Page 1

2.6 INITIAL SETUP

Place the TM 262TM Auto TympTM on a stable counter or table where it

will subsequently be used, and near a properly grounded wall outlet.

Attach accessories to their appropriately-labled connectors on the rear

panel of the TM 262 (see Figure 2-9).

Locate the POWER switch on the rear panel of the TM 262 and move

the switch to the ON ( ) position. Note that the lamp (F1) on the front

panel is illuminated, indicating the TM 262 is receiving power. The

TM 262 symbol will then appear on the display along with a listing of

the revision number for the Tymp/Reflex and Audiometry (if purchased)

software. Next, the display will default to the Tymp/Reflex mode and

the probe’s green lamp will begin to blink, indicating that the TM 262 is

ready to begin a test. If both the green and yellow lamps are illuminated at the same time, either the probe is occluded or the tymp/

reflex software did not properly initialize. Simply move the power

switch to the OFF ( ) position, inspect the probe tip for any signs of

an occlusion, and reposition the power switch to ON ( ). If both green

and yellow lamps are still illuminated and you are certain that the

probe is not occluded, contact the Welch Allyn Technical Service

Department (see page 55). In the meantime, it is still possible to

select the Audiometry mode (if purchased).

Allow the instrument to warm-up for about five minutes before conducting a test. This allows the electronic circuits to stabilize prior to use.

If the storage temperature is lower than the room temperature, allow

some additional time for the instrument to reach room temperature.

Warning

The TM 262 is designed to be used with a hospital grade outlet. Injury to personnel or damage to equipment can result when a three-prong to two-prong

adapter is connected between the TM 262 power plug and an AC outlet or

extension cord. Additionally, those TM 262 Auto Tymps that are equipped with

power transformers use a specific transformer (8000-0260, 8000-0261 or 8000-

0262) which should not be interchanged with any other transformer or supply.

The TM 262 is a specifically-calibrated device and the periodic service and

adjustments which the instrument may require should be done only by an

authorized Welch Allyn service technician.

11

Page 2

2.6.1 Loading The Paper

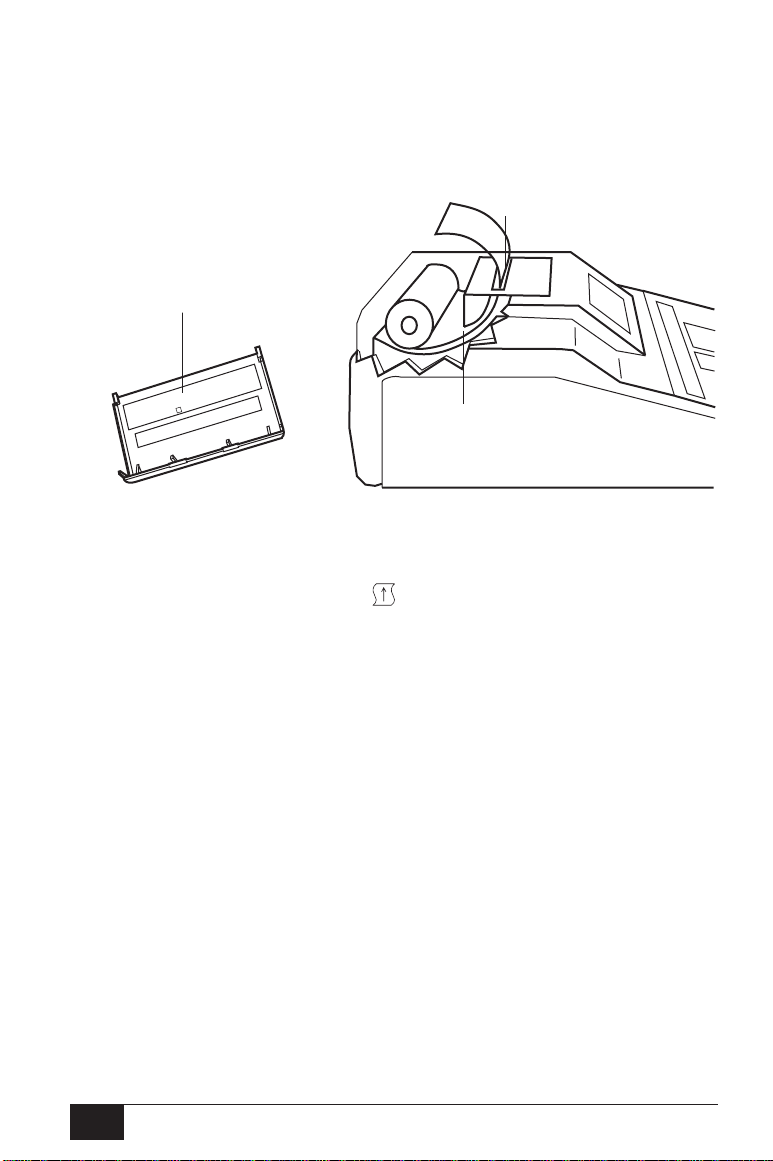

Remove the printer cover (see Fig. 2-3 for location) by placing your fingers along the back edge of the printer and pulling upward on the cover.

Cut the printer paper so that the leading edge of paper is straight across.

Place the roll of paper inside the paper well so that the paper will unroll

from the lower surface. See paper loading label for additional help

(Figure 2-11).

Paper exit

Paper loading

label

PAPER LOADING

INSERT THE LEADING EDGE SQUARELY INTO

THE PAPER ENTRANCE WHILE PRESSING THE

PAPER ADVANCE ON THE FRONT PANEL

FIGURE 2-11: Paper Loading

Position the leading edge of the paper roll into the paper entrance while

pressing the PAPER ADVANCE button. The paper will begin to appear out of the printer mechanism. Continue to advance the paper so

that a section of paper is long enough to pass through the printer cover

once it is repositioned over the printer.

Paper

entrance

2.6.2 Paper Storage

The TM 262TM Auto TympTM utilizes a thermal printer, which requires a

heat-sensitive paper to create an image. For maximum paper life, any

spare rolls of paper should be stored as follows:

1) Store in the dark, i.e., in a drawer or cabinet

2) Do not store above 77°F (25°C)

3) Store at less than 65% relative humidity

The above recommendations are for the maximum paper life (greater

than five years). Storing your TM 262 thermal paper at high temperatures

or high humidity levels will only shorten the total paper life.

