Page 1

Mach 5.0 and Mach 5.0 PLUS

Kreativ Menu

Manuals

Service Manual

Air Abrasion Units

Instructions for Use

Please read this manual thoroughly

prior to first use

CAUTION: This device must only be

purchased by, or sold to, a licensed dentist.

Manufactured by

Kreativ, Inc. (USA)

7360 Carroll Road

San Diego, CA 92121

Copyright Notice:

Copyright © 1999, Kreativ, Inc. All rights reserved. No part of this manual may be

reproduced without written permission from Kreativ, Inc.

European Authorized Representative

Welch Allyn LTD.

Navan, Co. Meath

Republic of Ireland

Ph: 353-46-79060

990008 Rev. H

Page 2

TABLE OF CONTENTS

1. INTRODUCTION AND GENERAL INFORMATION 4

SPECIFICATIONS 6

2. SAFETY 8

WARNINGS 8

CAUTIONS 8

SAFETY MARKINGS ON LABELS 10

3. CONTROLS AND CONNECTORS 11

ITEM DESCRIPTIONS 11

CONTROL PANEL 12

DRAWINGS OF CONTROLS 13

FUNCTIONAL DESCRIPTION 15

4. UNPACKING AND SETUP 17

GENERAL INFORMATION 17

UNPACKING AND SETUP 17

AIR SUPPLY REQUIREMENTS (M ACH 5.0 ONLY) 18

ELECTRICAL REQUIREMENTS 18

MACH 5.0/D ENTAL CHAIR PNEUMATIC INTEGRATION 18

5. INSTALLATION AND UNIT CHECKOUT 20

PRE -INSTALLATION REQUIREMENTS 20

UNIT CHECKOUT 20

FILLING THE MIXTURE CHAMBER 21

OPERATIONAL CHECKOUT 22

FOOTSWITCH OPERATION 22

UNIT SHUTDOWN 22

MIXING CHAMBER POWDER UNLOADING 22

6. STERILIZATION PROCEDURES 24

HANDPIECE 24

HANDPIECE CRADLE 24

ACCESSORIES 24

POWDER 25

7. ROUTINE MAINTENANCE 26

DAILY REQUIREMENTS 26

WEEKLY REQUIREMENTS 26

MONTHLY REQUIREMENTS 27

8. TROUBLESHOOTING 28

TROUBLESHOOTING TIPS 28

Page 2 990008 Rev. H

Page 3

ERROR CODES 30

9. HANDPIECES/NOZZLES AND ABRASIVES 31

STANDARD NOZZLES 31

SUPERSONIC TURBO (SST) TIPPED HANDPIECE ASSEMBLIES 31

ABRASIVES, GAMMAPURE

®

(GAMMA TREATED) 31

ORDERING INFORMATION 32

10. RECYCLING 34

RECYCLING INSTRUCTIONS FOR DEVICE, ACCESSORIES AND PACKAGING 34

ENVIRONMENTALLY RELEVANT MATERIAL 34

11. WARRANTY, RETURNS AND ADJUSTMENTS 36

RETURNS AND ADJUSTMENTS 36

LIMITED WARRANTY 36

STORAGE AND SHIPMENT 37

Page 3 990008 Rev. H

Page 4

1. Introduction and General Information

1

Introduction

The Kreativ Mach 5.0 and Mach 5.0 PLUS systems are compact, highly reliable, stateof-the-art instruments designed for Air Abrasive MicroDentistry. They are designed as

a means of removing tooth structure and other materials to prepare teeth for restoration,

and as an adjunct to the high speed dental handpiece and bur. These instruments were

developed after extensive consultation with dentists in order to provide the optimum

performance, taking into consideration patient comfort and the time constraints faced by

today’s 21st Century dental office.

Chapter

Note: Clinical use of the Kreativ Mach 5.0 and Mach 5.0 PLUS air abrasion systems

for procedures not included or suggested in this instruction guide is not advised.

Similarly, the Kreativ Mach 5.0 and Mach 5.0 PLUS systems should be only used by

dental professionals who have practiced on extracted teeth and who are thoroughly

familiar with this manual.

Purpose of this Manual

This manual should be thoroughly studied before installing and using the equipment.

Please call your nearest authorized Welch Allyn / Kreativ service representative if you

need additional information regarding installation, operation, or service of the instrument.

Information essential to the installation, operation, and routine maintenance of the Mach

5.0 and the Mach 5.0 PLUS devices manufactured by Kreativ, Inc., is included in this

manual. The instructions are written specifically for personnel who have been trained in

restorative and preventive dentistry.

A full selection of abrasive powders and nozzle sizes are available from your nearest

Welch Allyn / Kreativ sales representative. See the listing of supplies in Chapter 8.

All serviced components, such as control valves and hose connections, can be easily

accessed through the side doors of the instrument. A footswitch is provided to start the

powder flow. The instrument features a mixing chamber which can be quickly unloaded

in order to facilitate service, changing abrasive powders, or cleanup of the unit after use.

Page 4 990008 Rev. H

Page 5

General Information and Features

The Kreativ Mach 5.0 and Mach 5.0 PLUS systems are designed to provide controlled

flow of an abrasive powder and air mixture through a very precise nozzle. Applications

include amalgam removal, cutting, abrading, deburring, peening and etching of tooth

structures and other materials. Features of the Mach 5.0 and the Mach 5.0 PLUS air

abrasion systems include:

Operating Modes

• PowerPulse™ - optimized to remove amalgam

• MicroPulse™ - for removal of tooth structure

• Continuous - for microetching procedures

Remote Control

• Continuously Variable levels controlled by the user:

• Particle Energy (minimum is 30, maximum is 120), see Table 1 for psi-

to-kPa conversion in Chapter 3

• Beam Intensity (minimum powder is 0, maximum is powder 10)

• Remote Control module can be attached to dental units via an extension cable

• Easy to read LED display

• Visual and audible indicators

• Diagnostic/maintenance reminders

• Replace pinch tube in Pinch Valve #1

• Service Needed

• Powder Low

• Replace pinch tube in Pinch Valve #2

• Empty Exhaust Bottle

• Input Error

• Handpiece holder (bracket with sensor)

Interfaces with Dental Unit

• Remote Control offers movement of the control panel to the location of the

dentist’s choice, usually near other handpieces

• Keeps all controls at your fingertips

• Seamless integration of air abrasion with traditional dental instruments

Page 5 990008 Rev. H

Page 6

Full Diagnostic

• At start-up

• Continuous monitoring

Additional Features

• Quickly detachable handpiece for easy sterilization

• Double doors for simplifying preventive maintenance

• Exhaust bottle container

• Easy pinch tube replacement

• Easy access to powder canister

• Accessory drawer for nozzles, handpieces, etc.

