Page 1

HALOGEN

Exam / Procedure Light

Service Manual

EXAM LIGHT II

No. 48600 No. 48610

No. 48625 No. 48635

Thank you for purchasing the Welch Allyn

Halogen Exam Light II. We believe it is the

finest product of its kind available to you today.

By following the care and use guidelines found

in this booklet, you should be rewarded with

years of dependable, trouble-free service.

WARNING

The user of this equipment should be

thoroughly trained in the medical procedures appropriate to the instrumentation.

Furthermore, time should be taken to read

and understand these instructions before

performing any procedures. Instructions

for other equipment used in conjunction

with the Exam Light II (e.g., electrosurgical

generators, suction machines, etc.) should

also be read and understood. Failure to

do so may result in injury to the patient

and/or damage to the instrument.

Page 2

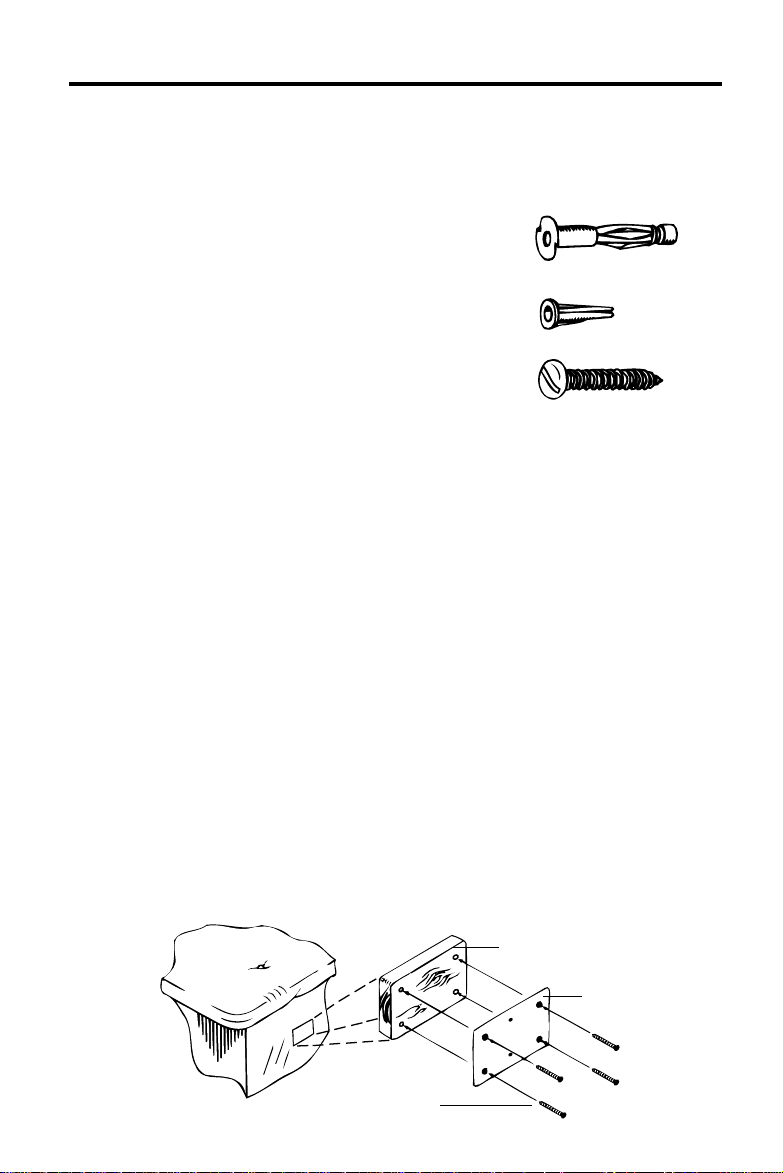

MOUNTING

W

ALL MOUNTING

• Choose appropriate mounting location.

• Using mounting plate as template, mark drilling holes as needed for your wall type:

Dry wall, paneling, thin plywood or plaster

walls less than 1 inch (2.5 cm) thick.

Drill four .31 inch (.79 cm) holes, insert hollow

metal wall anchors making sure barbs are extended.

Concrete block or thick plaster walls

greater than 1 inch (2.5 cm) thick.

Drill four .25 inch (.64 cm) holes, insert plastic anchors.

Metal panel or wood walls greater

than 1 inch (2.5 cm) thick.

