Page 1

Mach 4.0 and Mach 4.1

Kreativ Menu

Manuals

Service Manual

Air Abrasion Instruments

Instructions for Use

Please read this manual thoroughly

prior to first use

CAUTION: This device must only be

purchased by, or sold to, a licensed dentist.

Manufactured by

Kreativ, Inc. (USA)

9025 Balboa Avenue

San Diego, CA 92123

Copyright Notice:

Copyright © 1999, Kreativ, Inc. All rights reserved. No part of this manual may be

reproduced without written permission from Kreativ, Inc.

European Regulatory Manager

Welch Allyn LTD.

Navan, Co. Meath

Republic of Ireland

Ph: 353-46-79060

990242 Rev. A

Page 2

Chapter Description Page #

1 Introduction and General Information

Introduction...............................................................................................1

Purpose of this Manual .............................................................................1

General Information and Features.............................................................2

Specifications............................................................................................2

2 Safety

Warnings and Cautions.............................................................................3

3 Controls and Connectors

Names and Functions................................................................................5

Drawings of Controls................................................................................8

Functional Description..............................................................................9

4 Unpacking and Setup

General Information................................................................................10

List of Contents.......................................................................................11

Unpacking and Setup ..............................................................................12

Supply Requirements..............................................................................12

Electrical Requirements..........................................................................12

5 Installation and Unit Checkout

Pre-Installation Requirements.................................................................13

Unit Checkout.........................................................................................13

Filling the Mixture Chamber ..................................................................15

Operational Checkout .............................................................................15

Drawing of the Mixing Chamber............................................................16

Footswitch Operation..............................................................................16

Unit Shutdown ........................................................................................17

Unloading the Powder Chamber.............................................................17

6 Sterilization

Sterilization Procedures ..........................................................................18

7 Operating Instructions

Intra-Oral Applications ...........................................................................19

Extra-Oral Applications..........................................................................20

General Operating Procedures ................................................................21

Step-by-Step Operating Instructions.......................................................23

8 Troubleshooting and Maintenance

25

9 Handpieces and Abrasives

Handpieces..............................................................................................29

Abrasives ................................................................................................29

10 Warranty, Returns, and Adjustments

Returns and Adjustments........................................................................30

Limited Warranty....................................................................................30

Storage and Shipment .............................................................................31

990242 Rev. A

Page 3

1

Introduction

Introduction and General Information

The Kreativ Models

compact, highly reliable instrument designed for performing Air Abrasive MicroDentistry

procedures. It is designed as a means of removing tooth structure and other materials in

preparing teeth for restoration, and as an adjunct to the high speed dental handpiece and

bur. This instrument was designed after extensive consultation with dentists in order to

provide the optimum performance, taking into consideration patient comfort and the time

constraints faced by today’s 21st century dental office.

This manual should be thoroughly studied before installing and using the equipment.

Please call your nearest Welch Allyn / Kreativ service representative if you need additional

information regarding installation, operation or service of the unit.

Purpose of this Manual

Information essential to the installation, operation, and routine maintenance of the

and

4.0

instructions are written specifically for personnel who have been trained in restorative and

preventive dentistry.

APB devices, manufactured by Kreativ, Inc., are included in this manual. The

4.1

Mach 4.0

and

Advanced Particle Beam Systems (APB) are a

4.1

Mach

Page 1 990242 Rev. A

Page 4

General Information and Features

The Kreativ Models

an abrasive powder and air mixture through a very precise nozzle. Applications include

cutting, abrading, deburring, peening, and etching of tooth structures and other materials.

A full selection of abrasive powders and nozzle sizes are available from your nearest

Welch Allyn / Kreativ distributor. See the listing of supplies in Section 9.

All user serviced components, such as control valves and hose connections allow for easy

access through the front and rear panels of the instrument. A footswitch is provided to

activate the handpiece. The instrument features a mixing chamber which can be quickly

unloaded in order to facilitate service, changing abrasive powders or cleanup of the unit

after use.

Mach 4.0

and

APB are designed to provide a controlled flow of

4.1,

Specifications

Power Requirements: 110-220 volt, AC, 60 Hz.

•

220-240 volt, AC, 50 Hz.

Air Requirements : 80 PSI to 120 PSI (maximum)

•

(550 to 825 kPa)

(filtered dry air source)

Approximate Size: 13”W x 11”D x 11”H

•

(33 cm W x 28 cm D x 28 cm H)

Approximate Weight: 43 lb. (20 kg)

•

Environment Limitations: Temperature: 50 °F to 104 °F (+10 °C to 40 °C)

•

Humidity: 30% to 75%

Page 2 990242 Rev. A

Page 5

2

Warnings and Cautions

Safety

Always wear protective eye equipment

particles are deflected into the eye. This applies to all personnel including the patient.

Use a rubber dam

soft tissue. A rubber dam or latex matrix band is also required for interproximal

preparations to protect adjacent tooth surfaces.

In order to reduce the risk of embolism

chamber or at pulpal exposures

the gingiva when the air is activated

tissue, it may irritate it.

The handpiece should be directed precisely at surfaces and tooth structures which are to be

modified or removed. The nozzle tip should be placed two (2) millimeters from the tooth

and angled toward the area to be removed or modified. Unlike the high speed handpiece,

the

Mach 4.0

cutting.