• Full range of operation from 30 psi to 120 psi

• Convenient handles

• Mobility

• Wide range of nozzles in sizes/angles and cutting capabilities

• Locked doors to prevent unauthorized access

Specifications

• Power Requirements: Domestic

• Air Requirements: Mach 5.0, 80 to125 psi (550 to 860 kPa) with

Mach 5.0 100-127 V~, 60 Hz, 400 mA

Mach 5.0 PLUS 100-127 V~, 60 Hz, 6.5 A

International

Mach 5.0 220-240 V~, 50 Hz, 170 mA

Mach 5.0 PLUS 220-240 V~, 50 Hz, 3.5 A

NOTE: Verify unit has correct voltage for your

application.

at least 1.5 cfm (42.5 l/min) recommended; the

supply pressure must be at least 5 psi (35 kPa)

greater than the selected operating pressure.

The Mach 5.0 PLUS incorporates a built-in

compressor which has an automatic thermal

Page 6 990008 Rev. H

Page 7

cut-out if the head reaches approx. 212° F

(100° C), and a thermal cut-in when the

temperature drops to 140° F (60° C).

• Approximate Size: Mach 5.0, 12” x 18” x 8.5”

(30.4 x 45.7 x 21.5 cm)

Mach 5.0 PLUS, 25” x 18” x 8.5”

(63.5 x 45.7 x 21.5 cm)

• Approximate Weight: Mach 5.0, 30 lbs. (15.9 kg)

Mach 5.0 PLUS, 85 lbs. (38.6 kg)

• Environment Limitations: Operational Requirements:

Temperature: 50° F to 95° F (+10° C to 35° C)

Humidity: 30 % to 75 %

Atmospheric pressure range: 10.15 psia ( 70 kPa) to

Transport and Storage Requirements:

Temperature: 14° F to 122° F (-10° C to 50° C)

Humidity: 10 % to 90 %

Atmospheric pressure range: 7.25 psia ( 50 kPa)

15.37 psia (106 kPa)

to 15.37 psia (106 kPa)

• Equipment Classification: The Mach 5.0 and Mach 5.0 PLUS systems are

Class I devices requiring an electrical earth ground.

These devices are classified as ordinary with regard

to protection against water ingress.