12

Page 3

2.7 PRETEST TYMPANOMETRY CHECKS

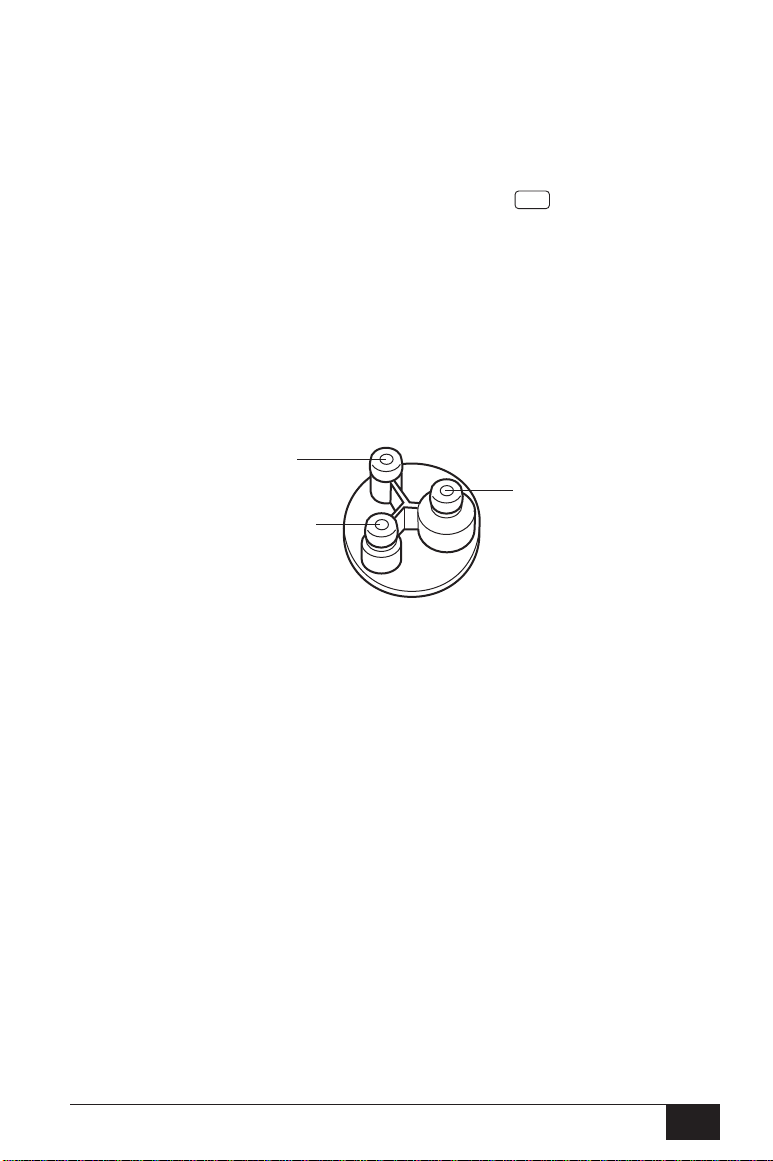

For your convenience, a test cavity is provided with your TM 262

Auto TympTM. This test cavity enables you to quickly verify the proper

calibration of your unit. Welch Allyn, Inc. strongly recommends that

you make this quick check a part of your daily routine.

2.7.1 Calibration

To initiate the quick check, select the Tymp only mode and insert

the probe (without a tip on it) into the 0.5 cm3 opening on the test

cavity. See Figure 2-12.

NOTE

Since the TM 262 is designed to start automatically, it is important that the

probe is inserted as quickly and as smoothly as possible. During the calibration check, the probe must be held carefully and without movement. Do not

place the probe on the same counter as the instrument or any moving object

during this check, as mechanical noise will be picked up by the probe and

interfere with the calibration check.

3

0.5 cm

3

2.0 cm

TYMP

5.0 cm

3

TM

FIGURE 2-12: Test Cavity

The calibration check will start automatically if the probe has been inserted into the cavity properly. This is confirmed by the green lamp

changing from blinking to a steady condition. If the orange lamp is illuminated, the probe is not properly positioned within the cavity so that

a large pressure leak exists. If the yellow lamp is illuminated, the probe

tip has been occluded. In either case, remove the probe and wait for

the blinking green lamp. Insert the probe once again. Clean the probe

tip if necessary (see Section 3.2).

13

Page 4

When the test sequence is completed, the green lamp on the probe is

no longer illuminated. Remove the probe from the test cavity and note

that the green lamp is blinking once again. The display will indicate a

flat line on the tympanogram along with the value of the test cavity next

to the letters ECV (ear canal volume), i.e., 0.5. The letters NP will appear next to the labels cm3 and daPa and three dashed lines will appear next to the letters GR (gradient). Since the test cavity is a hardwalled cavity, the tympanogram should be a flat line, indicating that

there is no mobility in the system. The TM 262TM Auto TympTM places the

letters NP next to the cm3 and daPa headers to indicate that there is no

peak compliance and, therefore, no peak pressure can be determined

during the quick check. Also, since there is no compliance peak detected, it is not possible to calculate a gradient. Therefore, the TM 262

displays the dashed lines when a gradient calculation isn’t possible.

Using the same sequence, place the probe in the test-cavity opening labelled 2.0 cm3. Note that the display looks the same as with the 0.5 cm

measurement, except for the value placed next to the letters ECV (2.0).

If you wish, the same sequence can be followed with the 5.0 cm3 opening on the test cavity. To keep a record of this test-cavity-calibration

check, simply press the PRINT ALL button on the front panel of

the TM 262.

2.7.2 Altitude Adjustment

Since sound pressure will vary with altitude and barometric pressure,

some variation from the 0.5, 2.0 and 5.0 cm3 readings may be observed.

Your TM 262 is carefully calibrated at our factory, which is at approximately 250 feet above sea level. If you are located at an elevation of

1000 feet or higher, your instrument may need to be recalibrated to

account for your elevation. It is not necessary to recalibrate for barometric pressure changes on a daily basis. Just keep in mind that a

change in barometric pressure (i.e., from low to high or high to low)

will slightly affect the test-cavity readings.

The altitude calibration adjustment allows for “corrections” to the Ear

Canal Volume (ECV) measurement and test cavity volume measurement for variations due to altitude. Because the TM 262 is a pressuresensitive device which makes measurements relative to ambient air

pressure, changes in air pressure due to weather or altitude will affect

the Ear Canal Volume (ECV) read-out of the instrument. The slight pressure change resulting from changing weather conditions will usually

yield volume read-outs within ±0.1 cm3 of the expected cavity value;

however, pressure changes due to altitude can shift these cavity values

by as much as 30%. These changes in pressure do not affect the

accuracy of the compliance measurement system in any way.

But, many instrument operators prefer that their equipment give ECV

values as they would appear at sea level. The altitude calibration mode

allows the operator to adjust his/her Auto Tymp without the services of

a qualified Welch Allyn Service Technician.

3

14

Page 5

TABLE 2-2: Altitude Correction

Altitude Correction

Altitude (ft.) Altitude Table (cm3)

0 to 1,500 2.0

2,000 to 3,500 2.1 ± 0.1

4,000 to 6,000 2.2 ± 0.1

6,500 to 7,500 2.3 ± 0.1

8,000 to 9,000 2.4 ± 0.1

9,500 to 10,000 2.5 ± 0.1

The altitude calibration mode can only be entered when the TM 262 is

powered up from its “off” state while the PROGRAM mode button,

is depressed. Hold the PROGRAM button for approximately

PROG

PROG

five seconds.

