Page 1

Halogen Exam Light III

Halogen Exam Light III with Fiberoptic Light Pipe

Model #’s - 48700, 48722, 48724, 48726, 48728

Halogen Exam Light III with Fiberoptic Light Cable

Model #’s - 48780, 48782, 48784, 48786, 48788

Halogen Exam Light III with Neonate Light Pipe

Model #’s - 48760, 48762, 48764, 48766, 48768

Halogen Exam Light III Light Box with Power Cord

Model #’s - 48740, 48742, 48744, 48746, 48748

INTRODUCTION

Thank you for purchasing the Welch Allyn Halogen Exam Light III. We believe

that it is the highest quality product of its kind available in the world today.

By following the simple guidelines found within this manual, you should be

rewarded with years of dependable, trouble free performance. If you have

any questions or concerns please feel free to contact our customer or

technical service departments at (800) 535-6663 during normal business

hours.

Welch Allyn remains committed to providing innovative, quality diagnostic

products for healthcare professionals. Call us at (800) 535-6663 to request a

full line product catalog or visit us at our Web Site, www.WelchAllyn.com.

SYMBOL DESCRIPTIONS

Attention: Consult user’s manual for additional information.

WARNING: Do not perform neonatal trans-illumination without the

use of the #48210 neonatal trans-illuminator (with U.V. filter). Do not

remove the focusing sleeve from the light pipe and use the light pipe

for trans-illumination. Severe burns may result.

General practices to minimize risk of harm to the skin from optical

radiation hazards include: minimizing illumination intensity at the tissue examination site, minimizing exposure times, and taking additional precautions when skin sensitivity has been altered through

tissue trauma or the use of anesthesia.

General good practices to minimize risk of harm to the eyes from

optical radiation hazards include: avoid looking at bright light sources

and their reflections, and protect eyes where normal pupil sizes and

aversion responses are not present.

There are no user serviceable/replaceable parts other than lamp and

fuses. Please refer any other service to qualified and authorized

service centers.

