Page 1

Audio Menu

Covers Welch Allyn AM232 Manual Audiometer

Operation Manual

Page 2

Warranty

We, Grason-Stadler, Inc. warrant that this product is free from defects in material and

workmanship and, when properly installed and used, will perform in accordance with

applicable specifications.

meet this standard, it will be repaired, or at our option, replaced at no charge except

for transportation costs, when returned to an authorized Grason-Stadler service facility.

If field service is requested, there will be no charge for labor or material, however, there

will be a charge for travel expense at the service center’s current rate.

If within one year after original shipment it is found not to

NOTE

Changes in the product not approved in writing

Grason-Stadler shall void this warranty. Grason-Stadler

shall not be liable for any indirect, special or

consequential damages, even if notice has been given

in advance of the possibility of such damages.

THIS WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO, ANY IMPLIED WARRANTY OF

MERCHANTABILITY OF FITNESS FOR A PARTICULAR

PURPOSE.

by

GSI

Grason-Stadler

A Welch Allyn Company

Grason-Stadler, Inc.

1 Westchester Drive

Milford, NH 03055-3056

Telephone: 603-672-0470

Fax: 603-672-0487

Service

Manual 1717-0110,,

Printed January, 1991

Printed April, 1991

Printed January, 1992

Printed January, 1994

i

(#1)

(#2)

(#3)

(#4)

Rev.

4

Page 3

Table of Contents

Warranty

Table of

Warning

...........................

.L.

..............................

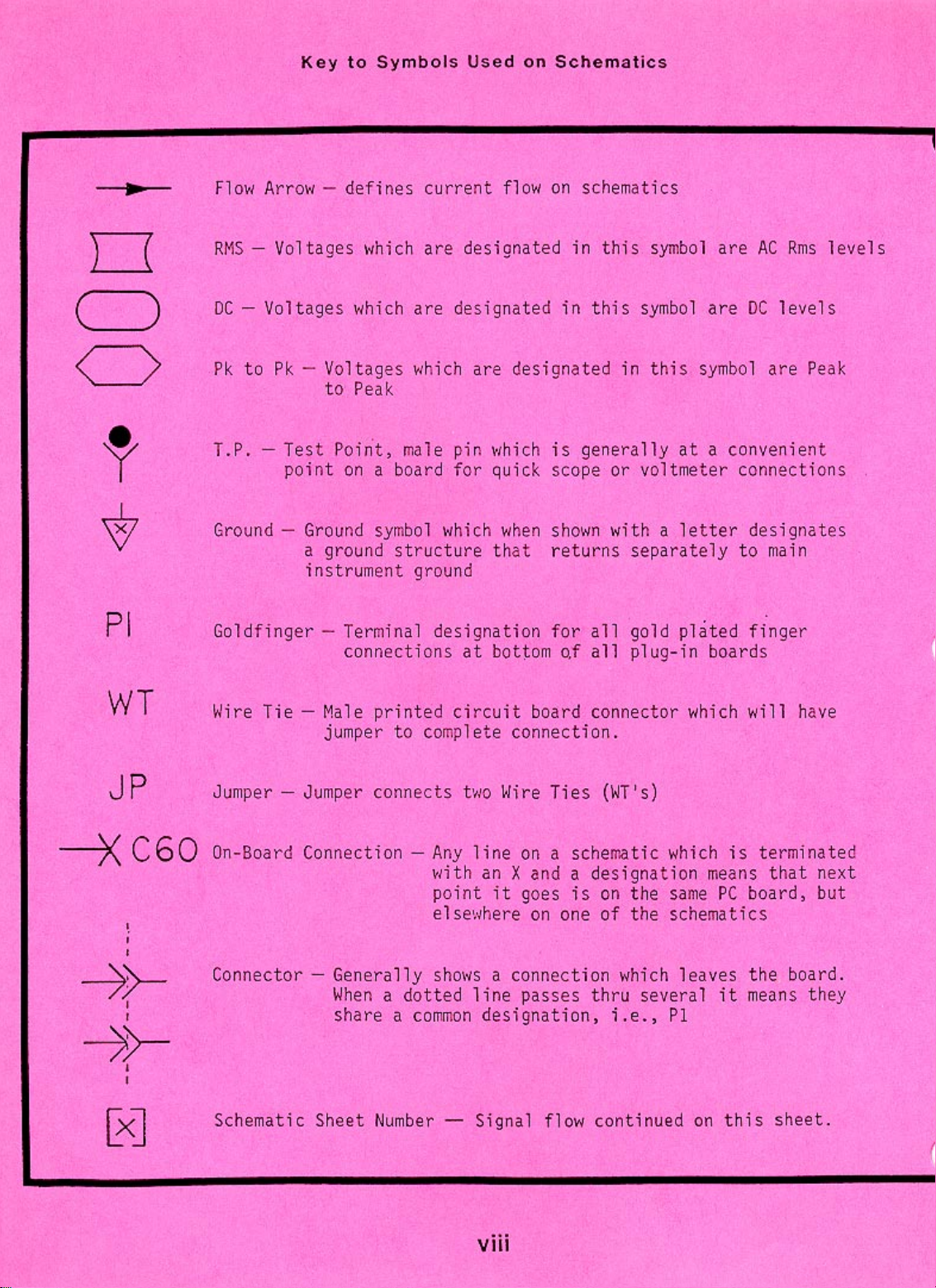

Key to Symbols Used on Schematics

Foreword

...........................

SECTION 1- PRODUCT SPECIFICATIONS

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

1.13

1.14

1.15

1.16

1.17

1.18

Catalog Listings

Standards

.....................

Test Stimulus

..................

..................

Output Hearing Level Controi

Signal to Noise Ratio

Tone Switch

Stimulus

Transducers

Front Panel

....................

......................

................

Controls/Rear

Power and Power Line

Battery Pack Voltage

...............

................

................

Environmental Conditions

Mechanical Dimensions

Material Used in

Leakage Test

Manufacture

....................

Headband Static Force

..............

...............

Earphone Cushion Attenuation

Accessories

....................

..............

............

Panel Connectors

..............

............

............

.....

: : 1

i

iii

vii

viii

ix

1

1

1

2

2

3"

3

3

5

5

5

6

6

6

6

6

7

-

SECTION 2

FUNCTIONAL DESCRIPTION

Figure 2-l:

2.1

2.2

2.3

2.4

2.5

SECTION 3

3.1

3.2

3.3

3.4

Front Panel Controls and Indicators

Rear Panel Connectors and Controls

General Operation of Controls

Power Up Initialization

Sleep Mode

-

ROUTINE MAINTENANCE

Earphone Cords

Hum and Random

Distortion and

Special Messages

3.4.1 CAL

3.4.2

Exx

Connectors, Controls, Indicators

........

.........

...........

..............

.....................

..................

Noise

Frequency Shift

..........

.......

..................

...

:

: :

........................

........................

. . .

iii

8

9

10

10

10

11

13

13

:

13

14

14

14

Page 4

SECTION

4- CALIBRATION

4.1

4.2

4.2.1

4.2.2

4.3

4.4

4.5

4.5.1

4.5.2

4.5.3

4.5.4

4.5.5

4.5.6

4.5.7

4.5.8

4.5.9

4.5.10

4.5.11

4.5.12

4.6

4.7

4.8

4.8.1

4.8.2

4.8.3

4.8.4

4.9

4.9.1

4.9.2

4.9.3

4.9.4

4.9.5

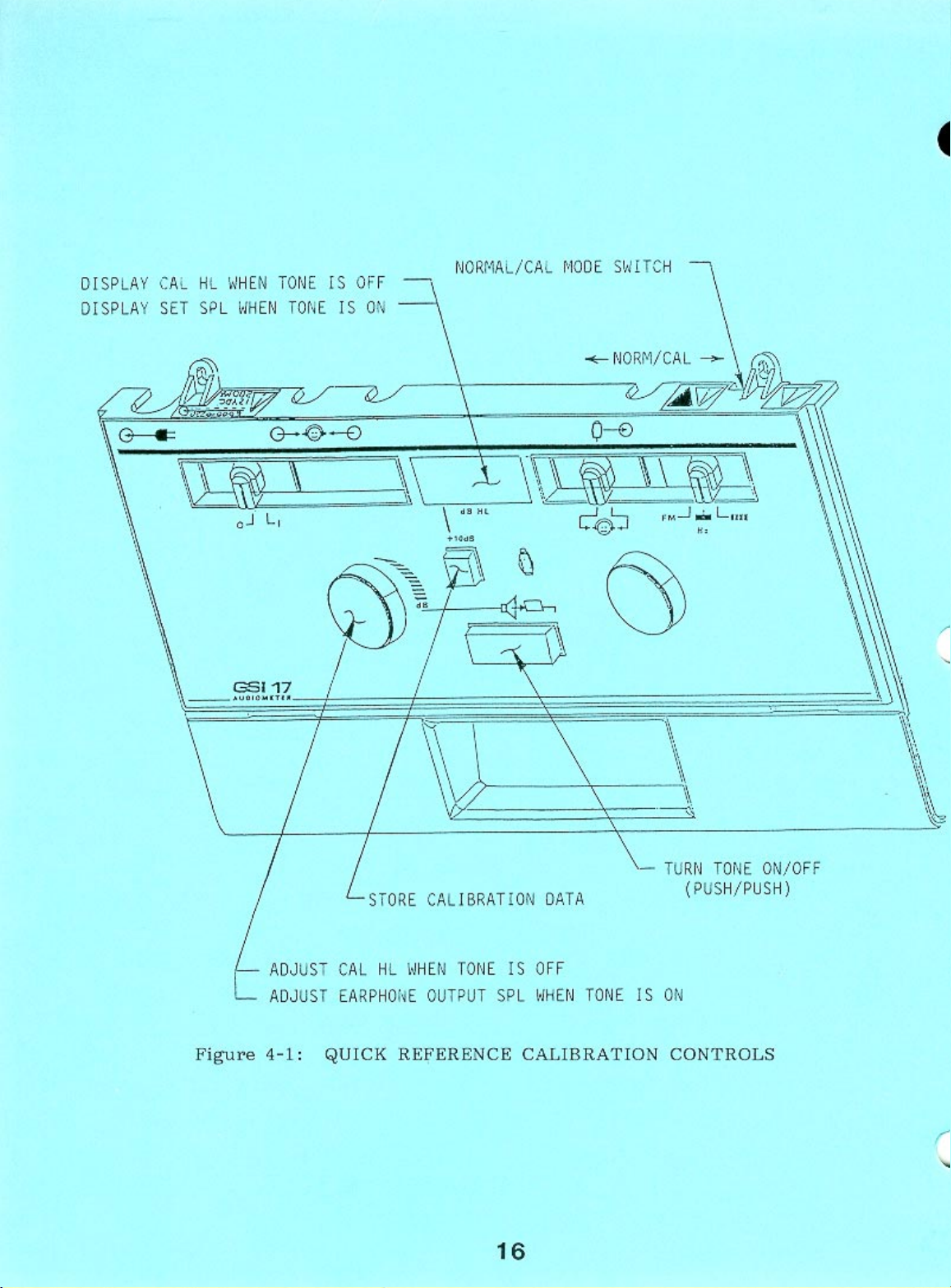

Quick Reference Calibration

Figure 4-l:

Figure 4-2:

Table 4-l:

Calibration Mode Operation

Quick Reference Calibration Control;

Access to Calibration Controls

Calibration Reference Threshold;

...........................

..........

....

....

Cal/Normal Switch

Calibration Mode Dip Switches

Calibration Mode Entry

Mode Initialization

Earphone SPL

Tone Type Switch

Calibration Mode

..................

...............

............................

............

Routing Switch

Frequency Selector'

Present Bar

HLl

Extended Range

.....................

.

...

Pushbution

Response Switch

HLDisplay

Response LED

Stimulus ON

.....................

....................

.....................

Low Battery Segment

"+"

LCD Segment

Calibration Mode Exit

Calibration Data Storage and Validation

Calibration Mode Dip Switch

Dip Switch S4

Dip Switch S3

Dip Switch S2

Dip Switch

....................

....................

....................

S1

....................

Selection of the Diagnostic Mode

Hardware Diagnostic Test (DO)

Pushbutton Diagnostic Test

..................................

................................

...................

.................

...................

................

.............

............

(D1)

.......

..........

...........

Display Diagnostic Test (D2)

A/D Converter Diagnostic Test

Attenuator Maximum Output Level Calibration

(D3) 1

(D4) .

: : 1 : 1 1 : :

16

: :

17

18

19

..

19

1

19

19

20

21

21

21

2";

22

22

22

23

23

23

23

23

23

24

24

25

25

25

27

27

28

29

31

33

34

..

38

SECTION

5

Figure 5-l:

5.1

Disassembly Instructions

5.2

5.3

SECTION

Accessories and Replacement Parts

6

6.1

Diagnostic Mode (DO)

6.2

6.3

-

DISASSEMBLY

Disassembly

Parts Numbers

-

TROUBLESHOOTING

....................

..............

..............

..........

Troubleshooting Using the Hardware

............

Figure 6-l:

Diagnostic

Functions

Output Related

Figure 6-2:

Troubleshooting

Block Diagram of Amplifier

Signal Flow

Left or Right Amplifier Troubleshooting Symptoms'

Mode

Controls and

.

..................

Symptoms

...

.......

iv

42

:3

44

45

46

48

48

49

Page 5

Page 6

Page 7

Page 8

Page 9

-

FOREWORD

GENERAL SERVICE INFORMATION

Operating,

can be found in the Instruction Manual (1717-0100).

and/or bench testing of GSI 17 Audiometers should only be

performed by trained personnel. The following instructions are

provided primarily for use by persons who are skilled in the

repair of electronic equipment.

CMOS HANDLING PRECAUTIONS

Many of the integrated circuits on the P.C. boards are CMOS and

NMOS type.

Failure to observe the following precautions whenever a circuit

board or an integrated-circuit package is handled can result in

damage to the GSI 17.

a.

b.

C.

Place instrument and parts on a grounded, conductive work

surface.

Ground yourself (with a strap having about 1 M ohm

resistance).

Ground the frame of any test instrument or soldering iron to

be used.

check-out procedures,

CAUTION

trouble-shooting hints, etc.,

Repair

d.

-

If any circuit boards are

enclose them in conductive (anti-static) envelopes.

to be stored or transported,

ix

Page 10

SECTION 1

._-

Product Specifications

1.1 CATALOG LISTINGS

1717-9700

1717-9710 GSI 17 Audiometer,

1717-9705 GSI 17 Audiometer, AC Power (Export)

1717-9715 GSI 17 Audiometer,

1.2 STANDARDS

This unit is a single channel,

It

is equipped with pure

conduction transducers (TDH39 Earphones).

ANSI S3.6 and IEC 645 Type 4 Audiometer Standards.

The GSI 17 is designed to meet current revisions of the following

standards and specifications for audiometers:

GSI 17 Audiometer, AC Power (USA)

AC Power and Battery (USA)

AC Power and Battery (Export)

pure tone screening audiometer.

tone stimulus signals, and air

This instrument meets

ANSI S3.6

IEC 645

IS0 389

IEC 601

1.3 TEST STIMULUS

PURE TONE SPECIFICATIONS

A pure tone is the only stimulus source for this audiometer.

DISCRETE FREQUENCIES

125, 250,

FREQUENCY ACCURACY

< +3%

TOTAL HARMONIC DISTORTION (FROM 125

ACOUSTICALLY)

500, 750, 1000, 1500, 2000, 3000, 4000, 6000, 8000 Hz

Frequency

125Hz

1000

3000

Hz

Hz

Test

60

dB

100

dB

100

dB

Hz TO

HL

4000 Hz, MEASURED

<2%

<

2%

<

2%

1

Page 11

1.4 OUTPUT HEARING LEVEL CONTROL

CALIBRATED IN dB

MEASURED IN INCREMENTS OF 5

HL

dB

RANGES

-10

to

125

Hz

500to

250

6000

and

Additionally A

Hz -10

8000

Hz

"+10 dB""

-10

Extended Range

maximum HL at all frequencies by 10

ACCURACY OF ALL SETTINGS

125 to 4000 Hz

6000 to 8000 Hz

1.5 SIGNAL TO NOISE RATIO (IN

>70

dB measured acoustically in dB HL

1.6 TONE SWITCH

This

electronic

switch turns the stimulus

OF

HEARING LEVEL CONTROL:

+3

+5 dB

1/3

50

to

90

to

70

dB.

dB

OCTAVE)

minimal audible distortion.

dBB

HL

dBB

HL

dBB

HL

Switch,

which

signal

extends

ON/OFF with

MODES

Normal State:

Activated State:

Stimulus OFF

Stimulus ON

RISE/FALL TIME

20-50

Measured at the -1 dB and

ms

-20

dB

points on the signal envelope.

ON/OFF RAT IO

With

the

Tone Switch OFF,

below standard reference equivalent threshold for any

the output will be at

least

1/3

-10

octave

dB

band with HL setting of 60 dB or below.

ABOVE 60 dB HL SETTING

>70

dB

CROSS CHANNEL LEAKAGE

At HL settings of 70 dB or greater,unwanted signals in the

non-

test earphone shall be at least 70 dB below the tone in the test

earphone.

dB2

Page 12

1.7 STIMULUS TYPES

Continuous Tone

Continuous FM Tone

Pulsed Tone

SIGNAL FORMAT

Continuous

Pulsed

-

Pulsed Rate:

Signal steady as long as Present Bar is depressed.

-

2.5

Pulses/sec

Pulse rate is synchronized to the "Present

first and last pulse will have 200 ms on time.

DUTY CYCLE

50%

RISE/FALLTIME

20-50 ms

ON/OFF RATIO (BETWEEN PULSES)

dB

>20

FREQUENCY MODULATION

FM Rate:

FM Deviation:

5 Hz

25%

Bar"

so that

the

1.8 TRANSDUCERS HEADSET TDH39 Earphones with 60 ohm impedance

1.9 FRONT PANEL CONTROLS AND REAR PANEL CONNECTORS

FRONT PANEL

CONTROLS

Frequency Selection

HL Select

Mode Selector (Pulsed/Steady/FM)

Routing (Left/Right)

Present Bar

Power Switch

"+10 dB"

Push-Button

3

Page 13

INDICATORS:

Power ON/OFF

Frequency Selector

dB

HL - LCD

Left/Right Earphone

Pulsed/Steady/FM

Subject

"Battery

Response - LED

Low"

(when applicable, i.e. Battery Option

purchased) - LCD

Tone ON - LED

Extended Range - LCD

REAR PANEL CONNECTORS

Left and Right Earphone -

Subject Response Switch

- 1/4"

Power Cord- 5 Pin DIN

LEFT AND RIGHT EARPHONE JACKS

Pin#

Tip

Sleeve

SUBJECT SWITCH

--Pin&

Tip

Sleeve

POWER INPUT

Function

Phone High

25 u VRMS to 2.5 VRMS

Phone Low

(J7)

Function

Switch High

Switch Low

(J1)