Always use your high volume evacuation system

Kreativ Models

evacuation system in close proximity to the operative site.

for all operative procedures in order to avoid injury to gingiva or other

. Also

and

handpiece nozzles cut only directly from the end, there is no side

4.1

Mach 4.0

and

4.1.

in order to avoid corneal abrasion or irritation if

never direct the handpiece toward an open pulp

never place the handpiece in direct contact with

. While the abrasive stream will not cut the gingival

when using the handpiece on the

Have the dental assistant place the high volume

Do not attempt to service the unit beyond those described items in the maintenance

section.

The Kreativ Models

the order of a dentist.

Call your nearest Welch Allyn / Kreativ service representative for advice.

Mach 4.0

Page 3 990242 Rev. A

and

APB systems are designed for use only by and on

4.1

Page 6

Make sure that the air hose and footswitch are connected to the Kreativ Models

and

and that the instruments are connected to a properly grounded electrical outlet.

4.1

Mach 4.0

Do not substitute non-Kreativ, Inc. materials. Use of materials supplied by other

manufacturers may result in damage to the unit and will void the factory warranty.

Use only clean dry air. Make sure that your air compressor system is equipped with air

dryer filter systems and that they are fully operational. Any moisture or oil in the air

supply will adversely affect your

Mach 4.0

or

4.1

instrument

.

Check to be sure that your air system produces a minimum of 80 psig (550 kPa) at 0.7 cfm

(19.8 l/m).

Sound clinical judgment, good common sense, and proper training are essential to the

successful use of the unit in order to provide safe and efficient patient care.

Always follow standard of care protocols in performing dental operative procedures. Air

Abrasive MicroDentistry technology does not replace current accepted standard of care,

rather it is a new technology designed to help accomplish them.

Page 4 990242 Rev. A

Page 7

3

Controls and Connectors

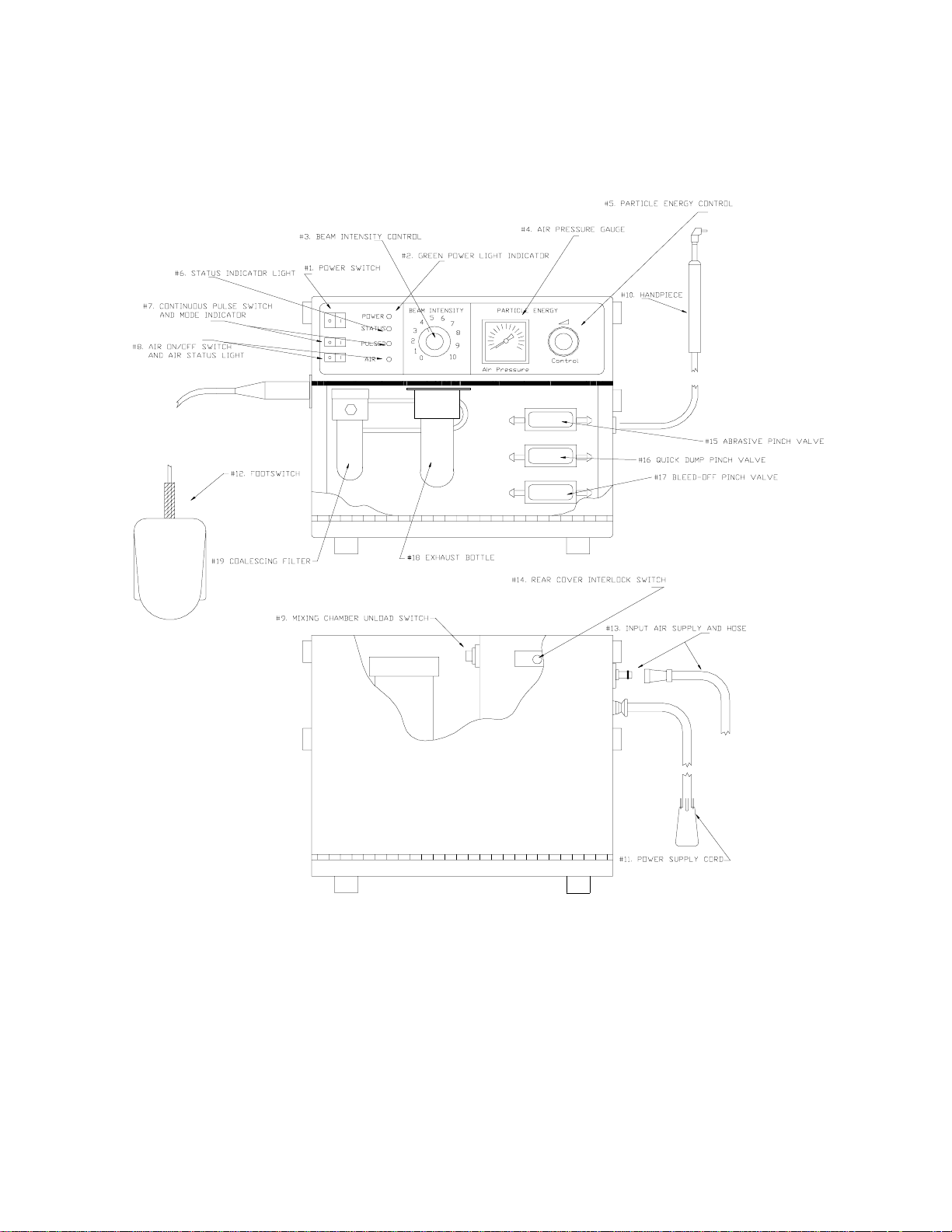

The diagram on page 8 illustrates the external controls, indicators, and connectors for the Kreativ

Models

Names and Functions

#1. Unit POWER Switch;

In the ON position, this switch activates the main power to the unit.

