Page 1

Mach 6.0

Kreativ Menu

Manuals

Operator Manual

Air Abrasion Unit

SERVICE MANUAL

Manufactured by

Welch Allyn Kreativ, Inc. (USA)

7360 Carroll Road

San Diego, CA 92121

990277 Rev. A

Copyright Notice:

Copyright © 1999, Kreativ, Inc. All rights reserved. No part of this manual may be

reproduced without written permission from Kreativ, Inc.

European Authorized Representative

Welch Allyn LTD.

Navan, Co. Meath

Republic of Ireland

Ph: 353-46-79060

Page 2

TABLE OF CONTENTS

1. GENERAL INFORMATION......................................................................................................................................................5

1.1 INTRODUCTION.......................................................................................................................................................................5

1.2 PURPOSE OF MANUAL...........................................................................................................................................................5

1.3 SAFETY SUMMARY................................................................................................................................................................5

1.4 APPLICATIONS........................................................................................................................................................................6

1.5 CONTRAINDICATIONS............................................................................................................................................................7

1.6 E NVIRONMENTAL CONSIDERATIONS..................................................................................................................................7

1.7 SYSTEM SPECIFICATIONS .....................................................................................................................................................8

2. THEORY OF OPERATION.......................................................................................................................................................9

2.1 INTRODUCTION.......................................................................................................................................................................9

2.2 FUNCTIONAL DESCRIPTION.................................................................................................................................................9

2.3 CONTROLS AND CONNE CTIONS MACH 6.0........................................................................................................................9

2.4 PNEUMATIC COMPONENTS DESCRIPTION.....................................................................................................................14

2.5 E LECTRICAL / ELECTRONIC COMPONENT DESCRIPTION.............................................................................................16

3. ROUTINE MAINTENANCE .....................................................................................................................................................19

3.1 ROUTINE MAINTENANCE OF THE MACH 6.0 .................................................................................................................19

3.2 DAILY REQUIREMENTS.......................................................................................................................................................19

3.3 WEEKLY REQUIREMENTS...................................................................................................................................................20

3.4 MONTHLY REQUIREMENTS...............................................................................................................................................20

3.4 QUARTERLY REQUIREMENTS............................................................................................................................................21

3.5 BI-ANNUAL REQUIREMENTS.............................................................................................................................................21

3.6 ANNUAL REQUIREMENTS...................................................................................................................................................22

3.7 MAINTENANCE SCHEDULE................................................................................................................................................23

3.7 MAINTENANCE PROCEDURES............................................................................................................................................24

4. TROUBLESHOOTING............................................................................................................................................................32

4.1 POWDER FLOW PROBLEMS.................................................................................................................................................32

5. INSTALLATION CONSIDERATIONS ................................................................................................................................33

5.1 SITE PREPARATION FOR KREATIV AIR ABRASION SYSTEMS......................................................................................33

5.2 PNEUMATIC FOOTSWITCH ADAPTER INSTALLATION INSTRUCTION.......................................................................36

6. SPARE PARTS LIST...............................................................................................................................................................37

6.1 POWDER FEED CHAMBER (K170180) COMPONENTS......................................................................................................37

6.2 PINCH TUBE V ALVE (K170179) COMPONENTS................................................................................................................38

6.3 SYSTEM MANIFOLD ASSEMBLY (K170175)......................................................................................................................39

6.4 AIR IN FILTER ASSEMBLY (K170198) COMPONENTS.....................................................................................................39

6.5 AIR OUT FILTER ASSEMBLY (K170203) COMPONENTS.................................................................................................40

6.6 MACH 6 MANIFOLD ASSEMBLY K170202) COMPONENTS...........................................................................................40

6.7 E XHAUST CATCH ASSEMBLY (K170204) COMPONENTS................................................................................................41

6.8 PINCH V ALVE REGULATOR ASSEMBLY (K170187) COMPONENTS...............................................................................42

6.9 SYSTEM REGULATOR ASSEMBLY (K170181) COMPONENTS.........................................................................................43

6.10 TUBING.................................................................................................................................................................................43

6.11ACCESSORIES , HANDPIECES, NOZZLES, AND MISCELLANEOUS..................................................................................43

6.12 ADHESIVES...........................................................................................................................................................................44

6.13 CHASSIS COMPONENTS......................................................................................................................................................44

6.14 E LECTRICAL COMPONENTS..............................................................................................................................................44

6.15 SHIPPING ACCESSORIES.....................................................................................................................................................44

6.16 MAINTENANCE KITS.........................................................................................................................................................44

990277 Rev. A Page 2 of 46

Page 3

7. WARRANTY, RETURNS AND ADJUSTMENTS...............................................................................................................45

7.1 RETURNS AND ADJUSTMENTS...........................................................................................................................................45

7.2 L IMITED WARRANTY..........................................................................................................................................................45

6.3 STORAGE AND SHIPMENT ..................................................................................................................................................45

990277 Rev. A Page 3 of 46

Page 4

TABLE OF FIGURES

FIGURE 1 SYSTEMS REAR PANEL CONNECTIONS......................................................................................................................11

FIGURE 2 SYSTEM FRONT PANEL CONTROLS AND CONNECTIONS .......................................................................................11

FIGURE 3 HAND PIECE HOLDER IN HORIZONTAL AND V ERTICAL POSITION......................................................................12

FIGURE 4 INTERNAL COMPONENTS LOCATIONS.......................................................................................................................13

FIGURE 5 INTERNAL COMPONENTS LOCATIONS.......................................................................................................................13

FIGURE 6 INTERNAL COMPONENTS LOCATIONS.......................................................................................................................14

FIGURE 7 PNEUMATIC TUBING DIAGRAM..................................................................................................................................15

FIGURE 8 PNEUMATIC BLOCK DIAGRAM....................................................................................................................................16

FIGURE 9 DISPLAY CONTROL PANEL ..........................................................................................................................................17

FIGURE 10 INTERCONNECT DIAGRAM.........................................................................................................................................18

FIGURE 11 SOLENOID V ALVE MANIFOLD ASSEMBLY..............................................................................................................18

FIGURE 12 TEST CONNECTIONS DIAGRAM.................................................................................................................................31

FIGURE 13 SOLENOID DRIVER CONNECTION LOCATIONS.......................................................................................................31

FIGURE 14 WELCH ALLYN KREATIV AIR ABRASION SYSTEM CONNECTIONS...................................................................33

FIGURE 15 CONNECTION OF AIR ABRASION SYSTEM TO IN-OFFICE AIR SUPPLY.............................................................34

FIGURE 16 CONNECTION OF WELCH ALLYN KREATIV COMPRESSOR SYSTEM ..................................................................34

FIGURE 17 USING BOTTLED/TANKL NITROGEN........................................................................................................................35

FIGURE 18 PNEUMATIC FOOT SWITH ADAPTER SCHEMATIC DIAGRAM..........................................................................36

FIGURE 19 CANISTER POWDER FEED ASSEMBLY COMPONENTS DIAGRAM (170180)........................................................37

FGURE 20 PINCH TUBE V ALVE ASSEMBLY COMPONENTS DIAGRAM (K170179) .................................................................38

FIGURE 21 SOLENOID MANIFOLD ASSEMBLY (K170175).........................................................................................................39

FIGURE 22 AIR IN FILTER ASSEMBLY COMPONENTS DIAGRAM (K170198).........................................................................39

FIGURE 23 AIR OUT FILTER ASSEMBLY COMPONENTS DIAGRAM (K170203).....................................................................40

FIGURE 24 MACH 6 MANIFOLD ASSEMBLY COMPONENTS DIAGRAM (K170202)..............................................................40

FIGURE 25 E XHAUST CATCH ASSEMBLY COMPONENTS DIAGRAM (K170204)....................................................................41

FIGURE 26 PINCH V ALVE REGULATOR ASSEMBLY COMPONENTS DIAGRAM (K170187) ...................................................42

FIGURE 27 SYSTEM REGULATOR ASSEMBLY COMPONENTS DIAGRAM (K170181).............................................................43

990277 Rev. A Page 4 of 46

Page 5

1. General Information

1.1 Introduction

The Welch Allyn Kreativ Mach 6 is a compact, highly reliable, state of the art instrument designed for Air Abrasive

Micro Dentistry. They are designed as a means of removing tooth structure and other materials to prepare teeth for

restoration, and as an adjunct to the high speed dental handpiece and bur.

Note: Clinical use of the Mach 6 Air abrasion system for procedures not included or suggested in this instruction

guide is not advised. Similarly, the Mach 6 system should be only used by dental professionals who have practiced

on extracted teeth and who are thoroughly familiar with this manual.

1.2 Purpose of Manual

This manual should be thoroughly studied before installing, using, or performing maintenance on the equipment.

Please feel free to call Welch Allyn Kreativ or their representative if you need additional information regarding

installation, operation, or service of the instrument.

Information essential to the installation, operation, and routine maintenance of the Mach 6 system manufactured by

Welch Allyn Kreativ, is included in this manual. The instructions are written specifically for personnel who have

been trained to perform maintenance on the unit.

1.3 Safety Summary

1.3.1 Read This Manual

Prior to operating or servicing the Mach 6.0, this manual must be read and understood. If something is not clear, call

the factory for assistance before proceeding. Keep this and other associated manuals for future reference.

1.3.2 Use Proper Power Connections

Use proper wiring and connection methods to satisfy appropriate electrical codes.

1.3.3 Do Not Remove Covers Or Panels

To avoid electrical shock hazard, do not remove covers or panels when power is supplied to the unit. Do not operate

the device when the covers or panels are removed.

1.3.4 Shock Hazard

Connect the Mach 6.0 to a properly grounded outlet in accordance with the National Electrical Code.

WARNING: Do not under any circumstance remove the ground wire or the ground prong from any power plug. Do

not use extension cords with the Mach 6.0 equipment.

1.3.5 Device Labeling

Do not under any circumstances remove any CAUTION, WARNING, or other descriptive labels from the device.

1.3.6 Other Safety Statements

Other safety statements are included within the manual text and are identified as follows:

• CAUTION: Caution statements identify conditions or practices that could result in equipment or

property damage.

990277 Rev. A Page 5 of 46

Page 6

• WARNING: Warning statements identify conditions or practices that could result in personal injury or

loss of life.