STEP 1

When entering the altitude mode the display will read as follows:

Altitude Mode

ECV 2.0

3

9.99

cm

Standard

(E71) is displayed in the bottom right corner of the display until the probe is

in the 2.0 cm

STEP 2

Place the probe into the 2.0 cm

check cm

STEP 3

If the measured volume is not within the published table value ±0.1cc, then

the operator should exit the altitude mode by pressing the PROGRAM

button and contact field service.

Providing the measured volume agrees with the published table ±0.1cc,

the operator may proceed with the altitude adjustment.

STEP 4

With the probe still in the 2.0 cm

enter the custom calibration mode. Custom will appear on the fourth line

of the display.

3

cavity.

3

3

value against the altitude correction table for accuracy.

cavity provided with the instrument and

3

cavity, select the PAGE button to

PAGE

PROG

STEP 5

The value now displayed in the cm

3

display area is the volume measured

and adjusted to the current altitude. If the value displayed is 2.0 cc, then

the volume is adjusted to the current site. If the value is not 2.0 cc ±0.1,

then press the SAVE button to customize the volume measurement

M+

to the current altitude. The measured volume should now read 2.0 cc.

STEP 6

To exit the altitude mode, press the PROGRAM button to return to

PROG

normal mode.

15

Page 6

2.8 PRETEST AUDIOMETRIC CHECKS

(Models with Audiometer Only)

2.8.1 Noise Recovery Period

Exposure to high levels of sound (e.g., unmuffled lawn mowers, loud

music, gunfire) tends to create a Temporary Threshold Shift (TTS) which

diminishes with time after exposure. Any subject tested soon after such

exposure may exhibit a hearing loss that does not reflect his/her normal

hearing threshold. This test procedure, therefore, generally prescribes a

16 hour interval between the last exposure to high-level sounds and the

administration of any hearing test.

2.8.2 Elimination of Ambient Noise

Excessive noise in the test environment during audiometric testing,

such as that produced by conversation, computers and public address

systems reduces test validity because it tends to mask the test signals,

particularly at the lower frequencies where earphone cushions provide

less effective attenuation. An acoustically-treated room may be

required if ambient noise reaches objectionable levels, i.e., sufficient

to cause apparent hearing loss at the low frequencies. Also, earphone

sound enclosures are available from Welch Allyn as an optional

accessory. If the person being tested is in the same room as the

audiometer, it is recommended that he/she be seated about three

feet (one meter) away from the TM 262TM Auto TympTM.

Maximum permissible noise levels are specified by the American National Standards Institute—Criteria for Permissible Background Noise

during Audiometric Testing, ears covered with earphones (S3.1-1991

revised). Table 2-3 shows the maximum background levels that can be

present inside the room while a valid hearing test is being conducted.

For more comprehensive information about hearing testing and hearing

conservation, refer to the Bibliography.

TABLE 2-3: Permissible Noise Levels

Test Tone

Frequency (Hz) 125 250 500 750 1000 1500 2000 3000 4000 6000 8000

Test Room

Ears covered 34.0 22.5 19.5 21.5 26.5 26.5 28.0 33.5 34.5 38.0 43.5

maximum

permissible octave

band levels

Ears covered

maximum

permissible one-third

octave band levels

29.0 17.5 14.5 16.5 21.5 21.5 23.0 28.5 29.5 33.0 38.5

16

Page 7

2.9 BIOLOGICAL CHECK

To determine that your TM 262 is functioning properly, perform a daily

check on a normal ear—your own if possible. This allows you to listen

for the probe tone and the stimulus tone (during reflex) and determine if

the air-pressure system is working properly. Keep a copy of your chart

for a day-to-day reference in checking your TM 262.

If you purchased the TM 262TM Auto TympTM with audiometry, select the

AUDIOMETRY button located in the center section of the front

panel. Note that the display changes to an audiogram format. The Hz

and Hz buttons allow you to select each frequency and the dB

HL knob allows you to alter the intensity of each frequency. Position the

test headset on your head so that each earphone is covering the appropriate ear (i.e., red is right and blue is left). Select the right earphone

by pressing the front panel button labelled R and check for the following while depressing the present bar:

• Depressing the Hz button causes the frequency to change to

a lower frequency, depressing the Hz button causes the frequency to change to a higher frequency.

• Each frequency or tone is pure, i.e., there is no distortion or

crackling sound present.

• Rotating the dB HL knob in a clockwise direction increases in

intensity of the tone.

• Rotating the dB HL knob in a counter-clockwise direction decreases the intensity of the tone.

AUD

17

Page 8

Specifications

STANDARDS:

IEC 601-1 Medical Electrical Equipment Requirements for Safety

CSA C22.2 No. 601-1-M90 Electromedical Equipment,

Warnock Hersey Listed

ANSI S3.39-1987 Aural Acoustic Impedance Admittance (Type 3)

IEC 1027-1991 Aural Acoustic Impedance/Admittance (Type 3)

ANSI S3.6-1989 Audiometers (Type 4)

IEC 645-1 Pure Tone Audiometers (Type 4)

TYMPANOMETRY/REFLEX MODES:

Probe Tone: 226 Hz, ± 3%

Sound Pressure Level: 85.5 dB SPL, ± 2.0 dB,

measured in a 2.0 cm3 coupler

Harmonic Distortion: <5%

Admittance (Compliance) Range: 0 to 1.5 cm

0 to 3.0 cm

NOTE:

1. The range is automatically selected based upon the amplitude

of the compensated (tymp only) tympanogram.

2. The maximum uncompensated (ECV + tympanogram peak)

admittance (compliance) range is 0 to 5.0 cm3.

3. ECV/cavity limits for initiating pressurization is 0.2 to 6.0 cm3.

Compliance Accuracy: ± 0.1 cm3 or ± 5%, whichever is greater

3

3

PNEUMATIC SYSTEM

Pressure Range: +200 to –400 daPa

NOTE:

1. 1 daPa = 1.02 mm H20

2. Pressure sweeps to at least –100 daPa. To save test time,

pressure sweep stops once tympanogram returns to baseline

after –100 daPa.

3. Full pressure sweep for 6 cm3 from sea level to 7000 ft.

altitude with no leak.

Pressure Accuracy: ±10 daPa or ±15%, whichever is greater

56

Page 9

Rate of Sweep: 600 daPa/sec except near tympanogram peak

where sweep rate slows to 200 daPa/sec to provide better

definition of peak compliance.

Direction of Sweep: Positive to negative

Tympanometric Test Time: approximately one second

NOTE:

High compliance tympanograms will take somewhat longer

Gradient: Tympanogram pressure width at 50% of peak

compliance.

ACOUSTIC REFLEX STIMULI:

Frequencies: 500, 1000, 2000, and 4000 Hz

Accuracy: ±3%

Total Harmonic Distortion: <5%

Rise/Fall Time: 5 to 10 msec

Output Levels:

IPSI: 500 and 4000 Hz:80, 90, 100 dB HL

1000 and 2000 Hz: 85, 95, 105 dB HL

NOTE:

1. Ipsi stimuli are time multiplexed with probe tone

(106 msec ON, 53 msec OFF).