Battery Power

No Power

Module

Pin #

Name

--

Attached

1/4"

Phone Jack

Phone Jack

(J4 & J5)

Output Voltaqe

0 Volts

Output Voltaqe

+5

Vdc

0 Volts

Power Module

Connected

w/NiCad

Battery

Installed

Impedance

(max)

130 ohms

0 ohms

Impedance

47 K ohms

0

Power Module

Connected

w/Alkaline

Battery

Installed

ohms

Power Module

Only

No

Battery

J1-1

J1-2

Jl-3

Jl-4

J1-5

VSUP

NC

CHASGND PROTECTIVE

GND

CGND

0 (REF)

BAT/LINE 2.6 to 3.0

VBAT

+7.3

to 9.0

NC

PROTECTIVE

GND

0 (REF)

3.7 to 4.3

+7.0

All values listed are in Volts DC

to 9.0

NC

PROTECTIVE

GND

0 (REF)

3.7 to 4.3

7.0 to 13.5

t9.0 to 16.0

PROTECTIVE

GND

0 (REF)

4.3 to 5.1

+7.5

to 13.5

Page 14

1.10

POWER AND POWER LINE

_-

POWER RATING

9 Watts power module operated while simultaneously charging battery.

0.6 Watts battery power

OPERATING MODES

Power Line (Mains)

Battery- Rechargeable

(NiCad)

or Non-Rechargeable (Alkaline)

LINE (MAINS) VOLTAGE

115 V or 220 V

LINE (MAINS) VOLTAGE VARIATION

+lo%

LINE (MAINS) FREQUENCY RANGE

50-60 Hz

LINE (MAINS) FREQUENCY VARIATION

+5%

1.11

BATTERY PACK VOLTAGE

BATTERY VOLTAGE OPERATING RANGE

7.0 v to 9.0 v

BATTERY PACK TYPICAL OPERATING LIFE

NiCad:

Alkaline:

22 Hours

45 Hours

1.12 ENVIRONMENTAL CONDITIONS

OPERATING TEMPERATURE RANGE

15 to 40 Degrees Celsius

SHELF TEMPERATURE RANGE

Power Module Operated:

-40 to 60 Degrees Celsius

Battery Operated: -40 to 40 Degrees Celsius

RELATIVE HUMIDITY RANGE

5% to 90%

5

Page 15

1.13

MECHANICAL DIMENSIONS

Weight:

5.6 lbs (2.53 Kg)

Weight of Battery Pack:

Size:

13.25"W

x

14"D

x

1.5 lbs (0.68 Kg)

3.75"H

(33.66 cm x 35.56 cm x 9.53 cm)

1.14 MATERIALS USED IN MANUFACTURE

-

GSI 17 Case Assembly

-

GE Cycolac T

Battery Option Case Assembly - GE Cycolac T

Power Module Case Assembly - Noryl SE -

100J

(Flame Retardant)

1.15 LEAKAGE TEST (AC) CONNECTED/SAFETY TEST

Leakage Current High Voltage Breakdown

<25 uamps

115 V operation

220 V operation

>3000

>4000

v

v

1.16 HEADBAND STATIC FORCE

1.6 to 2.0 pounds when

earcups

are 5.7 inches

apart.

Measured

with distance center of headband to center of earphones equal to

5 inches.

1.17 EARPHONE CUSHION ATTENUATION

Frequency (Hz)

125

250

500

750

1000

1500

Attenuation

6.5

4.5

7.0

10.0

15.5

18.5

2000 26.0

3000

4000

6000

8000

30.5

33.0

27.0

24.5

6

Page 16

1.18 ACCESSORIES

Supplied Cataloq Numbers

Test Headset (TDH39)

Audiogram Forms (1 pad of 50)

Instruction Manual

Battery Pack Assembly

(used with 1717-9710,

1717-9715 models only)

8000-0175

1717-9600

1717-0100

1717-2010

AC Power Cord,one of the following:

120 v (US)

220 V (Euro plug)

240 V (UK)

220 V (Generic)

8000-0240

8000-0241

8000-0242

8000-0250

GSI 17's with serial numbers below # 0856 require a

different power module.

See Section 9, Power Module,

for details.

Optional Catalog Numbers

Response Handswitch

Patch Cord, 2 Conductor

Audiocups

Battery Pack Assembly

7874-0156

4202-0505

8000-0155

1717-2010

Battery Pack includes GSI supplied NiCad Battery.

May also be used with six

(6),

Size C, Alkaline

Batteries (not included)

Replacement NiCad Battery

8410-0060

Page 17

P

R3

R5

io

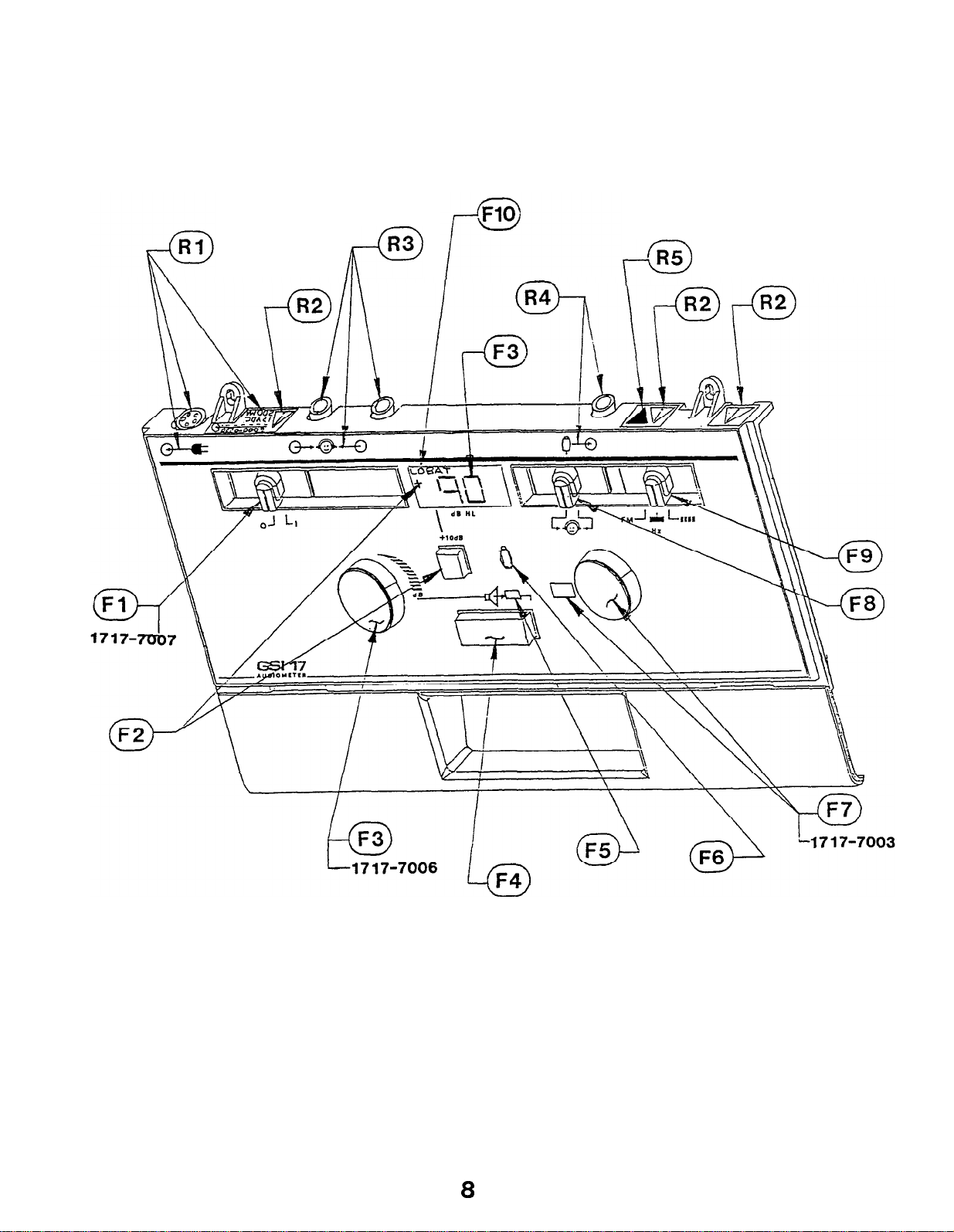

Figure 2-1:

CONNECTORS, CONTROLS, INDICATORS

8

Page 18

SECTION

2

-.

This

Connectors,

Figure

Controls,and Indicators.

2.1 THE FRONT PANEL CONTROLS AND INDICATORS (FIGURE 2-1)

section of

2-l for the layout and positioning of

F1

-

F2 - Range

F3

-

F4

-

Present Bar for stimulus presentation.

Functional Description

the Service Manual is

Controls,

Power switch and indicators for ON

increase

standard

operation is indicated by the

LCD.

HL control for setting stimulus

Level indicated on LCD.

and Indicators of the GSI 17.

extension pushbutton allows

the

stimulus intensity 10

maximum

HL at

used to

any

frequency

"+"

being lit on

intensity

describe

Refer to

all

(1)

Connectors,

and OFF (0).

operator to

dB

above

-

level.

the

the

its

the

F5

F6 - Subject response

F7 - Frequency

F8 - Routing

F9 -

F10 -

Loudspeaker

-

presentation indicated by illuminated LED.

that the test

button.

control for setting stimulus

Frequency indicated in window adjacent to control.

switch for routing the stimulus signal to

the

indicated by illustration of

Tone

type.