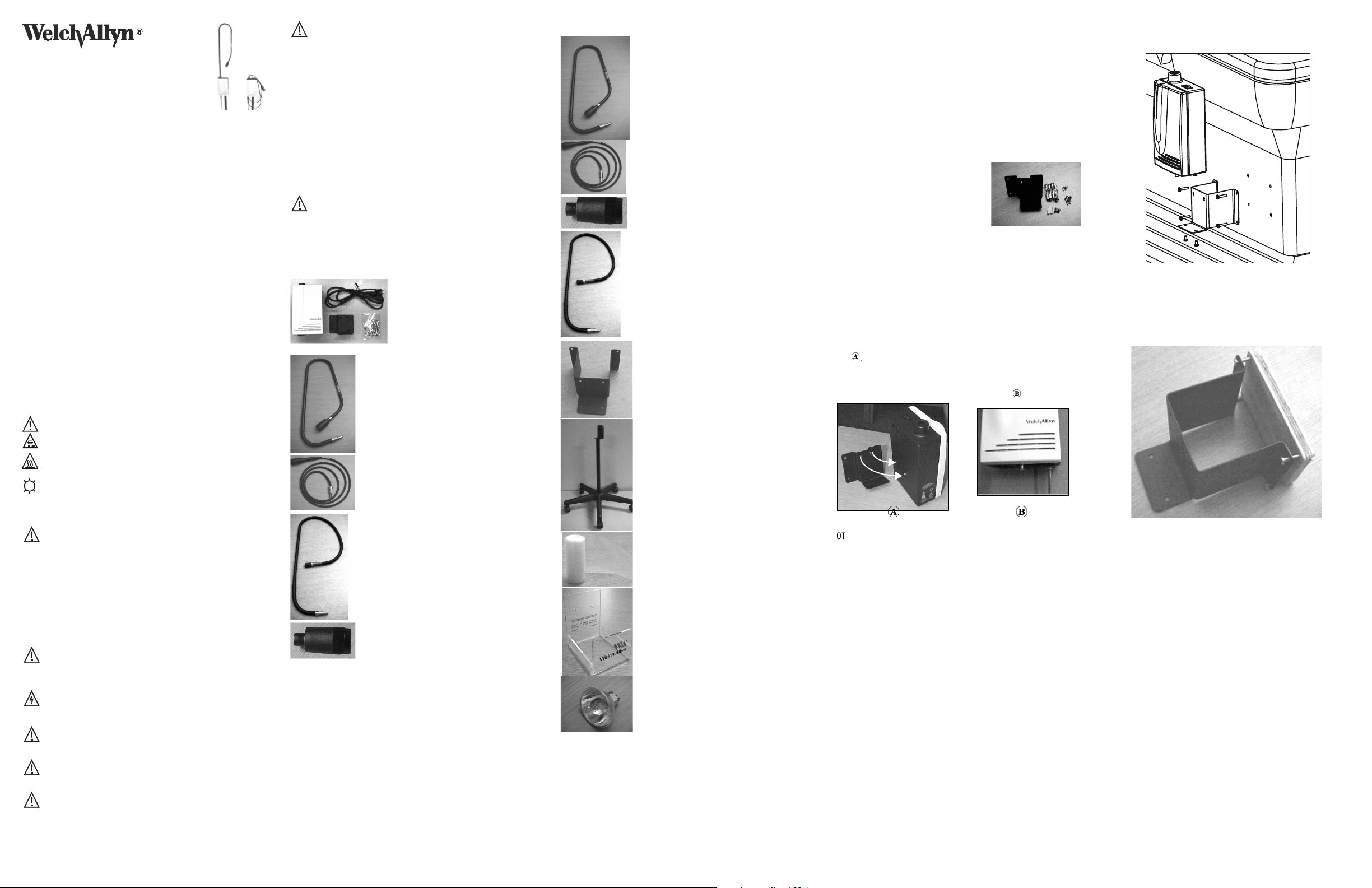

COMPONENTS

Standard

Light Box, Power Cord and Wall Mount

Model 48740 (Domestic)

Model 48742 (Europe)

Model 48744 (UK)

Model 48746 (Australia)

Model 48748 (Japan)

Fiberoptic Light Pipe (shown with focusing sleeve)

Model 48200

(Included only with Model #’s 48700, 48722,

48724, 48726, and 48728)

Accessories

Fiberoptic Light Pipe (Shown with Focusing Sleeve)

Model 48200

Fiberoptic Light Cable (Shown with Focusing Sleeve)

Model 48220

Focusing Sleeve

Model 48605

Neonatal Transilluminator

Model 48210

The optional neonatal Light Pipe/

transilluminator is used to assist in the

diagnosis of pneumothorax, to locate blood

vessels, etc. This transilluminator

incorporates a permanently attached

ultraviolet filter that minimizes the

transmission of ultraviolet light. The standard

Fiberoptic Light Pipe or Fiberoptic Light Cable

NOT

should

neonates.

be used for transillumination of

Table Mount Bracket

Model 48859

MOUNTING

Use one of the following three mounting options in order to ensure proper

operation of the light box.

Wall Mount

Choose appropriate mounting location. The length of the light pipe is 4 feet

totally extended (fiberoptic light cable is 7.5 feet). When choosing a mounting

location, keep these dimensions in mind in addition to accounting for the

actual application the light will be used for and what portion of the

examination table will need to be accessed.

1. Using the mounting plate as a template, mark drilling holes as needed

(depending on your wall type).

2. Dry Wall, Paneling, Plywood or Plaster

(1/8 inch (.3 cm) to 5/8 inch (1.6 cm)

thick) - drill four (4) 3/8 inch (1cm) holes,

insert hollow metal wall anchor

assembly.

3. Concrete Block - drill four (4) 3/16 inch

(.5 cm) holes, insert plastic anchors. Use #8 x 1/2 inch screws to

secure.

4. Metal Panel or Plywood walls greater than 5/8 inch (1.60 cm) thick drill four (4) 1/8 inch (.3 cm) holes. Use #8 x 1 inch screws to secure.