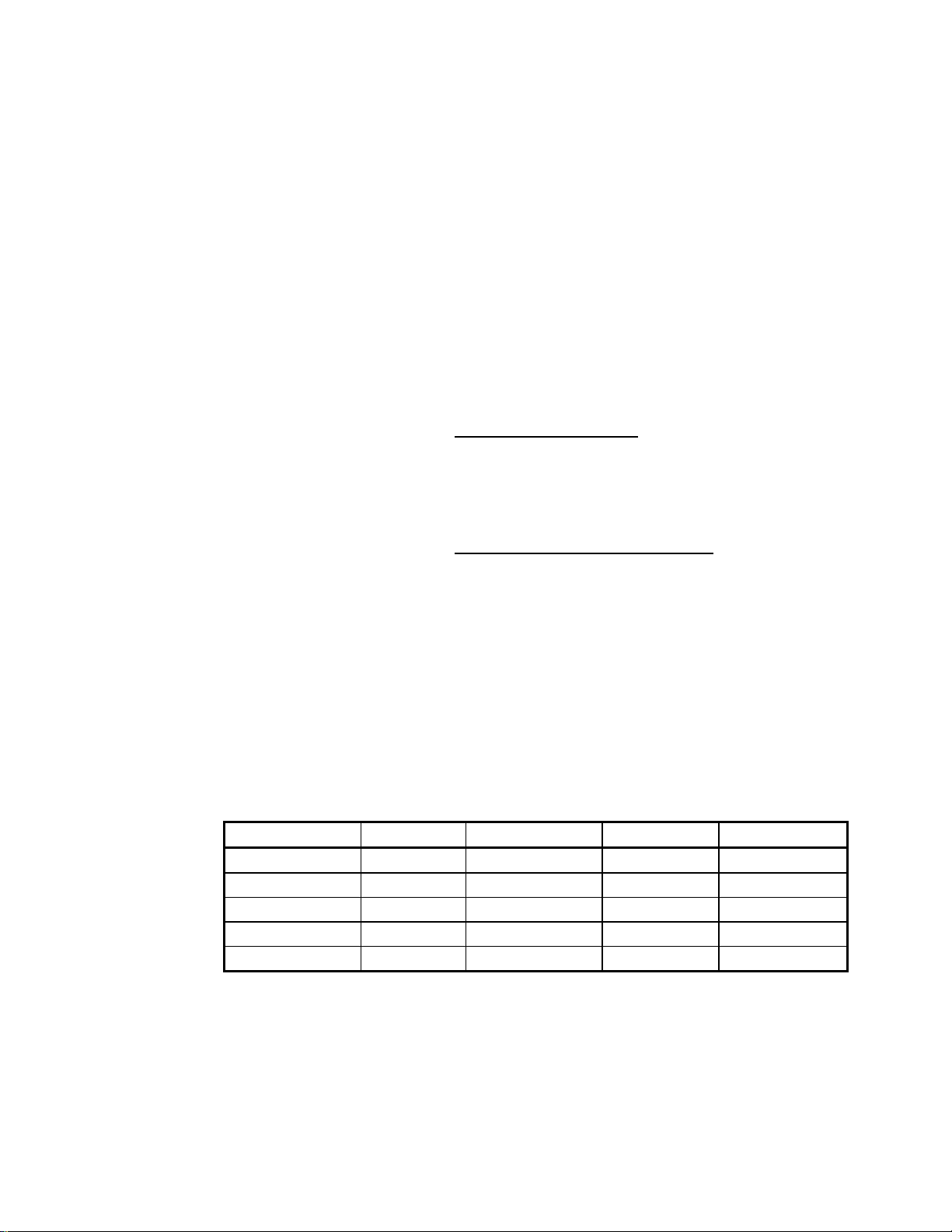

• Electrical Fuses: Littelfuse, SlowBlow

Model Fuse Mfr Mfr P/N Kreativ P/N Fuse Rating

Mach 5 115V Littelfuse Type 326-001 600089 1A, 250Vac

Mach 5+ 115V Littelfuse Type 326-010 600071 10A, 250Vac

or Bussmann Type MDA-10 600071 10A, 250Vac

Mach 5 230V Littelfuse Type 218-01.6 600096 1.6A, 250Vac

Mach 5+ 230V Littelfuse Type 218-06.3 600112 6.3A, 250Vac

• UL Canadian Classification Marking:

Air Abrasive Micro Dentistry Device, Model 9000-XX

(where XX can be any alphanumeric character)

WITH RESPECT TO ELECTRIC SHOCK, FIRE, MECHANICAL

Page 7 990008 Rev. H

Page 8

2. Safety

2

The Kreativ Mach 5.0 and Mach 5.0 PLUS systems are designed for use only by and

on the order of a dentist.

Warnings

Always wear protective eye equipment in order to avoid corneal abrasion or irritation if

particles are deflected into the eye. This applies to the dentist, staff, and patient.

A rubber dam is recommended in order to avoid injury to gingiva or other soft tissue,

and for interproximal preparations to protect adjacent tooth surfaces.

AND OTHER SPECIFIED HAZARDS ONLY

IN ACCORDANCE WITH CAN/CSA C22.2 NO. 601.1

21ZJ

Chapter

Never direct the handpiece to an open pulp chamber or at pulpal exposures. Also

never place the handpiece in direct contact with the gingiva when the air pressure is

activated. While the abrasive stream will not cut the gingival tissue, it may irritate it.

All Kreativ Mach 5.0 and Mach 5.0 PLUS accessories which come into contact with

the patient should be sterilized prior to each use. Always disinfect the handpiece cradle

in the remote control unit before each patient use.

Always use your high volume evacuation system when using the handpiece of the

Kreativ Mach 5.0 or Mach 5.0 PLUS. Have the dental assistant place the high volume

evacuation system in close proximity to the operative site.

Make sure that the Kreativ Mach 5.0 and Mach 5.0 PLUS systems are connected to a

properly grounded electrical outlet.

Always replace fuses with fuses of the proper rating, as indicated in the Chapter 1.

Cautions

For dental cleaning (prophylaxis) procedures, be absolutely sure that the

chamber and hose have been completely cleared of all abrasive powders and use

only bicarbonate in the chamber.

Page 8 990008 Rev. H

Page 9

The handpiece should be directed precisely at surfaces and tooth structures which are

to be modified or removed. The nozzle tip should be placed a few millimeters from the

tooth and angled toward the area to be removed or modified. Unlike the high speed

handpiece, the Mach 5.0 nozzle cuts only directly from the end; there is no side cutting.

Do not attempt to service the unit beyond those items described in the maintenance

section. Call your nearest Welch Allyn / Kreativ service representative for instructions.

Practice on extracted teeth prior to utilizing the Mach 5.0 and Mach 5.0 PLUS on

patients. Begin with the 27.5 micron aluminum oxide powder. Use only short bursts,

carefully monitoring your progress. Most users prefer the 27.5 micron powder at a

Particle Energy setting of 50 to 80 psi due to improved patient acceptance.

Do not substitute non-Kreativ, Inc., materials or accessories. Use of materials or

accessories supplied by other manufacturers may result in damage to the unit and will

void the factory warranty.

Use only clean dry air. Make sure that your air compressor system utilizes air dryer

filter systems and that they are fully operational. Any moisture or oil in the air supply

will adversely affect the performance of your Mach 5.0 or Mach 5.0 PLUS.

When using the Mach 5.0, check to be sure that your air system produces at least the

minimum pressure and flow rate indicated in the Air Requirements section of the

Specifications in Chapter 1.

Sound clinical judgment, good common sense and proper training are essential to the

successful use of the unit in order to provide safe and efficient patient care.

Always follow “standard of care” protocols in performing dental operative procedures.

The handle on the top of the Mach 5.0 PLUS units is intended to be used to pull the

units and is not meant for picking up the units.

Caution: Connecting the instrument’s input air supply line to a water outlet will

lead to damage to the instrument which is not covered under the limited

warranty. Repairs for such damage are at the customer’s expense.

Page 9 990008 Rev. H

Page 10

Safety Markings on Labels

Alternating current

Protective earth (ground)

Attention, consult accompanying documents

Off (power: disconnection from the mains)

On (power: connection to the mains)

Type B equipment (defines the degree of protection against

electrical shock)

Page 10 990008 Rev. H

Page 11

3. Controls and Connectors

3

The diagrams on the following pages illustrate the external controls, indicators, and

connectors for the Kreativ Mach 5.0 and Mach 5.0 PLUS instruments.

In both the Mach 5.0 and the Mach 5.0 PLUS, the handpiece hose connects to a

connector located under the Control Module.

