welch Allyn Vital Signs Monitor Service Manual

Revision 4.0

CLINICAL VITAL SIGNS MONITOR OPERATOR MANUAL

Section 3: Problem Diagnosis

3.7 TROUBLE SHOOTING GUIDE

Symptom Possible Cause Explanations and

Corrective Action

1. Inaccurate

Blood Pressure

Readings

Please note: Differences

‘10mmhg should be considered

‘normal and will occur for a

number of reasons including

intrapatient BP variability,

observer hearing differences,

and auscultatory deflation rate.

Incorrect Cuff Size

Patient’s Arm Position

Arm Movement During

blood pressure cycle

Blood Pressure taken

over clothing

Arrhythmia

Incorrect Reference

Determine correct cuff size:

• use reference markings on cuff

• measure patient’s arm circumference

midway between elbow and shoulder

(see page 42 of Operator’s Manual to

select correct cuff size).

Ensure Patient’s arm is at heart level.

Keep arm still during blood

pressure cycle:

• movement may cause inaccuracies

from artifact

Blood Pressure should be taken on

a bare arm.

Check for regularity of heart rate:

(palpate pulse or check monitor)

• moderate to severe heart rate irregularities

may make blood pressure difficult to measure.

Use 4th Korotkoff sound to determine

diastolic blood pressure.

• Many listener’s incorrectly equate diastolic

blood pressure with the disappearance of

sound. The Vital Signs Monitor was developed

using the 4th sound, as recommended by

the American Heart Association.

Change in blood pressure

from auscultatory reading

to Vital Signs Monitor

reading

Poor auscultatory sound

recognition by observer

Deflate cuff no faster than 3mmhg per second:

• One of the major sources of error in ausculta-

tory blood pressure measurement is deflating

the cuff to quickly. The American Heart Association

recommends deflation no faster than 3mmhg

per second.

Only use a spygnomometer that is known

to be in calibration:

• Blood pressure taken with un-calibrated

sphygmomanometer may be very inaccurate.