Drill four .31 inch (.79 cm) holes.

• Install mounting plate with appropriate screws. When tightened, there will be a gap

between the screw heads and surface of the mounting plate.

• Mount unit by fitting key hole slots on back of unit over screw heads.

• Push unit against wall while pushing down to lock screw heads into small end of key

hole slots.

TABLE MOUNTING

NOTE: Some table manufacturers supply table mounting hardware for mounting the

Exam Light II. Check with your table supplier for availability.

• Determine side of table for mounting the Exam Light II.

• Trace the outline of the mounting plate and mark the hole locations on a

1.00 inch (2.5 cm) thick piece of wood.

• Cut the piece of wood to the outline size and drill four .25 inch (.64 cm) holes.

• Using the mounting plate as template, mark the hole locations on the table and

drill four .25 inch (.64 cm) holes.

NOTE: Be sure mounting location is at least 10 inches (25.4 cm) below table cushion,

and that mounting will not obstruct table interior.

• Using four 10-32 x 2 inch (5.08 cm) machine screws with lock washers and nuts,

install the block of wood and the mounting plate to the table as shown in diagram.

• Mount unit as with wall mounting.

Wood Block

Mounting Plate

2 Inch (5.08 cm)

Long Screws

2

Page 3

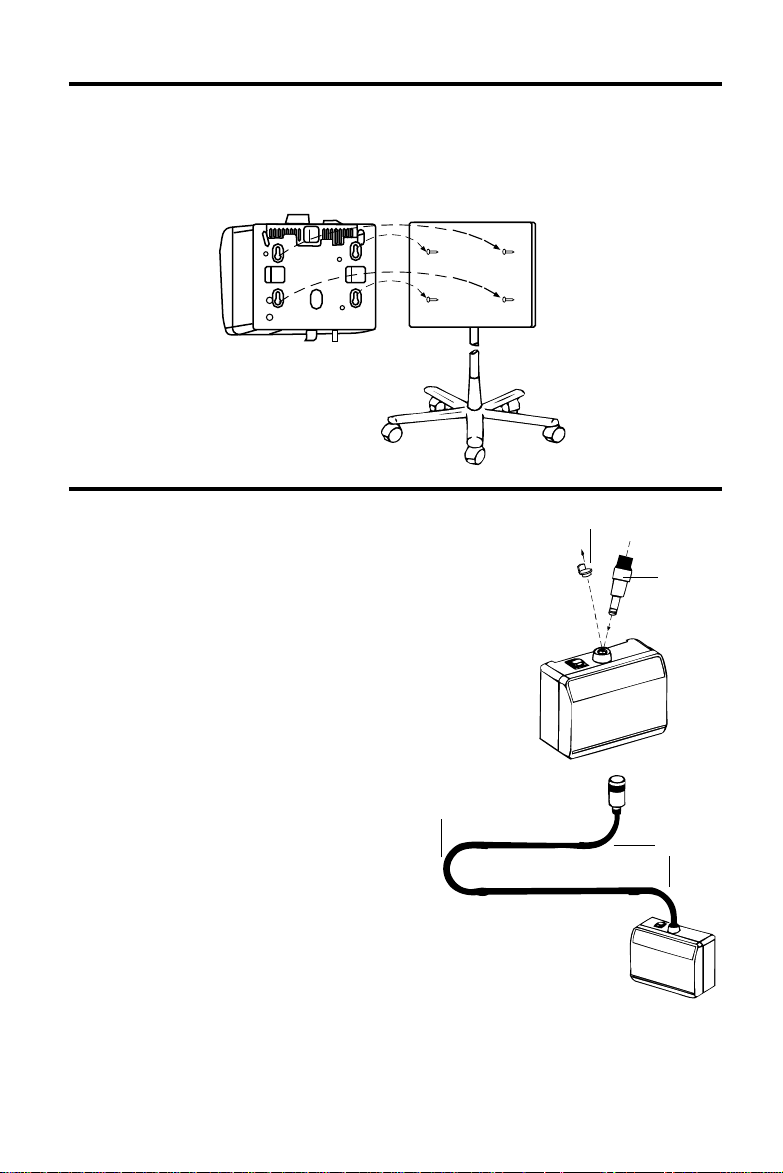

MOUNTING

M

OBILE MOUNTING

• Mount unit by fitting key hole slots on back of unit over screw heads.