1.3.7 Cautions

The handpiece should be directed precisely at surfaces and tooth structures which are to be modified or removed.

The nozzle tip should be placed a few millimeters from the surface and angled toward the area to be removed or

modified. Unlike the high speed handpiece, the Mach 6 nozzle cuts only directly from the end; there is no side

cutting.

Do not attempt to service the unit beyond those items described in the maintenance section. Call Welch Allyn

Kreativ or their representative for instructions.

Do not substitute non-Welch Allyn Kreativ , materials or accessories. Use of materials or accessories supplied by

other manufacturers may result in damage to the unit and will void the factory warranty.

Use only clean dry air. Make sure that your air compressor system utilizes air dryer filter systems and that they are

fully operational. Any moisture or oil in the air supply will adversely affect the performance of your Mach 6 system.

When using the Mach 6 system, check to be sure that your air system produces at least 80 psi (550 kPa) at 1.5 cfm

(42.5 liter/min).

Sound clinical judgment, good common sense, and proper training are essential to the successful service of the unit

in order to provide safe and efficient patient care.

1.3.8 Safety Markings on Labels

On (power: connected to the mains)

1.4 Applications

Alternating current

Protective earth (ground)

Attention, consult accompanying documents

Off (power: disconnection from the mains)

Type B equipment

The Mach 6.0 is designed for simple, reliable, and efficient operation with minimal maintenance. The Welch Allyn

Kreativ Mach 6.0 system is designed to deliver a controlled flow of abrasive powder and air mixture through a very

precise nozzle. Applications include amalgam removal, cutting, abrading, deburring, peening, and etching of tooth

structures and other materials.

990277 Rev. A Page 6 of 46

Page 7

1.5 Contra-indications

Welch Allyn Kreativ Air Abrasion products are designed for use by and on the order of a dentist. Furthermore,

Welch Allyn Kreativ products are not intended to be used outside the device’s specifications or limitations. Results

are not guaranteed or warranted if other than approved (Welch Allyn Kreativ) disposable products are used.

1.6 Environmental Considerations

Prior to the installation of the Mach 6.0 air abrasion unit, it will be necessary to provide utilities and create an

environment suitable for the trouble-free operation of the equipment.

1.6.1 POWER

All components operate on 100 - 240 VAC 50/60 Hz, single phase power. The use of surge protectors is recommended

when possible.

1.6.2 AIR

The Mach 6.0 air abrasion unit requires input air pressure at a minimum of 80 PSI and a maximum of 130 PSI. Air

pressure can be delivered to the Mach 6.0 via a main office air compressor, a compact portable compressor, or

compressed nitrogen.

1.6.3 Main Office Compressor

The main office compressor should be sized to deliver 80-130 PSI of constant, clean air pressure to the Mach 6.0 unit.

The Mach 6.0 unit is equipped with an internal Coalescing Filter which ensures a clean and dry air supply stream.

Under extreme environmental humid conditions an additional dryer is recommended to be installed on the air line

between the compressor and Operatory Regulator. This will ensure extra protection to the Mach 6.0 unit. If the

Operatory does not have the minimum air input requirement, the Mach 6.0 will not perform to the desired specification

level and the customer should be informed that auxiliary air supply may be required.

1.6.4 Compressed Nitrogen

Compressed nitrogen can be used to supply the air pressure for the Mach 6.0 unit. There are variously sized tanks

available from most local gas companies. The regulator on the nitrogen tank should not exceed 130 PSI.

990277 Rev. A Page 7 of 46

Page 8

1.7 System Specifications

Power Requirements: 100-127 volt, AC, 50/60Hz, 0.75 A

220-240 volt, AC, 50Hz, 0.35 A

Air Requirements: 80-130 PSI (550-896 kPa) with at least

1.2 cfm (34 l/min) recommended

Approximate Size: 10” W x 9” H x 15” D (cm W x 22.9 cm H x 38.1 cm D)

Approximate Weight: 12 lbs. (5.5 kg)

Environment Limitations: Operational Requirements:

Temperature: 50° F to 104° F (+10° C to 40° C)

Humidity: 30 % to 75 %

Atmospheric pressure range:

10.15 psia ( 70 kPa) to 15.37 psia (106 kPa)

Transport and Storage Requirements:

Temperature: -40° F to 122° F (-40° C to 70° C)

Humidity: 10 % to 90 %

Atmospheric pressure range:

7.25 psia (50 kPa) to 15.37 psia

Equipment Classification: The Mach 6 is a Type B device requiring an electrical earth

ground. This device is classified as ordinary with regard to

protection against water ingress. The device is designed for

continuous operation.

Electrical Fuses: There are no customer serviceable fuses.

990277 Rev. A Page 8 of 46

Page 9

2. Theory of Operation

2.1 Introduction

The Mach 6.0 is an air abrasion system. An external air supply is required to mix abrasive powder and air in a

pressurized chamber, which then moves through the nozzle tip of the handpiece. The Front panel control provides a

means of adjusting the required air pressure and powder flow.

2.2 Functional Description

When the unit is initially turned on, the microprocessor resets all solenoids. The Particle energy indicators flash while

the STAND-BY, ON, LOW, MEDIUM, AND HIGH indicators cycle one time, in that order. When the indicators stop

flashing or cycling, the unit is ready to operate. The last settings used will be displayed. The yellow Standby

indicator will be turned on.

When the Ready Mode is selected, the system timer is set for ten (10) minutes. The Feed solenoid (SV-6) energizes

closing the canister top valve, the Canister solenoid (SV-4) energizes and the Master solenoid (SV-5) opens flushing

the filter at the top and the orifice plate at the bottom of the powder canister. After 5 seconds the Canister solenoid

(SV-4) closes, the system is pressurized. The Air On LED lights, Air Standby light extinguishes, and the system is

ready.

If the hand piece was not in the cradle on power up, and the Footswitch is depressed, the Standby lamp will flash for

½ second indicating the hand piece must be placed in the cradle momentarily. The unit will remain in the “ON” state.

If the hand piece has been in the cradle and is removed, when the foot switch is depressed, the pinch valve is opened

by Pinch Valve Solenoid (SV-1). This opens the path for powder flow from the mixing chamber to the nozzle.

When the hand piece is returned to the cradle or if the system is placed into Standby, the Pinch Valve solenoid (SV-

1) closes off the pinch tube and the foot switch is disabled Feed solenoid (SV-6) opens the valve to the top of the

canister to relieve system pressure. When the foot switch is released, the Exhaust Purge solenoid (SV-3) opens an

exhaust path to stop powder flow. The Master solenoid (SV-5) closes.

The Low, Medium or High Beam Intensity selection can be adjusted to provide optimum powder flow.

Stand-by mode may be selected by a) depressing the Stand-by / On button, or b) inserting the hand piece into the

cradle, the unit de-pressurizes. Power can then be cycled to off. After 10 minutes of non-use the unit will

automatically go to stand-by.

Safety features built into the Mach 6 unit are:

• Depressurizing when the hand piece is placed into the holder. This prevents accidental discharge of the powder

if the foot switch is depressed.

The instrument should only be powered down with the unit in the Standby Mode.

Please refer to Section 3 for preventive maintenance requirements that will keep the instrument operational.

WARNING: Do not open the top lid of the unit with power turned on!

990277 Rev. A Page 9 of 46

Page 10

2.3 Connections and Controls (refer to Figure 1 and 2)

2.3.1 DC Power Cord Connector (refer to Figure 1)

The power cord connector is the connection point for the power cord.

2.3.2 Electric Footswitch Connector (refer to Figure 1)

The electric Footswitch is the connection point for the footswitch.

2.3.3 Air In (refer to Figure 1)

The Air Supply is the connection point for the external air source.

2.3.4 Beam Intensity (refer to Figure 2)

The Beam Intensity controls the amount or intensity of abrasive powder in the air stream, affecting the cutting speed.

The user should vary this setting (low, medium, or high) to find the best performance.

2.3.5 Air Indicator (refer to Figure 2)

Indicates the status of the air pressure as “On” or “Standby”.

2.3.6 ON/OFF Power Switch (refer to Figure 2)

The power switch is located on the lower left front panel of the Mach 6.0. The switch turns the unit ON or OFF.

2.3.7 Particle Energy Scale and Control (refer to Figure 2)

Indicates the pressure with which the abrasive powder is being delivered. When the light next to a PSI value is

initialized that value has been achieved. No intermediate PSI values are indicated. When adjusting the particle energy

down, there is a delay in the actual reading. The knob should be adjusted below the desired value then back up until

the value stabilizes.

2.3.8 Hand Piece Holder (refer to Figure 2 and 3)

Holds Hand piece when not in use. Hand Piece can be placed horizontally (down) or vertically (up).

2.3.9 Hand Piece Tubing connector (refer to Figure 2)

Hand piece hose connection to the unit.