The Control Module is removable from the front of the Mach 5.0 and the Mach 5.0

PLUS and can be attached to the Dental unit, as follows:

1. The Control Module is held to the front of the instrument by spring tension on the

interconnecting cable. With the handpiece mounted in the cradle on top of the

Control Module, the hose and the provided extension cable allow the Control

Module to be remotely located up to 10 feet from the main unit. The connector to

the air supply is located on the rear of the instrument.

Chapter

2. A mounting plate with clamp is supplied with the Mach 5.0 and the Mach 5.0

PLUS, to be mounted on the dental unit.

3. The Control Module will attach to the mounting plate for use at the dental unit,

remotely from the main instrument.

Item Descriptions

Refer to the Drawings in this section for the following items.

(1) On/Off Power Switch: turns power on or off to the entire instrument

(2) Power Cord Connector: connection point for the power cord.

(3) Fuse Box: the location of the instrument fuses. Always replace with the same

type of fuse with the same rating, indicated in Chapter 1.

(4) Pneumatic Footswitch Connector: connection point for the dental chair

pneumatic footswitch.

(5) Electric Footswitch Connector: connection point for the electrical foot-switch

Page 11 990008 Rev. H

Page 12

(6) Air Supply: connection point for the office air supply to the instrument (Mach

5.0 only)

Control Panel

Air Indicator: indicates the status of the air pressure as “On” or “Standby”

Mode: indicates the operating mode of the instrument as “PowerPulse,”

“MicroPulse,” or “Continuous.” The power up default is PowerPulse

Beam Intensity: indicates the relative amount of abrasive powder that is being

delivered to the handpiece nozzle

Warning Indicators: indicate the type of problem when operational problems occur

Particle Energy: indicates the pressure with which the abrasive powder is being

delivered. Numbers in the display indicate Pounds per Square Inch (PSI).

Conversion Table of PSI to kPa

PSI kPa PSI kPa

30 210 90 620

35 240 95 655

40 275 100 690

45 310 105 725

50 345 110 760

55 380 115 795

60 415 120 825

65 450 125 860

70 485 130 895

75 515 135 930

80 550 140 965

85 585

Table 1

Page 12 990008 Rev. H

Page 13

Drawings of Controls

Figure 1

Page 13 990008 Rev. H

Page 14

Figure 2

Page 14 990008 Rev. H

Page 15

Functional Description

When the unit is initially turned on, all lights on the Control Module will light and the

Beam Intensity and Particle Energy windows will show “8.8.8.” until the diagnostics are

complete (indicating the unit is ready to operate). The values shown will be the previous

settings used.

Kreativ Mach 5.0 and Mach 5.0 PLUS systems provide a controlled mixture of

powder particles in a dry air stream and delivers this mixture through a nozzle.

Three primary paths are provided for the air supply within the unit. One is to the

Exhaust Control Valve, another to the Abrasive Control Valve, and the third is through

the Mixing Chamber and the Abrasive Control Valve Tube to the nozzle. In the mixing

chamber, the stream of dry air is mixed with powder particles.

When the Air switch is set to “On”, the On/Off Air Valve Switch allows the air to flow

to the Mixing Chamber. With the footswitch depressed, the Abrasive Control Valve is

opened. This opens the path for the stream of powder particles from the Mixing

Chamber to the nozzle. The Beam Intensity and Particle Energy can be adjusted to

provide optimum powder flow.

The air stream combined with abrasive powder has the ability to cut and etch tooth

structure and ceramic. The abrasive powder/air stream is directed through a light,

flexible hose to the handpiece for precise cutting. Various nozzles and handpieces are

offered with different orifice sizes and angles to enable the practitioner to accomplish

specific tasks. In addition, a selection of abrasive powder is available. Nozzle and

abrasive powder types are listed in Chapter 9.

CAUTION: The unit should only be powered down with the Air control in

“Standby” mode.

NOTE: The unit will automatically go into “Standby” if left unattended for approximately

10 minutes.

When the Power switch is set to Off, the unit automatically bleeds off the internal air

pressure.

WARNING: Do not attempt to open the doors of the unit with power turned on!

Page 15 990008 Rev. H

Page 16

Page 16 990008 Rev. H

Page 17

4. Unpacking and Setup

4

General Information

SAVE THE CARTON!

The Mach 5.0 and Mach 5.0 PLUS and all accessories are shipped in a single

container. When unpacking, check items against the packing list included with the unit.

The shipping container and packing materials should be retained in the

unlikely event that the instrument has to be returned to the factory for service

or repair.

Chapter

To operate the Mach 5.0, the unit requires an external source of either clean, dry,

compressed air, or nitrogen together with a properly adjusted pressure regulator. For

additional information consult your Kreativ, Inc. dealer.

The Mach 5.0 PLUS instrument has a built-in air compressor, thus eliminating the need

for connection to an external air supply.

It is necessary to connect to a properly grounded electrical outlet.

Unpacking and Setup

Remove the Mach 5.0 or the Mach 5.0 PLUS unit from the shipping container and

proceed as follows:

• Unlock and open the left side door gently.

• Remove the foam packing (2 pieces) which prevents the vibrator from moving

during shipping. Retain the foam with the shipping box and packing materials. If the

unit is to be shipped again, the vibrator support foam packing should be reinstalled

to prevent possible damage to the vibrator and its mounts.

CAUTION: Failure to remove the foam packing will result in improper vibrator

operation and powder flow.

Page 17 990008 Rev. H

Page 18

• On Mach 5.0 PLUS only, remove the black plug from the air inlet on top of the

compressor module, and replace with the included filter.

CAUTION: Failure to replace the black plug with the filter will result in low air

condition, and damage to the compressor unit.

WARNING: The use of compressed oxygen as a gas supply for the unit

presents the possibility of having a gas that supports flammability. Under

NO circumstances should oxygen be used.

Air Supply Requirements (Mach 5.0 only)

For the Mach 5.0 only, be sure that the supplied air pressure and air flow volume to the

unit meet the minimum Air Requirements indicated in the Specifications section in

Chapter 1. Moisture filters must be used since compressed air lines may be

contaminated with moisture, oil or dirt, which are detrimental to the performance and

operation of the unit. Kreativ can supply a product (the Klean Pak) to assure a dry air

supply.