2. Stimuli are presented at lowest level first. If there is no

response, the intensity is increased by 10 dB until a

response is detected or the maximum dB HL is reached.

Pressure: Automatically set to pressure at peak compliance with

an offset of –20 daPa.

Reflex Determination: Compliance change of 0.05 cm3 or greater.

Reflex Test Time: 1 to 12 seconds depending upon the number of ipsi

test frequencies selected (four maximum) and intensity required.

Probe LED Indicators:

Steady yellow: occlusion

Blinking green: ready to start testing

Steady green: test in progress

Steady orange: leak

57

Page 10

AUDIOMETRY MODE (Model No. 26230, No. 26230-RS,

No. 26235 and No. 26235-RS only— marked “Version 4”)

Frequencies: 125, 250, 500, 750, 1000, 1500, 2000, 3000, 4000,

6000, 8000 Hz

Accuracy: ± 3%

Total Harmonic Distortion: < 3% (125 to 3000 Hz measured acous-

tically at maximum dB HL; 4000 & 6000 Hz measured electrically)

Intensity Levels: 125 Hz: –10 to 50 dB HL

500 to 6000 Hz: –10 to 90 dB HL

250 and 8000 Hz: –10 to 70 dB HL

NOTE:

An additional +10 dB is available per frequency via the

+10 dB button.

Accuracy: 125 to 4000 Hz ±3 dB

6000 and 8000 Hz ±5 dB

Step Size: 5 dB

Signal-to-Noise Ratio: > 70 dB in 1/3 octave;

less than –10 dB HL for levels less than 60 dB HL

Rise/Fall Time: 20 to 50 msec

Tone Format (tone is normally off until present bar is depressed):

Continuous: steady when present bar is depressed

Pulsed: 2.5/sec (i.e., 200 msec ON, 200 msec OFF)

FM (frequency modulated): 5 Hz, ±5%

TRANSDUCERS

IPSI: Welch Allyn design

Audiometric Headset: Pair TDH-39 earphones with MX41AR

cushions (60 ohms impedance)—Models No. 26230,

No. 26230-RS, No. 26235 and No. 26235-RS only

(marked “Version 4”)

PRINTER

Paper Roll Length: approximately 80 feet (960")

Tests/Roll: Tymp and Reflex = 420 tests or 210 people

Tymp and Reflex plus one audiogram =

230 tests or 115 people

Speed: approximately 1.5 minutes to print three screens

(including audiogram).

58

Page 11

POWER

Line Voltage: 120 V (±10%) or 220 V (±10%) or 240 V (±10%)

NOTE:

Wall mount power supply or internal power supply depending

upon country.

Frequency Range: 50 to 60 Hz (±5%)

Line Voltage Current: 0.2 amps at 120 V or 0.1 amps at 240 V AC

Power Consumption: 15 watts maximum while printing.

Low voltage input for wall mount power supplies 10 to 11 VDC

970 mA.

ENVIRONMENTAL

Temperature:

Operating: 60° F to 105° F Storage: –40° F to 140° F

15° C to 40° C –40° C to 60° C

NOTE:

Warm-up time is required if storage temperature is different

from room temperature.

Humidity: 5% to 90%

MECHANICAL

Dimensions: 13.15" W x 14.5" D x 4.3" H

33.66 cm W x 35.56 cm D x 9.53 cm H

Weight: 10 lbs (4.5 kg) net

14 lbs (6.4 kg) shipping

SUPPLIED ACCESSORIES

Instruction Manual #1738-0101

TDH-39 Headset

(Models #26230/#26235 Only) #23223

Test Cavity #26241

Eartips (6 sizes, 2 each) #26100

Paper — 3 rolls thermal 4"

(10.16 cm wide)

CATALOG

NUMBERS

59

Page 12

CALIBRATION

35

Page 13

EQUIPMENT REQUIRED FOR CALIBRATION

TYPE 1 SOUND LEVEL METER

ARTIFICIAL EAR

2 cc COUPLER (GSI #1700-2005 OR B&K #DB0138)

9A

(6 cc) COUPLER OR B&K ARTIFICIAL EAR (B&K #4153)

MANOMETER

VOLTMETER (RMS)

FREQUENCY COUNTER

1700-l 030 TEST CAVITY

SMALL STANDARD (SLOTTED) SCREWDRIVER

SMALL PHILLIPS (CROSS) SCREWDRIVER

36

Page 14

CALIBRATION PROCEDURE

CONFIG.

Confiq.

mode of operation and once programmed should never change. If a new

microprocessor is installed in location XU7 or

programmed. To program the

JP1

and JP3 then power up the unit. Almost immediately after power up the unit will

display

previously installed jumpers. The

DEFAULT DATA LOADING: Durina routine calibration it is not

Default Data.

set of calibration values into EEPROM. Also, if a new microprocessor has been

installed the Default Data loads critical power-up information that the processor requires

for operation into EEPROM. When a new microprocessor or

installed Default Data should be loaded. Load Default Data by setting Dip Switch

positions 6, 7, and 8 to the “ON” position. Set the

then power up the unit. At power-up the display should indicate the unit model and

version number (GSI 38 Version X), the

(Tymp/Reflex

XXX), and the Default Parameters which are currently being loaded into EEPROM

(Loading Audiometer Defautts, Loading Programmed Defautts, or Loading

Defaults). When the Default Data Loading sequence is complete the display will update

to the Main Calibration Mode Menu. At this point Dip Switches 6, 7, and 8 should be

returned to their normally OFF position.

REGISTER: Durinq routine Calibration it is not

Register.

Config.

Programming the

Register Programmed. At this point power down and remove the

Defautt Data Loading

Rev XXX), the Audiometer Software Revision Number (Audiometer Rev

Config.

Config.

Config.

allows

Register establishes the microprocessors

XU34

Register install temporary jumpers (shorts) on

Register is now programmed.

the

technician

Cal/Norm

Tymp/Reflex

necessary

its

Config.

to quickly store an

Switch to the Cal Mode,

Software Revision Number

to

program

Register must be

necessary

Auto/Tymp

to

averaged

Board is

Tymp/Reflex

the

load

The technician may also load an individual set of Default Data by first setting the

desired Dip Switch to the ON position then setting the Cal/Norm Switch to the Cal

Mode position.Dip Switch assignments are as follows:

Dip Switch

6

7

8

Function

Tymp/Reflex

Audiometer Defaults

Programmed Defaults

Defaults

37

Location Loaded

Tymp EEPROM

Audio EEPROM

Audio EEPROM

Page 15

‘..

NTERING

THE CALIBRATION MODE DIRECTLY (ROUTINE CALIBRATION)

1)

2)

3)

Verify that Dip Switches 6, 7, and 8 are in the OFF position.

Power up the unit.