5. Once holes are drilled, install the mounting plate with the appropriate

screws. Completely tighten the screw so there is no gap between the

screw head and the mounting plate.

6. Mount the Light Box to the plate by inserting the pins on the back of the

light box into the slots on the mounting plate. Let the light box drop

down to position the pins into the narrow portion of the mounting slots

.

7. To secure the Light Box to the plate, insert two (2) .50” (1.27cm) screws

through the bottom of the mounting plate and tighten into the bottom

of the Light Box using a phillips head screwdriver

.

5. To secure the Light Box to the mounting plate, insert two (2) .50” (1.27

cm) screws through the bottom of the mounting plate and tighten into

the bottom of the Light Box using a Phillips head screwdriver.

NOTE: Some tables require additional reinforcement of the mounting bracket

to support the mounted light. In this case, we recommend using a 1” (2.5 cm)

thick piece of plywood. When employing this reinforcement to the bracket,

please follow instructions 6 - 11 below.

6. Trace the outline of the mounting plate and mark the hole locations on

a 3/4 inch (1.9cm) thick piece of plywood.

Warning: Risk of fire. Replace fuses as marked.

Caution: High Temperatures

Caution: High Intensity Light

WARNINGS & CAUTIONS

WARNING: The user of this equipment should be thoroughly trained

in the medical procedures appropriate to the utilization of this

instrumentation. Furthermore, time should be taken to read and

understand the instructions contained within this manual prior to use

of this product. Instructions for other equipment used in conjunction

with the Exam Light III (for example: suction machines,

electrosurgical generators, etc.) should also be read and understood.

Failure to understand the operating requirements for this product

may result in injury to yourself, the patient and/or may damage the

instrument.

CAUTION: Electric Shock Hazard - Remove power cord from

electrical outlet and allow lamp to cool before replacing (Welch

Allyn lamp # 04200).

DANGER: Risk of explosion if used in the presence of flammable

anesthetics.

CAUTION: Federal Law restricts this device to sale by or on the order

of a physician.

CAUTION: Illumination is intense - Do not stare at the light source in

operation. May be harmful to eyes.

CAUTION: Use the examination light in its intended working range of

12 to 24 inches. Exposures at closer distances may be harmful to

skin.

Fiberoptic Light Cable (shown with focusing sleeve)

Model 48220

(Included only with Model #’s 48780, 48782,

48784, 48786, and 48788)

Neonatal Transilluminator

Model 48210

(Included only with Model #’s 48760, 48762,

48764, 48766, and 48768)

Focusing Sleeve

(Included only with Model #’s 48700, 48722, 48724,

Model 48605

48726, 48728, 48780, 48782, 48784, 48786, and 48788)

Mobile Stand

Model 48850

Disposable Sheaths

Model 52640

Disposable Sheath Dispenser

Model 52641

35W Halogen Replacement Lamp

Model 04200

NOTE: Some exam table manufacturers supply mounting hardware for

installation of the Exam Light III. Check with your table supplier for

availability.

WARNING: It is the responsibility of the health facility of user to ensure that

the mounting bracket is securely anchored to the wall or table, or that the

mobile stand is securely assembled, and the exam light is securely fastened

to the bracket or stand as directed below. Give consideration to the load that

is placed upon the mount. Welch Allyn, Inc. does not accept responsibility for

any installation, nor for damage or injury arising from the installation of any

mounting bracket or mobile stand, regardless of the type of fasteners and

technique used.

1. Determine the side of the table that is most optimal for mounting the

light. Consider the location of the nearest power outlet and patient

traffic.

NOTE: Verify that the top of the mounting bracket is at least 10 inches (25.4

cm) below the table top cushion and that the mounting position will not

interfere with the operation of the table.

2. Using the mounting plate as a template, mark the hole locations on the

table and drill four (4) .25 inch (.64 cm) holes in the table.

3. Using four 8-32 screws with lock washers and nuts, install the

mounting plate to the table as shown in the diagram.