Caution: Connecting the instrument’s input air supply line to a water outlet will

lead to damage to the instrument which is not covered under the limited

warranty. Repairs for such damage are at the customer’s expense.

Electrical Requirements

Reference the Specifications section of Chapter 1 of this manual for the power

requirements of the unit. The power requirements of your instrument are located on the

system label on the back cover of the instrument. Verify the unit is set up correctly for

your electrical supply. When replacing fuses, only use fuses supplied by Kreativ in your

customer kit. If your requirements are different, consult Kreativ, Inc., or your dealer

before operating this instrument.

Mach 5.0/Dental Chair Pneumatic Integration

Please refer to Figure 3.

1. Depress chair foot switch while holding foot switch air line. The tube you feel

pulsing is the “foot switch return” line, mark it for later reference (step 5).

2. Close valve from office compressor to dental chair/unit and bleed pressure from

line.

3. Install “Tee 1” on line from compressor to dental unit before the regulator.

Page 18 990008 Rev. H

Page 19

4. Route line from “Tee 1” to Mach 5.0. Install female quick disconnect to end and

connect to Mach 5.0 “Air In” port.

5. Install “Tee 2” on return line from foot switch.

6. Route line from “Tee 2” to Mach 5.0. Install male quick disconnect to end and

connect to Mach 5.0 “Foot Switch” port.

7. Open valve from compressor to restore pressure to the Dental chair/unit.

8. Check new connections for leaks.

Caution: When used in this manner, it is important to return the handpiece to

the holder prior to using other devices.

*Not required for the Mach 5.0 PLUS with compressor.

Figure 3 - Dental Chair Pneumatic Integration Diagram

Page 19 990008 Rev. H

Page 20

5. Installation and Unit Checkout

5

After completing the instructions in Chapter 4 you are now ready to install your Kreativ

Mach 5.0 or Mach 5.0 PLUS. Refer to the drawings and descriptions in Chapter 3 for

the identification of the external controls and connections.

Pre-Installation Requirements

• Adequate Air Supply, Mach 5.0 only. The most convenient set up will be to

integrate the Mach 5.0 into your Dental unit as explained in the previous section. If

you choose to hook up to your in-office air do the following:

Chapter

1. Ensure that you have at least the minimum air pressure and air flow volume of

clean, dry air (see Chapters 1 and 4 for Air Supply Requirements). Refer to the

Site Preparation information supplied by Kreativ. Ideally, air for the Mach 5.0

will be obtained by placing a "Tee" fitting prior to the final regulator at the

operatory, but after the dryer, traps and various filters.

2. If clean, dry air of adequate pressure and volume is not available, Kreativ

recommends using compressed Nitrogen with a regulator (Follow integration

instructions).

• Power supply/earth grounding. Note: route the power cord safely out of the way

and do not use an extension cord.

Unit Checkout

• Set the Power Switch on the back of the instrument to OFF.

• On the Mach 5.0, connect the end of the air supply hose with the quick disconnect

to the external air supply.

• Plug the power supply cord into a properly grounded receptacle.

• Set the Power Switch on the back of the instrument to ON. The Control Module

should now be illuminated.

Page 20 990008 Rev. H

Page 21

When first turned on, all lights on the Control Module will flash until the diagnostics are

complete, indicating that the unit is ready to operate. The values shown will be the

values from the last operation.

CAUTION: If the Control Module does not illuminate, it indicates absence of

electrical power. Verify that power is available and the fuses are correct. If

the Control Module still does not illuminate, call your nearest authorized Welch

Allyn / Kreativ service representative.

• Verify that a handpiece/nozzle is attached to the delivery hose.

• Plug the hose assembly into the front of the unit.

• Lift the handpiece from its cradle and actuate the footswitch. Air should flow from

the nozzle. Do not actuate the footswitch while the handpiece is in the cradle.

WARNING! Some residual powder may be in the unit from factory testing.

Always use goggles or protective eyewear when using the Kreativ Mach 5.0 or

Mach 5.0 PLUS systems and do not direct the nozzle towards the face when

operating the footswitch.

WARNING! Before filling the mixing chamber, with the Air Control Switch in

STANDBY, set the Power Switch on the back of the instrument to OFF. This

depressurizes the system.

• • Select the desired powder for the operation to be performed and proceed to fill the

mixing chamber as described in the following section.

Filling the Mixture Chamber

The unit must be powered down as described above. Failure to do so will prevent the

removal of the mixing chamber lid.

• Using the key, open the door on the left side of the instrument as you face the front

of the instrument.

• Tilt the mixing chamber towards you, allowing access to the lid.

• Clean off any dust or debris from the mixing chamber lid.

• Remove the mixing chamber lid by turning the lid counterclockwise.

• Carefully pour abrasive powder into the mixing chamber until it is 3/4 full.

• Replace the chamber lid and hand tighten.

• Tilt the powder chamber back into the unit and close the access door.

Page 21 990008 Rev. H

Page 22

• Lock both doors, removing key.

CAUTION: Make certain that no lint, dirt, or other foreign substances enter

the chamber. This can result in plugging the unit. Failure to turn the power off

will prevent removal of the mixing chamber lid.

Operational Checkout

• Place the Power Switch to ON and make sure the Particle Energy indicator is set to

the desired setting. If not, change it by touching the up or down arrow accordingly.

A Particle Energy setting of 80 is suggested when first using the instrument.

• Set the Beam Intensity to the desired setting, adjusting it up or down by touching the

appropriate arrow. A suggested beginning setting is 7.0 for the Beam Intensity.

• Touch the Air control to ON.

• • Lift the handpiece from the cradle. If the handpiece is not in the cradle, the

microswitch on top of the Remote must be depressed before the footswitch

is activated.

• • Press the footswitch to obtain powder flow through the nozzle.