FM

---

Low battery indicator to alert the

the

available

depending

are used).

left or

type

= warble tone

= steady tone

= pulsed tone

batteries

switch for setting

(recharge or

on whether

in operation as such.

indicator LED shows the operator

subject

right

have a

has pressed the handswitch

earphone.

limited

replace

NiCad

or

Left or

subject.

the

alkaline

stimulus

operator

operating

batteries

Actual

frequency.

right

soon,

batteries

tone

when

time

9

Page 19

2.2 REAR PANEL CONNECTORS AND INDICATORS

R1 -

Power input

position

and rear panel indication of input

jack with front panel

indication of

power

specifications.

-

Attention,consult accompanying documents.

R2

-

Earphone output jacks with front panel

R3

indication

of left and right phone provided by illustration of

subject.

R4

Subject response switch input jack with front panel

-

indication of position.

R5

-

Calibration switch indication.

2.3 GENERAL OPERATION OF CONTROLS

All

initialization is complete,

in

depends on the HL selection. When the Extended Range is

controls

this

document and for the Extended

are

valid at

except for special cases as indicated

all

times

Range

once

the

Pushbutton

power up

which

invalid

there will be no indication given to the operator other than

absence of the

"+"

LCD segment.

the

All polled

state.

All operations of all controls are

controls are checked every 12

msec

for a

debounced

change in

for 12

msec

before processing.

The

Extended

manner.

and

hold manner (except in the Calibration and Diagnostic modes

The Present Bar and Response Switch operate

Range pushbutton operates by a push ON,

by a

push OFF

press

where the Present Bar is push ON, push OFF).

When a press and hold type control is operated all other controls

are still active.

When the operation of a control is being processed the processing

of

all

other controls is delayed until the first

operation is

completed.

2.4 POWER UP INITIALIZATION

When

the power switch is set to the ON position

the

instrument

will go through the following initialization process:

All

microprocessor

internal

and

external

hardware

components of

system will be initialized for the

the

required

type of operation.

All

LEDs

and LCD segments will be turned on to indicate that

the power up initialization is in progress.

Page 20

The RAM will be tested using a read after write verification

process.

initialized

will be displayed on the HL display and the instrument

halt.

After each location is tested its value

to 0.

If an error is detected, an

will be

error

code

will

The

generate a

stored in the EPROM.

using any of the RAM.

will be displayed on the HL display and the instrument

halt.

The operating mode of the instrument will be determined by

the position of the Cal/Normal Switch and the four Cal

Option Dip Switches. Refer to Sections 3 for the

Calibration and Diagnostic Mode initialization.

remaining initialization process will be performed for the

Normal Mode.

The

initialized to 0 HL.

be

analog hardware

selections.

After

all controls active.

2.5 SLEEP MODE

EPROM will be tested by reading the complete

current

initialized to their currently selected positions.

initialization,

EPROM to

checksum which will be compared to a

This test will be performed without

If an error is detected an error code

HL selection

All other controls and displays

will

be initialized

the instrument will remain idle

and

the

HL display

according to

checksum

will be

will

The

will

All

these

with

The GSI 17 has a mode which is designed to lengthen battery life.

When

operation

Sleep

only when the unit

available when connected to mains (ac) power.

If a period

operated (front panel, internal,

"sleep",

Prior to entering the Sleep Mode,

indicate 3 dashes ' - - -

mode status.

7 Volt) which will disable much of the analog circuitry.

the

disconnected,

a STOP state which will halt its operation.

The

either the Present Bar or power switch are toggled.

the

unit

Sleep

unit has been left on, under

for

Mode.

thus drawing minirnal current.

enters

more than 5 minutes, the GSI 17 will

It is important to emphasize that this mode

is operating with batteries, and is not

of 5 minutes has elapsed

external) the unit will go to

the display will be updated to

'I

to advise the operator of its

It will also disable the voltage converter

the

the channel will turn OFF and the CPU

Mode is exited, and normal

sleep

mode,

battery power,

since

all

transducers

operation

any control was

resumed,

without

enter the

exists

sleep

(+7

to

When

will be

will

enter

when

-

Page 21

SECTION 3

-

3.1 EARPHONE CORDS

With extended use,earphone cords tend to fray internally at

junctions with

fraying

associated

cord is flexed.

To

check

control (F7) to 1000 or 2000 Hz, set HL control (F3) at a

comfortable audible level,

earphone cord

intermittent

scratchy

the

conditions signifies that the cord should be replaced.

Repeat the test for the other earphone.

3.2 HUM AND RANDOM NOISE

will ultimately either decrease the signal level in

earphone or cause signals to be intermittent as

for

signal,

sound superimposed over the signal that coincides

flexing of the cord.

Routine Maintenance

both earphone and audiometer

either condition, set

press the Present Bar (F4)

next to plug at

abrupt

changes in

The presence of any of

the

both ends,

audiometer

signal

the

connectors. This

the

the

frequency

and

listening

level, or a

these

flex

for

with

three

This test can be made during the check for attenuator noise.

With the instrument set on 1000 Hz,

0 to 60 dB and listen for low-frequency hum (60 to 120 Hz) and

random noise (hiss or low rushing

levels.

permissible.

audible.

naive subjects and affect the accuracy of the audiogram.

Schedule the audiometer for immediate service if any of these

symptoms are detected.

3.3

DISTORTION AND FREQUENCY SHIFT

This check is most easily performed by listening to the output of

the

frequencies at

dBHL for normal ears).

Listen for rattling, rasping or distortion in the tones

presented.

change when the Frequency Selector (F5) is moved to a new

position.

other,

should be replaced. In any case,the audiometer should be

immediately scheduled for maintenance.

GSI 17

Some audible random noise at levels above 60 dB is

Below 60

Any of these noises can be confused with the signal by

through

a loud,

Listen also to ascertain that signal frequencies

If distortion is heard in one earphone but not in the

the chances are high that the earphone is at fault and

dB

however, only the signal should be

the

earphones

but not uncomfortable, level (70 to 80

move the HL control (F2) from

sound) at all attenuator

while

presenting

all 11

13

Page 22

3.4 SPECIAL MESSAGES

The

GSI 17 is a

microprocessor-controlled

performs a self check each time the instrument is turned on

self check does not occur when the instrument is "awakened"

sleep mode).

the front panel LCD if any error in the instrument

on

is detected.

Certain messages will be displayed to the

These messages are described below.

instrument

operator

operation

which

(the

from

3.4.1 CAL

When a

calibration

"CAL" will be displayed to the operator.

function at

invalid results

displayed as long as the "problem" transducer and frequency

selected.

changing either

transducer or frequency is

error

this

can be

(i.e.

frequency with this transducer, so

right earphone at 2000

recorded.

The word

If the calibration error is an

the

frequency or

the

selected

which

Hz),

has a

the

word

The audiometer will not

that no

"CAL"

will be

are

isolated

transducer

situation,

(i.e. left

earphone or 3000 Hz) will restore normal instrument function.

As is

service technician should be contacted immediately.

make

the

case with any instrument

malfunction, a

note of the combination of transducer and

certified

Remember to

frequency which

resulted in the "CAL" message.

3.4.2 Exx

When an error code consisting of an

"E"

and a 2-digit number (xx,

= number) appears on the audiometer's display, a system error has

been detected.

not

will

permit the instrument to operate.

remain on

instrument will

The GSI 17 will enter a "lockout" mode which will

the

display

shut

The specific

for

several

seconds,

itself down completely.

error

then

Should an

code

the

Exx

appear on the LCD,take the following steps:

a.

Power down,

then power up again.

This error could be

only a temporary failure and may never appear again.

However,

should the Exx message

reappear,

proceed to

steps b. and c.

b.

C.

Record the numbers that appear on the display.

Contact your certified service representative and give

them the specific numbers you have recorded.

Page 23

Page 24

Page 25

4.1 QUICK

REFERENCE

CALIBRATION

--X

a.

b.

C.

d.

Select Calibration Mode using Cal/Norm Switch.

Select Frequency and Reference HL for calibration.

Select Earphone Routing (L or R).

Turn Tone ON using Present Bar.

NOTE:

Display will update to the ANSI

proper calibration

as necessary.

e.

f.

Adjust Output Level to the required SPL using the HL Dial.

Store data using the

LCD Segment will illuminate to indicate storage of data.

g.

h

i.

NOTE:

REPLACED,

r?

w

Repeat for all frequencies.

Repeat for opposite earphone.

. .

Return Cal Switch to NORM position.

If A CAL ERROR occurs or the MICROPROCESSOR HAS BEEN

the following steps should be performed:

Short

JP1

pins 1 and 2 then power-up for 2-3 seconds.

Power-down and remove jumper.

6.6).

SPL required for

subtract or add microphone

-

+10 dB

Range Extender Pushbutton

(See Troubleshooting, Section

corrections

(+)

b.

C

(2

6

e.

Load Default Data. (See Dip Switch 4, this section).

Battery low/shut down calibration.

(See Diagnostic Mode

(D3), this section).

Attenuator maximum output level calibration.

Diagnostic Mode

(D4),

this section).

Proceed with Transducer Calibration.