#2 Green POWER Indicator LED

This LED illuminates when the unit POWER switch is in the ON position indicating that

electrical power is ON..

Mach 4.0

and

units. The following describes their functions.

4.1

#3 Beam Intensity Control:

grams/min.)

This knob adjusts the desired rate of powder flow. To operate, begin with minimum abrasive

powder flow and increase until the desired cutting effect is achieved.

#4 Air Pressure Gauge:

Indicates amount of air pressure supplied to the Mixing Chamber and ultimately to the handpiece.

For normal operations, 50-80 psig (345 to 550 kPa) is used. For certain operations a lower or

higher pressure may be desirable.

#5 Particle Energy Control:

Adjusts output air pressure which is indicated on the Air Pressure Gauge.

( Continuously variable from 1-10 (approximately 0 to 7

Page 5 990242 Rev. A

Page 8

#6 Status Indicator LED:

Indicates the status of main (top) pinch valve. When the light is GREEN, the pinch valve is OK.

When the pinch valve tubing ruptures and requires replacing, the Status indicator will flash red

and an audible alarm will sound when the footswitch is depressed.

#7 Continuous/Pulse Switch, Mode Indicator LED:

Select either continuous mode or pulse mode. In continuous mode the indicator LED is AMBER.

In pulse mode the indicator LED is GREEN.

#8 Air ON/OFF switch, Air Status LED:

This switch enables the main air solenoid. When in the OFF (amber) position, the air flow

through the system is disabled. In the ON (green) position the system is pressurized.

#9 Powder Chamber Unload Switch:

This switch enables the vibrator assembly when depressed. When used with the powder chamber

in the unload position causes the abrasive to flow smoothly and easily from the chamber.

#10 Handpiece:

The handpiece holds the nozzle through which the abrasive powder/air flows.

#11 Power Supply Cord:

This power supply cord connects electrical power to the unit. This power requires a properly

grounded outlet.

#12 Footswitch:

The Footswitch is an electric switch. When the foot pedal is depressed the main solenoid is

enabled delivering air/abrasive to the nozzle. The orange protective housing will prevent

accidental activation of the system.

#13 Input Air Supply Hose:

This hose connects the external air supply to the unit. A 1/4-18 NPT fitting is provided on the end

of the hose. The air supply should be from a clean, dry air source.

#14 Rear Cover Interlock Switch:

Disables the air supply when the back cover is opened.

Page 6 990242 Rev. A

Page 9

#15 Main Abrasive Pinch Valve (top)

The top pinch valve opens and closes with depression of the footswitch. It controls the flow of

air/abrasive to the handpiece/nozzle. The Status Indicator LED monitors this pinch valve and will

flash red with a audible alarm when the pinch valve tubing is ruptured and needs replacing.

#16 Quick Dump Pinch Valve (middle)

This pinch valve relieves the pressure and abrasive in the hose and handpiece when the

Footswitch is released. When the footswitch is released the Quick Dump Pinch Valve opens

allowing the built up pressure and abrasive in the hose and handpiece to be expelled into the

Exhaust Bottle.

#17 Bleed Off Pinch Valve (bottom)

This pinch valve is used to depressurize the system when: a) the unit is turned off b) the Air

Switch is in the Off position or c) the Rear Door Interlock is open. In any of the 3 previous

situations the bottom pinch valve will open allowing any pressure in the unit to be released

through the Exhaust Bottle.

#18 Exhaust Bottle

The Exhaust Bottle is used as a relief port for air pressure and abrasive when the footswitch is

released or the unit is turned off or depressurized.. The air and/or abrasive is received via the

middle and/or bottom pinch valve. Any abrasive is filtered and the air is release via a port on the

side of the Exhaust Bottle. Since the Exhaust filters and collects abrasive, it must be periodically

be emptied.

#19 Coalescing Filter

The Coalescing Filter is in the incoming air supply line. It will remove

small

amounts of oil or

moisture that might be in the air supply. It automatically dumps any oil or moisture collected each

time the unit is turned off. If oil or moisture is noticed below the coalescing filter, the air supply

should be checked for the source.

Page 7 990242 Rev. A

Page 10

Page 8 990242 Rev. A

Page 11

Functional Description

The power Indicator LED is illuminated when the unit is ON and ready for use. This

indicates that AC input power is connected to the unit.

Kreativ Models

particles in a dry air stream and delivers this mixture through a nozzle.