You can now practice operative procedures on extracted teeth as described in

Chapter 2, Safety.

Footswitch Operation

• Depressing the footswitch enables the powder to flow through the handpiece/nozzle.

Unit Shutdown

• Set the Air Switch to the Standby position.

• Set the Power Switch to the OFF position.

Mixing Chamber Powder Unloading

• Follow unit shutdown instructions above.

• Unlock the left door and open.

• Loosen the black knob holding the block in place. The block will rotate down,

releasing the mixing chamber so it can be removed for emptying.

• Firmly hold the chamber and loosen the mixing chamber lid by turning it

counterclockwise.

Page 22 990008 Rev. H

Page 23

• Completely unscrew the lid from the mixing chamber.

• Turn the mixing chamber over to empty it into a container for re-use.

• Replace the lid, making sure the threads are free of powder and the lid gasket is

seated properly. Hand tighten the lid securely.

• Replace the mixing chamber into its original position.

• Replace the block holding the chamber, tightening the black knob securely.

• Check the two air hoses that attach to the mixing chamber to assure that they are

not kinked or pinched and that they make a large, free loop.

• • Close the door and lock it.

Page 23 990008 Rev. H

Page 24

6. Sterilization Procedures

6

WARNING: All Kreativ Mach 5.0 and Mach 5.0 PLUS accessories which

come into contact with the patient should be sterilized prior to each use. The

handpiece cradle should be wiped with disinfectant prior to each patient use.

Handpiece

Chapter

Sterilization of the cutting handpiece and nozzles can be accomplished by using any

conventional dental autoclave. The handpiece and nozzles are fully autoclaveable in a

dry heat, steam, or chemical autoclave. This is recommended prior to each use to

ensure that the handpiece and nozzles do not become a source for cross contamination

of disease or infection.

Prior to sterilizing, the SuperSonic Turbo™ (SST) Handpiece Assembly should be

cleared of all residual powder by blowing clean, dry air through the handpiece.

Handpiece Cradle

Always wipe down the handpiece cradle in the remote control unit before each patient

use to avoid contamination of the handpiece from an earlier patient session.

WARNING! Do not attempt to disassemble the SST Handpiece Assembly.

Accessories

The handpiece/nozzle hose assembly of the Kreativ Mach 5.0 and Mach 5.0 PLUS

should be sheathed or wiped down in accordance with standard dental procedures.

Page 24 990008 Rev. H

Page 25

Powder

It is recommended that only GammaPure® treated powder be used with the Mach 5.0

and Mach 5.0 PLUS air abrasion systems. Additional GammaPure powder can be

ordered from your Welch Allyn / Kreativ sales representative. Refer to the accessories

list in the back of this manual.

Page 25 990008 Rev. H

Page 26

7. Routine Maintenance

7

Proper maintenance of the Mach 5.0 and Mach 5.0 PLUS systems is necessary to

maintain a consistent cutting efficiency and top performance. Maintenance is limited to

general cleaning, inspecting internal components, pinch tube replacement, emptying

exhaust bottles, and keeping the powder chamber dry. The following are maintenance

procedures categorized by their required frequency.

Daily Requirements

Powder Chamber

• Open the powder chamber. Observe the powder level and refill as necessary.

Remove and clean the white lid gasket thoroughly before replacing the lid.

Thoroughly clean all mating surfaces. Tighten the lid ring to avoid air leaks. Refer

to Chapter 5 for detailed instructions.

Chapter

Exhaust bottle

• The exhaust bottle should be emptied daily, and every time the powder chamber is

filled. It is important to make sure the internal filter is clean and tight. If the filter is

not tight, it should be removed and cleaned. Pay extra attention to cleaning all

threads and mating surfaces. Do not let the bottle overfill.

Weekly Requirements

Powder Chamber

• •

Inspect the powder chamber for moisture contamination. Look for powder clumps

or wet powder and replace as necessary. Refer to Chapter 5 for detailed

instructions.

Exhaust bottle

• •

Remove and clean the exhaust bottle filter. When replacing, make sure all threads

and mating surfaces are clean and tight.

Pinch tubes

• •

There are three pinch tubes inside three pinch valves located between the exhaust

bottle and the powder chamber. Remove the pinch tubes by removing two thumb

screws and the black cover block. Pull the tube from the hose assembly. Inspect

Page 26 990008 Rev. H

Page 27

the tubes for signs of wear and replace with new tubes as necessary. Realign the

pinch tube assembly with the grooves and securely tighten the thumb screws.

Monthly Requirements

Compressor Oil (Mach 5.0 PLUS only)

• •

The Mach 5.0 PLUS is equipped with a portable compressor that does not require

general maintenance, except adding oil. The compressor is equipped with a viewing

window with a minimum/maximum indicator line. If the oil is below the minimum

line, add oil as follows;

1. Ensure the unit power is off and the power cord is removed.

2. Open the access door on the right side of the unit.

3. Remove the oil fill bolt from the top of the compressor head.

4. Using the bottle of oil and extra tubing shipped in the accessory kit, install

the tubing to the top of the oil bottle to allow access to the oil fill hole.

Squeeze small amounts of oil at a time, allowing time to settle before

rechecking the level indicator. DO NOT OVERFILL.

5. Replace top bolt and ensure it is tight.

Oil overflow bottle (Mach 5.0 PLUS only)

• Locate the clear oil overflow bottle at the bottom shelf of the Mach 5.0 PLUS unit.

Inspect the level of oil, and empty as necessary. Excess oil should be disposed of

as you would automobile motor oil.

Internal tubing

• Inspect internal tubing for wear and air leakage. Listen for audible leaking sounds

and look for powder accumulation internal to the unit. Soapy water and a small

paint brush is ideal for finding small air leaks. If a powder leak occurs, inspect the

tubing going from the pinch valves to the exhaust bottle first, paying particular

attention to any “Y” fittings. If no damage is found, make sure the exhaust bottle is

empty, the exhaust bottle filter is clean and tight, and excess powder is cleaned from

the unit. Clean up excess powder to avoid contamination of other components and

to help isolate the leak area.