4. Mount the light box to the plate by inserting the pins on the back of the

light box into the slots on the mounting plate. Let the light box drop

down to position the pins into the narrow portion of the mounting slots.

7. Cut the piece of wood to the outline size and drill four .25 inch (.64cm)

holes.

8. Using the mounting plate as a template, mark the hole locations on the

table and drill (4) .25 inch (.64 cm) holes in the table.

9. Using four 8-32 x 2 inch (5.08 cm) screws with lock washers and nuts,

install the block of wood and mounting plate to the table as shown in

the diagram.

10. Mount the light box to the plate by inserting the pins on the back of the

light box into the slots on the mounting plate. Let the light box drop

down to position the pins into the narrow portion of the mounting slots.

11. To secure the Light Box to the mounting plate, insert two (2) .50”

(1.27cm) screws through the bottom of the mounting plate and tighten

into the bottom of the Light Box using a phillips head screwdriver.

Page 2

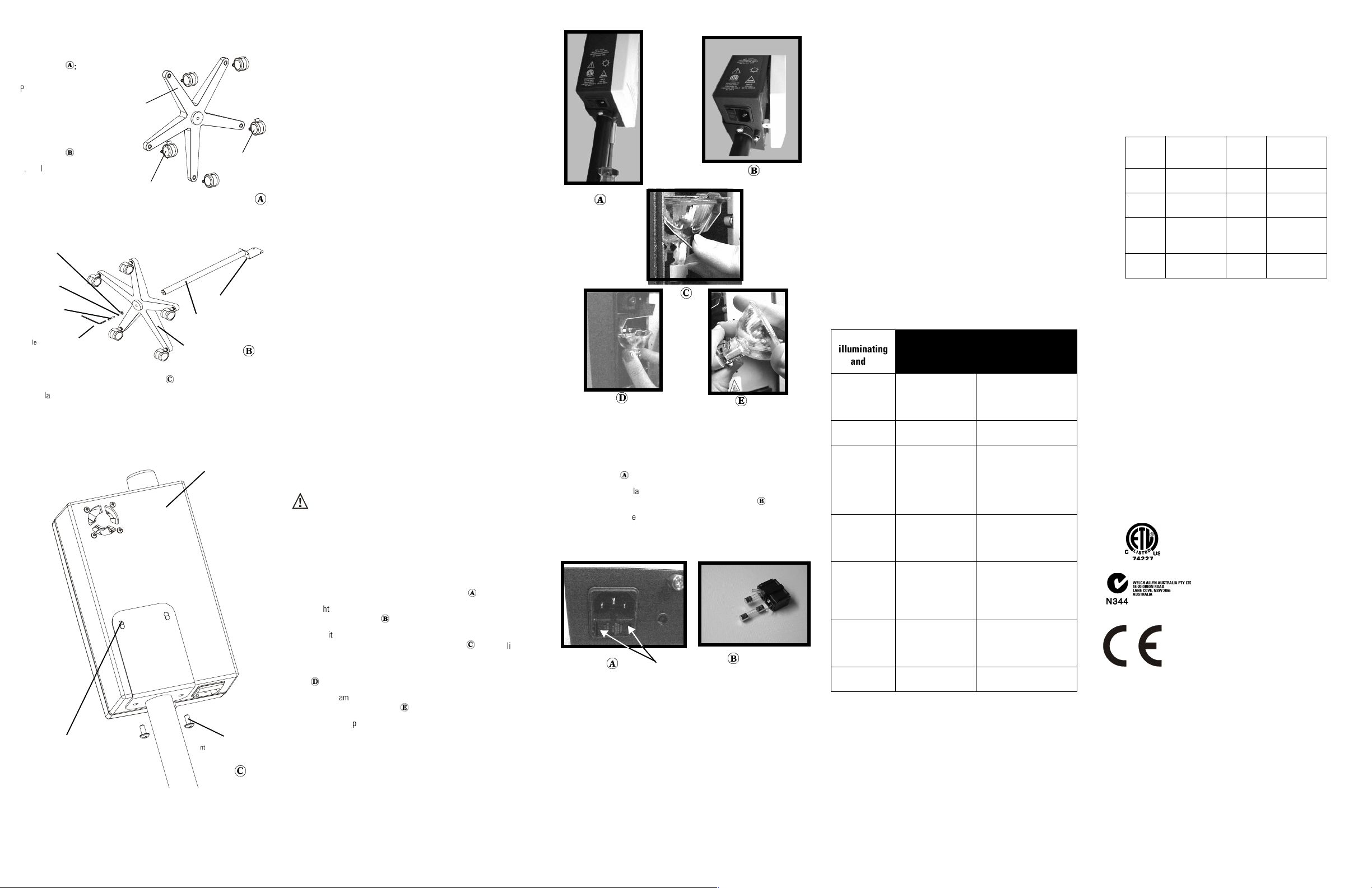

Mobile Stand

(Model # 48850)

Caster/Base Assembly

Instructions

:

Push casters into the holes of

the base unt il they “snap” into

place. Alternate casters as

Base

shown.

Base/Column Assembly

Instructions

:

Locking Caster

1. Insert column into

center hole of base.

2. Insert .25 inch (.64 cm)

Locking

Caster

lock washer, .75 inch

(1.9 cm) flat washer and

1 1/4” (3.2 cm) socket head bolt into center hole. Tighten socket head

bolt with hex socket wrench.

.75 inch (1.9 cm)

Flat Washer

.25 inch (.64 cm)

Lock Washer

Socket Head Bolt

Hex Socket Wrench

(Allen Wrench)

Exam Light/Mounting Plate Instructions

Mounting Plate

Column

Base

:

1. Place the keyhole pins on the back of the Exam Light into the slots on

the top of the mounting plate and slide down.

2. Line up the screw holes on the bottom of the Exam Light with the screw

holes on the mounting plate.

3. Insert the .50 inch (1.27 cm) screws through the bottom of the mounting

plate and tighten with a phillips head screw driver (not included).

Exam Light