The input air supply is routed throughout the system after passing through the main air

solenoid and coalescing filter. One path is through the main regulator (used to set the

desired operating pressure on the control panel) to the mixing chamber where the abrasive

particles are picked up. From there the air carries the particles through the main pinch

valve and on to the handpiece/nozzle when the footswitch is depressed. The second path

is through the pinch valve regulator and pinch valve control system.

The Beam Intensity control regulates the amount of abrasive particles fed into the main air

stream through the mixing chamber.

The air stream combined with abrasive powder is able to cut and etch tooth structure and

ceramic. The abrasive powder/air stream is directed through a light, flexible hose to the

handpiece for precise cutting. Various handpieces are offered with specific orifice (nozzle)

sizes to enable the practitioner to accomplish particular tasks. In addition, a selection of

abrasive powder is available to accommodate all desired uses. Nozzle and abrasive

powder types are listed in Section 9.

When the Power switch is set to

pressure.

Mach 4.0

and

provide a controlled mixture of abrasive powder

4.1

the unit automatically bleeds off the internal air

OFF

Caution

Do not attempt to open the covers of the unit with power turned on!

Page 9 990242 Rev. A

Page 12

4

Unpacking and Setup

General Information

SAVE THE CARTON AFTER UNPACKING THE SYSTEM!

The

Mach 4.0

unpacking, check items against the list of contents packed with the unit.

container and packing materials should be retained in the unlikely event that the unit

has to be returned to the factory for service or repair.

The table on page 11 lists the standard equipment supplied with the unit.

Operation of the

compressed air or nitrogen together with a properly adjusted pressure regulator. In most

cases your standard dental compressor and high volume evacuation system are adequate

for this purpose. For additional information consult your nearest authorized Welch Allyn /

Kreativ service representative.

or

and all accessories are shipped in a single container. When

4.1

Mach 4.0

or

The shipping

requires an external source of either clean, dry,

4.1

Page 10 990242 Rev. A

Page 13

List of Contents

Part Number Item Quantity

Standard Equipment

K01-00090-001 Kreativ

Model Mach 4.0

or

APB with Footswitch 1

4.1

Includes:

130041 Domestic Starter Kit 1

130045 Instructional Video 1

140008 Powder, 27.5 micron (Aluminum Oxide) 4 lbs. ea. 1

170010-2 Green Nozzle, 0.014” (0.36mm) 67° 1

170010-3 Green Nozzle, 0.014” (0.36mm), 90° 1

170011-2 Blue Nozzle, 0.018” (0.46mm), 67° 1

170011-3 Blue Nozzle, 0.018” (0.46mm), 90° 1

170053 Red SST Handpiece/Nozzle Assembly, 45° 1

170081 Footswitch Assembly 1

200002 Standard Handpiece Assembly 2

600105 Domestic Hospital Grade Power Cord 1

990242 Instruction Manual 1

K01-00058-1 Air Supply hose 10' with Quick Disconnect 1

K01-00325-1 Pinch Tube Kit 1

K99-00002-1 Protective Eyewear 3 pr.

K99-00015-1 Fuse, 1A 250V Slo Blo 5 x 20 mm 2

K99-00243-1 Brass Fitting 10-32 x 1/8 for Pneumatic Hose 1

Page 11 990242 Rev. A

Page 14

Unpacking and Setup

Open and remove the

Open the front and rear covers by releasing the latches.

•

Remove the foam packing (3 pieces) used to prevent the vibrator from moving during

•

shipping.

shipped again, the vibrator support foam packing should be reinstalled to

damage

to the vibrator and its mounts.

Failure to remove the foam packing will result in improper vibrator

operation and powder flow.

Supply Requirements

Air Supply:

unit.

A filtered compressed air line or nitrogen may be used as the gas supply for the

or

Mach 4.0

Retain the foam with the shipping box and packing materials.

unit from the shipping container and proceed as follows:

4.1

WARNING

If the unit is to be

prevent possible

The use of compressed oxygen as a gas supply presents a fire hazard.

Under

For optimal use the normal air supply to the unit should be a minimum of 80 psig (550 kPa) with a

maximum of 120 psig (825 kPa), the air source should provide a minimum of 1.5 CFM (42.5 l/m).

Since many dental office compressed air lines may be contaminated with moisture, oil and dirt

which are detrimental to the performance and operation of the unit, moisture filters and unloaders

must be used. Moisture filters for this purpose can be purchased directly from your Welch Allyn /

Kreativ sales representative.

Electrical Requirements

The electrical requirement for this unit is 100-127 VAC, 60 Hz., single phase or 220-240 VAC, 50

Hz. If your requirements are different, consult your nearest authorized Welch Allyn / Kreativ

service representative before operating this unit.

CAUTION!

circumstances should oxygen be used.

NO

Page 12 990242 Rev. A

Page 15

5

Installation and Unit Checkout

After completing the operations in Section 4 you are now ready to begin

installation of your Kreativ

Mach 4.0

Pre-Installation Requirements

1. Adequate Air Supply. Ensure that you have at least 80 PSI (550 kPa) @ 1.5 CFM

(42.5 l/m) of clean, dry air. (The ideal air for the

placing a "T" fitting prior to the final regulator at the operatory but after the dryer, traps

and various filters.)

or

4.1.

Mach 4.0

or

is obtained by

4.1

2. Power supply with earth grounding.

NOTE:

cord.