17

(See

Page 26

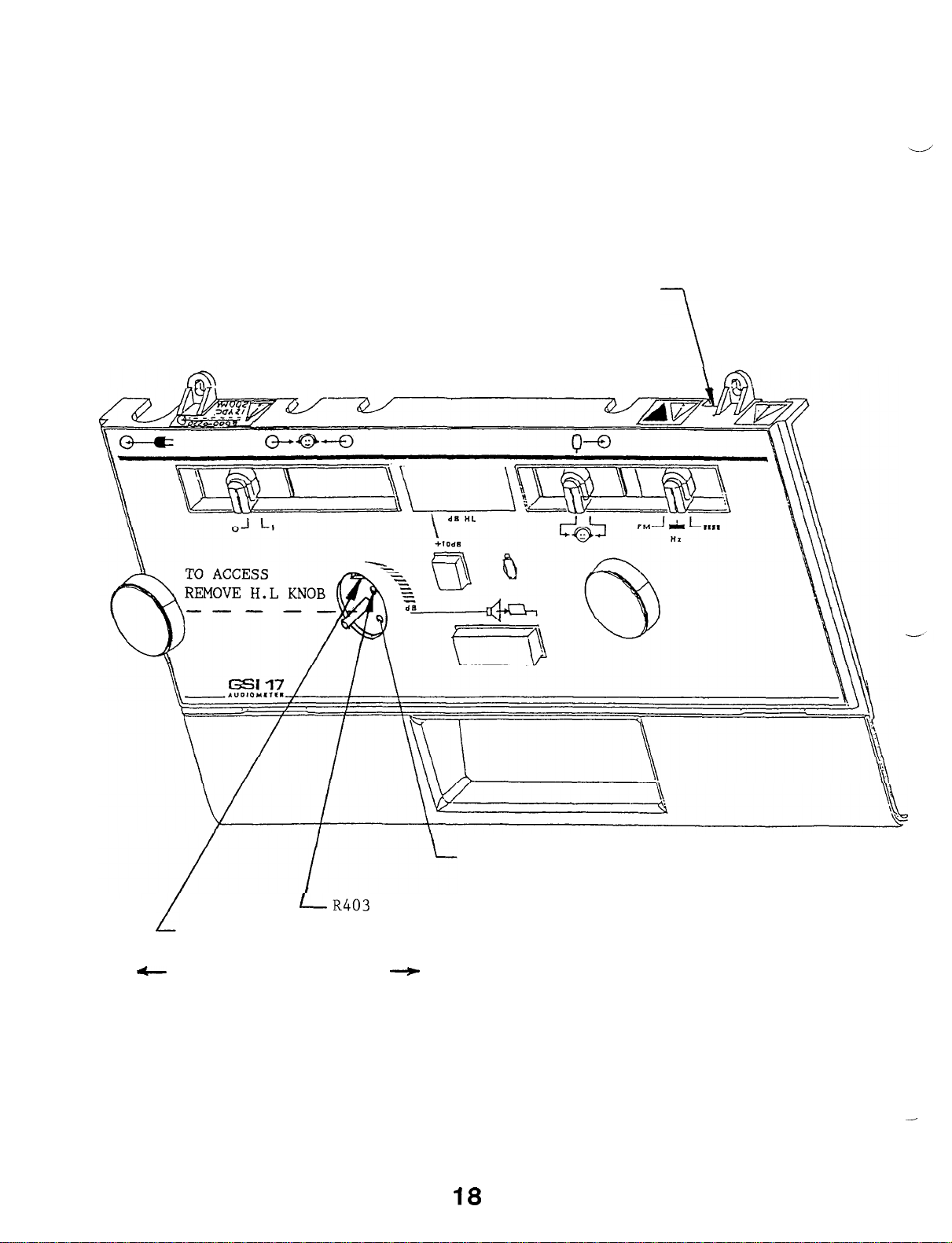

NORMAL/CAL MODE SWITCH

\

-

NORM/CAL

-

LR403

DIP SWITCH S2

(SQUARE PORT)

1

POSITION l/POSITION 4

Figure 4-2:

ACCESS TO CALIBRATION CONTROLS

R404

LINEARITY ADJUST

DISTORTION ADJUST

---t

18

-

Page 27

-

Freq

(Hz)

Table 4-l:

125 250 500

CALIBRATION REFERENCE THRESHOLDS

750

1000

1500 2000 3000

4000

6000

8000

dB 45.0 25.5 11.5 8.0

Standard Reference Threshold Levels re: 20

TDH39-P

9-A coupler.

earphones as measured on the National Bureau of Standards

Reference ANSI

7.0 6.5

S3.6-1989,

IS0 389-1975 Standards.

9.0

uPa

10.0

for

9.5

15.5

Telephonics

4.2 CALIBRATION MODE OPERATION

The

Calibration Mode is

calibration.

Normal

Mode

produce

the required SPL for the selected HL.

to determine the correct

This

used to

calibration information is used

perform

attenuator

the

transducer

during

position to

The

Calibration

the

Mode consists of two modes.

The Custom SPL Selection Mode allows the selection of

SPL values

Calibration

for

alternate

transducers.

Mode is used to calibrate the sound

The

Transducer

pressure

customized

SPL

level

(SPL) of each stimulus for each transducer.

4.2

.1

CAL/NORMAL SWITCH

This switch is used to select the operating mode of the

instrument.

switch to the CAL position while Dip Switch

position.

The Calibration Mode is entered by setting this

S1

is in the OFF

The Calibration Mode is exited by setting this switch

to the NORMAL position.

13.0

4.2.2 CALIBRATION MODE DIP SWITCHES

(See

"Calibration Mode Dip Switch In-Depth Description" later in

this section.)

These

Mode.

Dip Switches select various options of

They are read to determine the selected options when

Calibration Mode is entered.

the Calibration

the

79

Page 28

Switch

#

Function

OFF (down)

ON

(up)

(up)

s4

Default Data

OFF

Load

Loads the default Calibration

data into EEPROM when the

Calibration Mode is entered.

s3

Custom SPL Mode

GSI

Custom

Enables the selection of user

specified SPL values during

the transducer calibration

procedure when set to the

Custom position.

s2

S1

Not used

Diagnostic Mode

N/A

OFF

N/A

Selected

Selects the Calibration Mode

when the Cal/Normal Switch

is set to the Cal position

if this switch is in the OFF

position.

The status of Dip Switches #4 and #1 are read only when the

Calibration Mode is entered.

Dip Switch #3 is read and a change

in its position is processed if the Calibration Mode was entered

with this switch in the ON position.

Then the switch cay be

returned to the OFF position without exiting the Calibration

Mode.

-’

4.3 CALIBRATION MODE ENTRY The Calibration Mode can be entered via the Cal/Normal Switch at

any time except during the power up initialization phase or when

a stimulus is being presented.

In these cases the Cal Mode will

be entered when the initialization is complete or the stimulus

turned off.

The indication that the instrument is in the

Calibration Mode will be the non integer value in the format of

xx.x on the HL Display.

During the Calibration Mode initialization process all

controls

will be inactive.

When the Calibration Mode is entered,

low battery segment will be turned off.

all LCD segments except the

If Dip Switch S4 is

set

to the ON position the process of loading the default calibration

data

except

default data and checksum are being loaded.

will be started and the LCD display will have all

segments

the low battery segment turned on to indicate that the

When completed,

the

display will reinitialize to all segments except the low battery

segment will be off.

-

20

Page 29

id'

The EEPROM will then be tested by reading the complete EEPROM to

generate

in

the

flashed on

a checksum which will be compared to a checksum

EEPROM.

the HL display and the initialization

If an error is found the word

"CAL

"

process will

stored

will be

continue.

Dip Switch #3 will be checked to determine which CAL mode is to

be initialized.

If in the OFF position the transducer SPL

calibration mode is selected,and if in the ON position, the

Custom SPL selection mode will be selected.

4.4 MODE INITIALIZATION

When

the

transducer

SPL Calibration

Mode is

selected the

instrument will be initialized as follows:

Tone Type = Current selection

,=

Frequency

Current selection

Channel = OFF

Calibration HL = 10 dB below the nonextended HL limit

for.

the current transducer and frequency

Transducer SPL = Calibration HL + Current RTL

+10 dB

Pad = Out

Transducer Routing = Current selection

HL Display =Current custom SPL level stored in EEPROM

Response LED = OFF

Stimulus

On LED = OFF

Low Battery Segment = Current state

"+"

Segment = OFF

4.5 EARPHONE SPL CALIBRATION MODE

This Calibration Mode is used to calibrate the SPL for each

stimulus for each transducer.

This is done by adjusting the

selected transducer output SPL level to the specified value

displayed on the HL display.

This SPL value is the sum of the

calibration HL level and the Reference Threshold Level (RTL) for

the current transducer and frequency.

standard

RTL value or

a custom RTL

The RTL may be either the

value

depending on

the

position of Dip Switch #3 when the Calibration Mode was entered.

\_

The transducer

SPL calibration data is

stored in

EEPROM by

transducer and stimulus.

4.5

.1

TONE TYPE SWITCH

This switch

operates as in the Normal Mode to select

Type of the stimulus.

4.5.2 ROUTING SWITCH

This

switch

operates as

in the Normal

Mode to

transducer to be calibrated. All transducers must be

and they can be calibrated in any sequence.

21

the

select

Tone

the

calibrated

Page 30

4.5.3 FREQUENCY SELECTOR

This control

frequency

operates as

in the Normal

Mode to

select

to be calibrated. All frequencies must be

the

calibrated

and they can be calibrated in any sequence.

4.5.4

The

operates in

operated

PRESENT BAR

Present Bar controls the presentation of the

a push ON/push OFF manner.

If the Present

while the stimulus is off, the stimulus will be

stimulus.

Bar is

turned

It

on and remain on until the Present Bar is operated a second time.

The

stimulus will actually be turned ON or OFF when the

Present

Bar is pressed.

4.5.5

1.

HL DIAL

This control performs the dual function of selecting the HL

level at which the calibration is being performed and of

adjusting the output level of the transducer.

2.