Slide the Cal/Normal Switch to the Cal Mode position. The display should

appear as follows:

7

CALIBRATION MODES

l

ATTEN

XDUCER

MAX CAL

STIM

CAL

PRINT HEAD CAL

CUSTOM RTL CAL

PROBE

TONE/MIC

CAL

COMPLIANCE CAL

PRESSURE CAL

38

Page 16

AUDIOMETER CALIBRATION

ATTENUATOR MAXIMUM OUTPUT CALIBRATION: During routine calibration it

should not be necessary to calibrate the Attenuator Maximum Output. However, if

Audiometer Default Data has been loaded then the Attenuator Maximum Output

must be calibrated.

the

1)

2)

3)

4)

5)

Connect the right phone output unloaded

Use the

ATTEN

Press the Present Bar

(The Tone Indicator

Use the

the dB HL knob until the output level for currently display frequency is within the

minimum/maximum values listed in the following table. When the desired output

level has been reached store the value by pressing the pi Key. Repeat

all frequencies.

!=I

MAX CAL

p/

Hz

Hz

Frequencv

125

250

500

750

1000

1500

2000

3000

4000

6000

8000

[c]

Keys to position the cursor on the 38 display at the

position.

Key

to enter the

0

to lock on the tone.

*

F)

should now be present on the display.

to select the desired frequency for calibration.

(Hz)

.

to

an RMS Meter.

ATTEN

MAX CAL Mode.

Minimum - Maximum

2.05-2.30

2.05-2.30

2.33

-

2.5

1.69-1.9

2.28-2.5 vrms

2.28 -

2.55 -

2.28 -

2.55 -

2.28-2.50

2.28 -

2.5

2.70

2.50 vrms

2.70 vrms

2.50 vrms

vrms

vrms

vrms

vrms

vrms

vrrns

vrms

Adjust

for

After all frequencies have been calibrated press the

Calibration Mode Menu.

39

v]

Key to the Main

Page 17

AUDIOMETER

Use

1)

the a IHz[m IKeys

STIM CAL.

SPL OUTPUT LEVEL CALIBRATION

to position

the cursor on the

38

display at XDUCER

2)

Press

the

I=]

Key to

enter the XDUCER

STIM

CAL

MODE.

The display should now indicate:

XDUCER

STIM

CAL

40.0

125

dB

Hz

NOTE: Tone Bar is OFF

or Inactive

R

40.0

125 Hz

R

dB

Indicates the Current Hearing Level (HL) selected.

Indicates the Current Frequency (Hz) selected.

Indicates the Current Transducer selected.

Indicates a Steady Tone Presentation

The Tone Bar is active in this mode and serves a dual function. When the Tone Bar

as

is OFF or inactive the current hearing level is displayed

When the Tone Bar is pressed ON or active the stim on indicator

the display and the 40.0

dB

(HL) indicator will update

to

shown above.

will appear on

*

the ANSI Standard Reference

Threshold Level (RTL) measured in Sound Pressure Level (SPL) for the selected

frequency and hearing level.

Example:

40.0 dB (HL) at 125 Hz (Freq) will update to 85.0 dB SPL

when the Tone Bar is depressed.

Given:

Therefore:

The ANSI Standard (RTL) correction value for 125 Hz at 0 HL is

dB

equal to 45.0

At 40 dB HL which

Hz

125

will equal 85.0 dB SPL.

SPL.

is

For 125 Hz

ANSI Standard RTL for 0 dB HL

(+)40

dB HL

dB

40

HL

.

40 dB SPL higher that 0 dB HL the output for

=

=

=

40

45.0 dB SPL

(+)40.0 dB

85.0 dB SPL

SPL

Page 18

For 8

KHz

When calibrating using a Sound Level Meter (SLM) it is important to add or subtract the

appropriate microphone correction.

manufacturer or calibration facility should supply the microphone’s frequency response

curve.

response by using a piston phone or similar standard device. Below is an example of

a microphone frequency response curve.

MICROPHONE

CALIBRATION

ANSI Standard RTL for 0. dB HL

(+)60 dB

dB

60.

HL

HL

=

=

=

13.0 dB SPL

(+)

60.0 dB SPL

73.0 dB SPL

When the microphones are calibrated the

The microphone is then calibrated to the SLM which has a flat frequency

l

CHART

5

dB

+1

0

-1

-5

Provo,

Utah

-10

. .._,..., .q , , ,

I

-15

20 Hz 50 1DO

.,-_i..,

! I. ._ ! i, _

.I 11 1

._,‘_.,.., 1,. __, _,._ ,

200 ' 500

1K

2K

5K

10K

--1-\I--s’

20K

50K

The curve shows that the microphone response is flat between 20 Hz and 1.5 KHz,

KHz

high between 2

as

an example when a standard force is applied to the surface of this microphone its

dB

output is 1

1 dB to our expected value. Our formula for determining the proper calibration

add

high. Therefore, when calibrating 4

and 6

KHz,

and low at frequencies 8 KHz or greater. Using 4 KHz

KHz

using this microphone we must

level for 4 KHz is as follows:

100k'

200K

. 41

Page 19

4

KHz

ANSI Standard RTL for

Reference HL for Calibration

(+)80. dB

(+) or (-) Microphone Correction

0. dB HL

NA.

80.

dB

=

HL

=

HL

=

(+)80.0 dB

(+)

9.5 dB SPL

SPL

1.0 dB SPL

90.5 dB SPL

The following table contains the ANSI Standard Reference Threshold Levels

RTL's

at

0 HL for each frequency when using TDH-39P earphones.

Frequency (Hz)

ANSI Standardd

Measured

in dB SPL

RTL

125

45.0 25.5

Standard Reference Threshold Levels re:

250

11.5

500 750 1000 1500

7.5

20pPa

7.0 6.5

for

Telephonics

2000 3000

9.0

10.0

TDH-39P earphones

4000

0.5

as measured on the National Bureau of Standards 9-A coupler. Reference ANSI S3.6

6000 8000

15.5 13.0

-

1989, ISO 389 - 1975 Standards.

Grason-Stadler has made an effort to minimize calibration time by defaulting the

Reference HL Levels for Calibration to maintain an expected SPL Calibration Level of

between 85 and 95 dB SPL. The Default HL Levels are as follows:

Frequency

Default HL

(Hz)

125 250 500 750 1000 1500

40

60 80 80 80 80

2000 3000

80 80 80 80 60

4000

6000

8000

Because the 38 automatically adds the ANSI RTL and reference HL values on the

display (when the Tone Bar, is active) the technician needs only to add or subtract

the appropriate microphone correction to the displayed value when calibrating.

3)

4)

5)

Connect the right ear phone to the Sound Level Meter Artificial Ear.

Press (TONE BAR\ the display will update from the selected hearing level to

the ANSI Standard RTL value for calibration and the

appear).

indicator will

m+

Adjust the HL knob until the SPL Level measured on the SLM for the selected

frequency and transducer equals the value indicated on the 38 display (+ or

’

-

Microphone Correction).