Unit Checkout

Set the Power Switch on the front panel to OFF, and the POWDER FLOW knob

•

completely counter clockwise to the zero (0) position.

Connect the end of the air supply hose with the quick disconnect to the external air

•

supply.

Plug the power supply cord into a properly grounded receptacle.

•

Set the Power Switch to ON. The green pilot light should be illuminated.

•

Route the power cord safely out of the way and

Page 13 990242 Rev. A

do not use

an extension

Page 16

WARNING!

If the green pilot light does not go on, it indicates absence of electrical power. If,

after verifiying that power is available, the indicator light

consult your local Welch Allyn / Kreativ service representative.

Check the reading on the AIR PRESSURE gauge. Set Particle Energy Control

•

as follows:

1. Pull the black knob out and rotate knob to a reading of 80 PSI (550 kPa) on the

pressure gauge.

2. To prevent any changes push the black knob in/forward to lock it at that setting.

Verify that a Handpiece/Nozzle is attached to the delivery hose.

•

Actuate the Footswitch. Air should flow from the nozzle.

•

STILL

does not go on,

CAUTION!

Some residual powder may be in the unit from factory testing.

use goggles or protective eyewear when using the Kreativ Model

or

4.0

the face when operating the footswitch.

Set the Power Switch to OFF. This allows the system to depressurize.

•

Air Abrasion instrument and do not direct the nozzle toward

4.1

CAUTION!

After turning the Power Switch to the OFF position, monitor the Air

Pressure Gauge to be sure that the air pressure drops to 0. An additional

5 to 10 seconds of depressurizing time must be allowed after the gauge

reading reaches zero (0) before removing the Mixing Chamber Top, or

performing other services.

•

Fill the Powder Chamber as described on the next page.

Always

Mach

Page 14 990242 Rev. A

Page 17

Filling the Mixing Chamber

Observe the following procedures when filling the Mixing Chamber.

Place the Power Switch of the unit to OFF. This allows the system to depressurize.

•

After turning the Power Switch to the OFF position, monitor the Air Pressure Gauge

•

to be sure that the air pressure drops to 0. Allow an additional 5 to 10 seconds after

the gauge reaches 0 before opening the Powder Chamber.

Clean off any dust or debris from the Mixing Chamber top and cover.

•

Remove the Mixing Chamber lid by turning counterclockwise.

•

Carefully pour abrasive powder into the Mixing Chamber until it is 3/4 full.

•

Replace the Chamber lid and tighten.

•

CAUTION!

Make certain that no lint, dirt or other foreign substances enter the chamber.

This can result in plugging the unit.

Operational Checkout

Place the Power Switch to ON and set the Beam Intensity knob to obtain the desired

•

amount of powder flow for the operation to be performed. Powder flow is at a

minimum counterclockwise “zero” position and gradually increases to the clockwise

or “ten” position. Typical dental procedures use powder flow from 3-5 on the dial.

Place the Air Switch to the ON position.

•

Actuate the Footswitch to obtain powder flow through the nozzle.

•

You can now practice operative procedures on extracted teeth as described in Section 2,

Safety.

Page 15 990242 Rev. A

Page 18

Page 16 990242 Rev. A

Page 19

Footswitch Operation

Footswitch operation: depressing the footswitch starts the powder flow through the

•

handpiece/nozzle.

Unit Shutdown

Set the Power Switch to OFF.

•

Unloading Powder Chamber

The illustrations on page 16 show the parts involved in unloading the Mixing Chamber.

Follow these directions when unloading it.

Open the back access panel.

•

Firmly hold the chamber and vibrator and loosen the Mixing Chamber Lid by turning it

•

counterclockwise.

Completely unscrew the lid from the Mixing Chamber.

•

Loosen the locking knob on the Chamber Tilt Plate; slide the Chamber Clamp back to

•

release and tilt the chamber out of the cabinet.

NOTE:

A container must be placed under the chamber opening to catch the abrasive powder.

Set the Beam Intensity on the front panel to “10”.

•

Press the Mixing Chamber Unloading Switch to vibrate the abrasive powder out of the

•

Mixing Chamber.

Tilt the Mixing Chamber back to its upright position.

•

Slide the Chamber Clamp forward over the Chamber Tilt Plate and tighten the knob.

•

Replace the lid and nut making sure the threads are free of powder and the lid gasket

•

is properly seated.

Check the two air hoses attached to the Mixing Chamber to assure that they are not

•

kinked or pinched and that they make a large free loop.

Page 17 990242 Rev. A

Page 20

6

All Kreativ Model Mach 4.0 and 4.1 accessories which come into contact

with the patient

Sterilization Procedures:

Handpiece/Nozzle:

WARNING!

must be sterilized

Sterilization

prior to each use.

Any conventional dental (dry heat, steam or chemical) sterilizer or autoclave may be used to

decontaminate the cutting handpiece/nozzle.

ensures that the handpiece/nozzle cannot become a source for cross contamination of disease or

infection.

Accessories:

The handpiece/nozzle hose assembly of the Kreativ Models

close proximity to the patient or other sources of contamination, should be sheathed or wiped

down in accordance with standard procedures.

Page 18 990242 Rev. A

This is mandatory prior to each use.