While the stimulus is off,

Calibration HL level (Cal HL).

up by 5

dB

for each clockwise step of the selector and down

by 5 dB for each counter clockwise step.

the HL selector will select the

The level will be adjusted

For each change in

the Calibration HL level the transducer output level

(attenuator position) will be recalculated using the current

calibration data stored in the EEPROM.

the calibration HL will be from the nonextended

of

range) maximum HL limit to 20 dB below the limit.

the selector to select levels outside of this range

of

invalid.

When this occurs the level will default to the

The allowable range

(+10 dB

Operation

are

limit and the HL display will be flashed.

3.

While the stimulus is on,the HL selector (dial) will adjust

the transducer output level to allow the SPL level to be

adjusted to the required SPL level on the sound level meter.

The output level will be adjusted up by 0.5 dB for each

clockwise step of the selector and down by 0.5 dB for each

counter clockwise step. The output level is changed

according to the HL selector by directly setting the

attenuator position. Operation of the HL dial to select

positions outside of the instrument range will be invalid.

The attenuator position will be adjusted within the limits

and the displayed SPL value on the HL display will be

flashed.

4.5.6 EXTENDED RANGE PUSHBUTTON

This pushbutton is used to store the transducer SPL

data

stored,

Response LED will be turned on for 2 seconds.

data can

into

the

not be stored successfully, the word

EEPROM.

After the calibration data is

EEPROM checksum will be updated

and

If the calibration

calibration

successfully

the

"CAL"

Patient

"

will be

flashed on the HL display and the previously displayed SPL value

22

Page 31

will

can be continued for other frequencies.

4.5.7 RESPONSE SWITCH

be restored.

If this error occurs the calibration

process

This switch

Mode.

4.5.8 HL DISPLAY

a.

b.

c.

4.5.9 RESPONSE LED

This LED is used to indicate the correct storage of calibration

data in the EEPROM when the Extended Range Pushbutton is

operated.

seconds after the calibration data has been stored and verified.

If the data is not stored correctly the LED will remain off and

the word "CAL"

previously displayed transducer

restored.

Operations of the switch are not processed.

This display performsthe dual function displaying the

Calibration HL level and the SPL to which the transducer

output level must be adjusted for correct calibration.

When the stimulus is OFF,the HL display will show the

current Calibration HL level in

using digits 1, 2 and 3.

When the stimulus is ON,

required transducer output level in

xxx.x

the current Calibration HL and the Reference Threshold Level

(RTL) for the current transducer and frequency and does not

indicate correction for the sound level meter frequency

response.

using digits 1, 2, 3 and 4.

is not used during the transducer

dB

HL in the format xx.0

the HL display will show the

dB

This value is the sum of

This LED is normally OFF and will be turned ON for 2

will be flashed on the HL display and then the

output level SPL value will be

SPL Calibration

SPL in the format

4.5.10 STIMULUS ON LED

This LED is used to indicate the ON or OFF state of the stimulus.

While the stimulus is OFF the LED will be OFF and will be

ON while the stimulus is ON.

4.5.11 LOW BATTERY SEGMENT

This LCD segment will indicate a low battery voltage condition as

in the Normal Mode (ie:

4.5.12

This

Mode and will remain off.

"+"

LCD SEGMENT

segment is not used during the transducer

LOW BAT).

SPL Calibration

turned

23

Page 32

4.6 CALIBRATION MODE EXIT

The

the

calibration data is being loaded.

Calibration Mode can be exited back to the Normal

Cal/Normal

Switch at

any time

In this case the

except

for when

Calibration

Mode

default

via

Mode is exited when the loading of default data is complete.

When

initialize for the Normal Mode based on the current state of

controls,

4.7 CALIBRATION DATA STORAGE AND VALIDATION

All calibration data or other data which must be

the

the Calibration

as in the power up initialization.

instrument

is turned off is stored in

Mode is

exited

the

instrument

EEPROM.

retained

This data

will

the

when

consists of the following:

-

Transducer SPL calibration data by transducer and

frequency

-

Custom RTL values by transducer type

-

Custom RTL vs.

-

Attenuator

-

EEPROM checksum

2.5V

GSI RTL calibration selection

maximum output level limit by stimulus

The data is stored using a triple redundancy method (the same as

in the GSI 16 and GSI

data bit is stored 3 times, once in each of

within

blocks. When

location

data

This

the

EEPROM with a different format in

a specific data bit is required

in each of the 3 blocks is read and decoded.

to be valid the value from 2 of the 3 blocks

method will allow for the detection of data errors and

33

control Processor).

In this method each

3

different blocks

each of

the

appropriate

must

the

For

match.

the

the

3

correction of some errors.

If a calibration data read error is detected the frequency which

would use the data will not be available for testing in the

Normal Mode by forcing the stimulus off and not processing

operations

of the present bar.

The instrument will continue to

function and all other frequencies for which no calibration data

error

by displaying the word

exists will be available.

"CAL""

A data error will be

indicated

on the HL display until the

frequency or transducer is changed to a new selection that has no

data error.

addition to

In

individual pieces of data,

the

the

EEPROM which will allow the validity of all data

EEPROM to be determined.

the

triple redundancy validation

a 2 byte checksum will be

This check will be performed

used

for

stored in

stored in

when

the Calibration Mode is entered.

24

Page 33

4.8

CALIBRATION MODE DIP SWITCH IN-DEPTH DESCRIPTION

v

The Dip Switches,

in reverse numerical order. The reason for this is that they are

located beneath the HL dial, will be

in the order in which we anticipate the frequency of usage

described

will

be.

4.8.1 DIP SWITCH S4

IF

NOTE :

DEFAULT DATA IS LOADED, DIAGNOSTIC MODE D4 PROCEDURE

MUST BE PERFORMED!

DEFAULT CALIBRATION DATA

All calibration data or other data stored in the EEPROM will have

a corresponding set of default data stored in EEPROM which may be

used to initialize the EEPROM.

Calibration Mode with Dip Switch

This is performed by entering the

#4

in the ON position.

Transducer SPL calibration data:

This default data is typical of transducers supplied with the

instrument.

Custom RTL values:

This default data consists of the standard GSI RTL values for the

transducer types supplied with the instrument.

Custom RTL vs.

GSI RTL selection status:

This will default to the GSI RTL selection.

Attenuator 2.5 V maximum output level limit:

This will default to an attenuator limit for each stimulus.

Checksum:

The

EEPROM checksum

is calculated using the

contents of

the

EEPROM after all default data has been stored.

4.8.2 DIP SWITCH S3

CUSTOM

RTL

SELECTION MODE

This mode enables selection of the displayed custom RTL values

only and does not allow adjustment of the transducer's output

level.

If the user desires to use alternate transducers, this mode would

normally be selected first to set the custom RTL values and

the

earphone

SPL calibration would be performed.

When

Calibration Mode is entered with Dip Switch #3 in

position,

selection to

Dip Switch #3 can be used to switch from the custom SPL

the

transducer SPL mode while

remaining in

then

the

the ON

the

Calibration Mode.

25

Page 34

The

The RTL values for a left transducer and a right transducer

be the same.

in the RTL values.

MODE INITIALIZATION

custom RTL values are stored in EEPROM by transducer

The HL limits are directly affected by any

type.

changes

must

When

will be initialized as follows:

HL

The

level

down

output level (attenuator position) does not follow changes to the

custom RTL value.

The

Operation of the knob to select levels outside of this range will

not

will remain the same and will flash temporarily.

the

Tone Type= Current selection

Frequency = Current selection

Channel = Off

+10 dB

Transducer Routing

HL Display

Response LED = Off

Stimulus On LED = Off

Low

"

+

SELECTOR

HL Selector is used to select the custom

by 0.5 dB for each counter clockwise step.

allowable

be allowed.

Custom RTL selection mode is selected

Pad = Out

= Current selection

= Current RTL level stored in EEPROM

Battery Segment = Current state

II

Segment = Off

can be adjusted up by 0.5 dB for each clockwise

range of the custom RTL value is

If this occurs,the displayed custom RTL

the

RTL level.

The

+63.5

instrument

The

step

transducer

dB

and

SPL.

value

FREQUENCY SELECTOR

Selects the frequency for which the custom RTL is to be selected.

ROUTING SWITCH

Inactive in this mode.

EXTENDED RANGE PUSHBUTTON

This pushbutton is used to store the custom RTL value into

EEPROM.

checksum will be updated and the Patient Response LED will be

turned on for 2 seconds.

successfully, the word

and then the previously displayed RTL value will be restored. If

this error occurs,the calibration process may still be continued

for other frequencies.

After the RTL value is successfully stored the EEPROM

If the SPL value can not be stored

"CAL"

will be flashed on the HL display

26

Page 35

DIP

SWITCH #3 OPERATION WHILE IN CAL MODE

The

RTL calibration mode to the transducer SPL calibration mode.

OTHER CONTROLS

All

#3,

controls will not be processed.

HL

The

in

Negative values will be displayed with a minus sign.

This LCD segment indicates a low battery voltage condition as in

the Normal Mode.

PATIENT

This

successfully in the EEPROM by turning on for 2 seconds.

Cal Option Dip Switch #3 is used to switch from

other controls,

are

DISPLAY

HL display is used to display the selected custom RTL

the format

BATTERYSEGMENT

inactive

xx.x.

RESPONSE

LED indicates when the custom RTL value

except the Cal/Normal Switch and Dip

during this mode.

using digits 1 through 3 of the HL

mm

Operations of

has been stored

the

all

display.

custom

Switch

other

value

OTHER DISPLAYS

LEDs

All other

4.8.3 DIP SWITCH S2

NOT USED

4.8.4

DIAGNOSTIC MODE

The

components which

Calibration

and debugging of the board or instrument.