6)

7)

Press

Repeat for all frequencies, right phone, left phone, ipsi and contra by

theIF

Key to store the data in memory.

selecting the appropriate key on the 38 front panel.

NOTE: Both left phone and right phone must be calibrated.

-

8)

When finished press the

Menu.

vl

Key to return to the Main Calibration Mode

Page 20

CUSTOM RTL CAL

This mode is used primarily if a customer wants to calibrate using transducers other

than TDH-39P earphones. This mode allows the technician to program different

RTL values to be displayed when calibrating using the XDUCER

Once programmed, the Custom RTL values will be displayed each time the

XDUCER

63.5

Audiometry Mode is selected to indicate to the customer that Custom RTL values

have been programmed. To return to the ANSI Standard Values and extinguish the

#

sign, the technician must load Audiometry Default Calibration Data.

1)

STIM

CAL MODE is entered. The range of allowable

dB

A # sign will appear next to the dB HL indicator on the display when

Use

theF]Hz]=]Keys

display.

to position the cursor at Custom RTL Cal on the

STIM

CAL MODE.

RTL's

is -5 dB to

2)

3)

4)

5)

6)

7)

NOTE:

PROBE

Press the

Press

Adjust the dB HL dial to achieve the desired RTL value.

Store the value into memory by pressing the m Key.

Repeat for all desired frequencies.

Press

Use

Mode

IFZF]

thewlHz[c]Keys

the

]w]

Adjusting the Custom RTL values has no effect on the earphone

output level. After storing the Custom

must calibrate to the appropriate levels using the XDUCER

CAL MODE.

TONE/MIC

theI=] HzF]Key

position.

CAL

Key to enter the Custom RTL Cal Mode.

to select the desired frequency.

Key to return to the Main Calibration Menu.

RTL's

to position the cursor at the Probe

the technician

Tone/Mic

STIM

Cal

2)

Press the ) PROG 1 Key to enter Probe Tone/Mic Cal Mode. The display will

update to the following “flashing” display.

PROBE

ECV

At this point place the probe in the 2 cc coupler on the Sound Level Meter.

TONE/MIC

SLM

CAL 1.1

43

Page 21

3)

Press the

m

Key and the display will stop flashing.

4)

5)

6)

Use the dB HL dial to adjust the Probe Tone Level to 85.5 dB SPL

dB).

At this point the Probe Tone

226 Hz

Press the

(+/-

6 Hz).

LM+f

Key to store the data in memory. The display will update to

Frequency

may be verified. It should equal

the following ‘Washing” display.

j:l’:,‘““““*“‘I

.

At this

Press the

point

place the probe in the 2 cc test cavity.

m

Key to start the microphone calibration process. The display

will update to the following steady state display.

**I

(+/-

0.9

After a few seconds the SAVED indicator will extinguish and the 1.2

will change to 1.3. When the cycle is complete the display

following “flashing” display.

7)

Press the

,

~

-

COMPLIANCE CAL

1)

Use the

F]

Mode position.

2)

Press the

[=I

update to the following “flashing” display.

Hz

will update to the

Key to return to the Main Calibration Mode Menu.

-

LqKeys

to position the cursor

Key to enter the Compliance

at the Compliance Cal

Cal Model The display will

indicator

44

Page 22

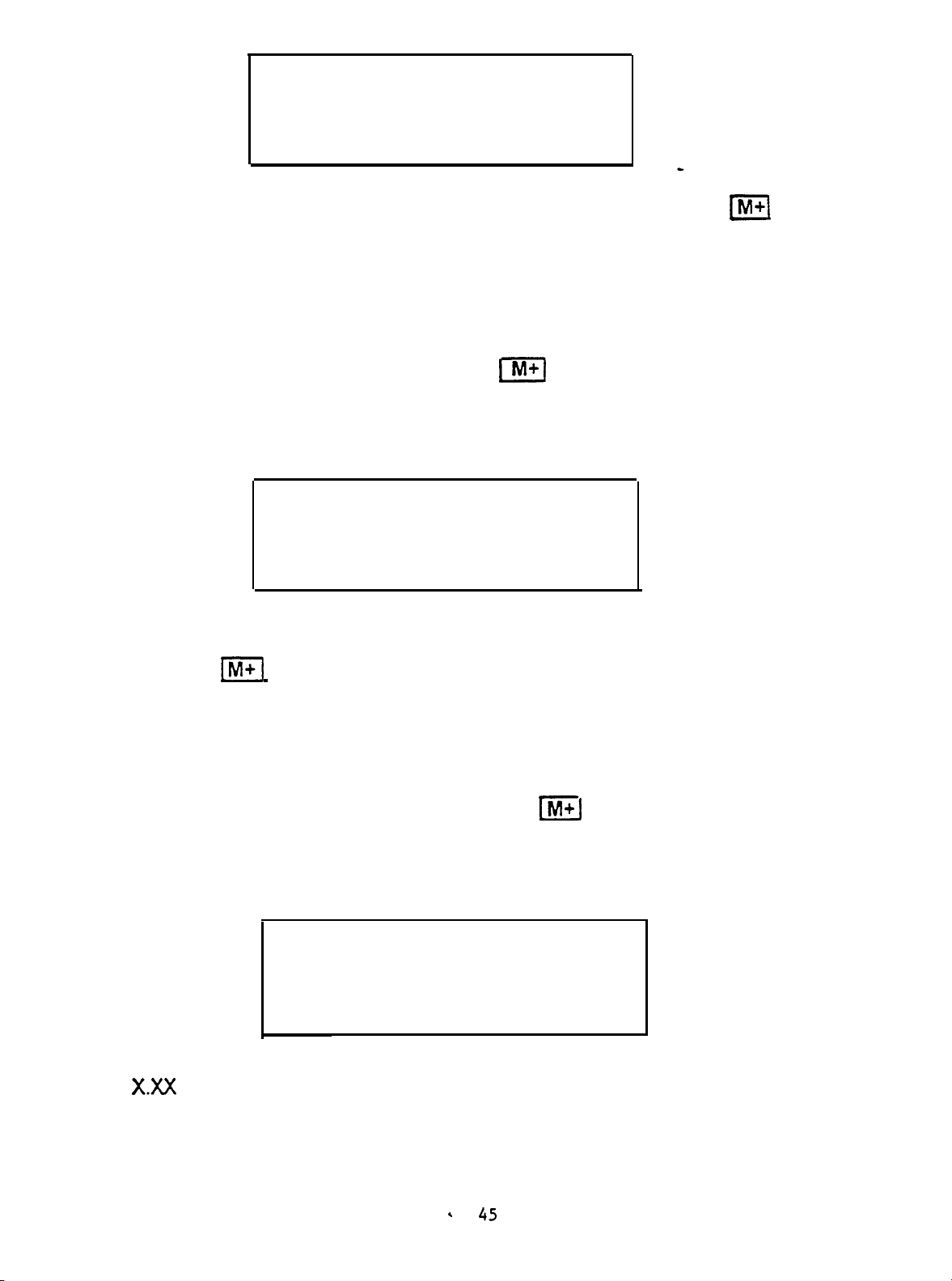

COMPLIANCE CAL 2.1

ECV 0.5

3

cm

3)

4)

Place the probe into the 0.5 cc calibration cavity then press the

[M+I

Key to

start the 0.5 cc calibration. The display will stop flashing and remain in steady

state to indicate that calibration is in progress.