990277 Rev. A Page 10 of 46

Page 11

Power In

Air In

Foot Switch

Figure 1 Systems Rear Panel Connections

Beam Intensity

Air Indicator

Main Power

Figure 2 System Front Panel Controls and connections

Particle Energy scale

Particle Energy Control

Hand Piece holder

Hand piece hose

connector

990277 Rev. A Page 11 of 46

Page 12

Figure 3 Hand Piece Holder in horizontal or vertical position

990277 Rev. A Page 12 of 46

Page 13

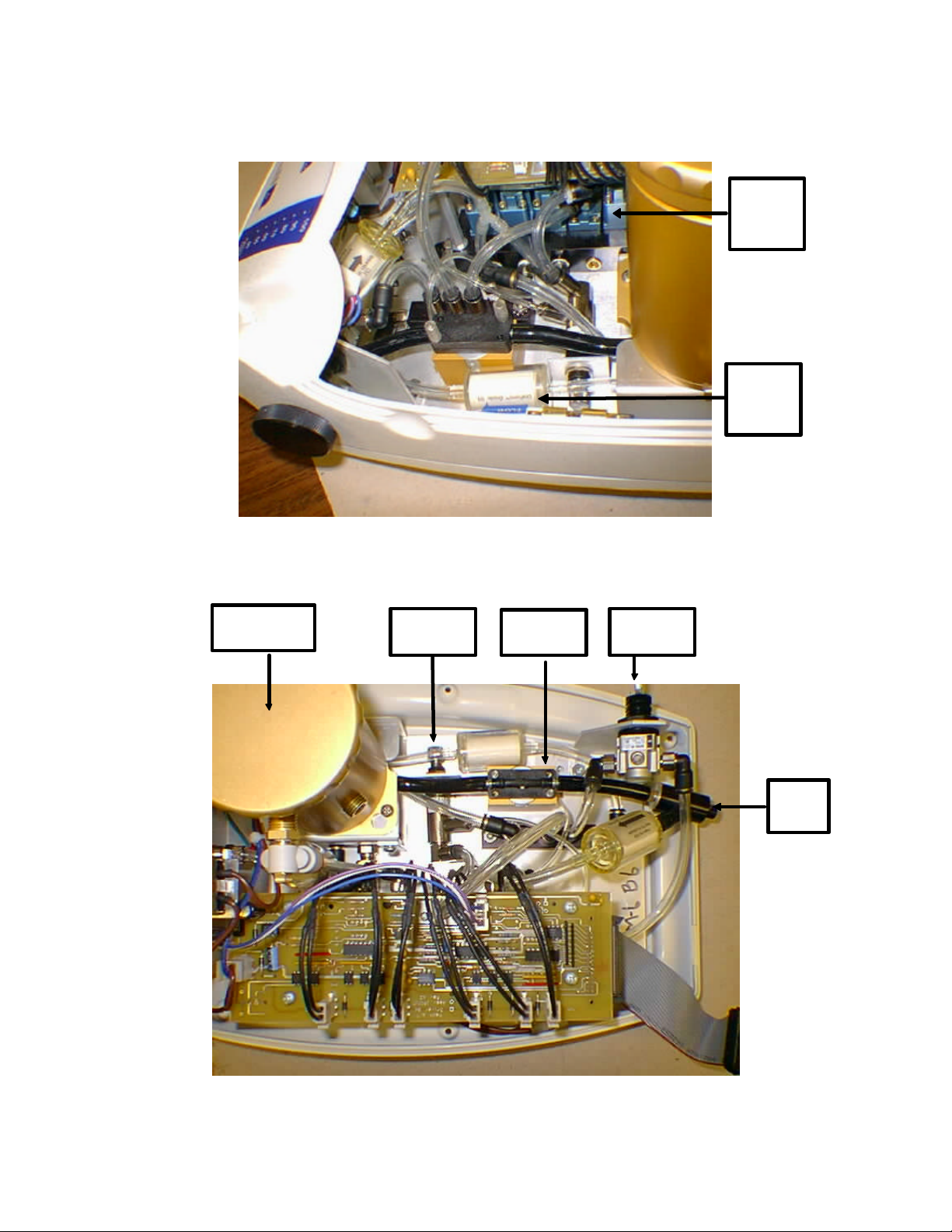

2.4 Internal Components of the Mach 6.0 (Refer to Figures 4, 5,and 6)

Solenoid

Manifold

assembly

Air In

Filter

assembly

Figure 4 Internal Components location

Powder Feed

Canister

Pinch Valve

Regulator

Pinch Tube

Valve

Pressure

Regulator

Exhaust

Catch

Figure 5 Internal Components Locations

990277 Rev. A Page 13 of 46

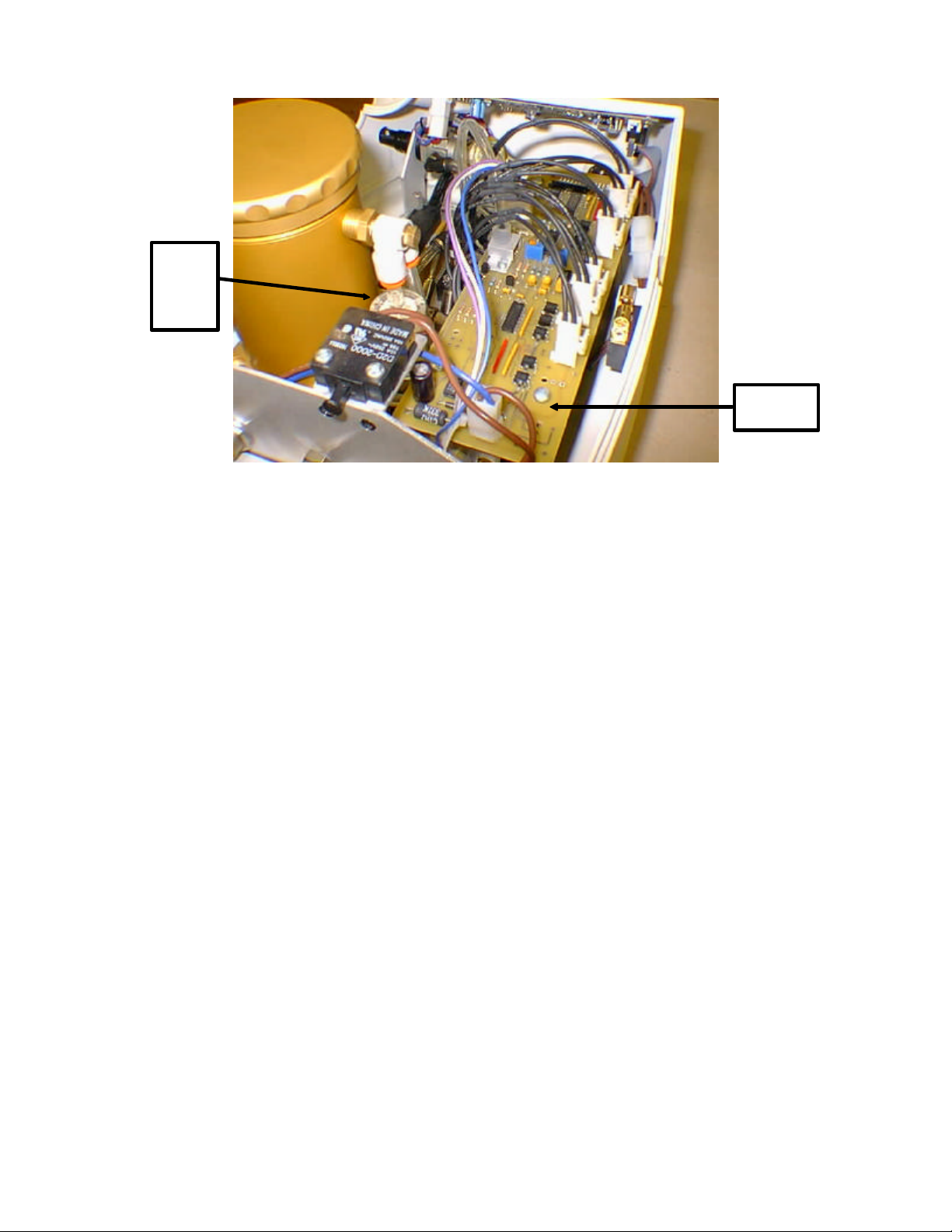

Page 14

Powder

Canister

Air Out

Filter

Figure 6 Internal Components location

2.4 Pneumatic components

(Refer to Figures 4, 5, and 6)

2.4.1 Solenoid Manifold Assembly (Figure 4)

Houses all system control solenoids that control air flow, powder flow, exhaust and de-pressurization.

2.4.2 Pinch Tube Valve Assembly (Figure 5)

Solenoid

Driver PCA

Houses the pinch tube which allows the powder - air mixture to flow to the handpiece.

2.4.3 Particle Energy Pressure Regulator (Figure 5)

The System Pressure Regulator is the mechanical device which controls the desired amount of air pressure.

2.4.4 Pinch Valve Regulator Assembly (Figure 5)

Adjusted to supply a constant amount of air for closing off the Pinch tube when needed. This is adjusted for 60 PSI.

2.4.5 Powder Canister Air In Filter Assembly (Figure 5)

Consists of a Coalescing and Silica Filters for filtering particulate matter and water vapor from entering the powder

canister. Aids in the prevention of powder clogs due to moisture or particulate matter.

2.4.6 Mach 6 Manifold Assembly (Figure 4)

Series of connections for tube routing

2.4.7 Powder Canister Air Out Filter Assembly (Figure 6)

Used to allow air to escape from the top of the canister and keep particles out of the solenoid valves.

2.4.8 Exhaust Catch Assembly (Figure 5)

Used as a method to stop powder flow when the foot switch is released.

990277 Rev. A Page 14 of 46

Page 15

2.4.9 Solenoid Driver PCA

Controls all solenoids based on input from the Display Control Panel and acts as an interface for the rest of the

system.

2.4.10 Display Control PCA

Converts user input to electronic signals for use by the solenoid Valve driver PCA to control the rest of the system.

Figure - 7 Pneumatic Tubing Diagram

990277 Rev. A Page 15 of 46

Page 16

Mach 6 Air Abrasion System Block Diagram

AC Voltage

In

Air

Input

External

12 V

Power

Supp

ly

F1

F2

ON/OFF

Switch

Atmosphere

Legend

Abrasive Fluid Path

Air Path

Electrical Connection

Interlock

SwitchPower

BV1

PF5

Powder

Canister

Mixing Chamber

SV1 Reg1

31

2

CV2

D isplay Control

PCA

Pressure

Transducer

2

31

F3

2

31

Atmosphere

30 pin Ribbon

Cable

Solenoid Driver PCA

SV2

Atmosphere

SV3

CV3

2

Pinch Valve

PV1

Foot switch

Reg2

SV4

31

2

31

F4CV1

Exhaust Catch

Manifold

SV5

SV6

31

Atmosphere

2

Handpiece / Nozzle

Figure - 8 Pneumatic Block Diagram

2.5 Electrical/Electronic Components

(Refer to Figures 8 9, and 10)

2.5.1 External Power Supply

Provides 12 VDC input to the rear of the Mach 6

2.6.2 Solenoid Driver PCA (Figure – 6)

Controls all solenoids based on input from the Display Control Panel and acts as an interface for the rest of the

system.

2.5.3 Display Control PCA (Figure -8)

Converts user input to electronic signals for use by the solenoid Valve driver PCA to control the rest of the system.

2.5.4 Foot Switch

Input on/off control signal to Display Control PCA from foot switch.