• Push unit against mounting plate while pushing down to lock screw heads into

small end of key hole slots.

SET UP

• Carefully remove plastic plug from light pipe holder on top of unit.

• Insert fiber optic light pipe into light pipe holder until it is secure.

• Plug power cord into base of unit and into AC grounded outlet.

• Position the power switch located on the top of the unit to ON.

Plug

NOTE: Please refer to use of light pipe section

prior to using unit.

Max.

180°

To ensure long unit life, high light output and continued position rigidity, we

recommend that you do not acutely

bend the Light Pipe. For example: Middle

Bend—not more than 180°. End Bends—

not more than 90° each.

WARNING:

Not for use in the presence of flammable anesthetic.

Do not use Model 48200 (Standard model) Light Pipe for neonate transillumination.

Even though the distal end of the light pipe does not feel warm to the touch, it can

burn neonates. Erythema may result from contact of more than 15 seconds. Use

Model 48210 Neonate Transilluminator for safe transillumination.

Light

Pipe

Max. 90°

3

Page 4

OPERATION OF LIGHT PIPE

The flexible portions of the fiber optic Light Pipe are designed to be bent, but not

twisted. Twisting, or torque, will decrease the life of the flexible portions, causing

drooping of the Light Pipe and eventual breakage of the fiber optics. As in the illustration, once a section is bent into position A, for example, it must first be returned

to the neutral position before bending into position B. This prevents the twisting motion

of moving directly from A to B that could prove harmful to the unit. For best response,

always position the fiber optic Light Pipe by moving in the same direction as gravity. If

the fiber optic bundle needs to be raised, raise it above the desired position and then

lower to the desired position.

Position A

Neutral

Position

Position B

SPECIAL NOTE: Upon manufacture, the Light Pipe is tested to assure maintenance

of position and absence of noise. Over a period of time it is normal for the Light Pipe to

soften and become less obedient. Abnormal softening or occurrence of noise should be

reported to Welch Allyn.

WARNING:

When pulling out the Light Pipe, push down on the light box to avoid

lifting it off of the mounting plate and possibly dropping it.

NEONATE TRANSILLUMINATOR

O. 48210

N

Use in place of Model 48200 for neonatal transillumination.

The neonate transilluminator is useful for transilluminating neonates as a means to help

diagnose pneumothorax, locate blood vessels, etc.

This transilluminator includes filters that prevent skin

temperature rise in excess of 39°F (4°C) when

in contact for five minutes or longer.

4

Page 5

NEONATE TRANSILLUMINATOR

AUTION:

C

Use only Welch Allyn Transilluminator No. 48210 for neonatal transillumination.

SET UP AND OPERATION

Refer to Set Up page for installation steps.

LAMP REPLACEMENT

ARNING:

W

Lamps operate at a high temperature and under pressure may shatter. Do not attempt

to replace lamp while hot. Wait until lamp is cool.

1. Turn power switch to “Off” position, unplug cord from outlet and from Light box.

2. Release interlock by sliding interlock arm to left. Pull lamp holder until lamp is fully

exposed. (Lamp holder will not slide down if Interlock is not released)

Diagram #1.

Diagram #1

Interlock Arm

3. Push release lever down; Diagram #2. Grasp expired lamp by its base and remove

from lamp holder.

4. IMPORTANT: Reposition release lever up to original position prior to installing new

lamp. Replace only with a Welch Allyn Lamp No. 04200.

5. Visually inspect replacement lamp reflector and bulb, and remove any grease or

fingerprints with a clean cloth moistened with alcohol, if required.

6. Slide new lamp into lamp holder socket until it “snaps” into place. Make sure

lamp is securely seated to assure maximum light output.

7. Slide lamp holder back into light box. Reengage interlock by moving arm to

the right.

Diagram #2

WARNING:

When sliding the lamp holder back into the light box, hold the light box down to avoid

pushing it off of the mounting plate and possibly dropping it.

8. Plug line cord back into unit, and into wall outlet.

5

Page 6

CLEANING

L

ENSES

• Remove the focusing sleeve from the fiber optic bundle by unthreading counterclockwise.

• Use a cotton swab soaked in warm water and mild detergent to clean both the

distal end of the fiber optics and the proximal side of the small lens. (See diagram

for locations.)

• Reassemble focusing sleeve to Light Pipe.