NOTE: If the wrong cavity size is used the display will indicate E74 in the lower

right hand corner. After approximately 5 seconds the ERROR MESSAGE will

extinguish and the calibration process may be continued by placing the probe

into 0.5 cc cavity and then pressing the

[WI

Key.

When the 0.5 cc calibration is complete the display will update to the following

“flashing” display.

COMPLIANCE CAL 2.2

ECV 2.0

3

cm

At this point place the probe into the 2.0 cc test cavity.

Press the

PI

Key to start the 2.0 cc calibration. The display will stop flashing

and remain in steady state to indicate that calibration is in progress.

NOTE: If the wrong cavity size is used the display will indicate E74 in the lower

right hand corner.

After approximately 5 seconds the ERROR

MESSAGE

extinguish and the calibration process may be continued by placing the probe

into the 2.0 cc cavity and then pressing the

m]

Key.

When the 2.0 cc calibration process is complete the display will update to the

following steady state display.

COMPLIANCE CAL 2.3

ECV 2.0

cm3

X.XX

X.XX

is equal to the current volume measurement.

.

45

Page 23

The calibration of compliance measuring devices is affected by air density. As

the air gets thinner, the volume measurement in a

hardwall

cavity increases.

Therefore, as you go up in altitude, barometric pressure decreases making the

hardwall

cavity appear larger than it is.The GSI 38 allows the flexibility to

display the real altitude effect or to correct the ear canal measurements relative

to sea level.

A)

If the customer prefers to correct the ear canal volumes relative to sea

level then adjust

2.00 After adjusting to the desired level store the value by pressing

the

]m

compliance calibration process is complete.

B)

If the customer prefers uncorrected ear canal volumes (actual at altitude

measurements) then adjust the

value indicates the appropriate volume measurement for the customer site

elevation according to the following altitude table.

Altitude

(ft)

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

Barometric Pressure

(mm

thep]HzlF]

Keys until the cm3 XXX value equals

Key. The display will start “flashing” indicating that the

i-1

Hz

[Fj

Keys until the cm’ XXX

Expected Volume Reading

Hg)

759.97

746.51

733.04

719.84

706.63

693.93

681.23

668.78

656.34

644.40

632.46

620.78

609.09

598.00

588.00

578.00

568.00

555.00

544.00

533.00

522.00

*

at Altitude (cc)

2.00

2.01

2.03

2.05

2.07

2.09

2.11

2.13

2.15

2.17

2.20

2.22

2.25

2.27

2.30

2.34

2.37 2.4~0.1

2.40

2.44

2.49 2.520.1

2.54

Calibration Volume

at

Altitude

(cc)

2.0

2.020.1

2.020.1

2.020.1

2.120.1

2.120.1

2.120.1

2.120.1

2.2zo.q

2.220.1

2.220.1

2.220.1

2.220.1

2.3~O.q

2.3~0.1

2.320.1

2.4~0.1

2.4~0.1

2.520.1

5)

Press the

]M+j

Key to store the customer altitude volume measurement. The

display will start “flashing” indicating that the Compliance Calibration process is

complete.

Press the

m]

Key to return to the Main Calibration Mode Menu.

46

Page 24

PRESSURE CAL

1)

2)

3)

Use the

Press the

update to the following “flashing” display.

At this point make sure that the probe tip is in open air.

Press

Pressure Calibration is complete the display will update to the following “flashing”

display.

[~~Hz~~~

I-1

I

1

M+ 1 Key to start the Ambient Pressure Calibration.

Keys to position the

Key

to enter the Pressure

‘PRESSURE CAL

ECV OPEN

A/D

daPa

cursorr

at the Pressure Cal position.

Cal Mode. The display will

3.1

When the

Ambient

.

PRESSURE

ECV MANOMETER

A/D

XXXX

daPa

-200

CAL

3.2

4)

5)

6)

At this point connect the probe tip to a manometer.

NOTE: Manometer internal volume must be less than 5 cc’s.

Press the

Use the

to -200

Press the

saved will appear in the lower right hand corner of the display. After 3 to 5

seconds the saved indicator will be extinguished and the display will update to

a steady state display as follows.

At this point verify that the leak rate is less than 2

Press the

manometer reading is within &15%) of the pressure value indicated on the 38

display.

Press the

-1

IzIHz [=I

daPa &15%)

wi

1-1

Ver

/=I

Key. At this point the pump will pressurize to -200

Key to store the -200

Key and the 38 will pressurize to +200

Key to return to the Main Calibration Mode Menu.

daPa

.

Keys to adjust the pressure on the external manometer

daPa

Calibration data. The messages

daPa/sec:

daPa.

47

Page 25

PRINT HEAD CAL

1)

2)

3)

Use the

Press

Press the

1x1 HzLG]

the

-1

[=I

Keys to move the cursor at the Print Head Cal position.

Key to enter the Print Head Cal Mode.

Hz to lighten

the

printout and the

[=I

Hz Key to darken the

printout. When either key is pressed the printer will print a test pattern (the

alphabet) on a single line. When the center of the adjustment range is crossed

the In Range indicator on the display will appear (when adjusting from a light

intensity to a dark intensity) or extinguish (when adjusting from a dark intensity

to a light intensity).

EXAMPLE

TOTAL RANGE

OF PRINT INTENSITY ADJUST RANGE.

=

20 STEPS OR 20 DIFFERENT INTENSITY LEVELS.

ABCDEFGHIJKLMNOPQRSTUVWXYZ:

ABCDEFGHIJKLMNOPQRSTUVWXYZ:

ABCDEFGHIJKLMNOPQRSTUVWXYZ:

ABCDEFGHIJKLMNOPQRSTUVWXYZ:

ABCDEFGHIJKLMNOPQRSTUVWXYZ:

ABCDEFGHIJKLMNOPQRSTUVWXYZ:

ABCDEFGHIJKLRNOPQRSTUVWXYZ:

ABCDEFGHIJKLRNOPQRSTUVWXYZ:

ABCDEFGHIJKLMNOPQRSTUVWXYZ:

ABCDEFGHIJKLMNOPQRSTUVWXYZ:

l ABCDEFGHIJKLNNOPQRSTUVWXYZ:

l ABCDEFGHIJKLMNOPQRSTUVWXYZ:

l ABCDEFGHIJKLMHOPQRSTUVWXYZ:

l

ABCDEFGHIJKLMNOPQRSTUVWXYZ;

l ABCDEFGHIJKLMNOPQRSTUVWXYZ:

l ABCDEFGHIJKLMNOPQRSTUVWXYZ:

l ABCDEFGHIJKLMNOPQRSTUVWXYZ:

l ABCDEFGHIJKLMNOPQRSTUVWXYZ:

lABCDEFGHIJKLMNOPQRSTUVWXYZ:

l ABCDEFGHIJKLMNOPQRSTUVWXYZ:

l “In Range” indicated on display.