Handpiece Nozzles

• Inspect all the handpiece nozzles for wear, paying close attention to the carbide insert

at the end of the tip. If there are any slits or chips, replace the nozzle. A worn

nozzle will greatly effect the performance of cutting and powder flow control. It is

possible to have a worn nozzle without any visible signs.

Page 27 990008 Rev. H

Page 28

8. Troubleshooting

8

The following table is intended to assist in communicating with your nearest authorized

Welch Allyn / Kreativ service representative.

Troubleshooting Tips

PROBLEM POSSIBLE CAUSE REMEDY

Chapter

“Lo Air” message

momentary warning

displays on Mach 5.0

“Lo Air” momentary

message displays on the

Mach 5.0 PLUS

No Power • Instrument not plugged in

No powder flow when

footswitch is activated

• Air supply drops below the

selected setting during

operation

• Handpiece is removed

• Nozzle is removed from the

handpiece

• The compressor intake plug

is still installed from shipping

• Main Switch OFF

• Blown Fuse

• Main Switch Bad

• Remote Not connected

• Blown Circuit Breaker

• Footswitch not plugged in

• Particle Energy not selected

• Handpiece/nozzle clogged

• Handpiece inoperable

• Reduce the setting or

• Install handpiece

• Install the nozzle on the

• Remove the plug and

• Check Plug

• Check Switch

• Change Fuse with

• Call local service rep.

• Check Connection

• Check Facility Power

increase the supply or

wait for additional

supply capacity

handpiece

install the pre-filter

specified fuse

Box

• Check connection

• Check LED display

• Check for clog

• Check micro-switch

on top of control

Page 28 990008 Rev. H

Page 29

• Tubing pinched

• Mixing Chamber empty

• Air Valve problem

• Clogged orifice in Chamber

Air flow from nozzle

when footswitch is not

depressed

• Loss of air pressure due to a

misadjusted air valve

regulator

• Faulty footswitch

• Pinch Valve block is not

tight

Erratic powder flow • Powder caking in chamber

• Chamber empty

• Nozzle partially clogged

• Vibrator inoperative

• Moisture in air line

• Blown pinch tube

Powder spray loses

definition

• Worn nozzle tip

• Too much distance from

cutting surface

Excessive powder inside

of unit

• Hole in tubing.

• Hole in pinch tube

• Exhaust bottle filter loose

Remote error light turns

on when foot switch is

• Remote handpiece micro

switch was not pressed

pressed

panel

• Check tubing

• Refill Mixing Chamber

with powder

• Call local service rep

• Disassemble and clean

Chamber

• Call local service rep

• Call local service rep

• Tighten thumb screws

• Replace powder

• Check powder level

• Check nozzle

• Call local service rep

• Check filters, replace

powder

• Change pinch tubes

• Replace nozzle

• Move closer

• Replace tubing

• Replace pinch tube

• Tighten or replace

filter

• Toggle micro switch

Page 29 990008 Rev. H

Page 30

Error Codes

The following are possible error codes that may appear on the control panel for the unit.

Follow the guidelines from the list above, cycle the power to the unit or call your nearest

authorized Welch Allyn / Kreativ service representative.

Error Code Description

E01 Processor check during power up initialization

E02 +12V status error condition

E04 EEPROM memory status error condition

E05 Zero crossing sensor if idle or if not 50 Hz or 60 Hz

E06 Control panel communications port error

E07 Pressure switch (should be open)

E08 Pressure sensor did not release

E09 Pressure sensor over-range condition

E10 Pressure sensor reads pressure even when solenoid is open

E11 +12V power drops excessively

E13 Bleed valve failure "Pin 3" (solenoid won't lower air pressure)

E14 Pressure won't increase above 40 on power up

E15 Excessive pressure abrading - stuck solenoid or circuit

Page 30 990008 Rev. H

Page 31

9. Handpieces/Nozzles and Abrasives

9

Standard Nozzles

Kreativ offers five nozzle sizes. The size indicates the diameter of the orifice with color

codes to ease identification. Also, each size is offered with the tip at 90°, 67°, or 45°

angles.

• 0.011 inch / 0.28 mm ID, Gray

• 0.014 inch / 0.36 mm ID, Green

• 0.018 inch / 0.46 mm ID, Blue

Chapter

• 0.026 inch / 0.66 mm ID, Brown

• 0.032 inch / 0.81 mm ID, Black

SuperSonic Turbo (SST) Tipped Handpiece Assemblies

This patented nozzle design is for rapid cutting and amalgam removal. They are offered

with the same 90°, 67° or 45° angle selection.

WARNING! Do not attempt to disassemble the SST Handpiece Assembly.

Sizes Available:

• 0.011 inch / 0.28 mm ID, Violet

• 0.014 inch / 0.36 mm ID, Gold

• 0.018 inch / 0.46 mm ID, Red

Abrasives, GammaPure® (Gamma Treated)

• 27 micron Aluminum Oxide, white color

• 27.5 Micron Aluminum Oxide, gray/brown color (recommended)

• 34 Micron Aluminum Oxide, white color

Page 31 990008 Rev. H

Page 32

• 50 Micron Aluminum Oxide, white color

Ordering Information

• 170009-1 .011”/ .28mm @ 45° Gray Assy.

• 170009-2 .011”/ .28mm @ 67.5° Gray Nozzle Assy.

• 170009-3 .011”/ .28mm @ 90° Gray Nozzle Assy.

• 170010-1 .014”/ .36mm @ 45° Green Nozzle Assy.

• 170010-2 .014”/ .36mm @ 67.5° Green Nozzle Assy.

• 170010-3 .014”/ .36mm @ 90° Green Nozzle Assy.

• 170011-1 .018”/ .46mm @ 45° Blue Nozzle Assy.

• 170011-2 .018”/ .46mm @ 67.5° Blue Nozzle Assy.