Keyhole Pin in slot.

.50 inch (1.27 cm)

mounting screw

SET-UP AND OPERATION

Set Up

1. Secure the Light Box to one of the mounting options per the appropriate

instructions.

2. Insert the Fiberoptic Light Pipe, Fiberoptic Light Cable, or Neonate Light

Pipe into the light pipe receptacle on the top of the Light Box.

3. Plug the power cord into the base of the Light Box and the remaining

end into a grounded AC outlet.

4. Toggle the light switch to the “ON” position to operate.

NOTE: Remember that the Fiberoptic Light Pipe, Fiberoptic Light Cable, and

Neonate Light Pipe contain several thousand individual optical fibers,

therefore appropriate handling is required to ensure long fiber life. Do not

bend the flexible portions of the light pipe at acute angles as this will break

individual fibers and reduce light transmission. For example, do not bend the

semi-flexible middle portion of the Fiberoptic Light Pipe more than 180

degrees and do not bend the proximal and distal sections more than 90

degrees. Be careful not to pull on the Fiberoptic Light Cable as this may cause

fibers to break.

Operation Of Light Pipe

The flexible portions of the Fiberoptic Light Pipe are designed to be

articulated, but not twisted. Twisting or applying torque to the flexible

sections will greatly decrease the life of the Light Pipe. This type of

movement will cause premature drooping of the Light Pipe (will not stay in

place once positioned) and eventually will result in breakage of the fiberoptic

bundle. For best results, always position the Light Pipe by moving it in the

same direction as gravity. For example, if the pipe needs to be raised, raise it

above the desired position and then lower it into place.

NOTE: Upon manufacture, the Light Pipe is tested to assure maintenance of

positioning and to verify the absence of noise upon articulation. Over a period

of time and use, it is normal for the Light Pipe positioning capability to reduce

and soften becoming less obedient. Abnormal softening or occurrence of

noise upon articulation should be reported to Welch Allyn Technical Service

(315-685-4560) immediately.