4)

5)

6)

Press

Press the

Slide the Cal/Norm Switch to Norm to return to Normal Mode Operation.

the[F]

1-1

Key to store the desired intensity value.

Key to return to the Main Cal Mode Menu.

. 48

Page 26

S4 DIP SWITCHES.

S1

S2

S3

S4 _

S5

S6

S7

S8

Unused

Factory Auto

To Be Defined

To Be Defined

To Be Defined

Tymp/Reflex Default Data

Audiometer

Program Default Data

ON

Cal

Default

Data

Unused

Norma! Cal Mode Operation

Normal Cal Mode Operation

Normal Cal Mode Operation

Normal Cal Mode Operation

Normal Cal Mode Operation

Normal Cal Mode Operation

Normal Cal Mode Operationon

*

OFF

49

Page 27

TROUBLE SHOOTING

50

Page 28

ERROR MESSAGES (EXX)

NOTE: If an Error Message is observed the associated code number should be

recorded for future reference.

specific block of circuitry which will enable the technician to repair the problem in a fast,

efficient manner. Most software errors are related to poor environmental conditions

such

as static electricity and power line interference and will generally clear with power

down/up. Contact your local sales and service organization and supply them with the

Error Code Number if the error will not clear with power down/up.

AUDIOMETER PROCESSOR RELATED MESSAGES

The Error Code Number is designed to point to a

Code Number

EPROM Checksum Error on power up / if

01

02

03

04

05

Description/Possible

non-recoverable possible defective

Board EPROM

Microprocessor Internal RAM Error on power up / if nonrecoverable replace Microprocessor U34.

Watch Dog Timer Timeout / the Watch Dog Timer Circuit

monitors the Microprocessor’s operation. The Processor

must periodically send an “I’m Okay” message ‘to the watch

dog or the watch dog will halt all operations. If non-

recoverable try replacing.

Audiomymp Board.

Microprocessor

defective crystal Y2 or Microprocessor U34.

Undefined Interrupt Error / this type of soft error should

always be recoverable.

Processor does not acknowledge or cannot execute. If nonrecoverable replace Audiomymp Board.

U30

Clock Failure / if non-recoverable possible

Cause

Auto/Tymp

or Microprocessor U34.

Microprocessor U34 or

It

relates to an Interrupt that the

06

07

08

Opcode Trap Interrupt Error /this type of error code should

always be recoverable.

Microprocessor

External

Audio RAM U32 or Microprocessor

Normal or Swap Stack

should always be recoverable.

Audio/Tymp Board.

RAM

U34

or Audiomymp Board.

Error / if non-recoverable possible defective

Overflow

51

If non-recoverable replace

U34.

into the Global Variables

If

non-recoverable replace

/

Page 29

Code Number

Description/Probable Cause

09

10

'12

‘13

'14

'15

Conf. Register Error / if non-recoverable re-calibrate

Config,

Register then replace Microprocessor U34.

Halt in Response to Remote Command

/

if non-recoverable

possible defective Audio/Tymp Communications Chip U36

or Microprocessor

Invalid

Keycode

U34.

detected in CMDTSK / if non-recoverable

possible defective Switch Panel, Switch Buffer U26, U27, or

U28, or Microprocessor U34.

Invalid

Invalid

Keysource detected in CMDTSK

Queue Power

Error detected in CMDTSK /same as

/

same as above.

above.

Bad Pointer to EEPROM Routine’/

Collision of the Normal Stack and Swap

Stack

/

‘16

‘17

'18

'19

‘20

‘21

22

Invalid function for a Banded Swapped Function

Printer RAM Error on power up / internal or micro

Tymp Hardware State is unknown

Non-Fatal Audiometer related error messages

Calibration Data Read Error

HL Limit exceeded /

Invalid Extended Range Selection due to HL not in range

where the Extend Range is valid

23

24

Calibration Data Write Error occurred

Invalid Present Bar Operation due to a

Calibration Data Error /

/

/

occured /

/

/

52

Page 30

Code Number

Description/Probable Cause

25

Remote Record received with a Bad Record Format, invalid

Key Code, or Invalid Record Type

26

27

28

EEPROM Checksum Error

EPROM TO EEPROM Data Load Error

Remote Command received from an external remote device

(factory auto

unsupported record type

29

Remote command received from an external remote device

(factory auto cal) which is ignored due to mode

30

GSI vs Custom RTL Calibration status Read Error from

EEPROM

31

32

Printer Calibration Data Read Error

No test available to print

/

/

/

cal)

which is invalid due to mode or is an

/

/

/

/

/

33

34

35

36

37

38

39

40

Tymp/Reflex

the Audio Processor or the

setting the Synch

No Free Memory available when going to a new test

Processor not responding to a command from

Tymp/Reflex

Processor is not

Stimo line on power up /

/

Invalid test type read from memory when trying to display

Print Head initialization failed /

Printer Ambient temperature out of Range

Record was received from the

Tymp/Reflex

/

Processor which

has a valid format but the record type was not the type

expected

/

Call Factory for instruction

Audiometry mode not enabled

Page 31

TYMP

PROCESSOR RELATED MESSAGES

Code Number

51

52

53

54

55

56

57

58

59

60

Description/Probable Cause

EPROM Checksum Error on power up

Internal RAM Error on power up

Watch Dog Timer Time Out

CPU Clock Failure

Undefined Interrupt Error

/

/

Opcode Trap Interrupt Error

External RAM Error

Stack Overflow Error

Config.

Register Error

/

/

/

Bad Pointer to EEPROM Routine

/

/

/

/

/

61

62

63-69

70

71

72

73

74

75

EEPROM Read Error in Norm or

Couldn’t Home Pump

/

Alt

Mode

/

Undefined

Non Fatal Errors

Probe is occluded or in cavity at power up

/

Probe not in 2.0 mL cavity during Altitude Adjustment Cal

Mode

End of gain reached in Microphone Cal Mode

/

Probe Tone Gain Error during Probe Tone Gain Verification

/

Cavity Error during Calibration /

Compliance Calibration Error /

76

Unused

54

Page 32

Code Number

77

Description/Probable Cause

A/D

Pressure Value out of range of Pressure Transducer

Gain

Error /

78

79

80

Remote Record Error

Non-Fatal Cal Data

Reflex Test

time /

81

82

83

84

Remote Command invalid for the mode

Leak or Occlusion Error

Pump end of stroke

Undefined Error Number Reported /

/

Read/Write

info

not received for the Audio within the allotted

Error

/

/

/

/

55

Loading...

Loading...