Mach 4.0

and

This procedure

which will be in

4.1,

Page 21

7

Operating Instructions

SPECIAL NOTE: As previously stated. you should practice on extracted teeth in order to

appreciate the unique cutting ability of the Kreativ

Intra-Oral Applications:

Cavity preparation for dental restorations.

•

Removal of composite restorations.

•

Partial removal of composite restorations and repair at failure sites.

•

Preparation for pit and fissure sealants.

•

Prophylaxis.

•

Removal of stains from teeth and removal of calculus/tartar from teeth.

•

Prepare teeth for veneer/facing restorations.

•

Etch metal/porcelain/composite restorations prior to repairing them.

•

Prepare teeth for cavity preparations, Class I, II, III, IV & V restorations.

•

Polish metallic restoration margins.

•

Remove old amalgam/porcelain restorations.

•

Remove residual stains from enamel & dentin.

•

Mach 4.0

or

4.1

systems.

Page 19 990242 Rev. A

Page 22

Extra-Oral Applications

Clean cement from a displaced crown prior to recementations.

•

Satinize metallic restoration to locate interference prior to cementation.

•

Etch internal surfaces of restorations.

•

Carve occlusal anatomy in porcelain restorations prior to bonding cementation.

•

Etching stainless steel crown.

•

Satinize restorations to check for seating interference.

•

Clean restorations prior to recementation.

•

CAUTION!

DO NOT USE the Kreativ Model

Mach 4.0

or

for procedures not included or

4.1

suggested in this instruction guide.

The Kreativ Model

Mach 4.0

and

systems should be used

4.1

only

by dental

professionals who have practiced on extracted teeth and who are thoroughly familiar

with this manual.

The use of the Kreativ Model

⇒

Mach 4.0

and

systems as described can generally be well tolerated

4.1

by patients without local anesthesia. If a patient reports discomfort, an anesthetic may be called for.

In general, cutting speed increases with:

⇒

⇒

⇒ ⇒

increased air pressure,

•

increased powder flow,

•

and decreased distance to the tooth structure.

•

Cutting speed decreases with:

⇒

decreased air pressure

•

decreased powder flow

•

and increased distance to the tooth.

•

Page 20 990242 Rev. A

Page 23

Enamel cuts slower than dentin thus:

⇒

It may take

•

But it may take

•

Increased powder flow and air pressure will increase cutting speed, but it will also deliver more

⇒

powder which must be controlled with the high volume evacuation.

Most preparation procedures can be easily accomplished with:

⇒

•

Start by using the general settings (above) and the 0.018 (0.46 mm) tip.

⇒

As you gain experience choose the nozzle size and system settings which suit your individual needs.

⇒

•

With experience you will find a comfortable balance between

cutting speed and controlling the powder flow in the mouth.

about 60-80 PSI (619-825 kPa)

the powder flow set at about 3-5.

1-2 minutes

only 5 seconds

to complete a class I preparation on a molar

to complete a class V preparation on a premolar.

General Operating Procedures

The Cutting Process:

The unit performs a cutting action by impinging sharp-edged powder particles onto a surface. A

cylindrical powder/air stream emerges from the nozzle for a short distance (approximately 1.6

mm) and then diverges into a cone shape, with a seven degree included angle. Within the 1.6 mm,

the nozzle makes small holes and straight walled cuts. As one moves the nozzle away from the

work, the hole diameter or width of cut increases, and the walls become angular. The angle can be

determined with a few trials. To obtain sharp definition (as in precise cutting) use the 0.014

(0.36mm) diameter nozzle and keep the nozzle tip to a minimum of 0.8 mm from the work.

Cutting Speed:

The cutting speed (removal of material) increases up to a certain nozzle distance.

Vary the cutting rate by:

1) adjusting the powder flow and/or air flow.

2) using different pressure settings .

3) using different powder sizes.

4) using special type nozzles.

Etch or remove broad areas of metallic film or coatings by increasing the nozzle tip distance and

diverting the air stream at an acute angle.

″

Page 21 990242 Rev. A

Page 24

Powder Flow Adjustment

Depressing the footswitch causes a mixture of powder and air to be discharged from the nozzle.

Control the mixture richness with the Beam Intensity Knob which adjusts the vibrator speed. We

suggest starting between the 3 and 5 position.

Pressure Behind the Nozzle

Necessary air pressure varies depending upon:

the material being cut.

•

the type of cut.

•

the abrading process desired.

•

the powder being used..

•

We suggest starting at 65 PSI (447 kPa).

Check the Progress of the Cavity Preparation

Stop frequently,(every few seconds) and make a visual inspection of the progress

As you begin using the Kreativ Model

of air/powder mixture.

DO NOT continue for more than 5 seconds without stopping to make a visual

•

inspection.

For class V restorations DO NOT continue for more than

•

to examine the results.

Mach 4.0

or

, we suggested that you use short bursts

4.1

2 seconds

.

without stopping

Use a Saliva Ejector

As with any other cavity preparation procedure, your conventional saliva ejector should be

normally positioned in the patient’s mouth to collect the saliva and rinse water.

Use Your High Volume Evacuation System

This is important when using the Kreativ Model

procedures. Place the HVE about ! to 1 cm from the operative site to collect the abrasive powder.