990277 Rev. A Page 16 of 46

Page 17

2.5.5 Main ON/OFF Solenoid Valve (SV-1)

Controlled by the Solenoid Driver board and pressurizes the system when the ready mode is selected.

2.5.6 Feed Purge Solenoid Valve (SV-2)

Controlled by the Solenoid Driver board and is used to back flush the porous filter located in the Powder Canister.

2.5.7 Feed Solenoid Valve (SV-3)

Controlled by the Solenoid Driver board and is used to release the pressure from the canister top. When foot switch

valve opens and powder flows from canister. The longer this is open to less powder flow.

2.5.8 Pinch Solenoid Valve (SV-4)

Controlled by the Solenoid Driver board and controls the pressurization and de-pressurization of the pinch valve.

When foot switch is depressed, the valves opens and closes 3 times a second.

2.5.9 Exhaust Catch Purge Solenoid Valve (SV-5)

Used to back flush Filter 4 each time the foot switched is depressed.

2.5.10 Exhaust Catch Solenoid Valve (SV-6)

Controlled by the Solenoid Driver board and opens and closes the low resistance flow path that causes venturi effect

and stops abrasive flow to the hand piece hose and nozzle.

Figure - 9 Display and Control PCA

990277 Rev. A Page 17 of 46

Page 18

Figure - 10 Interconnect Diagram

Pinch Solenoid

Valve (SV-4)

Exhaust Catch

Valve (SV-6)

Exhaust Catch

Purge (SV-5)

Figure - 11 Solenoid Valve Manifold Assembly

Feed Purge Valve

(SV-2)

Main ON/OFF

Valve (SV-1)

Feed Solenoid

Valve (SV-3)

990277 Rev. A Page 18 of 46

Page 19

3. ROUTINE MAINTENANCE

3.1 Routine Maintenance of the Mach 6.0

Welch Allyn Kreativ Air Abrasion systems have been designed to operate with a minimum of operator attention.

Like all mechanical systems, they will operate longer and with less trouble when operator maintenance is performed

regularly. Maintenance on a Welch Allyn Kreativ Air Abrasion system is limited to cleaning, infrequent lubrication,

pinch tube replacement, and filter cartridge replacement. The maintenance procedures have been categorized by their

frequency of action and are described in this chapter with specific instructions.

3.2 Daily Requirements

3.2.1 Powder Canister

Observe the powder level in the Powder Canister, and inspect for moisture contamination. If moisture contamination

is present, the powder will not flow evenly or will appear as wet sand. Replace the powder if it is contaminated. Add

new powder, and clean the threads on the top of the canister. Remove and clean the cap gasket, and cap. Clean the

cap threads, and install the cap and tighten securely. If the cap is not secure, air leaks can occur which will affect

cutting efficiency.

NOTE : To check the powder level in the Powder Canister, turn the unit off to release the internal pressure in the

canister. If the canister is pressurized or the unit in the READY mode, the user will not be able to unfasten the cap

ring.

Complete the following procedure to empty the Powder Canister:

1. Turn the unit off to de-pressurized the system.

2. Open the top.

3. Remove the hoses connected to the canister top and bottom.

4. Remove the lid from the Powder Canister by turning the cap counterclockwise.

5. Loosen the two screws that secure the canister to the mounting bracket then turn the canister counterclockwise to disengage.

6. Empty the Powder Canister.

7. Use a brush or a vacuum to remove any powder remaining in the canister.

NOTE: It is necessary to empty the Powder Canister if the unit will be stored for a period of six weeks or

more. This will ensure that the powder is not subject to humid air conditions which may contribute to

“heavy” powder, causing the Orifice Plate Holes to clog.

Cleaning the Powder Canister:

If the Air Supply source contains moisture or other contaminants, the powder may clog the Orifice Plate Holes.

Complete the following procedure to unclog the holes:

1. Repeat the procedures for “Emptying the Powder Canister”, steps 1-7.

2. If powder is heavily contaminated, discard it. If the powder looks “heavy”, place the powder in a

microwaveable container. With the microwave set on high, cook the powder for 45 seconds. Set aside

and let cool.

990277 Rev. A Page 19 of 46

Page 20

3. Re-install the Powder Canister without the powder. Also ensure that the two screws are securely

fastened.

4. In the bottom of the canister, there are a series of five small holes. With a .0015 Endo file or an Ortho

wire, gently penetrate through the openings.

NOTE: Only remove the clogs. Too much filing will result in excess powder flow.

5. Replace the canister lid securely.

6. Ensure that the handpiece nozzle is not clogged by gently penetrating the nozzle opening with an Endo

file.

7. With the unit in the Ready position, set the “Beam Intensity” to HIGH and the Particle Energy at the

highest available pressure, point the handpiece into the KleanAir® System or vacuum. Press the

Footswitch for approximately one minute to purge the system. Return to the Standby mode.

8. Refill the Powder Canister with abrasive powder.

3.3 Weekly Requirements

3.3.1 Filters

Inspect all in-line filters for damage, presence of moisture, or color change.

3.3.2 Pinch tube

The pinch tube should be inspected for wear and tear weekly. Replace as required.

Conditions which are common when the pinch tube fails are as follows:

1. Changes in air and powder flow will result in erratic and/or poor cutting efficiency.

2. The Particle Energy may have difficulty reaching and maintaining desired setting.

3. If the pinch tubes are not replaced when failure has occurred, an audible air leak will be apparent and

abrasive powder will eventually discharge into the chassis.

4. When changing pinch tubes, the user may inadvertently neglect to get the shoe block covers secure.

Tighten the thumb screws to minimize the gap to ensure proper performance.

3.3.3 Powder Chamber

Inspect the powder chamber for moisture.

Look for powder clumps or wet powder and discard or replace as necessary.

To dry wet powder:

1. Place powder to be used in a microwave safe container.

2. Microwave on high for 45 seconds to dry the powder prior to placing in the chamber.

NOTE: Care should be taken when removing the container from the microwave, as it may be hot.

3.4 Monthly Requirements

3.4.1 Internal tubing

Inspect internal tubing for wear and air leakage.

Listen for audible leaks and look for powder accumulation internal to the unit.

Soapy water and a small paint brush are ideal for finding small leaks. Clean up excess powder to help isolate the leak

area.

990277 Rev. A Page 20 of 46

Page 21

If leaks are found, try re-seating tubing in their fittings.

If leaking persists, contact your authorized Welch Allyn / Kreativ service representative.

3.4.2 Handpieces and Nozzles

The handpieces and nozzles for the Mach 6 can be sterilized by any standard dental autoclave, ultrasonic sterilizer, or

manual sterilization practices. After removal from the autoclave, it is important to allow the nozzles and handpieces to

dry completely before use. If the handpieces and nozzles are not allowed to dry, the handpiece and nozzles may

become clogged.

If clogging occurs, complete the following procedure:

1. Remove the handpiece assembly from the handpiece hose.

2. Blow air into both the nozzle and handpiece ends.

3. If the air fails to resolve the clogging, use an Endo file or Ortho wire to penetrate the nozzle opening.

The nozzles are subject to wear and will require replacement at some point in time. Indications of wearing on the

nozzle are a decrease in cutting efficiency, an undefined stream of powder flowing from the nozzle slits along the side

of the tip.

3.5 Quarterly Requirements

3.5.1 Pinch Tubes

The Pinch tube should be replaced quarterly. A package of is supplied with each handpiece kit.

Complete the following procedure to change a pinch tube:

1. Turn the unit off. Wait until the unit has depressurized.

2. Ensure that the unit is in the OFF position and that the power cord is disconnected from the electrical

outlet.

3. Remove the Top pinch valve block cover by turning the thumb screws counterclockwise.

4. Remove the worn pinch tube by gently pulling it from the fittings. Discard the tube.

5. Insert a new pinch tube, and place the fittings and pinch tube into the bottom block indentations.

6. Replace the top block, ensuring that the fittings and pinch tube align properly. Secure the top block

with the thumb screws.

CAUTION: Failure to ensure the top and bottom block are secure will result in an air leak situation or

may potentially cause damage to the internal components.

7. Resume normal operation.

An additional factory recommendation is to inspect the shoe block covers for wear whenever a pinch tube has been

replaced. Maintenance negligence of pinch tube replacement will result in scarred shoe block covers and may

contribute to additional internal component damage, again resulting in equipment malfunction.

3.6 BI-Annual Requirements

3.6.1 Pinch Valve Assemblies

Lubricate the Pinch valve assembly to ensure proper powder delivery. A Pinch Valve Maintenance Kit (P/N 150036)

is available with all of the necessary pinch valve parts.

Complete the following procedures to lubricate the pinch valve assembly:

990277 Rev. A Page 21 of 46

Page 22

1. Turn the unit off.

2. Ensure that the unit is in the OFF position and that the power cord is disconnected from the electrical

outlet.

3. Open the Top.

4. Remove the thumb screws, turning counterclockwise to remove the top shoe block. Discard the shoe

block. Set the thumb screws aside.

5. Pull the pinch tube from its fittings. Discard the pinch tube, and inspect the fittings for wear. Replace

the fittings if necessary.

6. With a small slotted screwdriver, remove the set screws for the bottom shoe block, turning

counterclockwise, ensuring that pressure is applied to the bottom shoe block, since a spring is behind

the shoe block which may dislodge unexpectedly. Discard the bottom shoe block. Lay the set screws

aside.

7. With the bottom shoe block removed, a spring and shoe will dislodge freely.

8. Discard the shoe. Set the spring aside.

9. With a small set of needle nose pliers, remove the retaining ring. Set it aside.

10. Remove the diaphragm. Discard it .

11. Remove the piston. Remove the o-ring from the piston, and discard it.

12. Clean all parts thoroughly.

13. Install the new piston o-ring, and lightly apply lubricant around the o-ring. NOTE: Only factory

specified lubricant (Superlube) should be used.

14. Set the piston aside.

15. Thoroughly clean the internal pinch valve assembly.

16. Generously lubricate the internal piston portion of the pinch valve assembly.

17. Re-assemble pinch valve assembly.

3.7 Annual Requirements

3.7.1 Air In and Out In-Line Filters

The following in line pre-filters will need to be replaced on an annual or “as needed” basis.