Operation of Focusing Sleeve

The focusing sleeve at the end of the Fiberoptic Light Pipe and Fiberoptic

Light Cable provides adjustment of the illumination spot size. Twisting the

knurled portion of the focusing sleeve in a clockwise direction will make the

spot smaller. Twisting the knurled portion of the focusing sleeve in a

counterclockwise direction will increase the spot size.

LAMP REPLACEMENT

CAUTION: Lamp may be hot. Allow the lamp to cool before replacing.

1. Turn the unit off and unplug the power cord from both the wall outlet

and the Light Box.

2. Remove the unit from the patient area.

3. Using a screwdriver, loosen the single panel fastener that protrudes

from the bottom of the unit. As the screw is loosened, there will be a

noticeable “drop” as the front cover is released.

4. Slightly lift the bottom of the front cover toward you and then slide the

cover up to remove it.

5. For initial lamp replacement only: Grasp wire clip at top of lamp. Rotate

clip toward the base of the unit until it pops out.

for shipping purposes only.

6. Grasp the lamp connector and pull the lamp straight out of its holder.

7. Pull the lamp from its connector and replace it with Welch Allyn

Replacement Lamp #04200.

8. Push the lamp back into the holder.

9. Attach the front cover by sliding the tabs at the top of the cover into the

slots at the top of the back housing and then tightening the screw at

the bottom of the unit.

10. Return the unit to the patient area and plug power cord back into

bottom of unit and wall outlet.

Discard clip. It was

FUSE REPLACEMENT

1. Turn the unit off and remove the power cord from both the wall outlet

and the light box.

2. Press the tabs on both ends of the fuse drawer in and pull the fuse

drawer out.

3. Remove and replace new fuses of the same type. There is no required

orientation of the fuses. Be sure to replace both fuses.

4. Reinsert the fuse holder by pressing it into the power connector until it

snaps into place.

5. If the new fuses blow, immediately contact Welch Allyn Technical

Service (315-685-4560).

Fuse Tabs

CLEANING

Focusing Sleeve

For best results, use the disposable sheath model #52640.

1. Remove the focusing sleeve from the Fiberoptic Light Pipe or Fiberoptic

Light Cable by rotating it counterclockwise to unthread.

2. Use a cotton swab soaked in warm water and mild detergent to clean

the distal end of the Fiberoptic Light Pipe or Light Cable, the proximal

side of the Focusing Sleeve (small end), and distal window on the large

end on the Focusing Sleeve.

3. Dry using a new cotton swab.

4. Reassemble the Focusing Sleeve to the Light Pipe or Light Cable by

rotating clockwise.

WARNING: Do not clean any part of the focusing sleeve with alcohol. Clean

only with a mild detergent and water.

NOTE: The focusing sleeve should not be sterilized or immersed.

Fiberoptic Light Pipe, Light Cable, Neonate Light Pipe

For best results, use the disposable sheath model #52640.

External surfaces may be cleaned with a solution of warm water and mild

detergent.

NOTE: The Fiberoptic Light Pipe, Light Cable, and Neonate Light Pipe should

not be sterilized or immersed.

Light Box

Note: The Light Box should not be sterilized or immersed.

1. Prior to cleaning, turn power off and disconnect the power cord from

both the wall outlet and the Light Box.

2. The external surfaces may be cleaned by wiping with a cloth dampened

with mild soap and water or by using the following cleaning/

disinfecting solutions. DO NOT IMMERSE.

• 70% Isopropyl Alcohol

• 10% mild bleach solution

• 10% Iodine Based Solution

The power cord may be wiped clean using the same cleaning/disinfecting

solutions listed above. Wipe dry with a clean cloth. Care must be taken not to

get the prongs wet. DO NOT IMMERSE.

TROUBLESHOOTING

If lamp is not

illuminating

Possible Cause Solution

and…

fan is not oper-

ating.

fan is operating. The lamp has burned

If light output

seems low.

Light box is not

plugged into either

the wall outlet or the

power cord socket.

Power switch is not

turned on.

One or both fuses

have blown.

Power cord is dam-

aged. This may cause

intermittent opera-

tion.