The

calibration mode as follows:

DIP SWITCH

-

Diagnostic

Diagnostic

Hardware Diagnostic test

Pushbutton Diagnostic test

Display Diagnostic test

A/D Diagnostic test

Attenuator Maximum Output Limit calibration

and LCD segments are not used and will remain off.

Exception when in Diagnostic Mode (Dip Switch

S1

Mode provides direct control over

Modes.

may

Mode consists of four diagnostic tests

not

This mode is provided to facilitate

be available in the Normal or

the

#1)

hardware

testing

and

one

The features of the Diagnostic Mode are controlled manually

the front panel.

from

27

Page 36

4.9 SELECTION OF THE DIAGNOSTIC MODE

CAL/NORMAL SWITCH

This

instrument.

switch

the

through #4 select the diagnostic test to be performed.

Diagnostic Mode is exited by setting the Cal/Normal switch back

to the Normal position.

When the Diagnostic Mode is entered the functions assigned to the

CAL Option Dip Switches, (except Switch

allow the selection of the desired diagnostic test.

The Dip Switches will be read only when the Calibration Mode is

+

entered.

exit

new test and then re-enter the Calibration Mode.

Switch

switch is used to

The Diagnostic

to the Cal position while Cal Option Dip Switch #1 is in

on position.

SWITCHES

To switch between diagnostic tests it is necessary to

the Calibration Mode,

#

S1

Diagnostic Mode

Enters the Diagnostic Mode when

the Cal/Normal Switch is set to

Cal.

When Dip Switch #1 is on,

Function

select

Mode is entered by setting this

reset the Dip Switches to select

the operating

Dip Switches

#1),

are redefined to

OFF (down) ON (up)

OFF

mode of

Selected

the

#2

The

the

-

s2, S3,

&

s4

DO ON

D1

ON

D2 ON OFF ON

\._*--D-

(-a

ON

ON ON

DO ON ON

DO ON ON ON

DO ON ON ON ON

xi?+

time except

selected via the switch,

the initialization is complete or the stimulus turned off.

These switches are used to

select the diagnostic test to

be performed when the Diagnostic

Mode is entered as follows:

Switch Setting Diagnostic Test

S1

s2 s3

OFF OFF

OFF

OFF ON ON

Diagnostic Mode is entered via the Cal/Normal Switch at

OFF ON

OFF

OFF ON

during the power up initialization phase. If

s4

OFF

OFF

OFF

OFF

Selected

Hardware Diagnostic

Pushbutton Diagnostic

Display Diagnostic

A/D Diagnostic

Attenuator Maximum Output Level Cal

Hardware Diagnostic

Hardware Diagnostic

Hardware Diagnostic

any

the Diagnostic Mode will be entered when

28

Page 37

When

switched

display a

selected.

into

code to

the Diagnostic Mode

indicate which diagnostic

The codes are as follows:

the

HL display

test

is being

will

"DO

"D1" =

"D2 "

I'

D3

"D4" =

The code will display for 2 seconds and then the instrument

initialize for the selected test.

= Hardware Diagnostic Test

"

Pushbutton Diagnostic Test

= Display Diagnostic Test

= A/D Diagnostic Test

"

Attenuator Maximum Output Level Cal

During this time all

will

controls

will be disabled.

4.9.1 HARDWARE DIAGNOSTIC TEST (DO)

TEST DESCRIPTION

This

diagnostic test provides direct and independent control of

the following hardware blocks:

Oscillator Frequency

Stimulus Multiplexer

Attenuator Position

+10

dB Pad Position

Transducer Routing

Each hardware block is controlled independent of all other blocks

i.e.,

selecting an

oscillator frequency will

not

change

the

attenuator position.

TEST INITIALIZATION

When switched into the hardware diagnostic test, the

will be initialized as follows:

Tone Type = Current Selection

Frequency= Current Selection

Stimulus M

UX

= Oscillator or External input based on current

frequency knob position

Channel = OFF

Attenuator position = 255

Response LED = OFF

Stimulus On LED = OFF

Low Battery Segment = Current State

II

+

II

Segment = OFF

TONE

This switch selects the Steady,

the Normal Mode.

any

used.

TYPE

SWITCH

FM or Pulsed Tone type just as in

The Steady and Pulsed Tone types will apply to

stimulus (internal

oscillator or external

The FM Tone type will always FM the internal

stimulus)

oscillator,

even if the external stimulus is selected.

instrument

being

29

Page 38

ROUTING SWITCH

This switch selects

routed just as in the Normal Mode.

FREQUENCY KNOB

The

frequency

to 8000 Hz are selected on the knob, the internal oscillator is

set for the frequency selected and the stimulus mux is set to the

internal oscillator.

between

set to

oscillator

external signal of 1 V RMS can be applied to J2 on the board.

PRESENT

The

operates in

(pressed and

be presented

a

the stimulus ON or OFF.

HL

frequency

and to control the stimulus multiplexer.

125 Hz and 8000 Hz is selected the stimulus mux will be

select

will

BAR

Present

second time.

SELECTOR

Bar controls the presentation of the

released) when the stimulus is off the stimulus will

and will remain on until the Present Bar is operated

knob is used to select

the

remain at the

a

push on/push off manner so, if it is

The

the transducer to which

the

When the unlabeled position on

external

+10 dB

pad will not be affected by

stimulus

last

selected

input.

the

internal

stimulus is

oscillator

When 125 Hz

the

The

frequency. An

stimulus.

knob

internal

It

operated

turning

u

This

position will be adjusted by

step

of the knob.

be

attenuator

flashed.

EXTENDED RANGE PUSHBUTTON

This pushbutton

pad.

selected

the pad is in.

the pad

attenuator will not be compensated for the pad position.

RESPONSE SWITCH

This

all operations will be ignored.

HL

knob is used to directly set the attenuator position.

+0.5 dB

of the knob and by

The allowable range of the attenuator position will

from 0 to 255.

position will not change and the HL display will be

When

switch is not used during the hardware diagnostic test

DISPLAY

this pushbutton is operated the

and the "+" LCD segment will turn on to

will be removed and the "+" segment

When either of these limits are

is used to control the position of the

When the pushbutton is operated a

-0.5

dB

for each counter clockwise

(1 step) for each clockwise

reached

+10 dB

pad

indicate

second

turned

+10 dB

will be

off.

The

step

the

that

time,

The

and

This display is used to display the the attenuator

the range of 0 to 255 as selected by the HL selector.

position in

30

It will be

Page 39

displayed in a right justified,

3.

integer format on digits 1, 2 and

L-

RESPONSE

LED

This LED is not used during the hardware diagnostic test and will

remain OFF.

STIMULUS

This

LED is

presented.

used to

The

LED is

indicate

when

OFF when the

the

stimulus is

stimulus is

not

being

being

presented and ON when it is being presented.

LOW

BATTERY SEGMENT

This LCD segment indicates a low battery voltage condition.

11 + 11

SEGMENT

This LCD segment indicates the position of the

the pad is "in"

the segment will be ON and when the pad is

+10 dB

pad.

When

"Out"

the segment will be OFF.

4.9.2 PUSHBUTTON DIAGNOSTIC TEST

(D1)

TEST DESCRIPTION

This

the

operated.

display the

display.

test provides a means of testing all controls,

Cal/Normal Switch,

While in this test,

keycode

This

of the new position of the control on the HL

keycode

will be displayed until another control is

for

proper

operation

the operation of any control

when

except

manually

will

for

operated.

TEST INITIALIZATION

When switched into the pushbutton diagnostic test, the instrument

will be initialized as follows:

Tone Type = Current selection

Frequency = Current selection

Stimulus M

UX

= Current position

Channel = OFF

Attenuator position = 255

+10 dB Pad = Out

Transducer Routing = None

HL Display = Displays

"D1"

for 2 seconds and then blanks

Response LED = OFF

Stimulus On LED = OFF

Low Battery Segment = Current state

II

+

II

Segment = OFF

31

Page 40

DESCRIPTION OF CONTROLS

In this test,

used to

purposes.

HL DISPLAY

This

operated.

LOW

BATTERY SEGMENT

This LCD segment will indicate a low battery voltage condition.

ALL OTHER DISPLAYS

All other

will remain OFF.

Control

Left

Right

Pulsed

FM

Steady

125 Hz

250 Hz

500 Hz

750 Hz

1000 Hz

1500 Hz

2000 Hz

3000 Hz

4000 Hz

6000 Hz

8000 Hz

Freq Position

Response Switch

Extended Range

Present Bar

HL Knob

Dip Switch

Dip Switch

Dip Switch

Dip Switch

select functions,

display

DISPLAYCODES FOR PUSHBUTTON/SWITCH SELECTIONS

Press

Release

Press

Release

the controls except the Cal/Normal Switch are

but are only operated

is used to display the

The

keycode

seqments and

#1

#2

#3

#4

will display on digits 1 and 2.

LEDs

are not used during this

Key

12

Cod

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

20

21

22

23

24

25

31

32

33

34

keycodes

e

as

for

controls

not

testing

are

test and

-

32

Page 41

4.9.3 DISPLAY DIAGNOSTIC TESTT

TEST DESCRIPTION

(D2)

This

all

"D2 "

segments and

all

inspection

test provides a means of visually testing the operation of

LCD segments and LEDS.

will

segments and

be displayed on the HL display for

LEDs

will then be blanked for 2 seconds, after which

LEDs

will be turned on for 2 seconds to

for

any displays which

When the test is selected, the

2 seconds.

do not

turn on.

code

All

allow

All

segments/LEDs will then be turned on individually for 1 second in

a

left to right,

of

any

been

shorts between segments.

sequenced through all segments/LEDs will be turned back on

top to bottom sequence to allow for inspection

After all segments/LEDs

have

to indicate the completion of the test.