1. Water Vapor Coalescing Filter K480023

2. Particulate Filter K480060

3. Absorbing Filter K480083

3.7.2 Internal Tubing

The internal tubing should be inspected for wear and for air leakage monthly. The unit internal tubing should be

replaced yearly.

3.7.3 Powder Canister

The Powder Canister cap gasket should be replaced yearly or when damage is found.

990277 Rev. A Page 22 of 46

Page 23

Maintenance Checks

No. Maintenance item 6 12 18 24

Mo. Mo. Mo. Mo.

PM 1 Maintain Pinch Valve XX XX XX XX

PM 2 Replace Filters & Tubing XX XX

PM 3 Maintain Powder Canister XX XX

PM 4 Calibrate system XX XX XX XX

PM 1. Maintain pinch valve block (Mach 6: P/N: 170179P; 6/12 Months): .50 hour

One Year Maintenance Kit K150034

Replace Components (1) K150036

Clean and lubricate pinch valve components

PM 2. Replace the Exhaust Catch and Air In/Out filter

assemblies and tubing (12 months): 1.0 hour

One Year Maintenance Kit K150034

Exhaust Catch Coalescing filter K480023

Air In Particulate filter (2) K480060

Air In Absorption filter K480083

Air Out Particulate filter K480060

Kynar “Y” K360004

Tubing, 1/16” ID (1.1 feet) K99-00200-1

Tubing, 1/8” ID (5.25 feet) K99-00200-3

Tubing, Pallethane (.55 feet) K390008

PM 3. Check Powder Canister (6/12 months): 0.5 hour

One Year Maintenance Kit K150034

Check Canister Gasket and lid

Clear powder ports and back flush canister

Clean Gasket and Canister lid

Clear and measure Orifice Plate holes

Replace powder and verify system operation

Maintain Powder Canister (12 month) 1.0 hour

Replace Canister Gasket K210207

990277 Rev. A Page 23 of 46

Page 24

Replace Orifice Plate Gasket K210082

Replace Gasket Base Cap K01-00153-1

Replace Orifice Plate K210140

Replace large super hose (black, XXX ft) K390008

PM 4. Calibrate system (6 months): 1.0 hour

Verify and calibrate using procedure in PM-4

990277 Rev. A Page 24 of 46

Page 25

PM-1 MAINTAIN PINCH VALVE BLOCK .5 hour

PARTS

1. Superlube (6 and 18 month Maintenance) K460015

2. Pinch Tube Maintenance Kit (12 and 24 month) K150036

TOOLS

1. Lint free cloth

2. #1 Flat blade screwdriver

3. Needle nose Pliers

DRAWINGS AND INSTRUCTIONS

1. Pinch Valve Body assembly KMP170179

Procedure

NOTE: If this is the 12 or 24 month PM, replace all parts

1. Disassemble pinch valve block.

2. If performing the 6 or 18 month PM, clean, inspect, and lubricate all parts. If there is any indication

of damage to the parts, replace the parts and proceed to step 6.

If performing the 12 or 24 month PM’s proceed to step 3.

3. Discard Diaphragms, “O” rings.

4. Inspect Shoe blocks, block top and bottoms. Discard block tops, bottoms, spring, piston, pinch

tube, and diaphragm.

5. Clean and lubricate pinch valve blocks and pistons.

6. Reassemble the pinch valve blocks per drawing.

7. Test and calibrate unit if required.

PM-2 REPLACE TUBING AND FILTERS (12months) 1.0 hour

PARTS

1. Exhaust Catch Coalescing filter K480023

2. Air In Particulate filter K480060

3. Air Out Particulate filter K480060

4. Air In Absorption filter K480083

5. Tubing (0.55 feet) K390008

6. Tubing (1.1 feet) K99-00200-1

7. Tubing (5.25 feet) K99-00200-3

8. Kynar Y K360004

TOOLS

1 Flat blade and Phillips screwdriver (# 2)

2 Side cutters

3 Alcohol or Leak Detect

990277 Rev. A Page 25 of 46

Page 26

4 Low pressure Air Source

DRAWINGS AND INSTRUCTIONS

1. Pneumatic Schematic K950028

Procedure

NOTE: When working with the powder, always work in a well ventilated

area.

1. Disassemble the unit to gain access to all sub-assemblies by:

a. Removing the hand piece dress nut from the front of the unit.

b. Disconnect the “On/Off switch cable at the 2 position connector.

c. Remove the Regulator knob from the right side of the unit.

d. Disconnect the 30 pin ribbon connector from the Display Control PCA.

e. Turn the unit over and remove the four phillips screws, located in the feet.

f. Remove the cover.

2. Replace the filters, Kynar “Y”, and tubing one length at a time so as not to get the

connections or paths mixed up. The tubing lengths can be found in Section 7 under each

individual sub-assembly.

3. Install cable ties and tubing clamps as required.

4. Reassemble the unit..

5. Test and calibrate unit

PM-3 INSPECT POWDER CANISTER (6 months) .5 hour

PARTS

1. None

DRAWINGS AND INSTRUCTIONS

1. KMP170180

TOOLS

1. Go/NoGo Pin Gage (.14/.16)

2. Phillips Screwdriver

3. Needle Nose Pliers

4. # 10 Endo file or Ortho wire

5. Air Source

6. Microwave Safe Dish

7. Alcohol Prep

8. Leak Detector

DRAWINGS AND INSTRUCTIONS

1. Canister Assembly KMP170180

Procedures

990277 Rev. A Page 26 of 46

Page 27

1. Place the unit in Standby condition or insert the handpiece into the holder.

2. De-energize the unit (main power switch located on the front of the unit).

3. Disconnect the power and air source from the unit.

4. Remove the canister by:

a. Removing the Pinch Tube top cover.

b. Remove the input tubing from the right side of the canister

c. Remove the outlet tubing from the Branch fitting on the upper left of the canister.

d. Loosen the 2 phillips screws

5. Remove the canister by twisting the canister and pulling upward.

6. Open the canister and pour the powder from the canister (place in a microwave safe dish

for drying).

7. Using an air source, blow out the CUP’d Porous filter from the outside in.

8. Remove the bottom of the canister removing the 3 countersink screws and removing the

bottom.

9. Clean the powder residue that may be built up on the gasket and mounting surfaces. Pay

attention as to how the rubber gasket was installed.

10. Clean off the gaskets and set aside for later use. The gaskets will be reused for the 6 month

PM and replaced for the 12 month.

11. Using a # 10 Endo file or Ortho wire, remove any debris or lodged powder from the five

holes in the bottom of the orifice plate.

12. When this is complete, reassemble the bottom of the canister.

13. Install the canister cap and connect the unit to correct power and air.

14. Energize the main power switch.

15. Remove the handpiece and place the unit into the “READY” condition.

16. Put on eye protection.

17. While holding the hand piece into an evacuation system or appropriate container for

disposal, operate the unit by manipulating the foot pedal. The unit will automatically stop

after one minute. You should pump the foot pedal and depress it continuously. You should

adjust to the maximum pressure available. This should help dislodge any possible powder

plugs the system may have developed.

18. Place the handpiece in the cradle.

19. Dry the powder out by placing in a microwave for approximately 45 seconds on high.

20. Fill the powder canister as required.

21. Reinstall the canister lid and re energize the system.

22. Test the cutting ability on a Learn-A-Prep.

23. Return the unit to ready state or repair as required.

PM-3 REPLACE CANISTER COMPONENTS (12 months) .5 hour

Follow the procedure as described above except replace the following parts

1. Orifice Plate K210140

2. Orifice Plate Gasket K210082

3. Base Cap Chamber Gasket K01-00153-1

990277 Rev. A Page 27 of 46

Page 28

4. Cover Powder Feed Gasket K210207

PM-4 Calibrate the Unit 1.0 hour

PARTS:

1. NONE

TOOLS

1. DMM (Fluke 77 or equivalent)

2. Air Pressure Gauge (0-160 PSI, 1 PSI resolution)

3. Various Pneumatic fittings

4. Small Adjustment screwdriver

5. Leak Detector (K360007)

6. TORQUE Seal (K450008)

7. Welch Allyn Kreativ 27.5 Micron Powder

8. Pin Gauges, 0.014, 0.016, 0.0175”, 0.018” & 0.0185”

9. Power Supply (12 V, 2.75 A; K590005)

10. Foot Switch Assembly, (K180086)

11. M6/7 Handpiece Hose Assembly; P/N 170210

12. Handpiece Standard Assembly; P/N 200002

13. Nozzle Assembly, Blue; P/N 170011-1

14. “T - 1”, ¼ “ T” fitting (K360030)

15. “T - 2”, ¼” x ¼” x 1/8” Reducer fitting (K360078)

16. Reducer, ¼ “ x 1/8 “ In-line reducer fitting (K360079)

DRAWINGS or PROCEDURES

MACH 6 Calibration procedure

CALIBRATION PROCEDURE:

Transducer Calibration.

1. Install a “T-1” fitting and calibrated pressure gauge inline between the pressure transducer and the

Manifold Assembly. Refer to “Leak Test Connection, Figure 12.

2. Connect clean dry air to the Mach 6 with at least 120 psi.

3. Turn power “ON” to the Mach 6 and override the interlock switch.

4. Set the DMM to measure “DC Volts” and connect the positive lead to R4 on the Solenoid Driver

PCA and the ground lead to the negative lead of C-18. Refer to Figure 13.

5. Adjust R9 on the Solenoid Driver PCA for a reading of 0.00 ± 0.01 Vdc.

990277 Rev. A Page 28 of 46

Page 29

6. Turn the unit from standby to ready, and adjust the Particle Energy to 100 psi.

7. Adjust R1 (span) on the Solenoid Driver PCA to yield a reading of 3.00 ± 0.01 Vdc (2.99 to

3.01).

8. Adjust the Particle Energy up and down to verify the pressure gauge matches the calibrated

pressure transducer. If the pressure gauge and Particle Energy display do not match, adjust R1,

and repeat this step until they are the same.

9. Turn the unit to standby.

10. Turn power “OFF”. Disconnect the air source and pressure gauge, reconnect the pressure

transducer to the Manifold Assembly.

11. Apply Torque Seal (P/N 450008) to potentiometers R1 and R9.

Pinch Valve Regulator Adjustment.