No power is sup-

plied to the wall out-

let.

out.

Lamp is not in opti-

mal orientation.

Plug the power cord into

the wall outlet and power

cord socket at bottom of

unit.

Depress the green side of

the power switch.

Replace both fuses. Follow

the instructions in the fuse

replacement section. If

fuses continue to blow,

return Light Box to an

authorized repair center.

Replace the power cord

with a new Welch Allyn

power cord.

Verify that the wall outlet

has power by checking the

circuit breaker status and

by operating other equip-

ment at that wall outlet.

Replace with a new Welch

Allyn lamp, model # 04200.

Refer to the Lamp Replace-

ment Section.

Rotate lamp 90° in the

lamp holder.

MAINTENANCE AND REPAIR

For minor trouble, refer to the troubleshooting section in this manual for

possible causes and corrective action. Only qualified personnel should make

electrical inspections of the Welch Allyn Light Box. To locate qualified

personnel, contact your local authorized Welch Allyn distributor, or call Welch

Allyn directly at 315-685-4560. Tampering with the unit will automatically

void all warranties expressed or implied.

WARRANTY

Light Box - Welch Allyn guarantees that the Light Box is free of any

manufacturing defects or Welch Allyn will repair or replace, free of charge,

any parts proven to be defective through causes other than misuse, neglect,

damage in shipment and normal wear and tear. The warranty is for a one year

period from the original date of purchase.

Fiberoptic Light Pipe - The fiberoptic light pipe has been designed to not drift

to a new position once positioned for an exam if the Light Box is mounted

vertically according to the instructions. The warranty is for a one year period

from the original date of purchase provided that the light pipe has not been

tampered with or abused. Any Light Pipe that does not meet these

performance requirements will be repaired or replaced at no charge to the

customer.

SPECIFICATIONS

Electrical

Ref

Model

48740 120VAC∼60Hz,

48742 230VAC∼50Hz,

48744 230/

48748 100VAC∼50/

Power Cord

#18AWG, 3 wire grounded cord set, 8 feet (2.5 meters) long.

Physical Characteristics

Weight: 4.75 lb (2.16 Kg), light box only

Light Box H: 8.75 inches (22.23 cm)

Dimensions: W: 5.25 inches (13.34 cm)

Environment

Operating: 60°F (15°C) to 104°F (40°C), 75%

R.H. Max, 500 hPa - 1060 hPa Altitude

Transport/Storage: -4°F (-20°C) to 120°F (49°C), 95%

Equipment Classification

Class I, Continuous Operation

IPXØ: Not protected against the ingress of water.

Approvals

NOTE: This product complies with current required standards for

electromagnetic interference and should not present problems to other

equipment or be affected by other devices. As a precaution, avoid using this

device in close proximity to other equipment.

NOTE: This product contains no hazardous materials. Its disposal will not

contaminate or harm the environment, or present any risk to individuals

disposing of the product. As a precaution, it is recommended you contact your

local disposal and/or recycling authority for information regarding the

disposal of the equipment.

Input Output Fuse

400mA

3.0A

12VAC,

12VAC,

250mA

3.0A

12VAC,

240VAC∼50Hz,

3.0A

250mA

12VAC,

60Hz, 500mA

3.0A

D: 3.50 inches (8.89 cm)

R.H. Max, 500 hPa - 1060 hPa Altitude

IEC 60601-1, UL 2601-1, CAN/CSA C22.2 No

601.1, AS3200.1, IEC 60601-1-2

EMC Framework of Australia

The CE mark on this product indicates that it has been

tested to and conforms with the provisions noted within

the 93/42/EEC Medical Device Directive.

Authorized European Representative Address:

European Regulatory Manager

Welch Allyn Ltd.,

Kells Road, Navan,

County Meath, Republic of Ireland.

Tel.: 353-46-79060

Fax: 353-46-27128

T500mAL,

250V

T315mAL,

250V

T315mAL,

250V

T630mAL,

250V

488068-4 Rev. E

Loading...

Loading...