• 170011-3 .018”/ .46mm @ 90° Blue Nozzle Assy.

• 170012-1 .026”/ .66mm @ 45° Brown Nozzle Assy.

• 170012-2 .018”/ .66mm @ 67.5° Brown Nozzle Assy.

• 170012-3 .018”/ .66mm @ 90° Brown Nozzle Assy.

• 170013-1 .026”/ .66mm @ 45° Black Nozzle Assy.

• 170013-2 .018”/ .66mm @ 67.5° Black Nozzle Assy.

• 170013-3 .018”/ .66mm @ 90° Black Nozzle Assy.

• 170053 .018”/ .46mm @ 45° Supersonic Handpiece, Red

• 170059 .018”/ .46mm @ 67° Supersonic Handpiece, Red

• 170060 .018”/ .46mm @ 90° Supersonic Handpiece, Red

• 170061 .014”/ .36mm @ 45° Supersonic Handpiece, Gold

• 170062 .014”/ .36mm @ 67° Supersonic Handpiece, Gold

• 170063 .014”/ .36mm @ 90° Supersonic Handpiece, Gold

• 170064 .011”/ .28mm @ 45° Supersonic Handpiece, Violet

• 170065 .011”/ .28mm @ 67° Supersonic Handpiece, Violet

• 170066 .011”/ .28mm @ 90° Supersonic Handpiece, Violet

• 170068 Mach 5.0 Chair Integration Kit

• 200002 Standard Handpiece

• 8000-1 Klean Air II, Domestic

• K01-00325-1 Pinch Tube Kit

Page 32 990008 Rev. H

Page 33

• K99-00002-1 Protective Goggles (3 pair)

• 140007 Cart, Mach 5.0

• K01-00398-1 Cart, Mach 4

• 120000 Klean Pak, Cartmount

• K01-00291-2 50 Micron Powder

• K99-00003-2 27.5 Micron Powder, Brown (recommended)

• 140000 34 Micron White Powder/ 2-2# Pkg

• • 140001 27 Micron White Powder/ 2-2# Pkg.

Kreativ also offers a complete line of composites and other restorative

materials. Call your Welch Allyn / Kreativ sales representative for more

information.

Page 33 990008 Rev. H

Page 34

10. Recycling

10

Recycling Instructions for Device, Accessories and

Packaging

Device

• Internal housing shell and brackets should be recycled as steel, or aluminum.

• Plastic parts should be removed from the metal pads before recycling (e.g., power

appliance inlet, footswitch connector, main switch).

• All printed circuit boards should be recycled as electronic devices.

• Doors, skirt and top cover should be recycled as plastic.

Chapter

Accessories

• All spare parts should be recycled according to the instructions above.

• Products which have been in contact with the patient need to be cleaned as

described in the Owner’s manual.

Packaging

• The carton, all other plastics and inserts should be recycled (cardboard, foam,

polyethylene)

ALL RECYCLING MUST BE IN COMPLIANCE WITH THE RELEVANT

NATIONAL LAWS. GOVERNMENT AUTHORIZED RECYCLING CENTERS

MUST BE USED.

Environmentally Relevant Material

COMPONENTS LIST OF MATERIALS

ENCLOSURE AND ALL BRACKETS • STEEL

PRINTED CIRCUIT BOARDS • EPOXY

DOORS, TOP COVER, SKIRT (PLASTIC) • FR ABS

• ALUMINUM

• FR4

TUBING • URETHANE

Page 34 990008 Rev. H

Page 35

THERE ARE NO HAZARDOUS MATERIALS PRESENT

Page 35 990008 Rev. H

Page 36

11. Warranty, Returns and Adjustments

11

Returns and Adjustments

Warranty claims must be made promptly and received by your nearest authorized

Welch Allyn / Kreativ service representative during the warranty period. The liability of

Kreativ Inc., under valid warranty claims, is limited to repair or replacement at the

purchaser’s authorized Service Center or the purchaser’s place of business, at the

option of the authorized service representative. If it is necessary to return a product for

repair or replacement, authorization for the return must first be obtained from the

authorized service representative.

All products returned for examination or warranty repair must be sent insured via a

means of transportation specified by the authorized service representative.

Chapter

Kreativ, Inc., or its authorized service representative claims the sole responsibility for

determining the cause of any instrument failure and the adjustments are subject to

Kreativ, Inc approval.

Limited Warranty

Kreativ Inc. warrants the equipment to be free from defects in material and

workmanship for a period of 12 months from the date of shipment. Damage due to

failure of customer to perform required user/preventive maintenance is not warranteed.

Certain components having limited life expectancy (pinch tubes, air/abrasive tubing,

handpieces and handpiece tips) are not warranteed against normal wear and tear or

customer damage. This limited warranty applies only to the original purchaser / user of

the equipment.

The foregoing limited warranty is exclusive and in lieu of all other warranties, whether

written, oral, or implied, and shall be purchaser’s sole remedy and Kreativ’s sole

liability under contract or warranty or otherwise for the product.

Kreativ, Inc., disclaims any implied warranty of merchantability or fitness for particular

purposes. In no event shall Kreativ, Inc. be liable for any incidental or consequential

damages, or for any incidental or consequential damages arising out of, or in connection

with, the use or performance of the product delivered hereunder.

Page 36 990008 Rev. H

Page 37

Storage And Shipment

The Kreativ Air Abrasion dental instruments have been designed for long term usage in

normal dental office environments. If it is to be stored for any reason for a long period,

it should be covered to protect it from adverse conditions. The area it is to be stored in

should meet the Environmental Limitations Transport and Storage Requirements

indicated the Specifications section of Chapter 1.

The unit has been designed for shipment by normal commercial carriers. Protective

packaging should be used, and the original packing materials should be reinstalled for

shipment. Shipping instructions must be followed closely. The purchaser will be

responsible for damage resulting from improper packing.

Page 37 990008 Rev. H

Loading...

Loading...