1. Insert a “T-2” and Reducer fitting and calibrated pressure gauge in the tube between the pinch valve

regulator and the “Solenoid Manifold Assembly”. Refer Pinch Tube Regulator hose on Figure 12.

2. Turn power “ON” .

3. Apply air pressure of 120 PSI to the input of the unit.

4. Place the system into the ready mode.

5. Adjust the pinch valve regulator to 60 PSI.

6. Toggle the unit from standby to ready a few times.

7. Measure the Pinch Valve Regulator pressure. If the measured pressure is 60 PSI ± 2 PSI, proceed

to step 8. If the criteria is not satisfied, repeat steps “4” through “7” until the criteria is satisfied.

8. Put the system into the standby mode.

9. Remove air pressure.

10. Remove the T” connector and calibrated pressure gauge.

11. Apply Torque Seal (P/N 450008) to Regulator Adjustment screw.

Solenoid Valve Tests.

Main On/Off Solenoid Test.

1. Turn the Unit power “ON”.

2. Remove the canister top.

3. Apply air pressure to the rear of the unit.

4. Set the unit to the ready mode.

5. Verify that air flows up through the bottom orifice plate of the canister.

6. Set unit back to standby.

990277 Rev. A Page 29 of 46

Page 30

Feed Purge Solenoid Test.

1. Clamp the tubing, use non-serrated clamping device, between the Manifold Assembly and the Air In

Filter Assembly. Refer to “Feed Purge Solenoid “ Figure 12.

2. If canister top is not removed, remove it now.

3. Place your hand over the porous filter located inside the canister.

4. Set the unit to the ready mode.

5. Verify that air flows from the porous filter located inside the canister. This air flow will only last

about 5 seconds, so if you miss the air flow turn the system back to the standby mode, and then

back to the ready mode.

6. Return the unit to the standby mode.

7. Replace the powder canister top.

8. Remove clamp from the tubing.

Feed Solenoid Test

1. Set the unit to the ready mode.

2. Ensure the hand piece is in the cradle. Remove the handpiece and push the foot pedal.

3. Verify that air flows from the “Air Silencer” on the rear of the “Solenoid Manifold Assembly”. When

the foot pedal is first pushed, there should be one long pulse and three pulses per second thereafter

while the foot pedal is pushed.

4. Release the foot pedal.

Pinch Solenoid Test

1. With the unit still in the ready mode, press the foot pedal.

2. Verify that the pinch valve solenoid, and the pinch valve is pulsing approximately three times a

second.

3. Release the foot pedal.

Exhaust Catch Purge Solenoid Test.

1. Remove the hose, refer to Figure 12, from the Solenoid Manifold..

2. With the unit still in the ready mode, press the foot pedal.

3. Verify that a burst of air flows from the port of the Solenoid Manifold that the tube was removed.

The burst will be for a short period of time each time the foot pedal is pushed. Push and release the

foot pedal a few times verify the burst of air for each push.

4. Replace the tubing, and verify it doesn’t leak by pushing the foot pedal, and using leak detector

around the connection.

990277 Rev. A Page 30 of 46

Page 31

Exhaust Catch Solenoid Test

1. Install a handpiece hose onto the Front panel connector.

2. With the unit in the ready mode, put your finger near the nozzle output, press the foot pedal for 3-5

seconds, and then release the foot pedal. When the foot pedal is released, the air coming out of the

nozzle should stop in approximately one second or less. If this happens, the Exhaust Catch

Solenoid is working properly. If air continues out the nozzle after one second, fix the problem and

retest.

Leak Test

1. Install “T-1” and a calibrated pressure gauge inline between the pressure transducer on the Solenoid

Driver PCA and the Manifold Assembly. Refer to “Leak Test Connection” on Figure 12.

2. Power up the Unit.

3. Set the unit to the ready mode.

4. Adjust the Particle Energy to 100 PSI.

5. Allow the air pressure to stabilize for 15 seconds, and verify the pressure gauge still reads 100 PSI.

Re-adjust if necessary (refer to Transducer Calibration).

6. While periodically cycling the unit, monitor the gauge for continuous drops in pressure, and apply

Leak Detector fluid P/N K360007 to every pneumatic connection in the system. Any bubbles

indicate a leak. If leaks are found fix all leaks and repeat the last two steps.

Power-Up Tests

1. Turn power “ON” .

2. Immediately after power-up, verify the following display sequences occur:

a. All LEDs and LED segments flash ON and OFF.

Powder Flow Test

1. Test operate the unit to verify unit will cut.

2. Because the powder flow is an objective item, we recommend you allow the doctor to operate the

unit and verify it is to his satisfaction. Powder Flow testing is performed at the factory using at

Beam Intensities of “Lo” and “High” with a Particle Energy of 70 PSI.

990277 Rev. A Page 31 of 46

Page 32

Exhaust Catch

Purge Solenoid

Pinch Valve

Regulator hose

Leak Test

Connection

Feed Purge

Solenoid

Figure 12 Mach 6 Test Connection Diagram

Negative lead

of C-18

Positive Lead

R-4

Offset Adjust

R-9

Gain Adjust

R-1

Figure 13 Solenoid Driver Component locations

990277 Rev. A Page 32 of 46

Page 33

4. TROUBLESHOOTING

4.1 Powder Flow Problems

PROBLEM SYMPTOM(S) SOLUTION

No powder or air from the

handpiece nozzle.

Air from the handpiece but no

powder flow.

Air and powder from the

handpiece flow for only a few

seconds then stop.

Air and powder flow continuously from handpiece even

when in the Standby mode.

Powder inside the unit

chassis.

Operational LEDs are fully

functional, but there is no

powder or air.

Operational LEDs are fully

functional.

Unit is fully operational, but

powder only flows for a few

seconds when the footswitch is

pressed.

• Change pinch tube.

Powder all throughout the unit. • Blown Pinch Tube

• The handpiece is clogged. Use an endo or

ortho wire to clear the nozzle. Disconnect the

handpiece from the handpiece hose and blow air

through it.

• No Powder

• Blown Pinch Tube

• Clogged orifice plate. Empty the powder from

the canister. With an endo or ortho wire, gently

move the wire back and forth in the small holes

in the bottom of the Powder Canister.

• Pinch Valve Piston stuck

• A pinch tube is sticking. Replace the pinch

tube.

• Pinch Valve Piston stuck

• Shoe block cover is scarred. Replace the shoe

block cover.

• Hole in Powder tubing

• Shoe block cover is scarred. Replace the shoe

block cover.

Unit Plugged into Water Contact Welch Allyn Service center for unit Repair

990277 Rev. A Page 33 of 46

Page 34

5. Installation Considerations

5.1 Site Preparation for Welch Allyn Kreativ Air Abrasion Systems

Welch Allyn Kreativ Air Abrasion systems require an external source of clean, dry, compressed air or nitrogen and a

standard 110 or 220 volt outlet. In most cases your existing dental compressor is adequate. Compressed nitrogen or

an alternative compressed air source can be used if your present office compressor cannot supply enough pressure.

Air Supply

110VAC or

220 VAC

Footswitch

Welch Allyn Kreativ Mach 6 System

(11" x 11" x 13")

Handpiece

Figure 14 Connection of the Welch Allyn Kreativ Air Abrasion

System

High Volume Evacuation system: Use of a high volume evacuation system (HVE) is necessary when using the Air

Abrasion System. Your in-office high volume evacuation system can be used. The abrasive should not damage your

system as long as it is properly maintained. Welch Allyn Kreativ KleanAir system used in conjunction with your

HVE will optimize the evacuation of any abrasive that escapes from the oral cavity as well as spray from rinsing and

gases of fumes from materials used in the preparation. (Review the KleanAir brochure for more information.)

There are three possible sources for compressed air/nitrogen available for use with the Welch Allyn Kreativ Air

Abrasion system. Review all three options to determine which is best for you.

• Option #1 Present In-Office Compressor System

• Option #2 Compact Compressor System

• Option #3 Compressed (bottled) Nitrogen

NOTE: Other bottled gases such as compressed air or CO2 are NOT usable. They contain water and oil which will

cause the system to clog and not work properly.

5.1.1 Option #1: Present In-Office Compressor System

In most cases the Welch Allyn Kreativ Air Abrasion system can use your existing dental compressor. The following

will enable you to determine if your compressor can supply the required pressures/air:

990277 Rev. A Page 34 of 46

Page 35

• Air pressure: The Welch Allyn Kreativ Air Abrasion system requires a maximum of 130 PSI and a

minimum of 80 PSI of clean, dry air. Check with your compressor service company regarding the

capability of your compressor system.

• Air Dryer System: Clean, dry air is absolutely essential for the Welch Allyn Kreativ Air Abrasion

system to operate properly. Moisture or oil in the air supply can cause clogging in the abrasive flow

path and prevent the unit from operating or cutting properly. Welch Allyn Kreativ suggests that you

have your dryer system checked and serviced prior to installation of the system. Welch Allyn Kreativ

offers a small in-line dryer/filter system that can be connected in-line with the air abrasion system if

clogging problems do occur.

• Connecting the Welch Allyn Kreativ Air Abrasion system to the office air supply: Since the proper

tools and training, as well as knowledge of how your system operates, are necessary, it is important for

your compressor service company to install the air supply connection. The Air Supply Line can be

connected at any point in the Main Air Line between the System Dryer and the Operatory Chair

Regulator (see Figure14). The most common hook up is a supply line with a “quick disconnect” fitting

so that the air abrasion system can be moved easily from operatory to operatory. A 10-foot long air

supply hose with a quick disconnect fitting on each end is provided with the air abrasion system. The

fitting is a standard size and type (Parker Company P/N #393P-4-4).

Compressor Dryer

Air Supply

to System

Quick Disconnect

Operatory

Regulator

Figure 15 Connecting Air Abrasion Unit to In-Office Air

5.1.2 Option #2: Compressor System

Welch Allyn Kreativ has designed an optional, small, quiet, and compact compressor system that is powerful enough

to supply dry, clean air. It operates on a standard 110 or 220 volt outlet. The compressor is small enough to fit in a

cabinet or under a counter. You may want to put it in a utility room and have the air supply hose run a short distance

to the Operatory. The compressor operates so quietly that one usually cannot hear it over the noise of other

equipment/instruments already in the Operatory. The system’s simple and reliable design insures minimal

maintenance.