Mach 4.0

or

for cavity preparation or cutting

4.1

Page 22 990242 Rev. A

Page 25

Stopping to Rinse

Most cavity preparations will take between 30 seconds to 1½ minutes. On longer procedures some

patients will experience discomfort from dryness and may wish to have their mouth rinsed with

the water syringe and evacuated with the saliva ejector.

WARNING!

Without adequate filtration, use of the

the metal parts of your vacuum system.

Step-by-Step Operating Instructions

Notes:

Proceed as follows:

1. Remove the Handpiece/Nozzle from its sterile package and place it on the Air Supply Hose.

2. Prepare your patient just as you would for traditional procedures.

A ) Always pre-load the Mixing Chamber with the abrasive powder appropriate for the

procedure to be performed.

B ) Make sure that the

air source

C ) Make sure the power cord is connected to a properly grounded receptacle.

Mach

4.0

or

4.1

may accelerate the wear on

is connected to the input

air supply hose

.

3. Turn the Kreativ Model

Mach 4.0

or

unit Power Switch to ON.

4.1

(The green light should be illuminated.)

4. Turn the Air Switch to the ON position.

5. Adjust the air pressure and powder flow to the rates needed for the procedure.

6. With the nozzle pointed into a receptacle such as a sink or your vacuum system, press the

footswitch to check that the air-powder mixture is flowing from the nozzle.

7. Direct the tip at the desired target tissue, and with the aspirator in place, begin the procedure.

Observe the progress carefully!

Page 23 990242 Rev. A

Page 26

8. When the procedure has been completed, turn the Power Switch to OFF. The Main Air Valve

will be closed, the input air supply will shut off, the unit will depressurize.

CAUTION!

When changing powders, you must discharge any residual powder

remaining in the air lines. To do this, depress the footswitch; it will take

several seconds to discharge the previous powder from the system

Page 24 990242 Rev. A

Page 27

8

Troubleshooting and Maintenance

PROBLEM PROBABLE CAUSE REMEDY

No power

No powder flow when

footswitch is depressed

Air flow from nozzle when

footswitch is not depressed

Erratic powder flow

Instrument not plugged in

•

Main switch OFF

•

•

•

Blown Fuse

• •

•

•

Main switch bad

• •

Footswitch not plugged in

•

Powder flow not selected

•

Handpiece/nozzle clogged

•

Tubing pinched

•

Air Valve problem

•

•

•

Mixing Chamber empty

• •

•

•

Loss of air pressure due to an

• •

improperly adjusted Air

Valve regulator

Powder caking in Chamber

•

Chamber empty

•

Nozzle partially clogged

•

Vibrator inoperative

•

Moisture in air line

•

Check plug

Check switch

Change fuse

Call Service Representative

Check connection

Check gauge

Check for clog

Check tubing

Call Service. Rep.

Refill Mixing Chamber with

abrasive powder

Call Service Representative

Replace powder

Check powder level

Check nozzle

Call Service Representative

Check filters

Page 25 990242 Rev. A

Page 28

PROBLEM PROBABLE CAUSE REMEDY

No powder flow

Powder spray loses definition

Status LED flashes red with

audible alarm

Periodic Service

The Kreativ Models MACH 4.0 and 4.1 should be inspected periodically for:

Damaged Mixing Chamber Cover, Cap, Cap Nut and cover seal on Chamber

•

Worn or damaged hoses.

•

Clogged orifice in Chamber Disassemble & clean

•

chamber

Worn nozzle tip

•

Too much distance

•

Indicates main (top) pinch

•

valve is ruptured

Replace nozzle

Move closer

Replace pinch valve tubing

Loose wire or hose connections.

•

Burned out indicator lamp.

•

Proper Operation of controls and gauges.

•

Worn nozzle or handpiece.

•

The unit should be periodically cleaned, as follows:

Clean dust and spilled powder from the unit

•

air or vacuum from the dust collector.

Remove stubborn dirt with a brush.

•

DO NOT USE FLUID

•

Clean the external surfaces of the unit with a cloth moistened with a mild cleaning

•

solution such as Windex or rubbing alcohol.

on the hoses or wire insulation.

Page 26 990242 Rev. A

interior

using low pressure compressed

Page 29

Handpiece/Nozzle Tips

The nozzle tips are made of tungsten carbide or sapphire which crack easily, so they

•

must be handled and stored with care.

Nozzle tips sometimes wear, enlarging the side wall. An air stream with lack of

•

definition signals that the nozzle is worn and the tip should be replaced. To do this

unscrew the nozzle from the handpiece and screw in a new one. Make certain that the

new nozzle is fastened securely to avoid powder leaks. Avoid cross threading.

The Red, Violet and Gold SST handpiece/nozzle assemblies do not come apart.

•

Replace a handpiece by disconnecting it from the air hose and replacing it with a new

•

one.

On occasion the nozzle of the handpiece will clog due to excessive flow of powder.

Unclog the nozzle as follows:

1) Remove the handpiece from the air hose and turn the Beam Intensity control knob completely

counterclockwise.

2) Hold the tip end of the nozzle tight against the air hose connector.

3) Turn the unit on end and actuate the Footswitch, supplying air to reverse flush the clogged tip.