• The window may also be cleaned with warm water and mild detergent.

LIGHT PIPE

• To maintain unit cleanliness, use disposable Sheath (No. 52640).

• May be cleaned with a mild detergent and water solution.

Light Pipe

Distal End

Of Fiber Optics

Cotton Swab

Small Lens

Focusing

Sleeve

WARNING:

Do not clean lens or window with alcohol.

LIGHT BOX

Do not Sterilize.

Do not Immerse in Cleaning Solutions.

1. Unplug the unit from the wall outlet prior to cleaning.

2. Insert the red plastic plug into the Light Pipe socket

prior to cleaning. This will prevent the cleaning solution

from getting into the filter inside the unit.

3. Wipe the surfaces of the unit with a cloth dampened in

a mild solution of detergent and water. Wipe dry with a

clean, dry cloth.

4. The power cord may be wiped clean using the same detergent solution as the

box. Care must be taken not to get the plug prongs wet. Wipe dry with a clean,

dry cloth.

5. Do not plug the unit back into the wall outlet until it is thoroughly dry.

6

Page 7

MAINTENANCE

ENERAL

G

Periodic electric inspections should be made by qualified personnel.

LEAKAGE CURRENT TEST

The leakage current measured from any exposed

metal to ground with input voltage of 120v, 60 Hz

(or 240v, 50 Hz) and the ground wires securely connected shall not exceed .0475v max. or 50 ma.

GROUND CONTINUITY

The resistance measured from the ground pin of the

plug to the exposed metal on unit should be 1.6v max.

Unit

10.2

10000

15 mf d

V

High Impedance

VTVM

REPAIR

For repair by qualified personnel, contact your local authorized Welch Allyn distributor,

or contact Welch Allyn directly at (315) 685-4560.

SPECIFICATIONS

Model No. 48600

Model No. 48625

2

Power Cord—3 x 10 mm

Model Input Output Slowblo 250V

48600 120 VAC, 60 Hz, 0.35A 12 VAC, 3.0A 500 MA

48620 100 VAC, 50/60 Hz, 0.42A 12 VAC, 3.0A 630 MA

48622 220 VAC, 50 Hz, 0.19A 12 VAC, 3.0A 200 MA

48624 240 VAC, 50 Hz, 0.18A 12 VAC, 3.0A 200 MA

48626 240 VAC, 50 Hz, 0.18A 12 VAC, 3.0A 200 MA

Supplied with 4 foot (122 cm) Fiber Optic Light Pipe.

Weight—Approximately 5.5 pounds (2.5 KGms) without mounting plate and

Light Pipe.

Dimensions:

H: 7.25 inches (18.42 cm)

W: 7.625 inches (19.37 cm)

D: 3.75 inches (9.53 cm)

Leakage Current: Less than

10 microamps from any metal

part when correct ground is

used; less than 100 microamps

from any metal part with

ground disconnected.

The CE mark on this product indicates it has been tested to and conforms with the

provisions noted within the 89/336/EEC electromagnetic compatibility directive.

, #18 AWG, 3 wire grounded cord set, 8 feet (3 meters) long.

Fuse: 2x

Circuit Diagram

Fuse

Fuse

Stepdown

Transformer

Chassis

(Back Plate)

On-Off

Switch

IEC 601-1

TYPE B, CLASS I

CONTINUOUS OPERATION

7

Page 8

WARRANTY

L

IGHT BOX

The Light Box is guaranteed by Welch Allyn against all manufacturing defects.

Welch Allyn will repair or replace, free of charge, any parts of its own manufacture

proven to be defective through causes other than misuse, neglect, damage in

shipment or normal wear.

LIGHT PIPE

The Welch Allyn Fiber Optic Light Pipe is guaranteed not to drift once positioned if

mounted vertically according to the enclosed instructions. This warranty is for a

two-year period from original date of purchase provided the Light Pipe has not

been tampered with or abused. Any Welch Allyn Fiber Optic Light Pipe which proves

to drift once positioned, will be repaired or replaced without charge upon receipt of

the unit, prepaid.

Welch Allyn, Inc.

Medical Division

4341 State Street Road

P.O. Box 220

Skaneateles Falls, NY 13153-0220

U.S.A.

Telephone: (315) 685-4560

Fax: (315) 685-3361

Printed in U.S.A. Part No. 488430-2

Loading...

Loading...