110 VAC or

220 VAC

Compact Compressor System

(Approx. 20" x 14" x 12")

Air

Supply

Line

Air Abrasion

System

Figure 16 Connecting Welch Allyn Kreativ Compressor System

990277 Rev. A Page 35 of 46

Page 36

5.1.3 Option #3: Compressed (bottled) Nitrogen

The Welch Allyn Kreativ Air Abrasion system can operate on compressed (bottled) nitrogen. Bottles and tanks of

various sizes are readily available anywhere in the country from your dental supply company or local bottled gas

supplier. The size of the bottle you order will depend on where you decide to store it. A smaller bottle could be

placed on a small cart and moved from room to room, but being smaller, it would need to be refilled more often. A

larger bottle can be stored in one place, and supply line(s) can then be run to the operatory(s) where you plan to use

the system. How long a bottle/tank will last will depend on the size of the tank and the daily usage. You should

consider the following when looking at this option:

• Size bottles/tanks that are available

• Storage requirements

• The cost of having the bottle/tank refilled

Welch Allyn Kreativ recommends a regulator that is adjustable to no more than 130 PSI. We have tested several

regulators and have found that either of the regulators listed below to be most suitable:

• Harris Company

Regulator model 425-125-580 SI

Contact your local gas supplier.

(Available from Welch / Allyn Kreativ)

• Victor Company

Regulator model VTS 253 D

Contact your local gas supplier.

CAUTION: Other regulators will work but can be adjusted to 200 PSI or higher. Damage can occur if pressure higher

than 130 PSI is applied. Damage due to extreme over pressure is not covered by the warranty.

Regulator

Tank of

Nitrogen

Air Abrasion

System

Figure 17 Using Bottled/Tanked Nitrogen

990277 Rev. A Page 36 of 46

Page 37

5.2 Dental Chair Pneumatic Integration Instructions Mach 6.0

5.2.1 Chair Integration Kit (P/N 140058)

Air Supply Hose Assembly (P/N 170206)

• K360015 Reducer Fitting

• K360016 Quick Disconnect Male Coupler

• K99-00283-1 Tube Clamps

• K390002 Tubing 3/16 ID x ¼ OD

Pneumatic Footswitch Adapter Assembly (P/N 170205)

Pneumatic Footswitch Adapter Installation Instruction

Enclosed in the Pneumatic Footswitch Adapter kit (140045 or 140058) please find:

• Pneumatic Footswitch Adapter box (part #170199) for M5/5+ or (part #170205) for M6, 7 and 8

• Interconnect tubing assembly (part #170206)

1. Locate the pneumatic lines connected to the Dental Chair Pneumatic Footswitch.

2. Repeatedly press and release the Dental Chair Footswitch while holding the pneumatic lines. The tube you feel

pulsing is the Footswitch Return line, mark it for later reference (step 4).

3. Close the valve from the office compressor to the dental chair/unit and bleed pressure from the line.

4. Install the Tee to the Footswitch Return line from the Pneumatic Footswitch.

5. Route interconnect tubing assembly from the Tee to the Pneumatic Footswitch Adapter box. Install the male

quick disconnect into the Adapter box pneumatic port.

6. Locate the electrical connector attached to the Adapter box and connect it to the Electrical Footswitch input on

the air abrasion instrument.

7. Open the valve from the compressor to restore pressure to the dental chair/unit.

8. Check new connections for leaks.

Figure 18 Pneumatic Footswitch Adapter Schematic

990277 Rev. A Page 37 of 46

Page 38

6. Spare Parts List

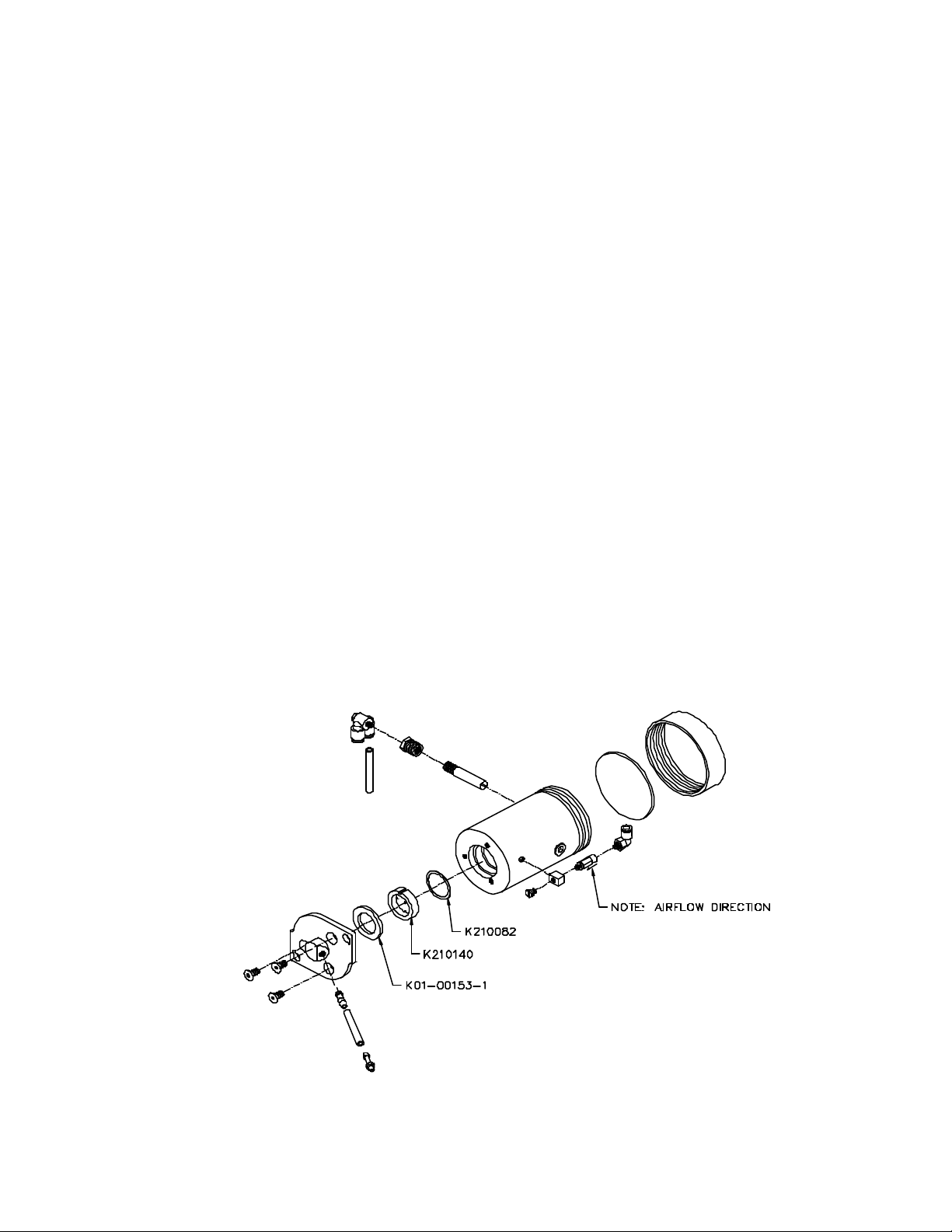

6.1 Canister Powder Feed Assembly Components

Part Number Description

K170180 Canister Powder Feed Assembly

K210140 Powder Feed Orifice Plate

K01-00172-1 Nipple Fitting Assembly

K170177 Canister Bottom Fitting Assembly

K210174 Powder Feed Canister Cover

K210207 Powder Feed Canister Cover Gasket

K01-00153-1 Gasket, Base Cap

K480089 Check Valve

K210082 Gasket, Orifice Plate

K480053 Filter Cup’D Porous

K390008 Tubing Black Pallethane (0.3 feet)

K210136 Fitting, Porous Filter Adapter

K99-00255-1 Fitting, 10-32 Nipple

K360045 Fitting, “T” x 10-32

K360038 Elbow Fitting

K99-00200-3 Clear Tubing 1/8 ID x ¼ OD (0.8 feet)

K360039 Fitting Elbow ¼ Push

990277 Rev. A Page 38 of 46

Page 39

Figure 19 Canister Powder Feed Assembly Components

6.2 Pinch Valve Components

Part Number Description

K170179 Pinch Tube Valve Assembly

K01-00164-2 Block, Bottom (*)

K01-00037-1 Block, Shoe

K99-00301-1 Spring

K01-00164-1 Block, Top (*)

K01-00155-1 Diaphragm, Pinch Valve

K01-00159-1 Gasket, Retainer

K99-00302-1 O-Ring, Pinch Valve

K99-00305-5 Pin, Dowel

K01-00152-1 Piston, Pinch Valve

K01-00168-1 Screw, Alignment for bottom block

K99-00303-1 Screw, Thumb for top block

K99-00200-1 Clear Tubing 1/16 ID x 1/8 OD

K99-00385-1 Fitting Elbow

K99-00319-3 Tube, Pinch (*)

Figure 20 Pinch Valve Components

990277 Rev. A Page 39 of 46

Page 40

6.3 Solenoid Manifold Assembly

Figure 21 Solenoid Manifold Assembly

6.4 Air In Filter Assembly (K170198)

Part Number Description

K99-00200-3 Clear Tubing 1/8 ID x ¼ OD (0.8 feet) (*)

K480083 Absorber Filter

K480060 In-Line Particulate

Figure 22 Air In Filter Assembly Components

990277 Rev. A Page 40 of 46

Page 41

6.5 Air Out Filter Assembly (K170203)

Part Number Description

K99-00200-3 Clear Tubing 1/8 ID x ¼ OD (0.3 feet)

K480060 In-Line Particulate

Figure 23 Air Out Filter Assembly Components

6.6 MACH 6 Manifold Assembly (K170202)

Part Number Description

K99-00200-3 Clear Tubing 1/8 ID x ¼ OD (1.3 feet)

K170150 5 Port Manifold Assembly

990277 Rev. A Page 41 of 46

Page 42

Figure 24 M6 Manifold Assembly Components

6.7 Exhaust Catch Assembly (K170204)

Part Number Description

K01-00172-1 Nipple Fitting Assembly (*)