NOTE:

This should be done in an exhaust chamber.

Handpiece/nozzles for special applications are available. Consult your Welch Allyn / Kreativ

sales representative for information.

Pinch Valve Tube Replacement:

The rubber pinch valve tube wears and will eventually leak.

NOTE:

The Pinch Valve body does NOT have to be removed from the unit for tube replacement.

Page 27 990242 Rev. A

Page 30

1) Set the Power Switch to the OFF position and monitor the Air Pressure Gauge to be sure that

the air pressure drops to 0. Allow an additional 5 to 10 seconds after the gauge reading

reaches 0.

2) Remove the front black block from the assembly by removing the two knurled screws.

3) Remove the tube from the fittings and carefully insert the new control valve tube between the

fittings.

4) Insert the new pinch tube and fittings into the bottom block indentation.

NOTE:

Be sure to align the pinch valve’s seam to the side of the block.

5) Carefully replace the front cover. Again making certain that the tube aligns with the

indentations in the top block. Secure the front cover in place with knurled screws, making

sure that the thumb screws are tightened down finger tight.

6) Turn the Power Switch to ON and check for proper operation and leaks.

Air ON/OFF Valve

The Air ON/OFF valve controls the flow of air into the unit. The valve is either open, providing

air flow, or closed, stopping the flow. The valve is not field repairable. Your nearest Welch

Allyn / Kreativ service representative will replace it if it malfunctions.

Air Pressure Gauge. The air pressure gauge is not field repairable and should be replaced with a

new one if it malfunctions or fails to operate.

Exhaust Bottle

The Exhaust Bottles in the

Mach 4.0

and

collect small amounts of powder each time the

4.1

footswitch is released or the system is turned off. Check the amount of powder collected in the

Exhaust Bottle every time you refill the canister with powder. It needs to be emptied when it is

approximately half full.

Page 28 990242 Rev. A

Page 31

9

Handpieces

These custom nozzles are available for the Kreativ Mach 4.0 and 4.1:

Handpieces and Abrasives

0.011” (.28mm) ID at either 45°, 67° or 90°

•

0.014” (.36mm) ID at either 45°, 67° or 90°

•

0.018” (.46mm) ID at either 45°, 67° or 90°

•

0.026” (.66mm) ID at 45° only

•

Supersonic handpiece / nozzle assemblies available for the Mach 4.0 and 4.1:

Abrasives

0.032” (.88mm) ID at 45° only

•

0.11” (0.28mm) ID Violet at 45°, 67° or 90°

•

0.14” (0.36mm) ID Gold at 45°, 67° or 90°

•

0.18” (0.46mm) ID Red at 45°, 67° or 90°

•

27.5 Micron Aluminum Oxide

•

27 Micron Aluminum Oxide

•

34 Micron Aluminum Oxide

•

50 Micron Aluminum Oxide

•

Page 29 990242 Rev. A

Page 32

10

Returns and Adjustments

Warranty claims must be made promptly and received by your nearest authorized Welch

Allyn / Kreativ service representative during the warranty period. The liability of Kreativ

Inc., under valid warranty claims, is limited to repair or replacement at the purchaser’s

authorized Welch Allyn / Kreativ Service Center or the purchaser’s place of business, at

the option of the authorized service representative. If it is necessary to return a product for

repair or replacement, authorization for the return must first be obtained from the

authorized service representative.

Warranty, Returns and Adjustments

All products returned for examination or warranty repair must be sent insured via a means

of transportation specified by your authorized Welch Allyn / Kreativ service

representative.

Kreativ, Inc., or its authorized service representative claims the sole responsibility for

determining the cause of any instrument failure.

Limited Warranty

Kreativ Inc. warrants the equipment to be free from defects in material and workmanship

for a period of 12 months from the date of shipment. Damage due to failure of customer

to perform required user/preventive maintenance is not warranteed. Certain components

having limited life expectancy (pinch tubes, air/abrasive tubing, handpieces and

Page 30 990242 Rev. A

Page 33

handpiece tips) are not warranteed against normal wear and tear or customer damage.

This limited warranty applies only to the original purchaser / user of the equipment.

The foregoing limited warranty is exclusive and in lieu of all other warranties, whether

written, oral, or implied, and shall be purchaser’s sole remedy and Kreativ’s sole liability

under contract or warranty or otherwise for the product.

Kreativ, Inc., disclaims any implied warranty of merchantability or fitness for particular

purposes. In no event shall Kreativ, Inc. be liable for any incidental or consequential

damages, or for any incidental or consequential damages arising out of, or in connection

with, the use or performance of the product delivered hereunder.

Storage And Shipment

The Kreativ Models

Mach 4.0

and

have been designed for long term storage in

4.1

normal dental office environments. If it is to be stored for any reason for a long period, it

should be covered to protect it from elements and the Mixing Chamber should be emptied.

The area it is to be stored in should meet the Environmental Limitations indicated in the

Specifications section of Chapter 1.

The unit has been designed for shipment by normal commercial carriers. Protective

packaging should be used, and the original packing materials should be reinstalled for

shipment. Shipping instructions must be followed closely. The purchaser will be

responsible for damage resulting from improper packing.

Page 31 990242 Rev. A

Loading...

Loading...