During

performed

this test the low battery voltage monitoring will not be

since the display is not available to indicate a

low

battery condition.

TEST INITIALIZATION

When

switched into the display diagnostic test,

the

instrument

will be initialized as follows:

Tone Type

= Current selection

Frequency = Current selection

Stimulus M

UX

= Current position

Channel = OFF

Attenuator position = 255

+10 dB

Pad = Out

Transducer Routing = None

HL Display = Displays

"D2"

for 2 seconds and then the

display test starts

Response LED = OFF

Stimulus On LED = OFF

Low Battery Segment = Current state

'I+r'

Segment = OFF

DESCRIPTION

All controls

this

diagnostic test.

OF

CONTROLS

except the Cal/Normal switch are

ignored.

DESCRIPTION

OF

DISPLAYS

All LCD segments and

There

are

no parameter or status information displayed on

displays.

inactive

during

Operations of all other controls will be

LEDs

are tested during this diagnostic test.

33

the

Page 42

4.9.4 A/D CONVERTER DIAGNOSTIC TEST (D3)

TEST DESCRIPTION

This test will provide a means to test the A/D converter

channel

used to measure the battery voltage. When this test is selected

the A/D input will be sampled every

msec

and the converted

value

displayed on the HL display.

During

this test the low battery voltage monitoring will not be

performed since the A/D converter is not available to measure the

battery voltage.

TEST INITIALIZATION

When

switched

into

the A/D

Converter

diagnostic

test,

the

instrument will be initialized as follows:

Tone Type= Current selection

Frequency

Stimulus M

= Current selection

UX

= Current position

Channel = OFF

Attenuator Position = 255

+10 dB

Pad = Out

Transducer Routing = None

HL Display = Displays

"D1"

for 2 seconds and then blanks

Response LED = OFF

Stimulus On LED = OFF

Low Battery Segment = Current State

II

+

II

Segment = OFF

DESCRIPTION OF CONTROLS

All

controls

except the Cal/Normal switch

and

Extended

Pushbutton are inactive during this diagnostic test.

Operations

Range

of all other controls will be ignored.

EXTENDED RANGE PUSHBUTTON

This pushbutton is used to store the A/D values in the EEPROM for

"LO

Bat"

detection

"shutdown" will

occur when the battery voltage is

and

instrument

"shutdown".

too

Instrument

low to

safely operate the GSI 17 circuitry.

When the Extended Range Pushbutton is pressed the first time, the

A/D value is

EEPROM.

The Patient Response LED will be turned ON and

be displayed on

previously displayed

value can not be stored properly, the word "CAL" will be

stored as the battery low warning

the

HL display

for

2 seconds.

A/D value will be restored.

limit in the

"L1"

will

Then

If the

the

A/D

flashed

on the HL display and the previously displayed value will be

restored.

The A/D value for battery low warning limit must be

stored successfully before allowing the next press of Extended

Range Pushbutton to store the battery shutdown limit.

After the

A/D value is stored properly the EEPROM checksum will be updated.

-

34

Page 43

Page 44

Page 45

EQUIPMENT REQUIRED

Variable DC power supply,

u

minimum DVM.

1.

Adjust DC power supply to 7.5 Vdc then connect the negative

terminal to

2.

Connect DVM to Audiometer Module

TP100

and the positive terminal to

operating range of

+6.5

TP1000

Vdc to

+7.5

Vdc

TP101.

(LOW) and TP102

(HIGH).

3.

Connect simulated battery input circuit to Audiometer Module

as indicated in Figure 4-3.

4.

5.

Power up the GSI 17.

Enter Diagnostic Mode (D3).

Place Dip Switch S2 positions 1, 3, 4 to the ON

a)

position.

Place the Cal/Norm Switch to the Cal position.

b)

6.

The GSI 17 display will momentarily display D3, then will

update to a converted A/D value.

voltage to obtain 7.30 Vdc

(+50 mV)

new A/D value in memory by pressing the

Extender Button.

indicating proper

important that the

The display will momentarily display

storage of data into memory.

+10 dB

button is pressed only once. If

L2 is displayed, exit Cal Mode,

Adjust the DC power supply

on the DVM.

Store the

+10 dB

Range

L1

(It is

return to Step 5 and repeat

procedure.)

7.

Adjust the DC power supply voltage to 7.0 Vdc

Store this A/D value into memory by pressing the

(+50 mV).

+10 dB

Range Extender Button. The display will momentarily display

L2 indicating proper storage of data into memory.

8.

Adjust DC power supply to 7.5 Vdc.

positions to OFF,

and place Cal/Norm Switch S6 to the Normal

Place all Dip Switch S2

Mode position.

9.

Slowly decrease the DC power

BAT indicator is displayed.

and 7.35 Vdc.

display should blank at 6.95 to 7.05 Vdc.

Continue decreasing the input voltage.

supply voltage until the LOW

This should occur between 7.25

The

NOTE:

To clear

the LOW BA T indication the unit must be returned to full

power and the power switch toggled.

After completing calibration and verification checks remove the

power supply and simulated battery input circuit and proceed with

calibration of transducers.

37

Page 46

4.9.5 ATTENUATOR MAXIMUM OUTPUT LEVEL CALIBRATION (D4)

NOTE:

If Default

Data is loaded,

this procedure must be

performed before calibration of earphones.

TEST DISCR

IPTION

__-

If the Microprocessor of the GSI 17 has been replaced or a major

calibration data loss has occurred the Attenuator Maximum output

level must be calibrated.

When performing this calibration, the

operator will measure the output level on the connector

(important

-unloaded)

of the currently

adjust the attenuator position

measured.

repeated for

calibrated in any order,

The calibration data is then stored and the process is

all remaining stimuli.

but all must be calibrated.

until correct output voltage is

selected transducer

The stimuli may be

all output levels were adjusted to 2.5 vrms

frequency.

The newer GSI

levels for calibration.

17's

have specific maximum output

Serial numbers and output levels are

Originally

*.15

vrms for each

and

outlined below.

NOTE

When performing this procedure,

:

output must be unloaded

(no phone plugged in).

SERIAL NUMBERS LESS THAN 1230 (EXCLUDING 1068, 1175r AND 1212)

All frequencies 2.5 vrms

(+.15

vrms)

SERIAL NUMBERS GREATER THAN 1230 (INCLUDING 1230, 1068, 1175, AND 1212)

Frequency (Hz)

Voltage (rms)

125

250

500

750

1K

2

K

3

K

4

K

6 K

8

K

2.30

2.30

2.15

1.90

2.50

2.50

2.50

2.50

2.50

2.50

(2.5

dB)

_

38

Page 47

TEST INITIALIZATION

--___

When switched

into the

attenuator maximum

output

level

calibration the instrument will be initialized as follows:

Tone Type

= Current Selection

Frequency = Current Selection

Stimulus M

UX

= Oscillator Position

Channel = OFF

Attenuator Position = 255

+10 dB

Pad = Out

Transducer Routing = Current Selection

HL Display = Displays

"D4"

for 2 seconds and then

"255"

Response LED = OFF

Stimulus On LED = OFF

Low Battery Segment = Current State

"+"

Segment = OFF

TONE TYPE SWITCH

This switch

selects

the

tone

type.

The

calibration

would

normally be performed with Steady selected.

SWITCH ROUTING

-___

This switch selects the transducer.

FREQUENCY SELECTOR

This

knob selects the stimulus to be calibrated.

Its

operation

is the same as in the Normal Mode.

PRESENT BAR

---- __

The

Present Bar controls the presentation of the

operates in a

stimulus.

push ON/push OFF manner so, if it is

operated

It

(pressed and released) when the stimulus is OFF the stimulus will

be presented and will remain ON until the Present Bar is operated

second time.

a

+10 dB

pad will not be affected by

turning

The

the stimulus ON or OFF.

HL

SELECTOR

This

knob is used to directly set the attenuator position.

position is adjusted by

of the knob and by

knob.

The

allowable range of the attenuator position

from 0 to 255.

attenuator

position will not change and the HL display will be

-0.5

When either of these limits

+0.5 dB

dB

for each counter clockwise step of the

(1 step) for each clockwise

will be

are

reached

The

step

the

flashed.

39

Page 48

EXTENDED RANGE PUSHBUTTON

------

-_-

(+10 dB

PAD)

This

EEPROM.

will be

properly after 3 attempts, the word

HL and

error

pushbutton is used to store the calibration

data in

After the calibration data is stored the EEPROM checksum

updated.

then the previously displayed value restored.

occurs

the calibration may still be continued

If the calibration data can

"CAL"

will be flashed on

not

be stored

If this

for

other

stimuli.

SWITCH RESPONSE

This switch

--is not used during the

attenuator

maximum

output

level calibration and all operations will be ignored.

HL DISPLAY

----This

range of

displayed in a right justified,

display is used to display the attenuator position in

0 to 255 as selected by the HL selector. It

will be

integer format on digits 1, 2 and

3.

LED RESPONSE

This

data in

operated.

seconds after the calibration data has been stored and

LED is used to indicate the correct storage of

the

EEPROM when

the

Extended

Range

Pushbutton is

This LED is normally OFF and will be turned ON for 2

calibration

verified.

If the data is not stored correctly, the LED will remain OFF

the

word

"CAL" will be flashed on the HL display and

then

previously displayed value will be restored.

the

the

the

and

the

STIMULUS ON

LED

This LED is used to indicate stimulus presentation. The LED is

OFF when the stimulus is not being presented and on when it is

being presented.

LOW

BATTERY

SEGMENT