K210227 Exhaust Catch Manifold

K360004 Fitting Kynar “Y”

K480023 Coalescing Filter

K99-00243-1 Brass Fitting (*)

K99-00200-3 Tubing, Urethane, 1/8” ID x ¼” OD, Clear (0.9 feet)

390008 Tubing, .095” ID x .4” OD, Black (.25 feet)k

Figure 25 Exhaust Catch Assembly Components

990277 Rev. A Page 42 of 46

Page 43

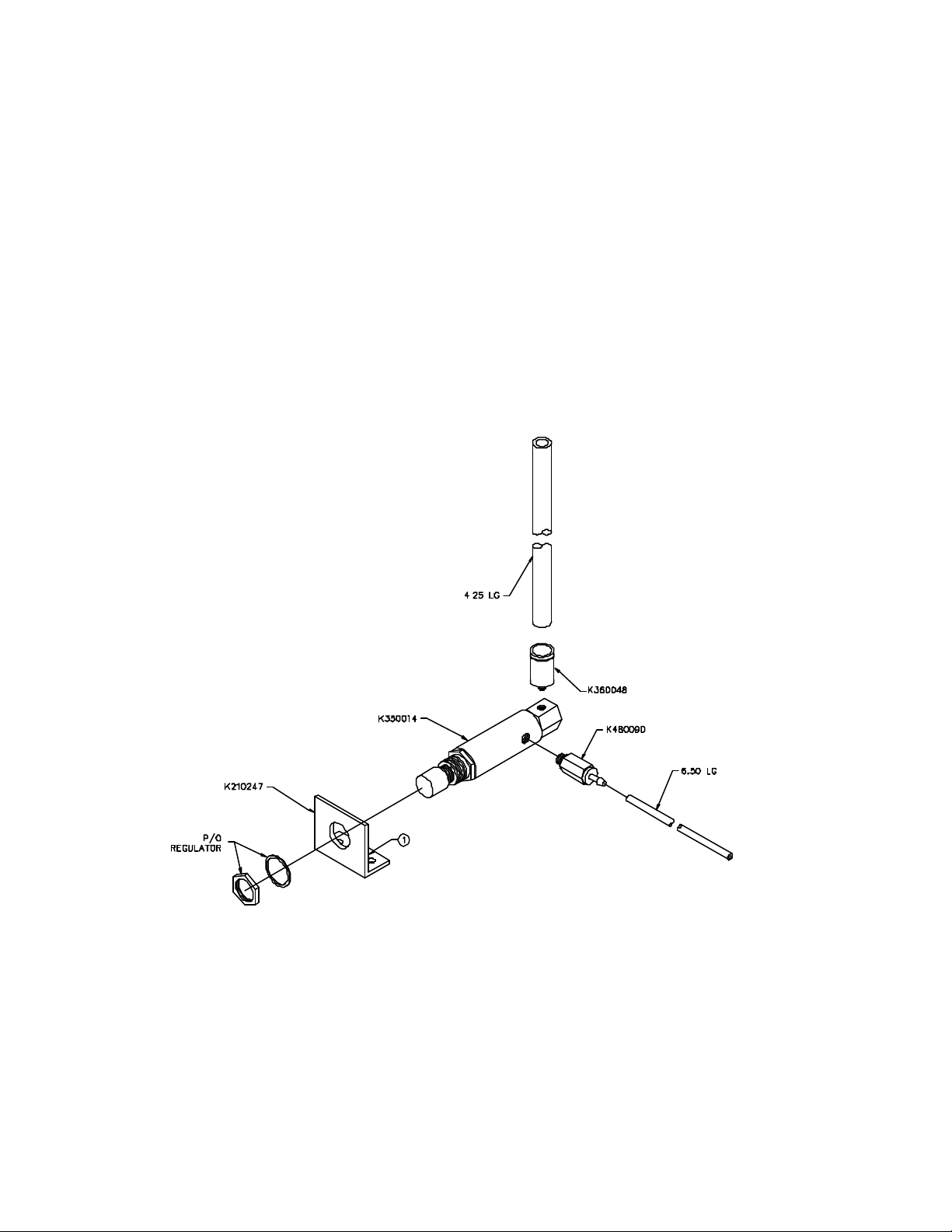

6.8 Pinch Valve Regulator Assembly (K170187)

Part Number Description

K350014 Pinch Valve Regulator

K360048 Fitting Legris Push

K210247 Pinch Valve Regulator Bracket

K480090 Check Valve

K99-00200-1 Tubing, Urethane, 1/16” ID x 1/8 ” OD, Clear (0.6 feet)

K99-00200-3 Tubing, Urethane, 1/8” ID x ¼” OD, Clear (0.4 feet)

Figure 26 Pinch Valve Regulator Assembly Components

990277 Rev. A Page 43 of 46

Page 44

6.9 System Regulator

Part Number Description

K170181 Pressure Regulator assembly

K360038 Fitting Elbow

K350008 Regulator

K99-00200-3 Tubing, Urethane, 1/8” ID x ¼” OD, Clear (1 foot)

K210211 Regulator Bracket

Figure 27 System Regulator Assembly Components

6.10 Tubing

Part Number Description

K99-00404-1 Tubing, Super Hose, Black

K99-00200-2 Tubing, Urethane, 3/32” ID x 5/32” OD, Clear

K99-00200-1 Tubing, Urethane, 3/32” ID x 5/32” OD, Clear

K99-00200-3 Tubing, Urethane, 1/8” ID x ¼” OD, Clear

390008 Tubing, .095” ID x .4” OD, Black

6.11 Accessories, Handpieces, Nozzles & Other

Part Number Description

K99-00243-1 Fitting, Coupler, 10/32” NPT x 1/8” Barb, Brass

K200002 Assy, Handpiece, Standard

K01-00211-1 Tool Kit

K01-00325-1 Kit, Pinch Tube

K170011-1 Nozzle, Blue, 45°, .018/46

K170011-2 Nozzle, Blue, 67°, .018/46

K170011-3 Nozzle, Blue, 90°, .018/46

K180086 Footswitch Assembly

K590005 Power Supply Assembly

990277 Rev. A Page 44 of 46

Page 45

K99-00002-1 Goggles, (3 Pack)

K01-00058-1 Hose, Air Supply, 10’

K210281 Barb, Handpiece Extension (*)

K370027 “O” ring for Handpiece Extension (*)

140008 Powder, Gamma Pure, 27.5 micron, gray

140013 Powder, 27 micron, white

140014 Powder, 34 micron, white

140012 Powder, 50 micron, white

600105 Power Cord, 115VAC

990155 Manual, Operators, Mach 6.0

6.12 Adhesives

Part Number Description

450000 Locktight, 680, Permanent Connection

460015 Lubricant, Superlube (*)

K99-00297-1 Pneumatic Sealant, High Pressure Connections

450008 Seal, Torque, Anti-Sabotage Inspectors

K99-00271-1 Tie Cable, Wire Holder

K99-00100-1 Tie Cable, Small

K99-00100-2 Tie Cable, Large

6.13 Chassis Components

Part Number Description

K170182 Hand Piece Holder

K180096 ON/OFF Cable Assembly

K170185 MACH 6 Case

K480084 Bumper Feet

6.14 Electrical/Electrical Components

Part Number Description

K190016-1 Display Control PCA

K190017 Solenoid Driver PCA

6.15 Shipping Accessories

Part Number Description

K470052 Accessory Box

K470104 Packaging Kit

6.16 Maintenance Kits

Part Number Description

K360078 Fitting, Union “T” Maintenance item

K360079 Fitting, Reducer ¼ “ x 1/8” Maintenance item

K140070 Technicians Manual Kit

K140058 Kit, Chair Integration

K150036 Kit, Pinch Valve Maintenance (*)

K150034 Kit, Year Maintenance, Mach 6.0

All Item with an asterisk (*) are recommended on hand spare parts.

990277 Rev. A Page 45 of 46

Page 46

7. Warranty, Returns and Adjustments

7.1 Returns and Adjustments

Warranty claims must be made promptly and received by your nearest authorized service representative during the

warranty period. The liability of Welch Allyn Kreativ, under valid warranty claims, is limited to repair or replacement

at the purchaser’s authorized service center or the purchaser’s place of business, at the option of the authorized

service representative. If it is necessary to return a product for repair or replacement, authorization for the return

must first be obtained from the authorized service representative.

All products returned for examination or warranty repair must be sent insured via a means of transportation specified

by the authorized service representative.

Welch Allyn Kreativ, or its authorized service representative claims the sole responsibility for determining the cause

of any instrument failure.

7.2 Limited Warranty

Welch Allyn Kreativ, warrants the equipment to be free from defects in material and workmanship for a period of 12

months from the date of shipment. Damage due to failure of customer to perform required user/preventative

maintenance is not warranted. Certain components having limited life expectancy (handpieces, nozzles, tubing, and

pinch tubes) are not warranted against normal wear and tear or customer damage. This limited warranty applies only

to the original purchaser/user of the equipment.

The foregoing limited warranty is exclusive and in lieu of all other warranties, whether written, oral, or implied, and

shall be purchaser’s sole remedy and Kreativ’s sole liability under contract or warranty or otherwise for the product.

Welch Allyn Kreativ , disclaims any implied warranty of merchantability or fitness for particular purposes. In no

event shall Welch Allyn Kreativ , be liable for any incidental or consequential damages, or for any incidental or

consequential damages arising out of, or in connection with, the use or performance of the product delivered

hereunder.

7.3 Storage And Shipment

The Welch Allyn Kreativ Model Mach 6.0 has been designed for long term storage in normal dental office

environments. If it is to be stored for any reason for a long period, it should be covered to protect it from adverse

conditions and the Powder Canister should be emptied. The area it is to be stored in should meet the Environmental

Limitations Transport and Storage Requirements indicated in Section 1.7, “System Specifications”.

The unit has been designed for shipment by normal commercial carriers. Protective packaging should be used, and

the original packing materials should be reinstalled for shipment. Shipping instructions must be followed closely.

The customer will be responsible for damage resulting from improper packing.

990277 Rev. A Page 46 of 46

Loading...

Loading...